lock SUZUKI GRAND VITARA 2013 Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2013, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2013Pages: 337, PDF Size: 6.21 MB

Page 255 of 337

7-6

INSPECTION AND MAINTENANCE

79K21-03E

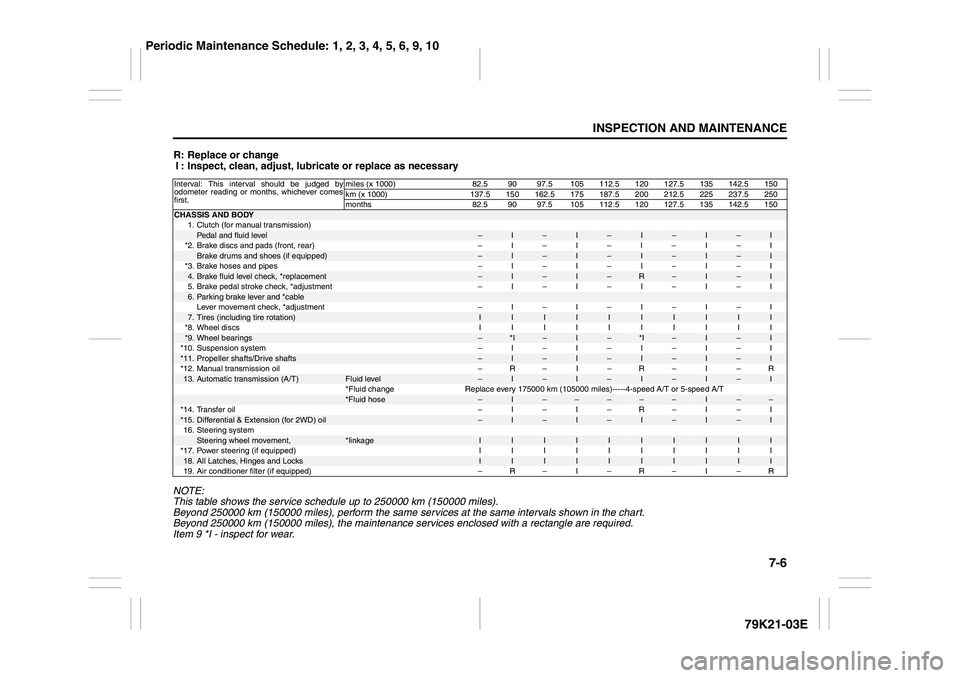

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessary

NOTE:

This table shows the service schedule up to 250000 km (150000 miles).

Beyond 250000 km (150000 miles), perform the same services at the same intervals shown in the chart.

Beyond 250000 km (150000 miles), the maintenance services enclosed with a rectangle are required.

Item 9 *I - inspect for wear.Interval: This interval should be judged by

odometer reading or months, whichever comes

first.miles (x 1000) 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

km (x 1000) 137.5 150 162.5 175 187.5 200 212.5 225 237.5 250

months 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150CHASSIS AND BODY

1. Clutch (for manual transmission)

Pedal and fluid level

–

I

–

I

–

I

–

I

–

I

*2. Brake discs and pads (front, rear) – I – I – I – I – I

Brake drums and shoes (if equipped)

–

I

–

I

–

I

–

I

–

I

*3. Brake hoses and pipes – I – I – I – I – I

4.Brake fluid level check, *replacement

–

I

–

I

–

R

–

I

–

I

5. Brake pedal stroke check, *adjustment – I – I – I – I – I

6.Parking brake lever and *cableLever movement check, *adjustment – I – I – I – I – I7.Tires (including tire rotation)

I

I

I

I

I

I

I

I

I

I

*8. Wheel discs I I I I I I I I I I

*9.

Wheel bearings

–

*I

–

I

–

*I

–

I

–

I

*10. Suspension system – I – I – I – I – I

*11.

Propeller shafts/Drive shafts

–

I

–

I

–

I

–

I

–

I

*12. Manual transmission oil – R – I – R – I – R

13.

Automatic transmission (A/T)

Fluid level

–

I

–

I

–

I

–

I

–

I

*Fluid change Replace every 175000 km (105000 miles)-----4-speed A/T or 5-speed A/T

*Fluid hose

–

I

–

–

–

–

–

I

–

–

*14. Transfer oil – I – I – R – I – I

*15.

Differential & Extension (for 2WD) oil

–

I

–

I

–

I

–

I

–

I

16. Steering system

Steering wheel movement,

*linkage

I

I

I

I

I

I

I

I

I

I

*17. Power steering (if equipped) I I I I I I I I I I

18.

All Latches, Hinges and Locks

I

I

I

I

I

I

I

I

I

I

19. Air conditioner filter (if equipped) – R – I – R – I – R

Periodic Maintenance Schedule: 1, 2, 3, 4, 5, 6, 9, 10

Page 261 of 337

7-12

INSPECTION AND MAINTENANCE

79K21-03E

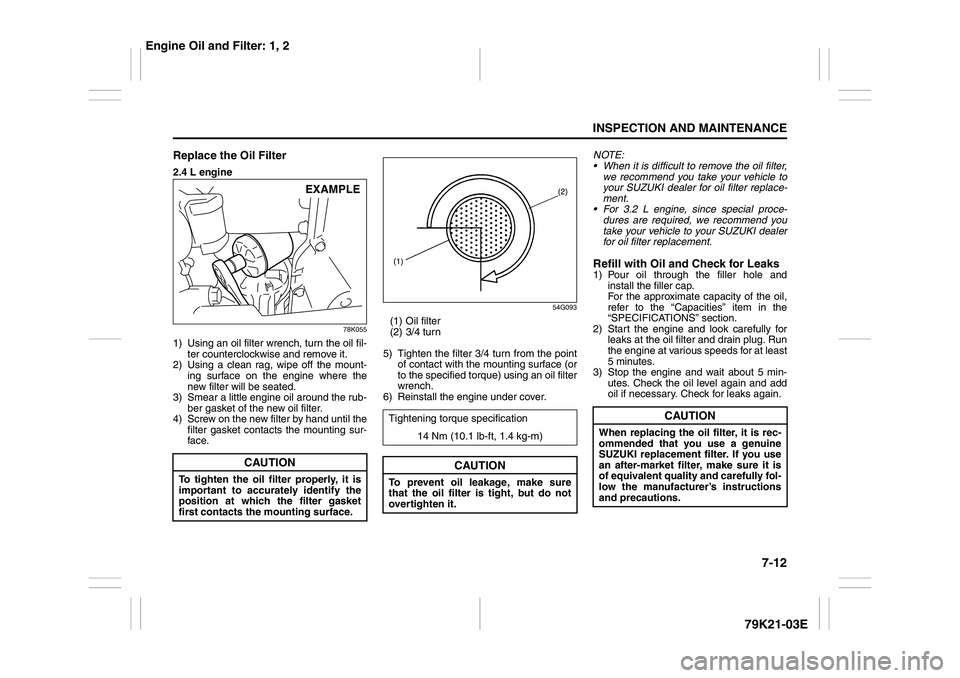

Replace the Oil Filter2.4 L engine

78K055

1) Using an oil filter wrench, turn the oil fil-

ter counterclockwise and remove it.

2) Using a clean rag, wipe off the mount-

ing surface on the engine where the

new filter will be seated.

3) Smear a little engine oil around the rub-

ber gasket of the new oil filter.

4) Screw on the new filter by hand until the

filter gasket contacts the mounting sur-

face.

54G093

(1) Oil filter

(2) 3/4 turn

5) Tighten the filter 3/4 turn from the point

of contact with the mounting surface (or

to the specified torque) using an oil filter

wrench.

6) Reinstall the engine under cover.NOTE:

When it is difficult to remove the oil filter,

we recommend you take your vehicle to

your SUZUKI dealer for oil filter replace-

ment.

For 3.2 L engine, since special proce-

dures are required, we recommend you

take your vehicle to your SUZUKI dealer

for oil filter replacement.

Refill with Oil and Check for Leaks1) Pour oil through the filler hole and

install the filler cap.

For the approximate capacity of the oil,

refer to the “Capacities” item in the

“SPECIFICATIONS” section.

2) Start the engine and look carefully for

leaks at the oil filter and drain plug. Run

the engine at various speeds for at least

5 minutes.

3) Stop the engine and wait about 5 min-

utes. Check the oil level again and add

oil if necessary. Check for leaks again.

CAUTION

To tighten the oil filter properly, it is

important to accurately identify the

position at which the filter gasket

first contacts the mounting surface.

EXAMPLE

Tightening torque specification

14 Nm (10.1 lb-ft, 1.4 kg-m)

CAUTION

To prevent oil leakage, make sure

that the oil filter is tight, but do not

overtighten it.

CAUTION

When replacing the oil filter, it is rec-

ommended that you use a genuine

SUZUKI replacement filter. If you use

an after-market filter, make sure it is

of equivalent quality and carefully fol-

low the manufacturer’s instructions

and precautions.

Engine Oil and Filter: 1, 2

Page 273 of 337

7-24

INSPECTION AND MAINTENANCE

79K21-03E

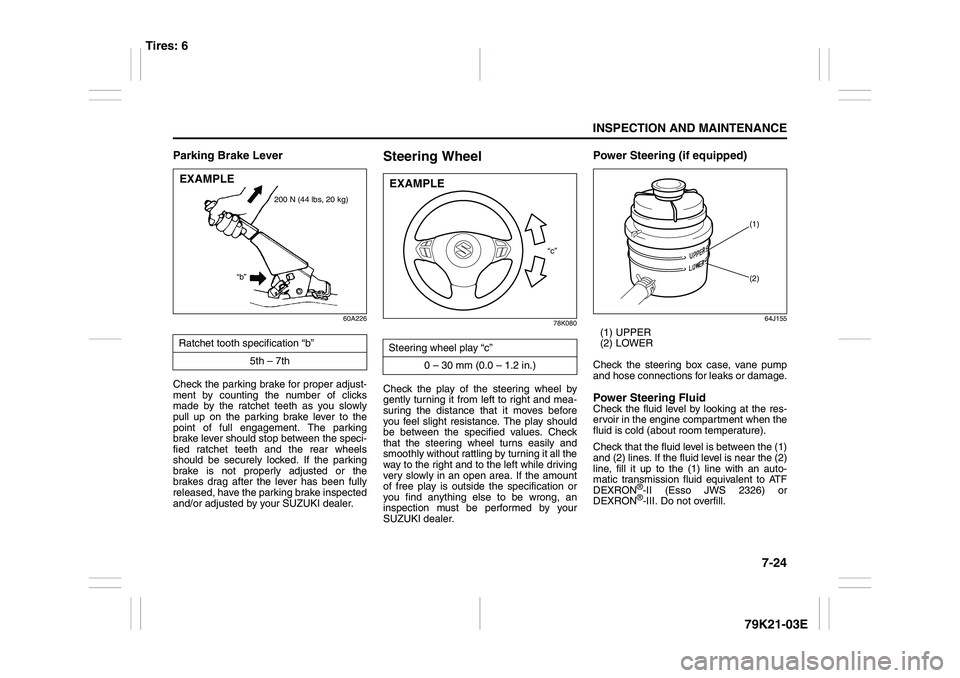

Parking Brake Lever

60A226

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to the

point of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your SUZUKI dealer.

Steering Wheel

78K080

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values. Check

that the steering wheel turns easily and

smoothly without rattling by turning it all the

way to the right and to the left while driving

very slowly in an open area. If the amount

of free play is outside the specification or

you find anything else to be wrong, an

inspection must be performed by your

SUZUKI dealer.

Power Steering (if equipped)

64J155

(1) UPPER

(2) LOWER

Check the steering box case, vane pump

and hose connections for leaks or damage.Power Steering FluidCheck the fluid level by looking at the res-

ervoir in the engine compartment when the

fluid is cold (about room temperature).

Check that the fluid level is between the (1)

and (2) lines. If the fluid level is near the (2)

line, fill it up to the (1) line with an auto-

matic transmission fluid equivalent to ATF

DEXRON

®-II (Esso JWS 2326) or

DEXRON®-III. Do not overfill. Ratchet tooth specification “b”

5th – 7th

200 N (44 lbs, 20 kg)

“b”

EXAMPLE

Steering wheel play “c”

0 – 30 mm (0.0 – 1.2 in.)

“c”

EXAMPLE

(1)

(2)

Tires: 6

Page 276 of 337

7-27INSPECTION AND MAINTENANCE

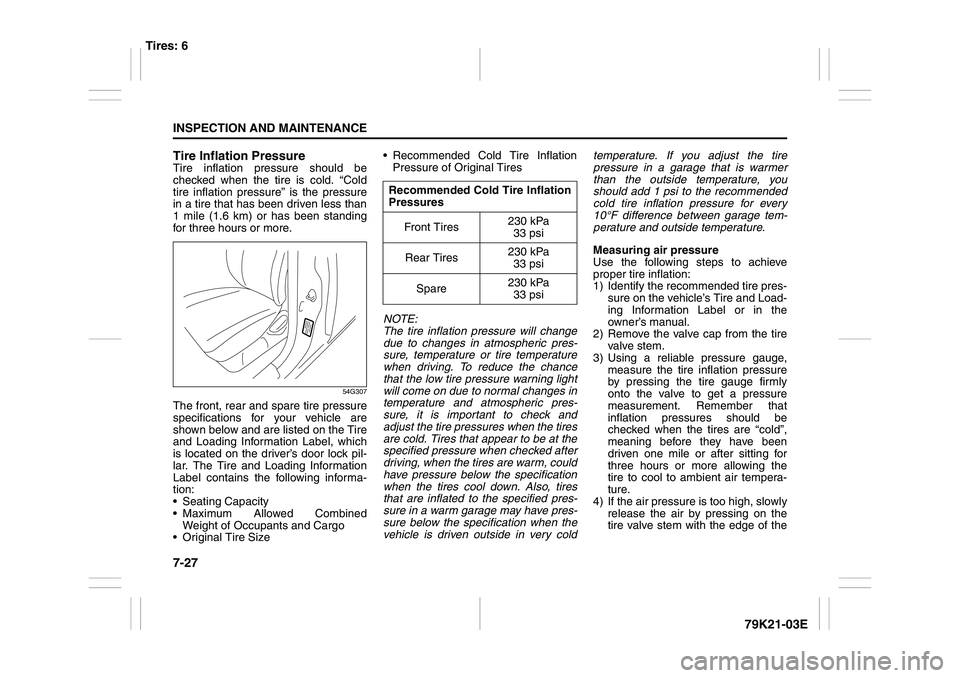

79K21-03E Tire Inflation Pressure

Tire inflation pressure should be

checked when the tire is cold. “Cold

tire inflation pressure” is the pressure

in a tire that has been driven less than

1 mile (1.6 km) or has been standing

for three hours or more.

54G307

The front, rear and spare tire pressure

specifications for your vehicle are

shown below and are listed on the Tire

and Loading Information Label, which

is located on the driver’s door lock pil-

lar. The Tire and Loading Information

Label contains the following informa-

tion:

Seating Capacity

Maximum Allowed Combined

Weight of Occupants and Cargo

Original Tire Size Recommended Cold Tire Inflation

Pressure of Original Tires

NOTE:

The tire inflation pressure will change

due to changes in atmospheric pres-

sure, temperature or tire temperature

when driving. To reduce the chance

that the low tire pressure warning light

will come on due to normal changes in

temperature and atmospheric pres-

sure, it is important to check and

adjust the tire pressures when the tires

are cold. Tires that appear to be at the

specified pressure when checked after

driving, when the tires are warm, could

have pressure below the specification

when the tires cool down. Also, tires

that are inflated to the specified pres-

sure in a warm garage may have pres-

sure below the specification when the

vehicle is driven outside in very coldtemperature. If you adjust the tire

pressure in a garage that is warmer

than the outside temperature, you

should add 1 psi to the recommended

cold tire inflation pressure for every

10°F difference between garage tem-

perature and outside temperature.

Measuring air pressure

Use the following steps to achieve

proper tire inflation:

1) Identify the recommended tire pres-

sure on the vehicle’s Tire and Load-

ing Information Label or in the

owner’s manual.

2) Remove the valve cap from the tire

valve stem.

3) Using a reliable pressure gauge,

measure the tire inflation pressure

by pressing the tire gauge firmly

onto the valve to get a pressure

measurement. Remember that

inflation pressures should be

checked when the tires are “cold”,

meaning before they have been

driven one mile or after sitting for

three hours or more allowing the

tire to cool to ambient air tempera-

ture.

4) If the air pressure is too high, slowly

release the air by pressing on the

tire valve stem with the edge of the

Recommended Cold Tire Inflation

Pressures

Front Tires230 kPa

33 psi

Rear Tires230 kPa

33 psi

Spare230 kPa

33 psi

Tires: 6

Page 280 of 337

7-31INSPECTION AND MAINTENANCE

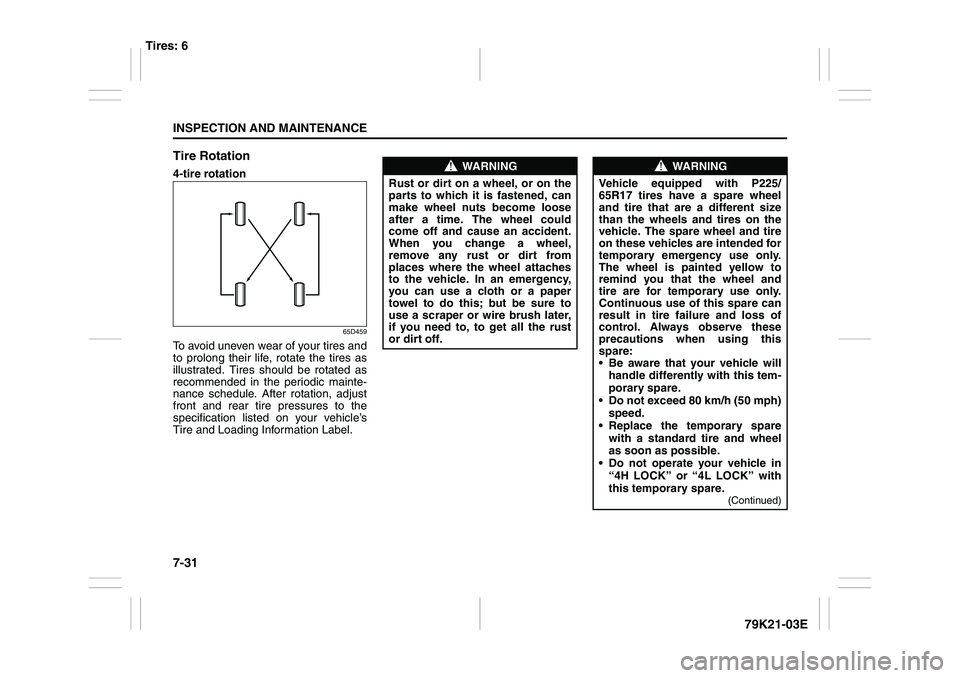

79K21-03E Tire Rotation

4-tire rotation

65D459

To avoid uneven wear of your tires and

to prolong their life, rotate the tires as

illustrated. Tires should be rotated as

recommended in the periodic mainte-

nance schedule. After rotation, adjust

front and rear tire pressures to the

specification listed on your vehicle’s

Tire and Loading Information Label.

WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose

after a time. The wheel could

come off and cause an accident.

When you change a wheel,

remove any rust or dirt from

places where the wheel attaches

to the vehicle. In an emergency,

you can use a cloth or a paper

towel to do this; but be sure to

use a scraper or wire brush later,

if you need to, to get all the rust

or dirt off.

WARNING

Vehicle equipped with P225/

65R17 tires have a spare wheel

and tire that are a different size

than the wheels and tires on the

vehicle. The spare wheel and tire

on these vehicles are intended for

temporary emergency use only.

The wheel is painted yellow to

remind you that the wheel and

tire are for temporary use only.

Continuous use of this spare can

result in tire failure and loss of

control. Always observe these

precautions when using this

spare:

Be aware that your vehicle will

handle differently with this tem-

porary spare.

Do not exceed 80 km/h (50 mph)

speed.

Replace the temporary spare

with a standard tire and wheel

as soon as possible.

Do not operate your vehicle in

“4H LOCK” or “4L LOCK” with

this temporary spare.

(Continued)

Tires: 6

Page 286 of 337

7-37INSPECTION AND MAINTENANCE

79K21-03E

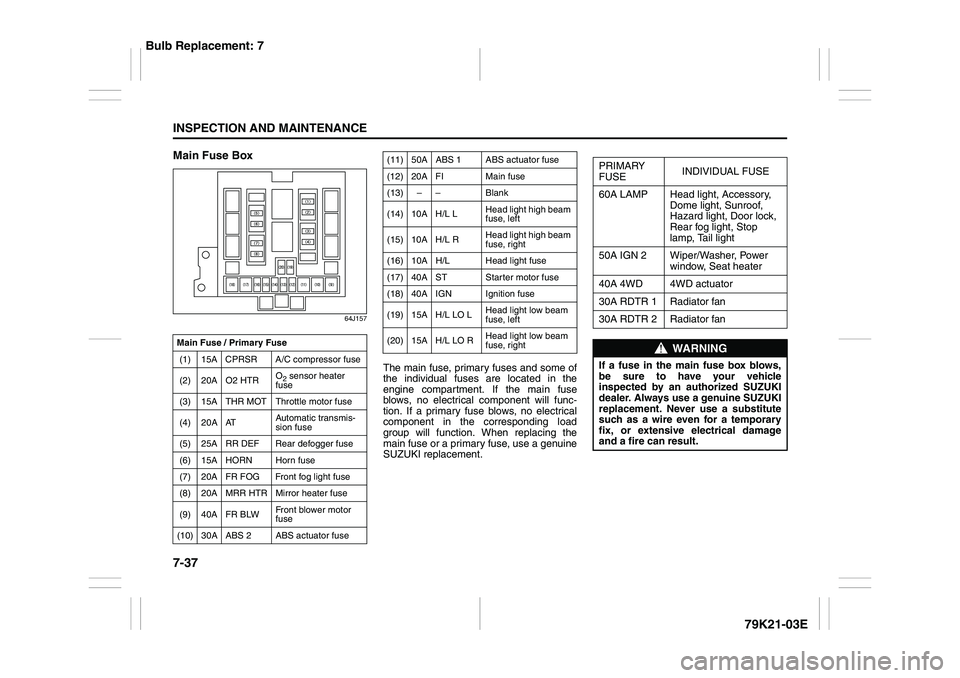

Main Fuse Box

64J157

The main fuse, primary fuses and some of

the individual fuses are located in the

engine compartment. If the main fuse

blows, no electrical component will func-

tion. If a primary fuse blows, no electrical

component in the corresponding load

group will function. When replacing the

main fuse or a primary fuse, use a genuine

SUZUKI replacement.

Main Fuse / Primary Fuse

(1) 15A CPRSR A/C compressor fuse

(2) 20A O2 HTRO

2 sensor heater

fuse

(3) 15A THR MOT Throttle motor fuse

(4) 20A ATAutomatic transmis-

sion fuse

(5) 25A RR DEF Rear defogger fuse

(6) 15A HORN Horn fuse

(7) 20A FR FOG Front fog light fuse

(8) 20A MRR HTR Mirror heater fuse

(9) 40A FR BLWFront blower motor

fuse

(10) 30A ABS 2 ABS actuator fuse

(11) 50A ABS 1 ABS actuator fuse

(12) 20A FI Main fuse

(13) – – Blank

(14) 10A H/L LHead light high beam

fuse, left

(15) 10A H/L RHead light high beam

fuse, right

(16) 10A H/L Head light fuse

(17) 40A ST Starter motor fuse

(18) 40A IGN Ignition fuse

(19) 15A H/L LO LHead light low beam

fuse, left

(20) 15A H/L LO RHead light low beam

fuse, right

PRIMARY

FUSEINDIVIDUAL FUSE

60A LAMP Head light, Accessory,

Dome light, Sunroof,

Hazard light, Door lock,

Rear fog light, Stop

lamp, Tail light

50A IGN 2 Wiper/Washer, Power

window, Seat heater

40A 4WD 4WD actuator

30A RDTR 1 Radiator fan

30A RDTR 2 Radiator fan

WARNING

If a fuse in the main fuse box blows,

be sure to have your vehicle

inspected by an authorized SUZUKI

dealer. Always use a genuine SUZUKI

replacement. Never use a substitute

such as a wire even for a temporary

fix, or extensive electrical damage

and a fire can result.

Bulb Replacement: 7

Page 287 of 337

7-38

INSPECTION AND MAINTENANCE

79K21-03E

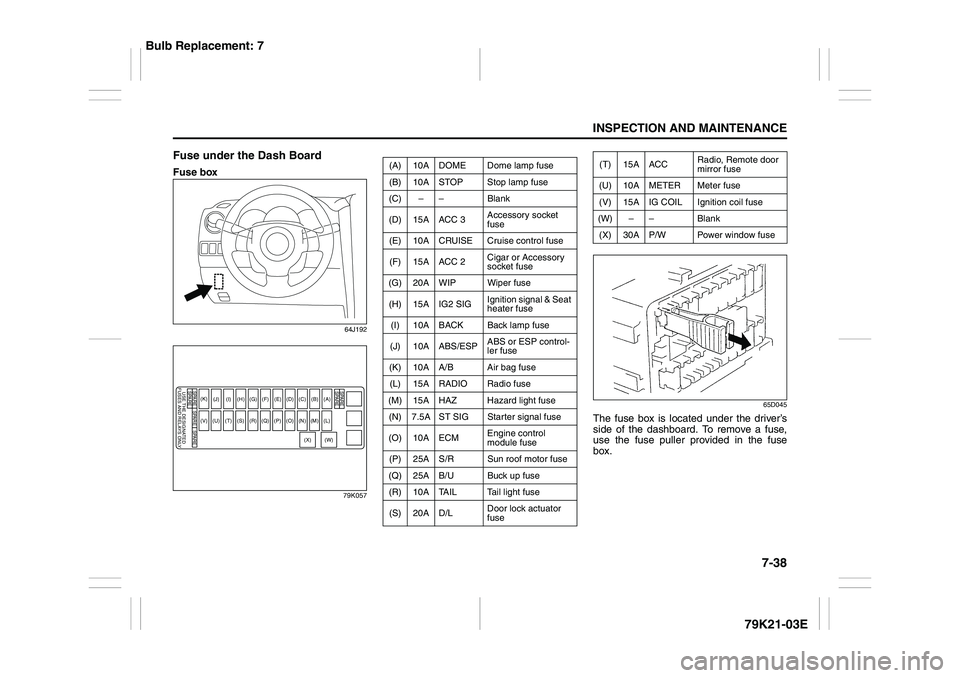

Fuse under the Dash BoardFuse box

64J192

79K05765D045

The fuse box is located under the driver’s

side of the dashboard. To remove a fuse,

use the fuse puller provided in the fuse

box.

SPARESPARE

SPARE

SPARE

USE THE DESIGNATED

FUSES AND RELAYS ONLYSPARE SPARE

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)(I)

(J)

(L)

(M)

(N)

(O)

(P)

(Q)

(R)

(S)

(T)

(U)

(V)(K)

(W)

(X)

(A) 10A DOME Dome lamp fuse

(B) 10A STOP Stop lamp fuse

(C) – – Blank

(D) 15A ACC 3Accessory socket

fuse

(E) 10A CRUISE Cruise control fuse

(F) 15A ACC 2Cigar or Accessory

socket fuse

(G) 20A WIP Wiper fuse

(H) 15A IG2 SIGIgnition signal & Seat

heater fuse

(I) 10A BACK Back lamp fuse

(J) 10A ABS/ESPABS or ESP control-

ler fuse

(K) 10A A/B Air bag fuse

(L) 15A RADIO Radio fuse

(M) 15A HAZ Hazard light fuse

(N) 7.5A ST SIG Starter signal fuse

(O) 10A ECMEngine control

module fuse

(P) 25A S/R Sun roof motor fuse

(Q) 25A B/U Buck up fuse

(R) 10A TAIL Tail light fuse

(S) 20A D/LDoor lock actuator

fuse

(T) 15A ACCRadio, Remote door

mirror fuse

(U) 10A METER Meter fuse

(V) 15A IG COIL Ignition coil fuse

(W) – – Blank

(X) 30A P/W Power window fuse

Bulb Replacement: 7

Page 290 of 337

7-41INSPECTION AND MAINTENANCE

79K21-03E

Spot Light (if equipped)Pull down the lens by using a flat blade

screwdriver covered with a soft cloth as

shown.

Ceiling-mount type (if equipped)

79K061

Remove the bulb holder by turning it coun-

terclockwise. Pull out the bulb.

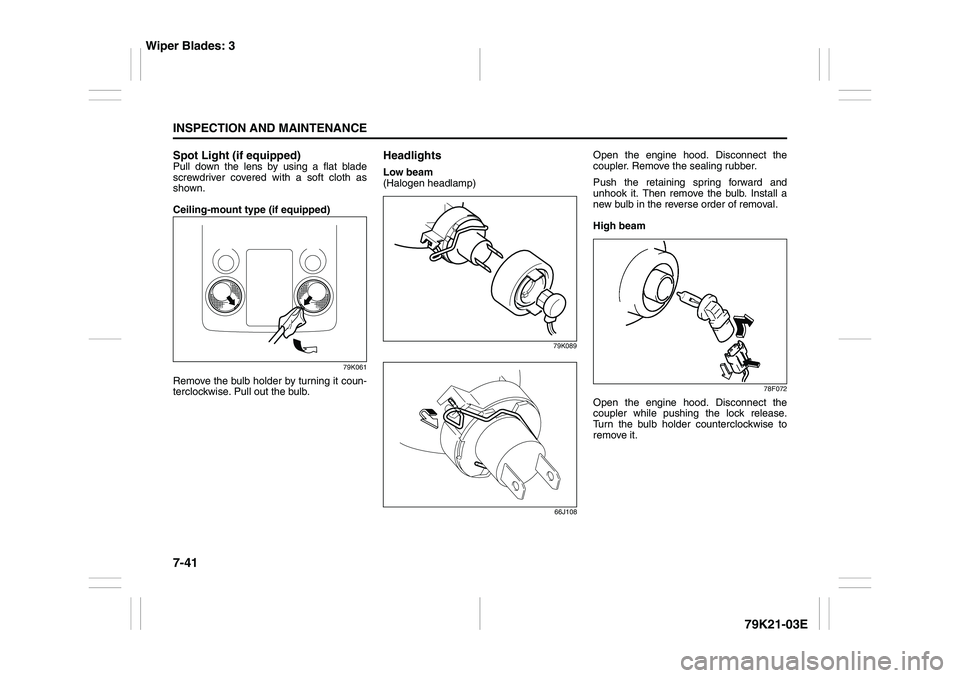

HeadlightsLow beam

(Halogen headlamp)

79K089

66J108

Open the engine hood. Disconnect the

coupler. Remove the sealing rubber.

Push the retaining spring forward and

unhook it. Then remove the bulb. Install a

new bulb in the reverse order of removal.

High beam

78F072

Open the engine hood. Disconnect the

coupler while pushing the lock release.

Turn the bulb holder counterclockwise to

remove it.

Wiper Blades: 3

Page 291 of 337

7-42

INSPECTION AND MAINTENANCE

79K21-03E

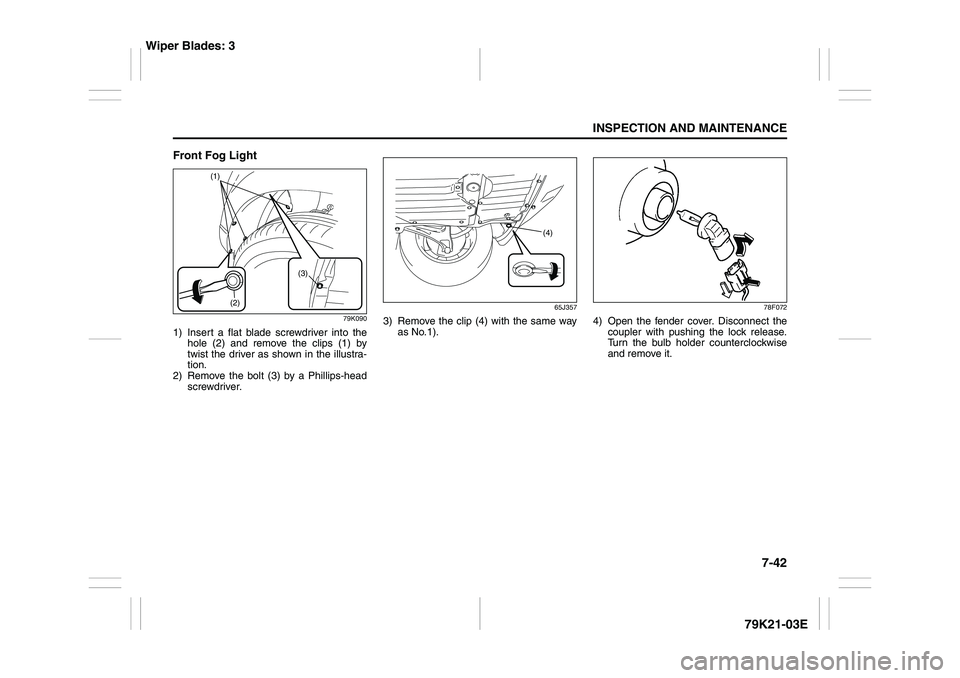

Front Fog Light

79K090

1) Insert a flat blade screwdriver into the

hole (2) and remove the clips (1) by

twist the driver as shown in the illustra-

tion.

2) Remove the bolt (3) by a Phillips-head

screwdriver.

65J357

3) Remove the clip (4) with the same way

as No.1).

78F072

4) Open the fender cover. Disconnect the

coupler with pushing the lock release.

Turn the bulb holder counterclockwise

and remove it.

(2)

(1)

(3)

(4)

Wiper Blades: 3

Page 292 of 337

7-43INSPECTION AND MAINTENANCE

79K21-03E

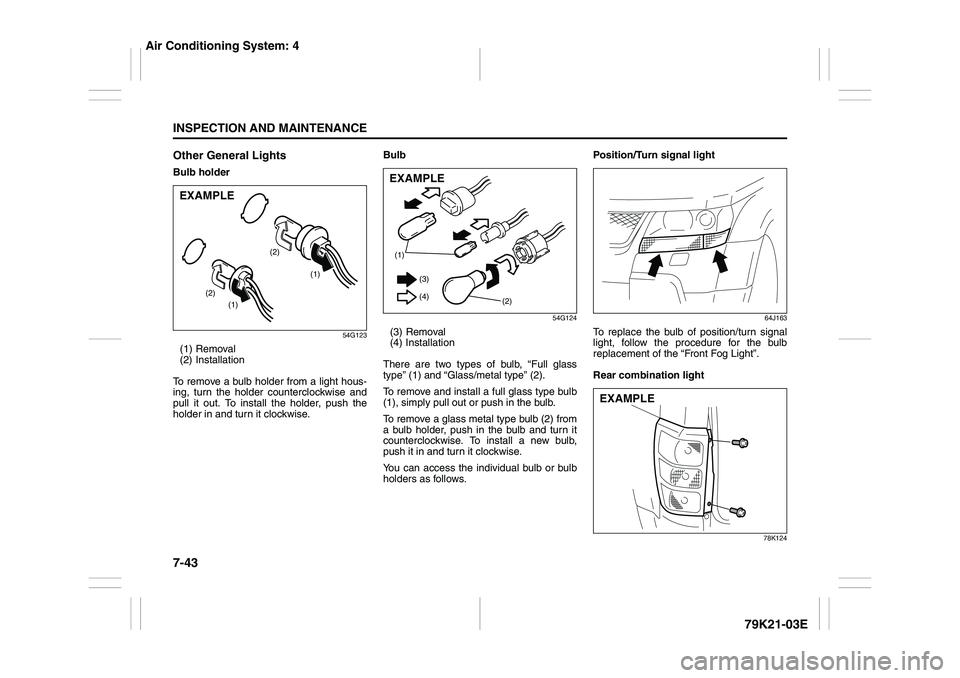

Other General LightsBulb holder

54G123

(1) Removal

(2) Installation

To remove a bulb holder from a light hous-

ing, turn the holder counterclockwise and

pull it out. To install the holder, push the

holder in and turn it clockwise.Bulb

54G124

(3) Removal

(4) Installation

There are two types of bulb, “Full glass

type” (1) and “Glass/metal type” (2).

To remove and install a full glass type bulb

(1), simply pull out or push in the bulb.

To remove a glass metal type bulb (2) from

a bulb holder, push in the bulb and turn it

counterclockwise. To install a new bulb,

push it in and turn it clockwise.

You can access the individual bulb or bulb

holders as follows.Position/Turn signal light

64J163

To replace the bulb of position/turn signal

light, follow the procedure for the bulb

replacement of the “Front Fog Light”.

Rear combination light

78K124

(1)

(1) (2)(2)

EXAMPLE

(1)

(2) (3)

(4)EXAMPLE

EXAMPLE

Air Conditioning System: 4