lock SUZUKI GRAND VITARA 2015 Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2015, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2015Pages: 482, PDF Size: 21 MB

Page 390 of 482

7-52

INSPECTION AND MAINTENANCE

54P00-01E

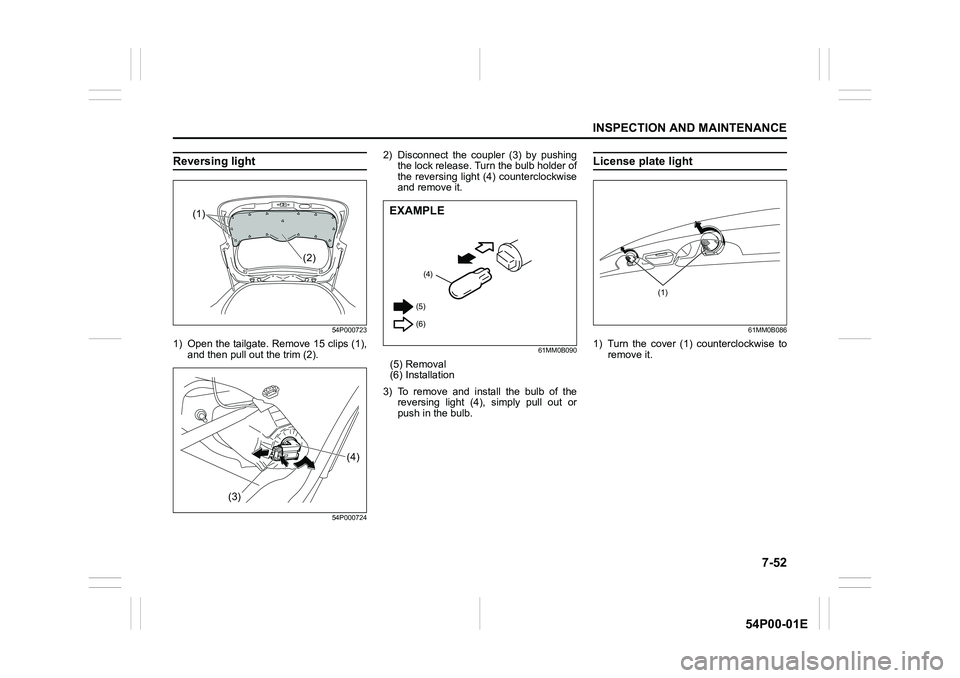

Reversing light

54P000723

1) Open the tailgate. Remove 15 clips (1),

and then pull out the trim (2).

54P000724

2) Disconnect the coupler (3) by pushing

the lock release. Turn the bulb holder of

the reversing light (4) counterclockwise

and remove it.

61MM0B090

(5) Removal

(6) Installation

3) To remove and install the bulb of the

reversing light (4), simply pull out or

push in the bulb.

License plate light

61MM0B086

1) Turn the cover (1) counterclockwise to

remove it.

(1)

(2)

(3)(4)

(4)

(5)

(6)

EXAMPLE

(1)

Page 391 of 482

7-53

INSPECTION AND MAINTENANCE

54P00-01E

61MM0B087

2) To remove and install the bulb of the

license plate light (2), simply pull out or

push in the bulb.

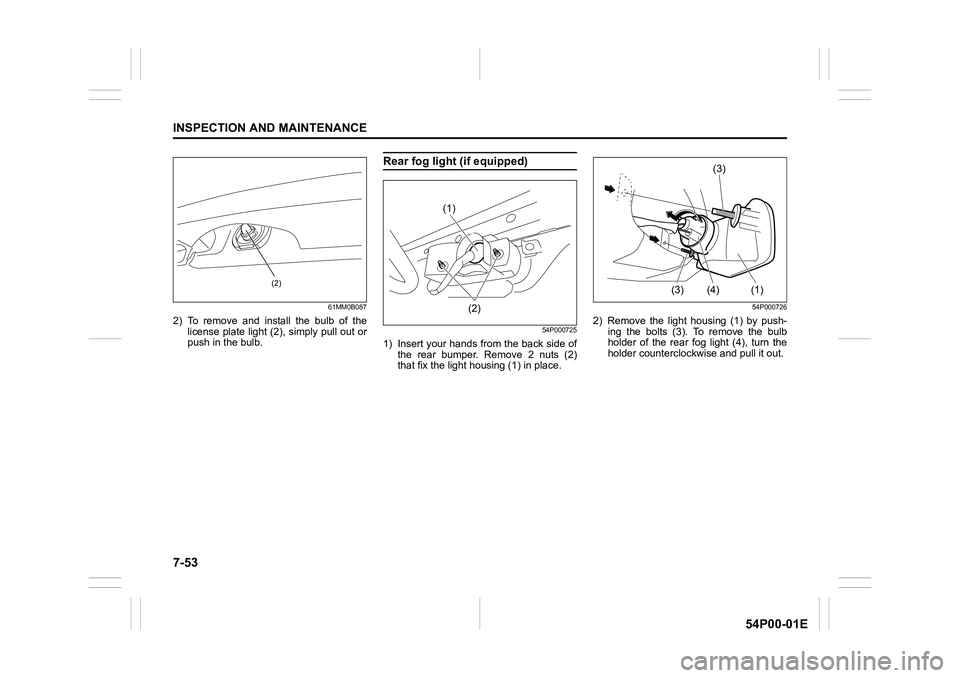

Rear fog light (if equipped)

54P000725

1) Insert your hands from the back side of

the rear bumper. Remove 2 nuts (2)

that fix the light housing (1) in place.

54P000726

2) Remove the light housing (1) by push-

ing the bolts (3). To remove the bulb

holder of the rear fog light (4), turn the

holder counterclockwise and pull it out.

(2)

(2) (1)

(1) (4) (3)(3)

Page 392 of 482

7-54

INSPECTION AND MAINTENANCE

54P00-01E

54P000727

(5) Removal

(6) Installation

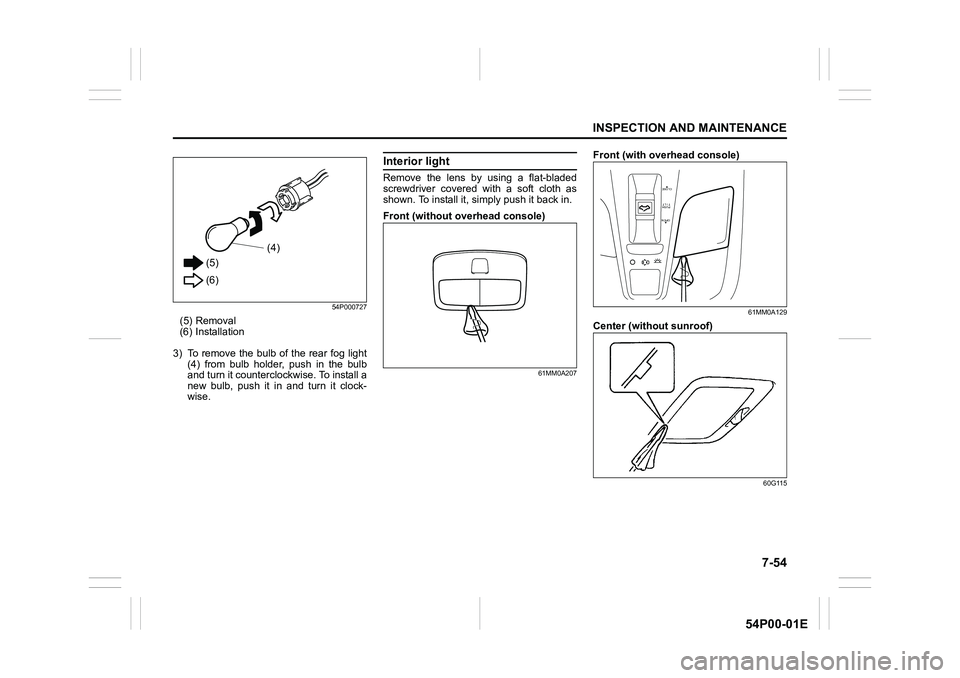

3) To remove the bulb of the rear fog light

(4) from bulb holder, push in the bulb

and turn it counterclockwise. To install a

new bulb, push it in and turn it clock-

wise.

Interior light

Remove the lens by using a flat-bladed

screwdriver covered with a soft cloth as

shown. To install it, simply push it back in.

Front (without overhead console)

61MM0A207

Front (with overhead console)

61MM0A129

Center (without sunroof)

60G115

(5)

(6)(4)

OPEN

PUSH

TILT

CLOSE

Page 394 of 482

7-56

INSPECTION AND MAINTENANCE

54P00-01E

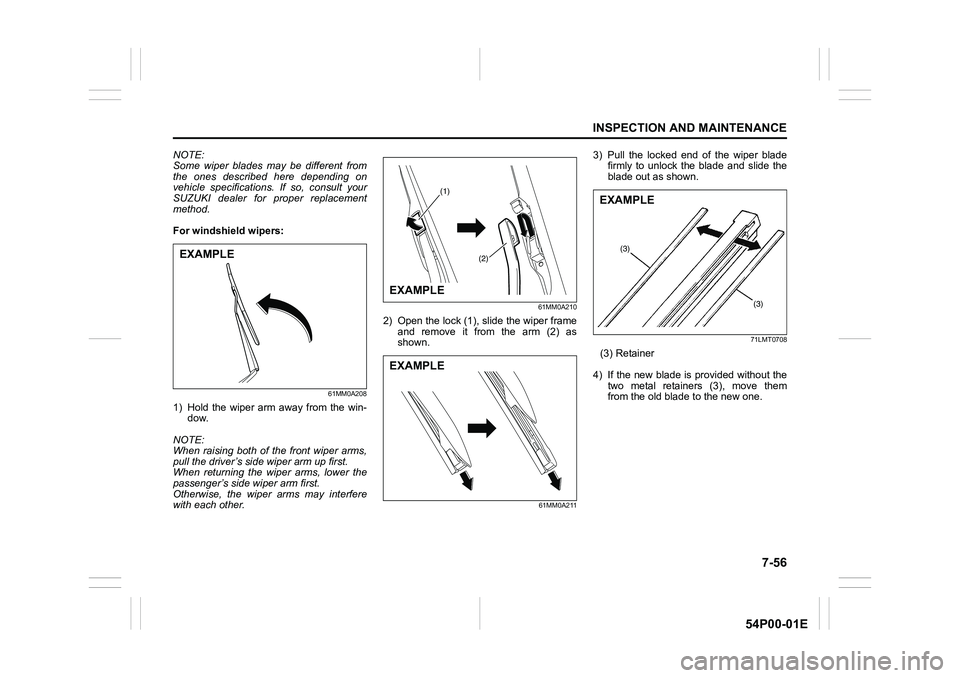

NOTE:

Some wiper blades may be different from

the ones described here depending on

vehicle specifications. If so, consult your

SUZUKI dealer for proper replacement

method.

For windshield wipers:

61MM0A208

1) Hold the wiper arm away from the win-

dow.

NOTE:

When raising both of the front wiper arms,

pull the driver’s side wiper arm up first.

When returning the wiper arms, lower the

passenger’s side wiper arm first.

Otherwise, the wiper arms may interfere

with each other.

61MM0A210

2) Open the lock (1), slide the wiper frame

and remove it from the arm (2) as

shown.

61MM0A211

3) Pull the locked end of the wiper blade

firmly to unlock the blade and slide the

blade out as shown.

71LMT0708

(3) Retainer

4) If the new blade is provided without the

two metal retainers (3), move them

from the old blade to the new one.

EXAMPLE

(1)

(2)

EXAMPLE

EXAMPLE

(3)

(3)

EXAMPLE

Page 395 of 482

7-57

INSPECTION AND MAINTENANCE

54P00-01E

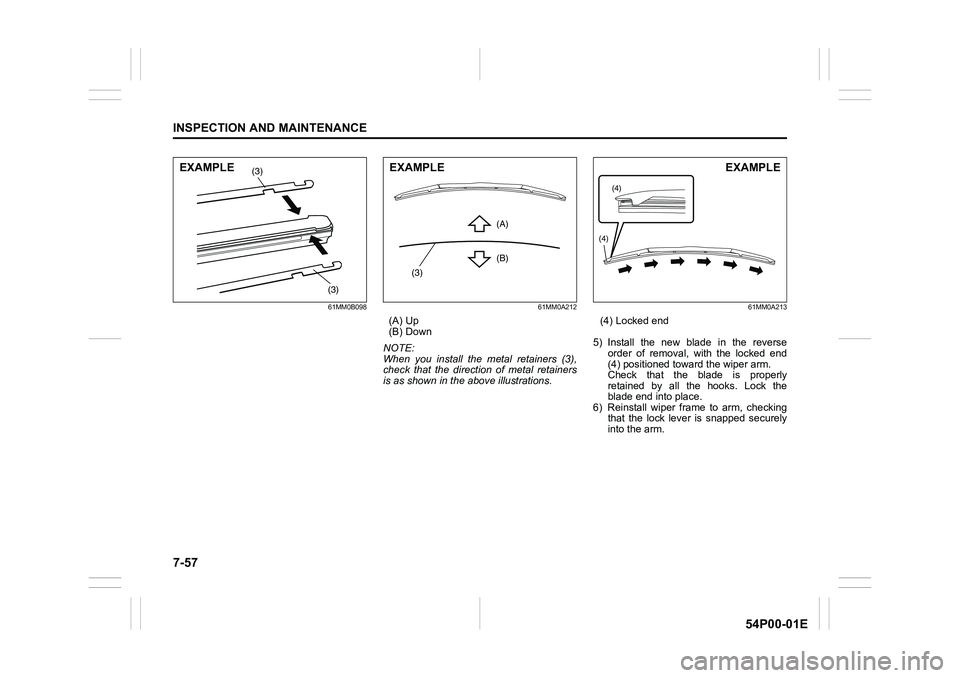

61MM0B098 61MM0A212

(A) Up

(B) Down

NOTE:

When you install the metal retainers (3),

check that the direction of metal retainers

is as shown in the above illustrations.

61MM0A213

(4) Locked end

5) Install the new blade in the reverse

order of removal, with the locked end

(4) positioned toward the wiper arm.

Check that the blade is properly

retained by all the hooks. Lock the

blade end into place.

6) Reinstall wiper frame to arm, checking

that the lock lever is snapped securely

into the arm.

(3)

(3)EXAMPLE

(3)(A)

(B)

EXAMPLE

(4)

(4)

EXAMPLE

Page 401 of 482

8-1

EMERGENCY SERVICE

54P00-01E

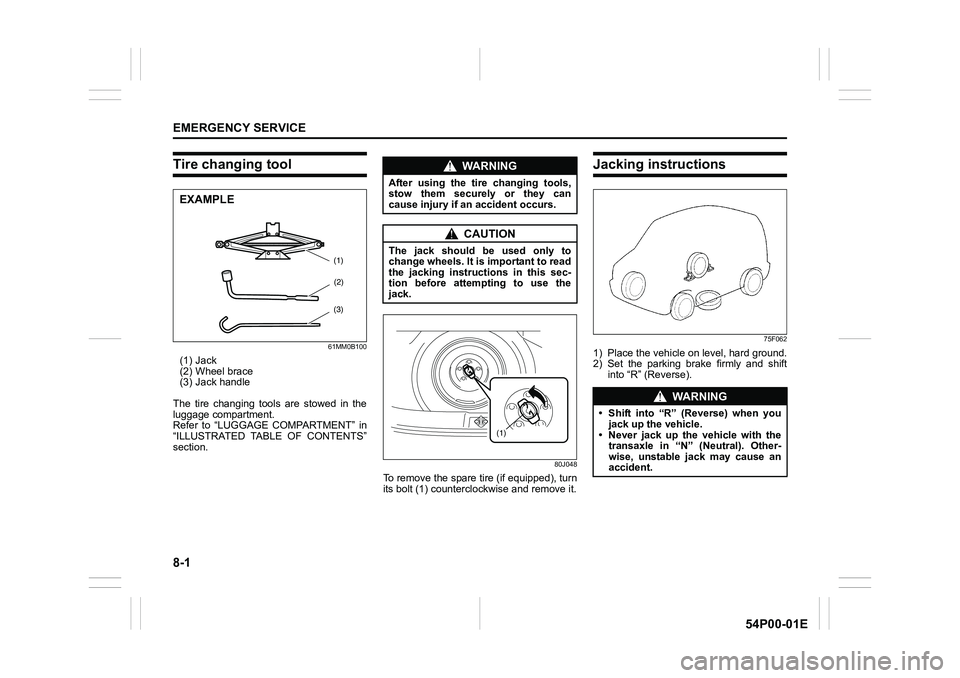

Tire changing tool

61MM0B100

(1) Jack

(2) Wheel brace

(3) Jack handle

The tire changing tools are stowed in the

luggage compartment.

Refer to “LUGGAGE COMPARTMENT” in

“ILLUSTRATED TABLE OF CONTENTS”

section.

80J048

To remove the spare tire (if equipped), turn

its bolt (1) counterclockwise and remove it.

Jacking instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).

EXAMPLE

(3)

(2)

(1)

WA R N I N G

After using the tire changing tools,

stow them securely or they can

cause injury if an accident occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

(1)

WA R N I N G

• Shift into “R” (Reverse) when you

jack up the vehicle.

• Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

Page 402 of 482

8-2

EMERGENCY SERVICE

54P00-01E

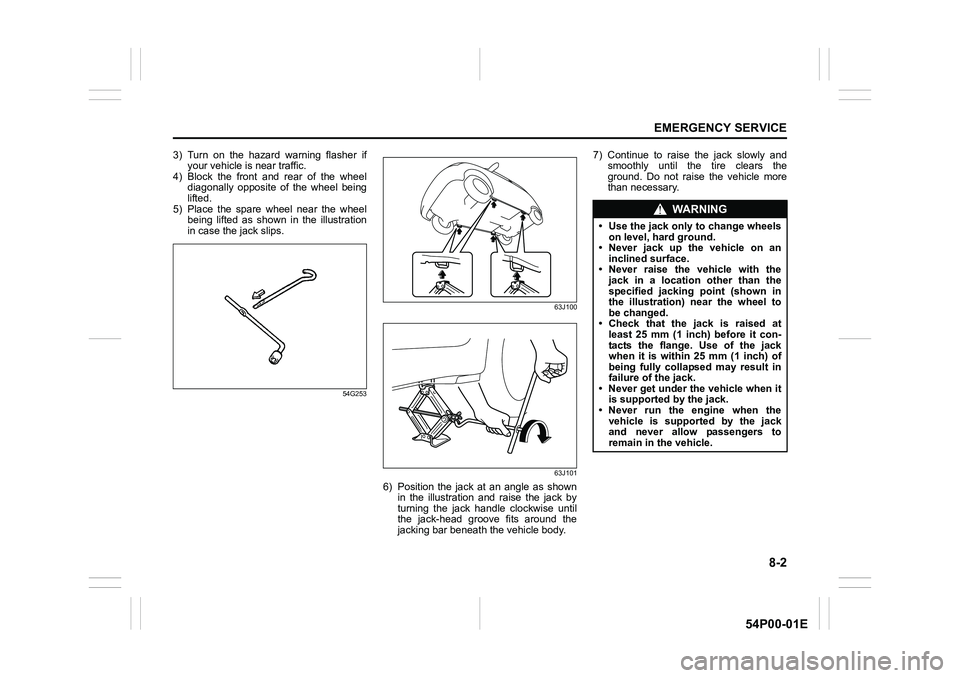

3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case the jack slips.

54G25363J100

63J101

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

WA R N I N G

• Use the jack only to change wheels

on level, hard ground.

• Never jack up the vehicle on an

inclined surface.

• Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

• Check that the jack is raised at

least 25 mm (1 inch) before it con-

tacts the flange. Use of the jack

when it is within 25 mm (1 inch) of

being fully collapsed may result in

failure of the jack.

• Never get under the vehicle when it

is supported by the jack.

• Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 407 of 482

8-7

EMERGENCY SERVICE

54P00-01E

Emergency repair

1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “R” (Reverse).

Turn on the hazard warning flasher if

your vehicle is near traffic.

Block the front and rear of the wheel

diagonally opposite of the wheel being

repaired.

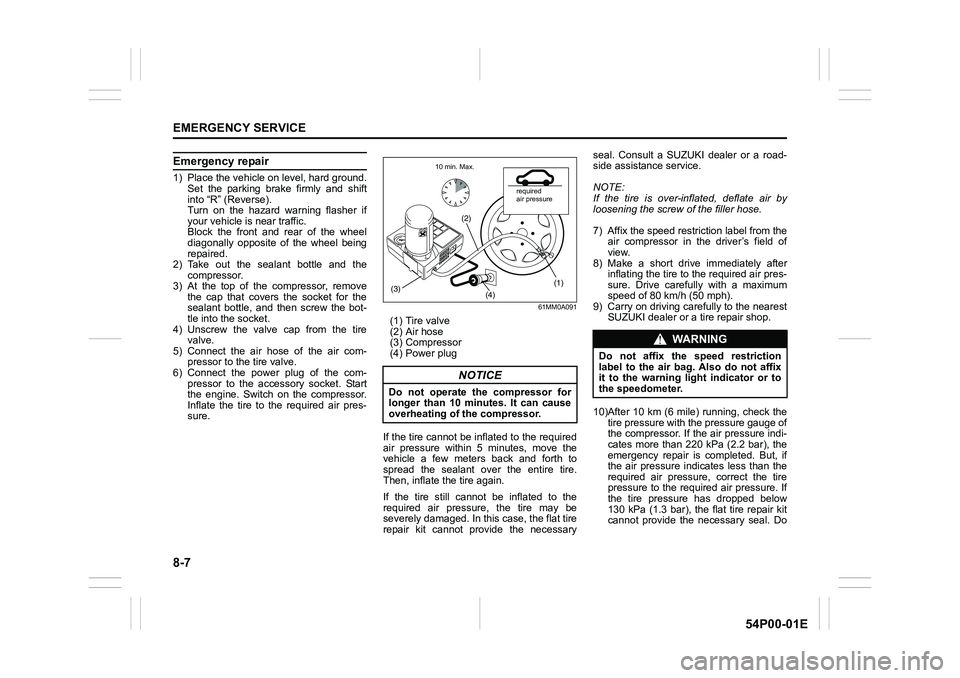

2) Take out the sealant bottle and the

compressor.

3) At the top of the compressor, remove

the cap that covers the socket for the

sealant bottle, and then screw the bot-

tle into the socket.

4) Unscrew the valve cap from the tire

valve.

5) Connect the air hose of the air com-

pressor to the tire valve.

6) Connect the power plug of the com-

pressor to the accessory socket. Start

the engine. Switch on the compressor.

Inflate the tire to the required air pres-

sure.

61MM0A091

(1) Tire valve

(2) Air hose

(3) Compressor

(4) Power plug

If the tire cannot be inflated to the required

air pressure within 5 minutes, move the

vehicle a few meters back and forth to

spread the sealant over the entire tire.

Then, inflate the tire again.

If the tire still cannot be inflated to the

required air pressure, the tire may be

severely damaged. In this case, the flat tire

repair kit cannot provide the necessaryseal. Consult a SUZUKI dealer or a road-

side assistance service.

NOTE:

If the tire is over-inflated, deflate air by

loosening the screw of the filler hose.

7) Affix the speed restriction label from the

air compressor in the driver’s field of

view.

8) Make a short drive immediately after

inflating the tire to the required air pres-

sure. Drive carefully with a maximum

speed of 80 km/h (50 mph).

9) Carry on driving carefully to the nearest

SUZUKI dealer or a tire repair shop.

10)After 10 km (6 mile) running, check the

tire pressure with the pressure gauge of

the compressor. If the air pressure indi-

cates more than 220 kPa (2.2 bar), the

emergency repair is completed. But, if

the air pressure indicates less than the

required air pressure, correct the tire

pressure to the required air pressure. If

the tire pressure has dropped below

130 kPa (1.3 bar), the flat tire repair kit

cannot provide the necessary seal. Do

NOTICE

Do not operate the compressor for

longer than 10 minutes. It can cause

overheating of the compressor.

(1)

(4)

(2)

(3)

required

air pressure 10 min. Max.

WA R N I N G

Do not affix the speed restriction

label to the air bag. Also do not affix

it to the warning light indicator or to

the speedometer.

Page 410 of 482

8-10

EMERGENCY SERVICE

54P00-01E

Towing

If you need to have your vehicle towed,

contact a professional service. Your dealer

can provide you with detailed towing

instructions.

2-wheel drive (2WD) manual tran-saxle

Manual transaxle vehicles may be towed

using either of the following methods.

1) From the front, with the front wheels

lifted and the rear wheels on the

ground. Before towing, check that the

parking brake is released.

2) From the rear, with the rear wheels

lifted and the front wheels on the

ground, provided the steering and

drivetrain are in operational condition.

Before towing, check that transaxle is in

neutral, the steering wheel is unlocked

(vehicle without keyless push start sys-

tem - the ignition key should be in

“ACC” position) (vehicle with keyless

push start system - the ignition mode is

“ACC”), and the steering wheel is

secured with a clamping device

designed for towing service.

4-wheel drive (4WD)

Your vehicle should be towed under one of

the following conditions:

1) With all four wheels on a flat-bed truck.

2) With the front or rear wheels lifted and a

dolly under the other wheels.

WA R N I N G

For vehicles equipped with the radar

brake support system, if your vehicle

is towed with the engine on, press

radar brake support OFF switch and

turn off the radar brake support sys-

tem. If not, unexpected accidents

related to the system being turned on

may occur.

NOTICE

Observe the following instructions

when towing your vehicle.

• To help avoid damage to your vehi-

cle during towing, proper equip-

ment and towing procedures must

be used.

• Using the frame hook, tow your

vehicle on paved roads for short

distances at low speed.

NOTICE

The steering column is not strong

enough to withstand shocks trans-

mitted from the front wheels during

towing. Always unlock the steering

wheel before towing.

Page 421 of 482

10-1

GENERAL INFORMATION

54P00-01E

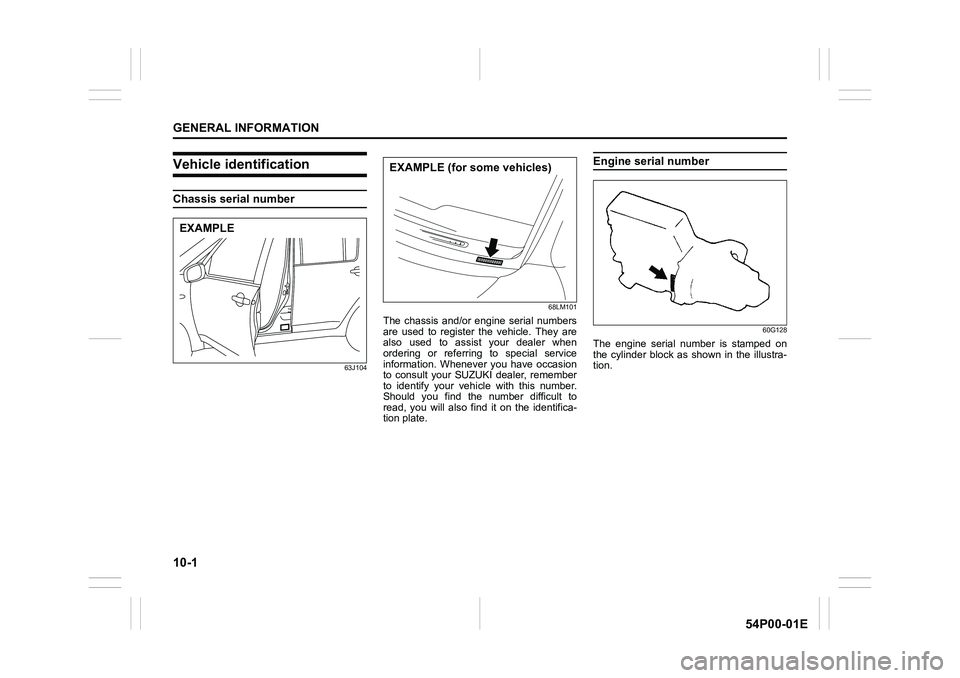

Vehicle identification

Chassis serial number

63J10468LM101

The chassis and/or engine serial numbers

are used to register the vehicle. They are

also used to assist your dealer when

ordering or referring to special service

information. Whenever you have occasion

to consult your SUZUKI dealer, remember

to identify your vehicle with this number.

Should you find the number difficult to

read, you will also find it on the identifica-

tion plate.

Engine serial number

60G128

The engine serial number is stamped on

the cylinder block as shown in the illustra-

tion.

EXAMPLE

EXAMPLE (for some vehicles)