spare tire SUZUKI IGNIS 2021 User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2021, Model line: IGNIS, Model: SUZUKI IGNIS 2021Pages: 505, PDF Size: 8.36 MB

Page 388 of 505

7-39INSPECTION AND MAINTENANCE

75RM4-01E

Tires

80JS025

The front and rear tire pressure specifica-

tions are listed on the tire information label.

Both front and rear tires should have the

specified tire pressure.

Note that the value does not apply to the

compact spare tire, if equipped.

NOTE:

The tire inflation pressure will change due

to changes in atmospheric pressure, tem-

perature or tire temperature when driving.

To reduce the chance that the low tire

pressure warning light (if equipped) will

come on due to normal changes in tem-

perature and atmospheric pressure, it is

important to check and adjust the tire pres-

sures when the tires are cold. If you check

tires after driving, they are warm. Even ifthe tire pressure seems to be good in this

condition, it could fall below the specified

pressure when tires co

ol down. Also, tires

that are inflated to the specified pressure

in a warm garage may have pressure

below the specification when the vehicle is

driven outside in very cold temperature. If

you adjust the tire pressure in a garage

that is warmer than the outside tempera-

ture, you should add 1 kPa to the recom-

mended cold tire inflation pressure for

every 0.8°C difference between garage

temperature and outside temperature.

Tire inspectionInspect your vehicle’s tires at least once a

month by performing the following checks:

1) Measure the air pressure with a tire gauge. Adjust the pressure if neces-

sary. Remember to check the spare

tire, too.

EXAMPLE

WA R N I N G

• Air pressures should be checkedwhen the tires are cold or you may

get inaccurate readings.

• Check the inflation pressure from time to time while inflating the tire

gradually, until the specified pres-

sure is obtained.

• Never under-inflate or over-inflate the tires.

Under-inflation can cause unusual

handling characteristics or can

cause the rim to slip on the tire

bead, resulting in an accident or

damage to the tire or rim.

Over-inflation can cause the tire to

burst, resulting in personal injury.

Over-inflation c an also cause

unusual handling characteristics

which may result in an accident.

Page 390 of 505

7-41INSPECTION AND MAINTENANCE

75RM4-01E

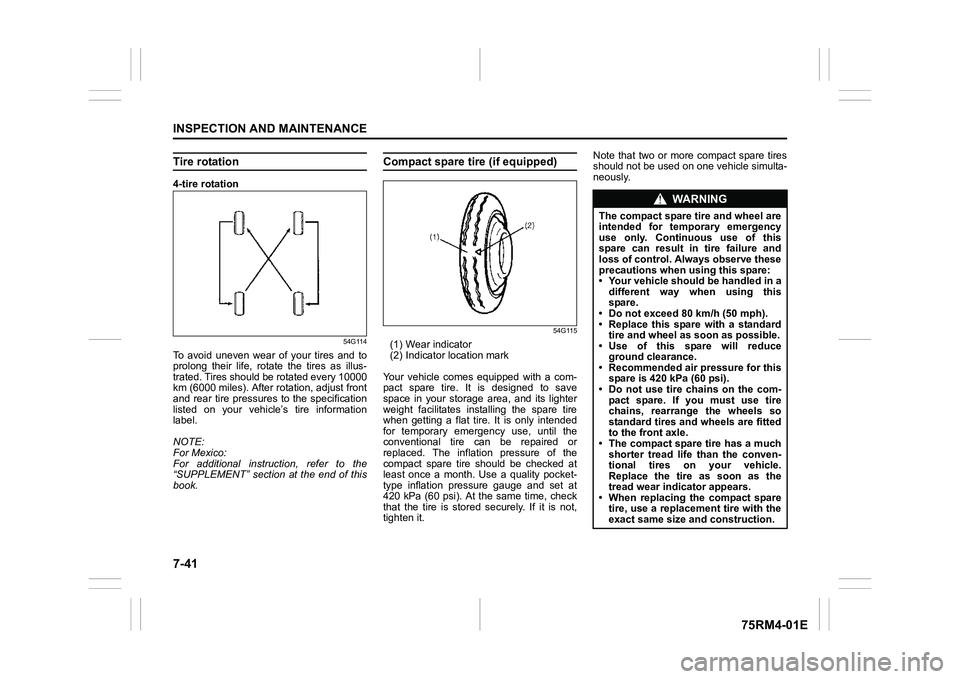

Tire rotation4-tire rotation

54G114

To avoid uneven wear of your tires and to

prolong their life, rotate the tires as illus-

trated. Tires should be rotated every 10000

km (6000 miles). After rotation, adjust front

and rear tire pressures to the specification

listed on your vehicle’s tire information

label.

NOTE:

For Mexico:

For additional instruction, refer to the

“SUPPLEMENT” section at the end of this

book.

Compact spare tire (if equipped)

54G115

(1) Wear indicator

(2) Indicator location mark

Your vehicle comes equipped with a com-

pact spare tire. It is designed to save

space in your storage area, and its lighter

weight facilitates installing the spare tire

when getting a flat tire. It is only intended

for temporary emergency use, until the

conventional tire can be repaired or

replaced. The inflation pressure of the

compact spare tire should be checked at

least once a month. Use a quality pocket-

type inflation pressure gauge and set at

420 kPa (60 psi). At the same time, check

that the tire is stored securely. If it is not,

tighten it. Note that two or more compact spare tires

should not be used on one vehicle simulta-

neously.

WA R N I N G

The compact spare tire and wheel are

intended for temporary emergency

use only. Continuous use of this

spare can result in tire failure and

loss of control. Always observe these

precautions when using this spare:

• Your vehicle should be handled in a

different way when using this

spare.

• Do not exceed 80 km/h (50 mph).

• Replace this spare with a standard tire and wheel as soon as possible.

• Use of this spare will reduce

ground clearance.

• Recommended air pressure for this spare is 420 kPa (60 psi).

• Do not use tire chains on the com- pact spare. If you must use tire

chains, rearrange the wheels so

standard tires and wheels are fitted

to the front axle.

• The compact spare tire has a much

shorter tread life than the conven-

tional tires on your vehicle.

Replace the tire as soon as the

tread wear indicator appears.

• When replacing the compact spare tire, use a replacement tire with the

exact same size and construction.

Page 410 of 505

8-1EMERGENCY SERVICE

75RM4-01E

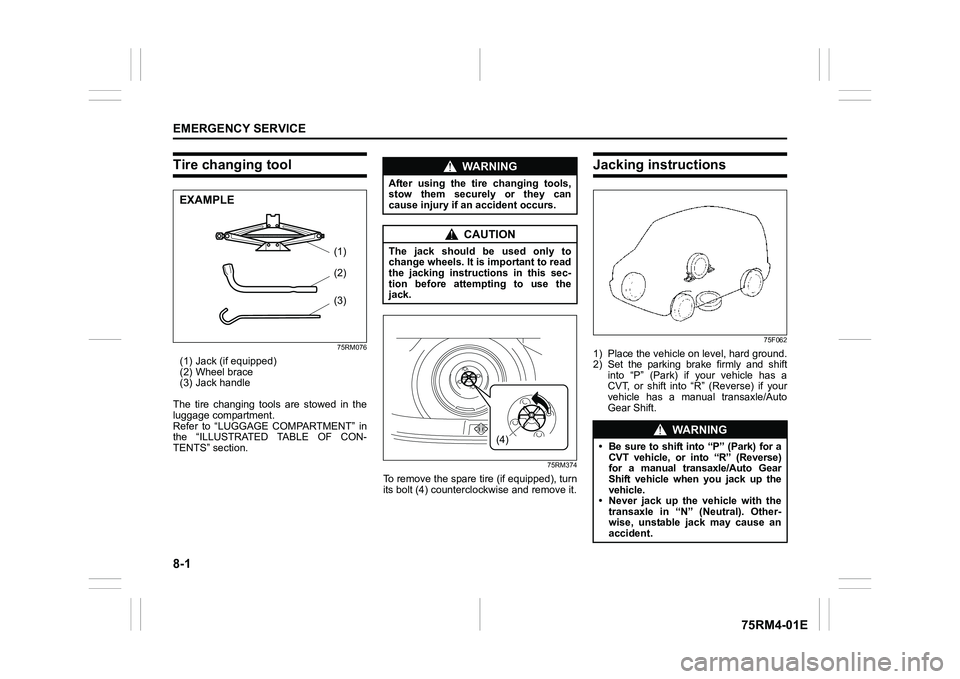

Tire changing tool

75RM076

(1) Jack (if equipped)

(2) Wheel brace

(3) Jack handle

The tire changing tools are stowed in the

luggage compartment.

Refer to “LUGGAGE COMPARTMENT” in

the “ILLUSTRATED TABLE OF CON-

TENTS” section.

75RM374

To remove the spare tire (if equipped), turn

its bolt (4) countercl ockwise and remove it.

Jacking instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift into “P” (Park) if your vehicle has a

CVT, or shift into “R” (Reverse) if your

vehicle has a manual transaxle/Auto

Gear Shift.

(3)(2)

(1)

EXAMPLE

WA R N I N G

After using the tire changing tools,

stow them securely or they can

cause injury if an accident occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

(4)

�:�Ν �5 �1 �, �1 �*

�

Page 411 of 505

8-2

EMERGENCY SERVICE

75RM4-01E

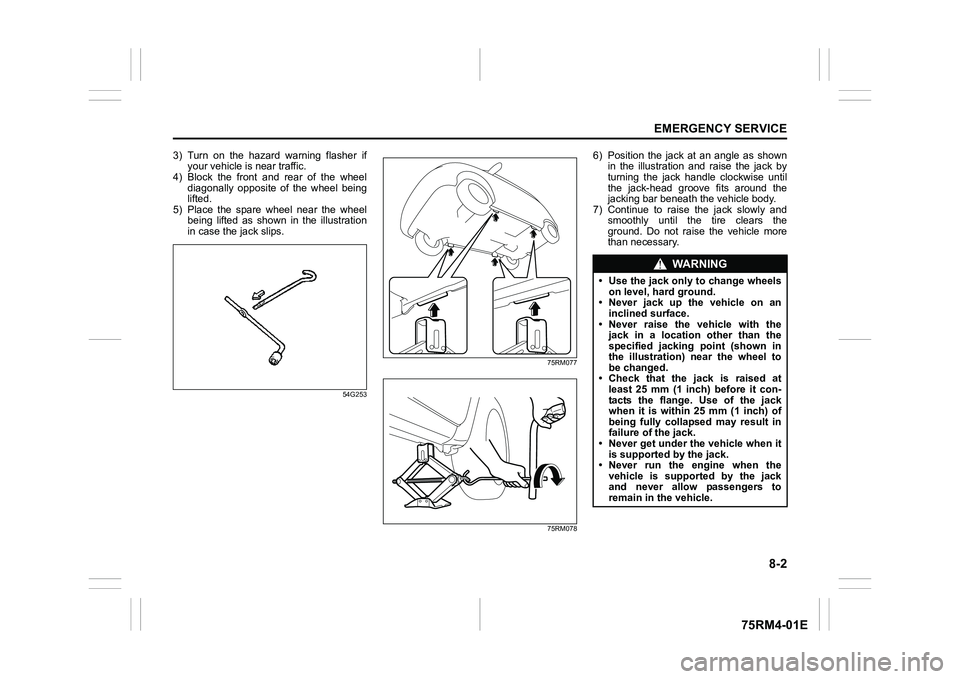

3) Turn on the hazard warning flasher ifyour vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case the jack slips.

54G253 75RM077

75RM078

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

WA R N I N G

• Use the jack only to change wheelson level, hard ground.

• Never jack up the vehicle on an inclined surface.

• Never raise the vehicle with the jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

• Check that the jack is raised at

least 25 mm (1 inch) before it con-

tacts the flange. Use of the jack

when it is within 25 mm (1 inch) of

being fully collapsed may result in

failure of the jack.

• Never get under the vehicle when it

is supported by the jack.

• Never run the engine when the vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 415 of 505

8-6

EMERGENCY SERVICE

75RM4-01E

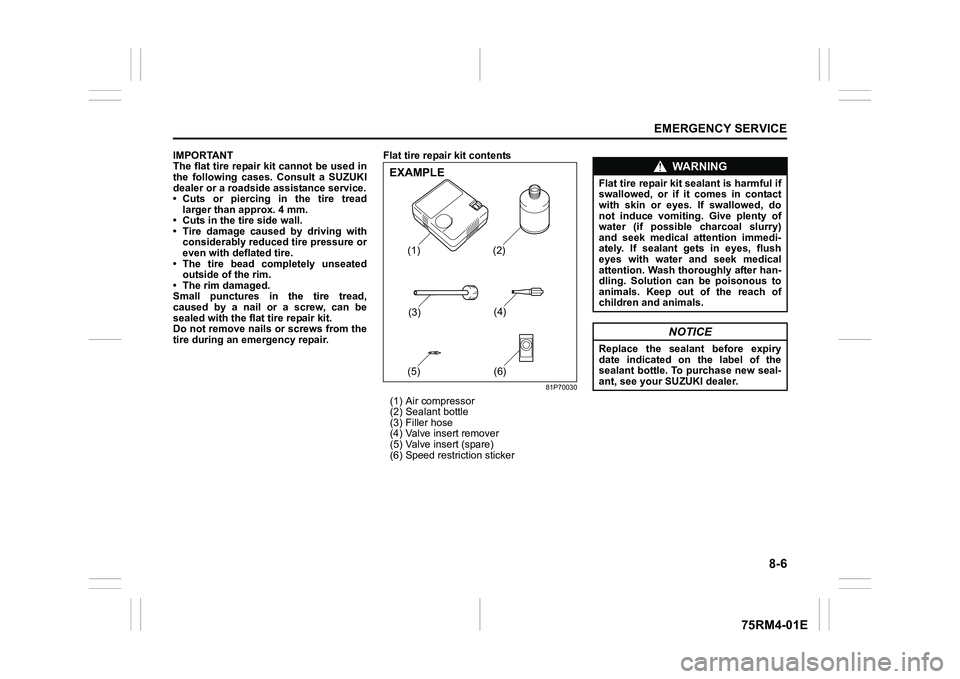

IMPORTANT

The flat tire repair kit cannot be used in

the following cases. Consult a SUZUKI

dealer or a roadside assistance service.

• Cuts or piercing in the tire treadlarger than approx. 4 mm.

• Cuts in the tire side wall.

• Tire damage caused by driving with considerably reduced tire pressure or

even with deflated tire.

• The tire bead completely unseated outside of the rim.

• The rim damaged.

Small punctures in the tire tread,

caused by a nail or a screw, can be

sealed with the flat tire repair kit.

Do not remove nails or screws from the

tire during an e mergency repair. Flat tire repair kit contents

81P70030

(1) Air compressor

(2) Sealant bottle

(3) Filler hose

(4) Valve insert remover

(5) Valve insert (spare)

(6) Speed restriction sticker

(1)(3)

(4)

(5)

(6)(2)

EXAMPLE

WA R N I N G

Flat tire repair kit sealant is harmful if

swallowed, or if it comes in contact

with skin or eyes. If swallowed, do

not induce vomiting. Give plenty of

water (if possible charcoal slurry)

and seek medical attention immedi-

ately. If sealant gets in eyes, flush

eyes with water and seek medical

attention. Wash thoroughly after han-

dling. Solution can be poisonous to

animals. Keep out of the reach of

children and animals.

NOTICE

Replace the sealant before expiry

date indicated on the label of the

sealant bottle. To purchase new seal-

ant, see your SUZUKI dealer.

Page 417 of 505

8-8

EMERGENCY SERVICE

75RM4-01E

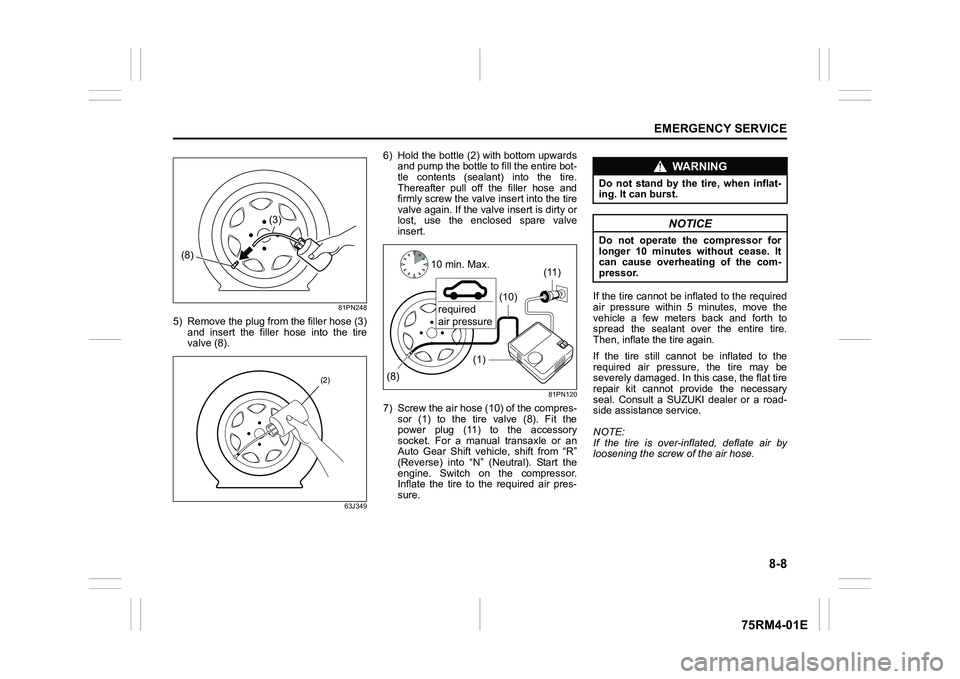

81PN248

5) Remove the plug from the filler hose (3)and insert the filler hose into the tire

valve (8).

63J349

6) Hold the bottle (2) with bottom upwardsand pump the bottle to fill the entire bot-

tle contents (sealant) into the tire.

Thereafter pull off the filler hose and

firmly screw the valve insert into the tire

valve again. If the valve insert is dirty or

lost, use the enclosed spare valve

insert.

81PN120

7) Screw the air hose (10) of the compres- sor (1) to the tire valve (8). Fit the

power plug (11) to the accessory

socket. For a manual transaxle or an

Auto Gear Shift vehicle, shift from “R”

(Reverse) into “N” (Neutral). Start the

engine. Switch on the compressor.

Inflate the tire to the required air pres-

sure. If the tire cannot be inflated to the required

air pressure within 5 minutes, move the

vehicle a few meters back and forth to

spread the sealant over the entire tire.

Then, inflate the tire again.

If the tire still cannot be inflated to the

required air pressure, the tire may be

severely damaged. In this case, the flat tire

repair kit cannot provide the necessary

seal. Consult a SUZUKI dealer or a road-

side assistance service.

NOTE:

If the tire is over-inflated, deflate air by

loosening the screw of the air hose.

(3)

(8)

(2)

(1)

(8) (11)

(10)

10 min. Max.required

air pressure

WA R N I N G

Do not stand by the tire, when inflat-

ing. It can burst.

NOTICE

Do not operate the compressor for

longer 10 minutes without cease. It

can cause overheating of the com-

pressor.

Page 440 of 505

12-1SUPPLEMENT

75RM4-01E

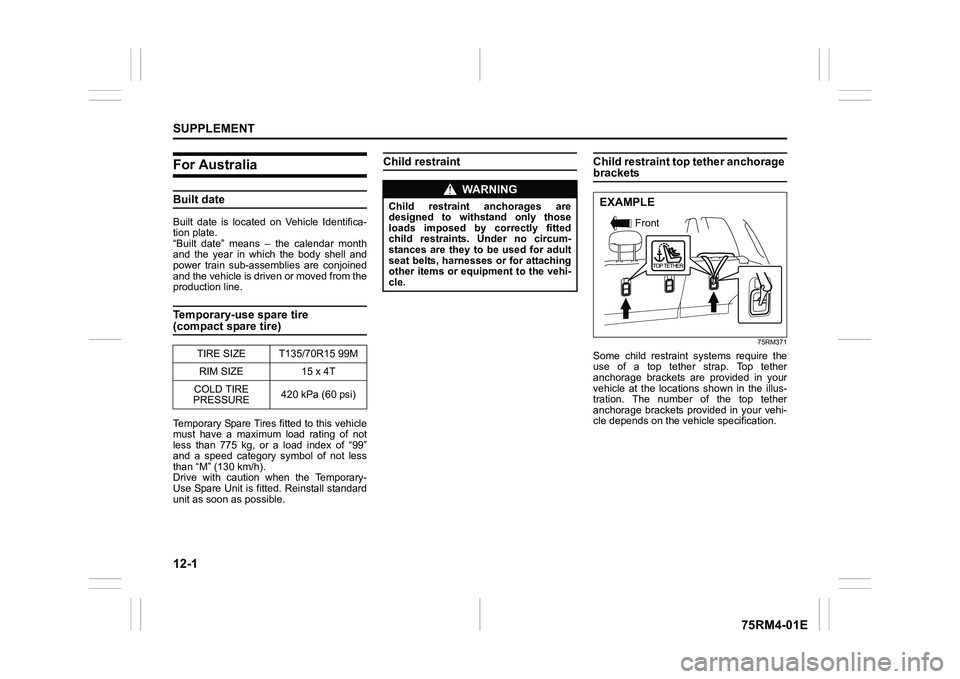

For AustraliaBuilt dateBuilt date is located on Vehicle Identifica-

tion plate.

“Built date” means – the calendar month

and the year in which the body shell and

power train sub-assemblies are conjoined

and the vehicle is driven or moved from the

production line.Temporary-use spare tire (compact spare tire)Temporary Spare Tires fitted to this vehicle

must have a maximum load rating of not

less than 775 kg, or a load index of “99”

and a speed category symbol of not less

than “M” (130 km/h).

Drive with caution when the Temporary-

Use Spare Unit is fitted. Reinstall standard

unit as soon as possible.

Child restraint

Child restraint top tether anchorage brackets

75RM371

Some child restraint systems require the

use of a top tether strap. Top tether

anchorage brackets are provided in your

vehicle at the locations shown in the illus-

tration. The number of the top tether

anchorage brackets provided in your vehi-

cle depends on the v ehicle specification.

TIRE SIZE T135/70R15 99M

RIM SIZE 15 x 4T

COLD TIRE

PRESSURE 420 kPa (60 psi)

WA R N I N G

Child restraint anchorages are

designed to withstand only those

loads imposed by correctly fitted

child restraints. Under no circum-

stances are they to be used for adult

seat belts, harnesses or for attaching

other items or equipment to the vehi-

cle.

EXAMPLE

Front

Page 450 of 505

13-2INDEX

75RM4-01E

Compact spare tire .............................................................. 7-41

Continuously variable transaxle (CVT) .......................... .... 3-19

Continuously variable transaxle (CVT) fluid .................... .7-32

Coolant level check ............................................ ................. 7-28

Coolant replacement ............................................ ............... 7-29

Corrosion prevention .......... .................................................. 9-1

Cruise control ................................................. ..................... 3-48

Cruise indicator light ......................................... ................ 2-115

Cup holder and storage area . ............................................... 5-8DDaily inspection checklist ..................................... ................ 3-1

Daytime running light .......................................... ................ 7-51

Daytime running light (D.R.L.) system.......................... ... 2-118

Dead lock system ............................................... ................... 2-4

Deceleration energy regeneratin g indicator light ........... 2-114

Depress brake pedal indicator .................................. ....... 2-115

Door locks ..................................................... ......................... 2-2

Drive belt ..................................................... ......................... 7-23

Drive mode indicator ........................................... ................ 2-78

Driver’s seat belt reminder light /

Front passenger’s seat belt remi nder light .....................2-106

Driving on hills ............................................... ........................ 4-3

Driving on slippery roads ...................................... ............... 4-4

Driving range.................................................. ............. 2-74, 2-94

Driving time ................................................... ....................... 2-74

Dual camera brake support ...................................... .......... 3-53

Dual camera brake support indicator light...................... 2-110

Dual camera brake support OFF indicator light ............. 2-110

Dual camera brake support OFF switch ........................... .3-61

Dual camera brake support warn ing light ....................... 2-116

EEco-Cool ....................................................... ........................ 3-48

Eco-driving display ............................................ .................. 2-79

Electric mirrors............................................... ...................... 2-24

Electric power steering ligh t ............................................. 2-109

Electric window controls ... .................................................. 2-20

Electronic stabi lity program (ESP

®) ................................... 3-78

Emergency locking retractor ( ELR) .................................... 2-35

Emergency stop signal (ESS) . ............................................ 3-71

Energy flow indicator.......................................... ........2-74, 3-46

ENG A-STOP indicator light ..................................... ......... 2-114

ENG A-STOP OFF light ........................................... ........... 2-114

ENG A-STOP OFF switch .......................................... .......... 3-45

ENG A-STOP system (e ngine auto stop start system) ..... 3-35

Engine coolant ................................................. .................... 7-28

Engine hood .................................................... ....................... 5-2

Engine oil and filter .......................................... .................... 7-23

Engine oil consumption ......................................... ............... 3-2

Engine serial number........................................... ................ 10-1

Engine switch .................................................. ....................... 3-5

Engine switch illumination ..................................... ............... 3-7

Engine trouble: Flooded engine ................................. ........ 8-13

Engine trouble: Overheating .................................... ........... 8-13

Engine trouble: Starter does not operate ....................... ... 8-13

ESP

® OFF indicator light ..........................................2 -105, 3-79

ESP® OFF switch .................................................... ............. 3-80

ESP® warning light ................................................. ..2-104, 3-79

Exhaust gas warning ............................................ ................. 3-1

FFlat tire repair kit .................................................................... 8-5

Floor mats ..................................................... ........................ 5-10

Page 454 of 505

13-6INDEX

75RM4-01E

Seat belt pretensioner system............................................ 2-52

Seat belt reminder ............................................. .................. 2-37

Seat belt warning .............................................. ................... 12-3

Seat belts and child restraint systems .............................. 2-33

Seat height adjustment lever ................................... ........... 2-27

Seat position adjustment lever................................. .2-27, 2-30

Seatback angle adjustment lever .............................. 2- 27, 2-30

Selection of coolant........................................... .................. 7-28

Selection of ignition modes .................................... .............. 3-7

Selector position.............................................. ........... 2-77, 2-93

Setting mode ................................................... ............ 2-79, 2-99

Shoulder anchor height adjuster ................................ ....... 2-39

SHVS (Smart Hybrid Ve hicle by Suzuki).......................... .. 3-46

Side air bags and side curtain air bags ............................. 2-60

Side door locks ................................................ ...................... 2-2

Side turn signal light ......................................... .................. 7-50

S-mode indicator ............................................... ......... 2-77, 2-93

Spark plugs .................................................... ...................... 7-31

SPECIFICATIONS...... ........................................................... 11-1

Specified fluid ................................................ ...................... 7-32

Specified oil.................................................. ........................ 7-23

Speed limiter .................................................. ...................... 3-51

Speedometer .................................................... .................... 2-69

Stability control system ....................................... ............... 3-78

Starting engine

(vehicle with keyless push sta rt system) ....................... ... 3-14

Starting engine

(vehicle without keyless push s tart system).....................3-13

Steering ....................................................... ......................... 7-38

Stereo camera .................................................. .................... 3-63

Stuck vehicle .................................................. ........................ 4-5Sun visor ......................................................

........................... 5-4

Supplemental restraint system (air bags)....................... ... 2-54

Switch of S-mode ............................................... .................. 3-21

TTachometer ........................................................................... 2-69

Tailgate....................................................... ............................. 2-5

Temporary-use spare tire (comp act spare tire)................. 12-1

Theft deterrent alarm system ................................... ........... 2-16

Theft deterrent light .......................................... ................... 2-19

Thermometer .................................................... ...........2-74, 2-97

Tilt steering lock lever .... ................................................... 2-128

Tire chains .................................................... .......................... 4-5

Tire changing tool ............................................. ..................... 8-1

Tire inspection................................................ ...................... 7-39

Tire pressure monitoring syst em (TPMS) ..........................3-85

Tire rotation .................................................. ........................ 7-41

Tires.......................................................... ............................. 7-39

Total idling fuel saved .... ..................................................... 2-74

Total idling stop time ......................................... .................. 2-74

Towing......................................................... .......................... 8-11

Traction control system ........................................ .............. 3-78

Trailer hitch installation points .............................. ............... 6-6

Trailer towing................................................. ......................... 6-1

Transaxle warning light ........................................ ............. 2-107

Transfer oil................................................... ......................... 7-34

Trip meter..................................................... ................2-78, 2-94

Turn signal control lever ...................................... ............. 2-123

Turn signal indicators......................................... ............... 2-112

Turn signal operation .......................................... .............. 2-124