Oil pressure sensor SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 380 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab](/img/20/7588/w960_7588-379.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis table

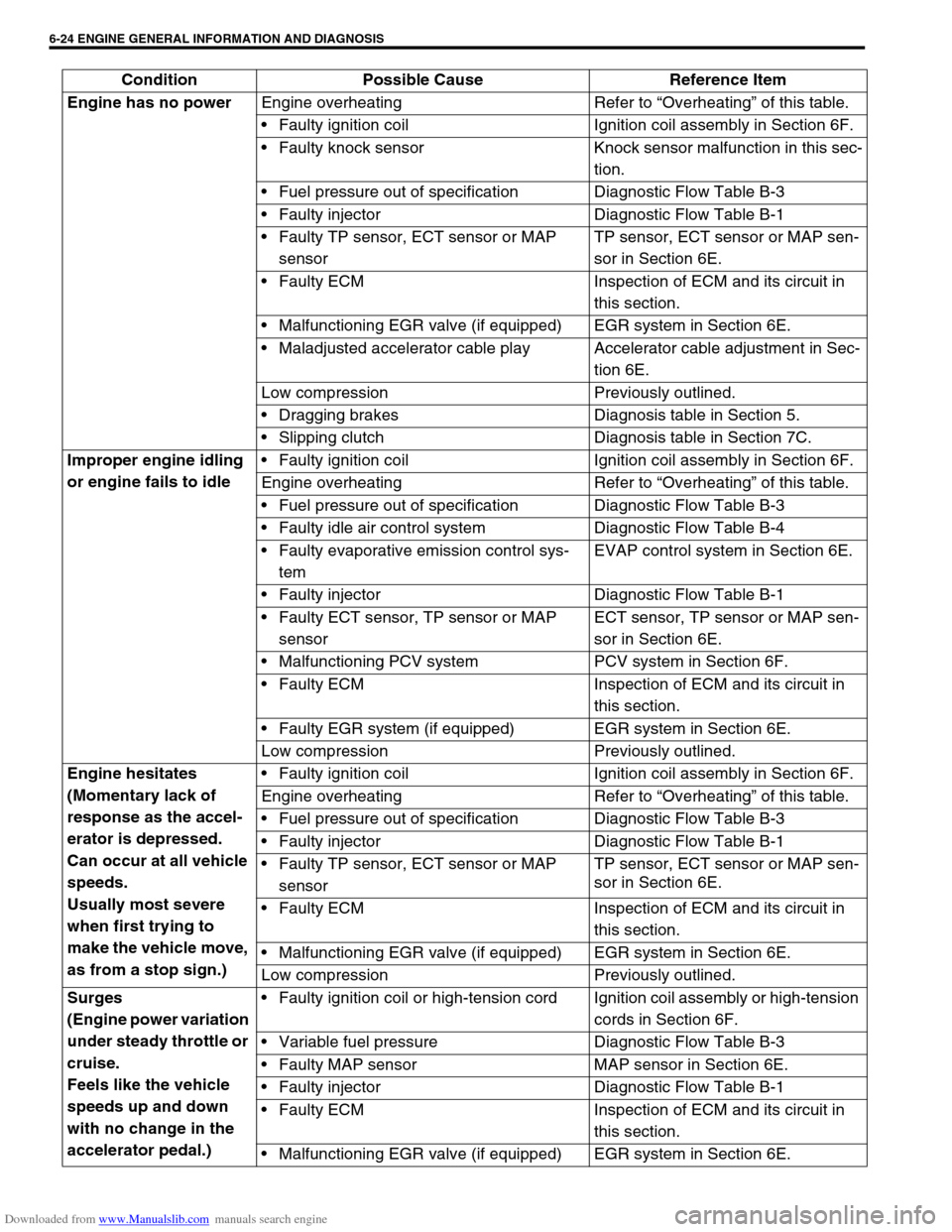

Perform troubleshooting referring to following table when ECM has no DTC and no abnormality found in visual

inspection and engine basic inspection previously.

Condition Possible Cause Reference Item

Hard Starting

(Engine cranks OK)Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty CMP sensing rotor or CKP sensing

rotorCMP sensing rotor or CKP sensing

rotor inspection in Section 6E.

Faulty idle air control system Diagnostic Flow Table B-4

Faulty ECT sensor, TP sensor, CKP sen-

sor, CMP sensor or MAP sensorECT sensor, TP sensor, CKP sensor,

CMP sensor or MAP sensor in Sec-

tion 6E.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty fuel injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning PCV system PCV system in Section 6E.

Low compression Compression check in Section 6A1.

Improper valve lash Valve lash in Section 6A1.

Improper valve timing Timing chain and chain tensioner in

Section 6A1.

Compression leak from valve seat Valves and cylinder head in Section

6A1.

Sticky valve stem Valves and cylinder head in Section

6A1.

Weak or damaged valve springs Valves and cylinder head in Section

6A1.

Compression leak at cylinder head gasket Valves and cylinder head in Section

6A1.

Sticking or damaged piston ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston, ring or cylinder Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Page 381 of 687

Downloaded from www.Manualslib.com manuals search engine 6-24 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Engine has no power

Engine overheating Refer to “Overheating” of this table.

Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Maladjusted accelerator cable play Accelerator cable adjustment in Sec-

tion 6E.

Low compression Previously outlined.

Dragging brakes Diagnosis table in Section 5.

Slipping clutch Diagnosis table in Section 7C.

Improper engine idling

or engine fails to idleFaulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty idle air control system Diagnostic Flow Table B-4

Faulty evaporative emission control sys-

temEVAP control system in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECT sensor, TP sensor or MAP

sensorECT sensor, TP sensor or MAP sen-

sor in Section 6E.

Malfunctioning PCV system PCV system in Section 6F.

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Engine hesitates

(Momentary lack of

response as the accel-

erator is depressed.

Can occur at all vehicle

speeds.

Usually most severe

when first trying to

make the vehicle move,

as from a stop sign.)Faulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Surges

(Engine power variation

under steady throttle or

cruise.

Feels like the vehicle

speeds up and down

with no change in the

accelerator pedal.)Faulty ignition coil or high-tension cord Ignition coil assembly or high-tension

cords in Section 6F.

Variable fuel pressure Diagnostic Flow Table B-3

Faulty MAP sensor MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E. Condition Possible Cause Reference Item

Page 382 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-25

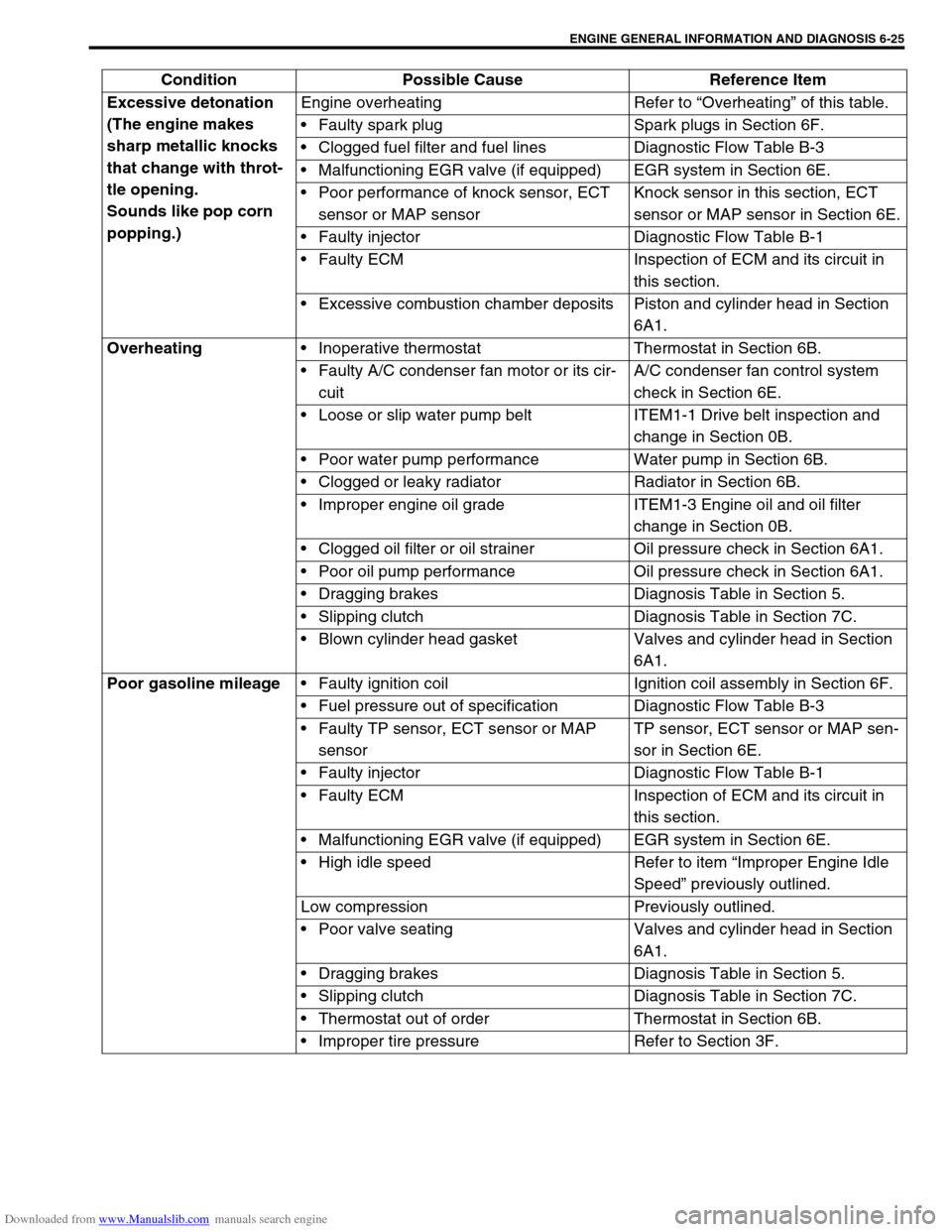

Excessive detonation

(The engine makes

sharp metallic knocks

that change with throt-

tle opening.

Sounds like pop corn

popping.)Engine overheating Refer to “Overheating” of this table.

Faulty spark plug Spark plugs in Section 6F.

Clogged fuel filter and fuel lines Diagnostic Flow Table B-3

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Poor performance of knock sensor, ECT

sensor or MAP sensorKnock sensor in this section, ECT

sensor or MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Excessive combustion chamber deposits Piston and cylinder head in Section

6A1.

Overheating

Inoperative thermostat Thermostat in Section 6B.

Faulty A/C condenser fan motor or its cir-

cuitA/C condenser fan control system

check in Section 6E.

Loose or slip water pump belt ITEM1-1 Drive belt inspection and

change in Section 0B.

Poor water pump performance Water pump in Section 6B.

Clogged or leaky radiator Radiator in Section 6B.

Improper engine oil grade ITEM1-3 Engine oil and oil filter

change in Section 0B.

Clogged oil filter or oil strainer Oil pressure check in Section 6A1.

Poor oil pump performance Oil pressure check in Section 6A1.

Dragging brakes Diagnosis Table in Section 5.

Slipping clutch Diagnosis Table in Section 7C.

Blown cylinder head gasket Valves and cylinder head in Section

6A1.

Poor gasoline mileage

Faulty ignition coil Ignition coil assembly in Section 6F.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

High idle speed Refer to item “Improper Engine Idle

Speed” previously outlined.

Low compression Previously outlined.

Poor valve seating Valves and cylinder head in Section

6A1.

Dragging brakes Diagnosis Table in Section 5.

Slipping clutch Diagnosis Table in Section 7C.

Thermostat out of order Thermostat in Section 6B.

Improper tire pressure Refer to Section 3F. Condition Possible Cause Reference Item

Page 384 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-27

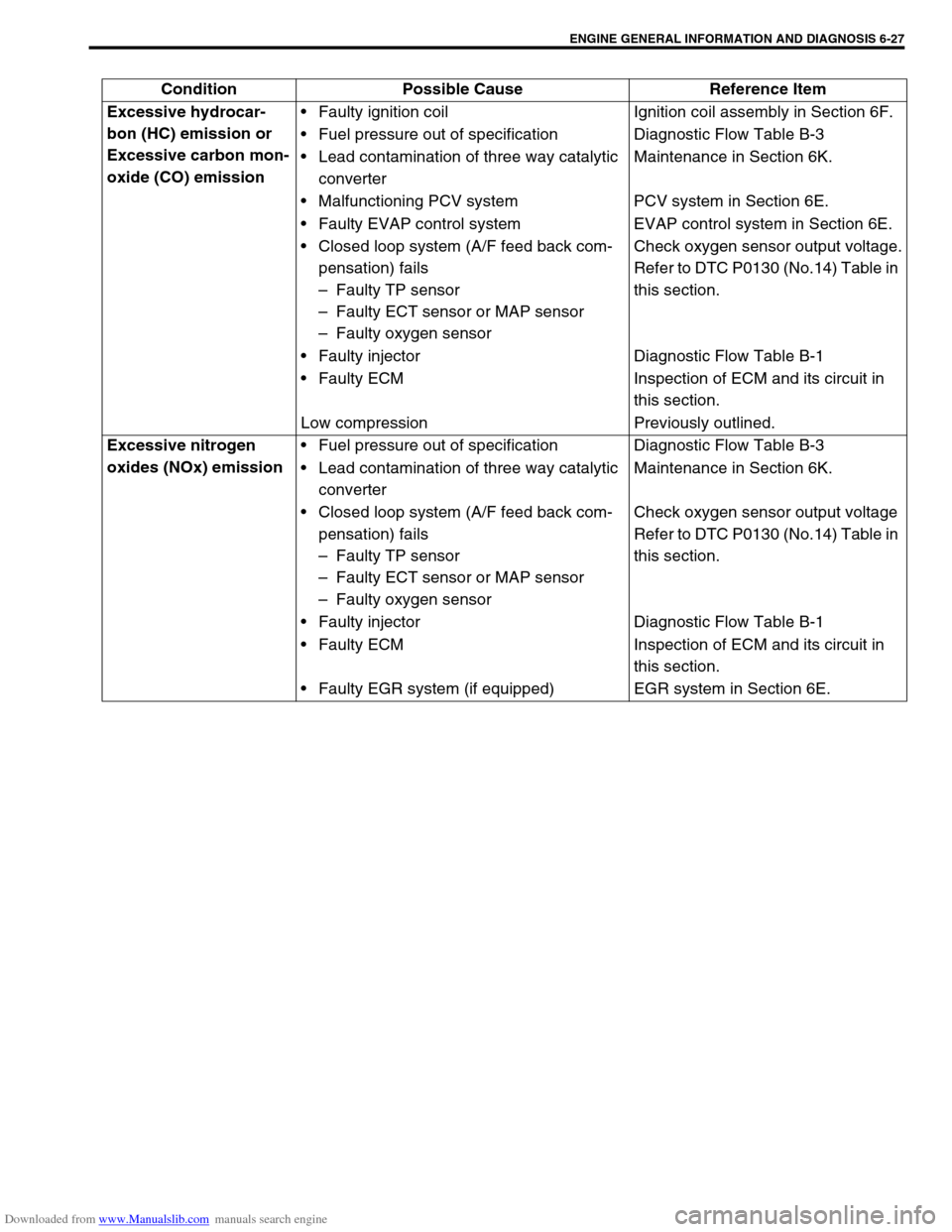

Condition Possible Cause Reference Item

Excessive hydrocar-

bon (HC) emission or

Excessive carbon mon-

oxide (CO) emissionFaulty ignition coil Ignition coil assembly in Section 6F.

Fuel pressure out of specification Diagnostic Flow Table B-3

Lead contamination of three way catalytic

converterMaintenance in Section 6K.

Malfunctioning PCV system PCV system in Section 6E.

Faulty EVAP control system EVAP control system in Section 6E.

Closed loop system (A/F feed back com-

pensation) fails

–Faulty TP sensor

–Faulty ECT sensor or MAP sensor

–Faulty oxygen sensorCheck oxygen sensor output voltage.

Refer to DTC P0130 (No.14) Table in

this section.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Low compression Previously outlined.

Excessive nitrogen

oxides (NOx) emissionFuel pressure out of specification Diagnostic Flow Table B-3

Lead contamination of three way catalytic

converterMaintenance in Section 6K.

Closed loop system (A/F feed back com-

pensation) fails

–Faulty TP sensor

–Faulty ECT sensor or MAP sensor

–Faulty oxygen sensorCheck oxygen sensor output voltage

Refer to DTC P0130 (No.14) Table in

this section.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Page 391 of 687

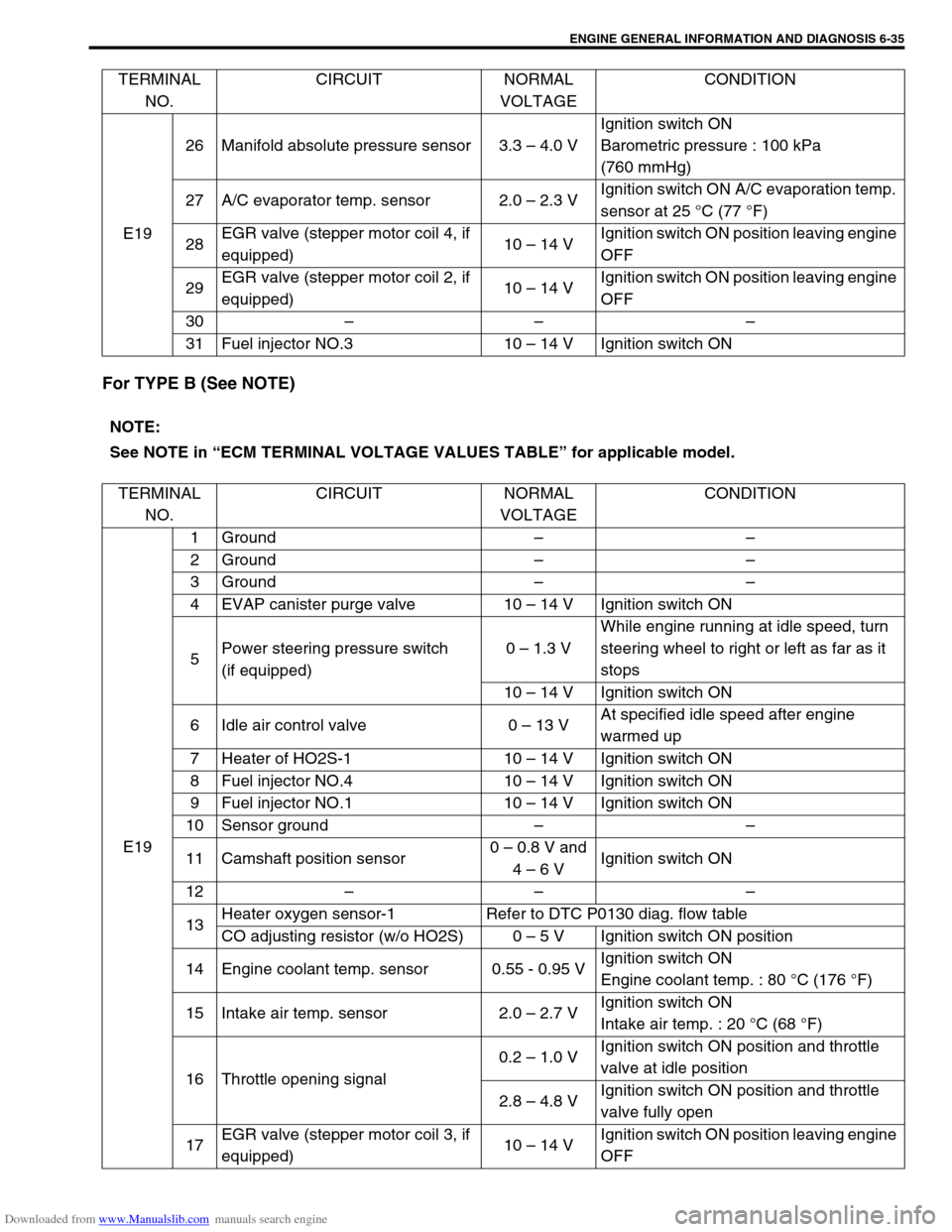

Downloaded from www.Manualslib.com manuals search engine 6-34 ENGINE GENERAL INFORMATION AND DIAGNOSIS

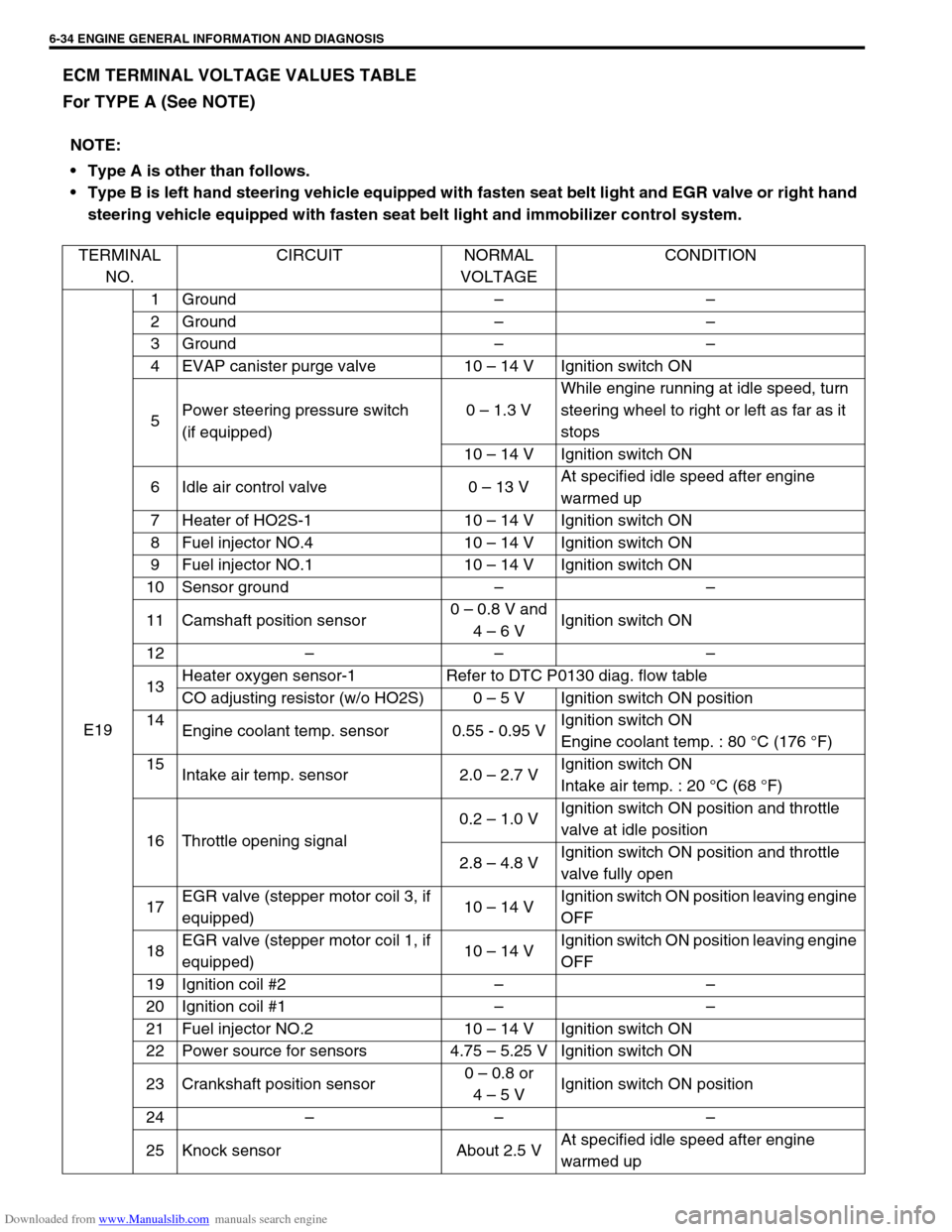

ECM TERMINAL VOLTAGE VALUES TABLE

For TYPE A (See NOTE)

NOTE:

Type A is other than follows.

Type B is left hand steering vehicle equipped with fasten seat belt light and EGR valve or right hand

steering vehicle equipped with fasten seat belt light and immobilizer control system.

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

E191Ground––

2Ground––

3Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5Power steering pressure switch

(if equipped)0 – 1.3 VWhile engine running at idle speed, turn

steering wheel to right or left as far as it

stops

10 – 14 V Ignition switch ON

6 Idle air control valve 0 – 13 VAt specified idle speed after engine

warmed up

7 Heater of HO2S-1 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor0 – 0.8 V and

4 – 6 VIgnition switch ON

12–– –

13Heater oxygen sensor-1 Refer to DTC P0130 diag. flow table

CO adjusting resistor (w/o HO2S) 0 – 5 V Ignition switch ON position

14

Engine coolant temp. sensor 0.55 - 0.95 VIgnition switch ON

Engine coolant temp. : 80 °C (176 °F)

15

Intake air temp. sensor 2.0 – 2.7 VIgnition switch ON

Intake air temp. : 20 °C (68 °F)

16 Throttle opening signal0.2 – 1.0 VIgnition switch ON position and throttle

valve at idle position

2.8 – 4.8 VIgnition switch ON position and throttle

valve fully open

17EGR valve (stepper motor coil 3, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

18EGR valve (stepper motor coil 1, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensors 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor0 – 0.8 or

4 – 5 VIgnition switch ON position

24–– –

25 Knock sensor About 2.5 VAt specified idle speed after engine

warmed up

Page 392 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-35

For TYPE B (See NOTE)

E1926 Manifold absolute pressure sensor 3.3 – 4.0 VIgnition switch ON

Barometric pressure : 100 kPa

(760 mmHg)

27 A/C evaporator temp. sensor 2.0 – 2.3 VIgnition switch ON A/C evaporation temp.

sensor at 25 °C (77 °F)

28EGR valve (stepper motor coil 4, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

29EGR valve (stepper motor coil 2, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

30–– –

31 Fuel injector NO.3 10 – 14 V Ignition switch ON TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

NOTE:

See NOTE in “ECM TERMINAL VOLTAGE VALUES TABLE” for applicable model.

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

E191 Ground––

2 Ground––

3 Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5Power steering pressure switch

(if equipped)0 – 1.3 VWhile engine running at idle speed, turn

steering wheel to right or left as far as it

stops

10 – 14 V Ignition switch ON

6 Idle air control valve 0 – 13 VAt specified idle speed after engine

warmed up

7 Heater of HO2S-1 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor0 – 0.8 V and

4 – 6 VIgnition switch ON

12–– –

13Heater oxygen sensor-1 Refer to DTC P0130 diag. flow table

CO adjusting resistor (w/o HO2S) 0 – 5 V Ignition switch ON position

14 Engine coolant temp. sensor 0.55 - 0.95 VIgnition switch ON

Engine coolant temp. : 80 °C (176 °F)

15 Intake air temp. sensor 2.0 – 2.7 VIgnition switch ON

Intake air temp. : 20 °C (68 °F)

16 Throttle opening signal0.2 – 1.0 VIgnition switch ON position and throttle

valve at idle position

2.8 – 4.8 VIgnition switch ON position and throttle

valve fully open

17EGR valve (stepper motor coil 3, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

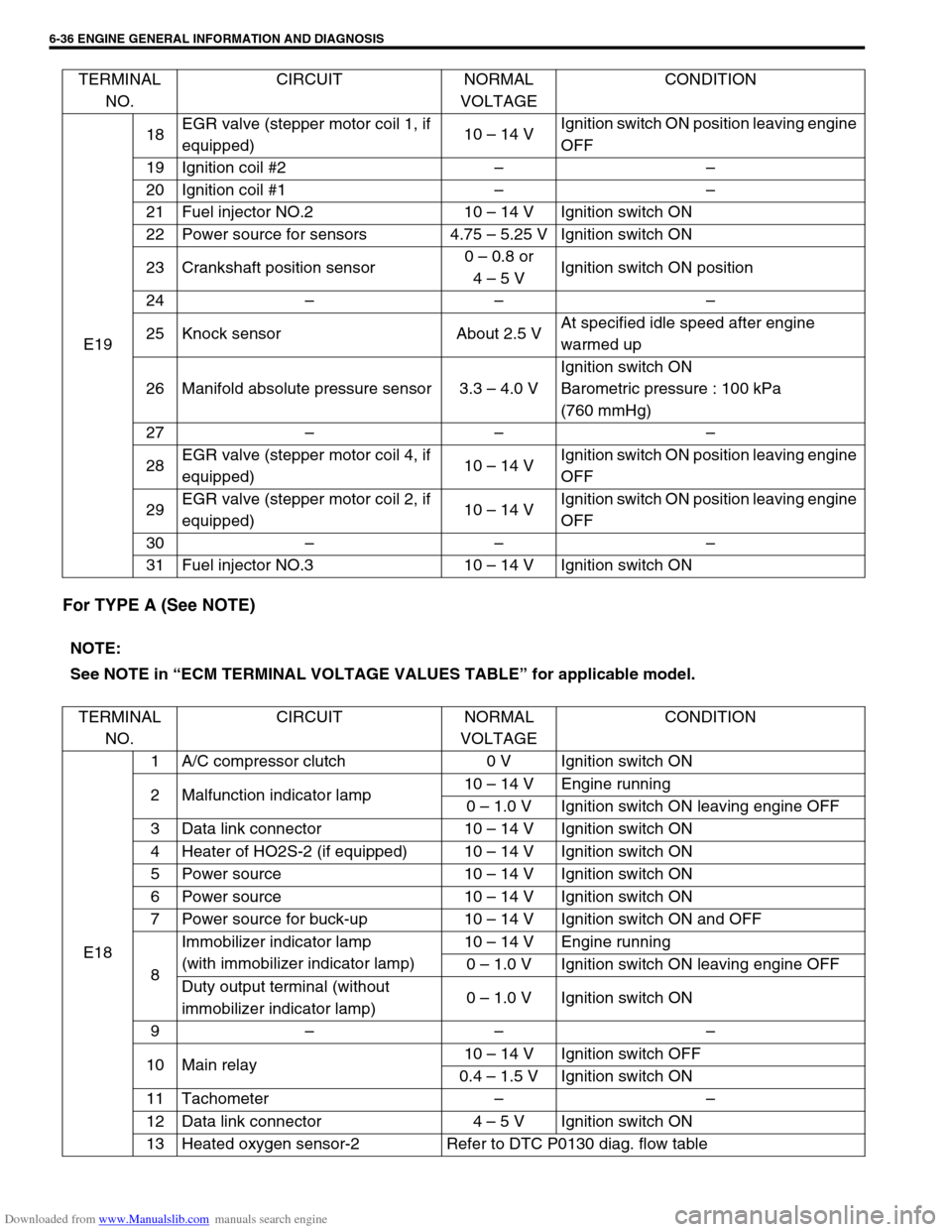

Page 393 of 687

Downloaded from www.Manualslib.com manuals search engine 6-36 ENGINE GENERAL INFORMATION AND DIAGNOSIS

For TYPE A (See NOTE)

E1918EGR valve (stepper motor coil 1, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensors 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor0 – 0.8 or

4 – 5 VIgnition switch ON position

24–– –

25 Knock sensor About 2.5 VAt specified idle speed after engine

warmed up

26 Manifold absolute pressure sensor 3.3 – 4.0 VIgnition switch ON

Barometric pressure : 100 kPa

(760 mmHg)

27–– –

28EGR valve (stepper motor coil 4, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

29EGR valve (stepper motor coil 2, if

equipped)10 – 14 VIgnition switch ON position leaving engine

OFF

30–– –

31 Fuel injector NO.3 10 – 14 V Ignition switch ON TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

NOTE:

See NOTE in “ECM TERMINAL VOLTAGE VALUES TABLE” for applicable model.

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

E181 A/C compressor clutch 0 V Ignition switch ON

2 Malfunction indicator lamp10 – 14 V Engine running

0 – 1.0 V Ignition switch ON leaving engine OFF

3 Data link connector 10 – 14 V Ignition switch ON

4 Heater of HO2S-2 (if equipped) 10 – 14 V Ignition switch ON

5 Power source 10 – 14 V Ignition switch ON

6 Power source 10 – 14 V Ignition switch ON

7 Power source for buck-up 10 – 14 V Ignition switch ON and OFF

8Immobilizer indicator lamp

(with immobilizer indicator lamp)10 – 14 V Engine running

0 – 1.0 V Ignition switch ON leaving engine OFF

Duty output terminal (without

immobilizer indicator lamp)0 – 1.0 V Ignition switch ON

9–– –

10 Main relay10 – 14 V Ignition switch OFF

0.4 – 1.5 V Ignition switch ON

11 Tachometer––

12 Data link connector 4 – 5 V Ignition switch ON

13 Heated oxygen sensor-2 Refer to DTC P0130 diag. flow table

Page 430 of 687

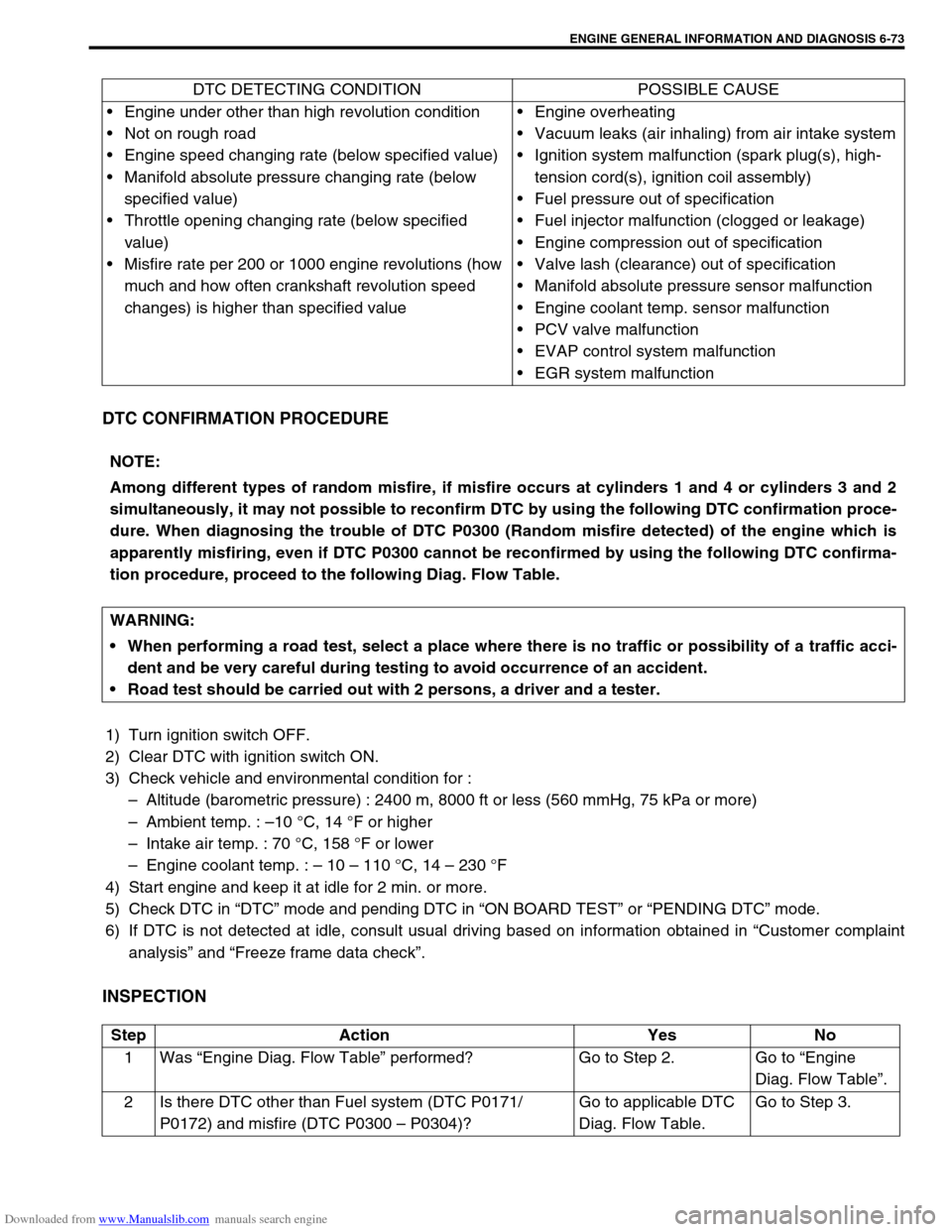

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-73

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–Engine coolant temp. : – 10 – 110 °C, 14 – 230 °F

4) Start engine and keep it at idle for 2 min. or more.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

6) If DTC is not detected at idle, consult usual driving based on information obtained in “Customer complaint

analysis” and “Freeze frame data check”.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine under other than high revolution condition

Not on rough road

Engine speed changing rate (below specified value)

Manifold absolute pressure changing rate (below

specified value)

Throttle opening changing rate (below specified

value)

Misfire rate per 200 or 1000 engine revolutions (how

much and how often crankshaft revolution speed

changes) is higher than specified valueEngine overheating

Vacuum leaks (air inhaling) from air intake system

Ignition system malfunction (spark plug(s), high-

tension cord(s), ignition coil assembly)

Fuel pressure out of specification

Fuel injector malfunction (clogged or leakage)

Engine compression out of specification

Valve lash (clearance) out of specification

Manifold absolute pressure sensor malfunction

Engine coolant temp. sensor malfunction

PCV valve malfunction

EVAP control system malfunction

EGR system malfunction

NOTE:

Among different types of random misfire, if misfire occurs at cylinders 1 and 4 or cylinders 3 and 2

simultaneously, it may not possible to reconfirm DTC by using the following DTC confirmation proce-

dure. When diagnosing the trouble of DTC P0300 (Random misfire detected) of the engine which is

apparently misfiring, even if DTC P0300 cannot be reconfirmed by using the following DTC confirma-

tion procedure, proceed to the following Diag. Flow Table.

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine

Diag. Flow Table”.

2 Is there DTC other than Fuel system (DTC P0171/

P0172) and misfire (DTC P0300 – P0304)?Go to applicable DTC

Diag. Flow Table.Go to Step 3.

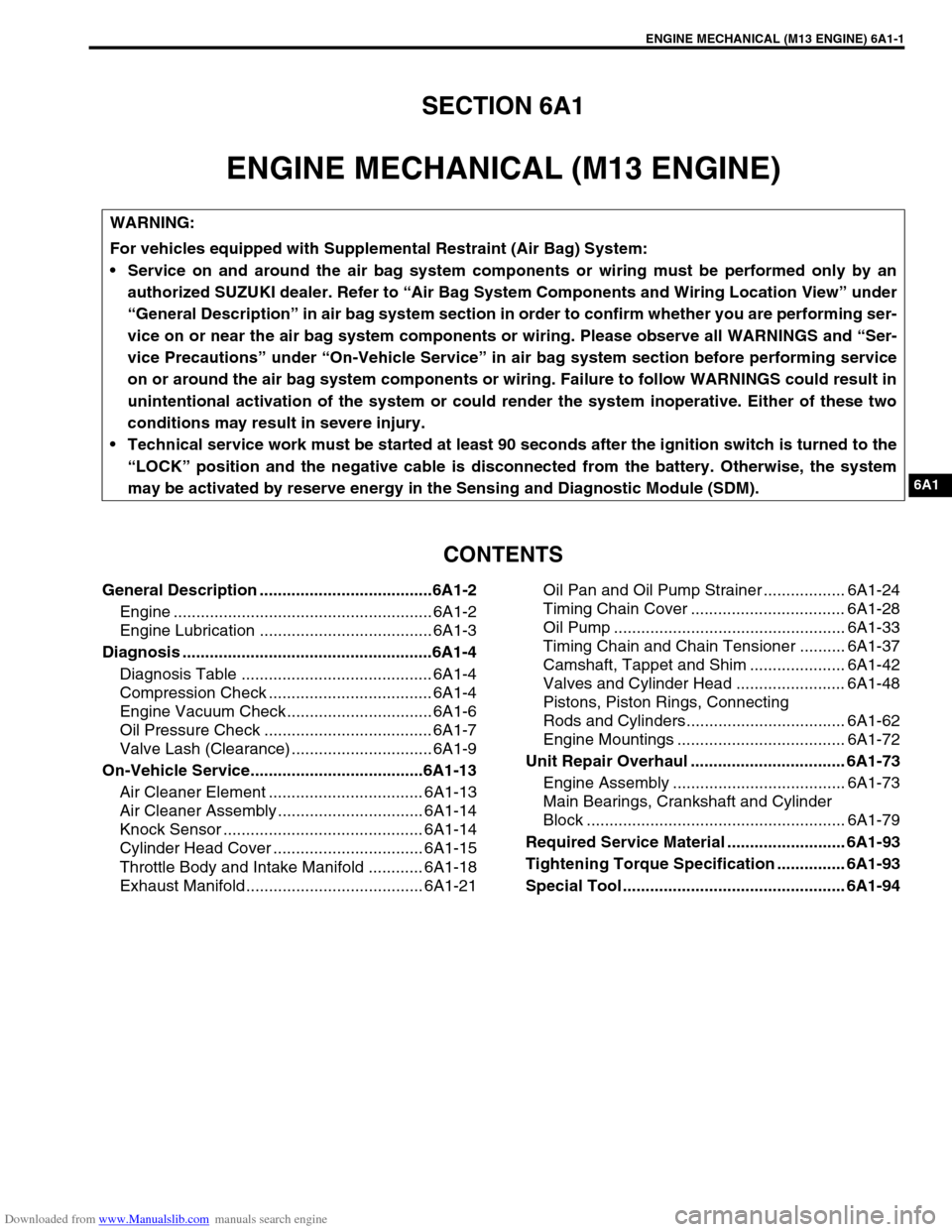

Page 482 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-1

6F1

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8C

6A1

8E

9

9

10B

SECTION 6A1

ENGINE MECHANICAL (M13 ENGINE)

CONTENTS

General Description ......................................6A1-2

Engine ......................................................... 6A1-2

Engine Lubrication ...................................... 6A1-3

Diagnosis .......................................................6A1-4

Diagnosis Table .......................................... 6A1-4

Compression Check .................................... 6A1-4

Engine Vacuum Check ................................ 6A1-6

Oil Pressure Check ..................................... 6A1-7

Valve Lash (Clearance) ............................... 6A1-9

On-Vehicle Service......................................6A1-13

Air Cleaner Element .................................. 6A1-13

Air Cleaner Assembly ................................ 6A1-14

Knock Sensor ............................................ 6A1-14

Cylinder Head Cover ................................. 6A1-15

Throttle Body and Intake Manifold ............ 6A1-18

Exhaust Manifold ....................................... 6A1-21Oil Pan and Oil Pump Strainer .................. 6A1-24

Timing Chain Cover .................................. 6A1-28

Oil Pump ................................................... 6A1-33

Timing Chain and Chain Tensioner .......... 6A1-37

Camshaft, Tappet and Shim ..................... 6A1-42

Valves and Cylinder Head ........................ 6A1-48

Pistons, Piston Rings, Connecting

Rods and Cylinders................................... 6A1-62

Engine Mountings ..................................... 6A1-72

Unit Repair Overhaul .................................. 6A1-73

Engine Assembly ...................................... 6A1-73

Main Bearings, Crankshaft and Cylinder

Block ......................................................... 6A1-79

Required Service Material .......................... 6A1-93

Tightening Torque Specification ............... 6A1-93

Special Tool ................................................. 6A1-94

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 530 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-49

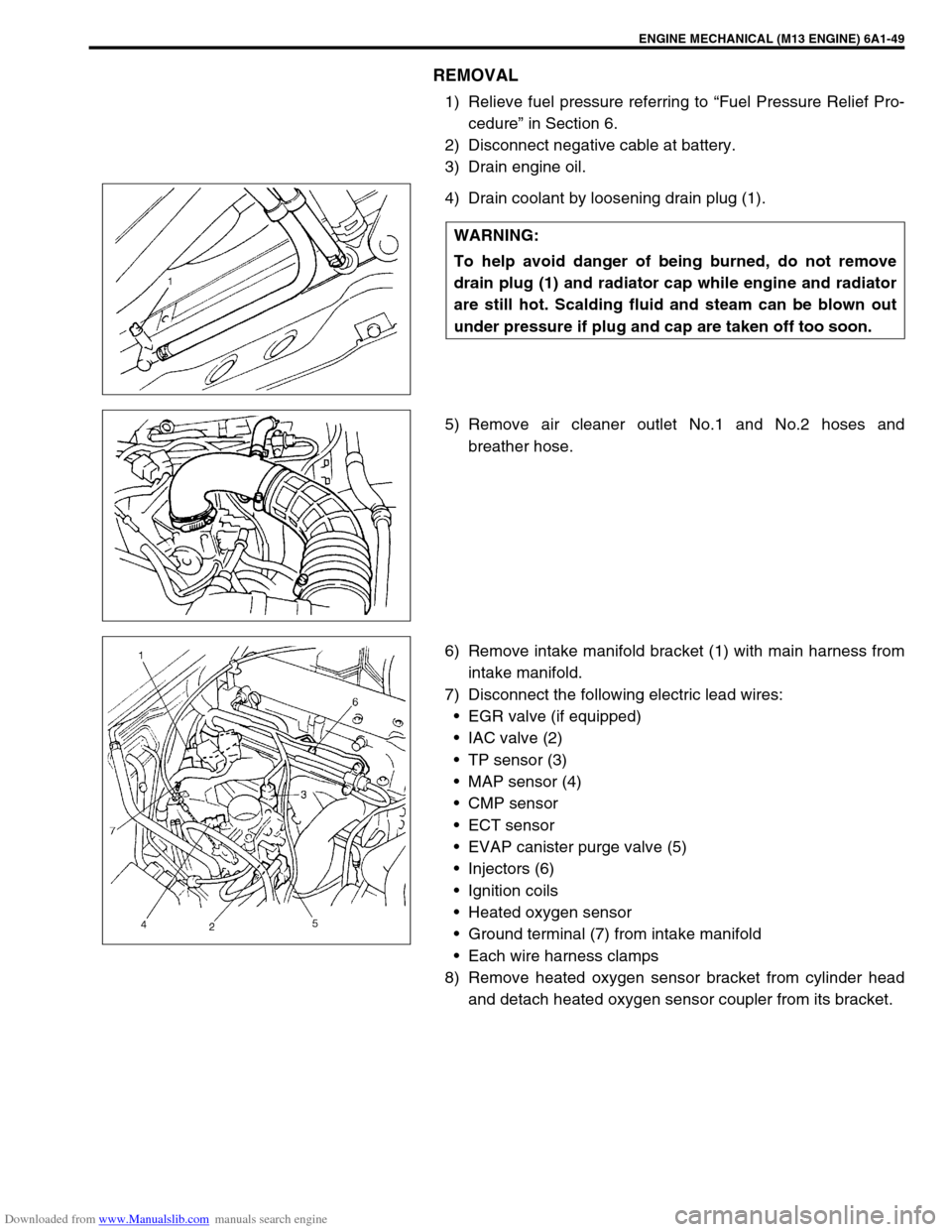

REMOVAL

1) Relieve fuel pressure referring to “Fuel Pressure Relief Pro-

cedure” in Section 6.

2) Disconnect negative cable at battery.

3) Drain engine oil.

4) Drain coolant by loosening drain plug (1).

5) Remove air cleaner outlet No.1 and No.2 hoses and

breather hose.

6) Remove intake manifold bracket (1) with main harness from

intake manifold.

7) Disconnect the following electric lead wires:

EGR valve (if equipped)

IAC valve (2)

TP sensor (3)

MAP sensor (4)

CMP sensor

ECT sensor

EVAP canister purge valve (5)

Injectors (6)

Ignition coils

Heated oxygen sensor

Ground terminal (7) from intake manifold

Each wire harness clamps

8) Remove heated oxygen sensor bracket from cylinder head

and detach heated oxygen sensor coupler from its bracket. WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.