wheel SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 454 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-97

[A] Fig. 1 for Step 3 / [B] Fig. 2 for Step 43 Check Idle Air Control System.

1) Connect SUZUKI s SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-97

[A] Fig. 1 for Step 3 / [B] Fig. 2 for Step 43 Check Idle Air Control System.

1) Connect SUZUKI s](/img/20/7588/w960_7588-453.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-97

[A] Fig. 1 for Step 3 / [B] Fig. 2 for Step 43 Check Idle Air Control System.

1) Connect SUZUKI scan tool to DLC with igni-

tion switch OFF, set parking brake and block

drive wheels. See Fig. 1.

2) Warm up engine to normal operating tem-

perature.

3) Clear DTC and select “MISC TEST” mode

on SUZUKI scan tool.

Is it possible to control (increase and reduce)

engine idle speed by using SUZUKI scan tool? Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Go to Step 5.

4 Check Idle Air Control System.

1) Remove IAC valve from throttle boy refer-

ring to “IAC Valve” in Section 6E.

2) Check IAC valve for operation referring to

“IAC Valve” in Section 6E. See Fig. 2.

Is check result satisfactory?Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Go to Step 5.

5 Check Wire Harness for Open and Short.

1) Turn ignition switch OFF.

2) Disconnect IAC valve connector.

3) Check for proper connection to IAC valve at

each terminals.

4) If OK, disconnect ECM connector.

5) Check for proper connection to ECM at

E19-6 terminal.

6) If OK, check “Bl/B”, “G/Y” and “B/R” circuit

for open and short.

Are they in good condition?Replace IAC valve and

recheck.Repair or replace. Step Action Yes No

Page 485 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-4 ENGINE MECHANICAL (M13 ENGINE)

Diagnosis

Diagnosis Table

Refer to “Engine Diagnosis Table” in Section 6.

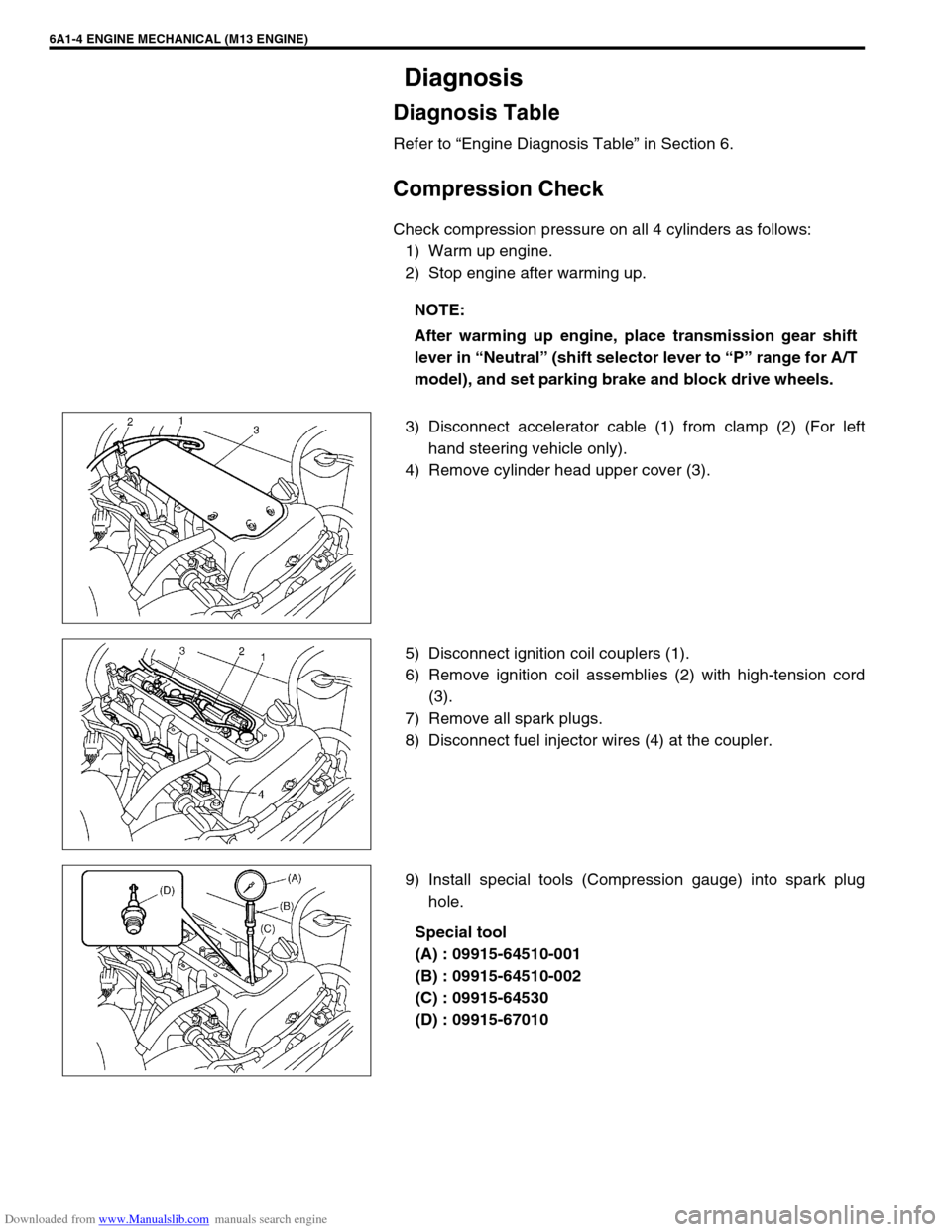

Compression Check

Check compression pressure on all 4 cylinders as follows:

1) Warm up engine.

2) Stop engine after warming up.

3) Disconnect accelerator cable (1) from clamp (2) (For left

hand steering vehicle only).

4) Remove cylinder head upper cover (3).

5) Disconnect ignition coil couplers (1).

6) Remove ignition coil assemblies (2) with high-tension cord

(3).

7) Remove all spark plugs.

8) Disconnect fuel injector wires (4) at the coupler.

9) Install special tools (Compression gauge) into spark plug

hole.

Special tool

(A) : 09915-64510-001

(B) : 09915-64510-002

(C) : 09915-64530

(D) : 09915-67010 NOTE:

After warming up engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

model), and set parking brake and block drive wheels.

Page 487 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-6 ENGINE MECHANICAL (M13 ENGINE)

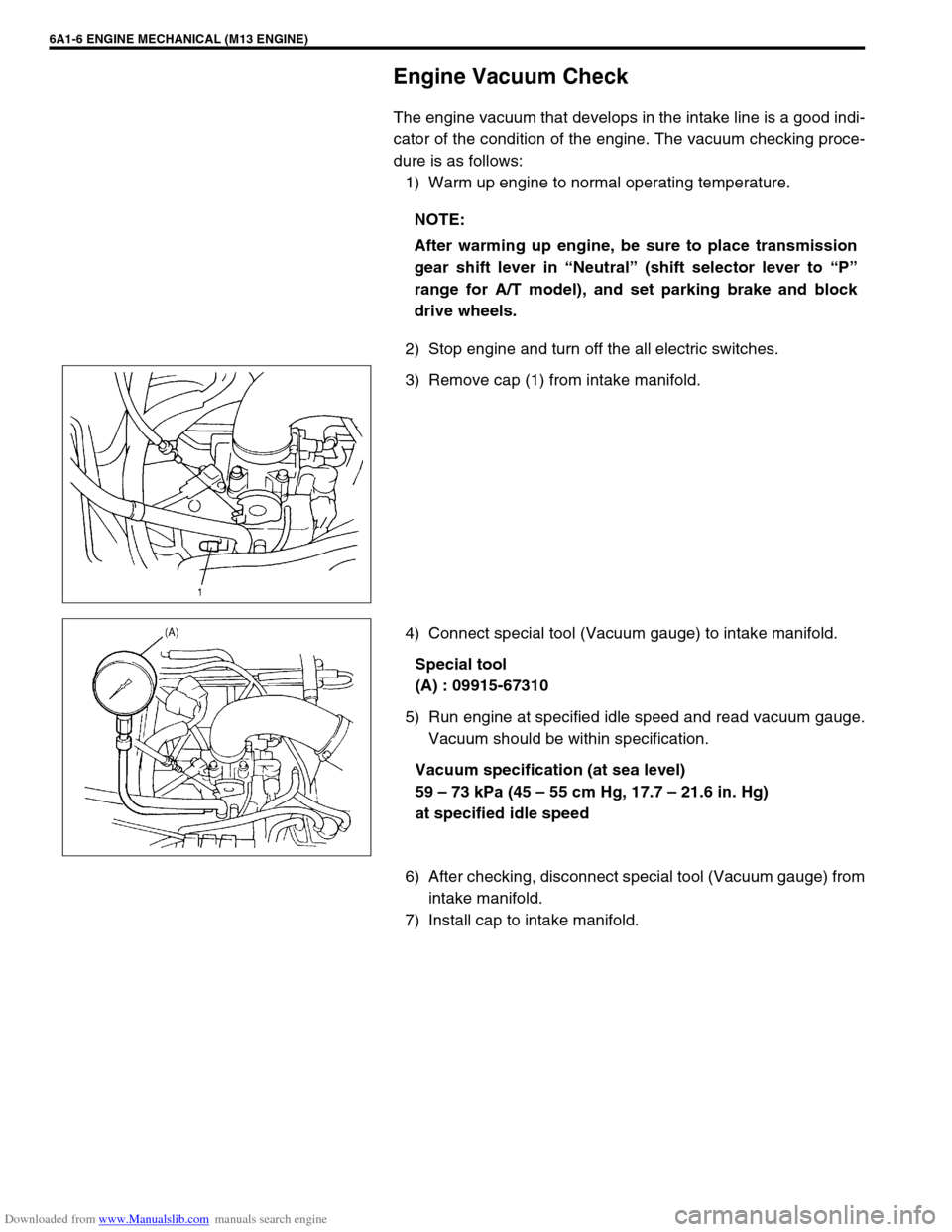

Engine Vacuum Check

The engine vacuum that develops in the intake line is a good indi-

cator of the condition of the engine. The vacuum checking proce-

dure is as follows:

1) Warm up engine to normal operating temperature.

2) Stop engine and turn off the all electric switches.

3) Remove cap (1) from intake manifold.

4) Connect special tool (Vacuum gauge) to intake manifold.

Special tool

(A) : 09915-67310

5) Run engine at specified idle speed and read vacuum gauge.

Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cm Hg, 17.7 – 21.6 in. Hg)

at specified idle speed

6) After checking, disconnect special tool (Vacuum gauge) from

intake manifold.

7) Install cap to intake manifold.NOTE:

After warming up engine, be sure to place transmission

gear shift lever in “Neutral” (shift selector lever to “P”

range for A/T model), and set parking brake and block

drive wheels.

Page 488 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-7

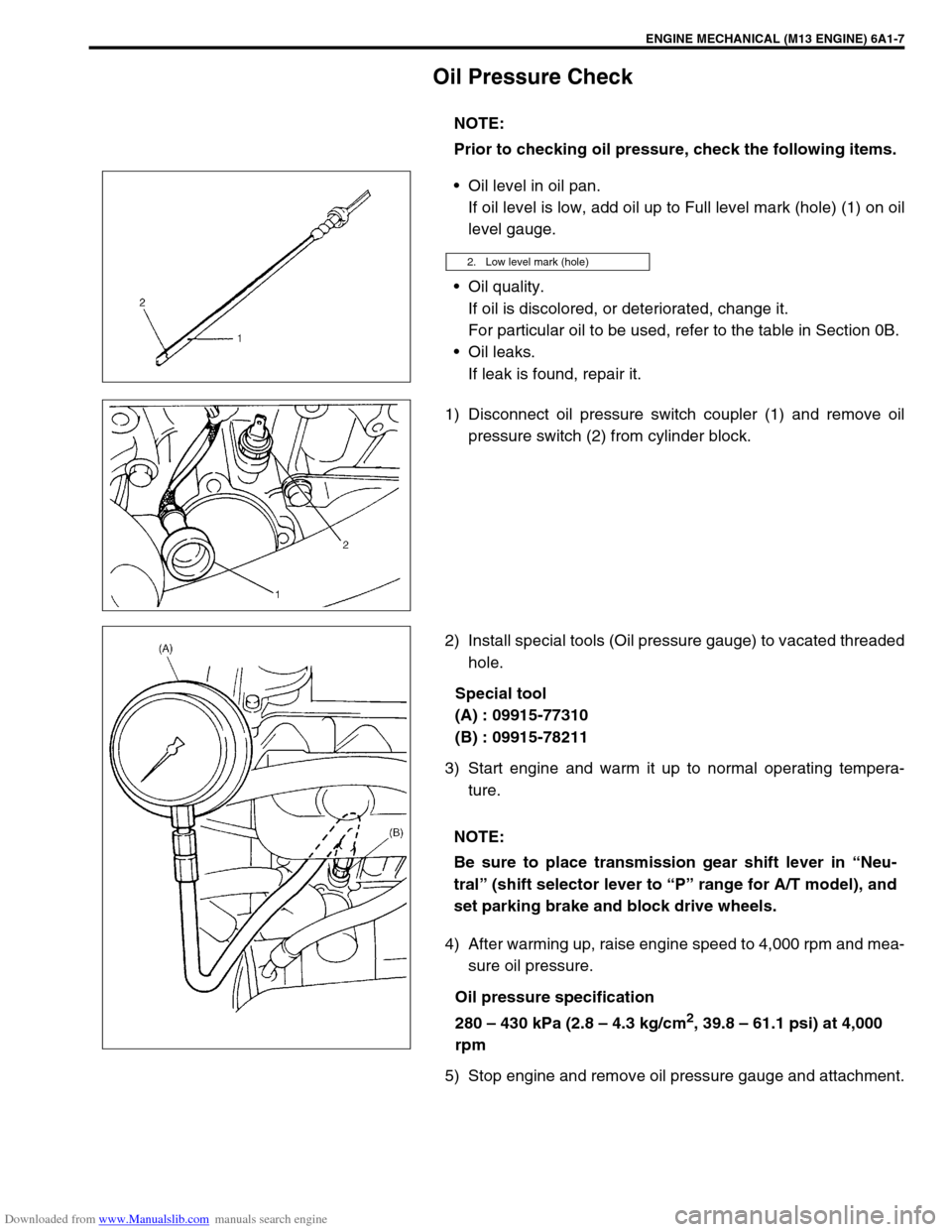

Oil Pressure Check

Oil level in oil pan.

If oil level is low, add oil up to Full level mark (hole) (1) on oil

level gauge.

Oil quality.

If oil is discolored, or deteriorated, change it.

For particular oil to be used, refer to the table in Section 0B.

Oil leaks.

If leak is found, repair it.

1) Disconnect oil pressure switch coupler (1) and remove oil

pressure switch (2) from cylinder block.

2) Install special tools (Oil pressure gauge) to vacated threaded

hole.

Special tool

(A) : 09915-77310

(B) : 09915-78211

3) Start engine and warm it up to normal operating tempera-

ture.

4) After warming up, raise engine speed to 4,000 rpm and mea-

sure oil pressure.

Oil pressure specification

280 – 430 kPa (2.8 – 4.3 kg/cm

2, 39.8 – 61.1 psi) at 4,000

rpm

5) Stop engine and remove oil pressure gauge and attachment.NOTE:

Prior to checking oil pressure, check the following items.

2. Low level mark (hole)

NOTE:

Be sure to place transmission gear shift lever in “Neu-

tral” (shift selector lever to “P” range for A/T model), and

set parking brake and block drive wheels.

Page 551 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-70 ENGINE MECHANICAL (M13 ENGINE)

INSTALLATION

1) Apply engine oil to pistons, rings, cylinder walls, connecting

rod bearings and crankpins.

2) Install guide hoses (1) over connecting rod bolts.

These guide hoses protect crank pin and threads of rod bolt

from damage during installation of connecting rod and piston

assembly.

3) When installing piston and connecting rod assembly into cyl-

inder bore, point front mark on piston head to crankshaft pul-

ley side.

4) Install piston and connecting rod assembly into cylinder

bore. Use special tool (Piston ring compressor) to compress

rings. Guide connecting rod into place on crankshaft.

Using a hammer handle, tap piston head to install piston into

bore. Hold ring compressor firmly against cylinder block until

all piston rings have entered cylinder bore.

Special tool

(A) : 09916-77310 NOTE:

Do not apply oil between connecting rod and bearing or

between bearing cap and bearing.

A : Crankshaft pulley side

B : Flywheel side

Page 560 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-79

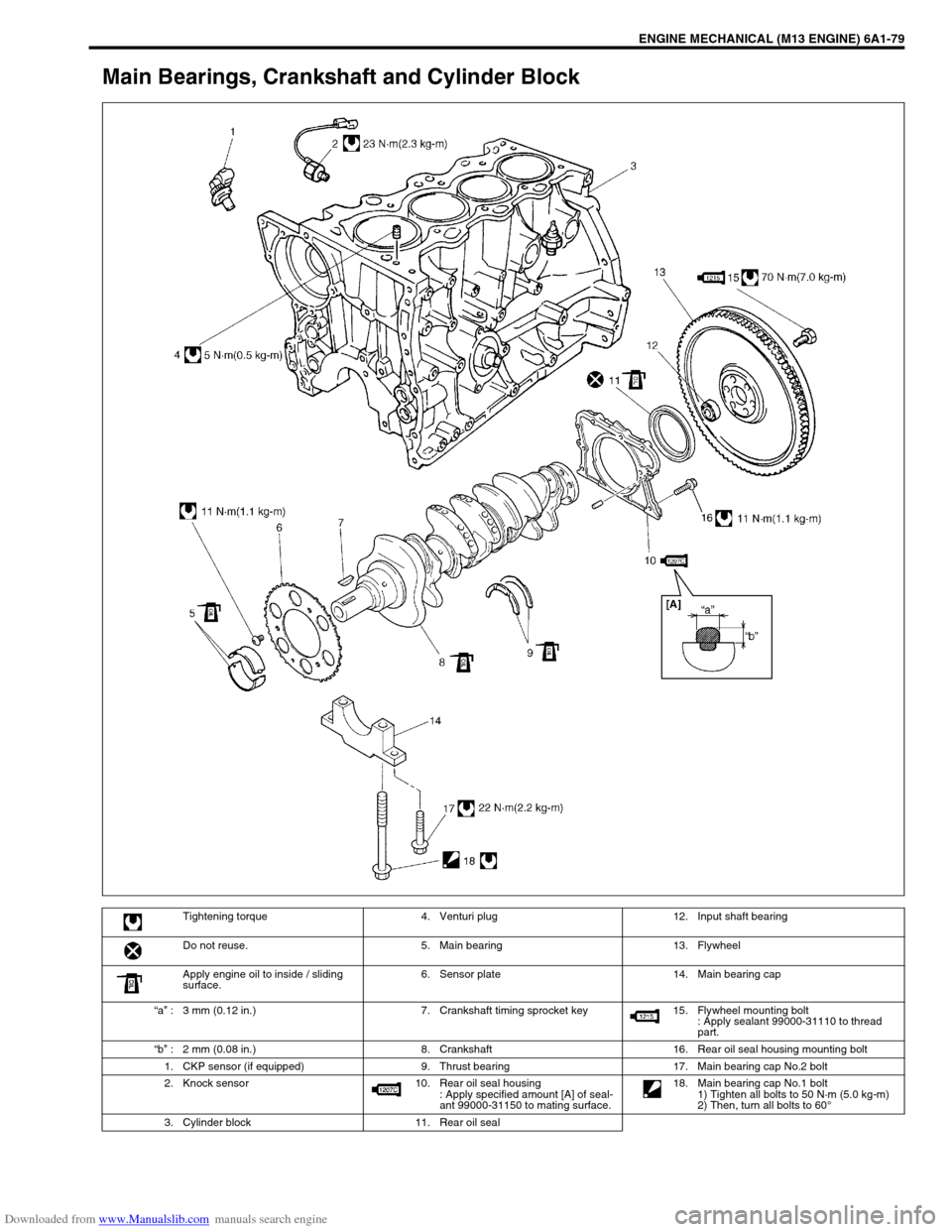

Main Bearings, Crankshaft and Cylinder Block

Tightening torque 4. Venturi plug 12. Input shaft bearing

Do not reuse. 5. Main bearing 13. Flywheel

Apply engine oil to inside / sliding

surface.6. Sensor plate 14. Main bearing cap

“a” : 3 mm (0.12 in.) 7. Crankshaft timing sprocket key 15. Flywheel mounting bolt

: Apply sealant 99000-31110 to thread

part.

“b” : 2 mm (0.08 in.) 8. Crankshaft 16. Rear oil seal housing mounting bolt

1. CKP sensor (if equipped) 9. Thrust bearing 17. Main bearing cap No.2 bolt

2. Knock sensor 10. Rear oil seal housing

: Apply specified amount [A] of seal-

ant 99000-31150 to mating surface. 18. Main bearing cap No.1 bolt

1) Tighten all bolts to 50 N·m (5.0 kg-m)

2) Then, turn all bolts to 60°

3. Cylinder block 11. Rear oil seal

Page 561 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-80 ENGINE MECHANICAL (M13 ENGINE)

REMOVAL

1) Remove engine assembly from vehicle as previously out-

lined.

2) Remove clutch cover, clutch disc and flywheel (drive plate

for A/T) by using special tool.

Special tool

(A) : 09924-17810

3) Remove the following parts from engine as previously out-

lined.

Oil pan and oil pump strainer

Intake manifold and exhaust manifold

Cylinder head cover

Timing chain cover

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Camshaft, tappet and shim

Cylinder head assembly

Piston and connecting rod

4) Remove rear oil seal housing (1).

5) Loosen bearing cap No.1 and No.2 bolts in such order as

indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

Page 569 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-88 ENGINE MECHANICAL (M13 ENGINE)

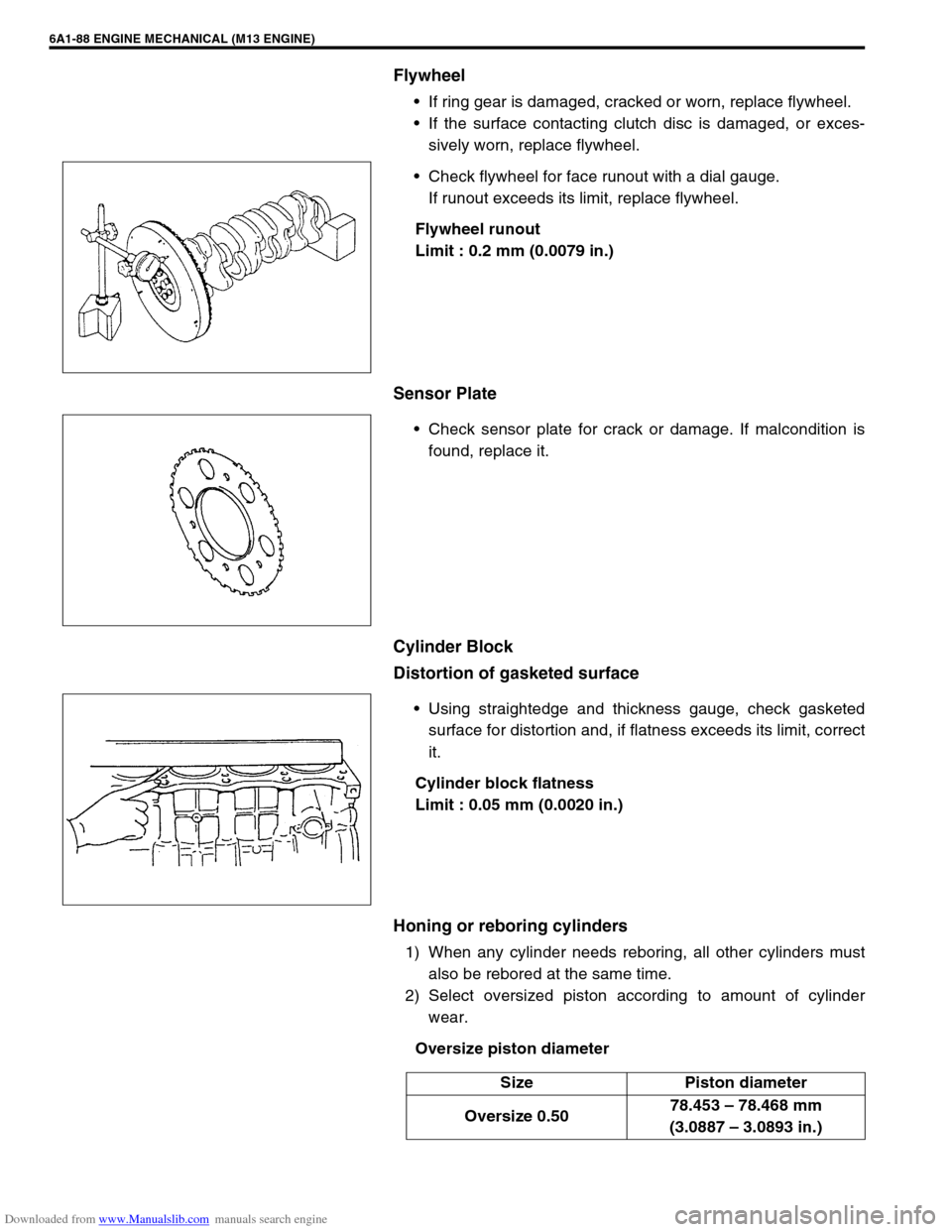

Flywheel

If ring gear is damaged, cracked or worn, replace flywheel.

If the surface contacting clutch disc is damaged, or exces-

sively worn, replace flywheel.

Check flywheel for face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel runout

Limit : 0.2 mm (0.0079 in.)

Sensor Plate

Check sensor plate for crack or damage. If malcondition is

found, replace it.

Cylinder Block

Distortion of gasketed surface

Using straightedge and thickness gauge, check gasketed

surface for distortion and, if flatness exceeds its limit, correct

it.

Cylinder block flatness

Limit : 0.05 mm (0.0020 in.)

Honing or reboring cylinders

1) When any cylinder needs reboring, all other cylinders must

also be rebored at the same time.

2) Select oversized piston according to amount of cylinder

wear.

Oversize piston diameter

Size Piston diameter

Oversize 0.5078.453 – 78.468 mm

(3.0887 – 3.0893 in.)

Page 573 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-92 ENGINE MECHANICAL (M13 ENGINE)

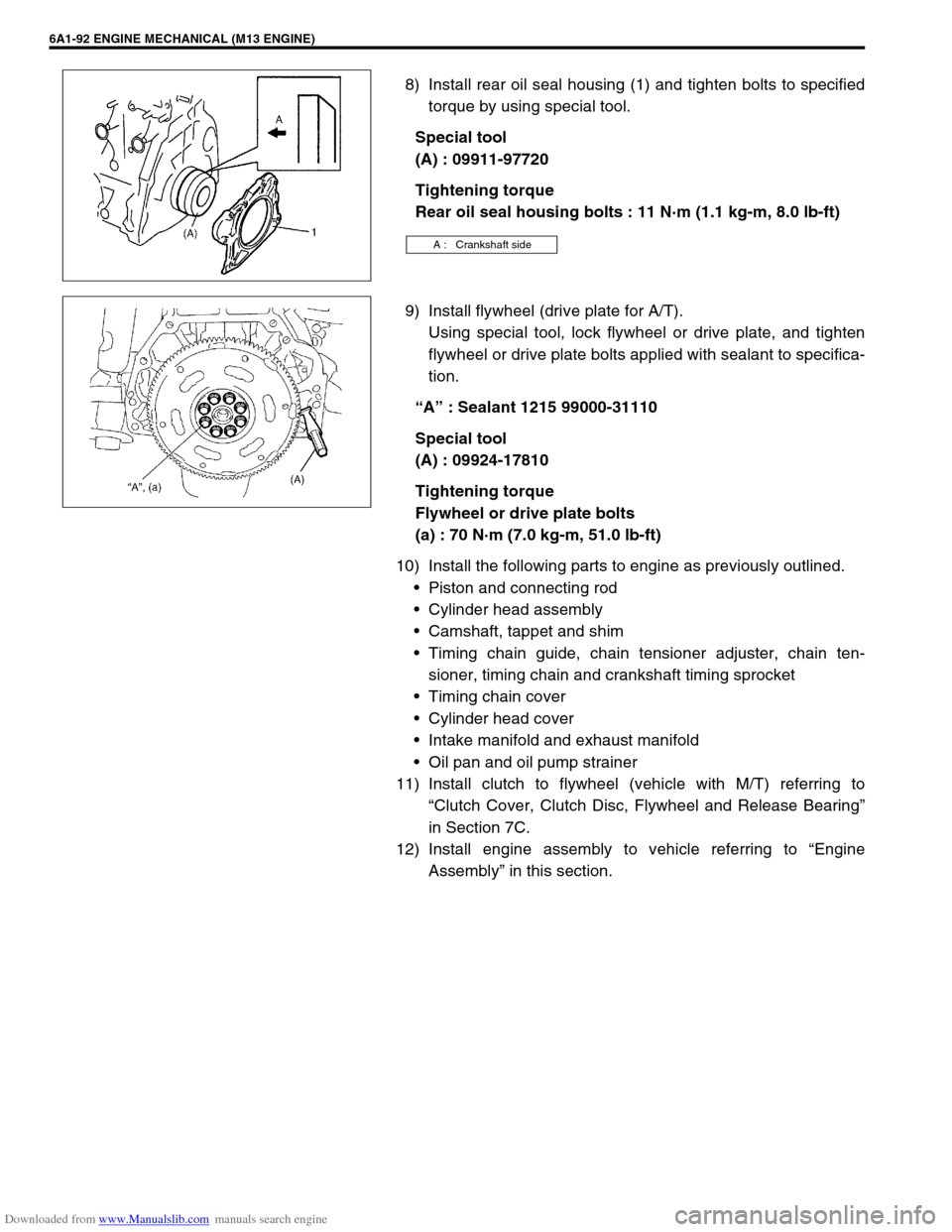

8) Install rear oil seal housing (1) and tighten bolts to specified

torque by using special tool.

Special tool

(A) : 09911-97720

Tightening torque

Rear oil seal housing bolts : 11 N·m (1.1 kg-m, 8.0 lb-ft)

9) Install flywheel (drive plate for A/T).

Using special tool, lock flywheel or drive plate, and tighten

flywheel or drive plate bolts applied with sealant to specifica-

tion.

“A” : Sealant 1215 99000-31110

Special tool

(A) : 09924-17810

Tightening torque

Flywheel or drive plate bolts

(a) : 70 N·m (7.0 kg-m, 51.0 lb-ft)

10) Install the following parts to engine as previously outlined.

Piston and connecting rod

Cylinder head assembly

Camshaft, tappet and shim

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Timing chain cover

Cylinder head cover

Intake manifold and exhaust manifold

Oil pan and oil pump strainer

11) Install clutch to flywheel (vehicle with M/T) referring to

“Clutch Cover, Clutch Disc, Flywheel and Release Bearing”

in Section 7C.

12) Install engine assembly to vehicle referring to “Engine

Assembly” in this section.

A : Crankshaft side

Page 574 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-93

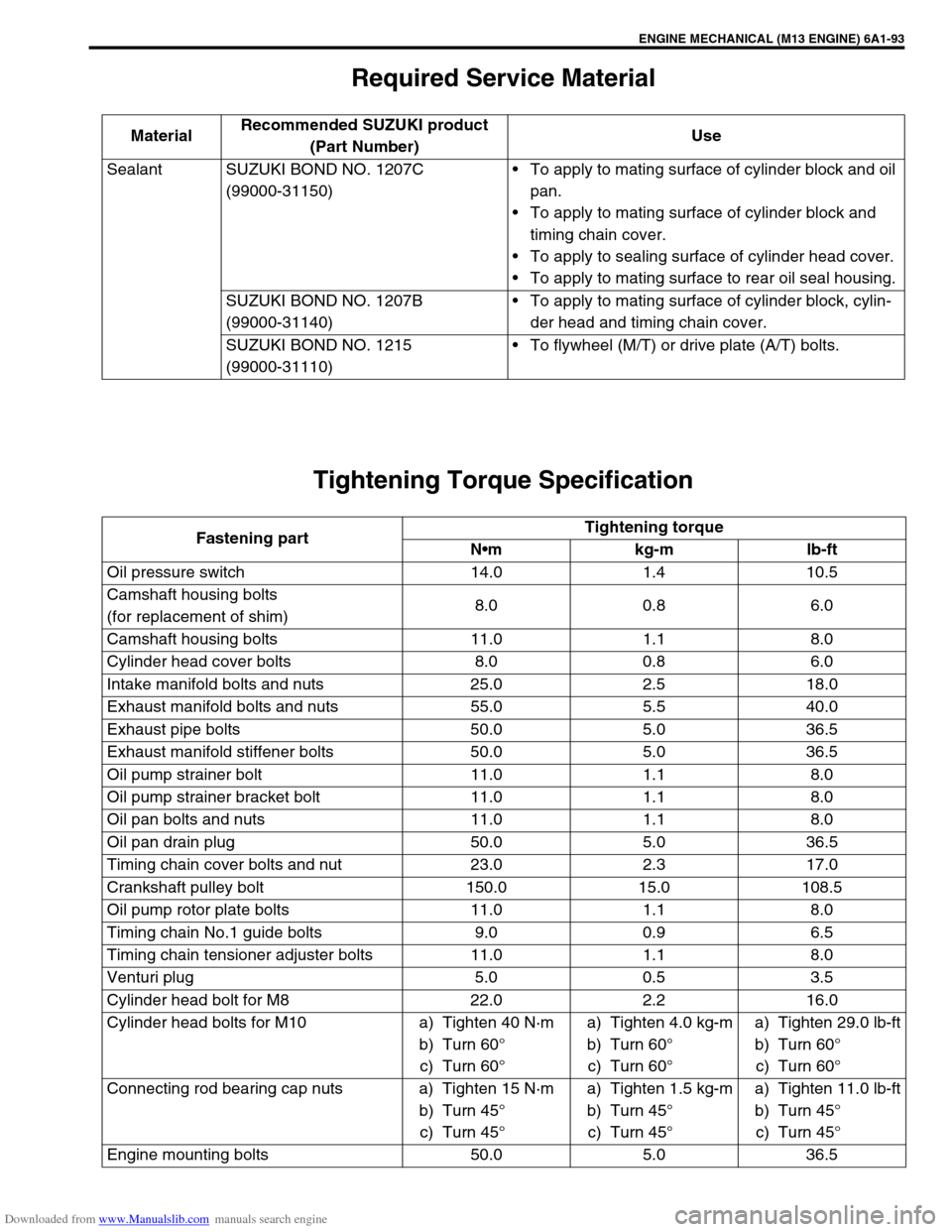

Required Service Material

Tightening Torque Specification

MaterialRecommended SUZUKI product

(Part Number)Use

Sealant SUZUKI BOND NO. 1207C

(99000-31150)To apply to mating surface of cylinder block and oil

pan.

To apply to mating surface of cylinder block and

timing chain cover.

To apply to sealing surface of cylinder head cover.

To apply to mating surface to rear oil seal housing.

SUZUKI BOND NO. 1207B

(99000-31140)To apply to mating surface of cylinder block, cylin-

der head and timing chain cover.

SUZUKI BOND NO. 1215

(99000-31110)To flywheel (M/T) or drive plate (A/T) bolts.

Fastening partTightening torque

Nm kg-m lb-ft

Oil pressure switch 14.0 1.4 10.5

Camshaft housing bolts

(for replacement of shim)8.0 0.8 6.0

Camshaft housing bolts 11.0 1.1 8.0

Cylinder head cover bolts 8.0 0.8 6.0

Intake manifold bolts and nuts 25.0 2.5 18.0

Exhaust manifold bolts and nuts 55.0 5.5 40.0

Exhaust pipe bolts 50.0 5.0 36.5

Exhaust manifold stiffener bolts 50.0 5.0 36.5

Oil pump strainer bolt 11.0 1.1 8.0

Oil pump strainer bracket bolt 11.0 1.1 8.0

Oil pan bolts and nuts 11.0 1.1 8.0

Oil pan drain plug 50.0 5.0 36.5

Timing chain cover bolts and nut 23.0 2.3 17.0

Crankshaft pulley bolt 150.0 15.0 108.5

Oil pump rotor plate bolts 11.0 1.1 8.0

Timing chain No.1 guide bolts 9.0 0.9 6.5

Timing chain tensioner adjuster bolts 11.0 1.1 8.0

Venturi plug 5.0 0.5 3.5

Cylinder head bolt for M8 22.0 2.2 16.0

Cylinder head bolts for M10 a) Tighten 40 N·m

b) Turn 60°

c) Turn 60°a) Tighten 4.0 kg-m

b) Turn 60°

c) Turn 60°a) Tighten 29.0 lb-ft

b) Turn 60°

c) Turn 60°

Connecting rod bearing cap nuts a) Tighten 15 N·m

b) Turn 45°

c) Turn 45°a) Tighten 1.5 kg-m

b) Turn 45°

c) Turn 45°a) Tighten 11.0 lb-ft

b) Turn 45°

c) Turn 45°

Engine mounting bolts 50.0 5.0 36.5