check engine SUZUKI IGNIS 2022 Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2022, Model line: IGNIS, Model: SUZUKI IGNIS 2022Pages: 505, PDF Size: 8.36 MB

Page 241 of 505

3-88

OPERATING YOUR VEHICLE

75RM4-01E

61MM0A198

NOTE:

• The information display shows theabove warning and indicator message

when this light comes on.

• When the tire inflation pressure is

adjusted in high altitude areas, the low

tire pressure light may not turn off even

after tire inflation pressure adjustment. In

this case, adjust the inflation pressure to

a slightly higher pressure than the one

shown on the tire information placard.

• The low tire pressure warning light may turn off temporarily after coming on. This

could be due to increase of surface tem-

perature after long distance driving or

traveling to a high temperature area.

Even if the tire pressure warning light

turns off after coming on, check the infla-

tion pressure of all tires.

• To reduce the chance that the low tire pressure warning light will come on due

to normal changes in temperature and

atmospheric pressure, it is important to

check and adjust the tire pressures

when the tires are cold. If you check tires after driving, they are warm. Even if the

tire pressure seems to be good in this

condition, it could fall below the specified

pressure when tires cool down. Also, if

tires are inflated to the specified pres-

sure in a warm garage, the tire pressure

could fall below the specified one when

you drive the vehicle outside in very cold

temperature. If you adjust the tire pres-

sure in a garage that is warmer than the

outside temperature, you should add

1 kPa to the recommended cold tire

inflation pressure for every 0.8°C differ-

ence between garage temperature and

outside temperature.

TPMS malfunction indicatorYour vehicle has also been equipped with

a TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is com-

bined with the low tire pressure telltale.

When the system detects a malfunction,

the telltale will flash for about 75 seconds

and then remain continuously illuminated.

This sequence will continue upon subse-

quent vehicle start-ups as long as the mal-

function exists.

The TPMS malfunction indicator is not

reset even after the engine is turned off; it

remains in the on state until the normal

conditions are restored.

When the malfunction indicator is illumi-

nated, the system may not be able to

detect or signal low tire pressure as

intended. TPMS malfunctions may occur

for a variety of reasons, including the

installation of replacement or alternate

tires or wheels on the vehicle that prevent

the TPMS from functioning properly.

Always check the TPMS malfunction tell-

tale after replacing one or more tires or

wheels on your vehicle to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

Page 252 of 505

4-5DRIVING TIPS

75RM4-01E

Tire chainsTire chains should only be used if they are

needed to increase traction or are required

by law. Check that the chains you use are

the correct size for your vehicle’s tires.

Also check that there is enough clearance

between the fenders and the chains as

installed on the tires.

Install the chains on the front tires tightly,

according to the chain manufacturer’s

instructions. Retighten the chains after

driving about 1.0 km (1/2 mile) if neces-

sary. With the chains installed, drive slowly.

Stuck vehicleIf your vehicle gets stuck in snow, mud or

sand, follow the directions below:

1) Shift the transaxle back and forthbetween a forward range (or first gear

for manual transaxle/Auto Gear Shift)

and reverse. This will create a rocking

motion which may give you enough

momentum to free the vehicle. Press

gently on the accelerator to keep wheel

spinning to a minimum wheel rpm.

Remove your foot from the accelerator

while shifting.

Do not race the engine. Excessive

wheel spin will cause the tires to dig

deeper, making it more difficult to free

the vehicle.

NOTE:

If your vehicle is equipped with the ESP

®

and/or grip control system, you may have

to turn the systems off in order to spin the

wheels. 2) If your vehicle rema

ins stuck after a few

minutes of rocking, we recommend you

to consult your SUZUKI dealer or a road-

side assistance service. If a towing ser-

vice is not available in an emergency,

your vehicle may be temporarily towed by

a towing cable or chain secured to the

towing hook either on the front of the

vehicle or on the rear of the vehicle. Refer

to “Frame hooks” in the “OTHER CON-

TROLS AND EQUIPMENT” section.

NOTICE

• If you hear the chains hitting against the vehicle body while driv-

ing, stop and tighten them.

• If your vehicle is equipped with full wheel caps, remove the wheel caps

before installing the chains or the

wheel caps can be damaged by the

chain bands.

WA R N I N G

Do not allow anyone to stand near

the vehicle when you are rocking it,

and do not spin the wheels faster

than an indicated 40 km/h (25 mph)

on the speedometer. Personal injury

and/or vehicle damage may result

from spinning the wheels too fast.

NOTICE

Do not continue rocking the vehicle

for more than a few minutes. Pro-

longed rocking can cause engine

overheating or transaxle damage.

Page 257 of 505

5-2

OTHER CONTROLS AND EQUIPMENT

75RM4-01E

To reinstall the fuel filler cap:

1) Turn the cap clockwise until you hearseveral clicks.

2) Close the fuel filler door.

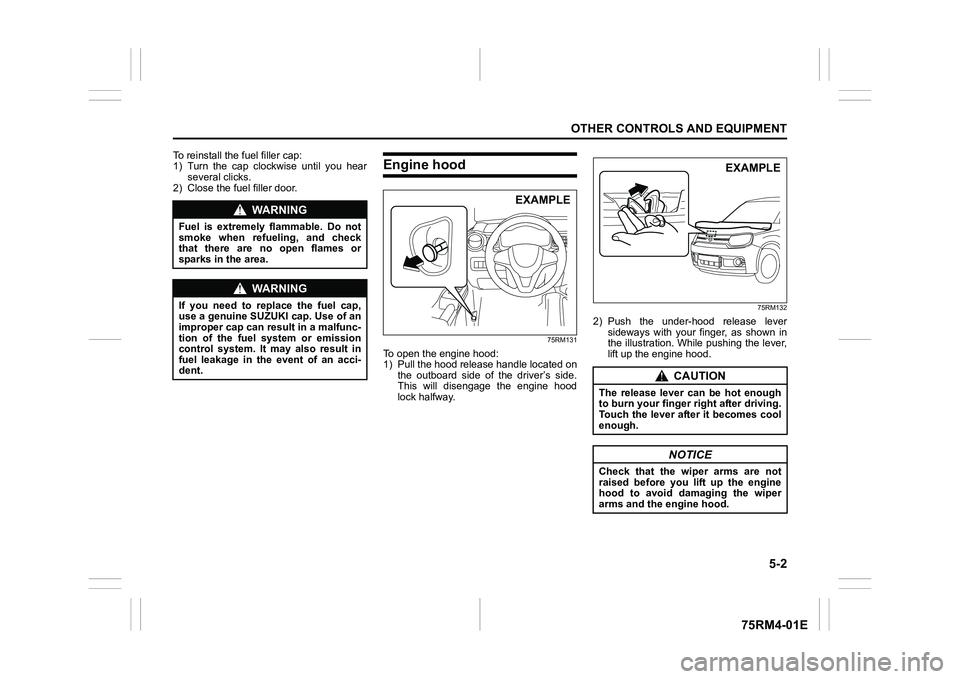

Engine hood

75RM131

To open the engine hood:

1) Pull the hood release handle located on the outboard side of the driver’s side.

This will disengage the engine hood

lock halfway.

75RM132

2) Push the under-hood release leversideways with your finger, as shown in

the illustration. While pushing the lever,

lift up the engine hood.

WA R N I N G

Fuel is extremely flammable. Do not

smoke when refueling, and check

that there are no open flames or

sparks in the area.

WA R N I N G

If you need to replace the fuel cap,

use a genuine SUZUKI cap. Use of an

improper cap can result in a malfunc-

tion of the fuel system or emission

control system. It may also result in

fuel leakage in the event of an acci-

dent.

EXAMPLE

CAUTION

The release lever can be hot enough

to burn your finger right after driving.

Touch the lever after it becomes cool

enough.

NOTICE

Check that the wiper arms are not

raised before you lift up the engine

hood to avoid damaging the wiper

arms and the engine hood.

EXAMPLE

Page 258 of 505

5-3OTHER CONTROLS AND EQUIPMENT

75RM4-01E

75RM133

3) While holding the hood, pull the proprod out from the holding clip, and then

insert the end of the rod into the desig-

nated hole in the hood. To close the engine hood:

1) Lift the hood up slightly and remove the

prop rod from the hole. Put the prop rod

back into the holding clip.

62R0074

2) Lower the hood to about 20 cm above

the hood latch, and then let it drop

down. Check that the hood is securely

latched after closing.

CAUTION

• The prop rod can be hot enough toburn your finger right after driving.

Touch the rod after it becomes cool

enough.

• Insert the end of the rod into the hole securely. If the rod slips out,

you may get caught in the closing

hood.

• The rod may slip out when the

hood is blown by wind. Be careful

on windy days.

EXAMPLE

WA R N I N G

Check that the hood is fully closed

and latched before d riving. If it is not,

it can fly up unexpectedly during

driving, obstructing your view and

resulting in an accident.

EXAMPLE

CAUTION

To avoid injury, check that no part of

the occupant’s body such as hands

or head is in the path of the hood

when closing it.

NOTICE

Pushing on the hood from the top

may damage it.

Page 343 of 505

6-2

VEHICLE LOADING AND TOWING

75RM4-01E

To w b a r sOnly use a tow bar that is designed to

attach to the chassis of your vehicle, and a

hitch that is designed to bolt to this tow bar.

We recommend that you use a genuine

SUZUKI tow bar (available as option), or

equivalent.Safety chainsAlways attach safety chains between your

vehicle and trailer. Cross safety chains

under the nose of the trailer so that the

nose will not drop to the road if the trailer

becomes separated from the tow bar. Fol-

low the manufacturer’s recommendation

for attaching safety chains. Always leave

just enough slack to permit full turning.

Never allow safety chains to drag on the

road.

Trailer lightsCheck that your trailer is equipped with

lights which meet local requirements.

Always check for the proper operation of

all trailer lights before you start to tow.Brakes

WA R N I N G

For vehicles equipped with the dual

camera brake support, if your vehicle

is used to tow a trailer, press the dual

camera brake support OFF switch

and turn off the dual camera brake

support. If not, unexpected acci-

dents related to the system being

turned on may occur.

NOTICE

Trailer towing puts additional stress

on the engine, drive train and brakes

of your vehicle. Never tow a trailer

during the first 960 km (600 miles) of

vehicle operation.

NOTICE

When towing by a vehicle with CVT

on a long steep hill, try to take some

rest on the way to prevent overheat

or damage of the engine or transaxle.

WA R N I N G

Never use a tow bar which attaches

to the axle or the bumper of your

vehicle.

WA R N I N G

Never attach safety chains to the

bumper of your vehicle. Secure con-

nections so that they cannot come

loose.

WA R N I N G

Never connect trailer lights directly

into your vehicle’s electrical system,

or electrical system damage may

occur.

WA R N I N G

If trailer brakes are used, follow all

instructions provided by the manu-

facturer. Never connect to the brake

system of your vehicle and never

take an electrical supply directly from

the wiring harness.

Page 346 of 505

6-5VEHICLE LOADING AND TOWING

75RM4-01E

60A186

WA R N I N G

(Continued)

• Be careful when overtaking othervehicles. Allow enough room for

your trailer before changing lanes,

and use turn signal lights properly

in advance.

• Slow down and shift into a lower gear before you reach long or steep

downhill grades. It is hazardous to

attempt downshifting while you are

descending a hill.

• Do not step on the brake pedal strongly. This could cause the

brakes to over-heat resulting in

reduced braking efficiency. Use

engine braking as much as possi-

ble.

• Because of the added trailer weight, your engine may overheat

on hot days when going up long or

steep hills. Pay attention to your

engine temperature. If the high

engine coolant temperature warn-

ing light (red color) indicates over-

heating, pull off the road and stop

the vehicle in a safe place. Refer to

“Engine trouble: Overheating” in

the “EMERGENCY SERVICE” sec-

tion.

WA R N I N G

When parking your vehicle and con-

nected trailer, always use the follow-

ing procedure:

1) Apply the vehicle’s brakes firmly.

2) Have another person place wheel

chocks under the wheels of the

vehicle and the trailer while you

are holding the brakes.

3) Slowly release the brakes until the wheel chocks absorb the load.

4) Fully engage the parking brake.

5) Manual transaxle – turn off the engine, then shift into reverse or

first gear.

Auto Gear Shift – shift into reverse

or first gear and check the gear

position indicator in the instru-

ment cluster to make sure that the

transaxle is engaged in 1st or

reverse, then turn off the engine.

CVT – shift into “P” (Park) and

turn off the engine.

When starting out after parking:

1) Depress the clutch and start the engine.

2) Shift into gear, release the parking brake, and slowly pull away from

the chocks.

3) Stop, apply the brakes firmly and hold them.

4) Have another person remove the

chocks.

Page 350 of 505

7-1INSPECTION AND MAINTENANCE

75RM4-01E

60B128S

WA R N I N G

Take extreme care when working on

your vehicle to prevent accidental

injury. Carefully observe the follow-

ing precautions:

• To prevent damage or unintendedactivation of the air bag system or

seat belt pretensioner system, check

that the lead-acid battery is discon-

nected and the ignition switch has

been in “LOCK” position or the igni-

tion mode has been LOCK (OFF) for

at least 90 seconds before perform-

ing any electrical service work on

your SUZUKI vehicle. Do not touch

air bag system components, seat

belt pretensioner system compo-

nents or wires.

The wires are wrapped with yellow

tape or yellow tubing, and the cou-

plers are yellow for easy identifica-

tion.

• Do not leave the engine running in garages or other confined areas. (Continued)

WA R N I N G

(Continued)

• When the engine is running, keep

hands, clothing, tools, and other

objects away from the fan and drive

belt. Even though the fan may not

be moving, it can automatically

turn on without warning.

• When it is necessary to perform

service work with the engine run-

ning, check that the parking brake

is set fully and the transaxle is in

Neutral (for manual transaxle or

Auto Gear Shift vehicles) or Park

(for CVT vehicles).

• Do not touch ignition wires or other ignition system parts when starting

the engine or when the engine is

running, or you could receive an

electric shock.

•Be careful not to touch a hot engine, exhaust manifold and

pipes, muffler, radiator and water

hoses.

• Do not allow smoking, sparks, or flames around fuel or the battery.

Flammable fumes are present.

• Do not get under your vehicle if it is supported only with the portable

jack provided in your vehicle.

• Be careful not to cause accidental short circuits between the positive

and negative battery terminals. (Continued)

WA R N I N G

(Continued)

• Keep used oil, coolant, and other

fluids away from children and pets.

Dispose of used fluids properly;

never pour them on the ground,

into sewers, etc.

Page 353 of 505

7-4

INSPECTION AND MAINTENANCE

75RM4-01E

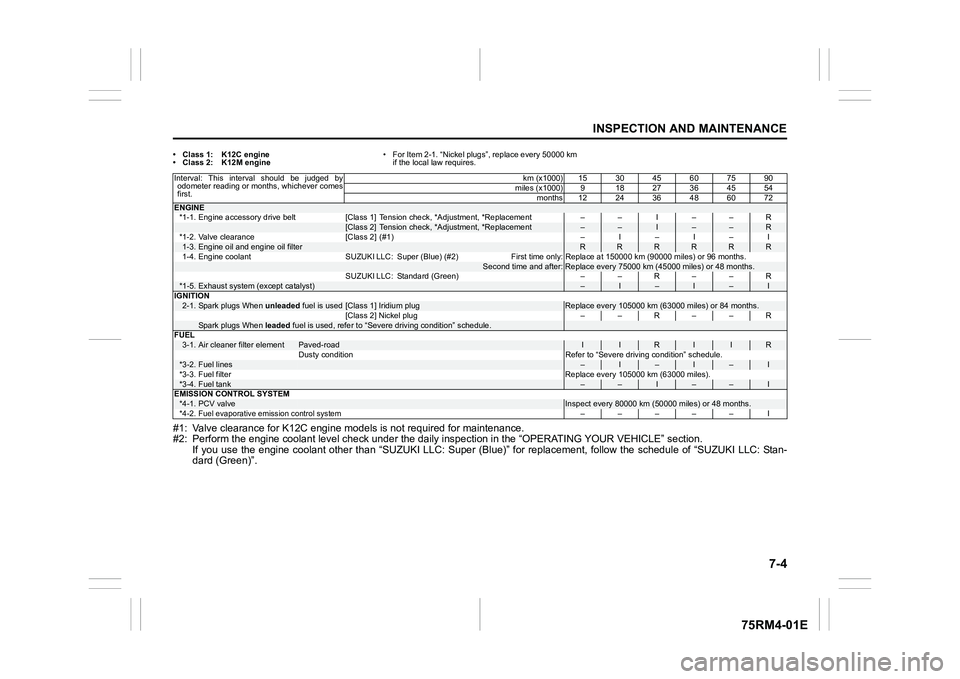

• Class 1: K12C engine

• Class 2: K12M engine• For Item 2-1. “Nickel plugs”, replace every 50000 km

if the local law requires.#1: Valve clearance for K12C engin e models is not required for maintenance.

#2: Perform the engine coolant l evel check under the daily inspection in the “OPERATING YOUR VEHICLE” section.

If you use the engine coolant other than “SUZUKI LLC: Super (Bl ue)” for replacement, follow the schedule of “SUZUKI LLC: Stan-

dard (Green)”.Interval: This interval should be judged by odometer reading or months, whichever comes

first. km (x1000) 15 30 45 60 75 90

miles (x1000) 9 18 27 36 45 54

months 12 24 36 48 60 72ENGINE*1-1. Engine accessory drive belt [Class 1] Tension check, *Adjust ment, *Replacement – – I – – R

[Class 2] Tension check, *Adjustment, *Replacement

–

–

I

–

–

R

*1-2. Valve clearance [Class 2] (#1) – I – I – I

1-3.

Engine oil and engine oil filter

R

R

R

R

R

R

1-4. Engine coolant SUZUKI LLC: Super (Blue) (#2)

First time only: Replace at 150000 km (90000 miles) or 96 months .

Second time and after:

Replace every 75000 km (45000 miles) or 48 months.

SUZUKI LLC: Standard (Green) – – R – – R

*1-5.

Exhaust system (except catalyst)

–

I

–

I

–

I

IGNITION

2-1.

Spark plugs When unleaded fuel is used

[Class 1] Iridium plug

Replace every 105000 km (63000 miles) or 84 months.

[Class 2] Nickel plug – – R – – R

Spark plugs When leaded fuel is used, refer to “Severe driving condition” schedule.

FUEL 3-1.

Air cleaner filter element

Paved-road

I

I

R

I

I

R

Dusty condition Refer to “Severe driving condition” schedule.

*3-2.

Fuel lines

–

I

–

I

–

I

*3-3. Fuel filter Replace every 105000 km (63000 miles).

*3-4.

Fuel tank

–

–

I

–

–

I

EMISSION CONTROL SYSTEM

*4-1.

PCV valve

Inspect every 80000 km (5 0000 miles) or 48 months.

*4-2.

Fuel evaporative emi ssion control system

––––– I

Page 354 of 505

7-5INSPECTION AND MAINTENANCE

75RM4-01E

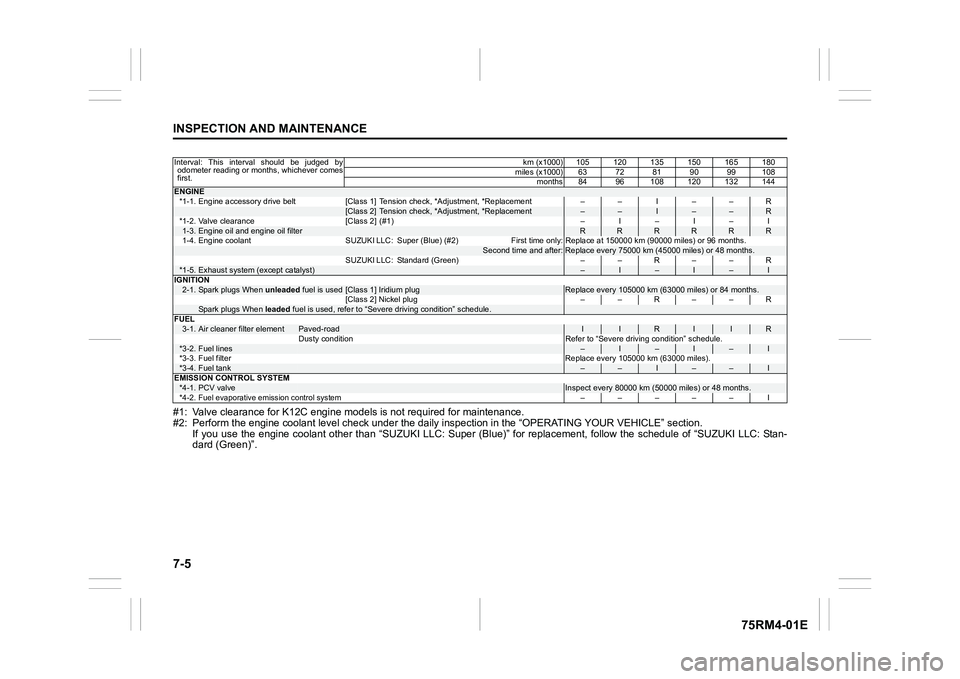

#1: Valve clearance for K12C engine models is not required for maintenance.

#2: Perform the engine coolant l evel check under the daily inspection in the “OPERATING YOUR VEHICLE” section.

If you use the engine coolant other than “SUZUKI LLC: Super (Bl ue)” for replacement, follow the schedule of “SUZUKI LLC: Stan-

dard (Green)”.Interval: This interval should be judged by odometer reading or months, whichever comes

first. km (x1000) 105 120 135 150 165 180

miles (x1000) 63 72 81 90 99 108 months 84 96 108 120 132 144ENGINE*1-1. Engine accessory drive belt [Class 1] Tension check, *Adjust ment, *Replacement – – I – – R

[Class 2] Tension check, *Adjustment, *Replacement

–

–

I

–

–

R

*1-2. Valve clearance [Class 2] (#1) – I – I – I

1-3.

Engine oil and engine oil filter

R

R

R

R

R

R

1-4. Engine coolant SUZUKI LLC: Super (Blue) (#2)

First time only: Replace at 150000 km (90000 miles) or 96 months .

Second time and after:

Replace every 75000 km (45000 miles) or 48 months.

SUZUKI LLC: Standard (Green) – – R – – R

*1-5.

Exhaust system (except catalyst)

–

I

–

I

–

I

IGNITION

2-1.

Spark plugs When unleaded fuel is used

[Class 1] Iridium plug

Replace every 105000 km (63000 miles) or 84 months.

[Class 2] Nickel plug – – R – – R

Spark plugs When leaded fuel is used, refer to “Severe driving condition” schedule.

FUEL 3-1.

Air cleaner filter element

Paved-road

I

I

R

I

I

R

Dusty condition Refer to “Severe driving condition” schedule.

*3-2.

Fuel lines

–

I

–

I

–

I

*3-3. Fuel filter Replace every 105000 km (63000 miles).

*3-4.

Fuel tank

–

–

I

–

–

I

EMISSION CONTROL SYSTEM

*4-1.

PCV valve

Inspect every 80000 km (5 0000 miles) or 48 months.

*4-2.

Fuel evaporative emi ssion control system

––––– I

Page 358 of 505

7-9INSPECTION AND MAINTENANCE

75RM4-01E

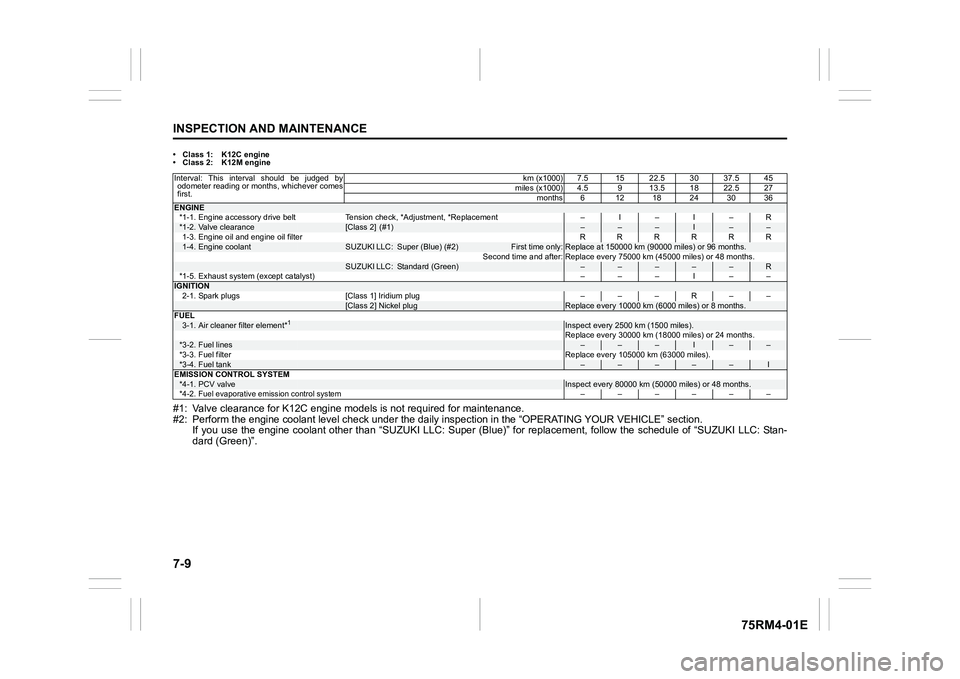

• Class 1: K12C engine

• Class 2: K12M engine#1: Valve clearance for K12C engine models is not required for maintenance.

#2: Perform the engine coolant l evel check under the daily inspection in the “OPERATING YOUR VEHICLE” section.

If you use the engine coolant other than “SUZUKI LLC: Super (Bl ue)” for replacement, follow the schedule of “SUZUKI LLC: Stan-

dard (Green)”.Interval: This interval should be judged by odometer reading or months, whichever comes

first. km (x1000) 7.5 15 22.5 30 37.5 45

miles (x1000) 4.5 9 13.5 18 22.5 27

months6 1218243036ENGINE*1-1. Engine accessory drive belt Tension check, *Adjustment, *Re placement – I – I – R*1-2.

Valve clearance

[Class 2] (#1)

–

–

–

I

–

–

1-3. Engine oil and engine oil filter RRRRRR

1-4.

Engine coolant

SUZUKI LLC:

Super (Blue) (#2)

First time only:

Replace at 150000 km (90000 miles) or 96 months.

Second time and after: Replace every 75000 km (45000 miles) or 48 months.

SUZUKI LLC:

Standard (Green)

–

–

–

–

–

R

*1-5. Exhaust system (except catalyst) ––– I ––

IGNITION

2-1. Spark plugs [Class 1] Iridium plug – – – R – –

[Class 2] Nickel plug

Replace every 10000 km (6000 miles) or 8 months.

FUEL

3-1.

Air cleaner filter element*

1

Inspect every 2500 km (1500 miles).

Replace every 30000 km (18000 miles) or 24 months.

*3-2.

Fuel lines

–

–

–

I

–

–

*3-3. Fuel filter Replace every 105000 km (63000 miles).

*3-4.

Fuel tank

–

–

–

–

–

I

EMISSION CONTROL SYSTEM

*4-1.

PCV valve

Inspect every 80000 km (5 0000 miles) or 48 months.

*4-2.

Fuel evaporative emi ssion control system

––––––