maintenance SUZUKI RENO 2008 1.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: RENO, Model: SUZUKI RENO 2008 1.GPages: 226, PDF Size: 4.98 MB

Page 153 of 226

5-9SERVICE AND APPEARANCE CARE

85Z14-03E

If you are in an area of extreme cold,

where the temperature falls below –22°F

(–30°C), it is recommended that you use

either an SAE 5W-30 synthetic oil or an

SAE 0W-30 oil. Both will provide easier

cold starting and better protection for your

engine at extremely low temperatures.

Engine Oil Additives

Don’t add anything to your oil. The recom-

mended oils with the starburst symbol are

all you will need for good performance and

engine protection.

When to Change Engine Oil

If any one of these is true for you, use the

short trip/city maintenance schedule:

Most trips are less than 5 miles (8 km).

This is particularly important when out-

side temperatures are below freezing.

Most trips include extensive idling (such

as frequent driving in stop-and-go traf-

fic).

The vehicle is used for delivery service,

police, taxi or other commercial applica-

tion.Driving under these conditions causes

engine oil to break down sooner. If any one

of these is true for your vehicle, then you

need to change your oil and filter every

3,750 miles (6,000 km) or 3 months –

whichever occurs first.

If none of them is true, use the long trip/

highway maintenance schedule. Change

the oil and filter every 7,500 miles (12,000

km) or 6 months – whichever occurs first.

Driving a vehicle with a fully warmed

engine under highway conditions will

cause engine oil to break down slower.

What to Do with Used Oil

Used engine oil contains certain elements

that may be unhealthy for your skin and

could even cause cancer. Don’t let used oil

stay on your skin for very long. Clean your

skin and nails with soap and water, or a

good hand cleaner. Wash or properly dis-

pose of clothing or rags containing used

engine oil. See the manufacturer’s warn-

ings about the use and disposal of oil prod-

ucts.

Used oil can be a threat to the environ-

ment. If you change your own oil, be sure

to drain all the oil from the filter before dis-

posal. Never dispose of oil by putting it in

the trash, pouring it on the ground, into

sewers, or into streams or bodies of water.

Instead, recycle it by taking it to a place

that collects used oil. If you have a problem

properly disposing of your used oil, askyour SUZUKI dealer, a service station or a

local recycling center for help.

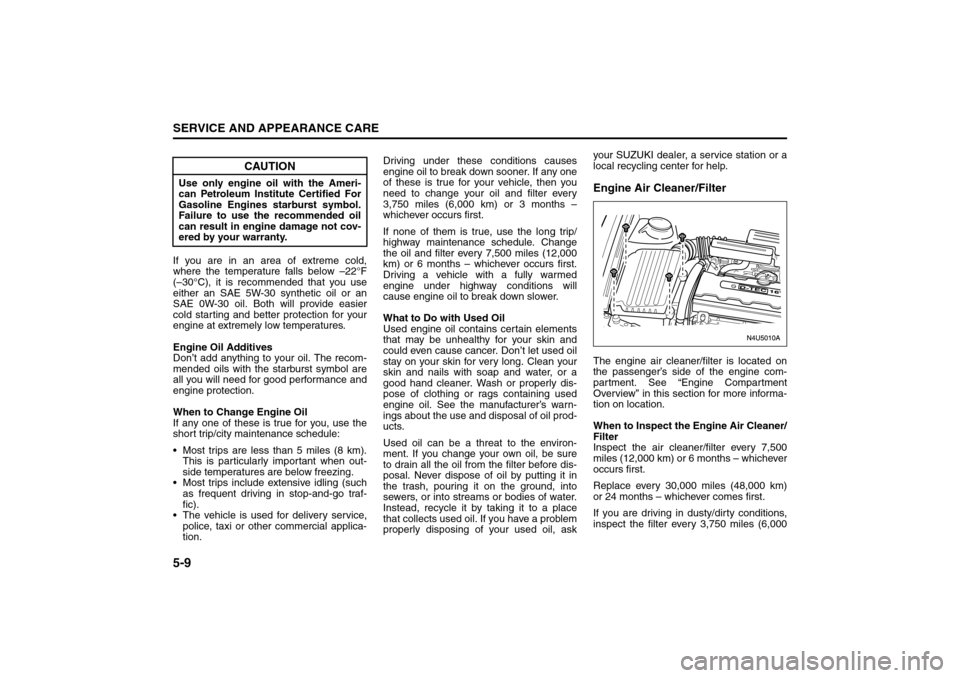

Engine Air Cleaner/FilterThe engine air cleaner/filter is located on

the passenger’s side of the engine com-

partment. See “Engine Compartment

Overview” in this section for more informa-

tion on location.

When to Inspect the Engine Air Cleaner/

Filter

Inspect the air cleaner/filter every 7,500

miles (12,000 km) or 6 months – whichever

occurs first.

Replace every 30,000 miles (48,000 km)

or 24 months – whichever comes first.

If you are driving in dusty/dirty conditions,

inspect the filter every 3,750 miles (6,000

CAUTION

Use only engine oil with the Ameri-

can Petroleum Institute Certified For

Gasoline Engines starburst symbol.

Failure to use the recommended oil

can result in engine damage not cov-

ered by your warranty.

Checking Things Under the Hood:

Page 155 of 226

5-11SERVICE AND APPEARANCE CARE

85Z14-03E

4) Remove filler plug.

5) Make sure the fluid reaches the bottom

edge of the filler plug hole.

6) If the level is low, add fluid until it begins

to run out the filler hole.

7) After filling to the correct level, reinstall

the plug securely.

Recommend Automatic Transmission

Fluid and Maintenance Schedule

Change both the fluid and filter every

37,500 miles (60,000 km) if the vehicle is

mainly driven under one or more of these

conditions:

In heavy city traffic where the outside

temperature regularly reaches 90°F

(32°C) or higher.

In hilly or mountainous terrain.

For business uses such as taxi, police or

delivery service.If you do not use your vehicle under any of

these conditions, the fluid and filter do not

require changing.

See “Recommended Fluids and Lubri-

cants” in section 6 for the proper fluid to

use.

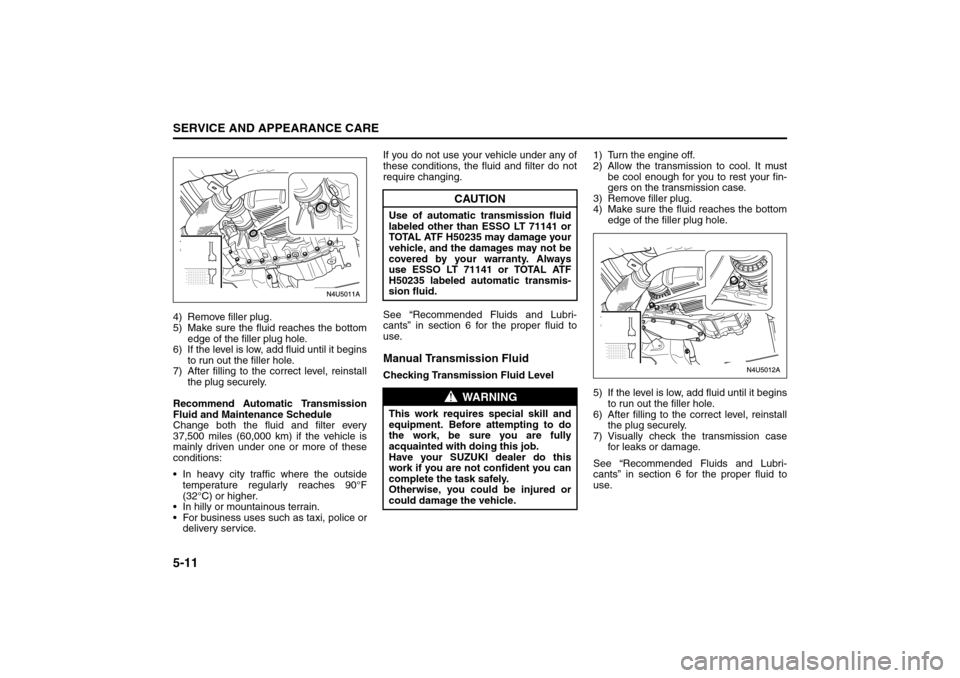

Manual Transmission FluidChecking Transmission Fluid Level1) Turn the engine off.

2) Allow the transmission to cool. It must

be cool enough for you to rest your fin-

gers on the transmission case.

3) Remove filler plug.

4) Make sure the fluid reaches the bottom

edge of the filler plug hole.

5) If the level is low, add fluid until it begins

to run out the filler hole.

6) After filling to the correct level, reinstall

the plug securely.

7) Visually check the transmission case

for leaks or damage.

See “Recommended Fluids and Lubri-

cants” in section 6 for the proper fluid to

use.

CAUTION

Use of automatic transmission fluid

labeled other than ESSO LT 71141 or

TOTAL ATF H50235 may damage your

vehicle, and the damages may not be

covered by your warranty. Always

use ESSO LT 71141 or TOTAL ATF

H50235 labeled automatic transmis-

sion fluid.

WARNING

This work requires special skill and

equipment. Before attempting to do

the work, be sure you are fully

acquainted with doing this job.

Have your SUZUKI dealer do this

work if you are not confident you can

complete the task safely.

Otherwise, you could be injured or

could damage the vehicle.

Checking Things Under the Hood:

Page 156 of 226

5-12

SERVICE AND APPEARANCE CARE

85Z14-03E

Hydraulic ClutchThere is one reservoir for both the brake

and the hydraulic clutch fluid. See “Brakes”

in this section for more information.

The hydraulic clutch linkage in your vehicle

is self-adjusting. The master cylinder res-

ervoir is filled with hydraulic fluid.

A fluid loss in this system could indicate a

problem. Have the system inspected and

repaired.

When to Check and What to Use

Refer to the Maintenance Schedule to

determine how often you should check the

fluid level and for the proper fluid. See sec-

tion 6.

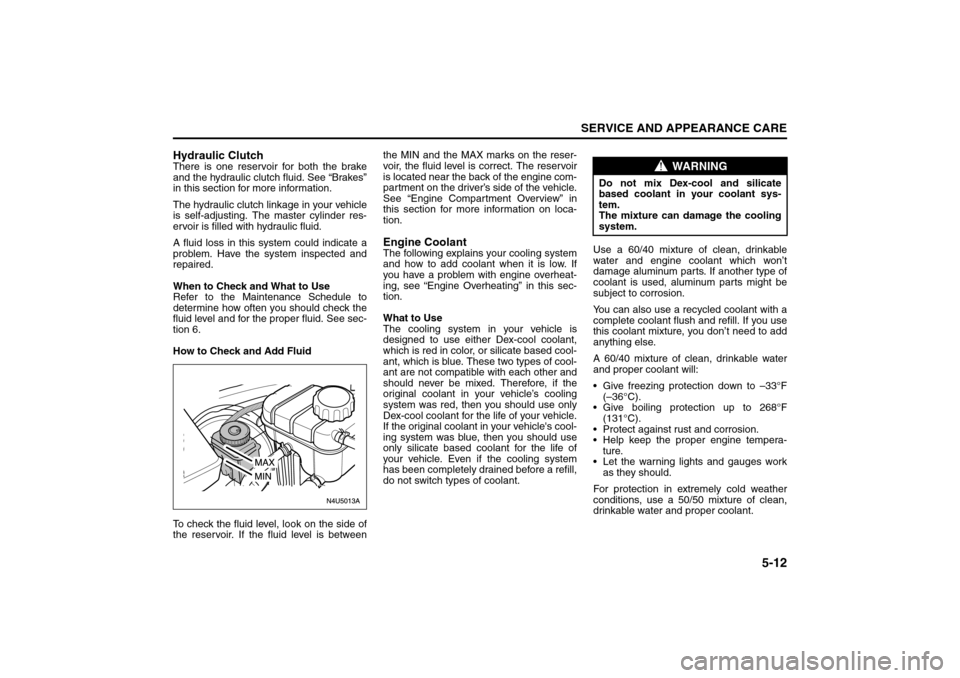

How to Check and Add Fluid

To check the fluid level, look on the side of

the reservoir. If the fluid level is betweenthe MIN and the MAX marks on the reser-

voir, the fluid level is correct. The reservoir

is located near the back of the engine com-

partment on the driver’s side of the vehicle.

See “Engine Compartment Overview” in

this section for more information on loca-

tion.

Engine CoolantThe following explains your cooling system

and how to add coolant when it is low. If

you have a problem with engine overheat-

ing, see “Engine Overheating” in this sec-

tion.

What to Use

The cooling system in your vehicle is

designed to use either Dex-cool coolant,

which is red in color, or silicate based cool-

ant, which is blue. These two types of cool-

ant are not compatible with each other and

should never be mixed. Therefore, if the

original coolant in your vehicle’s cooling

system was red, then you should use only

Dex-cool coolant for the life of your vehicle.

If the original coolant in your vehicle's cool-

ing system was blue, then you should use

only silicate based coolant for the life of

your vehicle. Even if the cooling system

has been completely drained before a refill,

do not switch types of coolant.Use a 60/40 mixture of clean, drinkable

water and engine coolant which won’t

damage aluminum parts. If another type of

coolant is used, aluminum parts might be

subject to corrosion.

You can also use a recycled coolant with a

complete coolant flush and refill. If you use

this coolant mixture, you don’t need to add

anything else.

A 60/40 mixture of clean, drinkable water

and proper coolant will:

Give freezing protection down to –33°F

(–36°C).

Give boiling protection up to 268°F

(131°C).

Protect against rust and corrosion.

Help keep the proper engine tempera-

ture.

Let the warning lights and gauges work

as they should.

For protection in extremely cold weather

conditions, use a 50/50 mixture of clean,

drinkable water and proper coolant.

WARNING

Do not mix Dex-cool and silicate

based coolant in your coolant sys-

tem.

The mixture can damage the cooling

system.

Checking Things Under the Hood:

Page 176 of 226

5-32

SERVICE AND APPEARANCE CARE

85Z14-03E

Speed Rating:

An alphanumeric code assigned to a tire

indicating the maximum speed at which a

tire can operate.

Tr a c t i o n :

The friction between the tire and the road

surface. The amount of grip provided.

Tr e a d :

The portion of a tire that comes into con-

tact with the road.

Treadwear Indicators:

Narrow bands, sometimes called “wear

bars,” that show across the tread of a tire

when only 2/32 inch of tread remains.

UTQGS:

Uniform Tire Quality Grading Standards, a

tire information system that provides con-

sumers with ratings for a tire’s traction,

temperature and treadwear. Ratings are

determined by tire manufacturers using

government testing procedures. The rat-

ings are molded into the sidewall of the

tire.

Vehicle Capacity Weight:

The number of designated seating posi-

tions multiplied by 150 lbs (68 kg) plus the

rated cargo load.

Vehicle Maximum Load on the Tire:

The load on an individual tire that is deter-

mined by distributing to each axle its share

of the maximum loaded vehicle weight and

dividing by two.Vehicle Normal Load on the Tire:

The load on an individual tire that is deter-

mined by distributing to each axle its share

of the curb weight, accessory weight, and

normal occupant weight (distributed in

accordance with Table 1 shown below) and

dividing by 2.

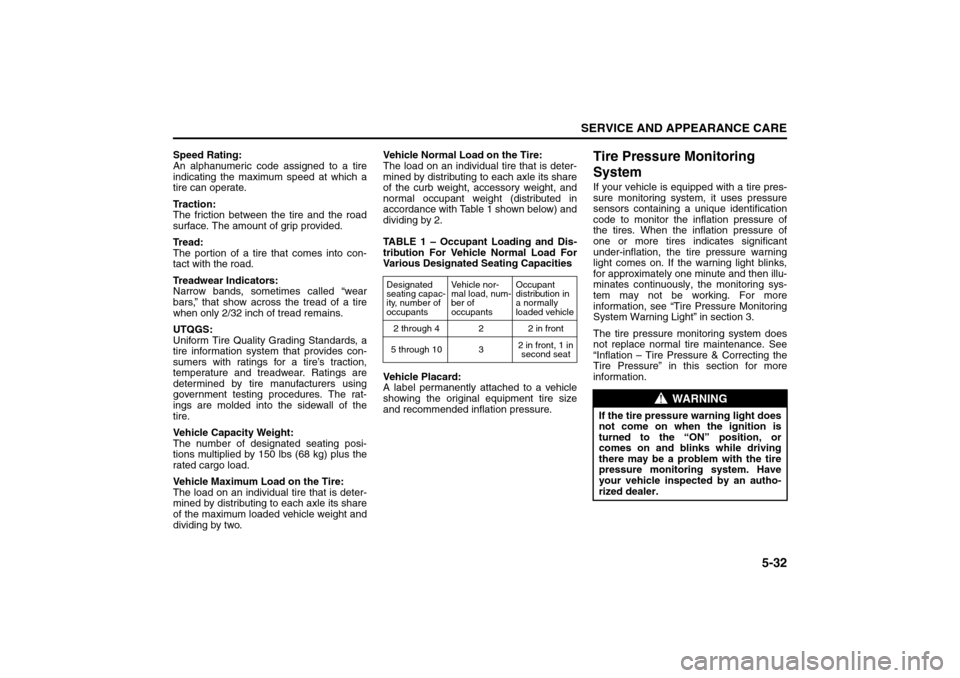

TABLE 1 – Occupant Loading and Dis-

tribution For Vehicle Normal Load For

Various Designated Seating Capacities

Vehicle Placard:

A label permanently attached to a vehicle

showing the original equipment tire size

and recommended inflation pressure.

Tire Pressure Monitoring

SystemIf your vehicle is equipped with a tire pres-

sure monitoring system, it uses pressure

sensors containing a unique identification

code to monitor the inflation pressure of

the tires. When the inflation pressure of

one or more tires indicates significant

under-inflation, the tire pressure warning

light comes on. If the warning light blinks,

for approximately one minute and then illu-

minates continuously, the monitoring sys-

tem may not be working. For more

information, see “Tire Pressure Monitoring

System Warning Light” in section 3.

The tire pressure monitoring system does

not replace normal tire maintenance. See

“Inflation – Tire Pressure & Correcting the

Tire Pressure” in this section for more

information.

Designated

seating capac-

ity, number of

occupantsVehicle nor-

mal load, num-

ber of

occupantsOccupant

distribution in

a normally

loaded vehicle

2 through 4 2 2 in front

5 through 10 32 in front, 1 in

second seat

WARNING

If the tire pressure warning light does

not come on when the ignition is

turned to the “ON” position, or

comes on and blinks while driving

there may be a problem with the tire

pressure monitoring system. Have

your vehicle inspected by an autho-

rized dealer.

Tires:

Page 179 of 226

5-35SERVICE AND APPEARANCE CARE

85Z14-03E

When to Check

Check your tires each time you fill your fuel

tank or at least once a month using a tire

pressure gauge.

Don’t forget your compact spare tire. It

should be at 60 psi (420 kPa).

How to check

Use a good quality pocket-type gauge to

check tire pressure. You can’t tell if your

tires are properly inflated simply by looking

at them. Radial tires may look properly

inflated even when they’re underinflated.

Check the tire’s inflation pressure when the

tires are cold. Cold means your vehicle has

been sitting for at least three hours or

driven no more than 1 mile (1.6 km).

Remove the valve cap from the tire valve

stem. Press the tire gauge firmly onto the

valve to get a pressure measurement. If

the cold tire inflation pressure is low, add

air until you reach the recommended pres-

sure.

If you overfill the tire, release air by push-

ing on the metal stem in the center of the

tire valve. Recheck the tire pressure with

the tire gauge.

Be sure to put the valve caps back on the

valve stems. They help prevent leaks by

keeping out dirt and moisture.

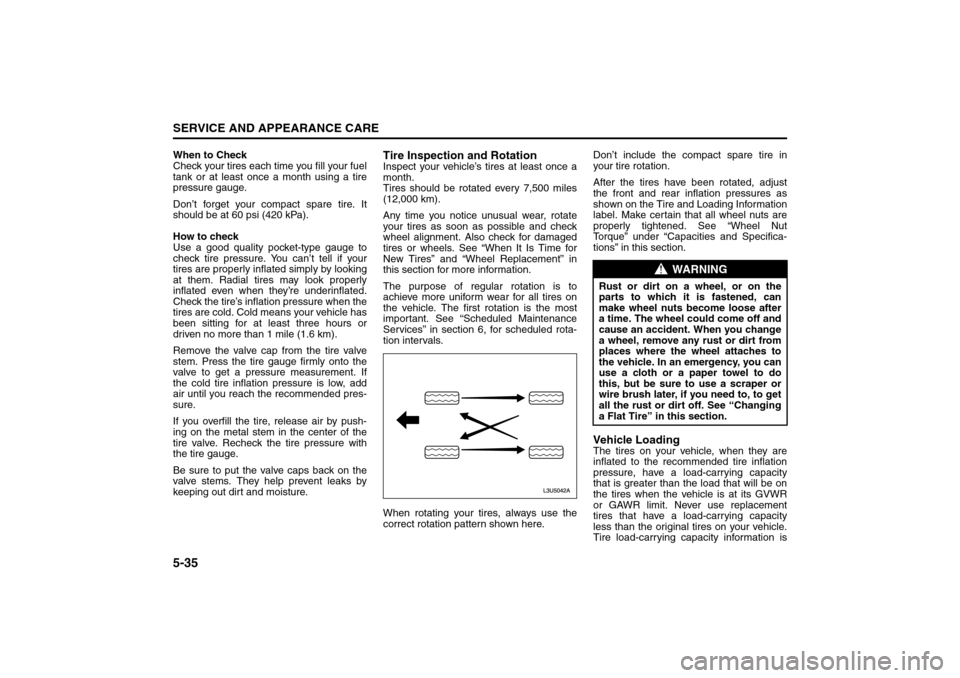

Tire Inspection and RotationInspect your vehicle’s tires at least once a

month.

Tires should be rotated every 7,500 miles

(12,000 km).

Any time you notice unusual wear, rotate

your tires as soon as possible and check

wheel alignment. Also check for damaged

tires or wheels. See “When It Is Time for

New Tires” and “Wheel Replacement” in

this section for more information.

The purpose of regular rotation is to

achieve more uniform wear for all tires on

the vehicle. The first rotation is the most

important. See “Scheduled Maintenance

Services” in section 6, for scheduled rota-

tion intervals.

When rotating your tires, always use the

correct rotation pattern shown here.Don’t include the compact spare tire in

your tire rotation.

After the tires have been rotated, adjust

the front and rear inflation pressures as

shown on the Tire and Loading Information

label. Make certain that all wheel nuts are

properly tightened. See “Wheel Nut

Torque” under “Capacities and Specifica-

tions” in this section.

Vehicle LoadingThe tires on your vehicle, when they are

inflated to the recommended tire inflation

pressure, have a load-carrying capacity

that is greater than the load that will be on

the tires when the vehicle is at its GVWR

or GAWR limit. Never use replacement

tires that have a load-carrying capacity

less than the original tires on your vehicle.

Tire load-carrying capacity information is

WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose after

a time. The wheel could come off and

cause an accident. When you change

a wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, you can

use a cloth or a paper towel to do

this, but be sure to use a scraper or

wire brush later, if you need to, to get

all the rust or dirt off. See “Changing

a Flat Tire” in this section.

Tires:

Page 183 of 226

5-39SERVICE AND APPEARANCE CARE

85Z14-03E

it’s much more likely to leak out slowly. But

if you should ever have a “blowout”, here

are a few tips about what to expect and

what to do:

If a front tire fails, the flat tire will create a

drag that pulls the vehicle toward that side.

Take your foot off the accelerator pedal

and grip the steering wheel firmly. Steer to

maintain lane position, and then gently

brake to a stop well out of the traffic lane.

A rear blowout, particularly on a curve,

acts much like a skid and may require the

same correction you’d use in a skid. In any

rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under

control by steering the way you want the

vehicle to go. It may be very bumpy and

noisy, but you can still steer. Gently brake

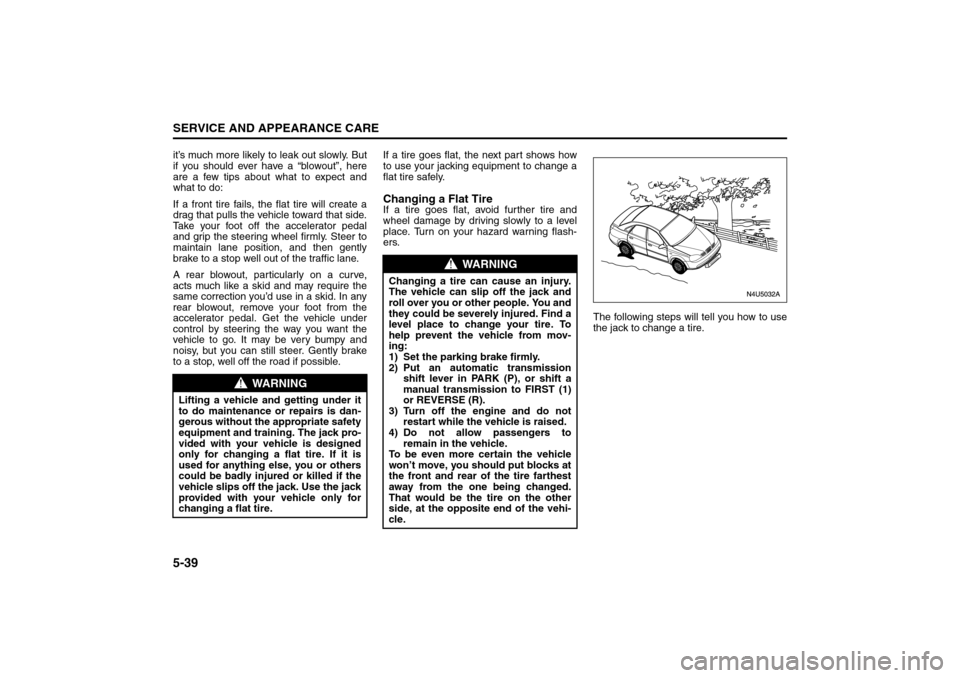

to a stop, well off the road if possible.If a tire goes flat, the next part shows how

to use your jacking equipment to change a

flat tire safely.

Changing a Flat TireIf a tire goes flat, avoid further tire and

wheel damage by driving slowly to a level

place. Turn on your hazard warning flash-

ers.

The following steps will tell you how to use

the jack to change a tire.

WARNING

Lifting a vehicle and getting under it

to do maintenance or repairs is dan-

gerous without the appropriate safety

equipment and training. The jack pro-

vided with your vehicle is designed

only for changing a flat tire. If it is

used for anything else, you or others

could be badly injured or killed if the

vehicle slips off the jack. Use the jack

provided with your vehicle only for

changing a flat tire.

WARNING

Changing a tire can cause an injury.

The vehicle can slip off the jack and

roll over you or other people. You and

they could be severely injured. Find a

level place to change your tire. To

help prevent the vehicle from mov-

ing:

1) Set the parking brake firmly.

2) Put an automatic transmission

shift lever in PARK (P), or shift a

manual transmission to FIRST (1)

or REVERSE (R).

3) Turn off the engine and do not

restart while the vehicle is raised.

4) Do not allow passengers to

remain in the vehicle.

To be even more certain the vehicle

won’t move, you should put blocks at

the front and rear of the tire farthest

away from the one being changed.

That would be the tire on the other

side, at the opposite end of the vehi-

cle.

Tires:

Page 191 of 226

5-47SERVICE AND APPEARANCE CARE

85Z14-03E

Sheet Metal DamageIf your vehicle is damaged and requires

sheet metal repair or replacement, make

sure the body repair shop applies anti-cor-

rosion material to parts repaired or

replaced to restore corrosion protection.

Original manufacturer replacement parts

will provide the corrosion protection while

maintaining the warranty.Finish DamageAny stone chips, fractures or deep

scratches in the finish should be repaired

right away. Bare metal will corrode quickly

and may develop into major repair

expense.

Minor chips and scratches can be repaired

with touch-up materials available from your

SUZUKI dealer. Larger areas of finish

damage can be corrected in your SUZUKI

dealer’s body and paint shop.

Underbody MaintenanceChemicals used for ice and snow removal

and dust control can collect on the under-

body. If these are not removed, acceler-

ated corrosion (rust) can occur on the

underbody parts such as fuel lines, frame,

floor pan and exhaust system even though

they have corrosion protection.

At least every spring, flush these materials

from the underbody with plain water. Clean

any areas where mud and debris can col-

lect. Dirt packed in close areas of the

frame should be loosened before being

flushed. Your SUZUKI dealer or an under-

body car washing system can do this for

you.Chemical Paint SpottingSome weather and atmospheric conditions

can create a chemical fallout. Airborne pol-

lutants can fall upon and attack painted

surfaces on your vehicle. This damage can

take two forms: blotchy, ring-shaped discol-

orations, and small, irregular dark spots

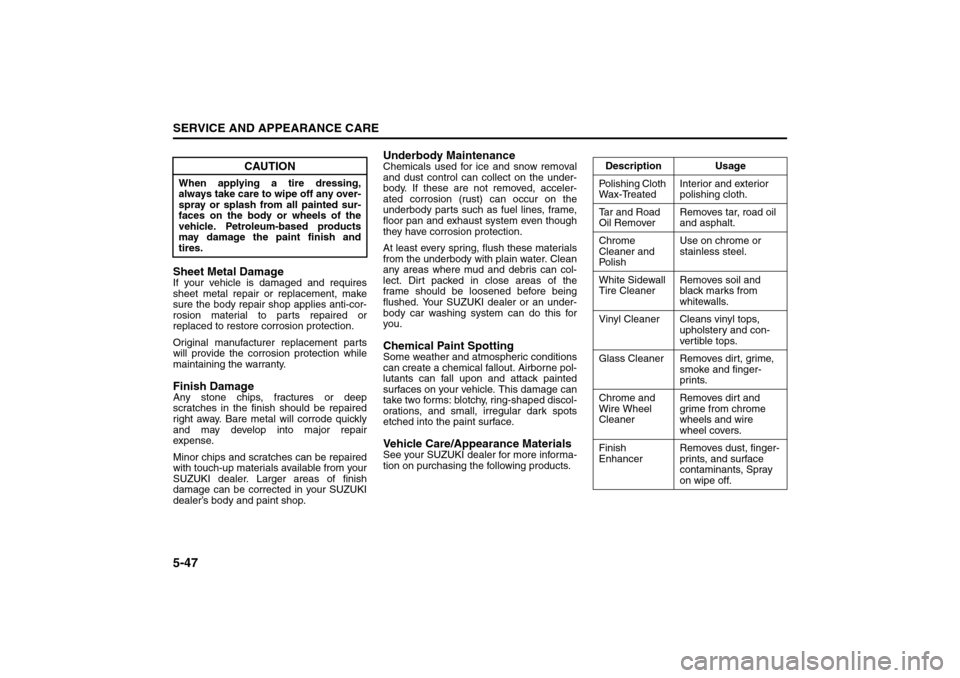

etched into the paint surface.Vehicle Care/Appearance MaterialsSee your SUZUKI dealer for more informa-

tion on purchasing the following products.

CAUTION

When applying a tire dressing,

always take care to wipe off any over-

spray or splash from all painted sur-

faces on the body or wheels of the

vehicle. Petroleum-based products

may damage the paint finish and

tires.

Description Usage

Polishing Cloth

Wax-TreatedInterior and exterior

polishing cloth.

Tar and Road

Oil RemoverRemoves tar, road oil

and asphalt.

Chrome

Cleaner and

Po l i s hUse on chrome or

stainless steel.

White Sidewall

Tire CleanerRemoves soil and

black marks from

whitewalls.

Vinyl Cleaner Cleans vinyl tops,

upholstery and con-

ver tible tops.

Glass Cleaner Removes dirt, grime,

smoke and finger-

prints.

Chrome and

Wire Wheel

CleanerRemoves dirt and

grime from chrome

wheels and wire

wheel covers.

Finish

EnhancerRemoves dust, finger-

prints, and surface

contaminants, Spray

on wipe off.

Electrical System:

Page 200 of 226

MAINTENANCE SCHEDULE

6

85Z14-03E

MAINTENANCE SCHEDULEGeneral Information ............................................................ 6-1

Maintenance ........................................................................ 6-2

Page 201 of 226

6-1MAINTENANCE SCHEDULE

85Z14-03E

General InformationNOTICE (for U.S.A.)

Maintenance, replacement or repair of

the emission control devices and sys-

tems may be performed by any automo-

bile repair establishment or individual

using any part which has been certified

under the provisions in the Clean Air

Act sec. 207. (a) (2).

This section provides the maintenance

schedule which is necessary to ensure

that your vehicle gives many years of satis-

fying motoring.

You are responsible for properly operating

and maintaining your vehicle in accor-

dance with the instructions described in

this manual. Failure to do so is likely to

result in the denial of warranty coverage.

It is your responsibility to properly maintain

and operate your vehicle. Be sure that you

follow the periodic required maintenance

schedule and general operation instruc-

tions in this manual.

It is also your responsibility to keep records

and receipts as proof of regular mainte-

nance. Records and receipts together with

this owner’s manual should be transferred

to any subsequent owner.

You may have maintenance services per-

formed on your vehicle by any qualified

person or facility. However, it is recom-

mended that the maintenance services beperformed by an authorized SUZUKI

dealer who will have well-trained techni-

cians and genuine parts.

Non-SUZUKI genuine parts and accesso-

ries have not been examined or approved

by SUZUKI. SUZUKI can certify neither the

suitability nor the safety of non-SUZUKI

parts and accessories and is not liable for

damage caused by their use.

Inadequate, incomplete, or insufficient ser-

vicing may result in operational problems

with your vehicle that could even lead to

vehicle damage, an accident, or personal

injury.

Selecting the Right ConditionFirst you’ll need to decide which of the two

conditions is right for your vehicle. Here’s

how to decide which condition to follow.

You should follow the required mainte-

nance schedule for the condition that best

describes your driving.

Normal Condition

The normal condition for driving means

driving under typical, everyday driving con-

ditions. You may follow the ordinary main-

tenance schedule.

Severe Condition

If the vehicle is operated under any of the

following conditions, some of the mainte-

nance schedule items need to be serviced

more frequently. See “Maintenance Rec-ommended under Severe Driving Condi-

tions” in this section.

Repeated short-distance driving less

than 5 miles (8 km).

Extensive idling and/or slow-speed driv-

ing in stop-and-go traffic.

Driving on dusty roads.

Driving on hilly or mountainous terrain.

Driving in heavy city traffic where the

outside temperatures regularly reach

90°F (32°C) or higher.

Driving as a taxi, police or delivery vehi-

cle.

Frequent driving when outside tempera-

ture remains below freezing.

Page 202 of 226

6-2

MAINTENANCE SCHEDULE

85Z14-03E

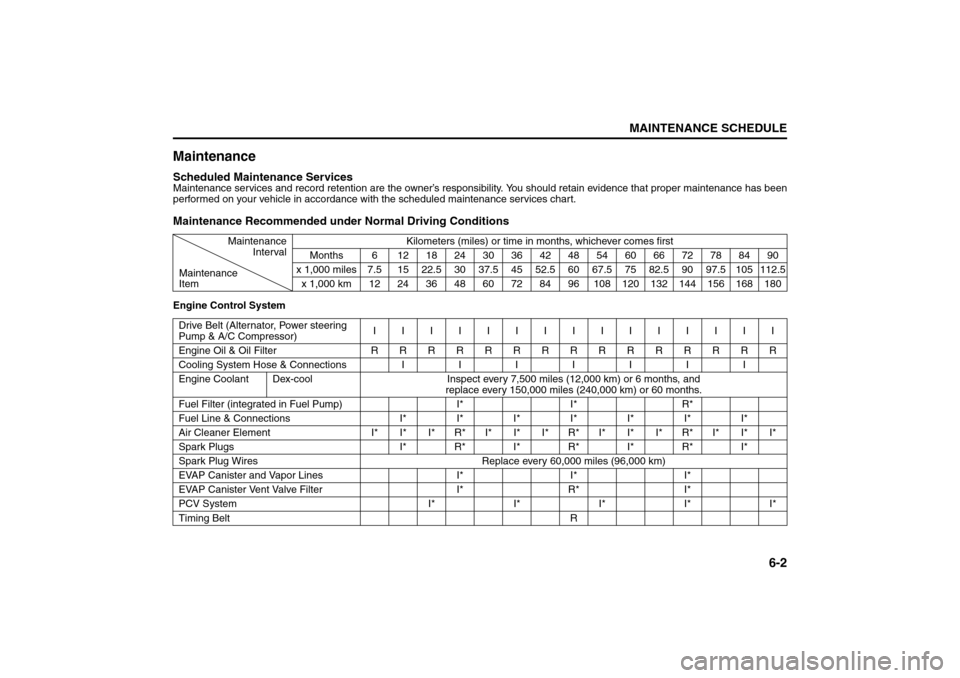

MaintenanceScheduled Maintenance ServicesMaintenance services and record retention are the owner’s responsibility. You should retain evidence that proper maintenance has been

performed on your vehicle in accordance with the scheduled maintenance services chart.Maintenance Recommended under Normal Driving ConditionsEngine Control SystemMaintenance

IntervalKilometers (miles) or time in months, whichever comes first

Months 6 1218243036424854606672788490

Maintenance

Itemx 1,000 miles 7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

x 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Drive Belt (Alternator, Power steering

Pump & A/C Compressor)IIIIIIIIIIIIIII

Engine Oil & Oil Filter RRRRRRRRRRRRRRR

Cooling System Hose & Connections I I I I I I I

Engine Coolant Dex-cool Inspect every 7,500 miles (12,000 km) or 6 months, and

replace every 150,000 miles (240,000 km) or 60 months.

Fuel Filter (integrated in Fuel Pump) I* I* R*

Fuel Line & Connections I* I* I* I* I* I* I*

Air Cleaner Element I* I* I* R* I* I* I* R* I* I* I* R* I* I* I*

Spark Plugs I*R*I*R*I*R*I*

Spark Plug Wires Replace every 60,000 miles (96,000 km)

EVAP Canister and Vapor Lines I* I* I*

EVAP Canister Vent Valve Filter I* R* I*

PCV System I* I* I* I* I*

Timing BeltR