propeller shaft SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 241 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-22 REAR SUSPENSION

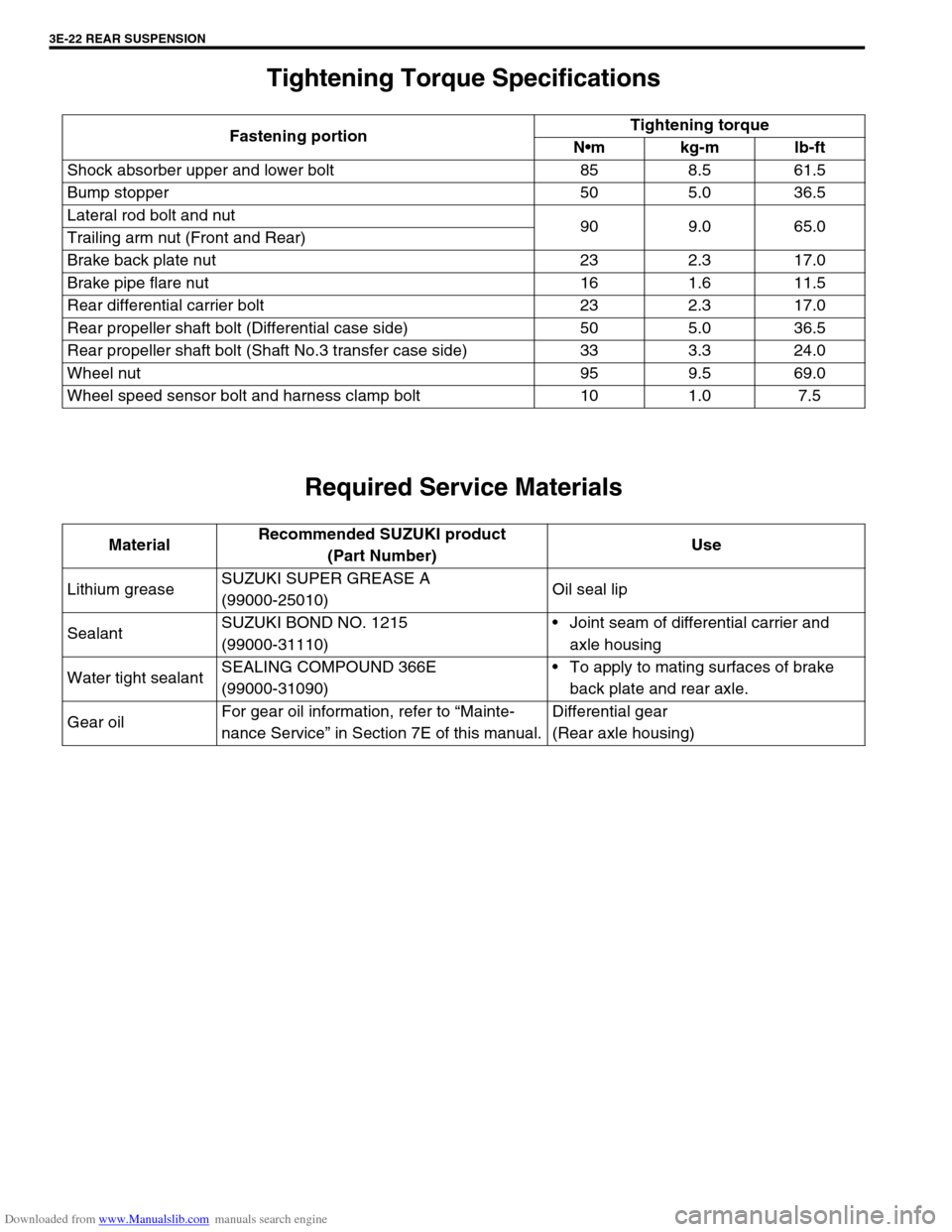

Tightening Torque Specifications

Required Service Materials

Fastening portionTightening torque

Nm kg-m lb-ft

Shock absorber upper and lower bolt 85 8.5 61.5

Bump stopper 50 5.0 36.5

Lateral rod bolt and nut

90 9.0 65.0

Trailing arm nut (Front and Rear)

Brake back plate nut 23 2.3 17.0

Brake pipe flare nut 16 1.6 11.5

Rear differential carrier bolt 23 2.3 17.0

Rear propeller shaft bolt (Differential case side) 50 5.0 36.5

Rear propeller shaft bolt (Shaft No.3 transfer case side) 33 3.3 24.0

Wheel nut 95 9.5 69.0

Wheel speed sensor bolt and harness clamp bolt 10 1.0 7.5

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium greaseSUZUKI SUPER GREASE A

(99000-25010)Oil seal lip

SealantSUZUKI BOND NO. 1215

(99000-31110)Joint seam of differential carrier and

axle housing

Water tight sealantSEALING COMPOUND 366E

(99000-31090)To apply to mating surfaces of brake

back plate and rear axle.

Gear oilFor gear oil information, refer to “Mainte-

nance Service” in Section 7E of this manual.Differential gear

(Rear axle housing)

Page 254 of 687

Downloaded from www.Manualslib.com manuals search engine PROPELLER SHAFTS 4B-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

4B

8D

8E

9

8E

9

10

10A

10B

SECTION 4B

PROPELLER SHAFTS

CONTENTS

General Description ....................................... 4B-2

Components ................................................. 4B-2

Diagnosis ........................................................ 4B-2

Diagnosis Table ........................................... 4B-2

Propeller Shaft Joint Check .......................... 4B-2

On-Vehicle Service......................................... 4B-3Propeller Shafts ........................................... 4B-3

Universal Joint ............................................. 4B-5

Tightening Torque Specification .................. 4B-7

Required Service Material ............................. 4B-7

Special Tool .................................................... 4B-8

NOTE:

All propeller shaft fasteners are an important attaching part in that it could affect the performance

of vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not

use a replacement part of lesser quality or substitute design. Torque values must be used as speci-

fied during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any propeller shaft part. Replace it with a new part, or

damage to the part may result.

Page 255 of 687

Downloaded from www.Manualslib.com manuals search engine 4B-2 PROPELLER SHAFTS

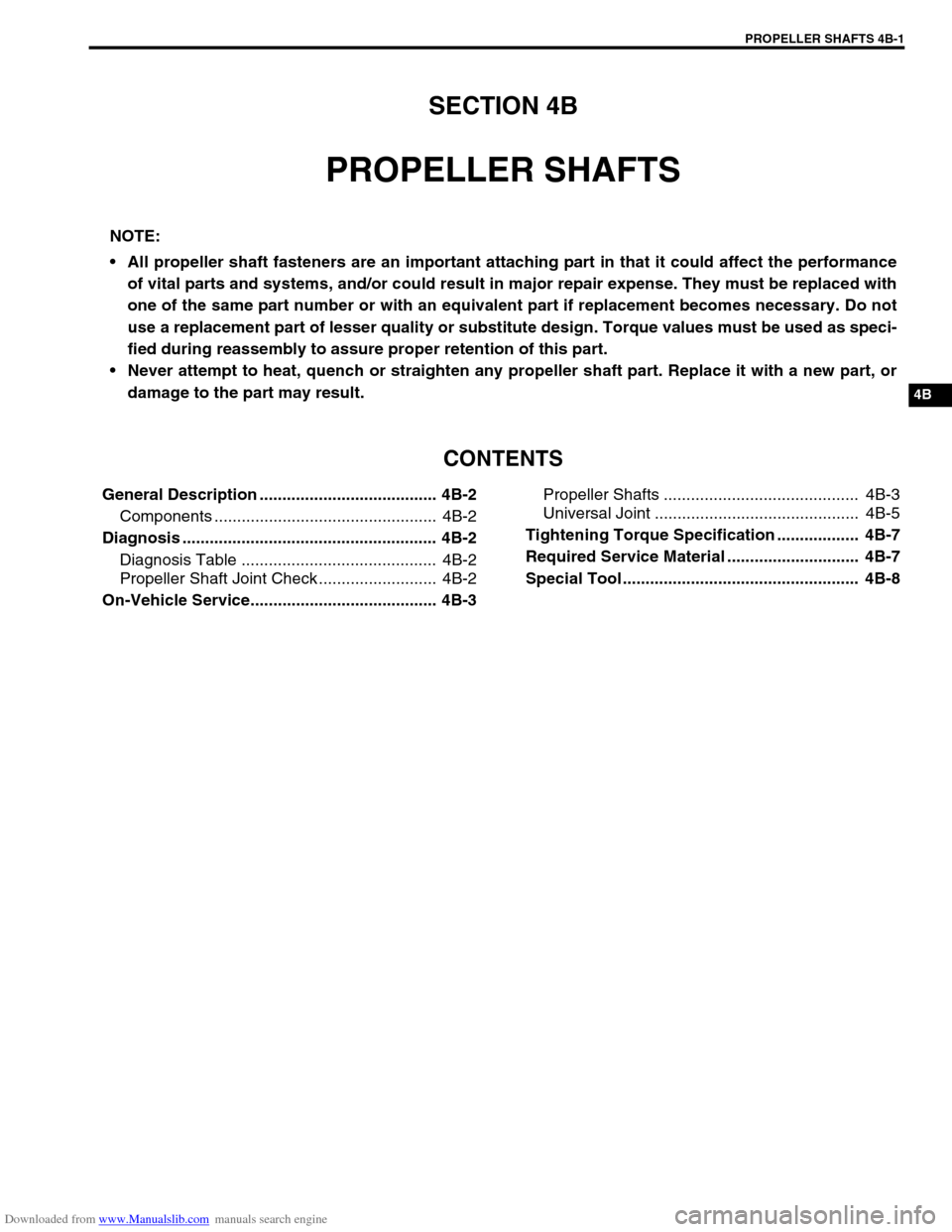

General Description

Components

Diagnosis

Diagnosis Table

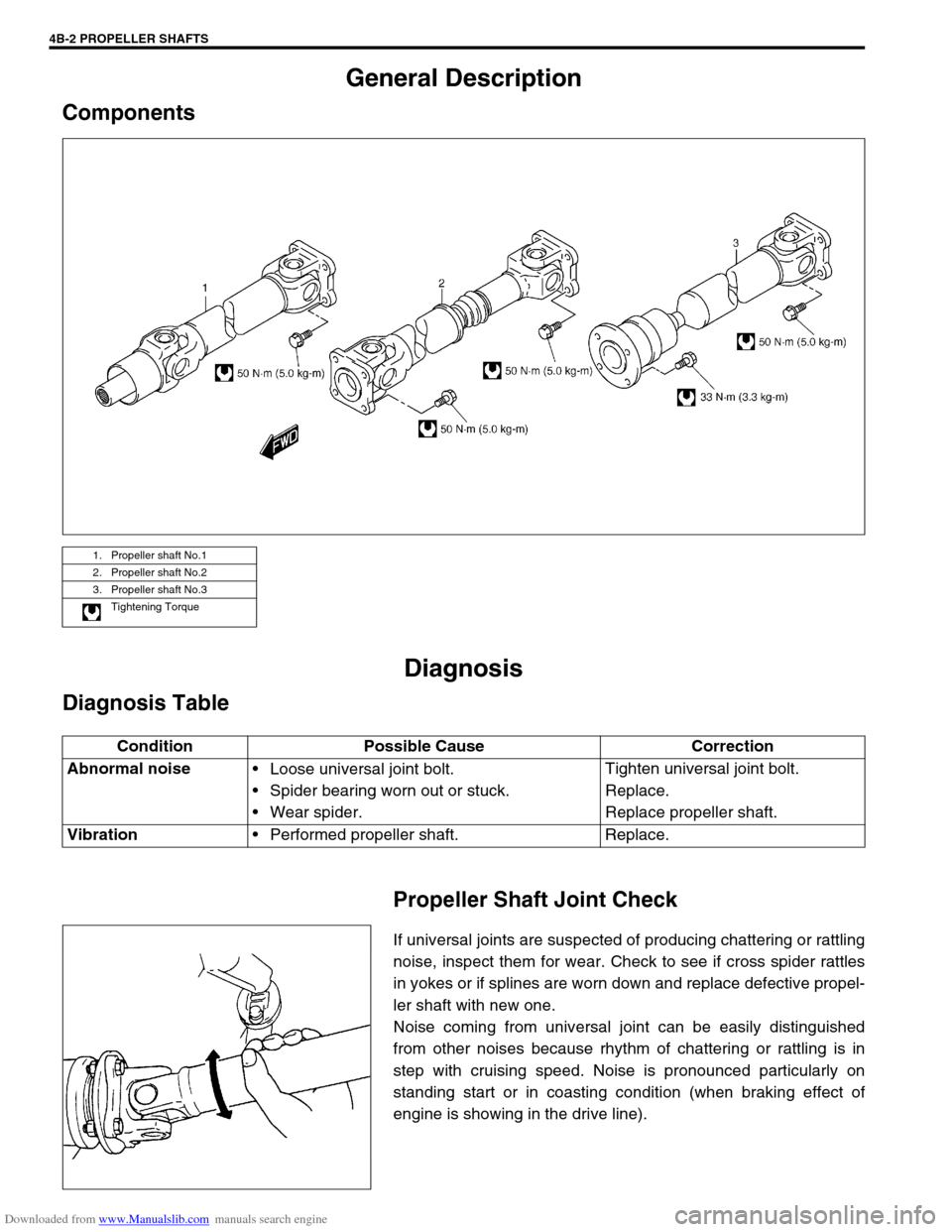

Propeller Shaft Joint Check

If universal joints are suspected of producing chattering or rattling

noise, inspect them for wear. Check to see if cross spider rattles

in yokes or if splines are worn down and replace defective propel-

ler shaft with new one.

Noise coming from universal joint can be easily distinguished

from other noises because rhythm of chattering or rattling is in

step with cruising speed. Noise is pronounced particularly on

standing start or in coasting condition (when braking effect of

engine is showing in the drive line).

1. Propeller shaft No.1

2. Propeller shaft No.2

3. Propeller shaft No.3

Tightening Torque

Condition Possible Cause Correction

Abnormal noise

Loose universal joint bolt.

Spider bearing worn out or stuck.

Wear spider.Tighten universal joint bolt.

Replace.

Replace propeller shaft.

Vibration

Performed propeller shaft. Replace.

Page 256 of 687

Downloaded from www.Manualslib.com manuals search engine PROPELLER SHAFTS 4B-3

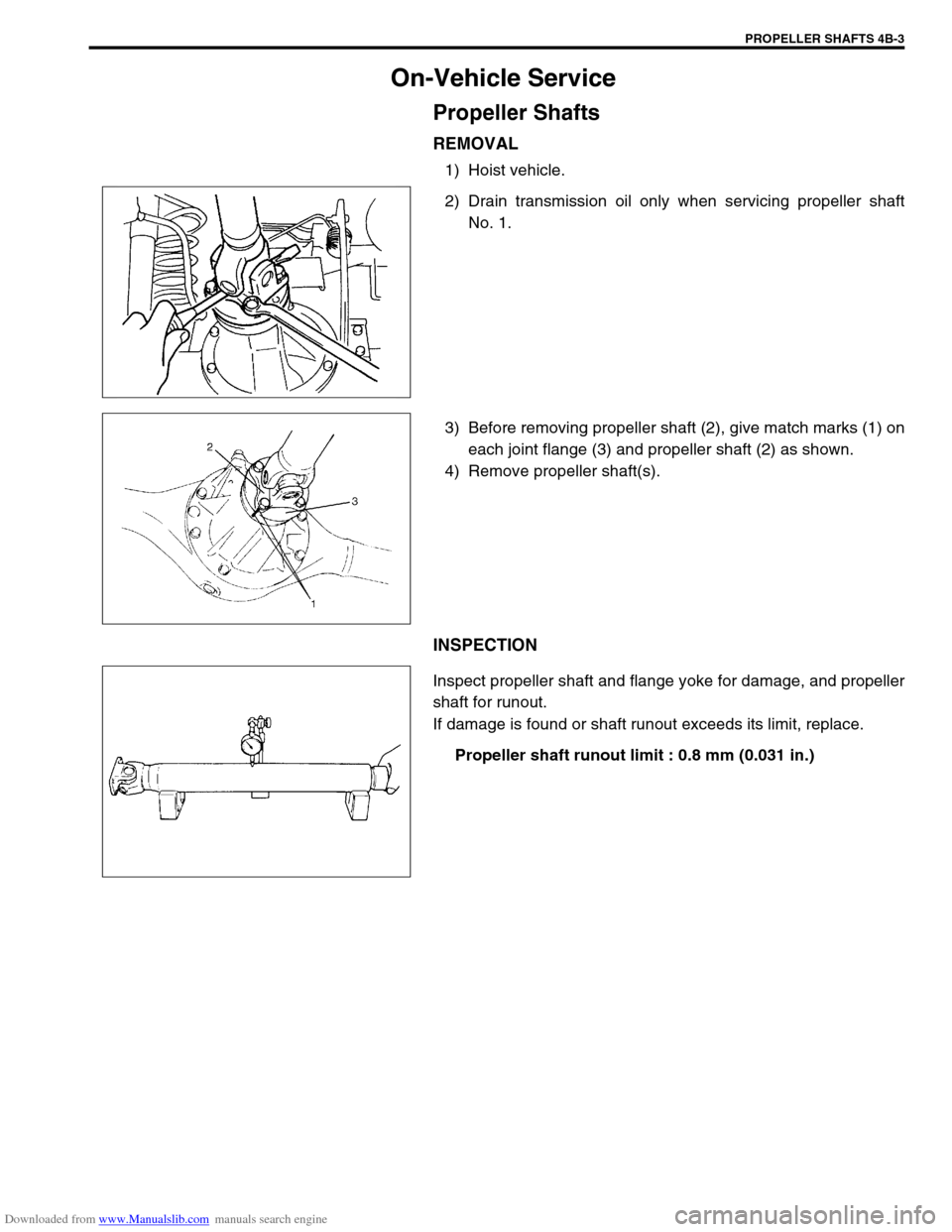

On-Vehicle Service

Propeller Shafts

REMOVAL

1) Hoist vehicle.

2) Drain transmission oil only when servicing propeller shaft

No. 1.

3) Before removing propeller shaft (2), give match marks (1) on

each joint flange (3) and propeller shaft (2) as shown.

4) Remove propeller shaft(s).

INSPECTION

Inspect propeller shaft and flange yoke for damage, and propeller

shaft for runout.

If damage is found or shaft runout exceeds its limit, replace.

Propeller shaft runout limit : 0.8 mm (0.031 in.)

Page 257 of 687

Downloaded from www.Manualslib.com manuals search engine 4B-4 PROPELLER SHAFTS

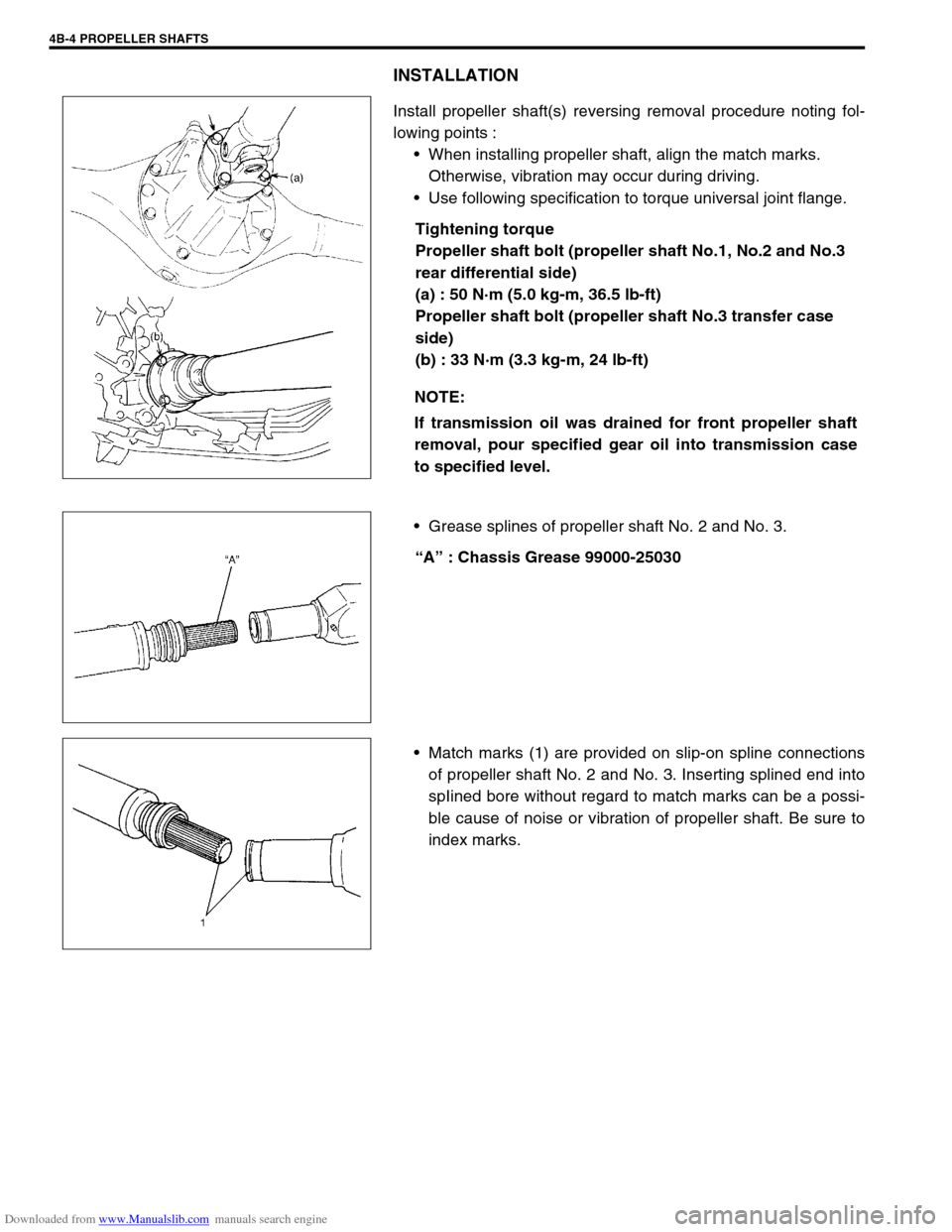

INSTALLATION

Install propeller shaft(s) reversing removal procedure noting fol-

lowing points :

When installing propeller shaft, align the match marks.

Otherwise, vibration may occur during driving.

Use following specification to torque universal joint flange.

Tightening torque

Propeller shaft bolt (propeller shaft No.1, No.2 and No.3

rear differential side)

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Propeller shaft bolt (propeller shaft No.3 transfer case

side)

(b) : 33 N·m (3.3 kg-m, 24 lb-ft)

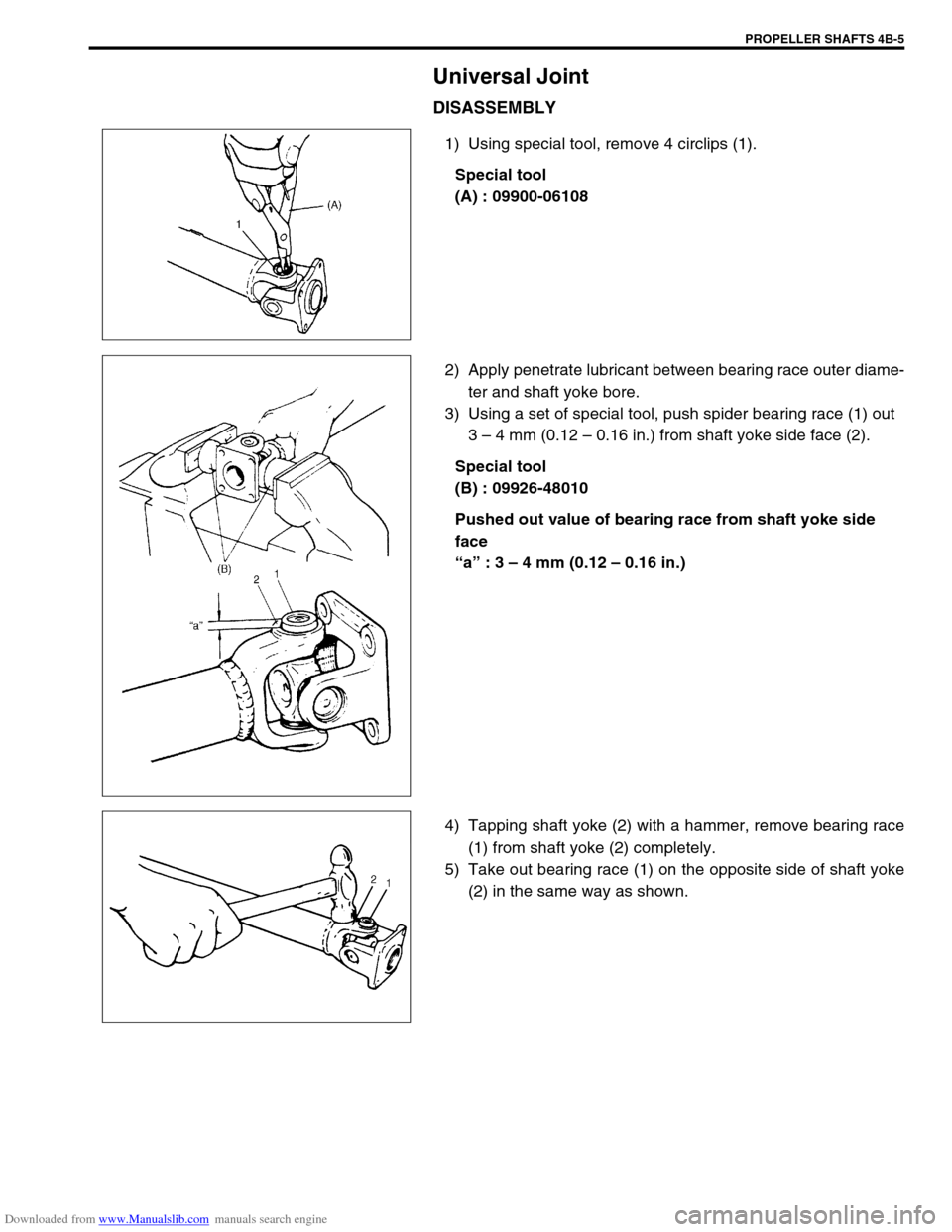

Grease splines of propeller shaft No. 2 and No. 3.

“A” : Chassis Grease 99000-25030

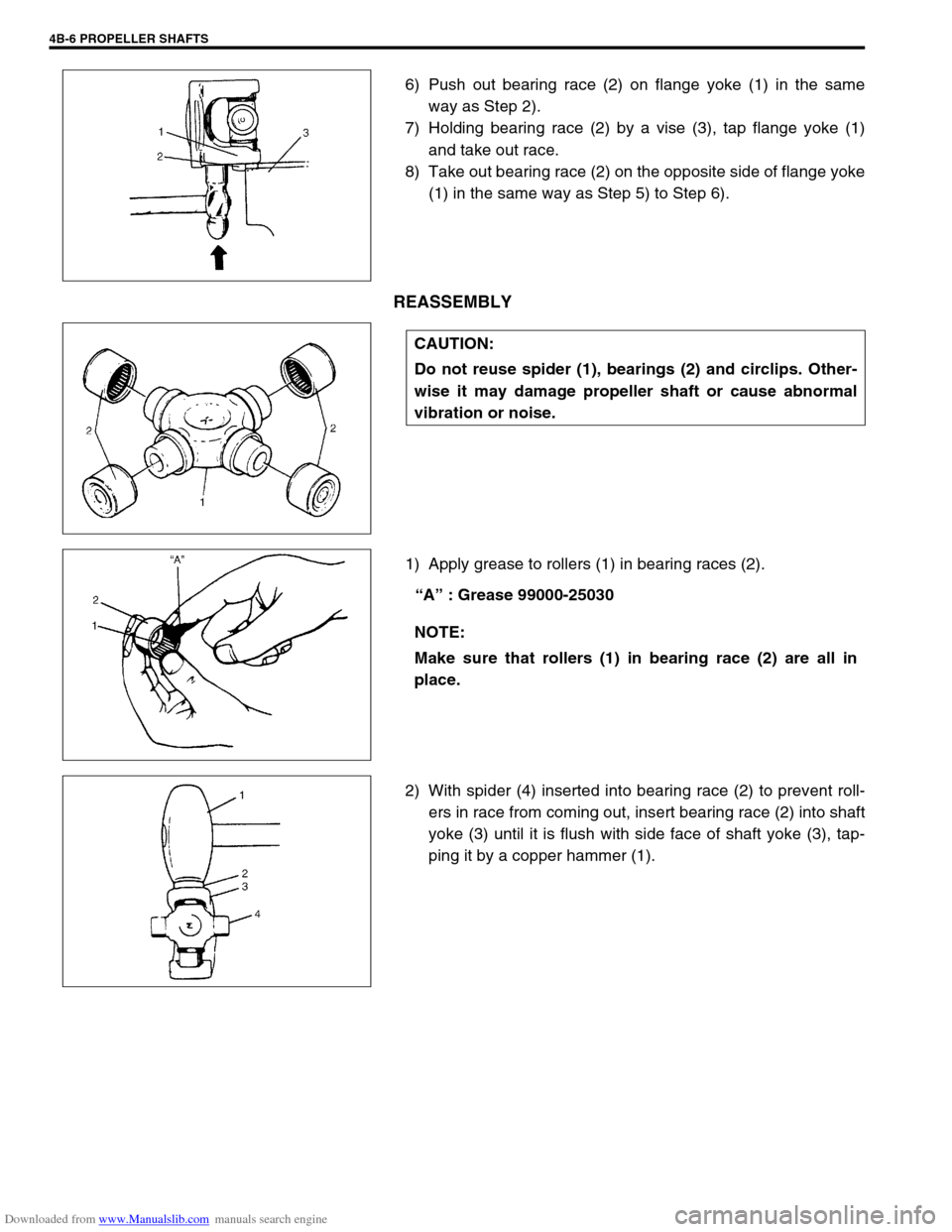

Match marks (1) are provided on slip-on spline connections

of propeller shaft No. 2 and No. 3. Inserting splined end into

spIined bore without regard to match marks can be a possi-

ble cause of noise or vibration of propeller shaft. Be sure to

index marks. NOTE:

If transmission oil was drained for front propeller shaft

removal, pour specified gear oil into transmission case

to specified level.

Page 258 of 687

Downloaded from www.Manualslib.com manuals search engine PROPELLER SHAFTS 4B-5

Universal Joint

DISASSEMBLY

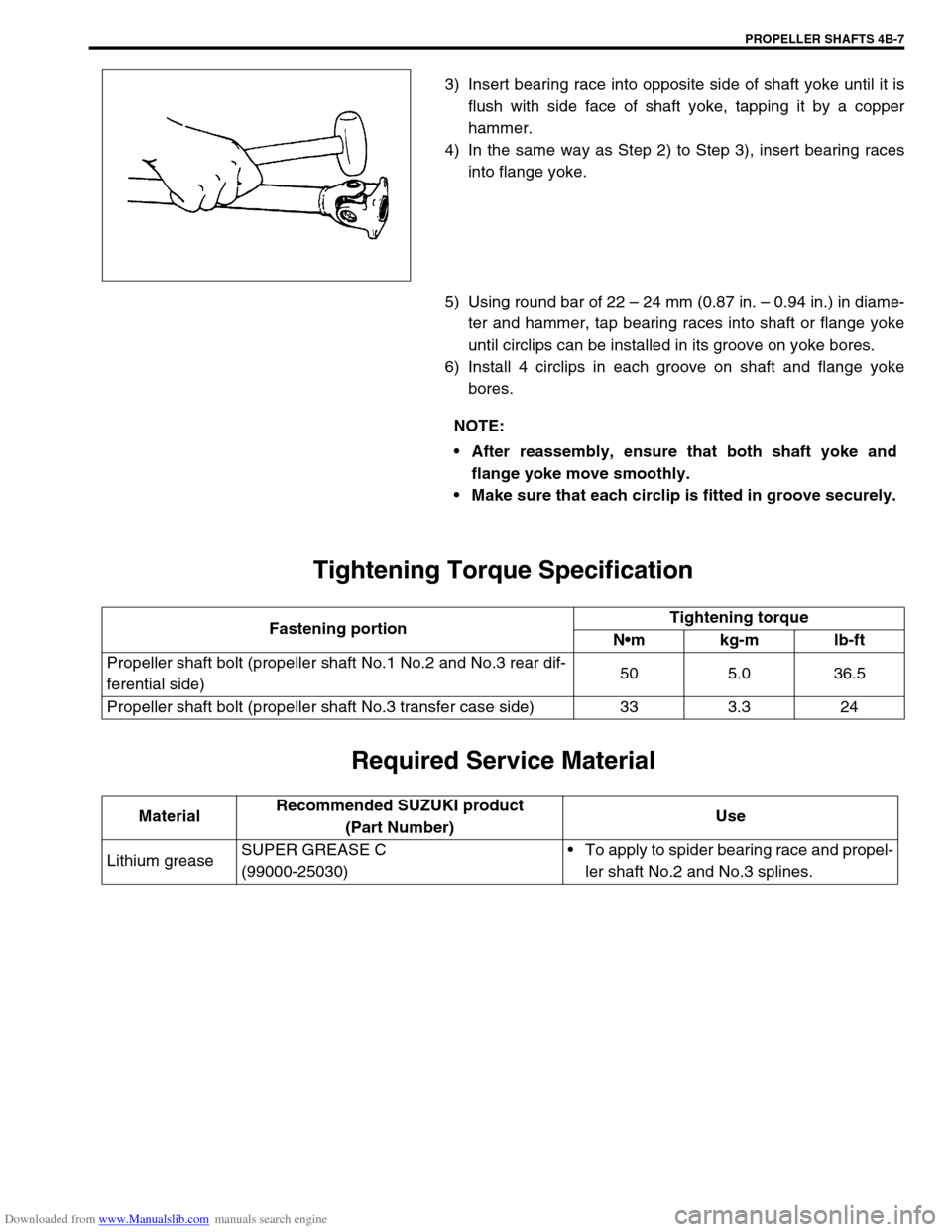

1) Using special tool, remove 4 circlips (1).

Special tool

(A) : 09900-06108

2) Apply penetrate lubricant between bearing race outer diame-

ter and shaft yoke bore.

3) Using a set of special tool, push spider bearing race (1) out

3 – 4 mm (0.12 – 0.16 in.) from shaft yoke side face (2).

Special tool

(B) : 09926-48010

Pushed out value of bearing race from shaft yoke side

face

“a” : 3 – 4 mm (0.12 – 0.16 in.)

4) Tapping shaft yoke (2) with a hammer, remove bearing race

(1) from shaft yoke (2) completely.

5) Take out bearing race (1) on the opposite side of shaft yoke

(2) in the same way as shown.

Page 259 of 687

Downloaded from www.Manualslib.com manuals search engine 4B-6 PROPELLER SHAFTS

6) Push out bearing race (2) on flange yoke (1) in the same

way as Step 2).

7) Holding bearing race (2) by a vise (3), tap flange yoke (1)

and take out race.

8) Take out bearing race (2) on the opposite side of flange yoke

(1) in the same way as Step 5) to Step 6).

REASSEMBLY

1) Apply grease to rollers (1) in bearing races (2).

“A” : Grease 99000-25030

2) With spider (4) inserted into bearing race (2) to prevent roll-

ers in race from coming out, insert bearing race (2) into shaft

yoke (3) until it is flush with side face of shaft yoke (3), tap-

ping it by a copper hammer (1).

CAUTION:

Do not reuse spider (1), bearings (2) and circlips. Other-

wise it may damage propeller shaft or cause abnormal

vibration or noise.

NOTE:

Make sure that rollers (1) in bearing race (2) are all in

place.

Page 260 of 687

Downloaded from www.Manualslib.com manuals search engine PROPELLER SHAFTS 4B-7

3) Insert bearing race into opposite side of shaft yoke until it is

flush with side face of shaft yoke, tapping it by a copper

hammer.

4) In the same way as Step 2) to Step 3), insert bearing races

into flange yoke.

5) Using round bar of 22 – 24 mm (0.87 in. – 0.94 in.) in diame-

ter and hammer, tap bearing races into shaft or flange yoke

until circlips can be installed in its groove on yoke bores.

6) Install 4 circlips in each groove on shaft and flange yoke

bores.

Tightening Torque Specification

Required Service Material

NOTE:

After reassembly, ensure that both shaft yoke and

flange yoke move smoothly.

Make sure that each circlip is fitted in groove securely.

Fastening portionTightening torque

Nm kg-m lb-ft

Propeller shaft bolt (propeller shaft No.1 No.2 and No.3 rear dif-

ferential side)50 5.0 36.5

Propeller shaft bolt (propeller shaft No.3 transfer case side) 33 3.3 24

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium greaseSUPER GREASE C

(99000-25030)To apply to spider bearing race and propel-

ler shaft No.2 and No.3 splines.

Page 261 of 687

Downloaded from www.Manualslib.com manuals search engine 4B-8 PROPELLER SHAFTS

Special Tool

09900-06108 09926-48010

Snap ring pliers (Closing

type)Universal joint disassem-

bling tool set

Page 600 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE FUEL 6C-5

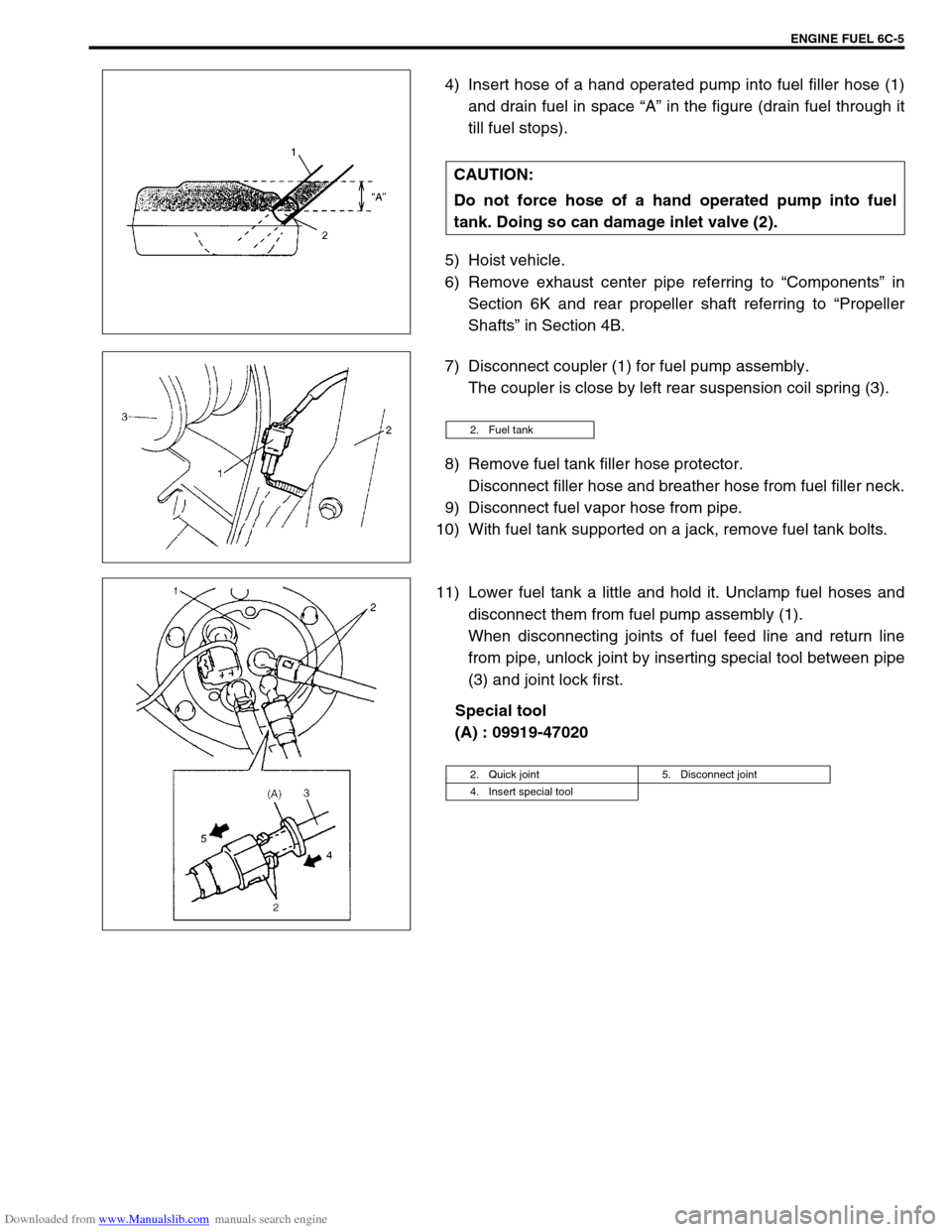

4) Insert hose of a hand operated pump into fuel filler hose (1)

and drain fuel in space “A” in the figure (drain fuel through it

till fuel stops).

5) Hoist vehicle.

6) Remove exhaust center pipe referring to “Components” in

Section 6K and rear propeller shaft referring to “Propeller

Shafts” in Section 4B.

7) Disconnect coupler (1) for fuel pump assembly.

The coupler is close by left rear suspension coil spring (3).

8) Remove fuel tank filler hose protector.

Disconnect filler hose and breather hose from fuel filler neck.

9) Disconnect fuel vapor hose from pipe.

10) With fuel tank supported on a jack, remove fuel tank bolts.

11) Lower fuel tank a little and hold it. Unclamp fuel hoses and

disconnect them from fuel pump assembly (1).

When disconnecting joints of fuel feed line and return line

from pipe, unlock joint by inserting special tool between pipe

(3) and joint lock first.

Special tool

(A) : 09919-47020 CAUTION:

Do not force hose of a hand operated pump into fuel

tank. Doing so can damage inlet valve (2).

2. Fuel tank

2. Quick joint 5. Disconnect joint

4. Insert special tool