coolant level SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 39 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-8 MAINTENANCE AND LUBRICATION

6) Replenish oil until oil level is brought to FULL level mark on

dipstick. (oil pan and oil filter capacity). The filler inlet is at

the top of the cylinder head cover.

It is recommended to use engine oil of SE, SF, SG, SH, SJ or

SL grade.

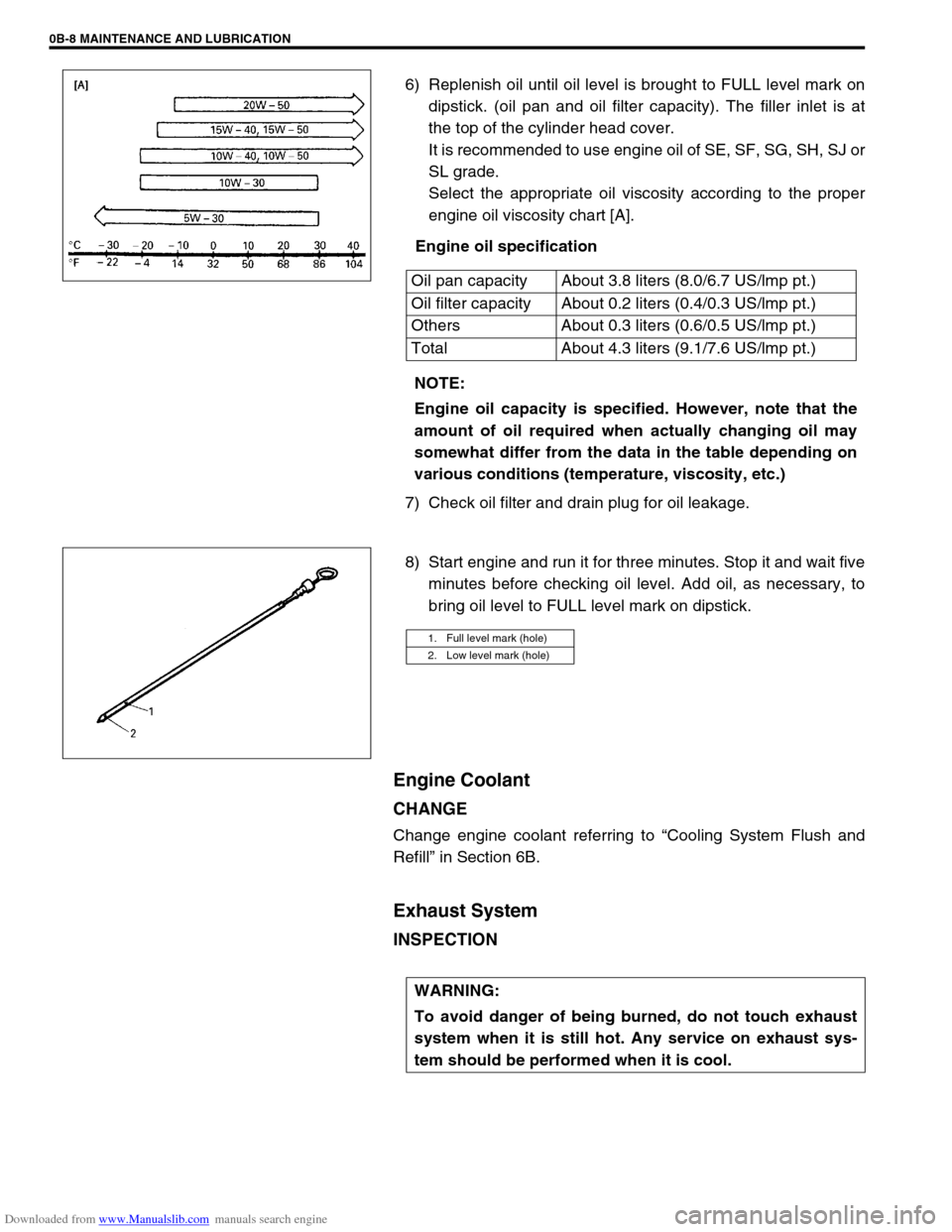

Select the appropriate oil viscosity according to the proper

engine oil viscosity chart [A].

Engine oil specification

7) Check oil filter and drain plug for oil leakage.

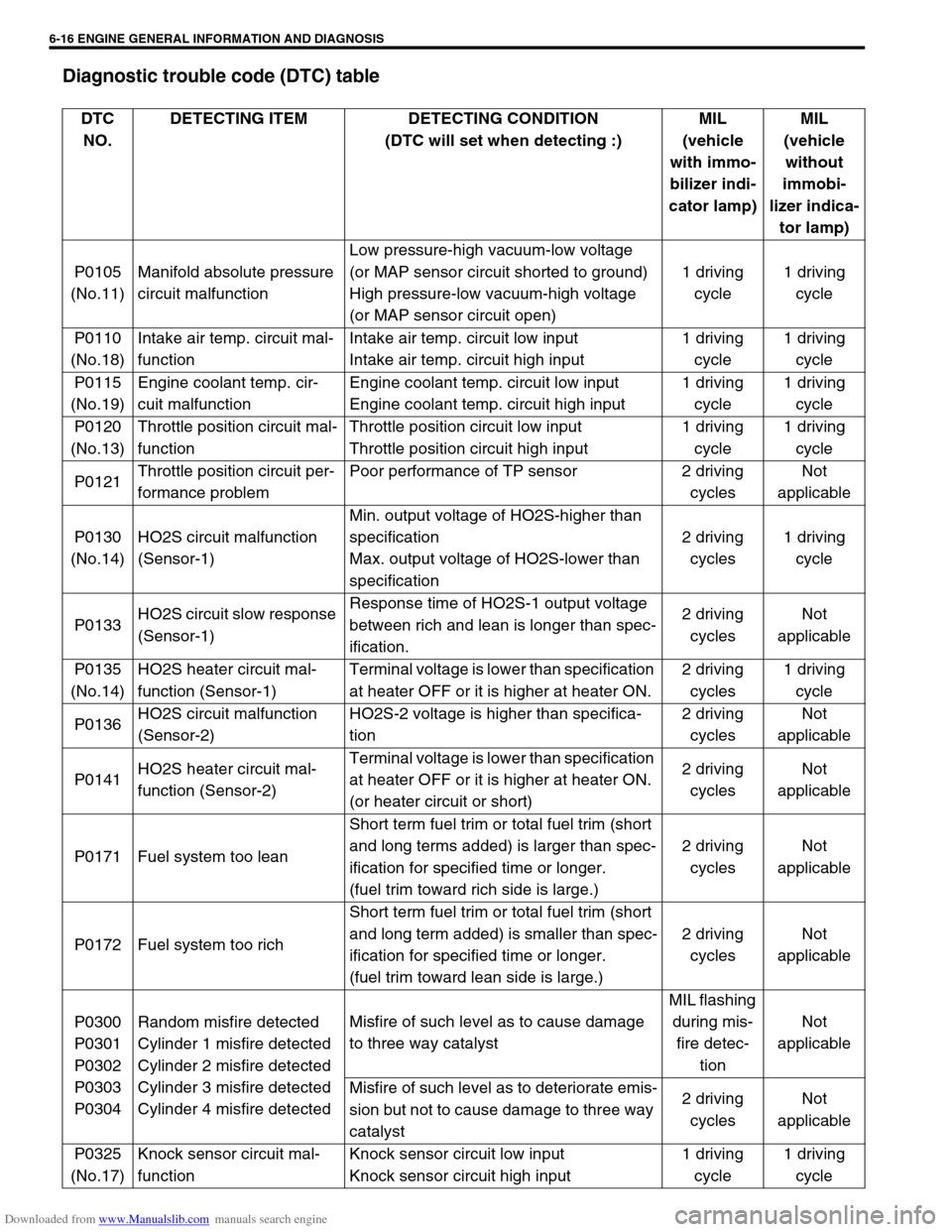

8) Start engine and run it for three minutes. Stop it and wait five

minutes before checking oil level. Add oil, as necessary, to

bring oil level to FULL level mark on dipstick.

Engine Coolant

CHANGE

Change engine coolant referring to “Cooling System Flush and

Refill” in Section 6B.

Exhaust System

INSPECTION

Oil pan capacity About 3.8 liters (8.0/6.7 US/lmp pt.)

Oil filter capacity About 0.2 liters (0.4/0.3 US/lmp pt.)

Others About 0.3 liters (0.6/0.5 US/lmp pt.)

Total About 4.3 liters (9.1/7.6 US/lmp pt.)

NOTE:

Engine oil capacity is specified. However, note that the

amount of oil required when actually changing oil may

somewhat differ from the data in the table depending on

various conditions (temperature, viscosity, etc.)

1. Full level mark (hole)

2. Low level mark (hole)

WARNING:

To avoid danger of being burned, do not touch exhaust

system when it is still hot. Any service on exhaust sys-

tem should be performed when it is cool.

Page 373 of 687

Downloaded from www.Manualslib.com manuals search engine 6-16 ENGINE GENERAL INFORMATION AND DIAGNOSIS

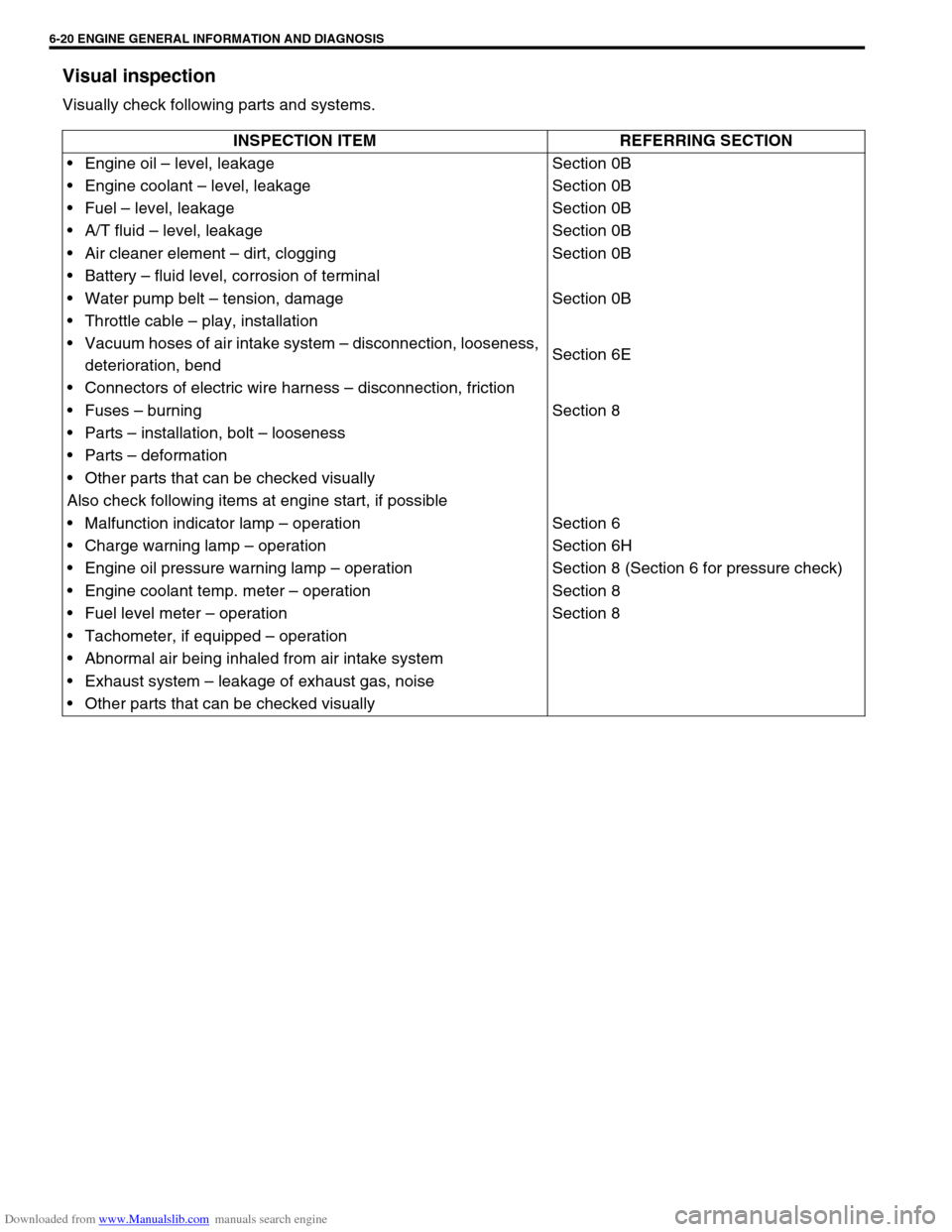

Diagnostic trouble code (DTC) table

DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

P0105

(No.11)Manifold absolute pressure

circuit malfunctionLow pressure-high vacuum-low voltage

(or MAP sensor circuit shorted to ground)

High pressure-low vacuum-high voltage

(or MAP sensor circuit open)1 driving

cycle1 driving

cycle

P0110

(No.18)Intake air temp. circuit mal-

functionIntake air temp. circuit low input

Intake air temp. circuit high input1 driving

cycle1 driving

cycle

P0115

(No.19)Engine coolant temp. cir-

cuit malfunctionEngine coolant temp. circuit low input

Engine coolant temp. circuit high input1 driving

cycle1 driving

cycle

P0120

(No.13)Throttle position circuit mal-

functionThrottle position circuit low input

Throttle position circuit high input1 driving

cycle1 driving

cycle

P0121Throttle position circuit per-

formance problemPoor performance of TP sensor 2 driving

cyclesNot

applicable

P0130

(No.14)HO2S circuit malfunction

(Sensor-1)Min. output voltage of HO2S-higher than

specification

Max. output voltage of HO2S-lower than

specification2 driving

cycles1 driving

cycle

P0133HO2S circuit slow response

(Sensor-1)Response time of HO2S-1 output voltage

between rich and lean is longer than spec-

ification.2 driving

cyclesNot

applicable

P0135

(No.14)HO2S heater circuit mal-

function (Sensor-1)Terminal voltage is lower than specification

at heater OFF or it is higher at heater ON.2 driving

cycles1 driving

cycle

P0136HO2S circuit malfunction

(Sensor-2)HO2S-2 voltage is higher than specifica-

tion2 driving

cyclesNot

applicable

P0141HO2S heater circuit mal-

function (Sensor-2)Terminal voltage is lower than specification

at heater OFF or it is higher at heater ON.

(or heater circuit or short)2 driving

cyclesNot

applicable

P0171 Fuel system too leanShort term fuel trim or total fuel trim (short

and long terms added) is larger than spec-

ification for specified time or longer.

(fuel trim toward rich side is large.)2 driving

cyclesNot

applicable

P0172 Fuel system too richShort term fuel trim or total fuel trim (short

and long term added) is smaller than spec-

ification for specified time or longer.

(fuel trim toward lean side is large.)2 driving

cyclesNot

applicable

P0300

P0301

P0302

P0303

P0304Random misfire detected

Cylinder 1 misfire detected

Cylinder 2 misfire detected

Cylinder 3 misfire detected

Cylinder 4 misfire detectedMisfire of such level as to cause damage

to three way catalystMIL flashing

during mis-

fire detec-

tionNot

applicable

Misfire of such level as to deteriorate emis-

sion but not to cause damage to three way

catalyst2 driving

cyclesNot

applicable

P0325

(No.17)Knock sensor circuit mal-

functionKnock sensor circuit low input

Knock sensor circuit high input1 driving

cycle1 driving

cycle

Page 377 of 687

Downloaded from www.Manualslib.com manuals search engine 6-20 ENGINE GENERAL INFORMATION AND DIAGNOSIS

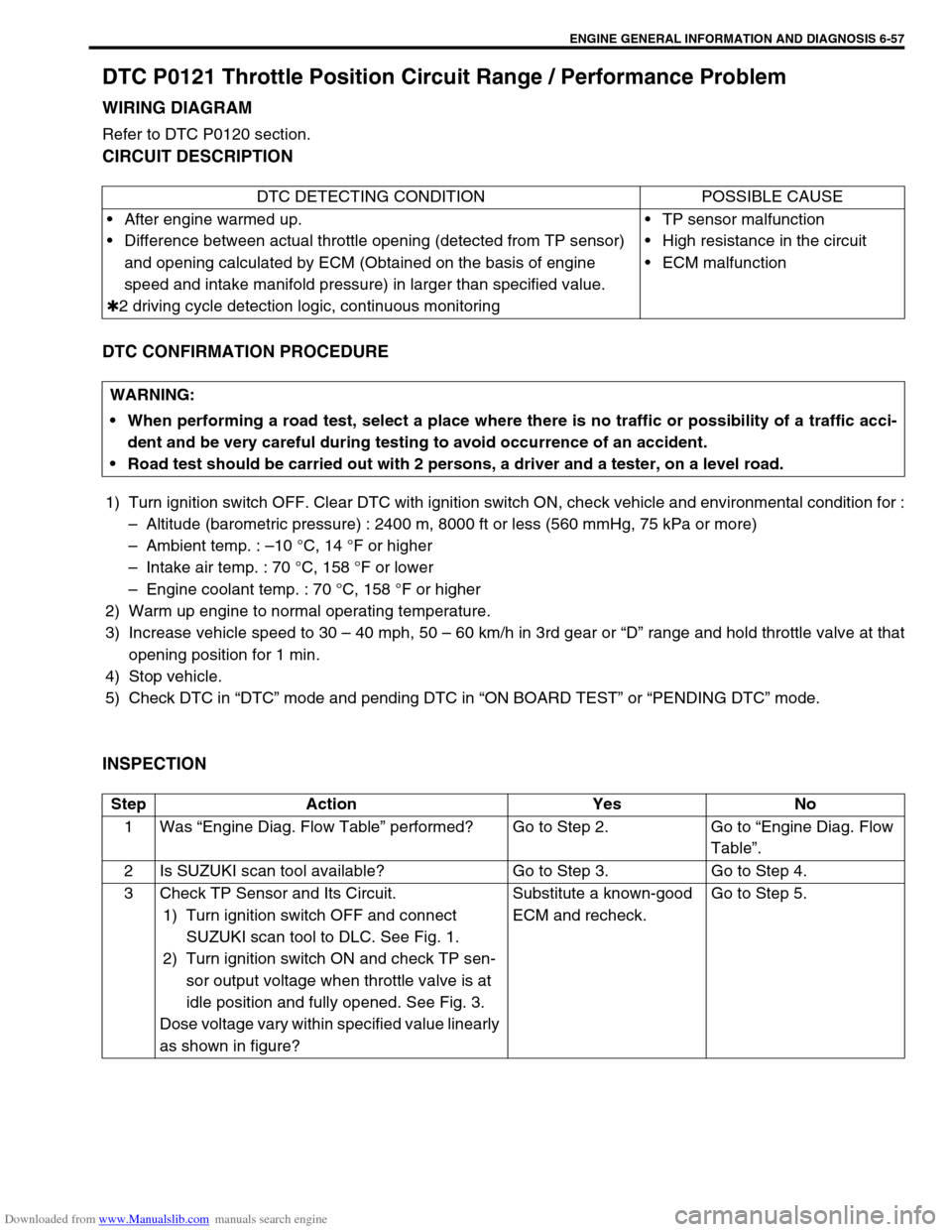

Visual inspection

Visually check following parts and systems.

INSPECTION ITEM REFERRING SECTION

Engine oil – level, leakage Section 0B

Engine coolant – level, leakage Section 0B

Fuel – level, leakage Section 0B

A/T fluid – level, leakage Section 0B

Air cleaner element – dirt, clogging Section 0B

Battery – fluid level, corrosion of terminal

Water pump belt – tension, damage Section 0B

Throttle cable – play, installation

Section 6E Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend

Connectors of electric wire harness – disconnection, friction

Fuses – burning Section 8

Parts – installation, bolt – looseness

Parts – deformation

Other parts that can be checked visually

Also check following items at engine start, if possible

Malfunction indicator lamp – operation Section 6

Charge warning lamp – operation Section 6H

Engine oil pressure warning lamp – operation Section 8 (Section 6 for pressure check)

Engine coolant temp. meter – operation Section 8

Fuel level meter – operation Section 8

Tachometer, if equipped – operation

Abnormal air being inhaled from air intake system

Exhaust system – leakage of exhaust gas, noise

Other parts that can be checked visually

Page 414 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-57

DTC P0121 Throttle Position Circuit Range / Performance Problem

WIRING DIAGRAM

Refer to DTC P0120 section.

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF. Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–Engine coolant temp. : 70 °C, 158 °F or higher

2) Warm up engine to normal operating temperature.

3) Increase vehicle speed to 30 – 40 mph, 50 – 60 km/h in 3rd gear or “D” range and hold throttle valve at that

opening position for 1 min.

4) Stop vehicle.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

After engine warmed up.

Difference between actual throttle opening (detected from TP sensor)

and opening calculated by ECM (Obtained on the basis of engine

speed and intake manifold pressure) in larger than specified value.

✱2 driving cycle detection logic, continuous monitoringTP sensor malfunction

High resistance in the circuit

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Is SUZUKI scan tool available? Go to Step 3. Go to Step 4.

3 Check TP Sensor and Its Circuit.

1) Turn ignition switch OFF and connect

SUZUKI scan tool to DLC. See Fig. 1.

2) Turn ignition switch ON and check TP sen-

sor output voltage when throttle valve is at

idle position and fully opened. See Fig. 3.

Dose voltage vary within specified value linearly

as shown in figure?Substitute a known-good

ECM and recheck.Go to Step 5.

Page 446 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-89

DTC CONFIRMATION PROCEDURE

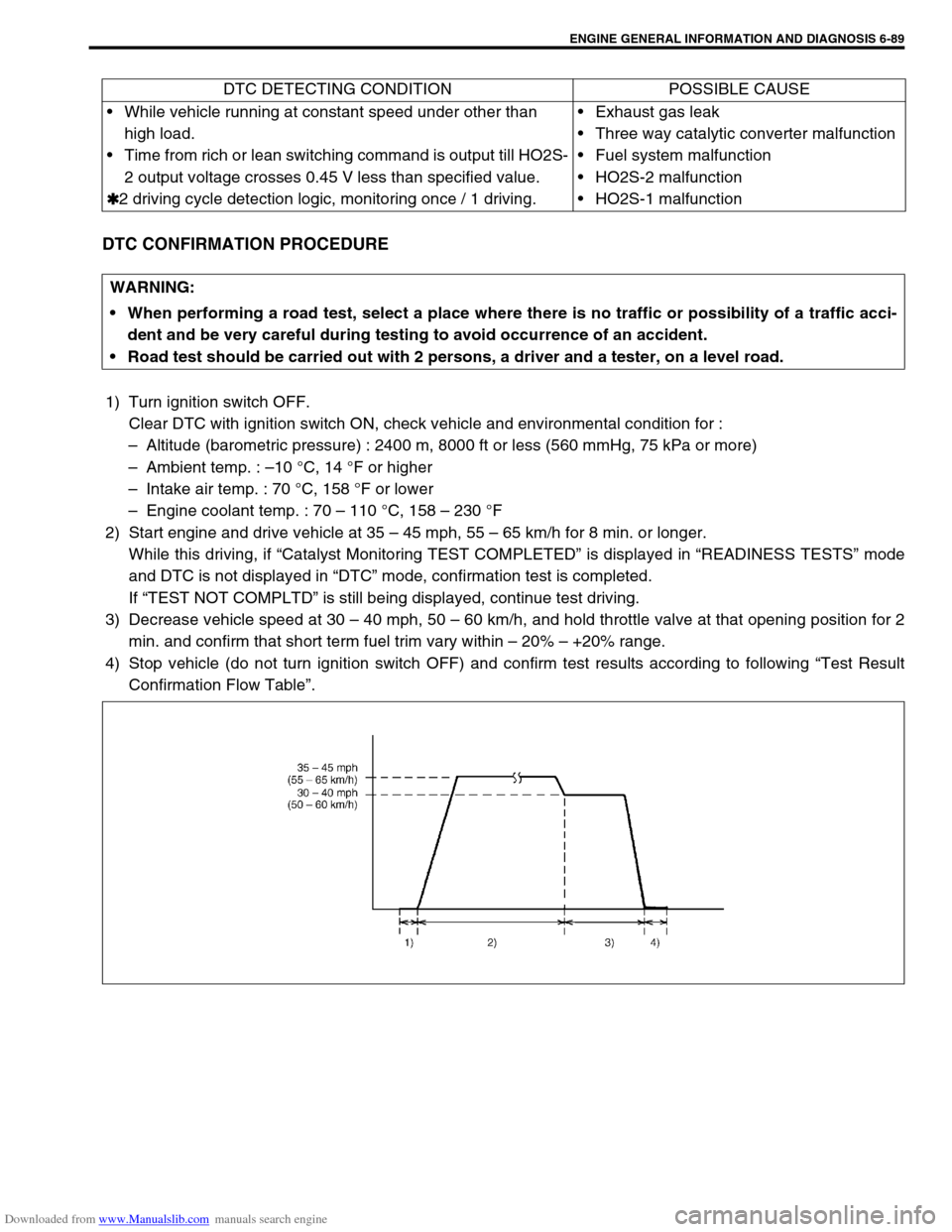

1) Turn ignition switch OFF.

Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–Engine coolant temp. : 70 – 110 °C, 158 – 230 °F

2) Start engine and drive vehicle at 35 – 45 mph, 55 – 65 km/h for 8 min. or longer.

While this driving, if “Catalyst Monitoring TEST COMPLETED” is displayed in “READINESS TESTS” mode

and DTC is not displayed in “DTC” mode, confirmation test is completed.

If “TEST NOT COMPLTD” is still being displayed, continue test driving.

3) Decrease vehicle speed at 30 – 40 mph, 50 – 60 km/h, and hold throttle valve at that opening position for 2

min. and confirm that short term fuel trim vary within – 20% – +20% range.

4) Stop vehicle (do not turn ignition switch OFF) and confirm test results according to following “Test Result

Confirmation Flow Table”. DTC DETECTING CONDITION POSSIBLE CAUSE

While vehicle running at constant speed under other than

high load.

Time from rich or lean switching command is output till HO2S-

2 output voltage crosses 0.45 V less than specified value.

✱

✱✱ ✱2 driving cycle detection logic, monitoring once / 1 driving.Exhaust gas leak

Three way catalytic converter malfunction

Fuel system malfunction

HO2S-2 malfunction

HO2S-1 malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 578 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-1

6B

SECTION 6B

ENGINE COOLING

CONTENTS

General Description ........................................6B-2

Cooling System Circulation ........................... 6B-2

Radiator Cap ................................................. 6B-3

Coolant Reservoir ......................................... 6B-3

Water Pump .................................................. 6B-4

Thermostat .................................................... 6B-4

Cooling Fan Clutch ........................................ 6B-4

Coolant (Water) Temperature Gauge............ 6B-4

Diagnosis .........................................................6B-5

Maintenance ....................................................6B-6

Coolant .......................................................... 6B-6

Coolant Level ................................................ 6B-7

Cooling System Service ................................ 6B-7Cooling System Flush and Refill ................... 6B-8

Water Pump Belt Tension ............................. 6B-9

On-Vehicle Service ....................................... 6B-10

Cooling System Component ....................... 6B-10

Coolant Draining ......................................... 6B-11

Cooling Water Pipes or Hoses .................... 6B-11

Thermostat .................................................. 6B-11

Water Pump Belt and Cooling Fan ............. 6B-13

Radiator ...................................................... 6B-14

Water Pump ................................................ 6B-15

Required Service Material ............................ 6B-17

Tightening Torque Specification ................. 6B-17

Page 580 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-3

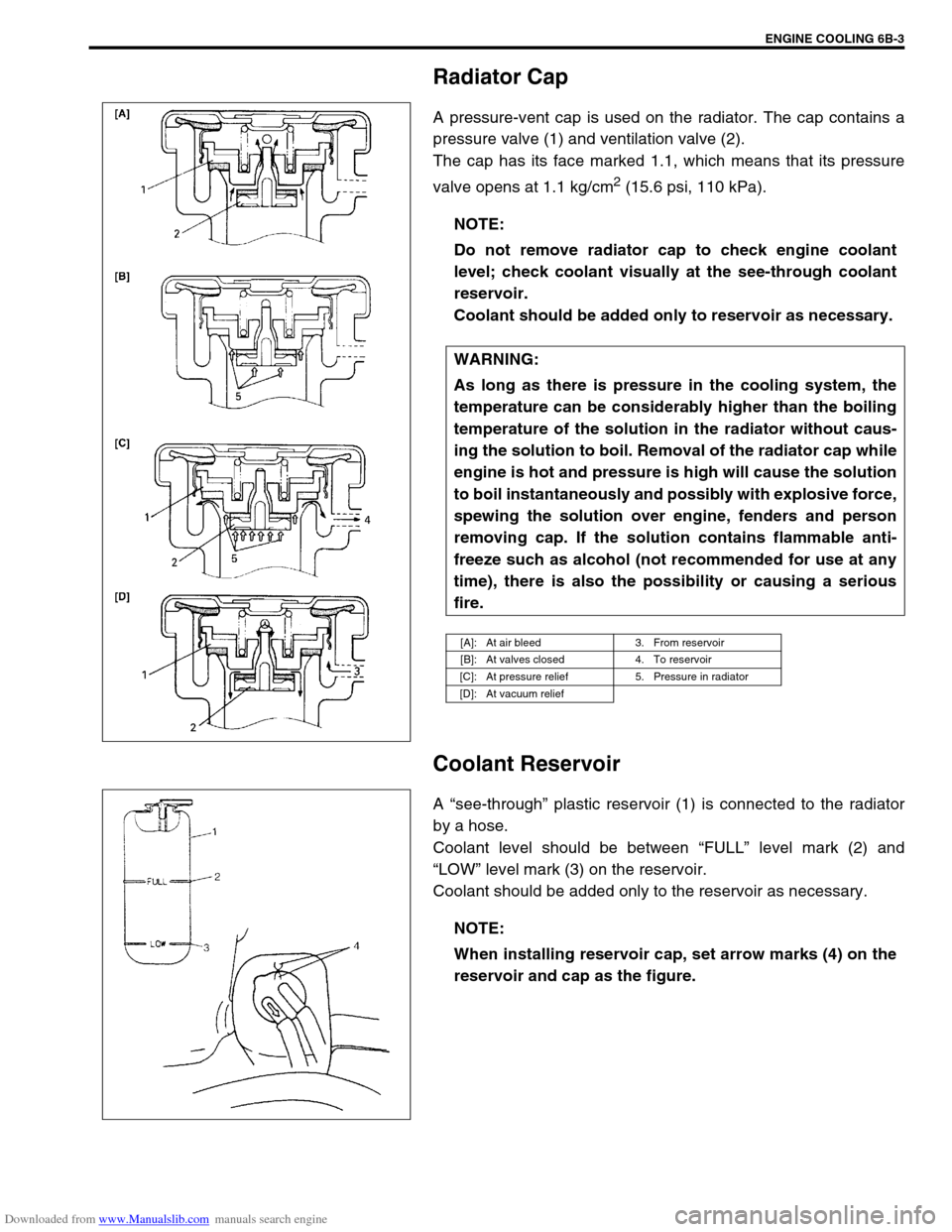

Radiator Cap

A pressure-vent cap is used on the radiator. The cap contains a

pressure valve (1) and ventilation valve (2).

The cap has its face marked 1.1, which means that its pressure

valve opens at 1.1 kg/cm

2 (15.6 psi, 110 kPa).

Coolant Reservoir

A “see-through” plastic reservoir (1) is connected to the radiator

by a hose.

Coolant level should be between “FULL” level mark (2) and

“LOW” level mark (3) on the reservoir.

Coolant should be added only to the reservoir as necessary.NOTE:

Do not remove radiator cap to check engine coolant

level; check coolant visually at the see-through coolant

reservoir.

Coolant should be added only to reservoir as necessary.

WARNING:

As long as there is pressure in the cooling system, the

temperature can be considerably higher than the boiling

temperature of the solution in the radiator without caus-

ing the solution to boil. Removal of the radiator cap while

engine is hot and pressure is high will cause the solution

to boil instantaneously and possibly with explosive force,

spewing the solution over engine, fenders and person

removing cap. If the solution contains flammable anti-

freeze such as alcohol (not recommended for use at any

time), there is also the possibility or causing a serious

fire.

[A]: At air bleed 3. From reservoir

[B]: At valves closed 4. To reservoir

[C]: At pressure relief 5. Pressure in radiator

[D]: At vacuum relief

NOTE:

When installing reservoir cap, set arrow marks (4) on the

reservoir and cap as the figure.

Page 582 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-5

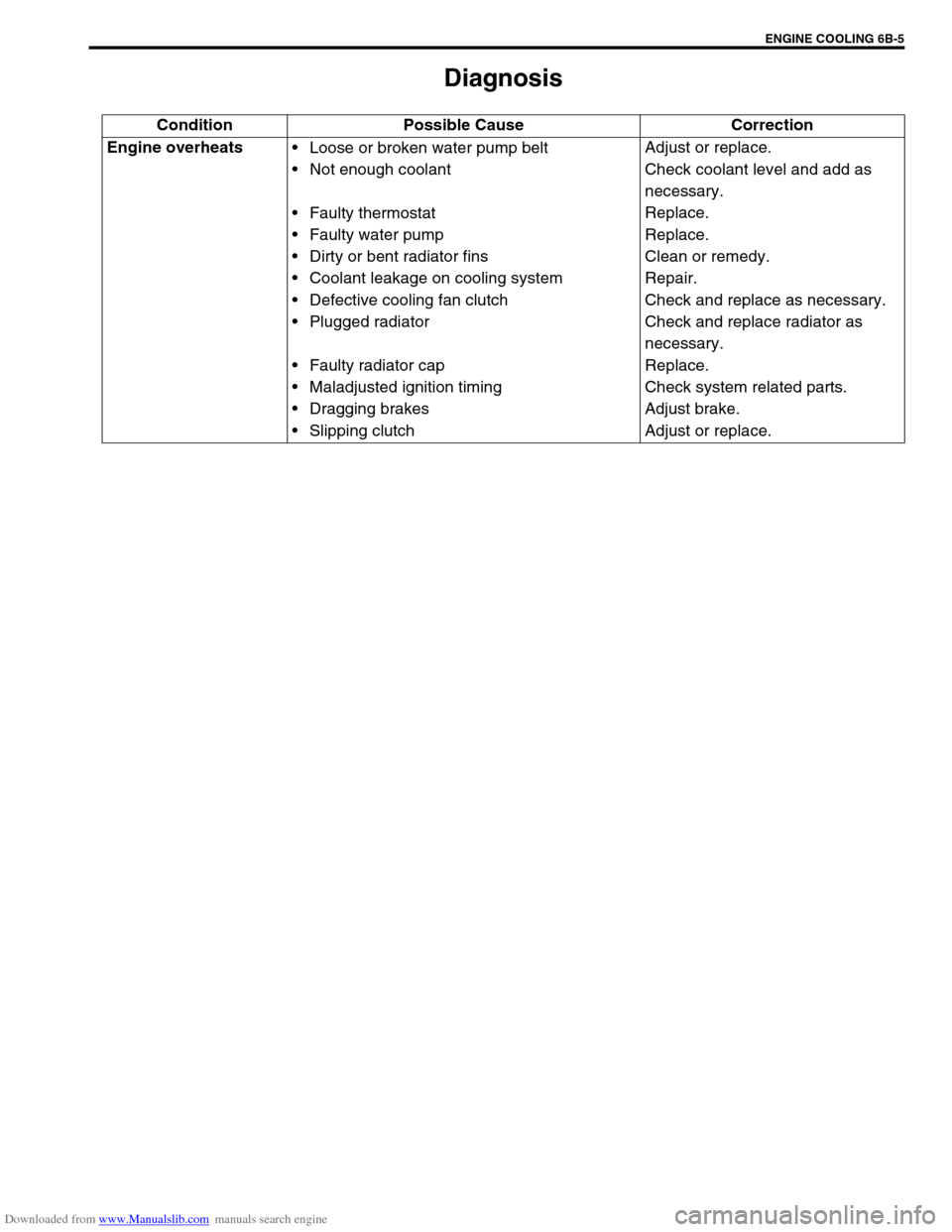

Diagnosis

Condition Possible Cause Correction

Engine overheats

Loose or broken water pump belt

Not enough coolant

Faulty thermostat

Faulty water pump

Dirty or bent radiator fins

Coolant leakage on cooling system

Defective cooling fan clutch

Plugged radiator

Faulty radiator cap

Maladjusted ignition timing

Dragging brakes

Slipping clutchAdjust or replace.

Check coolant level and add as

necessary.

Replace.

Replace.

Clean or remedy.

Repair.

Check and replace as necessary.

Check and replace radiator as

necessary.

Replace.

Check system related parts.

Adjust brake.

Adjust or replace.

Page 584 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-7

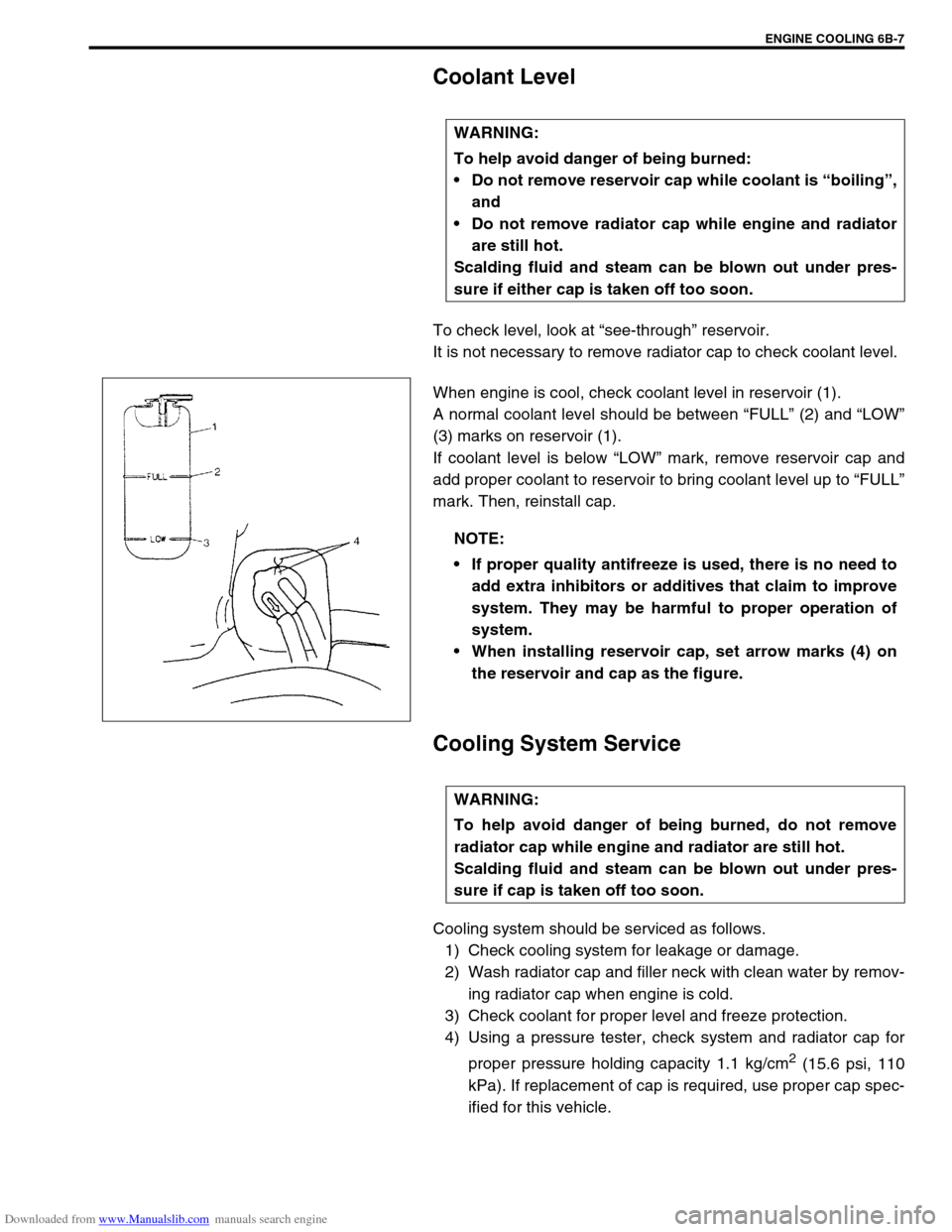

Coolant Level

To check level, look at “see-through” reservoir.

It is not necessary to remove radiator cap to check coolant level.

When engine is cool, check coolant level in reservoir (1).

A normal coolant level should be between “FULL” (2) and “LOW”

(3) marks on reservoir (1).

If coolant level is below “LOW” mark, remove reservoir cap and

add proper coolant to reservoir to bring coolant level up to “FULL”

mark. Then, reinstall cap.

Cooling System Service

Cooling system should be serviced as follows.

1) Check cooling system for leakage or damage.

2) Wash radiator cap and filler neck with clean water by remov-

ing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

4) Using a pressure tester, check system and radiator cap for

proper pressure holding capacity 1.1 kg/cm

2 (15.6 psi, 110

kPa). If replacement of cap is required, use proper cap spec-

ified for this vehicle. WARNING:

To help avoid danger of being burned:

Do not remove reservoir cap while coolant is “boiling”,

and

Do not remove radiator cap while engine and radiator

are still hot.

Scalding fluid and steam can be blown out under pres-

sure if either cap is taken off too soon.

NOTE:

If proper quality antifreeze is used, there is no need to

add extra inhibitors or additives that claim to improve

system. They may be harmful to proper operation of

system.

When installing reservoir cap, set arrow marks (4) on

the reservoir and cap as the figure.

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.

Page 585 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-8 ENGINE COOLING

5) Tighten hose clamps and inspect all hoses.

Replace hoses whenever cracked, swollen or otherwise

deteriorated.

6) Clean frontal area of radiator core.

Cooling System Flush and Refill

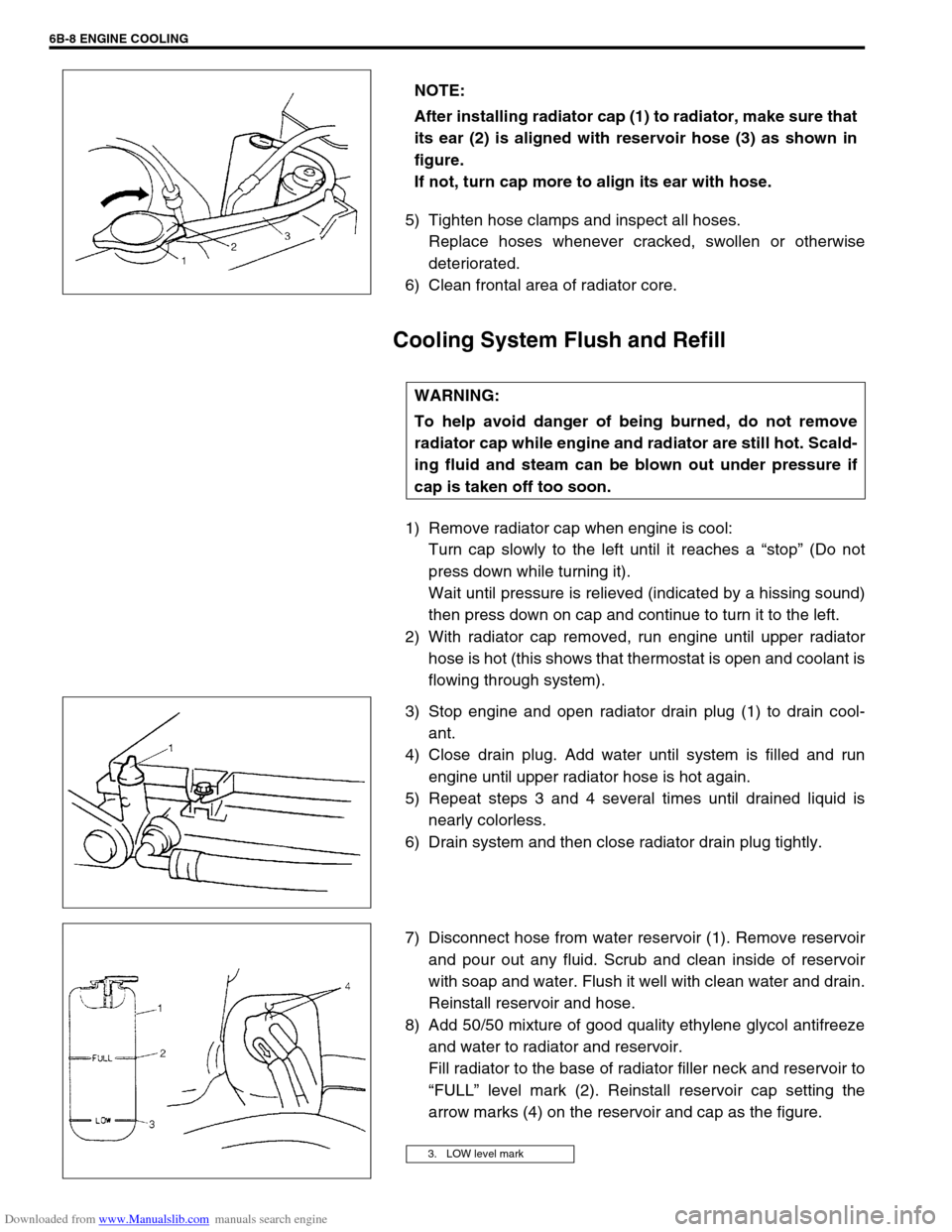

1) Remove radiator cap when engine is cool:

Turn cap slowly to the left until it reaches a “stop” (Do not

press down while turning it).

Wait until pressure is relieved (indicated by a hissing sound)

then press down on cap and continue to turn it to the left.

2) With radiator cap removed, run engine until upper radiator

hose is hot (this shows that thermostat is open and coolant is

flowing through system).

3) Stop engine and open radiator drain plug (1) to drain cool-

ant.

4) Close drain plug. Add water until system is filled and run

engine until upper radiator hose is hot again.

5) Repeat steps 3 and 4 several times until drained liquid is

nearly colorless.

6) Drain system and then close radiator drain plug tightly.

7) Disconnect hose from water reservoir (1). Remove reservoir

and pour out any fluid. Scrub and clean inside of reservoir

with soap and water. Flush it well with clean water and drain.

Reinstall reservoir and hose.

8) Add 50/50 mixture of good quality ethylene glycol antifreeze

and water to radiator and reservoir.

Fill radiator to the base of radiator filler neck and reservoir to

“FULL” level mark (2). Reinstall reservoir cap setting the

arrow marks (4) on the reservoir and cap as the figure. NOTE:

After installing radiator cap (1) to radiator, make sure that

its ear (2) is aligned with reservoir hose (3) as shown in

figure.

If not, turn cap more to align its ear with hose.

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot. Scald-

ing fluid and steam can be blown out under pressure if

cap is taken off too soon.

3. LOW level mark