oil type SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 430 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-73

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–Engine coolant temp. : – 10 – 110 °C, 14 – 230 °F

4) Start engine and keep it at idle for 2 min. or more.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

6) If DTC is not detected at idle, consult usual driving based on information obtained in “Customer complaint

analysis” and “Freeze frame data check”.

INSPECTION

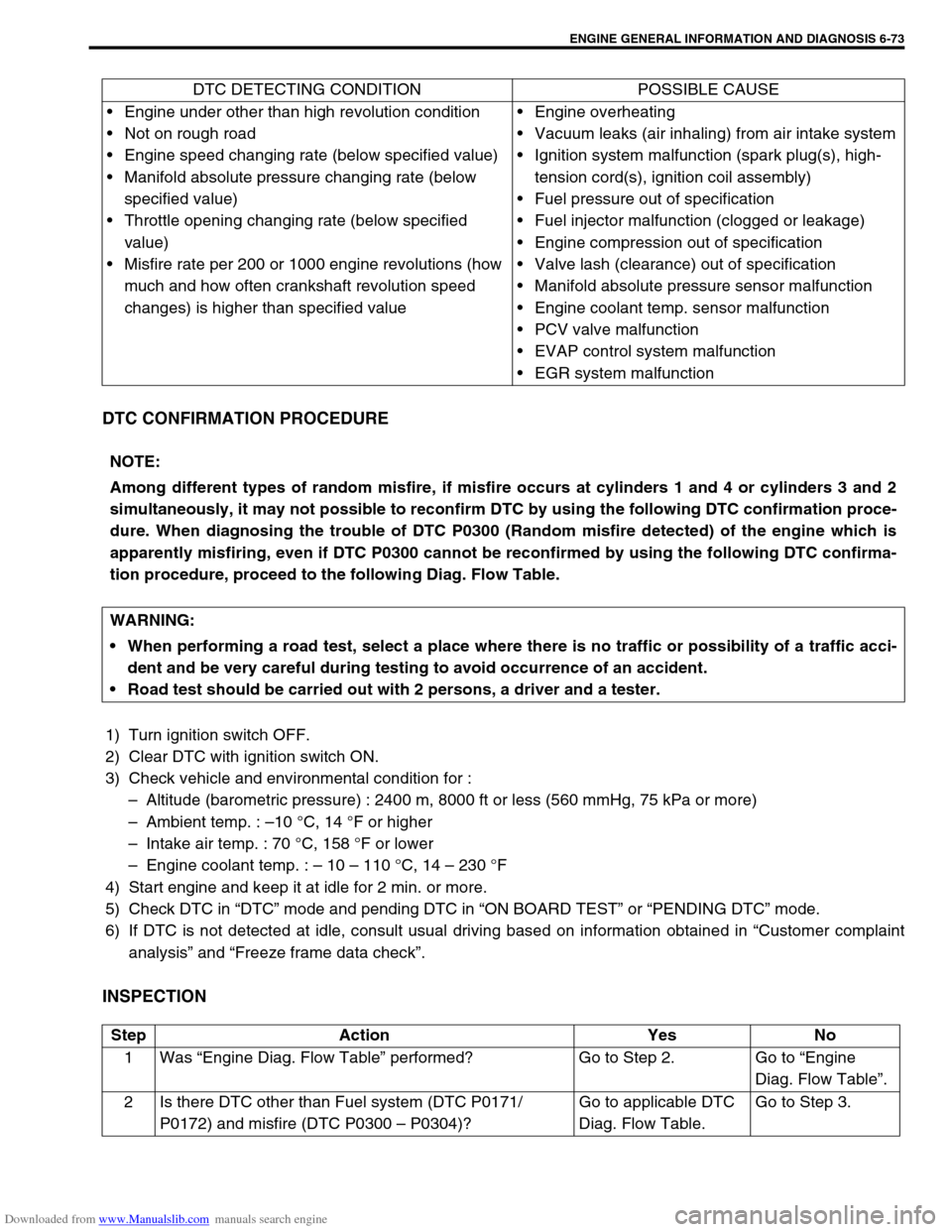

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine under other than high revolution condition

Not on rough road

Engine speed changing rate (below specified value)

Manifold absolute pressure changing rate (below

specified value)

Throttle opening changing rate (below specified

value)

Misfire rate per 200 or 1000 engine revolutions (how

much and how often crankshaft revolution speed

changes) is higher than specified valueEngine overheating

Vacuum leaks (air inhaling) from air intake system

Ignition system malfunction (spark plug(s), high-

tension cord(s), ignition coil assembly)

Fuel pressure out of specification

Fuel injector malfunction (clogged or leakage)

Engine compression out of specification

Valve lash (clearance) out of specification

Manifold absolute pressure sensor malfunction

Engine coolant temp. sensor malfunction

PCV valve malfunction

EVAP control system malfunction

EGR system malfunction

NOTE:

Among different types of random misfire, if misfire occurs at cylinders 1 and 4 or cylinders 3 and 2

simultaneously, it may not possible to reconfirm DTC by using the following DTC confirmation proce-

dure. When diagnosing the trouble of DTC P0300 (Random misfire detected) of the engine which is

apparently misfiring, even if DTC P0300 cannot be reconfirmed by using the following DTC confirma-

tion procedure, proceed to the following Diag. Flow Table.

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine

Diag. Flow Table”.

2 Is there DTC other than Fuel system (DTC P0171/

P0172) and misfire (DTC P0300 – P0304)?Go to applicable DTC

Diag. Flow Table.Go to Step 3.

Page 484 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-3

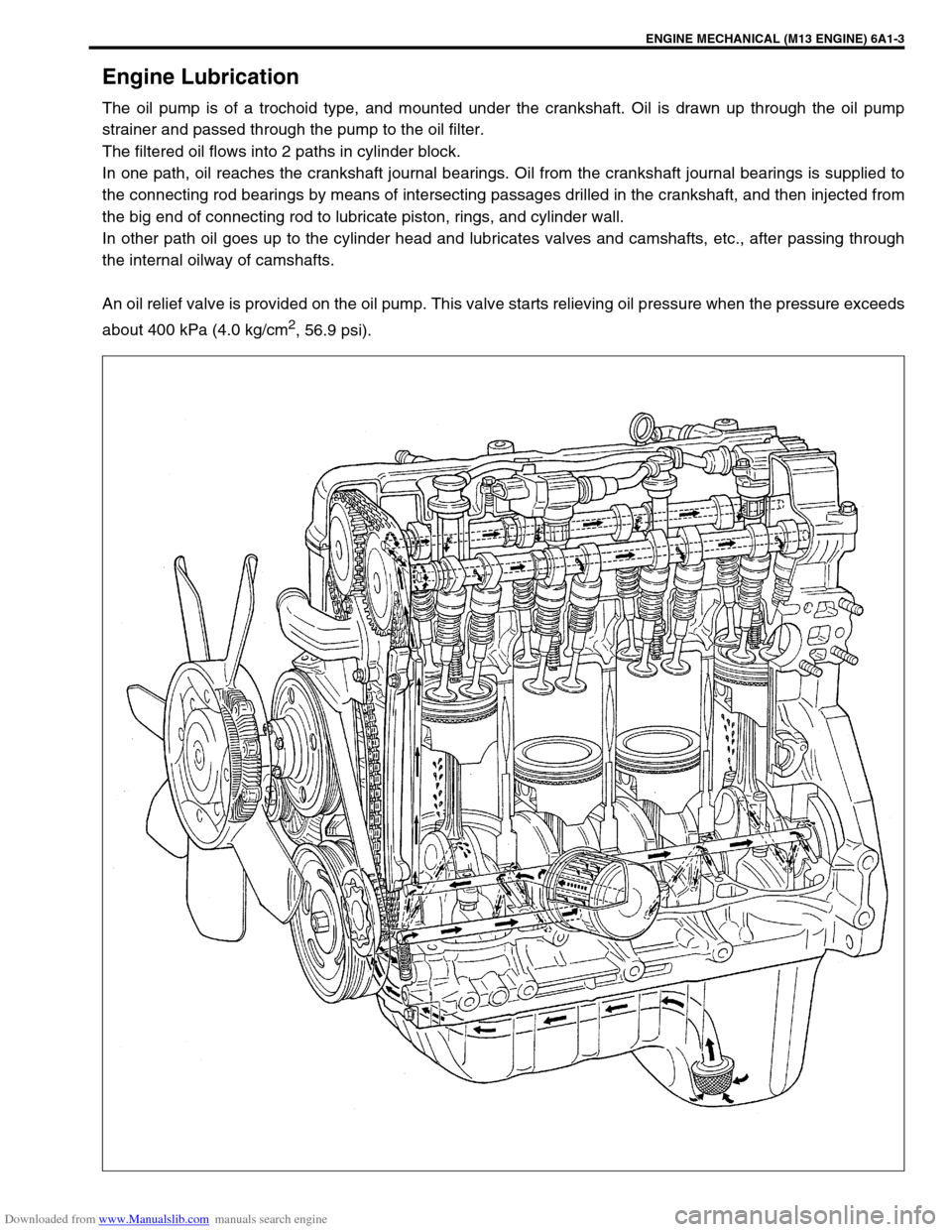

Engine Lubrication

The oil pump is of a trochoid type, and mounted under the crankshaft. Oil is drawn up through the oil pump

strainer and passed through the pump to the oil filter.

The filtered oil flows into 2 paths in cylinder block.

In one path, oil reaches the crankshaft journal bearings. Oil from the crankshaft journal bearings is supplied to

the connecting rod bearings by means of intersecting passages drilled in the crankshaft, and then injected from

the big end of connecting rod to lubricate piston, rings, and cylinder wall.

In other path oil goes up to the cylinder head and lubricates valves and camshafts, etc., after passing through

the internal oilway of camshafts.

An oil relief valve is provided on the oil pump. This valve starts relieving oil pressure when the pressure exceeds

about 400 kPa (4.0 kg/cm

2, 56.9 psi).

Page 618 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-13

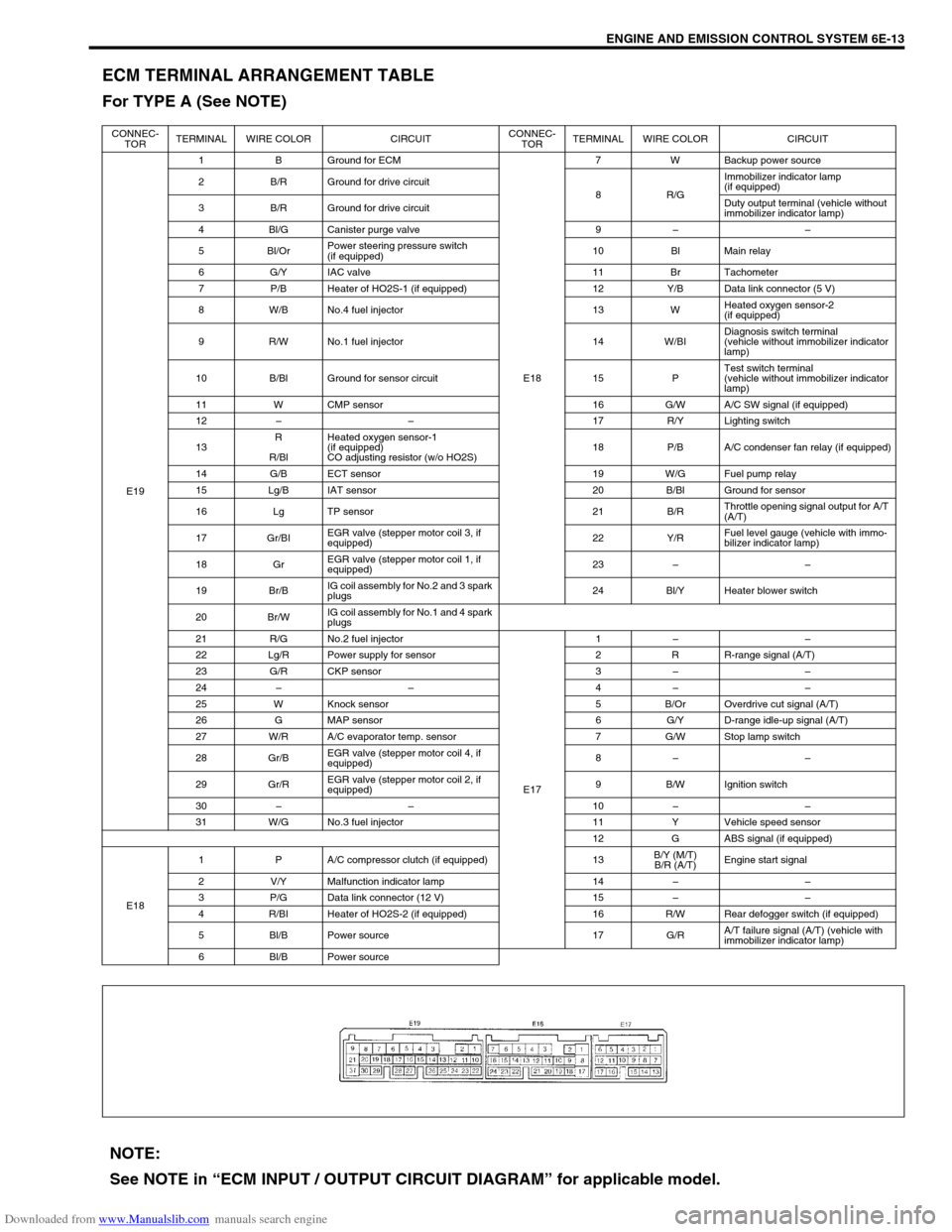

ECM TERMINAL ARRANGEMENT TABLE

For TYPE A (See NOTE)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

E191 B Ground for ECM

E187 W Backup power source

2 B/R Ground for drive circuit

8R/GImmobilizer indicator lamp

(if equipped)

3 B/R Ground for drive circuitDuty output terminal (vehicle without

immobilizer indicator lamp)

4 Bl/G Canister purge valve 9––

5 Bl/OrPower steering pressure switch

(if equipped)10 Bl Main relay

6 G/Y IAC valve 11 Br Tachometer

7 P/B Heater of HO2S-1 (if equipped) 12 Y/B Data link connector (5 V)

8 W/B No.4 fuel injector 13 WHeated oxygen sensor-2

(if equipped)

9 R/W No.1 fuel injector 14 W/BIDiagnosis switch terminal

(vehicle without immobilizer indicator

lamp)

10 B/Bl Ground for sensor circuit 15 PTest switch terminal

(vehicle without immobilizer indicator

lamp)

11 W CMP sensor 16 G/W A/C SW signal (if equipped)

12––17 R/Y Lighting switch

13R

R/BlHeated oxygen sensor-1

(if equipped)

CO adjusting resistor (w/o HO2S)18 P/B A/C condenser fan relay (if equipped)

14 G/B ECT sensor 19 W/G Fuel pump relay

15 Lg/B IAT sensor 20 B/Bl Ground for sensor

16 Lg TP sensor 21 B/RThrottle opening signal output for A/T

(A/T)

17 Gr/BIEGR valve (stepper motor coil 3, if

equipped)22 Y/RFuel level gauge (vehicle with immo-

bilizer indicator lamp)

18 GrEGR valve (stepper motor coil 1, if

equipped)23––

19 Br/BIG coil assembly for No.2 and 3 spark

plugs24 Bl/Y Heater blower switch

20 Br/WIG coil assembly for No.1 and 4 spark

plugs

21 R/G No.2 fuel injector

E171––

22 Lg/R Power supply for sensor 2 R R-range signal (A/T)

23 G/R CKP sensor 3––

24––4––

25 W Knock sensor 5 B/Or Overdrive cut signal (A/T)

26 G MAP sensor 6 G/Y D-range idle-up signal (A/T)

27 W/R A/C evaporator temp. sensor 7 G/W Stop lamp switch

28 Gr/BEGR valve (stepper motor coil 4, if

equipped)8––

29 Gr/REGR valve (stepper motor coil 2, if

equipped)9 B/W Ignition switch

30––10––

31 W/G No.3 fuel injector 11 Y Vehicle speed sensor

12 G ABS signal (if equipped)

E181 P A/C compressor clutch (if equipped) 13B/Y (M/T)

B/R (A/T)Engine start signal

2 V/Y Malfunction indicator lamp 14––

3 P/G Data link connector (12 V) 15––

4 R/BI Heater of HO2S-2 (if equipped) 16 R/W Rear defogger switch (if equipped)

5 Bl/B Power source 17 G/RA/T failure signal (A/T) (vehicle with

immobilizer indicator lamp)

6 Bl/B Power source

NOTE:

See NOTE in “ECM INPUT / OUTPUT CIRCUIT DIAGRAM” for applicable model.

Page 619 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-14 ENGINE AND EMISSION CONTROL SYSTEM

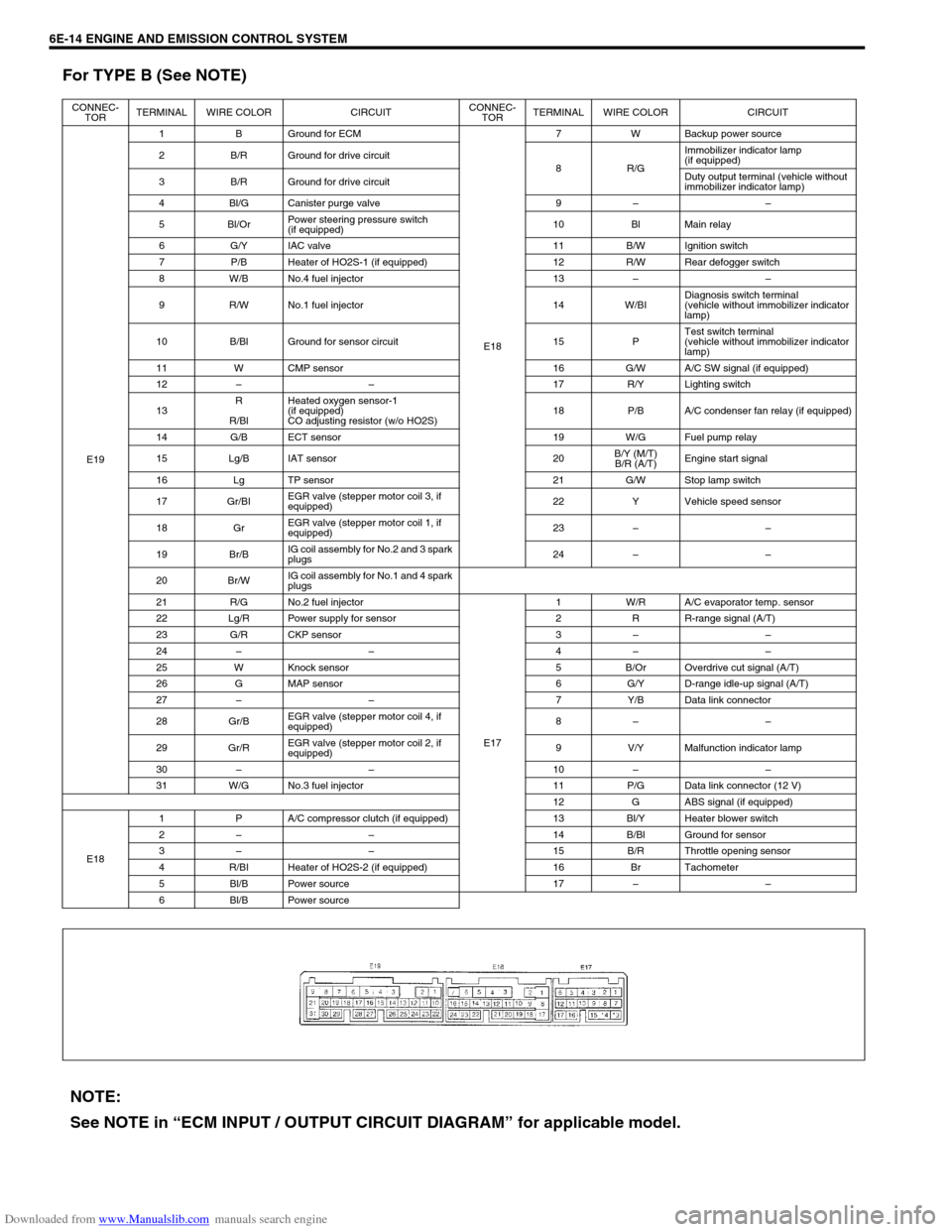

For TYPE B (See NOTE)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

E191 B Ground for ECM

E187 W Backup power source

2 B/R Ground for drive circuit

8R/GImmobilizer indicator lamp

(if equipped)

3 B/R Ground for drive circuitDuty output terminal (vehicle without

immobilizer indicator lamp)

4 Bl/G Canister purge valve 9––

5 Bl/OrPower steering pressure switch

(if equipped)10 Bl Main relay

6 G/Y IAC valve 11 B/W Ignition switch

7 P/B Heater of HO2S-1 (if equipped) 12 R/W Rear defogger switch

8 W/B No.4 fuel injector 13––

9 R/W No.1 fuel injector 14 W/BIDiagnosis switch terminal

(vehicle without immobilizer indicator

lamp)

10 B/Bl Ground for sensor circuit 15 PTest switch terminal

(vehicle without immobilizer indicator

lamp)

11 W CMP sensor 16 G/W A/C SW signal (if equipped)

12––17 R/Y Lighting switch

13R

R/BlHeated oxygen sensor-1

(if equipped)

CO adjusting resistor (w/o HO2S)18 P/B A/C condenser fan relay (if equipped)

14 G/B ECT sensor 19 W/G Fuel pump relay

15 Lg/B IAT sensor 20B/Y (M/T)

B/R (A/T)Engine start signal

16 Lg TP sensor 21 G/W Stop lamp switch

17 Gr/BIEGR valve (stepper motor coil 3, if

equipped)22 Y Vehicle speed sensor

18 GrEGR valve (stepper motor coil 1, if

equipped)23––

19 Br/BIG coil assembly for No.2 and 3 spark

plugs24––

20 Br/WIG coil assembly for No.1 and 4 spark

plugs

21 R/G No.2 fuel injector

E171 W/R A/C evaporator temp. sensor

22 Lg/R Power supply for sensor 2 R R-range signal (A/T)

23 G/R CKP sensor 3––

24––4––

25 W Knock sensor 5 B/Or Overdrive cut signal (A/T)

26 G MAP sensor 6 G/Y D-range idle-up signal (A/T)

27––7 Y/B Data link connector

28 Gr/BEGR valve (stepper motor coil 4, if

equipped)8––

29 Gr/REGR valve (stepper motor coil 2, if

equipped)9 V/Y Malfunction indicator lamp

30––10––

31 W/G No.3 fuel injector 11 P/G Data link connector (12 V)

12 G ABS signal (if equipped)

E181 P A/C compressor clutch (if equipped) 13 Bl/Y Heater blower switch

2––14 B/Bl Ground for sensor

3––15 B/R Throttle opening sensor

4 R/BI Heater of HO2S-2 (if equipped) 16 Br Tachometer

5 Bl/B Power source 17––

6 Bl/B Power source

NOTE:

See NOTE in “ECM INPUT / OUTPUT CIRCUIT DIAGRAM” for applicable model.

Page 653 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

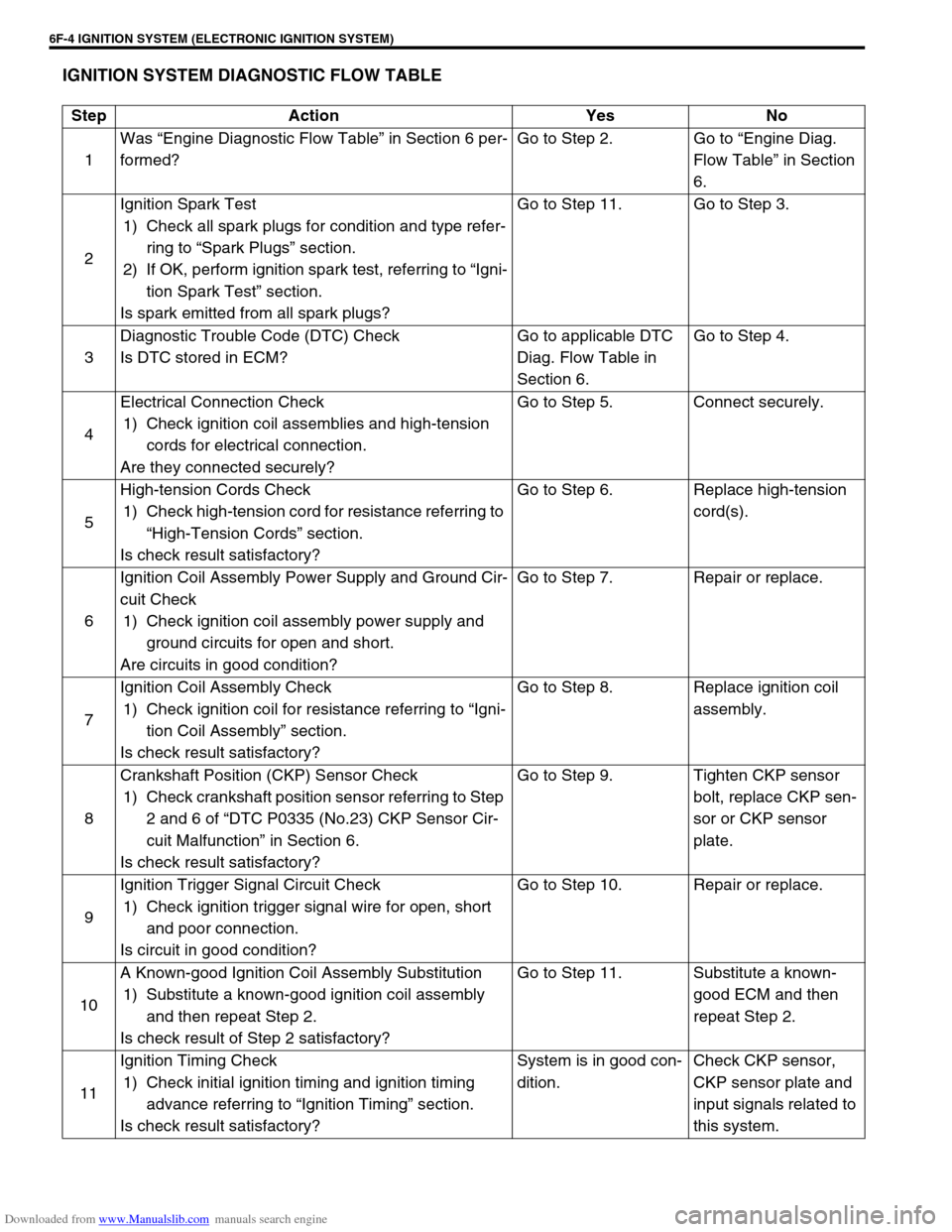

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “Engine Diagnostic Flow Table” in Section 6 per-

formed?Go to Step 2. Go to “Engine Diag.

Flow Table” in Section

6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check

Is DTC stored in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

2 and 6 of “DTC P0335 (No.23) CKP Sensor Cir-

cuit Malfunction” in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” section.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.

Page 654 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-5

On-Vehicle Service

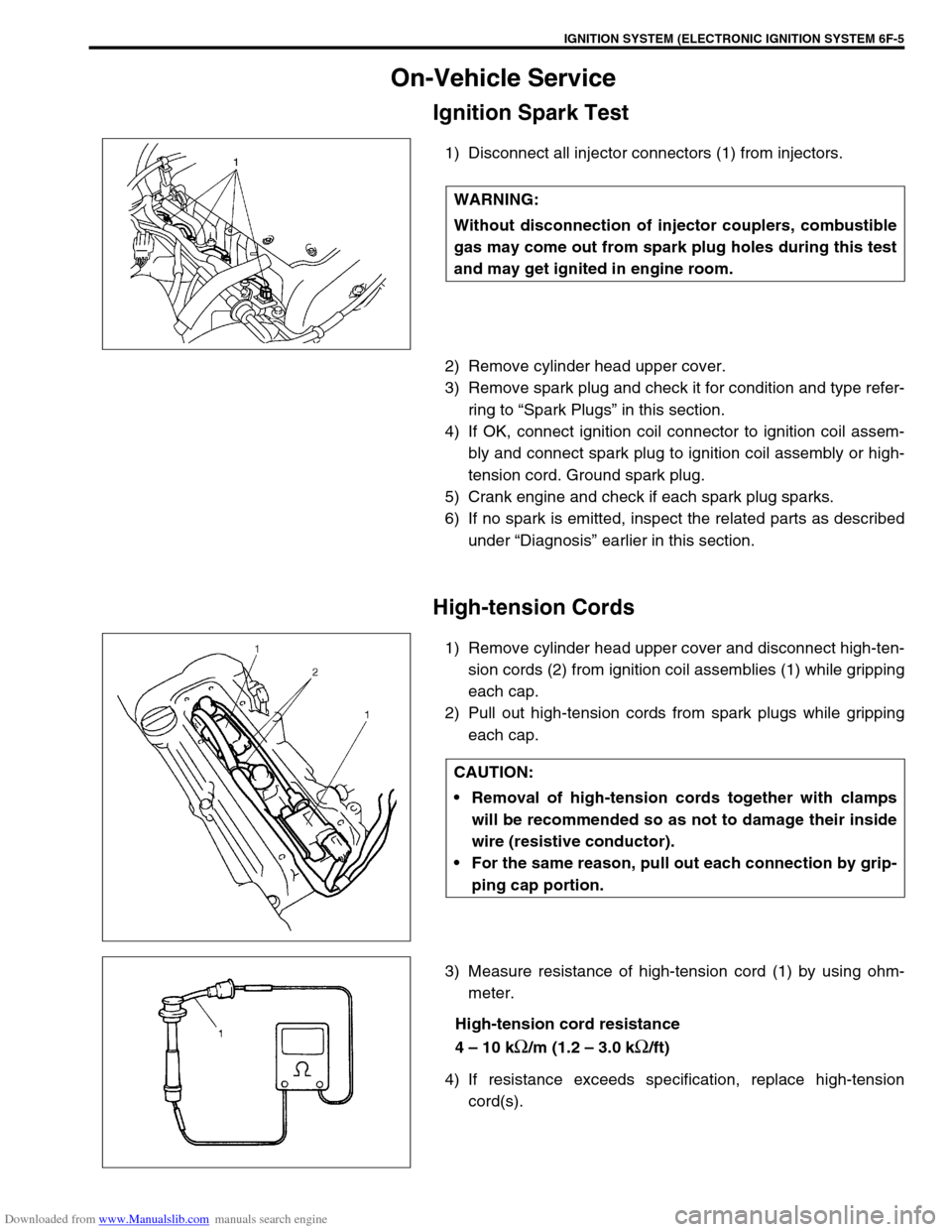

Ignition Spark Test

1) Disconnect all injector connectors (1) from injectors.

2) Remove cylinder head upper cover.

3) Remove spark plug and check it for condition and type refer-

ring to “Spark Plugs” in this section.

4) If OK, connect ignition coil connector to ignition coil assem-

bly and connect spark plug to ignition coil assembly or high-

tension cord. Ground spark plug.

5) Crank engine and check if each spark plug sparks.

6) If no spark is emitted, inspect the related parts as described

under “Diagnosis” earlier in this section.

High-tension Cords

1) Remove cylinder head upper cover and disconnect high-ten-

sion cords (2) from ignition coil assemblies (1) while gripping

each cap.

2) Pull out high-tension cords from spark plugs while gripping

each cap.

3) Measure resistance of high-tension cord (1) by using ohm-

meter.

High-tension cord resistance

4 – 10 k

Ω/m (1.2 – 3.0 kΩ/ft)

4) If resistance exceeds specification, replace high-tension

cord(s). WARNING:

Without disconnection of injector couplers, combustible

gas may come out from spark plug holes during this test

and may get ignited in engine room.

CAUTION:

Removal of high-tension cords together with clamps

will be recommended so as not to damage their inside

wire (resistive conductor).

For the same reason, pull out each connection by grip-

ping cap portion.

Page 656 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-7

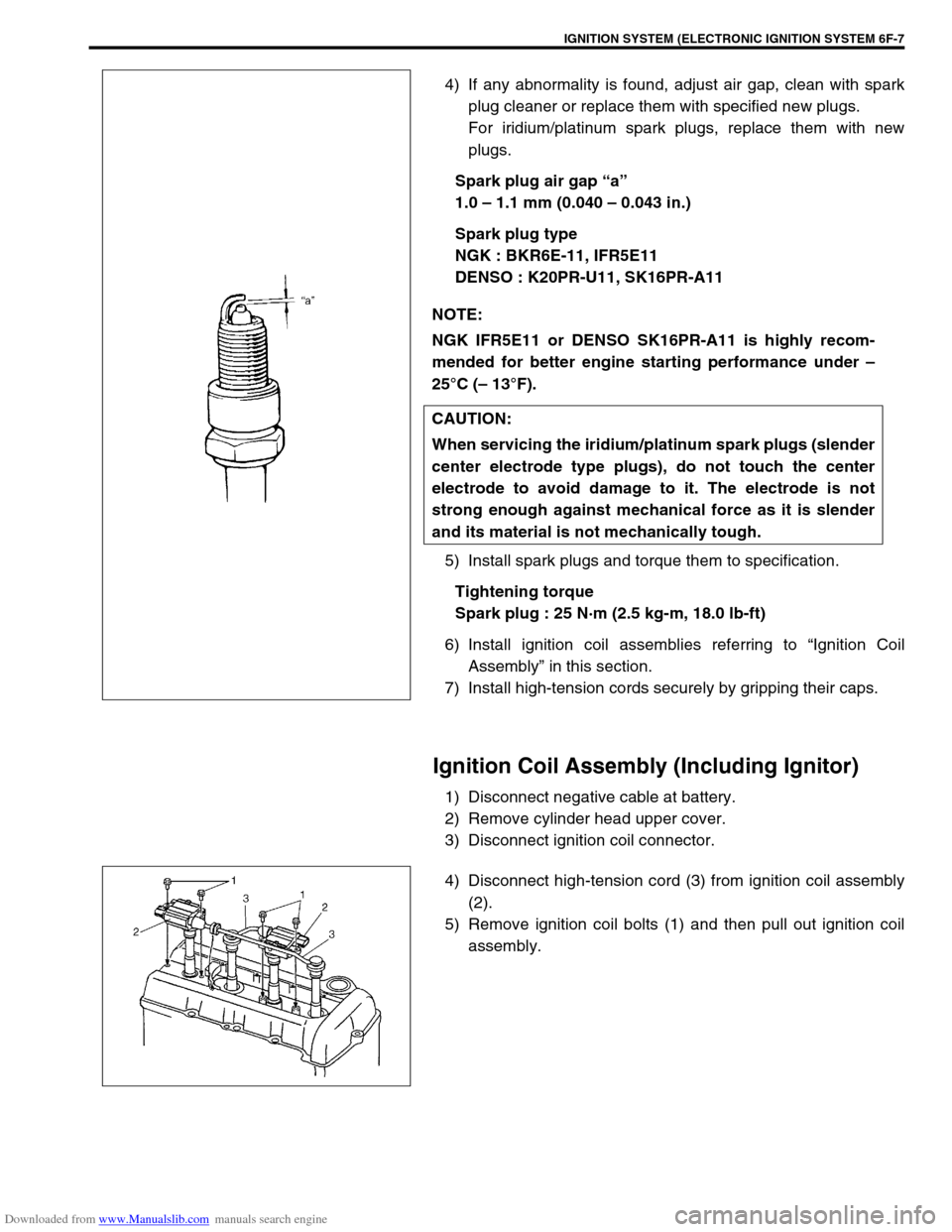

4) If any abnormality is found, adjust air gap, clean with spark

plug cleaner or replace them with specified new plugs.

For iridium/platinum spark plugs, replace them with new

plugs.

Spark plug air gap “a”

1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type

NGK : BKR6E-11, IFR5E11

DENSO : K20PR-U11, SK16PR-A11

5) Install spark plugs and torque them to specification.

Tightening torque

Spark plug : 25 N·m (2.5 kg-m, 18.0 lb-ft)

6) Install ignition coil assemblies referring to “Ignition Coil

Assembly” in this section.

7) Install high-tension cords securely by gripping their caps.

Ignition Coil Assembly (Including Ignitor)

1) Disconnect negative cable at battery.

2) Remove cylinder head upper cover.

3) Disconnect ignition coil connector.

4) Disconnect high-tension cord (3) from ignition coil assembly

(2).

5) Remove ignition coil bolts (1) and then pull out ignition coil

assembly. NOTE:

NGK IFR5E11 or DENSO SK16PR-A11 is highly recom-

mended for better engine starting performance under –

25°C (– 13°F).

CAUTION:

When servicing the iridium/platinum spark plugs (slender

center electrode type plugs), do not touch the center

electrode to avoid damage to it. The electrode is not

strong enough against mechanical force as it is slender

and its material is not mechanically tough.

Page 657 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-8 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

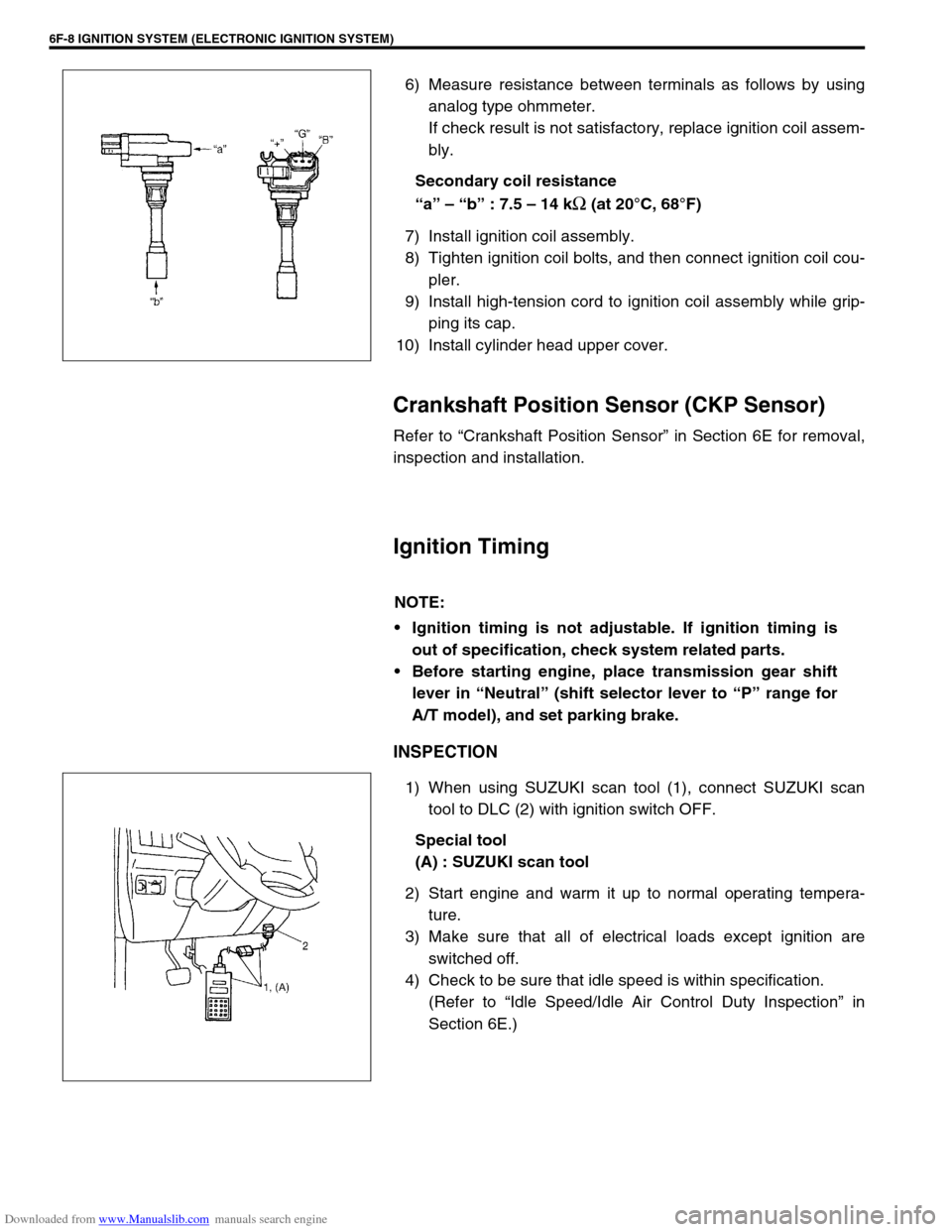

6) Measure resistance between terminals as follows by using

analog type ohmmeter.

If check result is not satisfactory, replace ignition coil assem-

bly.

Secondary coil resistance

“a” – “b” : 7.5 – 14 k

Ω (at 20°C, 68°F)

7) Install ignition coil assembly.

8) Tighten ignition coil bolts, and then connect ignition coil cou-

pler.

9) Install high-tension cord to ignition coil assembly while grip-

ping its cap.

10) Install cylinder head upper cover.

Crankshaft Position Sensor (CKP Sensor)

Refer to “Crankshaft Position Sensor” in Section 6E for removal,

inspection and installation.

Ignition Timing

INSPECTION

1) When using SUZUKI scan tool (1), connect SUZUKI scan

tool to DLC (2) with ignition switch OFF.

Special tool

(A) : SUZUKI scan tool

2) Start engine and warm it up to normal operating tempera-

ture.

3) Make sure that all of electrical loads except ignition are

switched off.

4) Check to be sure that idle speed is within specification.

(Refer to “Idle Speed/Idle Air Control Duty Inspection” in

Section 6E.)

NOTE:

Ignition timing is not adjustable. If ignition timing is

out of specification, check system related parts.

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for

A/T model), and set parking brake.

Page 671 of 687

Downloaded from www.Manualslib.com manuals search engine 6H-4 CHARGING SYSTEM

When keeping battery on vehicle over a long period of time, follow

instructions given below.

Weekly, start the engine and run it until it reaches normal

operating temperature with engine speed of 2,000 to 3,000

rpm. Make sure all electric switches are off before storing the

vehicle.

Recharge the battery twice a month to prevent it from dis-

charging excessively. This is especially important when

ambient temperature is low.

The battery discharges even when it is not used, while vehi-

cles are being stored. Battery electrolyte can freeze and bat-

tery case can crack at cold ambient condition if battery is not

properly charged.

2) Keep the battery cable connections clean.

The cable connections, particularly at the positive (+) termi-

nal post, tend to become corroded. The product of corrosion,

or rust, on the mating faces of conductors resists the flow of

current.

Clean the terminals and fittings periodically to ensure good

metal-to-metal contact, and grease the connections after

each cleaning to protect them against rusting.

3) Be always in the know as to the state of charge of the bat-

tery. The simplest way to tell the state of charge is to carry

out a hydrometer test. The hydrometer is an instrument for

measuring the specific gravity (S.G.) of the battery electro-

lyte. The S.G. of the electrolyte is indicative of the state of

charge. Refer to “HYDROMETER TEST” in this section.

Generator

The generator is a small and high performance type with an IC regulator incorporated.

The internal components are connected electrically as shown below figure.

The generator features are as follows:

Solid state regulator is mounted inside the generator.

All regulator components are enclosed into a solid mold.

This unit along with the brush holder assembly is attached to the rear housing.

The IC regulator uses integrated circuits and controls the voltage produced by the generator, and the volt-

age setting cannot be adjusted.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication. Two

brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal con-

ditions will provide long period of attention-free service.

The stator windings are assembled on the inside of a laminated core that forms part of the generator frame.

A condenser mounted in the rear housing suppresses radio noise.