warning SUZUKI GRAND VITARA 2015 Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2015, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2015Pages: 482, PDF Size: 21 MB

Page 288 of 482

5-46

OTHER CONTROLS AND EQUIPMENT

54P00-01E

Part 15 of the FCC Rules

FCC Warning:

Any unauthorized changes or modifica-

tions to this equipment would void the

user’s authority to operate this device.The Bluetooth

® word mark and logo are

registered trademarks and are owned by

the Bluetooth SIG, Ink.

NOTE:

This equipment complies with FCC radia-

tion exposure limits set forth for uncon-

trolled equipment and meets the FCC

radio frequency (RF) Exposure Guidelines

in Supplement C to OET65. This equip-

ment has very low level of RF energy

which does not comply with maximum per-

missive exposure (MPE) evaluation. But it

is desirable that it should be installed and

operated with at least 20cm and more

between the radiator and person’s body

(excluding extremities: hands, wrists, feet

and ankles).Stop using this unit and a Bluetooth

®

ready device whenever requested.

This unit shares the communication fre-

quency with other private or public wireless

communication equipment such as a wire-

less LAN and other wireless communica-

tion radios.

You should stop using this unit whenever

you are notified that your unit disturbs

other wireless communication immediately.

WA R N I N G

This is a class I laser product. Use of

controls or adjustments or perfor-

mance of procedures other than

those specified herein may result in

hazardous radiation exposure.

Do not open covers and do not

attempt to repair this unit by yourself.

Ask an authorized dealer for the

repair.

Page 335 of 482

6-3

VEHICLE LOADING AND TOWING

54P00-01E

Tires

Mirrors

Check if your vehicle’s mirrors meet local

requirements for mirrors used on towing

vehicles. If they do not, you must install the

required mirrors before you tow.

Vehicle/trailer loading

To load your vehicle and trailer properly,

you must know how to measure gross

trailer weight and trailer nose weight.

Gross trailer weight is the weight of the

trailer plus all the cargo in it. You can mea-

sure gross trailer weight by putting the fully

loaded trailer on a vehicle scale.

Nose weight is the downward force

exerted on the tow bar by the trailer cou-pler, with the trailer fully loaded and the

coupler at its normal towing height. This

weight can be measured using a bathroom

scale.

The weight of your loaded trailer (gross

trailer weight) should never exceed towing

capacity.

Distribute cargo in your trailer so that nose

weight is about 10% of gross trailer weight,

but does not exceed the maximum vertical

load on trailer hitch point. You should mea-

sure gross trailer weight and nose weight

before towing to check that your load is

properly distributed.

Additional trailer towing warnings

WA R N I N G

When towing a trailer, it is very

important for your vehicle and trailer

to have properly inflated tires. Your

vehicle’s tires should be inflated to

the pressures listed on your vehicles

tire information label. If laden pres-

sures are listed on the label, the tires

should be inflated to the laden pres-

sures. Inflate trailer tires according to

the specifications provided by the

trailer manufacturer.

WA R N I N G

Improper weight distribution of your

trailer may result in poor vehicle han-

dling and swaying of the trailer.

Always check that trailer nose weight

is about 10% of gross trailer weight,

but does not exceed the maximum

vertical load on trailer hitch point.

Also check that the cargo is properly

secured. Failure to observe this

requirement may result in an acci-

dent.

WA R N I N G

Never overload cargo on your trailer

or your vehicle. Gross trailer weight

must never exceed towing capacity.

Gross vehicle weight (sum of the

weights of the vehicle, all the occu-

pants, accessories including tow

bars and a trailer hitch, cargo and

trailer nose weight) must never

exceed the Gross Vehicle Weight Rat-

ing (GVWR) listed in “SPECIFICA-

TIONS” section.

WA R N I N G

Connect trailer lights and hook up

safety chains every time you tow.

NOTICE

Because towing a trailer puts addi-

tional stress on your vehicle, more

frequent maintenance will be

required than under normal driving

conditions. Follow the schedule in

“Maintenance recommended under

severe driving conditions”.

Page 339 of 482

7-1

INSPECTION AND MAINTENANCE

54P00-01E

60B128S

WA R N I N G

Take extreme care when working on

your vehicle to prevent accidental

injury. Carefully observe the follow-

ing precautions:

• To prevent damage or unintended

activation of the air bag system or

seat belt pretensioner system, check

that the battery is disconnected and

the ignition switch has been in

“LOCK” position or the ignition

mode has been “LOCK” (OFF) for at

least 90 seconds before performing

any electrical service work on your

SUZUKI vehicle. Do not touch air

bag system components, seat belt

pretensioner system components or

wires.

The wires are wrapped with yellow

tape or yellow tubing, and the cou-

plers are yellow for easy identifica-

tion.

• Do not leave the engine running in

garages or other confined areas.

(Continued)

WA R N I N G

(Continued)

• When the engine is running, keep

hands, clothing, tools, and other

objects away from the fan and drive

belt. Even though the fan may not

be moving, it can automatically

turn on without warning.

• When it is necessary to perform

service work with the engine run-

ning, check that the parking brake

is set fully and the transaxle is in

Neutral.

• Do not touch ignition wires or other

ignition system parts when starting

the engine or when the engine is

running, or you could receive an

electric shock.

• Be careful not to touch a hot

engine, exhaust manifold and

pipes, muffler, radiator and water

hoses.

• Do not allow smoking, sparks, or

flames around fuel or the battery.

Flammable fumes are present.

• Do not get under your vehicle if it is

supported only with the portable

jack provided in your vehicle.

• Be careful not to cause accidental

short circuits between the positive

and negative battery terminals.

(Continued)

WA R N I N G

(Continued)

• Keep used oil, coolant, and other

fluids away from children and pets.

Dispose of used fluids properly;

never pour them on the ground,

into sewers, etc.

Page 360 of 482

7-22

INSPECTION AND MAINTENANCE

54P00-01E

Pull out the oil dipstick, wipe oil off with a

clean cloth, insert the dipstick all the way

into the engine, and then remove it again.

The oil on the stick should be between the

upper and lower limits shown on the stick.

If the oil level indication is near the lower

limit, add enough oil to raise the level to

the upper limit.NOTE:

When the soot particles accumulated in

the DPF

® are combusted, the amount of

the engine oil may increase due to the dilu-

tion with the fuel. This is not a vehicle mal-

function. The soot particles accumulated in

the DPF

® are combusted automatically

during driving. However, they may not be

combusted in the following cases.

• When you drive at low speed for a long

time

• When you repeat a short-time or short-

distance driving

1) When the DPF

® warning light comes

on, drive at a speed of 50 km/h (31

mph) or higher for more than 25 min-

utes to regenerate the DPF

® properly.

For details, refer to “Diesel particulate

filter (DPF

®)” in “OPERATING YOUR

VEHICLE” section.

2) When the oil change request light

blinks, change the engine oil and oil fil-

ter, and reset the oil life monitoring sys-

tem. To reset the oil life monitoring

system, consult your SUZUKI dealer.

3) When the engine oil level exceeds the

MAX level on the dipstick, consult your

SUZUKI dealer.

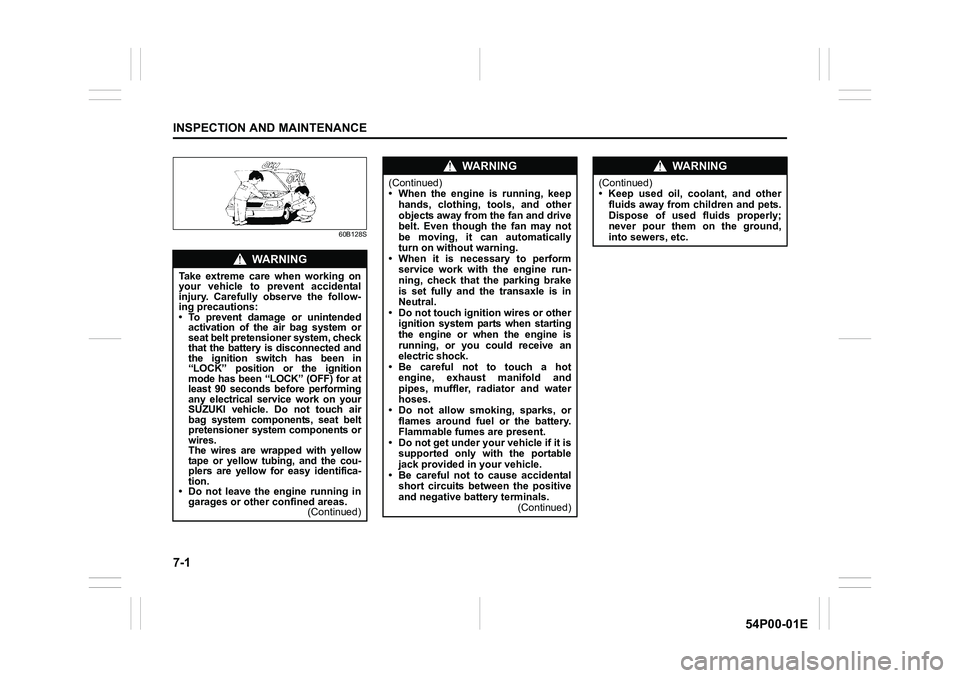

Refilling

81A147

Remove the oil filler cap and pour oil slowly

through the filler hole to bring the oil level

to the upper limit on the dipstick. Be careful

not to overfill the oil. Too much oil is almost

as bad as too little oil. After refilling, start the

engine and allow it to idle for about a min-

ute. Stop the engine, wait about 5 minutes

and check the oil level again.

NOTICE

Failure to check the oil level regularly

could lead to serious engine trouble

due to insufficient oil.

NOTICE

(For diesel engine model)

Do not top up the oil over the MAX

limit. Too much oil causes serious

engine trouble.

EXAMPLE

Open Close

Page 371 of 482

7-33

INSPECTION AND MAINTENANCE

54P00-01E

Fuel filter (diesel engine)

If the fuel filter warning light comes on

when driving, there is a possibility that

water is in the fuel filter. Drain water as

soon as possible. Have your vehicle

inspected by an authorized SUZUKI

dealer.

Brakes

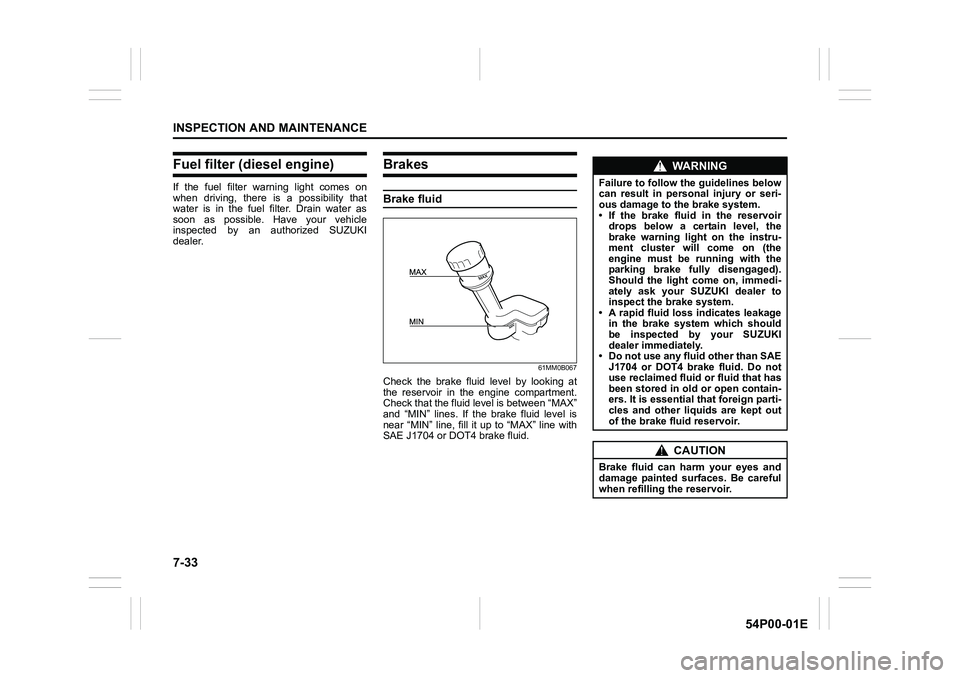

Brake fluid

61MM0B067

Check the brake fluid level by looking at

the reservoir in the engine compartment.

Check that the fluid level is between “MAX”

and “MIN” lines. If the brake fluid level is

near “MIN” line, fill it up to “MAX” line with

SAE J1704 or DOT4 brake fluid.

WA R N I N G

Failure to follow the guidelines below

can result in personal injury or seri-

ous damage to the brake system.

• If the brake fluid in the reservoir

drops below a certain level, the

brake warning light on the instru-

ment cluster will come on (the

engine must be running with the

parking brake fully disengaged).

Should the light come on, immedi-

ately ask your SUZUKI dealer to

inspect the brake system.

• A rapid fluid loss indicates leakage

in the brake system which should

be inspected by your SUZUKI

dealer immediately.

• Do not use any fluid other than SAE

J1704 or DOT4 brake fluid. Do not

use reclaimed fluid or fluid that has

been stored in old or open contain-

ers. It is essential that foreign parti-

cles and other liquids are kept out

of the brake fluid reservoir.

CAUTION

Brake fluid can harm your eyes and

damage painted surfaces. Be careful

when refilling the reservoir.

Page 374 of 482

7-36

INSPECTION AND MAINTENANCE

54P00-01E

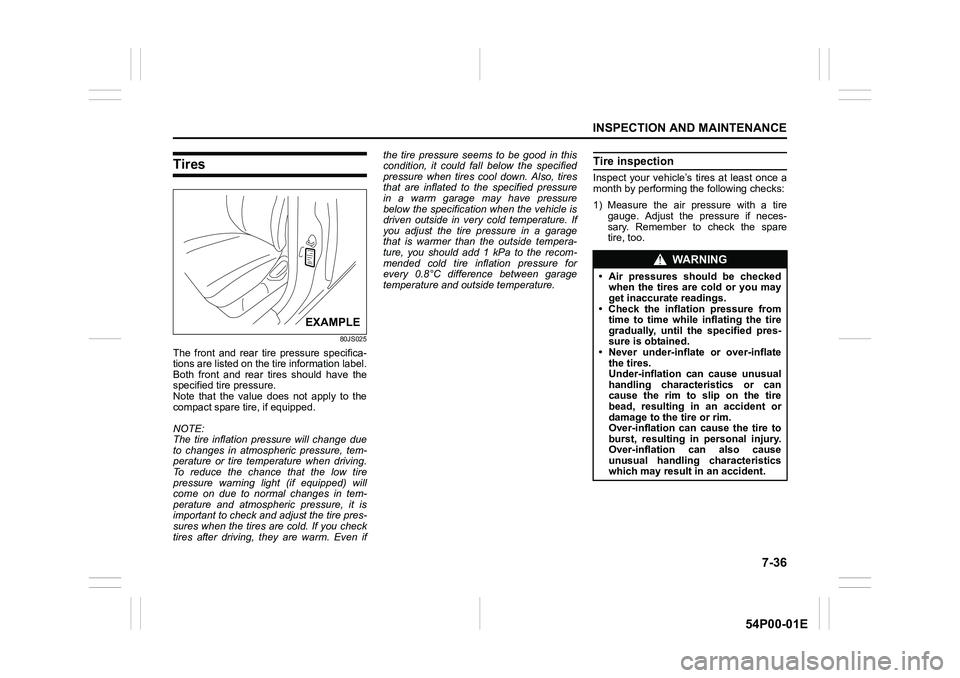

Tires

80JS025

The front and rear tire pressure specifica-

tions are listed on the tire information label.

Both front and rear tires should have the

specified tire pressure.

Note that the value does not apply to the

compact spare tire, if equipped.

NOTE:

The tire inflation pressure will change due

to changes in atmospheric pressure, tem-

perature or tire temperature when driving.

To reduce the chance that the low tire

pressure warning light (if equipped) will

come on due to normal changes in tem-

perature and atmospheric pressure, it is

important to check and adjust the tire pres-

sures when the tires are cold. If you check

tires after driving, they are warm. Even ifthe tire pressure seems to be good in this

condition, it could fall below the specified

pressure when tires cool down. Also, tires

that are inflated to the specified pressure

in a warm garage may have pressure

below the specification when the vehicle is

driven outside in very cold temperature. If

you adjust the tire pressure in a garage

that is warmer than the outside tempera-

ture, you should add 1 kPa to the recom-

mended cold tire inflation pressure for

every 0.8°C difference between garage

temperature and outside temperature.

Tire inspection

Inspect your vehicle’s tires at least once a

month by performing the following checks:

1) Measure the air pressure with a tire

gauge. Adjust the pressure if neces-

sary. Remember to check the spare

tire, too.

EXAMPLE

WA R N I N G

• Air pressures should be checked

when the tires are cold or you may

get inaccurate readings.

• Check the inflation pressure from

time to time while inflating the tire

gradually, until the specified pres-

sure is obtained.

• Never under-inflate or over-inflate

the tires.

Under-inflation can cause unusual

handling characteristics or can

cause the rim to slip on the tire

bead, resulting in an accident or

damage to the tire or rim.

Over-inflation can cause the tire to

burst, resulting in personal injury.

Over-inflation can also cause

unusual handling characteristics

which may result in an accident.

Page 402 of 482

8-2

EMERGENCY SERVICE

54P00-01E

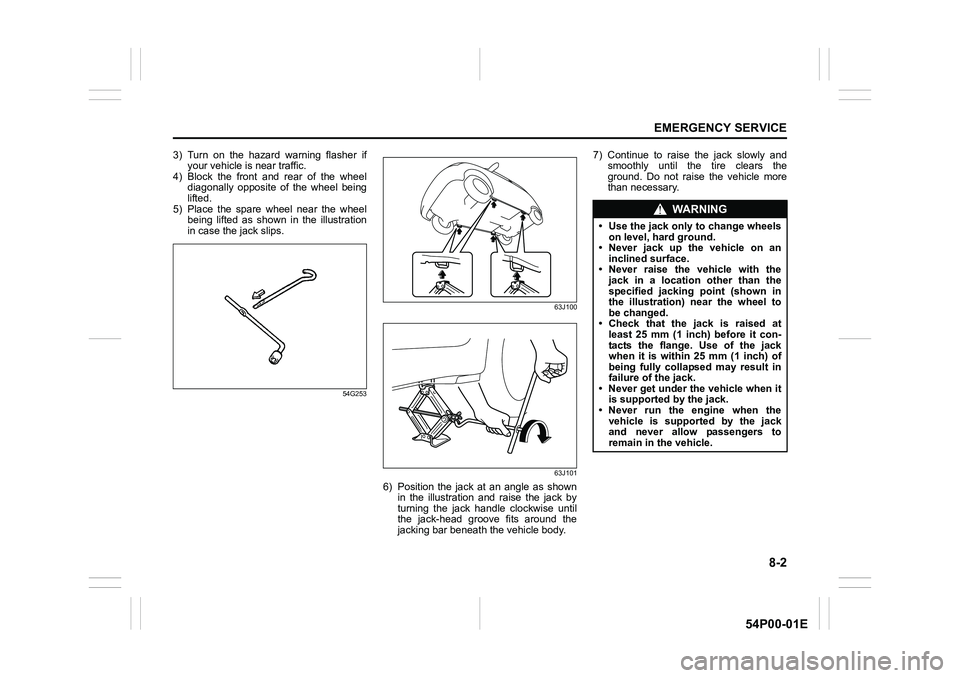

3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case the jack slips.

54G25363J100

63J101

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

WA R N I N G

• Use the jack only to change wheels

on level, hard ground.

• Never jack up the vehicle on an

inclined surface.

• Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

• Check that the jack is raised at

least 25 mm (1 inch) before it con-

tacts the flange. Use of the jack

when it is within 25 mm (1 inch) of

being fully collapsed may result in

failure of the jack.

• Never get under the vehicle when it

is supported by the jack.

• Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 407 of 482

8-7

EMERGENCY SERVICE

54P00-01E

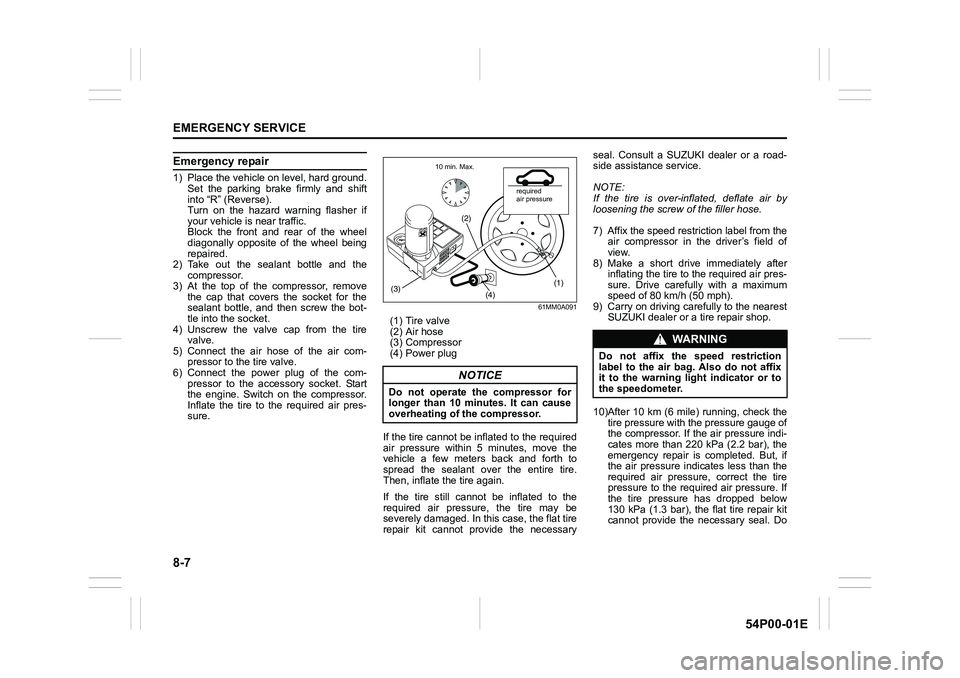

Emergency repair

1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “R” (Reverse).

Turn on the hazard warning flasher if

your vehicle is near traffic.

Block the front and rear of the wheel

diagonally opposite of the wheel being

repaired.

2) Take out the sealant bottle and the

compressor.

3) At the top of the compressor, remove

the cap that covers the socket for the

sealant bottle, and then screw the bot-

tle into the socket.

4) Unscrew the valve cap from the tire

valve.

5) Connect the air hose of the air com-

pressor to the tire valve.

6) Connect the power plug of the com-

pressor to the accessory socket. Start

the engine. Switch on the compressor.

Inflate the tire to the required air pres-

sure.

61MM0A091

(1) Tire valve

(2) Air hose

(3) Compressor

(4) Power plug

If the tire cannot be inflated to the required

air pressure within 5 minutes, move the

vehicle a few meters back and forth to

spread the sealant over the entire tire.

Then, inflate the tire again.

If the tire still cannot be inflated to the

required air pressure, the tire may be

severely damaged. In this case, the flat tire

repair kit cannot provide the necessaryseal. Consult a SUZUKI dealer or a road-

side assistance service.

NOTE:

If the tire is over-inflated, deflate air by

loosening the screw of the filler hose.

7) Affix the speed restriction label from the

air compressor in the driver’s field of

view.

8) Make a short drive immediately after

inflating the tire to the required air pres-

sure. Drive carefully with a maximum

speed of 80 km/h (50 mph).

9) Carry on driving carefully to the nearest

SUZUKI dealer or a tire repair shop.

10)After 10 km (6 mile) running, check the

tire pressure with the pressure gauge of

the compressor. If the air pressure indi-

cates more than 220 kPa (2.2 bar), the

emergency repair is completed. But, if

the air pressure indicates less than the

required air pressure, correct the tire

pressure to the required air pressure. If

the tire pressure has dropped below

130 kPa (1.3 bar), the flat tire repair kit

cannot provide the necessary seal. Do

NOTICE

Do not operate the compressor for

longer than 10 minutes. It can cause

overheating of the compressor.

(1)

(4)

(2)

(3)

required

air pressure 10 min. Max.

WA R N I N G

Do not affix the speed restriction

label to the air bag. Also do not affix

it to the warning light indicator or to

the speedometer.

Page 433 of 482

12-3

SUPPLEMENT

54P00-01E

Seat belt warning

Follow this warning as well as the instruc-

tion for seat belt in this book.

In the case where a “Seat Belt Assembly”

incorporates an “Automatic Length Adjust-

ing and Locking Retractor” or an “Emer-

gency Locking Retractor”.

For Mexico

Fuel recommendation

54P000101

Your vehicle requires regular unleaded

gasoline with a minimum rating of 87 pump

octane ((R + M)/2 method). In some areas,

the only fuels that are available are oxy-

genated fuels.

Oxygenated fuels which meet the mini-

mum octane requirement and the require-

ments described below may be used in

your vehicle without jeopardizing the New

Vehicle Limited Warranty.

WA R N I N G

Seat belts are designed to bear upon

the bony structure of the body, and

should be worn low across the front

of the pelvis or the pelvis, chest and

shoulders, as applicable; wearing the

lap section of the belt across the

abdominal area must be avoided.

• Seat belts should be adjusted as

firmly as possible, consistent with

comfort, to provide the protection

for which they have been designed.

A slack belt will greatly reduce the

protection afforded to the wearer.

• Care should be taken to avoid con-

tamination of the webbing with pol-

ishes, oils and chemicals, and

particularly battery acid. Cleaning

may safely be carried out using

mild soap and water. The belt

should be replaced if webbing

becomes frayed, contaminated or

damaged.

(Continued)

WA R N I N G

(Continued)

• It is essential to replace the entire

assembly after it has been worn in

a severe impact even if damage to

the assembly is not obvious.

• Belts should not be worn with

straps twisted.

• Each belt assembly must only be

used by one occupant; it is danger-

ous to put a belt around a child

being carried on the occupant’s

lap.

WA R N I N G

• No modifications or additions

should be made by the user which

will either prevent the seat belt

adjusting devices from operating to

remove slack, or prevent the seat

belt assembly from being adjusted

to remove slack.

• Referring to the instruction for seat

belt in this book, adjust the seat

belt so that the lap and sash por-

tions of the “Seat Belt Assembly”

fit as firmly as possible consistent

with comfort.

EXAMPLE

Page 437 of 482

12-7

SUPPLEMENT

54P00-01E

How to stop the alarm

Should the alarm be triggered accidentally,

unlock the doors using the keyless push

start system remote controller, the request

switch or the keyless entry system trans-

mitter, or press the engine switch to

change the ignition mode to “ON” or turn

the ignition switch to “ON” position. The

alarm will then stop.

NOTE:

Even after the alarm has stopped, if you

lock the doors using the keyless push

start system remote controller, the

request switch or the keyless entry sys-

tem transmitter, the theft deterrent alarm

system will be rearmed with a delay of

about 20 seconds.

If you disconnect the battery while the

theft deterrent alarm system is in the

armed condition or the alarm is actually

in operation, the alarm will be triggered

or re-triggered when the battery is then

reconnected, although, in the latter case,

the alarm remains stopped for the period

between disconnection and reconnec-

tion of the battery.

Even after the alarm has stopped at the

end of the predetermined operation time,

it will be triggered again if any door or

engine hood (for EU specification vehi-

cle) is opened without disarming the

theft deterrent alarm system.Checking whether the alarm has been

triggered during parking

If the alarm was triggered due to an unau-

thorized entry into the vehicle and you then

press the engine switch to change the igni-

tion mode to “ON” or turn the ignition

switch to “ON” position, the theft deterrent

light will blink rapidly for about 8 seconds

and a buzzer will beep 4 times during this

period. If this happens, check whether your

vehicle has been broken into while you

were away from it.

Enabling and disabling the theft deter-

rent alarm system

The theft deterrent alarm system can be

either enabled or disabled.

When enabled (factory setting)

When the system is enabled, it causes the

hazard warning lights to flash for about 40

seconds if any of the alarm trigger condi-

tions is met. The system also causes the

interior buzzer to beep intermittently for

about 10 seconds, which is followed by

intermittent sounding of the horn for about

30 seconds.

The theft deterrent light continues to blink

during this time.

When disabled

When the system is disabled, it stays dis-

armed even if you perform any system

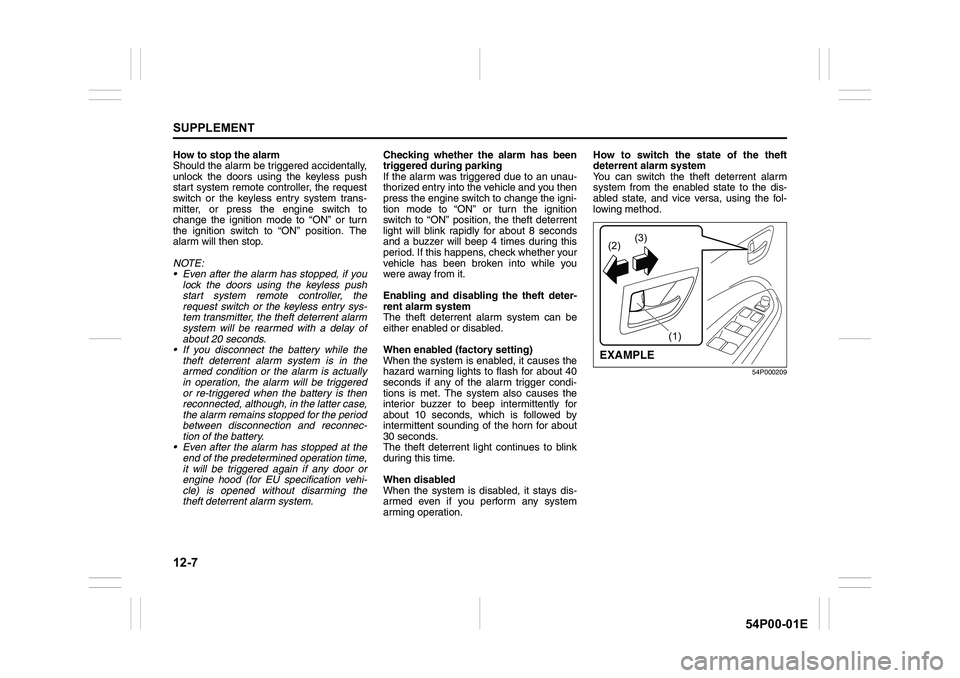

arming operation.How to switch the state of the theft

deterrent alarm system

You can switch the theft deterrent alarm

system from the enabled state to the dis-

abled state, and vice versa, using the fol-

lowing method.

54P000209

(2)(3)

(1)

EXAMPLE