ATE SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 34 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-3

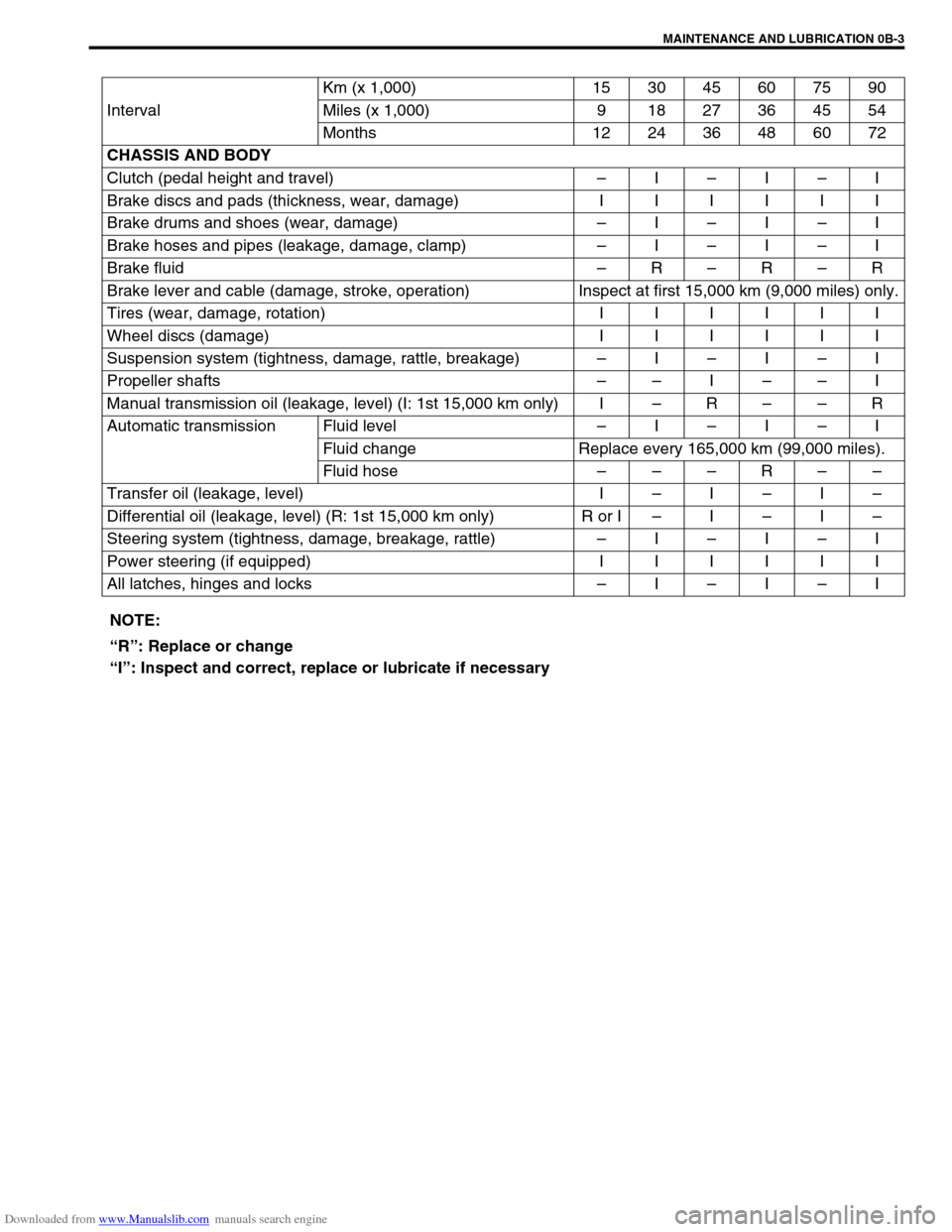

IntervalKm (x 1,000) 153045607590

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

CHASSIS AND BODY

Clutch (pedal height and travel)–I–I–I

Brake discs and pads (thickness, wear, damage) I I I I I I

Brake drums and shoes (wear, damage)–I–I–I

Brake hoses and pipes (leakage, damage, clamp)–I–I–I

Brake fluid–R–R–R

Brake lever and cable (damage, stroke, operation) Inspect at first 15,000 km (9,000 miles) only.

Tires (wear, damage, rotation) I I I I I I

Wheel discs (damage) I I I I I I

Suspension system (tightness, damage, rattle, breakage)–I–I–I

Propeller shafts––I––I

Manual transmission oil (leakage, level) (I: 1st 15,000 km only) I–R––R

Automatic transmission Fluid level–I–I–I

Fluid change Replace every 165,000 km (99,000 miles).

Fluid hose–––R––

Transfer oil (leakage, level) I–I–I–

Differential oil (leakage, level) (R: 1st 15,000 km only) R or I–I–I–

Steering system (tightness, damage, breakage, rattle)–I–I–I

Power steering (if equipped) I I I I I I

All latches, hinges and locks–I–I–I

NOTE:

“R”: Replace or change

“I”: Inspect and correct, replace or lubricate if necessary

Page 35 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-4 MAINTENANCE AND LUBRICATION

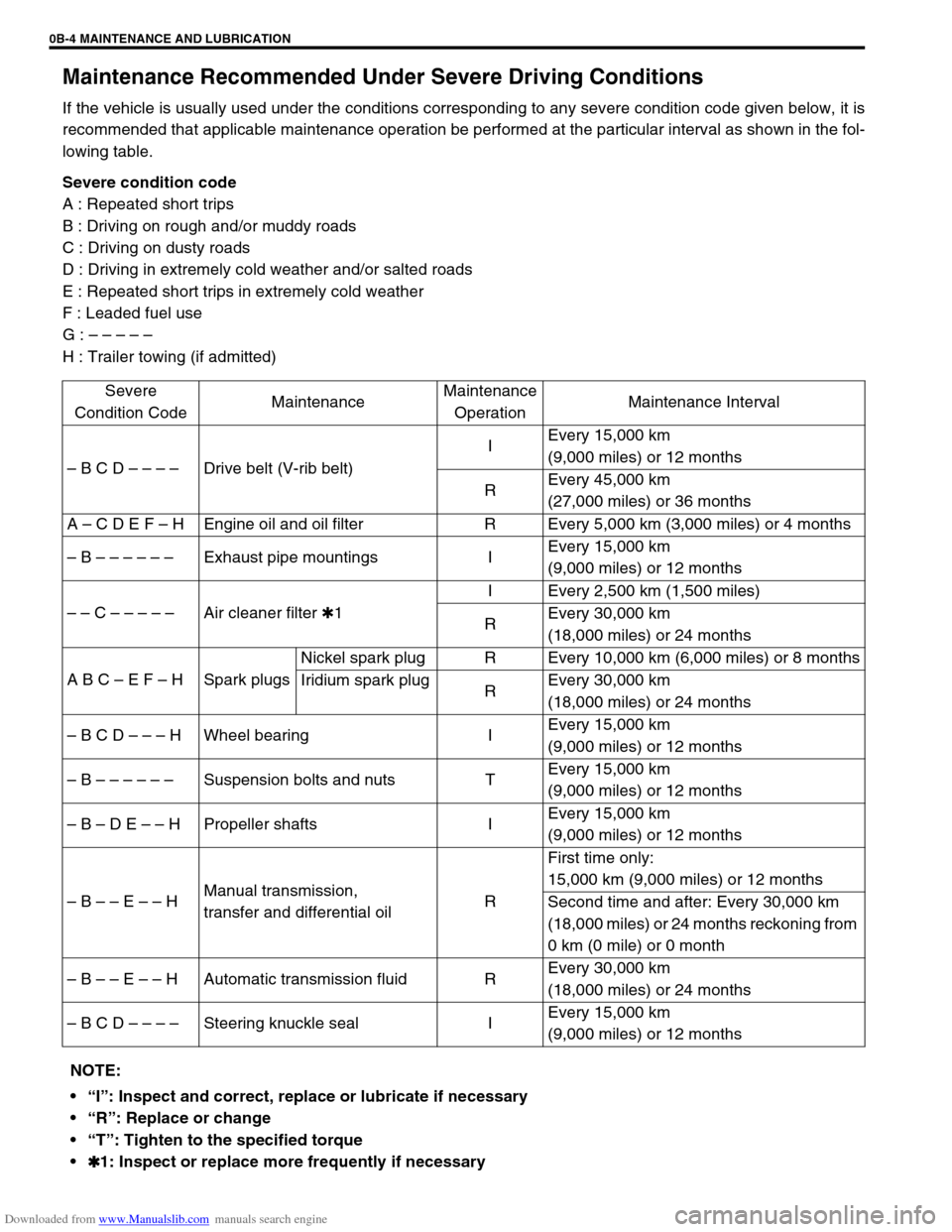

Maintenance Recommended Under Severe Driving Conditions

If the vehicle is usually used under the conditions corresponding to any severe condition code given below, it is

recommended that applicable maintenance operation be performed at the particular interval as shown in the fol-

lowing table.

Severe condition code

A : Repeated short trips

B : Driving on rough and/or muddy roads

C : Driving on dusty roads

D : Driving in extremely cold weather and/or salted roads

E : Repeated short trips in extremely cold weather

F : Leaded fuel use

G : – – – – –

H : Trailer towing (if admitted)

Severe

Condition CodeMaintenanceMaintenance

OperationMaintenance Interval

– B C D – – – –Drive belt (V-rib belt)IEvery 15,000 km

(9,000 miles) or 12 months

REvery 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter R Every 5,000 km (3,000 miles) or 4 months

– B – – – – – –Exhaust pipe mountings IEvery 15,000 km

(9,000 miles) or 12 months

– – C – – – – –Air cleaner filter ✱1I Every 2,500 km (1,500 miles)

REvery 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugsNickel spark plug R Every 10,000 km (6,000 miles) or 8 months

Iridium spark plug

REvery 30,000 km

(18,000 miles) or 24 months

– B C D – – – H Wheel bearing IEvery 15,000 km

(9,000 miles) or 12 months

– B – – – – – –Suspension bolts and nuts TEvery 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Propeller shafts IEvery 15,000 km

(9,000 miles) or 12 months

– B – – E – – HManual transmission,

transfer and differential oilRFirst time only:

15,000 km (9,000 miles) or 12 months

Second time and after: Every 30,000 km

(18,000 miles) or 24 months reckoning from

0 km (0 mile) or 0 month

– B – – E – – H Automatic transmission fluid REvery 30,000 km

(18,000 miles) or 24 months

– B C D – – – –Steering knuckle seal IEvery 15,000 km

(9,000 miles) or 12 months

NOTE:

“I”: Inspect and correct, replace or lubricate if necessary

“R”: Replace or change

“T”: Tighten to the specified torque

✱

✱✱ ✱1: Inspect or replace more frequently if necessary

Page 36 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-5

Maintenance Service

Engine

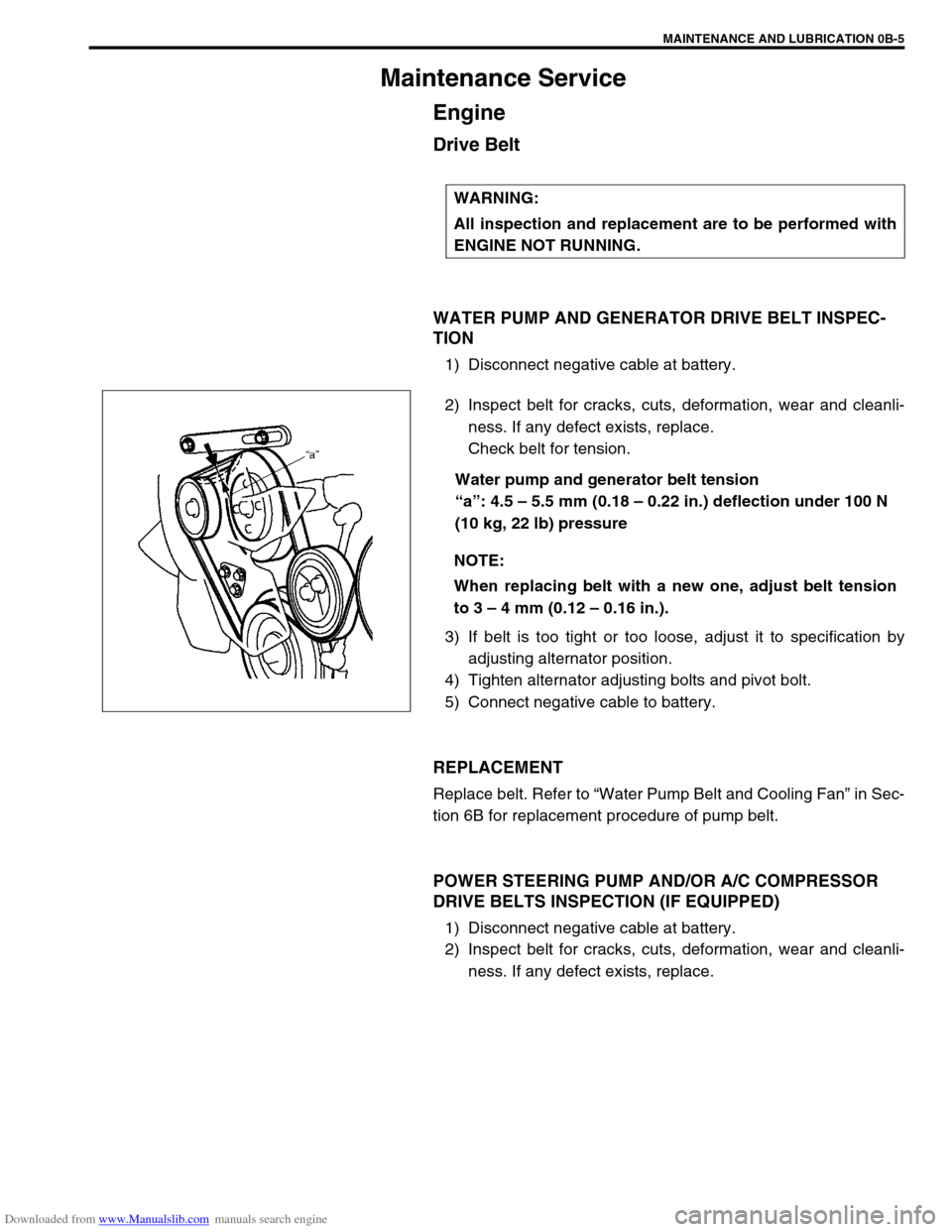

Drive Belt

WATER PUMP AND GENERATOR DRIVE BELT INSPEC-

TION

1) Disconnect negative cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanli-

ness. If any defect exists, replace.

Check belt for tension.

Water pump and generator belt tension

“a”: 4.5 – 5.5 mm (0.18 – 0.22 in.) deflection under 100 N

(10 kg, 22 lb) pressure

3) If belt is too tight or too loose, adjust it to specification by

adjusting alternator position.

4) Tighten alternator adjusting bolts and pivot bolt.

5) Connect negative cable to battery.

REPLACEMENT

Replace belt. Refer to “Water Pump Belt and Cooling Fan” in Sec-

tion 6B for replacement procedure of pump belt.

POWER STEERING PUMP AND/OR A/C COMPRESSOR

DRIVE BELTS INSPECTION (IF EQUIPPED)

1) Disconnect negative cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanli-

ness. If any defect exists, replace. WARNING:

All inspection and replacement are to be performed with

ENGINE NOT RUNNING.

NOTE:

When replacing belt with a new one, adjust belt tension

to 3 – 4 mm (0.12 – 0.16 in.).

Page 37 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-6 MAINTENANCE AND LUBRICATION

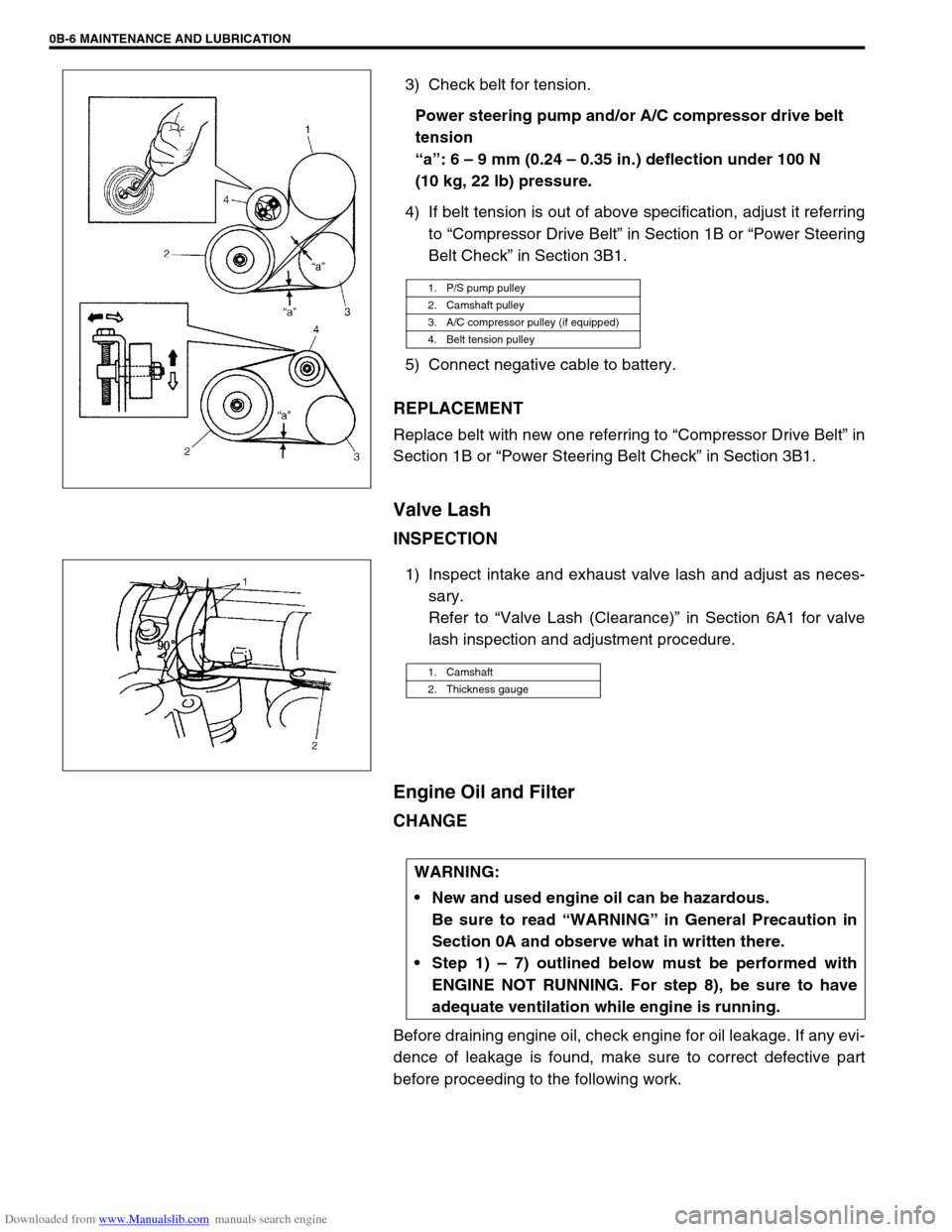

3) Check belt for tension.

Power steering pump and/or A/C compressor drive belt

tension

“a”: 6 – 9 mm (0.24 – 0.35 in.) deflection under 100 N

(10 kg, 22 lb) pressure.

4) If belt tension is out of above specification, adjust it referring

to “Compressor Drive Belt” in Section 1B or “Power Steering

Belt Check” in Section 3B1.

5) Connect negative cable to battery.

REPLACEMENT

Replace belt with new one referring to “Compressor Drive Belt” in

Section 1B or “Power Steering Belt Check” in Section 3B1.

Valve Lash

INSPECTION

1) Inspect intake and exhaust valve lash and adjust as neces-

sary.

Refer to “Valve Lash (Clearance)” in Section 6A1 for valve

lash inspection and adjustment procedure.

Engine Oil and Filter

CHANGE

Before draining engine oil, check engine for oil leakage. If any evi-

dence of leakage is found, make sure to correct defective part

before proceeding to the following work.

1. P/S pump pulley

2. Camshaft pulley

3. A/C compressor pulley (if equipped)

4. Belt tension pulley

1. Camshaft

2. Thickness gauge

WARNING:

New and used engine oil can be hazardous.

Be sure to read “WARNING” in General Precaution in

Section 0A and observe what in written there.

Step 1) – 7) outlined below must be performed with

ENGINE NOT RUNNING. For step 8), be sure to have

adequate ventilation while engine is running.

Page 38 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-7

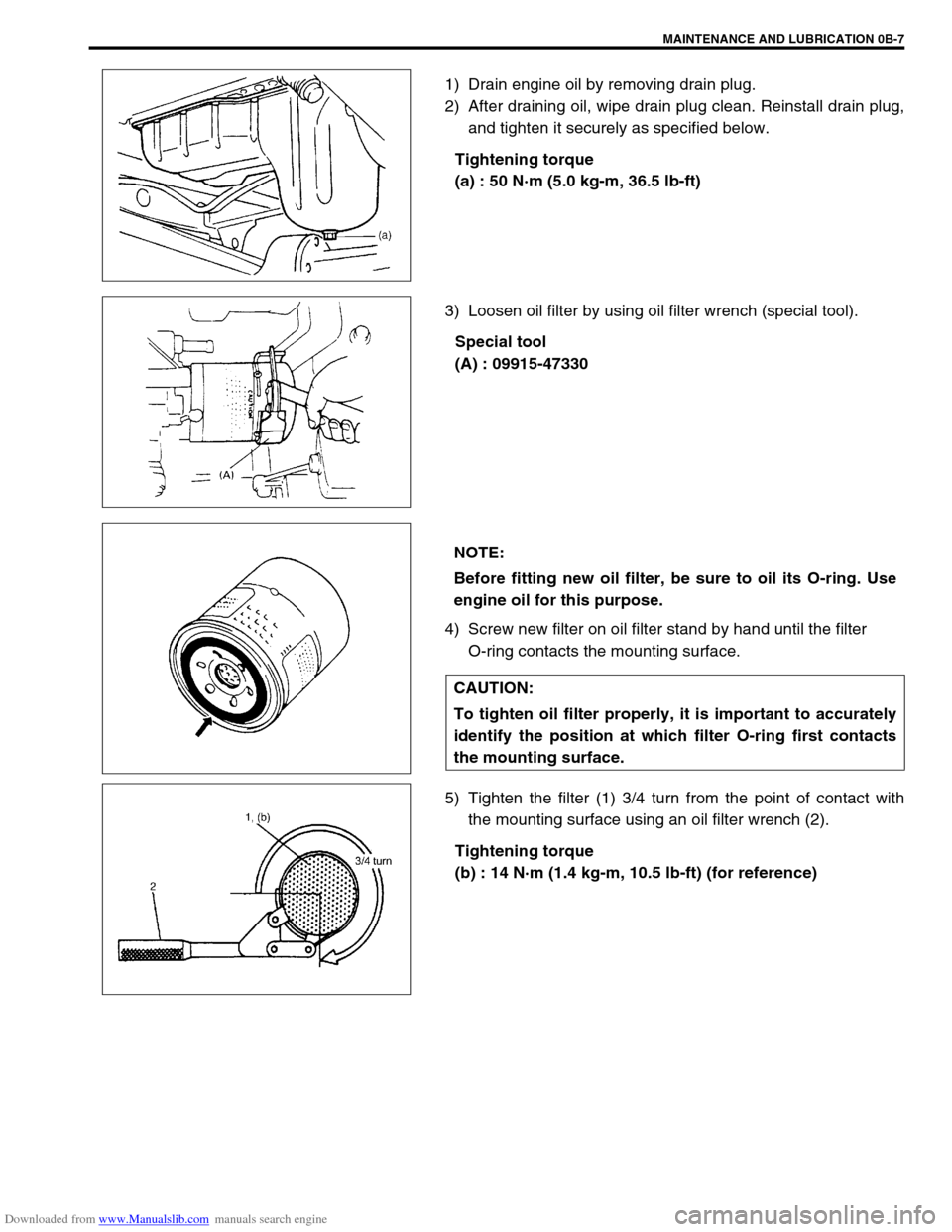

1) Drain engine oil by removing drain plug.

2) After draining oil, wipe drain plug clean. Reinstall drain plug,

and tighten it securely as specified below.

Tightening torque

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

3) Loosen oil filter by using oil filter wrench (special tool).

Special tool

(A) : 09915-47330

4) Screw new filter on oil filter stand by hand until the filter

O-ring contacts the mounting surface.

5) Tighten the filter (1) 3/4 turn from the point of contact with

the mounting surface using an oil filter wrench (2).

Tightening torque

(b) : 14 N·m (1.4 kg-m, 10.5 lb-ft) (for reference)

NOTE:

Before fitting new oil filter, be sure to oil its O-ring. Use

engine oil for this purpose.

CAUTION:

To tighten oil filter properly, it is important to accurately

identify the position at which filter O-ring first contacts

the mounting surface.

Page 39 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-8 MAINTENANCE AND LUBRICATION

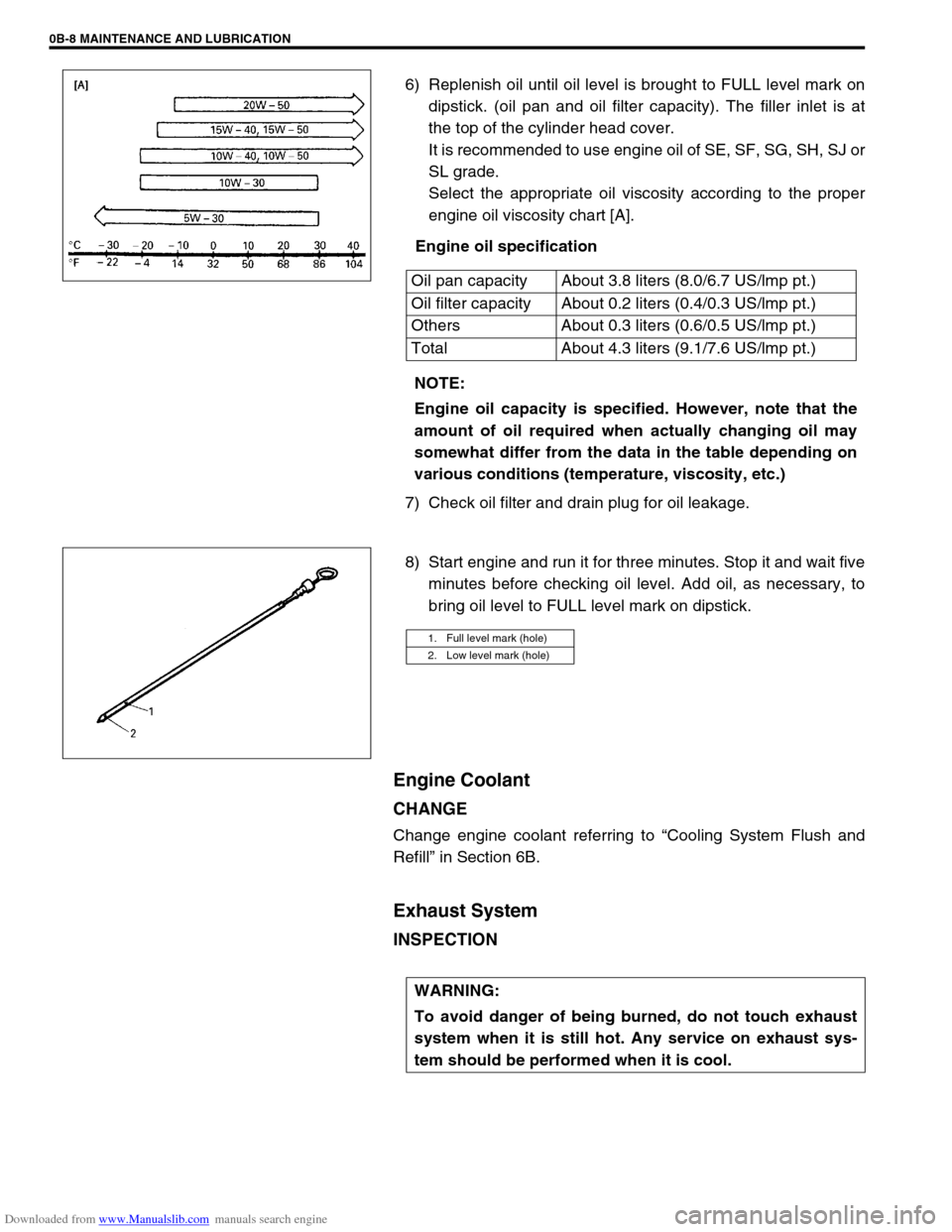

6) Replenish oil until oil level is brought to FULL level mark on

dipstick. (oil pan and oil filter capacity). The filler inlet is at

the top of the cylinder head cover.

It is recommended to use engine oil of SE, SF, SG, SH, SJ or

SL grade.

Select the appropriate oil viscosity according to the proper

engine oil viscosity chart [A].

Engine oil specification

7) Check oil filter and drain plug for oil leakage.

8) Start engine and run it for three minutes. Stop it and wait five

minutes before checking oil level. Add oil, as necessary, to

bring oil level to FULL level mark on dipstick.

Engine Coolant

CHANGE

Change engine coolant referring to “Cooling System Flush and

Refill” in Section 6B.

Exhaust System

INSPECTION

Oil pan capacity About 3.8 liters (8.0/6.7 US/lmp pt.)

Oil filter capacity About 0.2 liters (0.4/0.3 US/lmp pt.)

Others About 0.3 liters (0.6/0.5 US/lmp pt.)

Total About 4.3 liters (9.1/7.6 US/lmp pt.)

NOTE:

Engine oil capacity is specified. However, note that the

amount of oil required when actually changing oil may

somewhat differ from the data in the table depending on

various conditions (temperature, viscosity, etc.)

1. Full level mark (hole)

2. Low level mark (hole)

WARNING:

To avoid danger of being burned, do not touch exhaust

system when it is still hot. Any service on exhaust sys-

tem should be performed when it is cool.

Page 41 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-10 MAINTENANCE AND LUBRICATION

REPLACEMENT

Replace air cleaner filter with new one according to steps 1), 2)

and 5), 6) of inspection procedure.

Fuel Lines and Connections

INSPECTION

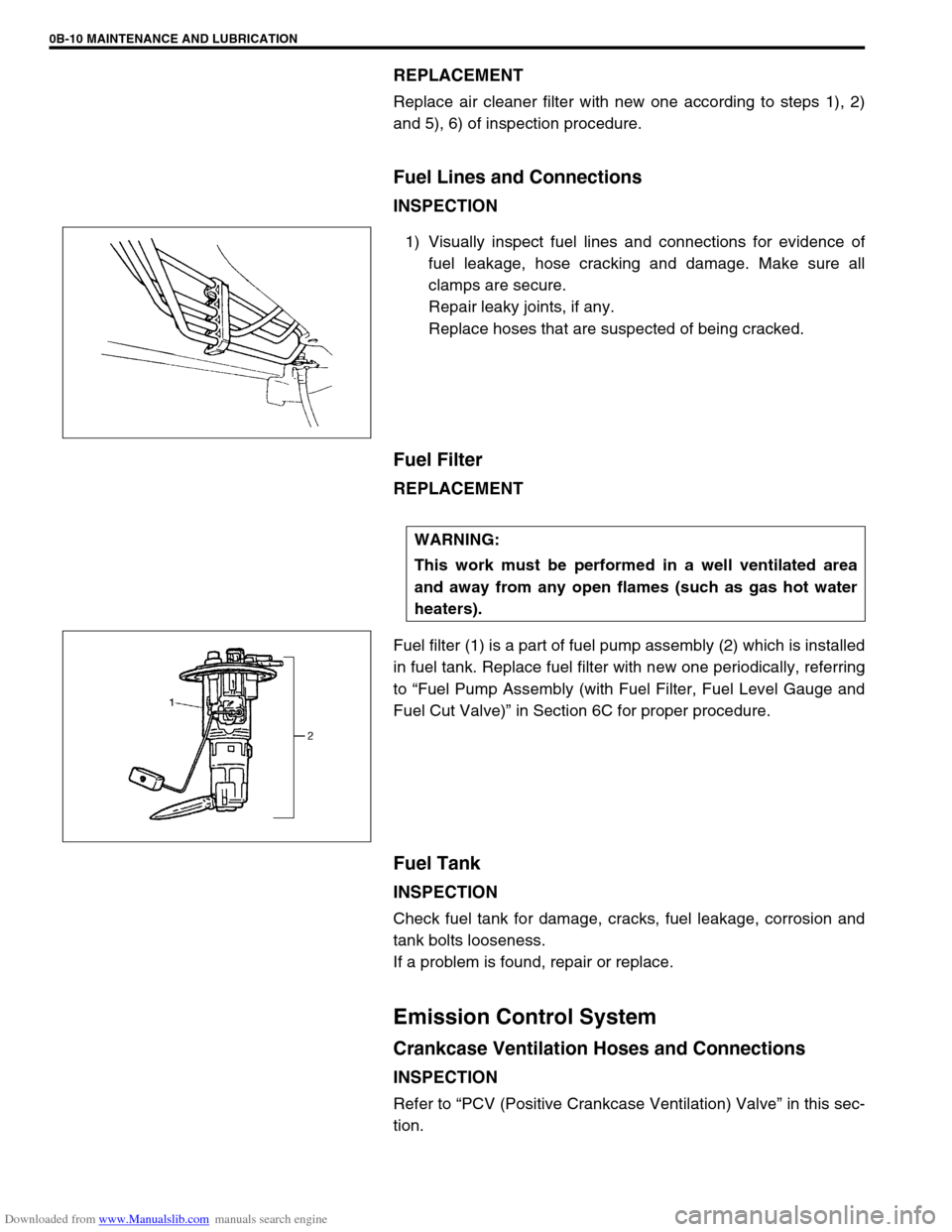

1) Visually inspect fuel lines and connections for evidence of

fuel leakage, hose cracking and damage. Make sure all

clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

Fuel Filter

REPLACEMENT

Fuel filter (1) is a part of fuel pump assembly (2) which is installed

in fuel tank. Replace fuel filter with new one periodically, referring

to “Fuel Pump Assembly (with Fuel Filter, Fuel Level Gauge and

Fuel Cut Valve)” in Section 6C for proper procedure.

Fuel Tank

INSPECTION

Check fuel tank for damage, cracks, fuel leakage, corrosion and

tank bolts looseness.

If a problem is found, repair or replace.

Emission Control System

Crankcase Ventilation Hoses and Connections

INSPECTION

Refer to “PCV (Positive Crankcase Ventilation) Valve” in this sec-

tion.

WARNING:

This work must be performed in a well ventilated area

and away from any open flames (such as gas hot water

heaters).

Page 44 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-13

Parking Brake Lever and Cable

INSPECTION

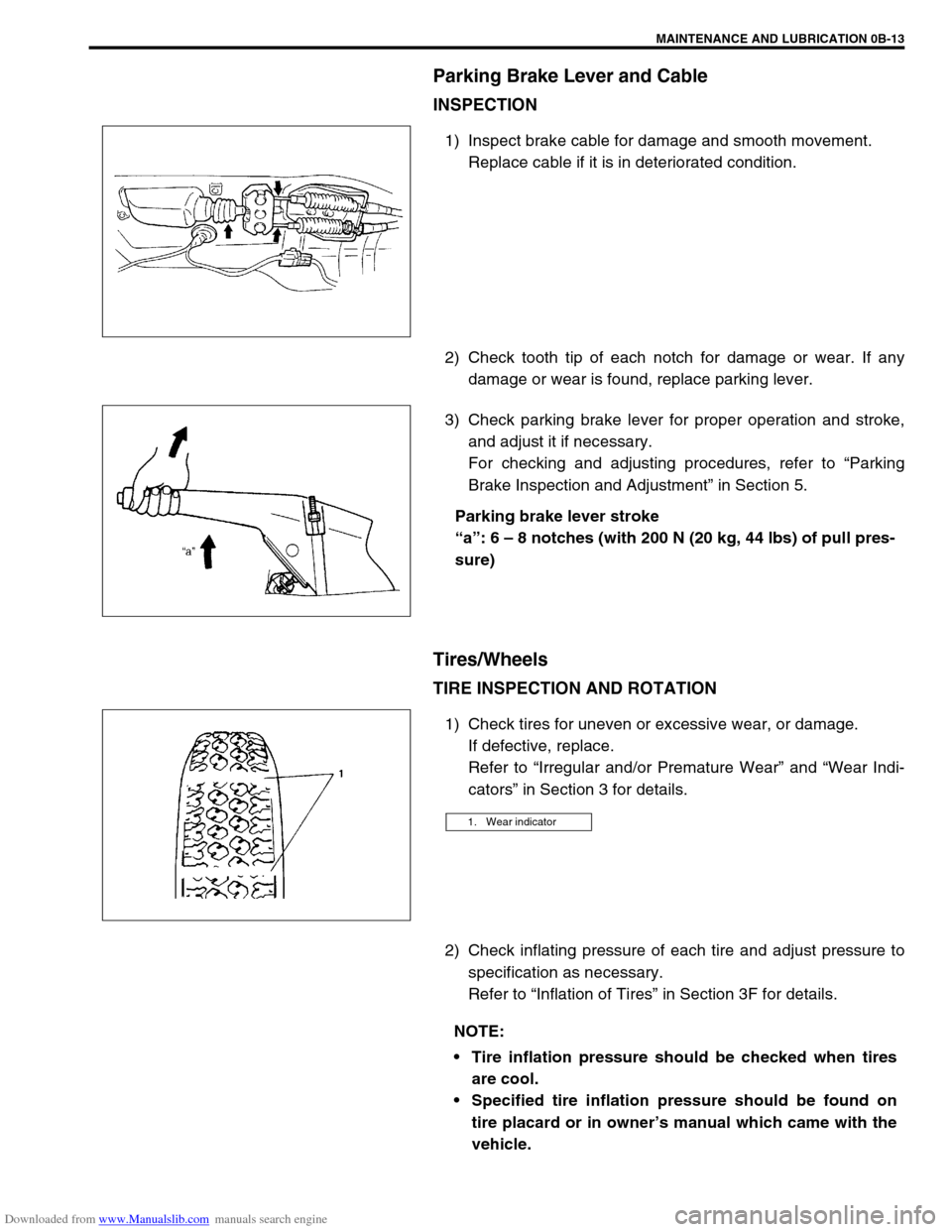

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition.

2) Check tooth tip of each notch for damage or wear. If any

damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and stroke,

and adjust it if necessary.

For checking and adjusting procedures, refer to “Parking

Brake Inspection and Adjustment” in Section 5.

Parking brake lever stroke

“a”: 6 – 8 notches (with 200 N (20 kg, 44 lbs) of pull pres-

sure)

Tires/Wheels

TIRE INSPECTION AND ROTATION

1) Check tires for uneven or excessive wear, or damage.

If defective, replace.

Refer to “Irregular and/or Premature Wear” and “Wear Indi-

cators” in Section 3 for details.

2) Check inflating pressure of each tire and adjust pressure to

specification as necessary.

Refer to “Inflation of Tires” in Section 3F for details.

1. Wear indicator

NOTE:

Tire inflation pressure should be checked when tires

are cool.

Specified tire inflation pressure should be found on

tire placard or in owner’s manual which came with the

vehicle.

Page 45 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-14 MAINTENANCE AND LUBRICATION

3) Rotate tires.

For details, refer to “Tire Rotation” in Section 3F.

WHEEL DISCS INSPECTION

Inspect each wheel disc for dents, distortion and cracks. A disc in

badly damaged condition must be replaced.

WHEEL BEARING INSPECTION

1) Check front wheel bearing for wear, damage, abnormal

noise or rattles. For details, refer to “Wheel Disc, Nut and

Bearing Check” in Section 3D.

2) Check rear wheel bearing for wear, damage, abnormal noise

or rattles. For details, refer to “Wheel Disc, Nut and Bearing

Check” in Section 3E.

Suspension System

INSPECTION

Check suspension bolts and nuts for tightness and retighten them

as necessary.

Repair or replace defective parts, if any.

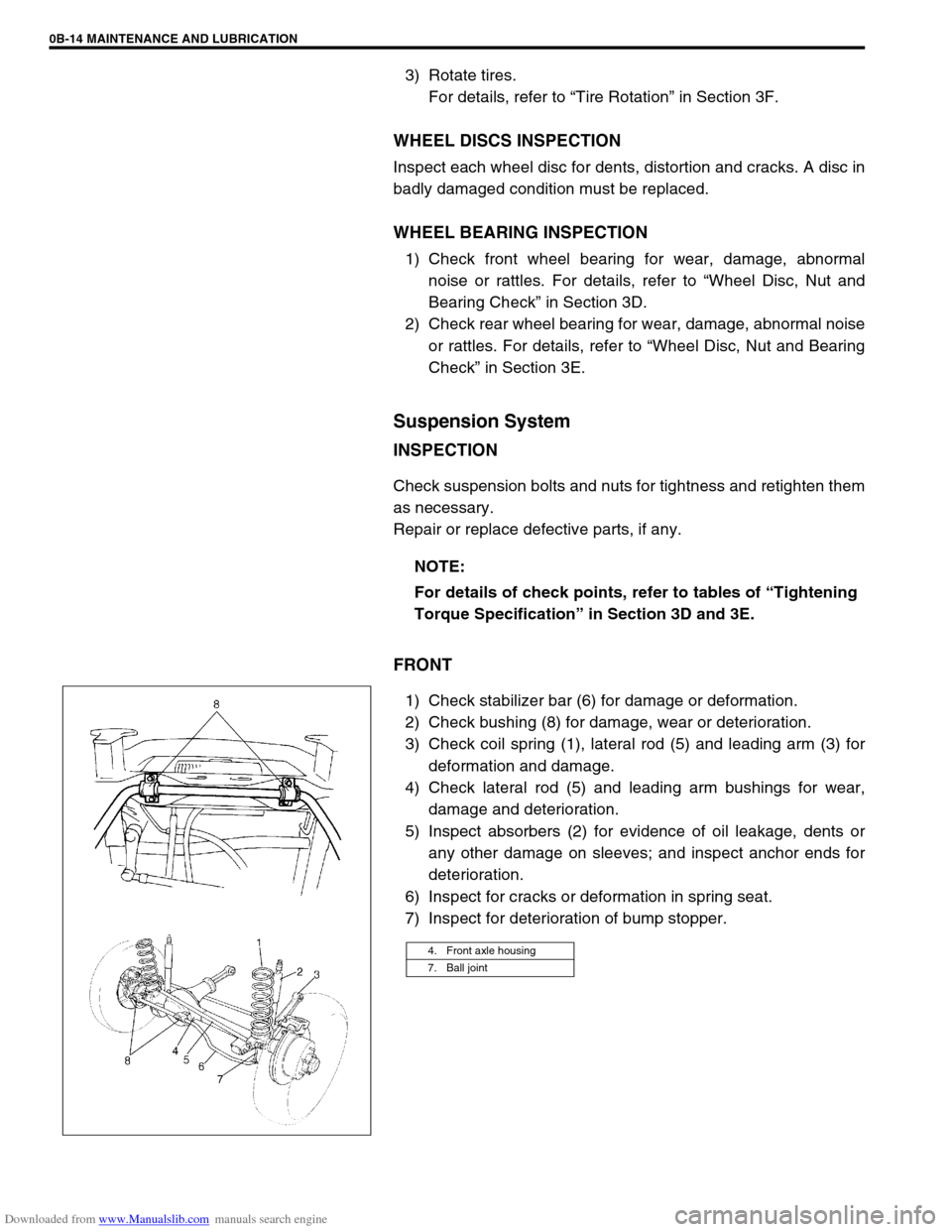

FRONT

1) Check stabilizer bar (6) for damage or deformation.

2) Check bushing (8) for damage, wear or deterioration.

3) Check coil spring (1), lateral rod (5) and leading arm (3) for

deformation and damage.

4) Check lateral rod (5) and leading arm bushings for wear,

damage and deterioration.

5) Inspect absorbers (2) for evidence of oil leakage, dents or

any other damage on sleeves; and inspect anchor ends for

deterioration.

6) Inspect for cracks or deformation in spring seat.

7) Inspect for deterioration of bump stopper.NOTE:

For details of check points, refer to tables of “Tightening

Torque Specification” in Section 3D and 3E.

4. Front axle housing

7. Ball joint

Page 46 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-15

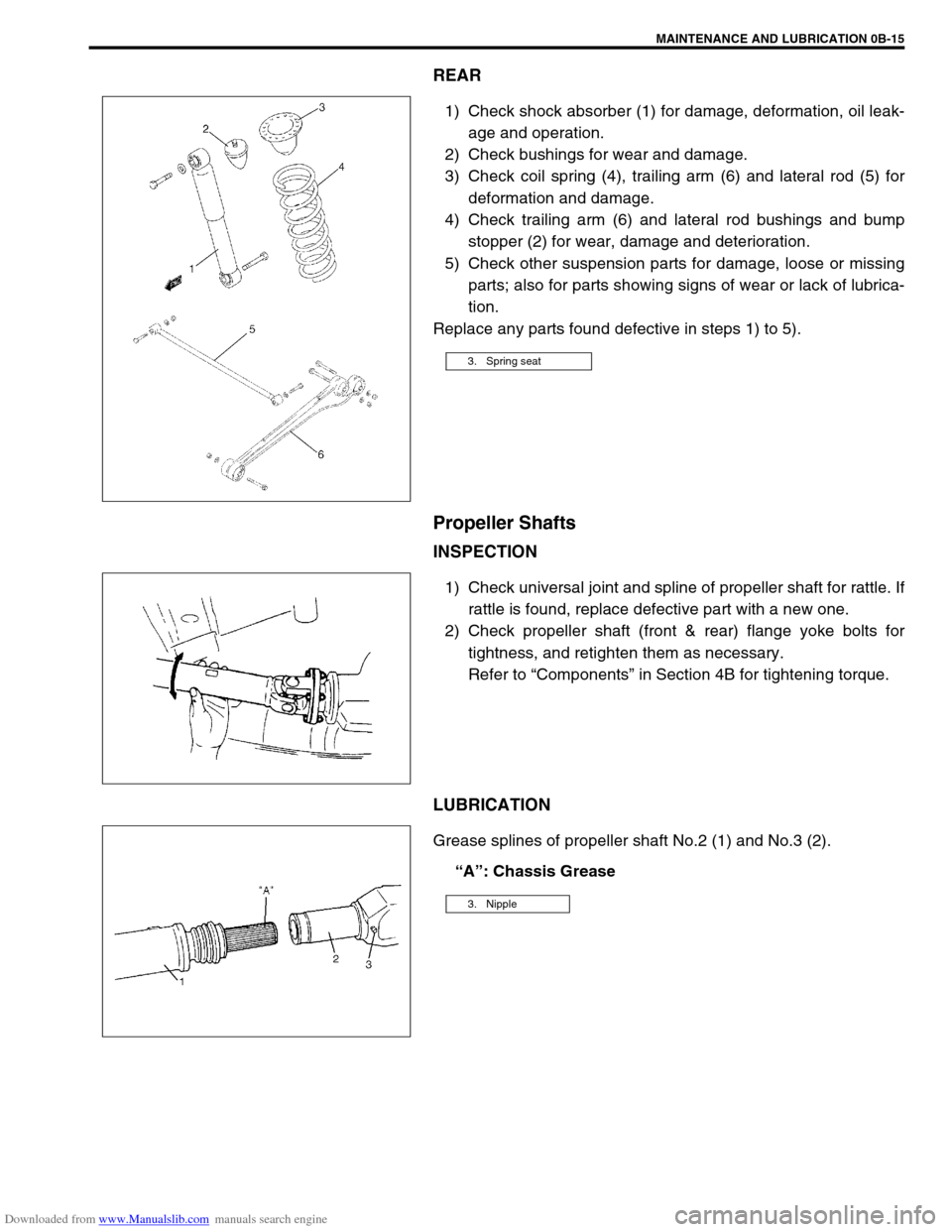

REAR

1) Check shock absorber (1) for damage, deformation, oil leak-

age and operation.

2) Check bushings for wear and damage.

3) Check coil spring (4), trailing arm (6) and lateral rod (5) for

deformation and damage.

4) Check trailing arm (6) and lateral rod bushings and bump

stopper (2) for wear, damage and deterioration.

5) Check other suspension parts for damage, loose or missing

parts; also for parts showing signs of wear or lack of lubrica-

tion.

Replace any parts found defective in steps 1) to 5).

Propeller Shafts

INSPECTION

1) Check universal joint and spline of propeller shaft for rattle. If

rattle is found, replace defective part with a new one.

2) Check propeller shaft (front & rear) flange yoke bolts for

tightness, and retighten them as necessary.

Refer to “Components” in Section 4B for tightening torque.

LUBRICATION

Grease splines of propeller shaft No.2 (1) and No.3 (2).

“A”: Chassis Grease

3. Spring seat

3. Nipple