Steering bleed SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 264 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-3

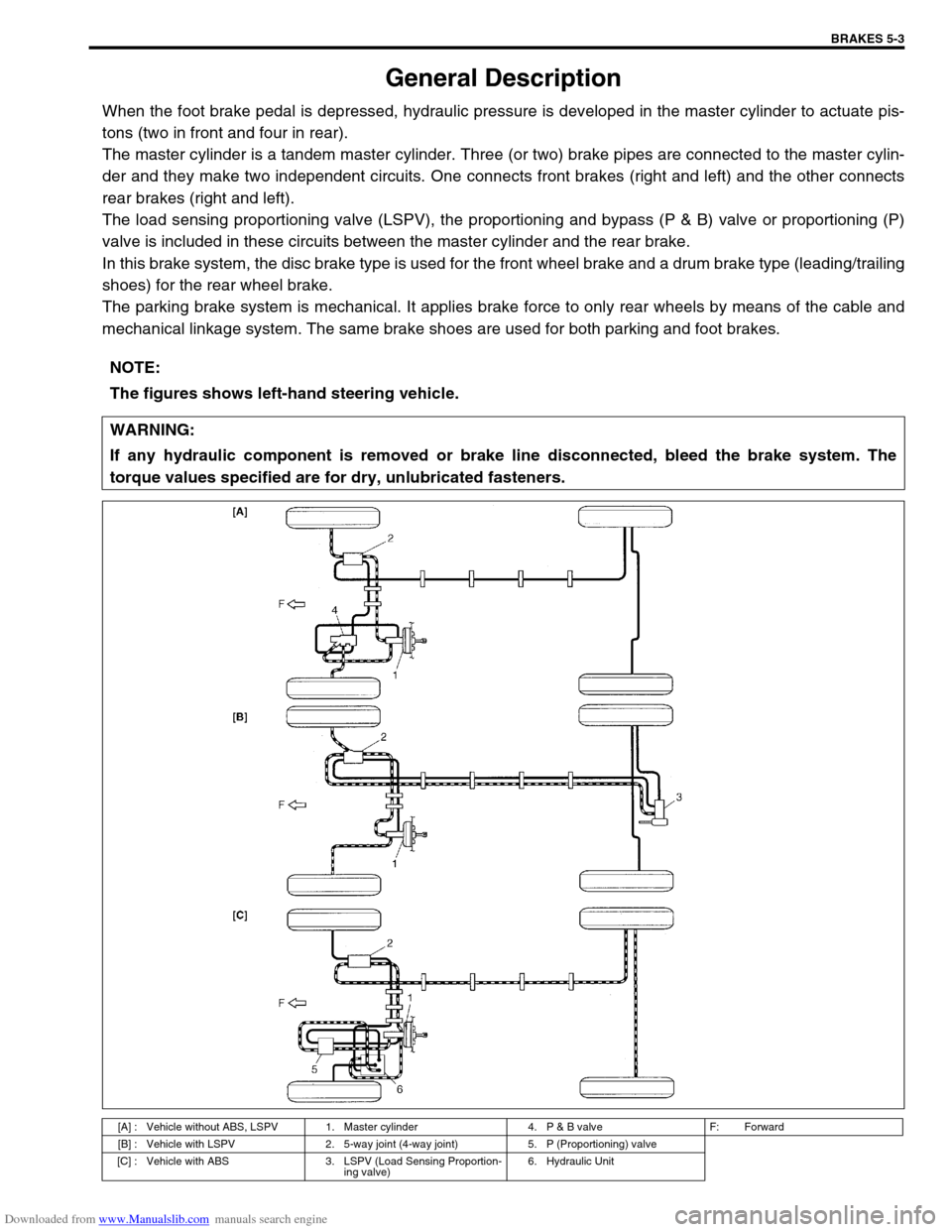

General Description

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pis-

tons (two in front and four in rear).

The master cylinder is a tandem master cylinder. Three (or two) brake pipes are connected to the master cylin-

der and they make two independent circuits. One connects front brakes (right and left) and the other connects

rear brakes (right and left).

The load sensing proportioning valve (LSPV), the proportioning and bypass (P & B) valve or proportioning (P)

valve is included in these circuits between the master cylinder and the rear brake.

In this brake system, the disc brake type is used for the front wheel brake and a drum brake type (leading/trailing

shoes) for the rear wheel brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes are used for both parking and foot brakes.

NOTE:

The figures shows left-hand steering vehicle.

WARNING:

If any hydraulic component is removed or brake line disconnected, bleed the brake system. The

torque values specified are for dry, unlubricated fasteners.

[A] : Vehicle without ABS, LSPV 1. Master cylinder 4. P & B valve F: Forward

[B] : Vehicle with LSPV 2. 5-way joint (4-way joint) 5. P (Proportioning) valve

[C] : Vehicle with ABS 3. LSPV (Load Sensing Proportion-

ing valve)6. Hydraulic Unit

Page 267 of 687

Downloaded from www.Manualslib.com manuals search engine 5-6 BRAKES

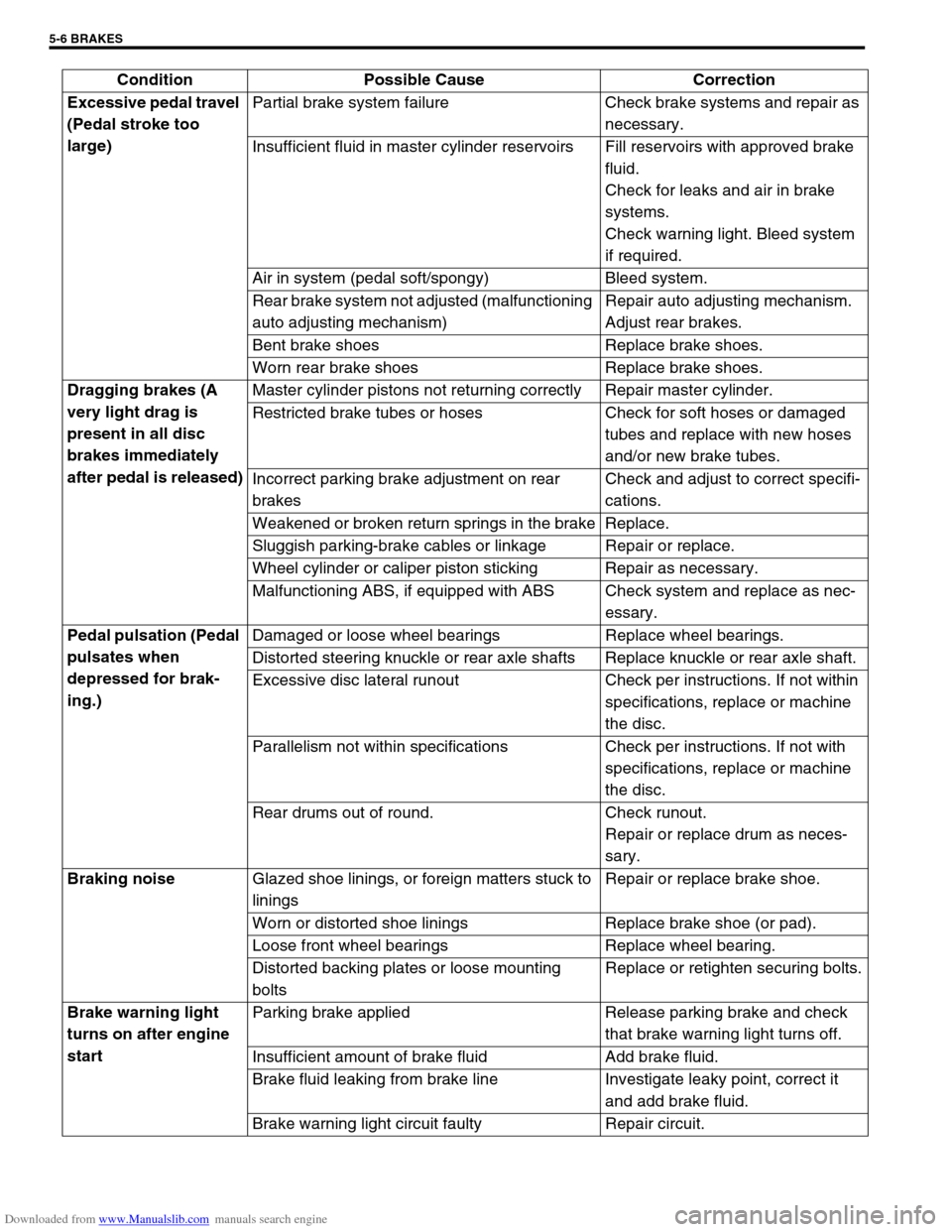

Excessive pedal travel

(Pedal stroke too

large)Partial brake system failure Check brake systems and repair as

necessary.

Insufficient fluid in master cylinder reservoirs Fill reservoirs with approved brake

fluid.

Check for leaks and air in brake

systems.

Check warning light. Bleed system

if required.

Air in system (pedal soft/spongy) Bleed system.

Rear brake system not adjusted (malfunctioning

auto adjusting mechanism)Repair auto adjusting mechanism.

Adjust rear brakes.

Bent brake shoes Replace brake shoes.

Worn rear brake shoes Replace brake shoes.

Dragging brakes (A

very light drag is

present in all disc

brakes immediately

after pedal is released)Master cylinder pistons not returning correctly Repair master cylinder.

Restricted brake tubes or hoses Check for soft hoses or damaged

tubes and replace with new hoses

and/or new brake tubes.

Incorrect parking brake adjustment on rear

brakesCheck and adjust to correct specifi-

cations.

Weakened or broken return springs in the brake Replace.

Sluggish parking-brake cables or linkage Repair or replace.

Wheel cylinder or caliper piston sticking Repair as necessary.

Malfunctioning ABS, if equipped with ABS Check system and replace as nec-

essary.

Pedal pulsation (Pedal

pulsates when

depressed for brak-

ing.) Damaged or loose wheel bearings Replace wheel bearings.

Distorted steering knuckle or rear axle shafts Replace knuckle or rear axle shaft.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine

the disc.

Parallelism not within specifications Check per instructions. If not with

specifications, replace or machine

the disc.

Rear drums out of round. Check runout.

Repair or replace drum as neces-

sary.

Braking noise

Glazed shoe linings, or foreign matters stuck to

liningsRepair or replace brake shoe.

Worn or distorted shoe linings Replace brake shoe (or pad).

Loose front wheel bearings Replace wheel bearing.

Distorted backing plates or loose mounting

boltsReplace or retighten securing bolts.

Brake warning light

turns on after engine

startParking brake applied Release parking brake and check

that brake warning light turns off.

Insufficient amount of brake fluid Add brake fluid.

Brake fluid leaking from brake line Investigate leaky point, correct it

and add brake fluid.

Brake warning light circuit faulty Repair circuit. Condition Possible Cause Correction

Page 270 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-9

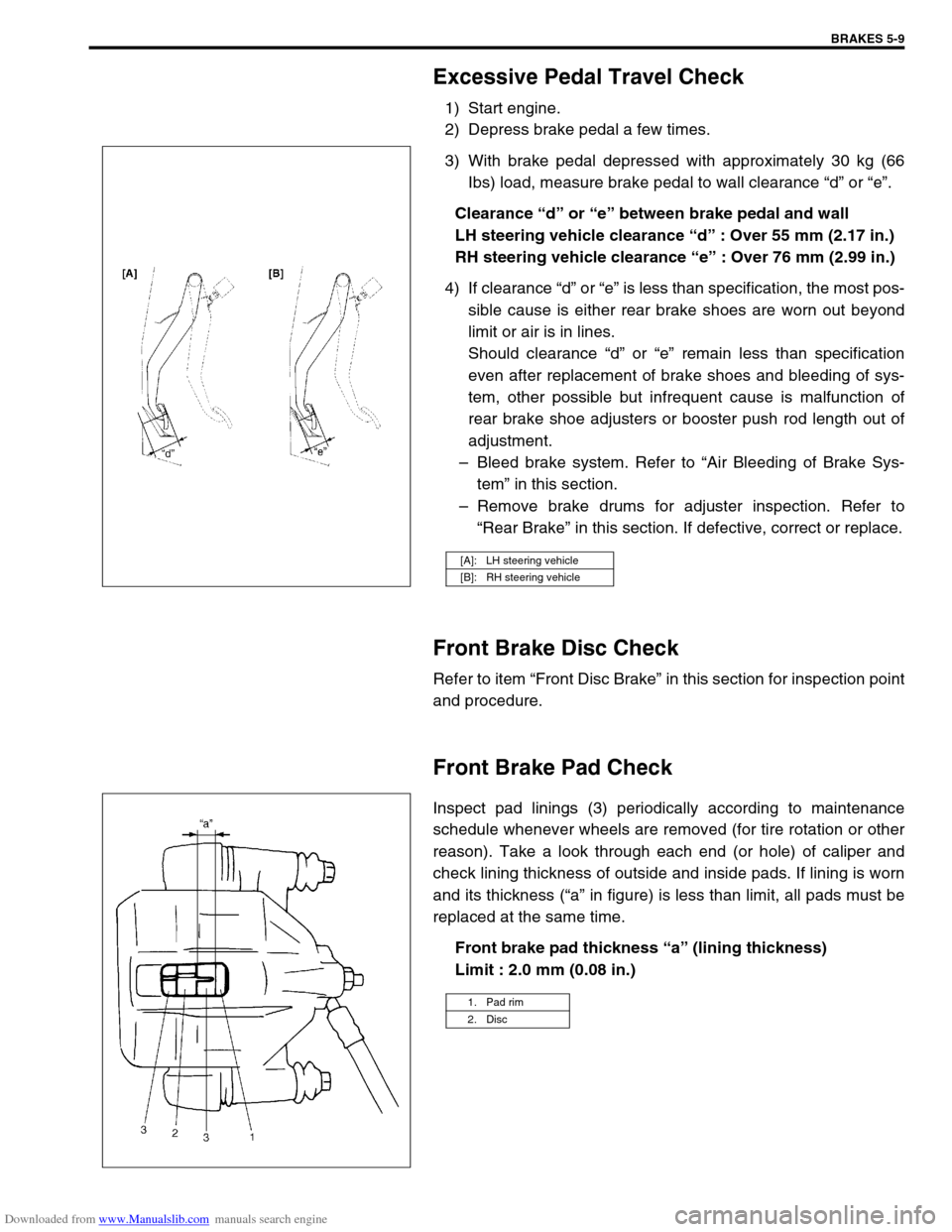

Excessive Pedal Travel Check

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 30 kg (66

Ibs) load, measure brake pedal to wall clearance “d” or “e”.

Clearance “d” or “e” between brake pedal and wall

LH steering vehicle clearance “d” : Over 55 mm (2.17 in.)

RH steering vehicle clearance “e” : Over 76 mm (2.99 in.)

4) If clearance “d” or “e” is less than specification, the most pos-

sible cause is either rear brake shoes are worn out beyond

limit or air is in lines.

Should clearance “d” or “e” remain less than specification

even after replacement of brake shoes and bleeding of sys-

tem, other possible but infrequent cause is malfunction of

rear brake shoe adjusters or booster push rod length out of

adjustment.

–Bleed brake system. Refer to “Air Bleeding of Brake Sys-

tem” in this section.

–Remove brake drums for adjuster inspection. Refer to

“Rear Brake” in this section. If defective, correct or replace.

Front Brake Disc Check

Refer to item “Front Disc Brake” in this section for inspection point

and procedure.

Front Brake Pad Check

Inspect pad linings (3) periodically according to maintenance

schedule whenever wheels are removed (for tire rotation or other

reason). Take a look through each end (or hole) of caliper and

check lining thickness of outside and inside pads. If lining is worn

and its thickness (“a” in figure) is less than limit, all pads must be

replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Limit : 2.0 mm (0.08 in.)

[A]: LH steering vehicle

[B]: RH steering vehicle

1. Pad rim

2. Disc

Page 311 of 687

Downloaded from www.Manualslib.com manuals search engine 5-50 BRAKES

REMOVAL

1) Raise, suitably support vehicle. Remove wheel if necessary.

2) Clean dirt and foreign material from both hose end or pipe end fittings. Remove brake hose and pipe.

INSTALLATION

1) Install brake hose and pipe by reversing removal procedure, noting the following points.

For installation, make sure that steering wheel is in straightforward position and hose has no twist or kink.

Check to make sure that hose doesn’t contact any part of suspension, both in extreme right and extreme left

turn conditions. If it does at any point, remove and correct. Fill and maintain brake fluid level in reservoir.

Bleed brake system.

2) Perform brake test and check installed part for fluid leakage.