piston SUZUKI JIMNY 2005 3.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 544 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-63

8) Install guide hose (1) over threads of rod bolts.

This prevents damage to bearing journal and rod bolt

threads when removing connecting rod.

9) Decarbon top of cylinder bore before removing piston from

cylinder.

10) Push piston and connecting rod assembly out through the

top of cylinder bore.

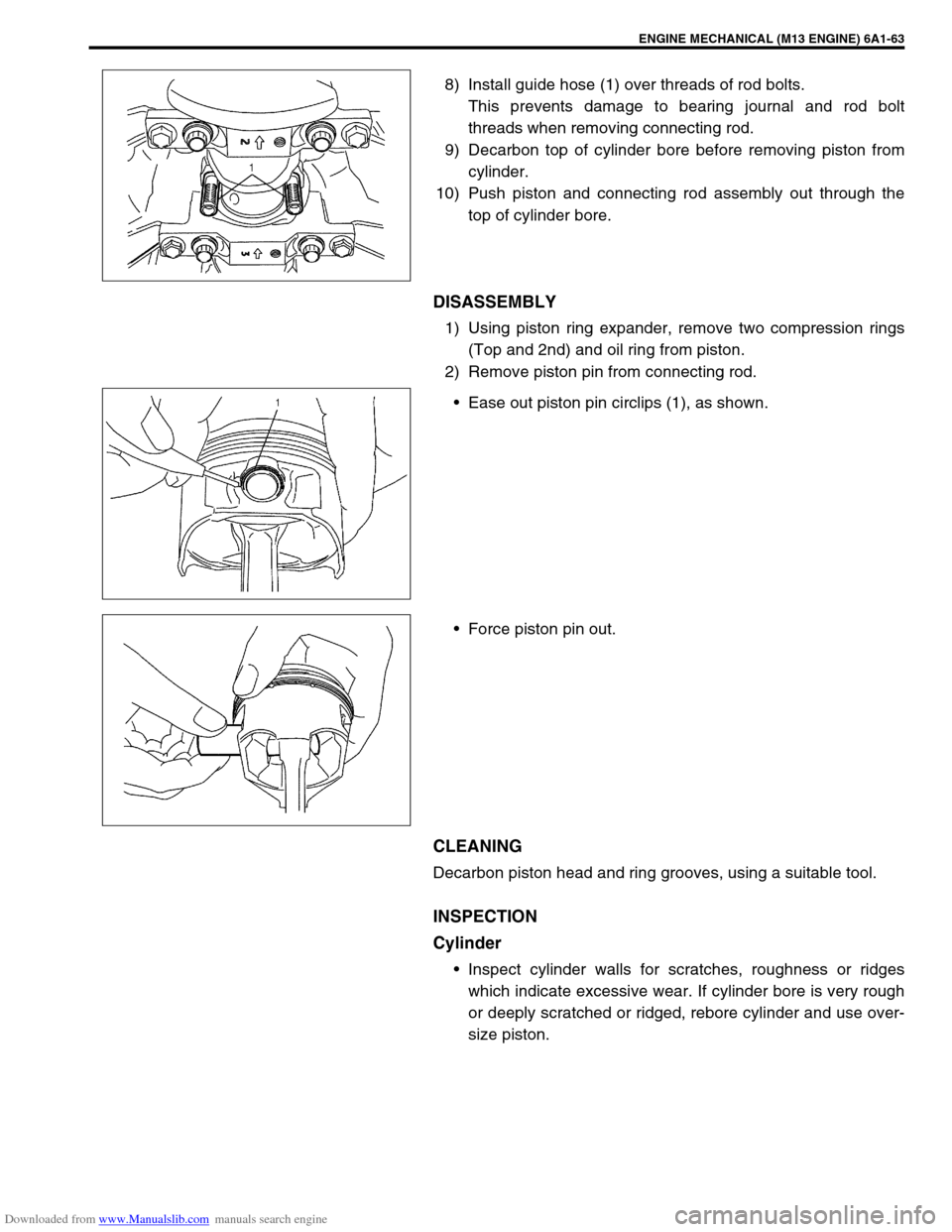

DISASSEMBLY

1) Using piston ring expander, remove two compression rings

(Top and 2nd) and oil ring from piston.

2) Remove piston pin from connecting rod.

Ease out piston pin circlips (1), as shown.

Force piston pin out.

CLEANING

Decarbon piston head and ring grooves, using a suitable tool.

INSPECTION

Cylinder

Inspect cylinder walls for scratches, roughness or ridges

which indicate excessive wear. If cylinder bore is very rough

or deeply scratched or ridged, rebore cylinder and use over-

size piston.

Page 545 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-64 ENGINE MECHANICAL (M13 ENGINE)

Using a cylinder gauge (1), measure cylinder bore in thrust

and axial directions at two positions (βaβ and βbβ) as shown in

figure.

If any of the following conditions is noted, rebore cylinder.

1) Cylinder bore dia. exceeds limit.

2) Difference of measurements at two positions exceeds taper

limit.

3) Difference between thrust and axial measurements exceeds

out-of-round limit.

Limit on cylinder bore diameter

78.114 mm (3.073 in.)

Limit on taper and out-of-round for cylinder

0.10 mm (0.004 in.)

Pistons

Inspect piston for faults, cracks or other damaged.

Damaged or faulty piston should be replaced.

Piston diameter:

As indicated in figure, piston diameter should be measured

at a position 19.5 mm (0.77 in.) from piston skirt end in the

direction perpendicular to piston pin.

Piston diameter specification NOTE:

If any one of four cylinders has to be rebored, rebore all

four to the same next oversize. This is necessary for the

sake of uniformity and balance.

βaβ : 50 mm (1.96 in.)

βbβ : 95 mm (3.74 in.)

Standard size77.953 β 77.968 mm

(3.0690 β 3.0696 in.)

Oversize

0.50 mm (0.0196 in.)78.453 β 78.468 mm

(3.0887 β 3.0893 in.)

βaβ : 19.5 mm (0.77 in.)

Page 546 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-65

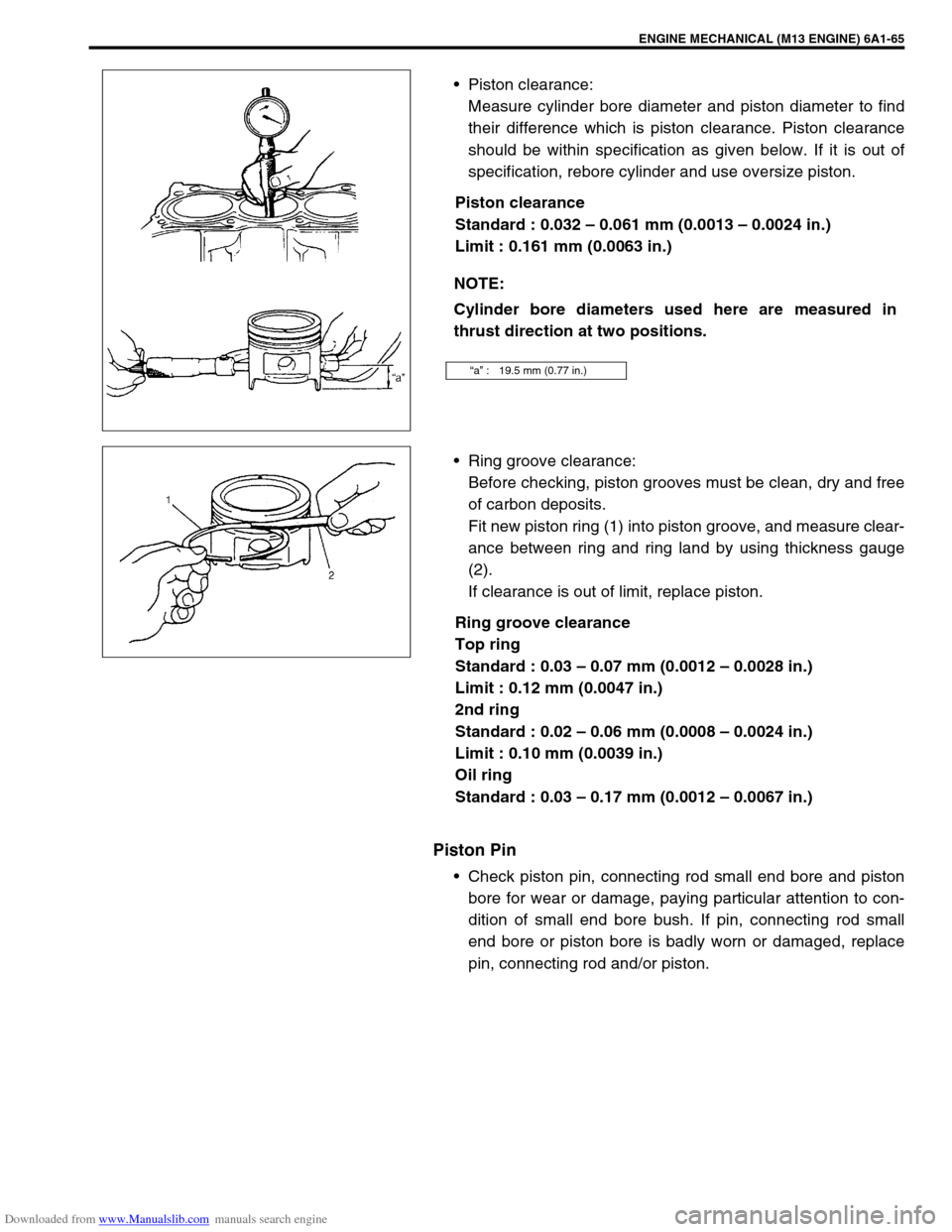

Piston clearance:

Measure cylinder bore diameter and piston diameter to find

their difference which is piston clearance. Piston clearance

should be within specification as given below. If it is out of

specification, rebore cylinder and use oversize piston.

Piston clearance

Standard : 0.032 β 0.061 mm (0.0013 β 0.0024 in.)

Limit : 0.161 mm (0.0063 in.)

Ring groove clearance:

Before checking, piston grooves must be clean, dry and free

of carbon deposits.

Fit new piston ring (1) into piston groove, and measure clear-

ance between ring and ring land by using thickness gauge

(2).

If clearance is out of limit, replace piston.

Ring groove clearance

Top ring

Standard : 0.03 β 0.07 mm (0.0012 β 0.0028 in.)

Limit : 0.12 mm (0.0047 in.)

2nd ring

Standard : 0.02 β 0.06 mm (0.0008 β 0.0024 in.)

Limit : 0.10 mm (0.0039 in.)

Oil ring

Standard : 0.03 β 0.17 mm (0.0012 β 0.0067 in.)

Piston Pin

Check piston pin, connecting rod small end bore and piston

bore for wear or damage, paying particular attention to con-

dition of small end bore bush. If pin, connecting rod small

end bore or piston bore is badly worn or damaged, replace

pin, connecting rod and/or piston. NOTE:

Cylinder bore diameters used here are measured in

thrust direction at two positions.

βaβ : 19.5 mm (0.77 in.)

Page 547 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-66 ENGINE MECHANICAL (M13 ENGINE)

Piston pin clearance:

Check piston pin clearance in small end and piston. Replace

connecting rod and/or piston if its small end is badly worn or

damaged or if measured clearance exceeds limit.

Piston pin clearance in connecting rod small end

0.003 β 0.014 mm (0.0001 β 0.0006 in.)

Piston pin clearance in piston

0.006 β 0.017 mm (0.00024 β 0.00067 in.)

Small-end bore for connecting rod

20.003 β 20.011 mm (0.7875 β 0.7878 in.)

Piston pin diameter

19.997 β 20.000 mm (0.7873 β 0.7874 in.)

Piston bore

20.006 β 20.014 mm (0.7876 β 0.7880 in.)

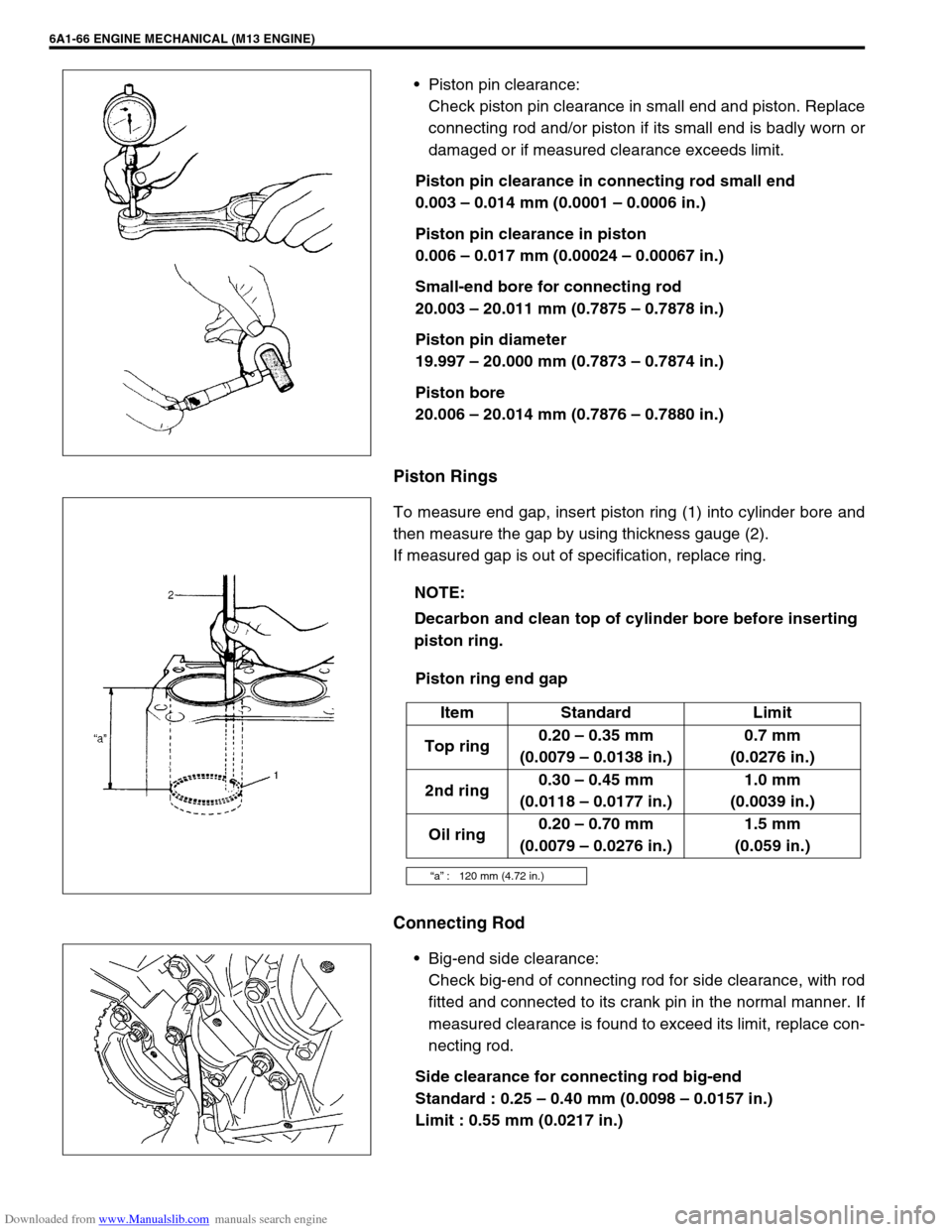

Piston Rings

To measure end gap, insert piston ring (1) into cylinder bore and

then measure the gap by using thickness gauge (2).

If measured gap is out of specification, replace ring.

Piston ring end gap

Connecting Rod

Big-end side clearance:

Check big-end of connecting rod for side clearance, with rod

fitted and connected to its crank pin in the normal manner. If

measured clearance is found to exceed its limit, replace con-

necting rod.

Side clearance for connecting rod big-end

Standard : 0.25 β 0.40 mm (0.0098 β 0.0157 in.)

Limit : 0.55 mm (0.0217 in.)

NOTE:

Decarbon and clean top of cylinder bore before inserting

piston ring.

Item Standard Limit

Top ring0.20 β 0.35 mm

(0.0079 β 0.0138 in.)0.7 mm

(0.0276 in.)

2nd ring0.30 β 0.45 mm

(0.0118 β 0.0177 in.)1.0 mm

(0.0039 in.)

Oil ring0.20 β 0.70 mm

(0.0079 β 0.0276 in.)1.5 mm

(0.059 in.)

βaβ : 120 mm (4.72 in.)

Page 550 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-69

6) If clearance can not be brought to within its limit even by

using a new standard size bearing, regrind crankpin to

undersize and use 0.25 mm undersize bearing.

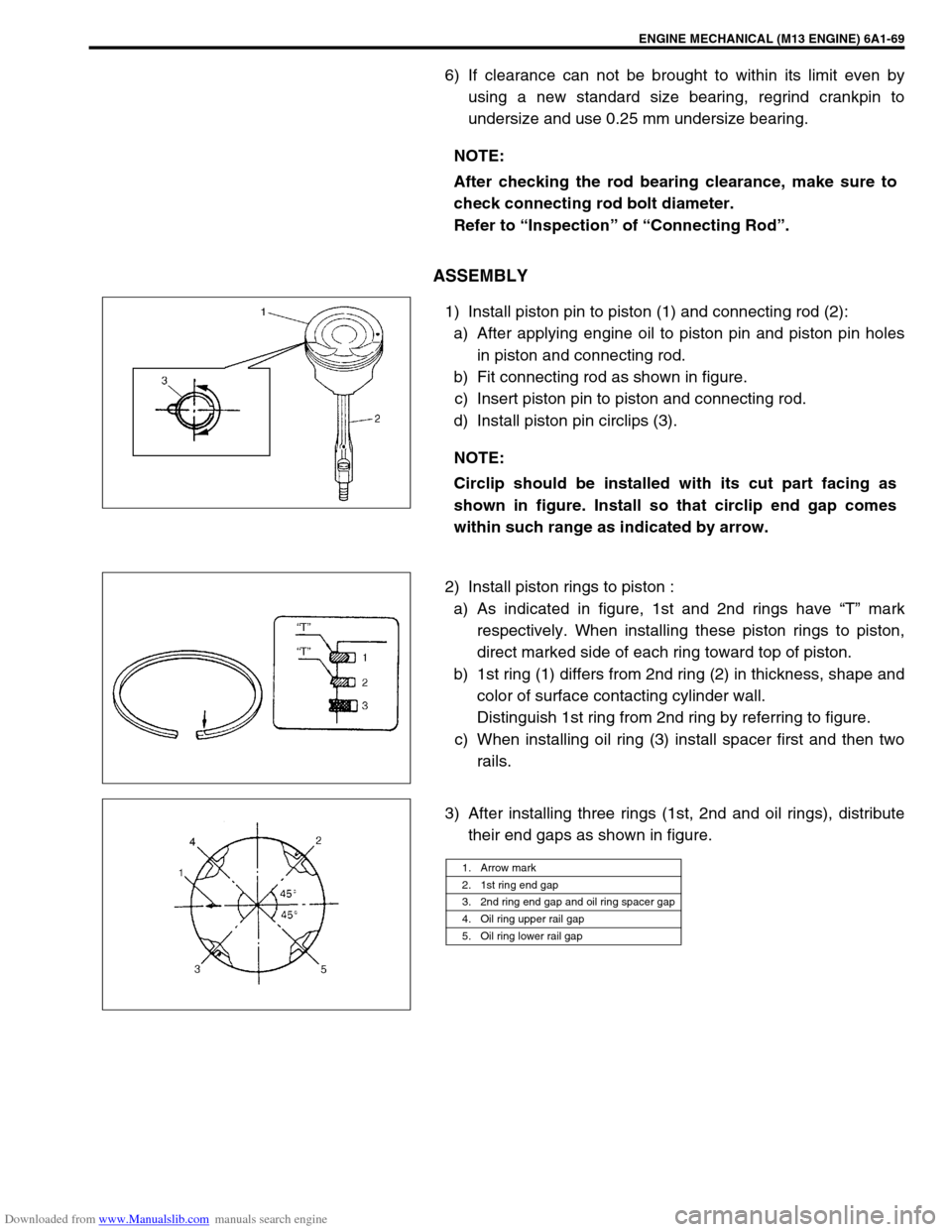

ASSEMBLY

1) Install piston pin to piston (1) and connecting rod (2):

a) After applying engine oil to piston pin and piston pin holes

in piston and connecting rod.

b) Fit connecting rod as shown in figure.

c) Insert piston pin to piston and connecting rod.

d) Install piston pin circlips (3).

2) Install piston rings to piston :

a) As indicated in figure, 1st and 2nd rings have βTβ mark

respectively. When installing these piston rings to piston,

direct marked side of each ring toward top of piston.

b) 1st ring (1) differs from 2nd ring (2) in thickness, shape and

color of surface contacting cylinder wall.

Distinguish 1st ring from 2nd ring by referring to figure.

c) When installing oil ring (3) install spacer first and then two

rails.

3) After installing three rings (1st, 2nd and oil rings), distribute

their end gaps as shown in figure. NOTE:

After checking the rod bearing clearance, make sure to

check connecting rod bolt diameter.

Refer to βInspectionβ of βConnecting Rodβ.

NOTE:

Circlip should be installed with its cut part facing as

shown in figure. Install so that circlip end gap comes

within such range as indicated by arrow.

1. Arrow mark

2. 1st ring end gap

3. 2nd ring end gap and oil ring spacer gap

4. Oil ring upper rail gap

5. Oil ring lower rail gap

Page 551 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-70 ENGINE MECHANICAL (M13 ENGINE)

INSTALLATION

1) Apply engine oil to pistons, rings, cylinder walls, connecting

rod bearings and crankpins.

2) Install guide hoses (1) over connecting rod bolts.

These guide hoses protect crank pin and threads of rod bolt

from damage during installation of connecting rod and piston

assembly.

3) When installing piston and connecting rod assembly into cyl-

inder bore, point front mark on piston head to crankshaft pul-

ley side.

4) Install piston and connecting rod assembly into cylinder

bore. Use special tool (Piston ring compressor) to compress

rings. Guide connecting rod into place on crankshaft.

Using a hammer handle, tap piston head to install piston into

bore. Hold ring compressor firmly against cylinder block until

all piston rings have entered cylinder bore.

Special tool

(A) : 09916-77310 NOTE:

Do not apply oil between connecting rod and bearing or

between bearing cap and bearing.

A : Crankshaft pulley side

B : Flywheel side

Page 561 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-80 ENGINE MECHANICAL (M13 ENGINE)

REMOVAL

1) Remove engine assembly from vehicle as previously out-

lined.

2) Remove clutch cover, clutch disc and flywheel (drive plate

for A/T) by using special tool.

Special tool

(A) : 09924-17810

3) Remove the following parts from engine as previously out-

lined.

Oil pan and oil pump strainer

Intake manifold and exhaust manifold

Cylinder head cover

Timing chain cover

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Camshaft, tappet and shim

Cylinder head assembly

Piston and connecting rod

4) Remove rear oil seal housing (1).

5) Loosen bearing cap No.1 and No.2 bolts in such order as

indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

Page 569 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-88 ENGINE MECHANICAL (M13 ENGINE)

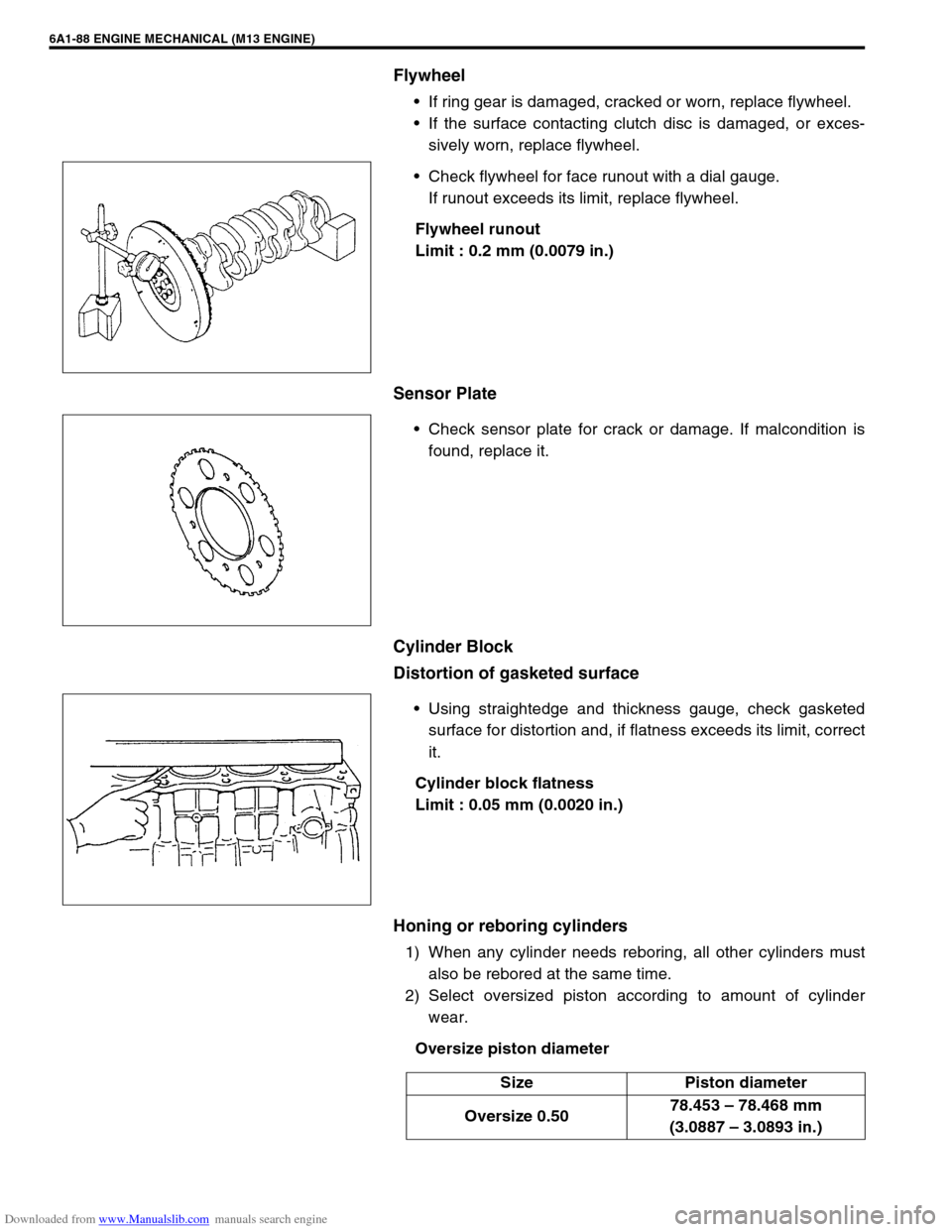

Flywheel

If ring gear is damaged, cracked or worn, replace flywheel.

If the surface contacting clutch disc is damaged, or exces-

sively worn, replace flywheel.

Check flywheel for face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel runout

Limit : 0.2 mm (0.0079 in.)

Sensor Plate

Check sensor plate for crack or damage. If malcondition is

found, replace it.

Cylinder Block

Distortion of gasketed surface

Using straightedge and thickness gauge, check gasketed

surface for distortion and, if flatness exceeds its limit, correct

it.

Cylinder block flatness

Limit : 0.05 mm (0.0020 in.)

Honing or reboring cylinders

1) When any cylinder needs reboring, all other cylinders must

also be rebored at the same time.

2) Select oversized piston according to amount of cylinder

wear.

Oversize piston diameter

Size Piston diameter

Oversize 0.5078.453 β 78.468 mm

(3.0887 β 3.0893 in.)

Page 570 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-89

3) Using micrometer, measure piston diameter.

Measurement position for piston diameter

βaβ : 19.5 mm (0.77 in.)

4) Calculate cylinder bore diameter to be rebored as follows.

D = A + B β C

D : Cylinder bore diameter to be rebored.

A : Piston diameter as measured.

B : Piston clearance = 0.02 β0.04 mm (0.0008 β 0.0016 in.)

C : Allowance for honing = 0.02 mm (0.0008 in.)

5) Rebore and hone cylinder to calculated dimension.

6) Measure piston clearance after honing.

NOTE:

Before reboring, install all main bearing caps in place

and tighten to specification to avoid distortion of bearing

bores.

Page 571 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-90 ENGINE MECHANICAL (M13 ENGINE)

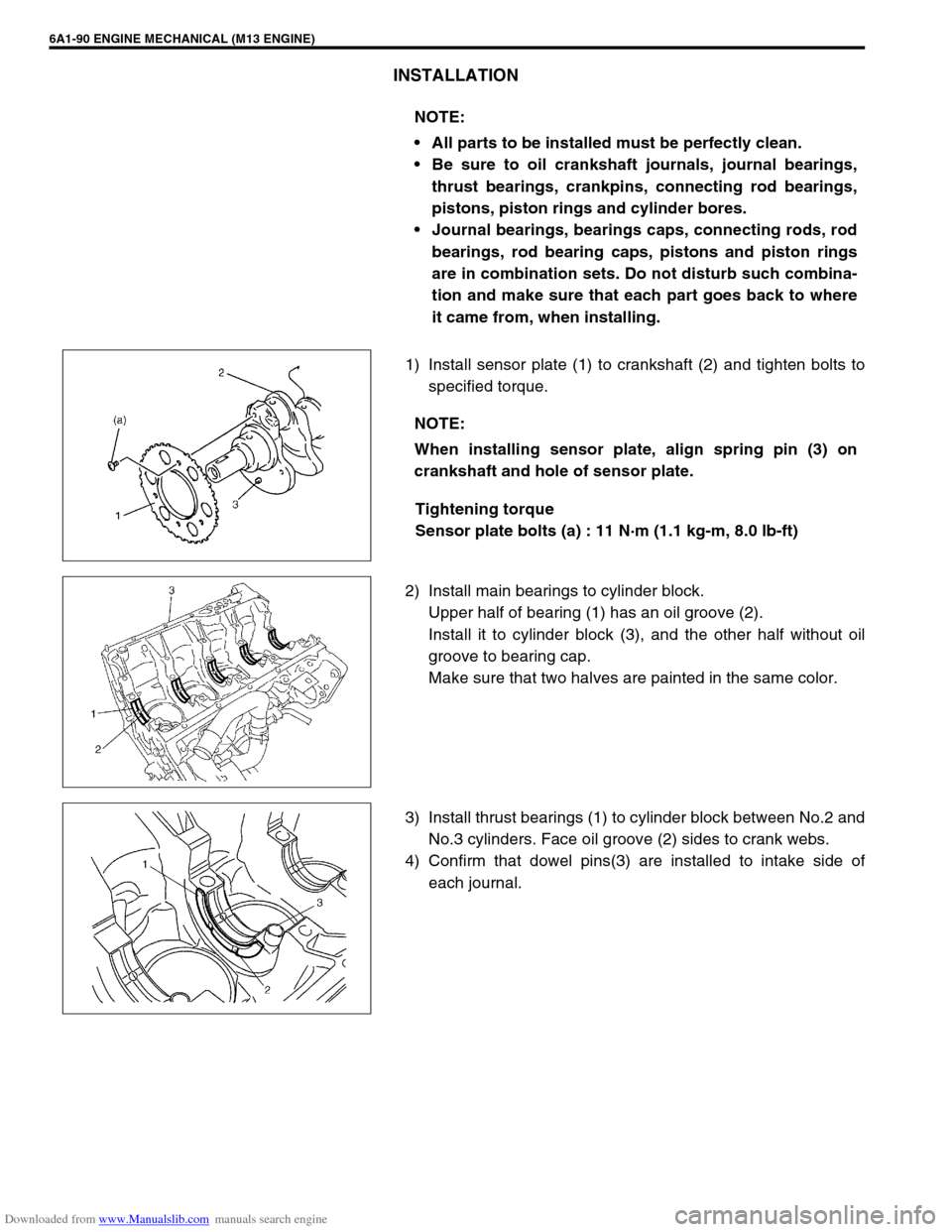

INSTALLATION

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to

specified torque.

Tightening torque

Sensor plate bolts (a) : 11 NΒ·m (1.1 kg-m, 8.0 lb-ft)

2) Install main bearings to cylinder block.

Upper half of bearing (1) has an oil groove (2).

Install it to cylinder block (3), and the other half without oil

groove to bearing cap.

Make sure that two halves are painted in the same color.

3) Install thrust bearings (1) to cylinder block between No.2 and

No.3 cylinders. Face oil groove (2) sides to crank webs.

4) Confirm that dowel pins(3) are installed to intake side of

each journal. NOTE:

All parts to be installed must be perfectly clean.

Be sure to oil crankshaft journals, journal bearings,

thrust bearings, crankpins, connecting rod bearings,

pistons, piston rings and cylinder bores.

Journal bearings, bearings caps, connecting rods, rod

bearings, rod bearing caps, pistons and piston rings

are in combination sets. Do not disturb such combina-

tion and make sure that each part goes back to where

it came from, when installing.

NOTE:

When installing sensor plate, align spring pin (3) on

crankshaft and hole of sensor plate.