servic SUZUKI GRAND VITARA 2017 Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2017Pages: 482, PDF Size: 21 MB

Page 357 of 482

7-19

INSPECTION AND MAINTENANCE

54P00-01E

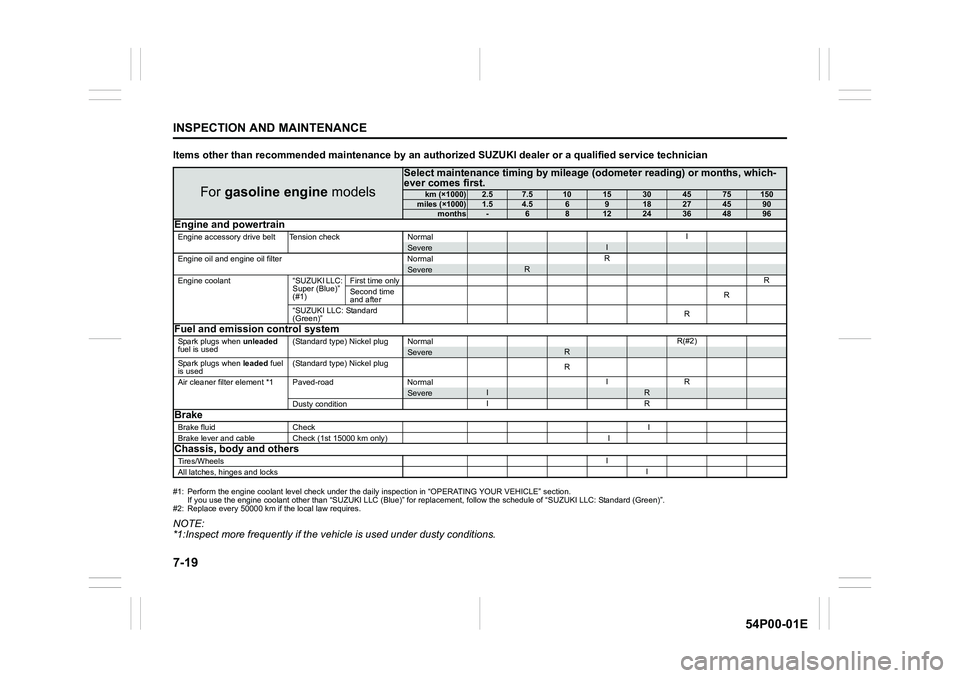

Items other than recommended maintenance by an authorized SUZUKI dealer or a qualified service technician

#1: Perform the engine coolant level check under the daily inspection in “OPERATING YOUR VEHICLE” section.

If you use the engine coolant other than “SUZUKI LLC (Blue)” for replacement, follow the schedule of “SUZUKI LLC: Standard (Green)”.

#2: Replace every 50000 km if the local law requires.

NOTE:

*1:Inspect more frequently if the vehicle is used under dusty conditions.

For gasoline engine models

Select maintenance timing by mileage (odometer reading) or months, which-

ever comes first.

km (×1000)2.57.51015304575150miles (×1000)1.54.56918274590months-681224364896Engine and powertrain

Engine accessory drive belt Tension check NormalISevereI

Engine oil and engine oil filter NormalRSevereR

Engine coolant “SUZUKI LLC:

Super (Blue)”

(#1)First time onlyR

Second time

and afterR

“SUZUKI LLC: Standard

(Green)”R

Fuel and emission control system

Spark plugs when unleaded

fuel is used(Standard type) Nickel plug NormalR(#2)SevereR

Spark plugs when leaded fuel

is used(Standard type) Nickel plug

R

Air cleaner filter element *1 Paved-road NormalIR

SevereIR

Dusty conditionIRBrake

Brake fluid CheckI

Brake lever and cable Check (1st 15000 km only) I

Chassis, body and others

Tires/WheelsI

All latches, hinges and locksI

Page 367 of 482

7-29

INSPECTION AND MAINTENANCE

54P00-01E

(For diesel engine model)

61MM0A126

1) Unclamp the side clamps and remove

the element from the air cleaner case. If

it appears to be dirty, replace it with a

new one.

2) Clamp the side clamps securely.

Spark plugs

Spark plug replacement and inspec-

tion

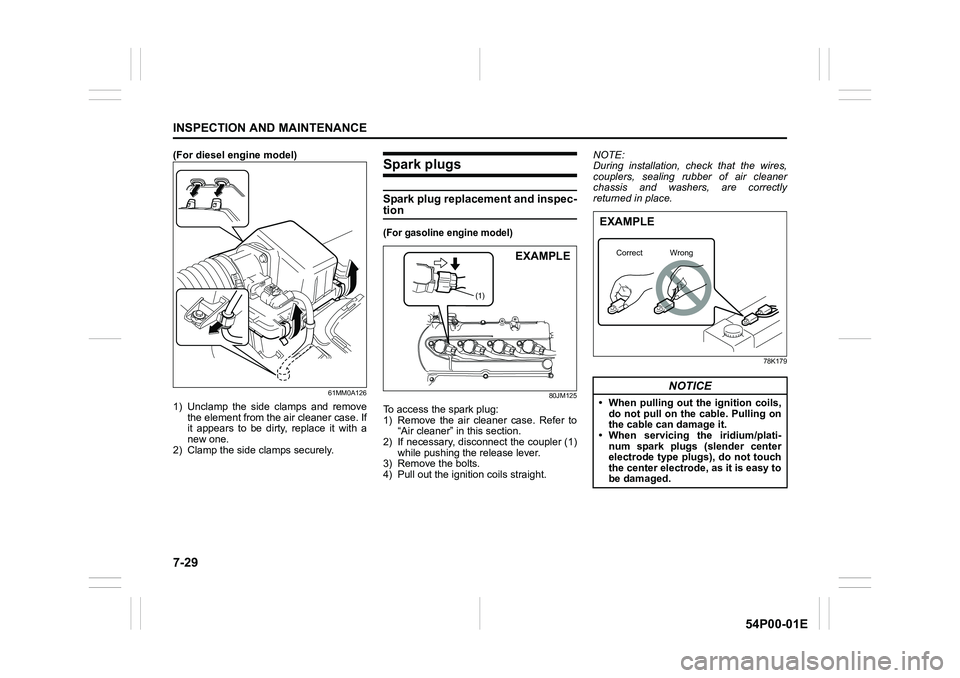

(For gasoline engine model)

80JM125

To access the spark plug:

1) Remove the air cleaner case. Refer to

“Air cleaner” in this section.

2) If necessary, disconnect the coupler (1)

while pushing the release lever.

3) Remove the bolts.

4) Pull out the ignition coils straight.NOTE:

During installation, check that the wires,

couplers, sealing rubber of air cleaner

chassis and washers, are correctly

returned in place.

78K179

(1)

EXAMPLE

NOTICE

• When pulling out the ignition coils,

do not pull on the cable. Pulling on

the cable can damage it.

• When servicing the iridium/plati-

num spark plugs (slender center

electrode type plugs), do not touch

the center electrode, as it is easy to

be damaged.

EXAMPLE

Correct Wrong

Page 377 of 482

7-39

INSPECTION AND MAINTENANCE

54P00-01E

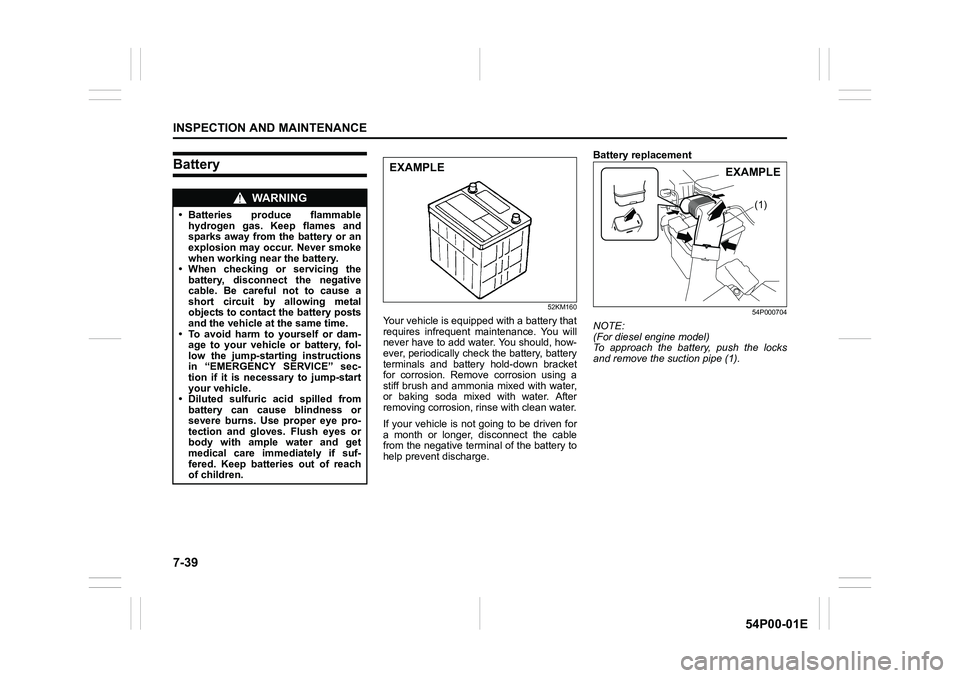

Battery

52KM160

Your vehicle is equipped with a battery that

requires infrequent maintenance. You will

never have to add water. You should, how-

ever, periodically check the battery, battery

terminals and battery hold-down bracket

for corrosion. Remove corrosion using a

stiff brush and ammonia mixed with water,

or baking soda mixed with water. After

removing corrosion, rinse with clean water.

If your vehicle is not going to be driven for

a month or longer, disconnect the cable

from the negative terminal of the battery to

help prevent discharge.Battery replacement54P000704

NOTE:

(For diesel engine model)

To approach the battery, push the locks

and remove the suction pipe (1).

WA R N I N G

• Batteries produce flammable

hydrogen gas. Keep flames and

sparks away from the battery or an

explosion may occur. Never smoke

when working near the battery.

• When checking or servicing the

battery, disconnect the negative

cable. Be careful not to cause a

short circuit by allowing metal

objects to contact the battery posts

and the vehicle at the same time.

• To avoid harm to yourself or dam-

age to your vehicle or battery, fol-

low the jump-starting instructions

in “EMERGENCY SERVICE” sec-

tion if it is necessary to jump-start

your vehicle.

• Diluted sulfuric acid spilled from

battery can cause blindness or

severe burns. Use proper eye pro-

tection and gloves. Flush eyes or

body with ample water and get

medical care immediately if suf-

fered. Keep batteries out of reach

of children.

EXAMPLE

(1)

EXAMPLE

Page 400 of 482

EMERGENCY SERVICE

8

54P00-01E

60G411

EMERGENCY SERVICE

Tire changing tool ............................................................... 8-1

Jacking instructions ........................................................... 8-1

Flat tire repair kit (if equipped) .......................................... 8-5

Jump-starting instructions ................................................. 8-8

Towing .................................................................................. 8-10

Engine trouble: Starter does not operate ......................... 8-11

Engine trouble: Flooded engine ........................................ 8-11

Engine trouble: Overheating .............................................. 8-12

Page 401 of 482

8-1

EMERGENCY SERVICE

54P00-01E

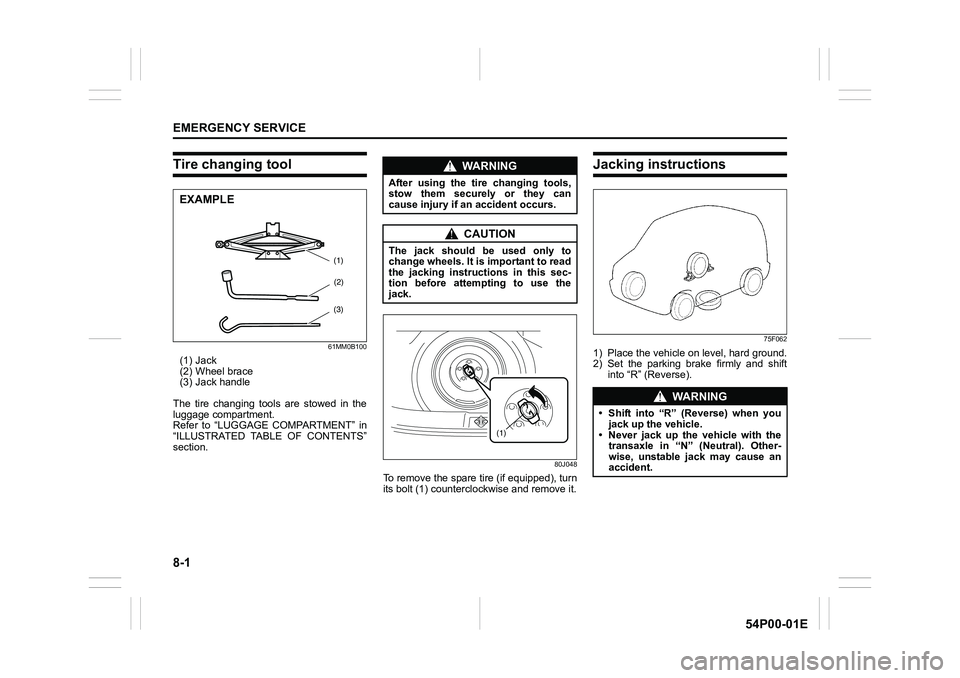

Tire changing tool

61MM0B100

(1) Jack

(2) Wheel brace

(3) Jack handle

The tire changing tools are stowed in the

luggage compartment.

Refer to “LUGGAGE COMPARTMENT” in

“ILLUSTRATED TABLE OF CONTENTS”

section.

80J048

To remove the spare tire (if equipped), turn

its bolt (1) counterclockwise and remove it.

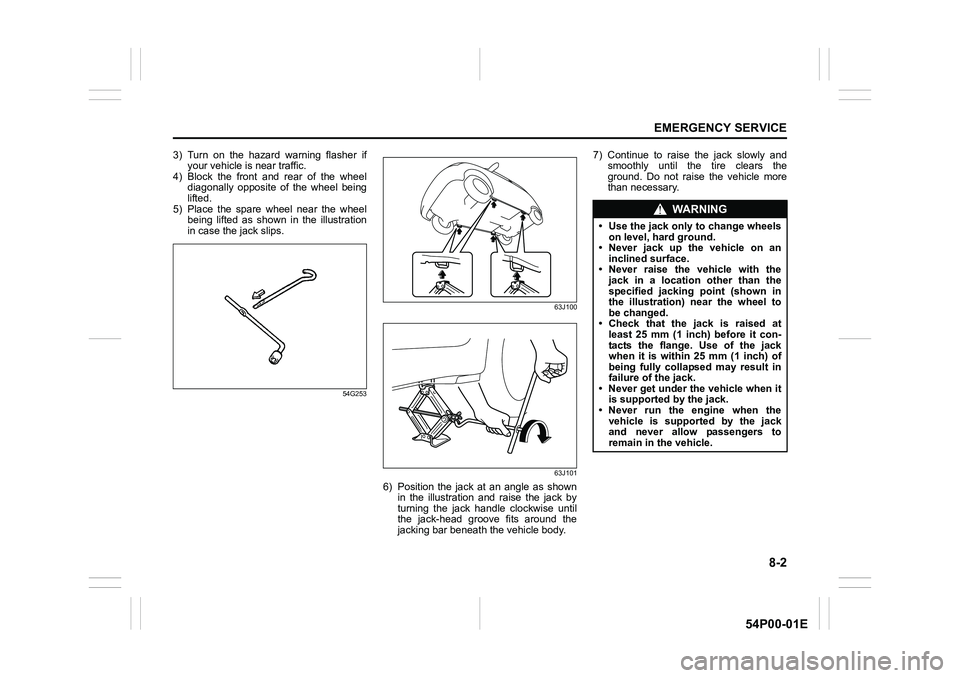

Jacking instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).

EXAMPLE

(3)

(2)

(1)

WA R N I N G

After using the tire changing tools,

stow them securely or they can

cause injury if an accident occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

(1)

WA R N I N G

• Shift into “R” (Reverse) when you

jack up the vehicle.

• Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

Page 402 of 482

8-2

EMERGENCY SERVICE

54P00-01E

3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case the jack slips.

54G25363J100

63J101

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

WA R N I N G

• Use the jack only to change wheels

on level, hard ground.

• Never jack up the vehicle on an

inclined surface.

• Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

• Check that the jack is raised at

least 25 mm (1 inch) before it con-

tacts the flange. Use of the jack

when it is within 25 mm (1 inch) of

being fully collapsed may result in

failure of the jack.

• Never get under the vehicle when it

is supported by the jack.

• Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 403 of 482

8-3

EMERGENCY SERVICE

54P00-01E

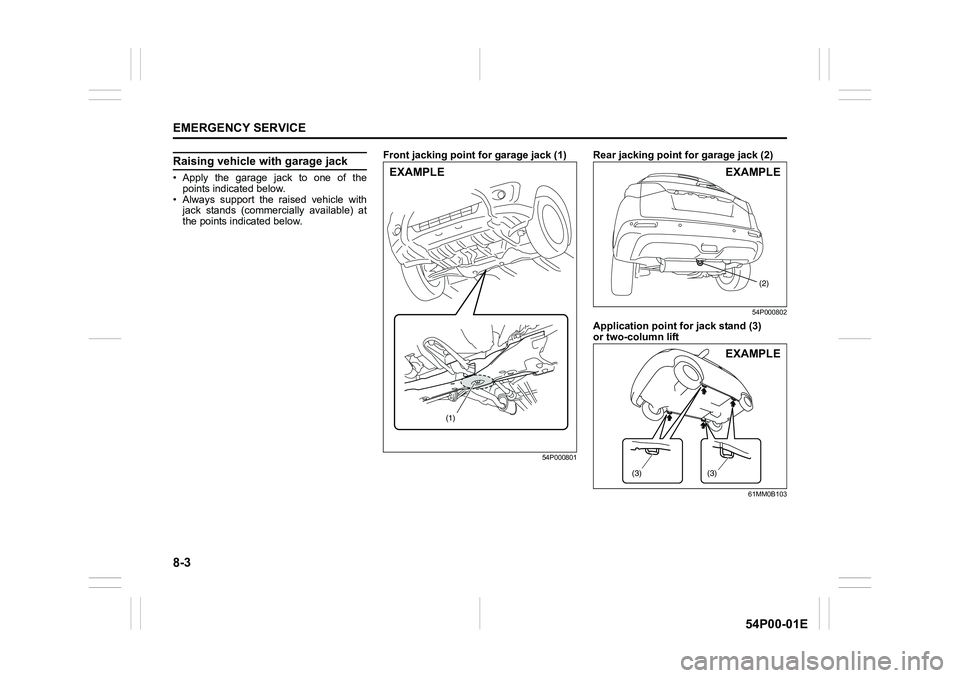

Raising vehicle with garage jack

• Apply the garage jack to one of the

points indicated below.

• Always support the raised vehicle with

jack stands (commercially available) at

the points indicated below.Front jacking point for garage jack (1)

54P000801

Rear jacking point for garage jack (2)

54P000802

Application point for jack stand (3)

or two-column lift

61MM0B103

(1)

EXAMPLE

(2)

EXAMPLE

(3)(3)

EXAMPLE

Page 404 of 482

8-4

EMERGENCY SERVICE

54P00-01E

NOTE:

For more details, contact an authorized

SUZUKI dealer.

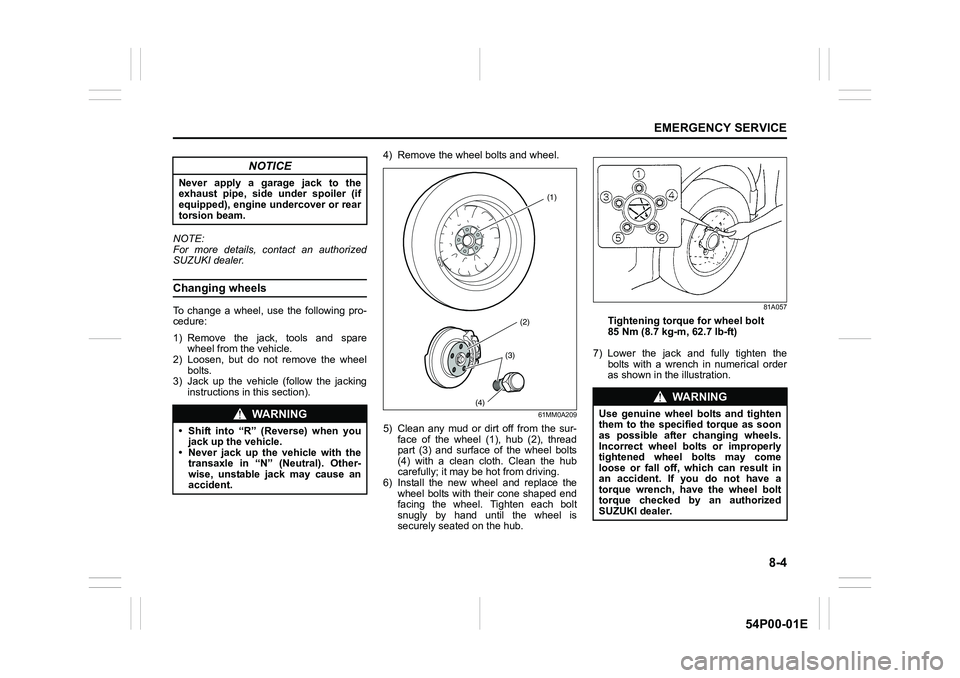

Changing wheels

To change a wheel, use the following pro-

cedure:

1) Remove the jack, tools and spare

wheel from the vehicle.

2) Loosen, but do not remove the wheel

bolts.

3) Jack up the vehicle (follow the jacking

instructions in this section).4) Remove the wheel bolts and wheel.

61MM0A209

5) Clean any mud or dirt off from the sur-

face of the wheel (1), hub (2), thread

part (3) and surface of the wheel bolts

(4) with a clean cloth. Clean the hub

carefully; it may be hot from driving.

6) Install the new wheel and replace the

wheel bolts with their cone shaped end

facing the wheel. Tighten each bolt

snugly by hand until the wheel is

securely seated on the hub.

81A057

Tightening torque for wheel bolt

85 Nm (8.7 kg-m, 62.7 lb-ft)

7) Lower the jack and fully tighten the

bolts with a wrench in numerical order

as shown in the illustration.

NOTICE

Never apply a garage jack to the

exhaust pipe, side under spoiler (if

equipped), engine undercover or rear

torsion beam.

WA R N I N G

• Shift into “R” (Reverse) when you

jack up the vehicle.

• Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

(2)

(4)

(1)

(3)

WA R N I N G

Use genuine wheel bolts and tighten

them to the specified torque as soon

as possible after changing wheels.

Incorrect wheel bolts or improperly

tightened wheel bolts may come

loose or fall off, which can result in

an accident. If you do not have a

torque wrench, have the wheel bolt

torque checked by an authorized

SUZUKI dealer.

Page 405 of 482

8-5

EMERGENCY SERVICE

54P00-01E

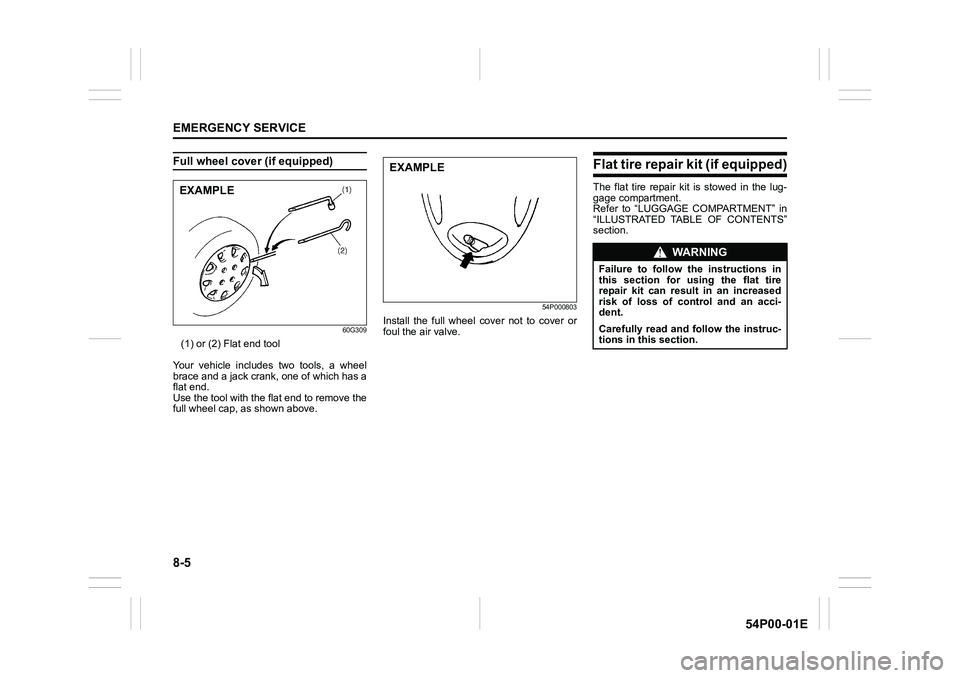

Full wheel cover (if equipped)

60G309

(1) or (2) Flat end tool

Your vehicle includes two tools, a wheel

brace and a jack crank, one of which has a

flat end.

Use the tool with the flat end to remove the

full wheel cap, as shown above.

54P000803

Install the full wheel cover not to cover or

foul the air valve.

Flat tire repair kit (if equipped)

The flat tire repair kit is stowed in the lug-

gage compartment.

Refer to “LUGGAGE COMPARTMENT” in

“ILLUSTRATED TABLE OF CONTENTS”

section.EXAMPLE

EXAMPLE

WA R N I N G

Failure to follow the instructions in

this section for using the flat tire

repair kit can result in an increased

risk of loss of control and an acci-

dent.

Carefully read and follow the instruc-

tions in this section.

Page 406 of 482

8-6

EMERGENCY SERVICE

54P00-01E

IMPORTANT

The flat tire repair kit cannot be used in

the following cases. Consult a SUZUKI

dealer or a roadside assistance service.

• Cuts or piercing in the tire tread

larger than approx. 4 mm.

• Cuts in the tire side wall.

• Tire damage caused by driving with

considerably reduced tire pressure or

even with deflated tire.

• The tire bead completely unseated

outside of the rim.

• The rim damaged.

Small punctures in the tire tread,

caused by a nail or a screw, can be

sealed with the flat tire repair kit.

Do not remove nails or screws from the

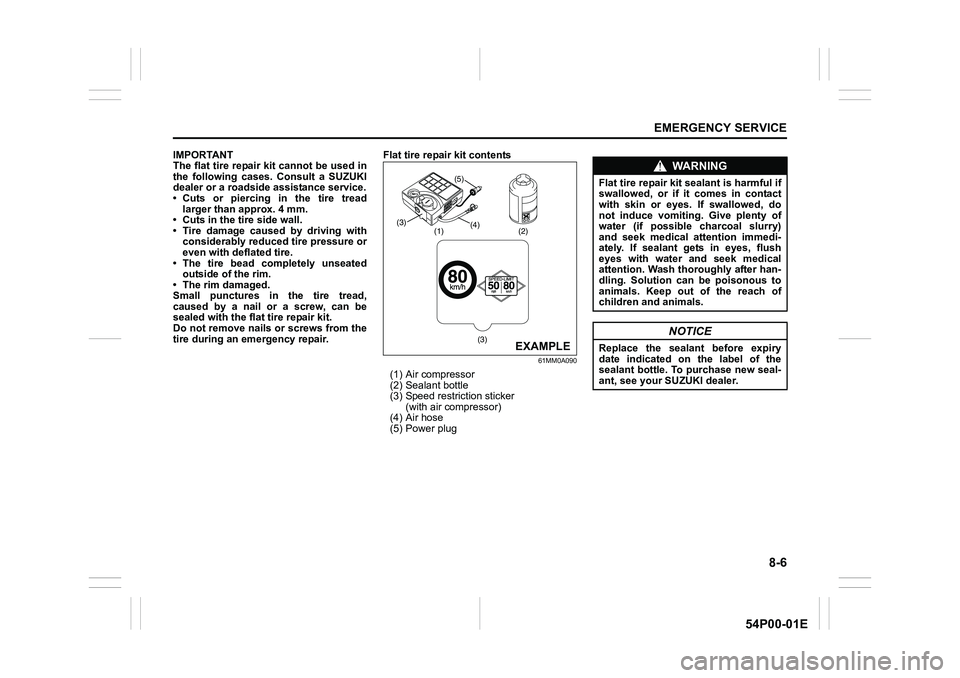

tire during an emergency repair.Flat tire repair kit contents

61MM0A090

(1) Air compressor

(2) Sealant bottle

(3) Speed restriction sticker

(with air compressor)

(4) Air hose

(5) Power plug

(1)(4) (5)

(3)(2)(3)

EXAMPLE

WA R N I N G

Flat tire repair kit sealant is harmful if

swallowed, or if it comes in contact

with skin or eyes. If swallowed, do

not induce vomiting. Give plenty of

water (if possible charcoal slurry)

and seek medical attention immedi-

ately. If sealant gets in eyes, flush

eyes with water and seek medical

attention. Wash thoroughly after han-

dling. Solution can be poisonous to

animals. Keep out of the reach of

children and animals.

NOTICE

Replace the sealant before expiry

date indicated on the label of the

sealant bottle. To purchase new seal-

ant, see your SUZUKI dealer.