Switch SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 363 of 687

Downloaded from www.Manualslib.com manuals search engine 6-6 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Engine Diagnosis

General Description

This vehicle is equipped with an engine and emission control system which are under control of ECM.

The engine and emission control system in this vehicle are controlled by ECM. ECM has an On-Board Diagnos-

tic system which detects a malfunction in this system and abnormality of those parts that influence the engine

exhaust emission. When diagnosing engine troubles, be sure to have full understanding of the outline of “On-

Board Diagnostic System” and each item in “Precaution in Diagnosing Trouble” and execute diagnosis accord-

ing to “ENGINE DIAGNOSTIC FLOW TABLE”.

There is a close relationship between the engine mechanical, engine cooling system, ignition system, exhaust

system, etc. and the engine and emission control system in their structure and operation. In case of an engine

trouble, even when the malfunction indicator lamp (MIL) doesn’t turn ON, it should be diagnosed according to

this flow table.

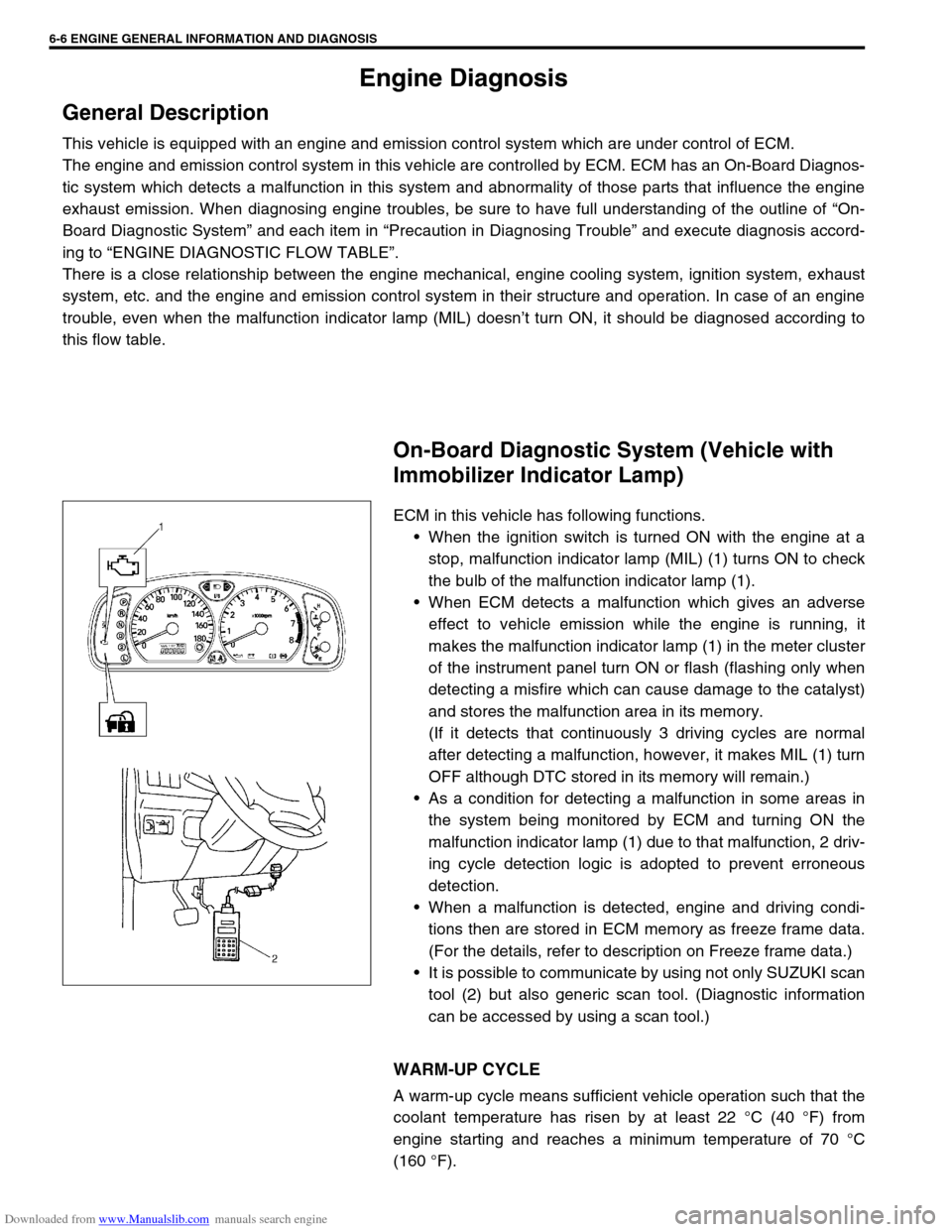

On-Board Diagnostic System (Vehicle with

Immobilizer Indicator Lamp)

ECM in this vehicle has following functions.

When the ignition switch is turned ON with the engine at a

stop, malfunction indicator lamp (MIL) (1) turns ON to check

the bulb of the malfunction indicator lamp (1).

When ECM detects a malfunction which gives an adverse

effect to vehicle emission while the engine is running, it

makes the malfunction indicator lamp (1) in the meter cluster

of the instrument panel turn ON or flash (flashing only when

detecting a misfire which can cause damage to the catalyst)

and stores the malfunction area in its memory.

(If it detects that continuously 3 driving cycles are normal

after detecting a malfunction, however, it makes MIL (1) turn

OFF although DTC stored in its memory will remain.)

As a condition for detecting a malfunction in some areas in

the system being monitored by ECM and turning ON the

malfunction indicator lamp (1) due to that malfunction, 2 driv-

ing cycle detection logic is adopted to prevent erroneous

detection.

When a malfunction is detected, engine and driving condi-

tions then are stored in ECM memory as freeze frame data.

(For the details, refer to description on Freeze frame data.)

It is possible to communicate by using not only SUZUKI scan

tool (2) but also generic scan tool. (Diagnostic information

can be accessed by using a scan tool.)

WARM-UP CYCLE

A warm-up cycle means sufficient vehicle operation such that the

coolant temperature has risen by at least 22 °C (40 °F) from

engine starting and reaches a minimum temperature of 70 °C

(160 °F).

Page 366 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-9

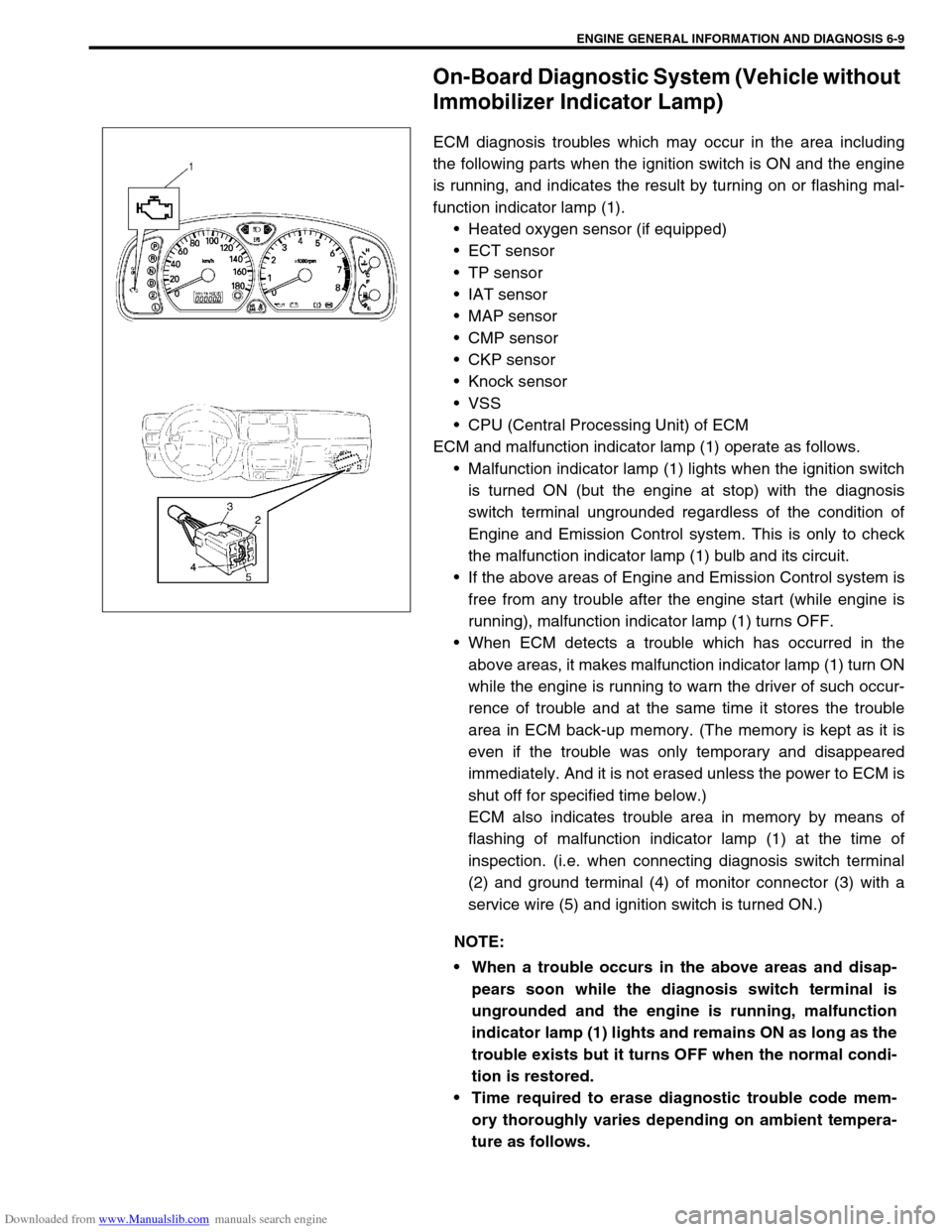

On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)

ECM diagnosis troubles which may occur in the area including

the following parts when the ignition switch is ON and the engine

is running, and indicates the result by turning on or flashing mal-

function indicator lamp (1).

Heated oxygen sensor (if equipped)

ECT sensor

TP sensor

IAT sensor

MAP sensor

CMP sensor

CKP sensor

Knock sensor

VSS

CPU (Central Processing Unit) of ECM

ECM and malfunction indicator lamp (1) operate as follows.

Malfunction indicator lamp (1) lights when the ignition switch

is turned ON (but the engine at stop) with the diagnosis

switch terminal ungrounded regardless of the condition of

Engine and Emission Control system. This is only to check

the malfunction indicator lamp (1) bulb and its circuit.

If the above areas of Engine and Emission Control system is

free from any trouble after the engine start (while engine is

running), malfunction indicator lamp (1) turns OFF.

When ECM detects a trouble which has occurred in the

above areas, it makes malfunction indicator lamp (1) turn ON

while the engine is running to warn the driver of such occur-

rence of trouble and at the same time it stores the trouble

area in ECM back-up memory. (The memory is kept as it is

even if the trouble was only temporary and disappeared

immediately. And it is not erased unless the power to ECM is

shut off for specified time below.)

ECM also indicates trouble area in memory by means of

flashing of malfunction indicator lamp (1) at the time of

inspection. (i.e. when connecting diagnosis switch terminal

(2) and ground terminal (4) of monitor connector (3) with a

service wire (5) and ignition switch is turned ON.)

NOTE:

When a trouble occurs in the above areas and disap-

pears soon while the diagnosis switch terminal is

ungrounded and the engine is running, malfunction

indicator lamp (1) lights and remains ON as long as the

trouble exists but it turns OFF when the normal condi-

tion is restored.

Time required to erase diagnostic trouble code mem-

ory thoroughly varies depending on ambient tempera-

ture as follows.

Page 369 of 687

Downloaded from www.Manualslib.com manuals search engine 6-12 ENGINE GENERAL INFORMATION AND DIAGNOSIS

1. CUSTOMER COMPLAINT ANALYSIS

Record details of the problem (failure, complaint) and how it occurred as described by the customer. For this

purpose, use of such an inspection form will facilitate collecting information to the point required for proper anal-

ysis and diagnosis.

2. DIAGNOSTIC TROUBLE CODE (DTC) / FREEZE FRAME DATA CHECK, RECORD AND CLEAR-

ANCE

First, check DTC (including pending DTC), referring to “DTC check” section. If DTC is indicated, print it and

freeze frame data or write them down and then clear them by referring to “DTC clearance” section. DTC indi-

cates malfunction that occurred in the system but does not indicate whether it exists now or it occurred in the

past and the normal condition has been restored now. To check which case applies, check the symptom in ques-

tion according to Step 4 and recheck DTC according to Step 5.

Attempt to diagnose a trouble based on DTC in this step only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit or difficulty in troubleshooting.

3. AND 4. VISUAL INSPECTION

As a preliminary step, be sure to perform visual check of the items that support proper function of the engine

referring to “Visual Inspection” section.

5. TROUBLE SYMPTOM CONFIRMATION

Based on information obtained in Step 1 Customer complaint analysis and Step 2 DTC / freeze frame data

check, confirm trouble symptoms. Also, reconfirm DTC according to “DTC Confirmation Procedure” described in

each DTC Diagnosis section.

6. AND 7. RECHECKING AND RECORD OF DTC / FREEZE FRAME DATA

Refer to “DTC Check” section for checking procedure.

8. ENGINE BASIC INSPECTION AND ENGINE DIAGNOSIS TABLE

Perform basic engine check according to the “Engine Basic Inspection” first. When the end of the flow table has

been reached, check the parts of the system suspected as a possible cause referring to “Engine Diagnosis

Table” and based on symptoms appearing on the vehicle (symptoms obtained through steps of customer com-

plaint analysis, trouble symptom confirmation and / or basic engine check) and repair or replace faulty parts, if

any.

9. TROUBLESHOOTING FOR DTC (SEE EACH DTC DIAG. FLOW TABLE)

Based on the DTC indicated in Step 5 and referring to the applicable DTC diag. flow table in this section, locate

the cause of the trouble, namely in a sensor, switch, wire harness, connector, actuator, ECM or other part and

repair or replace faulty parts.

10. CHECK FOR INTERMITTENT PROBLEM

Check parts where an intermittent trouble is easy to occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection” in Section 0A and related circuit of DTC recorded in Step 2.

11. FINAL CONFIRMATION TEST

Confirm that the problem symptom has gone and the engine is free from any abnormal conditions. If what has

been repaired is related to the DTC, clear the DTC once, perform DTC confirmation procedure and confirm that

no DTC is indicated.NOTE:

If only Automatic transmission DTCs (P0702-P1717) or Immobilizer DTCs (P1620-P1623) are indicated

in this step, perform trouble diagnosis according to “Diagnosis” in Section 7B or Section 8G.

Page 371 of 687

Downloaded from www.Manualslib.com manuals search engine 6-14 ENGINE GENERAL INFORMATION AND DIAGNOSIS

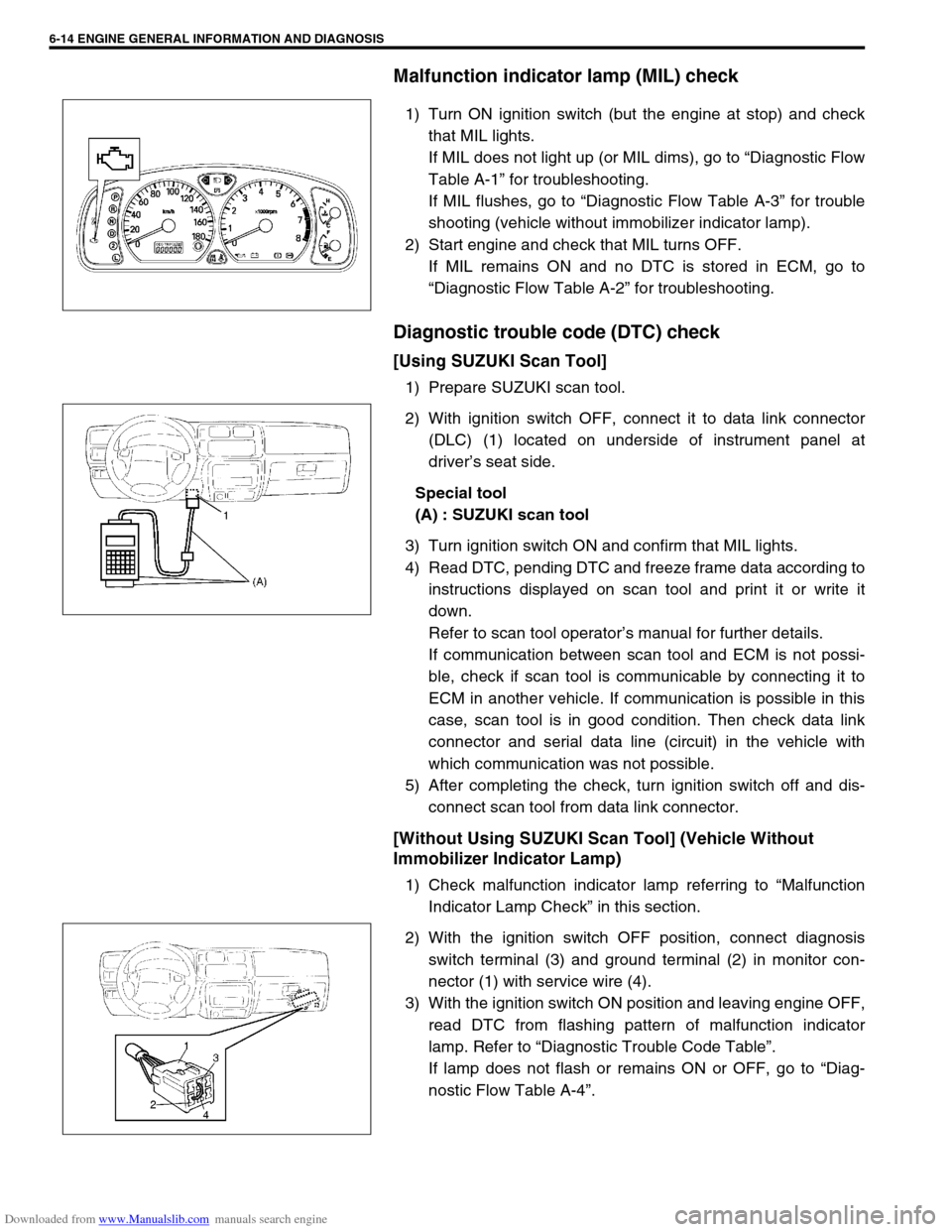

Malfunction indicator lamp (MIL) check

1) Turn ON ignition switch (but the engine at stop) and check

that MIL lights.

If MIL does not light up (or MIL dims), go to “Diagnostic Flow

Table A-1” for troubleshooting.

If MIL flushes, go to “Diagnostic Flow Table A-3” for trouble

shooting (vehicle without immobilizer indicator lamp).

2) Start engine and check that MIL turns OFF.

If MIL remains ON and no DTC is stored in ECM, go to

“Diagnostic Flow Table A-2” for troubleshooting.

Diagnostic trouble code (DTC) check

[Using SUZUKI Scan Tool]

1) Prepare SUZUKI scan tool.

2) With ignition switch OFF, connect it to data link connector

(DLC) (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A) : SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to

instructions displayed on scan tool and print it or write it

down.

Refer to scan tool operator’s manual for further details.

If communication between scan tool and ECM is not possi-

ble, check if scan tool is communicable by connecting it to

ECM in another vehicle. If communication is possible in this

case, scan tool is in good condition. Then check data link

connector and serial data line (circuit) in the vehicle with

which communication was not possible.

5) After completing the check, turn ignition switch off and dis-

connect scan tool from data link connector.

[Without Using SUZUKI Scan Tool] (Vehicle Without

Immobilizer Indicator Lamp)

1) Check malfunction indicator lamp referring to “Malfunction

Indicator Lamp Check” in this section.

2) With the ignition switch OFF position, connect diagnosis

switch terminal (3) and ground terminal (2) in monitor con-

nector (1) with service wire (4).

3) With the ignition switch ON position and leaving engine OFF,

read DTC from flashing pattern of malfunction indicator

lamp. Refer to “Diagnostic Trouble Code Table”.

If lamp does not flash or remains ON or OFF, go to “Diag-

nostic Flow Table A-4”.

Page 372 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-15

4) After completing the check, turn the ignition switch OFF posi-

tion and disconnect service wire from monitor coupler.

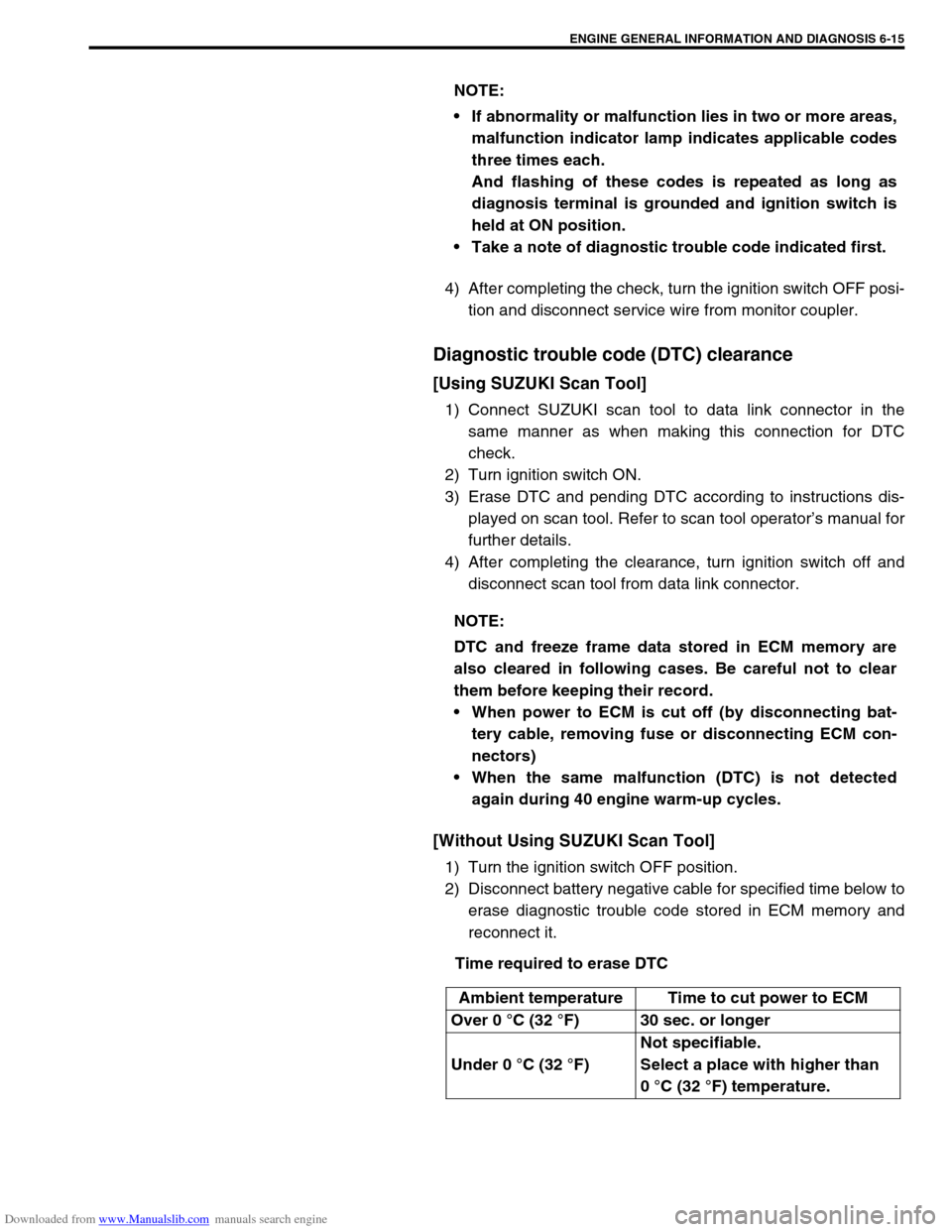

Diagnostic trouble code (DTC) clearance

[Using SUZUKI Scan Tool]

1) Connect SUZUKI scan tool to data link connector in the

same manner as when making this connection for DTC

check.

2) Turn ignition switch ON.

3) Erase DTC and pending DTC according to instructions dis-

played on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clearance, turn ignition switch off and

disconnect scan tool from data link connector.

[Without Using SUZUKI Scan Tool]

1) Turn the ignition switch OFF position.

2) Disconnect battery negative cable for specified time below to

erase diagnostic trouble code stored in ECM memory and

reconnect it.

Time required to erase DTC NOTE:

If abnormality or malfunction lies in two or more areas,

malfunction indicator lamp indicates applicable codes

three times each.

And flashing of these codes is repeated as long as

diagnosis terminal is grounded and ignition switch is

held at ON position.

Take a note of diagnostic trouble code indicated first.

NOTE:

DTC and freeze frame data stored in ECM memory are

also cleared in following cases. Be careful not to clear

them before keeping their record.

When power to ECM is cut off (by disconnecting bat-

tery cable, removing fuse or disconnecting ECM con-

nectors)

When the same malfunction (DTC) is not detected

again during 40 engine warm-up cycles.

Ambient temperature Time to cut power to ECM

Over 0 °C (32 °F) 30 sec. or longer

Under 0 °C (32 °F)Not specifiable.

Select a place with higher than

0 °C (32 °F) temperature.

Page 378 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-21

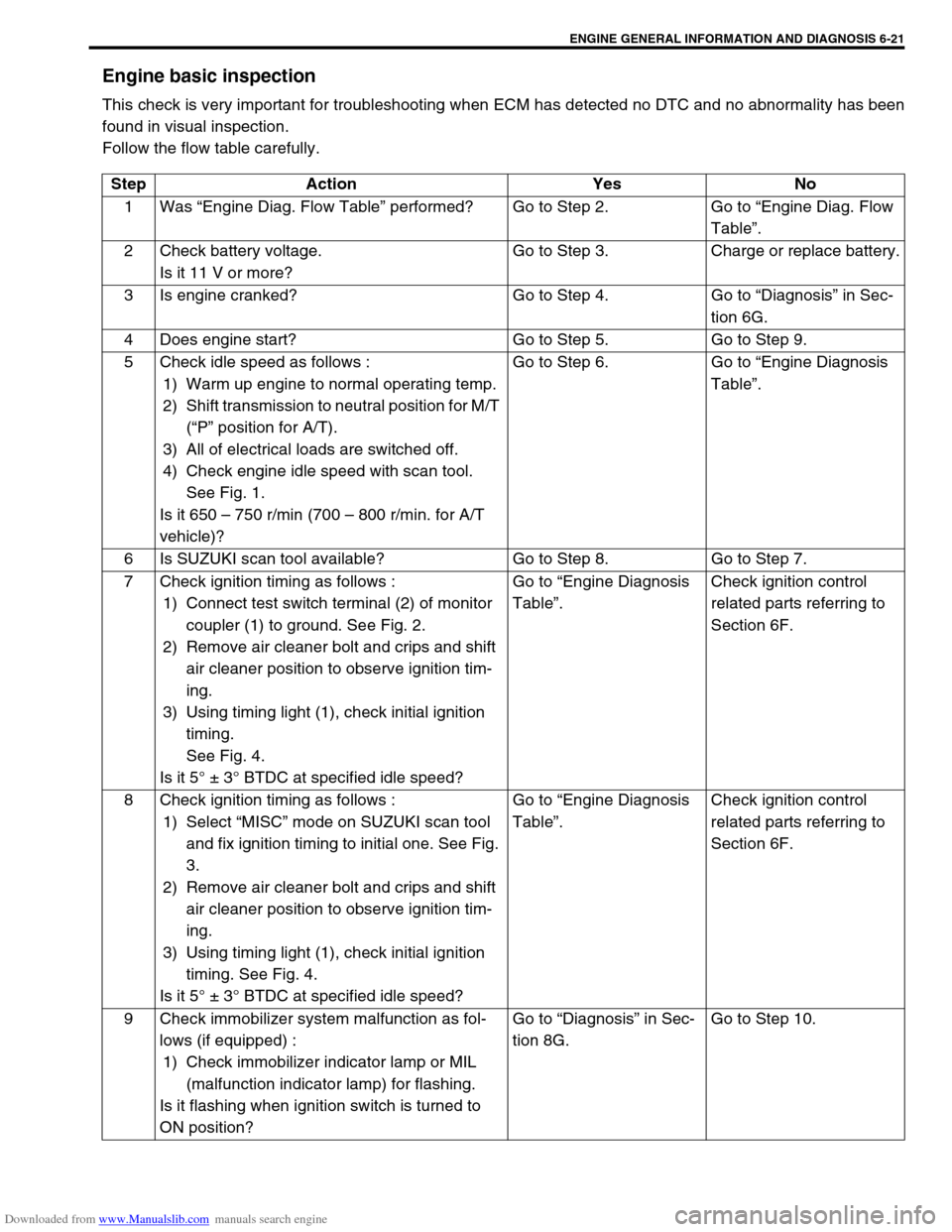

Engine basic inspection

This check is very important for troubleshooting when ECM has detected no DTC and no abnormality has been

found in visual inspection.

Follow the flow table carefully.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check battery voltage.

Is it 11 V or more?Go to Step 3. Charge or replace battery.

3 Is engine cranked? Go to Step 4. Go to “Diagnosis” in Sec-

tion 6G.

4 Does engine start? Go to Step 5. Go to Step 9.

5 Check idle speed as follows :

1) Warm up engine to normal operating temp.

2) Shift transmission to neutral position for M/T

(“P” position for A/T).

3) All of electrical loads are switched off.

4) Check engine idle speed with scan tool.

See Fig. 1.

Is it 650 – 750 r/min (700 – 800 r/min. for A/T

vehicle)?Go to Step 6. Go to “Engine Diagnosis

Table”.

6 Is SUZUKI scan tool available? Go to Step 8. Go to Step 7.

7 Check ignition timing as follows :

1) Connect test switch terminal (2) of monitor

coupler (1) to ground. See Fig. 2.

2) Remove air cleaner bolt and crips and shift

air cleaner position to observe ignition tim-

ing.

3) Using timing light (1), check initial ignition

timing.

See Fig. 4.

Is it 5° ± 3° BTDC at specified idle speed?Go to “Engine Diagnosis

Table”.Check ignition control

related parts referring to

Section 6F.

8 Check ignition timing as follows :

1) Select “MISC” mode on SUZUKI scan tool

and fix ignition timing to initial one. See Fig.

3.

2) Remove air cleaner bolt and crips and shift

air cleaner position to observe ignition tim-

ing.

3) Using timing light (1), check initial ignition

timing. See Fig. 4.

Is it 5° ± 3° BTDC at specified idle speed?Go to “Engine Diagnosis

Table”.Check ignition control

related parts referring to

Section 6F.

9 Check immobilizer system malfunction as fol-

lows (if equipped) :

1) Check immobilizer indicator lamp or MIL

(malfunction indicator lamp) for flashing.

Is it flashing when ignition switch is turned to

ON position?Go to “Diagnosis” in Sec-

tion 8G.Go to Step 10.

Page 379 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-22 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 7 / [C] Fig. 3 for Step 810 Check fuel supply as foll SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-22 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 7 / [C] Fig. 3 for Step 810 Check fuel supply as foll](/img/20/7588/w960_7588-378.png)

Downloaded from www.Manualslib.com manuals search engine 6-22 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 7 / [C] Fig. 3 for Step 810 Check fuel supply as follows :

1) Check to make sure that enough fuel is filled

in fuel tank.

2) Turn ON ignition switch for 2 seconds and

then OFF. See Fig. 5.

Is fuel return pressure (returning sounds) felt

from fuel feed hose (1) when ignition switch is

turned ON?Go to Step 12. Go to Step 11.

11 Check fuel pump for operating.

1) Was fuel pump operating sound heard from

fuel filler for about 2 seconds after ignition

switch ON and stop?Go to “Diag. Flow Table

B-3”.Go to “Diag. Flow Table

B-2”.

12 Check ignition spark as follows :

1) Disconnect injector couplers.

2) Remove spark plugs and connect them to

high tension cords.

3) Ground spark plugs.

4) Crank engine and check if each spark plug

sparks.

Is it in good condition?Go to Step 13. Go to “Ignition Spark Test”

in Section 6F.

13 Check fuel injector for operation as follows :

1) Install spark plugs and connect injector con-

nectors.

2) Using sound scope (2), check operating

sound of each injector (3) when cranking

engine. See Fig. 6.

Was injector operating sound heard from all

injectors?Go to “Engine Diagnosis

Table”.Go to “Diag. Flow Table

B-1”. Step Action Yes No

[B] : When not using SUZUKI scan tool :

[C] : When using SUZUKI scan tool

Page 383 of 687

Downloaded from www.Manualslib.com manuals search engine 6-26 ENGINE GENERAL INFORMATION AND DIAGNOSIS

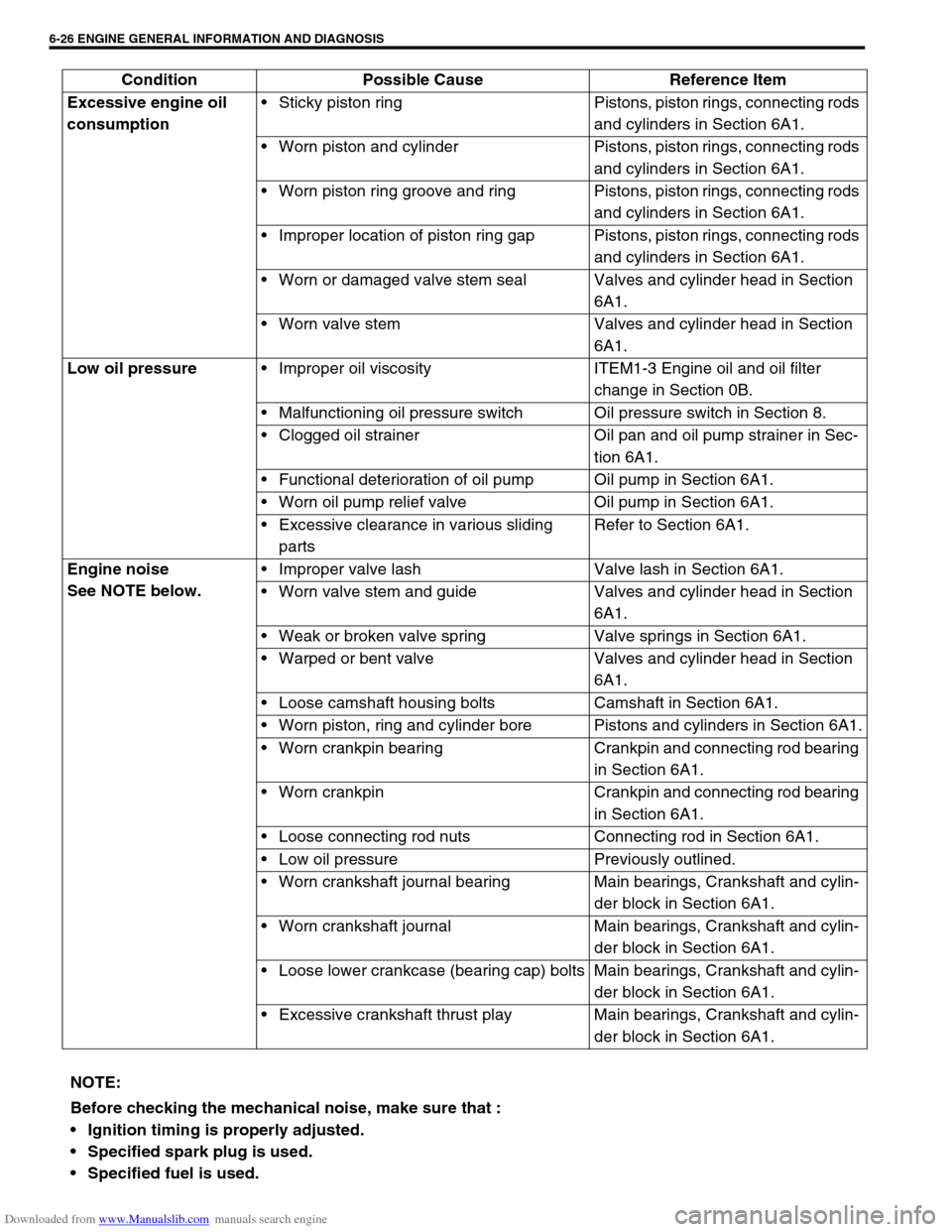

Excessive engine oil

consumptionSticky piston ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston and cylinder Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston ring groove and ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Improper location of piston ring gap Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn or damaged valve stem seal Valves and cylinder head in Section

6A1.

Worn valve stem Valves and cylinder head in Section

6A1.

Low oil pressure

Improper oil viscosity ITEM1-3 Engine oil and oil filter

change in Section 0B.

Malfunctioning oil pressure switch Oil pressure switch in Section 8.

Clogged oil strainer Oil pan and oil pump strainer in Sec-

tion 6A1.

Functional deterioration of oil pump Oil pump in Section 6A1.

Worn oil pump relief valve Oil pump in Section 6A1.

Excessive clearance in various sliding

partsRefer to Section 6A1.

Engine noise

See NOTE below.Improper valve lash Valve lash in Section 6A1.

Worn valve stem and guide Valves and cylinder head in Section

6A1.

Weak or broken valve spring Valve springs in Section 6A1.

Warped or bent valve Valves and cylinder head in Section

6A1.

Loose camshaft housing bolts Camshaft in Section 6A1.

Worn piston, ring and cylinder bore Pistons and cylinders in Section 6A1.

Worn crankpin bearing Crankpin and connecting rod bearing

in Section 6A1.

Worn crankpin Crankpin and connecting rod bearing

in Section 6A1.

Loose connecting rod nuts Connecting rod in Section 6A1.

Low oil pressure Previously outlined.

Worn crankshaft journal bearing Main bearings, Crankshaft and cylin-

der block in Section 6A1.

Worn crankshaft journal Main bearings, Crankshaft and cylin-

der block in Section 6A1.

Loose lower crankcase (bearing cap) bolts Main bearings, Crankshaft and cylin-

der block in Section 6A1.

Excessive crankshaft thrust play Main bearings, Crankshaft and cylin-

der block in Section 6A1. Condition Possible Cause Reference Item

NOTE:

Before checking the mechanical noise, make sure that :

Ignition timing is properly adjusted.

Specified spark plug is used.

Specified fuel is used.

Page 385 of 687

Downloaded from www.Manualslib.com manuals search engine 6-28 ENGINE GENERAL INFORMATION AND DIAGNOSIS

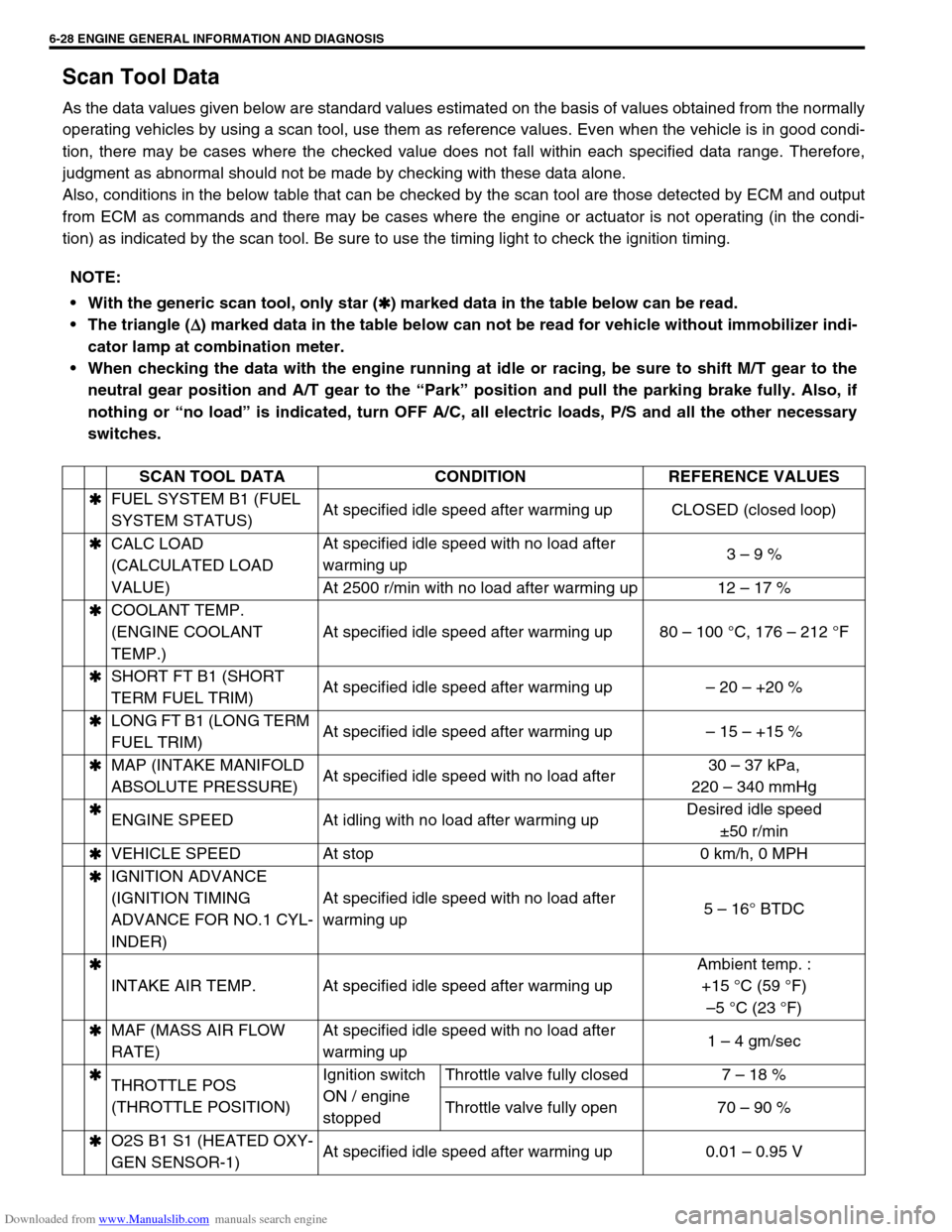

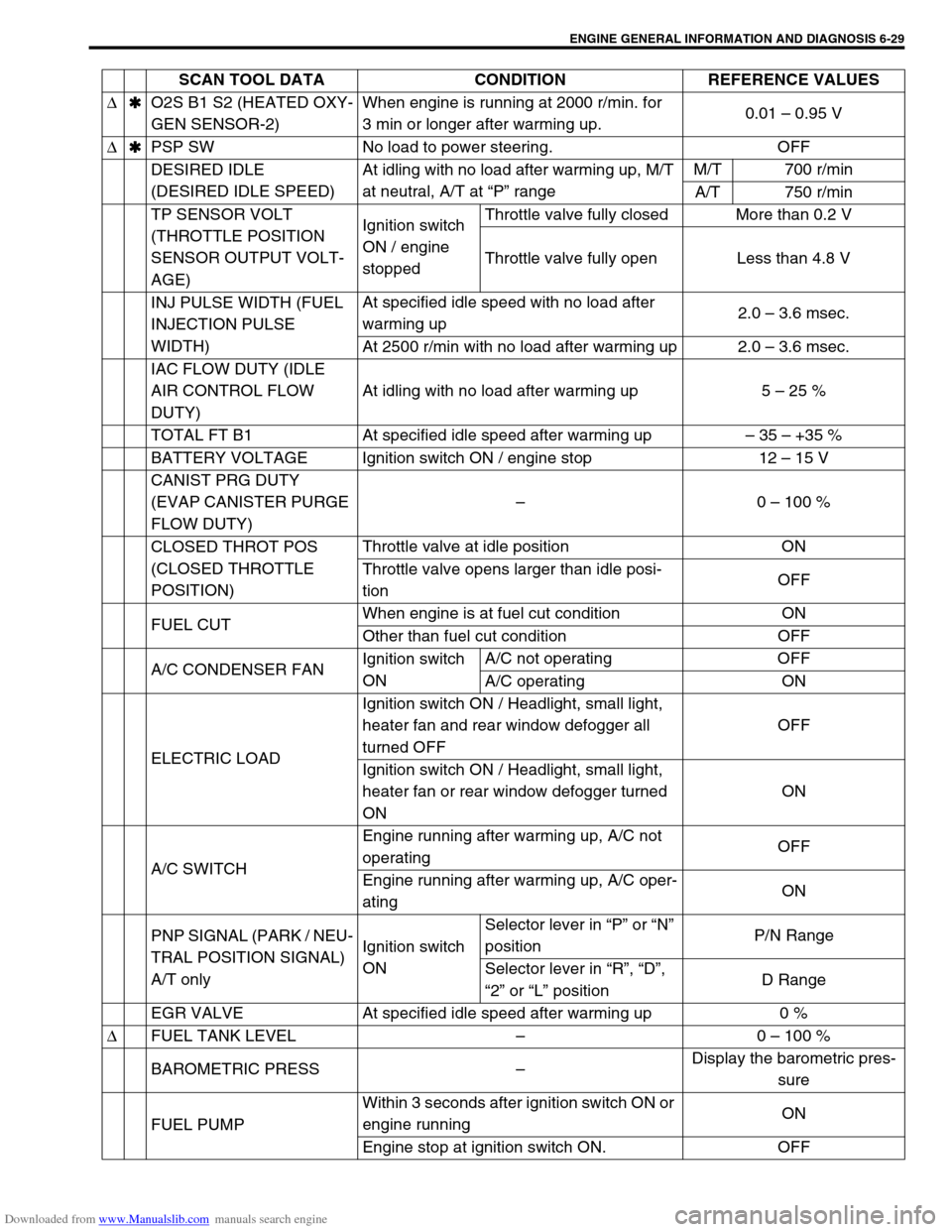

Scan Tool Data

As the data values given below are standard values estimated on the basis of values obtained from the normally

operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condi-

tion, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, conditions in the below table that can be checked by the scan tool are those detected by ECM and output

from ECM as commands and there may be cases where the engine or actuator is not operating (in the condi-

tion) as indicated by the scan tool. Be sure to use the timing light to check the ignition timing.

NOTE:

With the generic scan tool, only star (

✱

✱✱ ✱) marked data in the table below can be read.

The triangle (

∆

∆∆ ∆) marked data in the table below can not be read for vehicle without immobilizer indi-

cator lamp at combination meter.

When checking the data with the engine running at idle or racing, be sure to shift M/T gear to the

neutral gear position and A/T gear to the “Park” position and pull the parking brake fully. Also, if

nothing or “no load” is indicated, turn OFF A/C, all electric loads, P/S and all the other necessary

switches.

SCAN TOOL DATA CONDITION REFERENCE VALUES

✱

✱✱ ✱FUEL SYSTEM B1 (FUEL

SYSTEM STATUS)At specified idle speed after warming up CLOSED (closed loop)

✱

✱✱ ✱

CALC LOAD

(CALCULATED LOAD

VALUE)At specified idle speed with no load after

warming up3 – 9 %

At 2500 r/min with no load after warming up 12 – 17 %

✱

✱✱ ✱COOLANT TEMP.

(ENGINE COOLANT

TEMP.)At specified idle speed after warming up 80 – 100 °C, 176 – 212 °F

✱

✱✱ ✱SHORT FT B1 (SHORT

TERM FUEL TRIM)At specified idle speed after warming up– 20 – +20 %

✱

✱✱ ✱LONG FT B1 (LONG TERM

FUEL TRIM)At specified idle speed after warming up– 15 – +15 %

✱

✱✱ ✱MAP (INTAKE MANIFOLD

ABSOLUTE PRESSURE)At specified idle speed with no load after30 – 37 kPa,

220 – 340 mmHg

✱

✱✱ ✱

ENGINE SPEED At idling with no load after warming upDesired idle speed

±50 r/min

✱

✱✱ ✱VEHICLE SPEED At stop 0 km/h, 0 MPH

✱

✱✱ ✱IGNITION ADVANCE

(IGNITION TIMING

ADVANCE FOR NO.1 CYL-

INDER)At specified idle speed with no load after

warming up5 – 16° BTDC

✱

✱✱ ✱

INTAKE AIR TEMP. At specified idle speed after warming upAmbient temp. :

+15 °C (59 °F)

–5 °C (23 °F)

✱

✱✱ ✱MAF (MASS AIR FLOW

RATE)At specified idle speed with no load after

warming up1 – 4 gm/sec

✱

✱✱ ✱

THROTTLE POS

(THROTTLE POSITION)Ignition switch

ON / engine

stoppedThrottle valve fully closed 7 – 18 %

Throttle valve fully open 70 – 90 %

✱

✱✱ ✱O2S B1 S1 (HEATED OXY-

GEN SENSOR-1)At specified idle speed after warming up 0.01 – 0.95 V

Page 386 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-29

∆✱

✱✱ ✱O2S B1 S2 (HEATED OXY-

GEN SENSOR-2)When engine is running at 2000 r/min. for

3 min or longer after warming up.0.01 – 0.95 V

∆✱

✱✱ ✱PSP SW No load to power steering. OFF

DESIRED IDLE

(DESIRED IDLE SPEED)At idling with no load after warming up, M/T

at neutral, A/T at “P” rangeM/T 700 r/min

A/T 750 r/min

TP SENSOR VOLT

(THROTTLE POSITION

SENSOR OUTPUT VOLT-

AGE)Ignition switch

ON / engine

stoppedThrottle valve fully closed More than 0.2 V

Throttle valve fully open Less than 4.8 V

INJ PULSE WIDTH (FUEL

INJECTION PULSE

WIDTH)At specified idle speed with no load after

warming up2.0 – 3.6 msec.

At 2500 r/min with no load after warming up 2.0 – 3.6 msec.

IAC FLOW DUTY (IDLE

AIR CONTROL FLOW

DUTY)At idling with no load after warming up 5 – 25 %

TOTAL FT B1 At specified idle speed after warming up– 35 – +35 %

BATTERY VOLTAGE Ignition switch ON / engine stop 12 – 15 V

CANIST PRG DUTY

(EVAP CANISTER PURGE

FLOW DUTY)–0 – 100 %

CLOSED THROT POS

(CLOSED THROTTLE

POSITION)Throttle valve at idle position ON

Throttle valve opens larger than idle posi-

tionOFF

FUEL CUTWhen engine is at fuel cut condition ON

Other than fuel cut condition OFF

A/C CONDENSER FANIgnition switch

ONA/C not operating OFF

A/C operating ON

ELECTRIC LOADIgnition switch ON / Headlight, small light,

heater fan and rear window defogger all

turned OFFOFF

Ignition switch ON / Headlight, small light,

heater fan or rear window defogger turned

ONON

A/C SWITCHEngine running after warming up, A/C not

operatingOFF

Engine running after warming up, A/C oper-

atingON

PNP SIGNAL (PARK / NEU-

TRAL POSITION SIGNAL)

A/T onlyIgnition switch

ONSelector lever in “P” or “N”

positionP/N Range

Selector lever in “R”, “D”,

“2” or “L” positionD Range

EGR VALVE At specified idle speed after warming up 0 %

∆FUEL TANK LEVEL–0 – 100 %

BAROMETRIC PRESS–Display the barometric pres-

sure

FUEL PUMPWithin 3 seconds after ignition switch ON or

engine runningON

Engine stop at ignition switch ON. OFF SCAN TOOL DATA CONDITION REFERENCE VALUES