check engine SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 537 of 698

6A1-36 ENGINE MECHANICAL (M13 ENGINE)

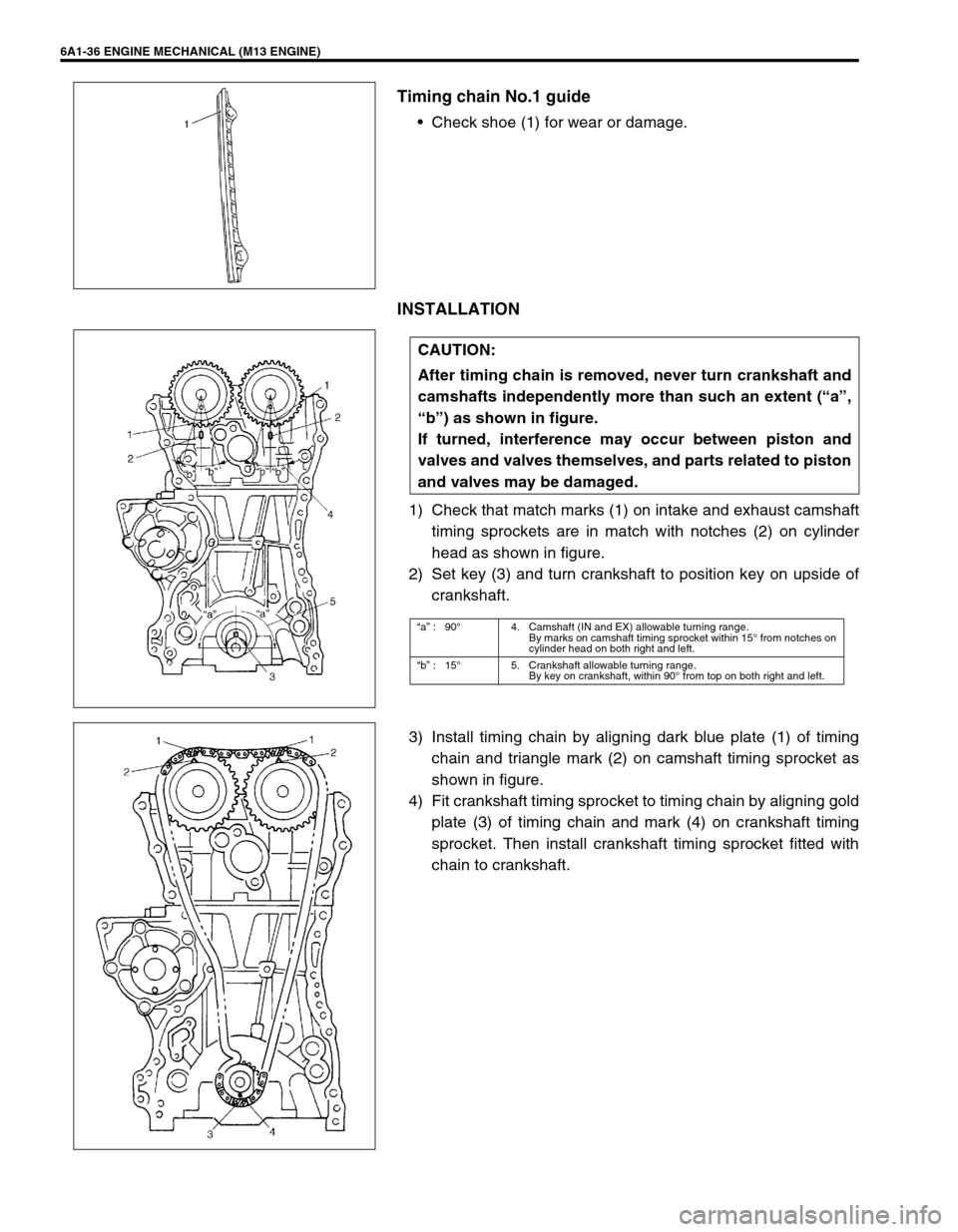

Timing chain No.1 guide

Check shoe (1) for wear or damage.

INSTALLATION

1) Check that match marks (1) on intake and exhaust camshaft

timing sprockets are in match with notches (2) on cylinder

head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of

crankshaft.

3) Install timing chain by aligning dark blue plate (1) of timing

chain and triangle mark (2) on camshaft timing sprocket as

shown in figure.

4) Fit crankshaft timing sprocket to timing chain by aligning gold

plate (3) of timing chain and mark (4) on crankshaft timing

sprocket. Then install crankshaft timing sprocket fitted with

chain to crankshaft.

CAUTION:

After timing chain is removed, never turn crankshaft and

camshafts independently more than such an extent (“a”,

“b”) as shown in figure.

If turned, interference may occur between piston and

valves and valves themselves, and parts related to piston

and valves may be damaged.

“a” :90°4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15° from notches on

cylinder head on both right and left.

“b” :15°5. Crankshaft allowable turning range.

By key on crankshaft, within 90° from top on both right and left.

Page 538 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-37

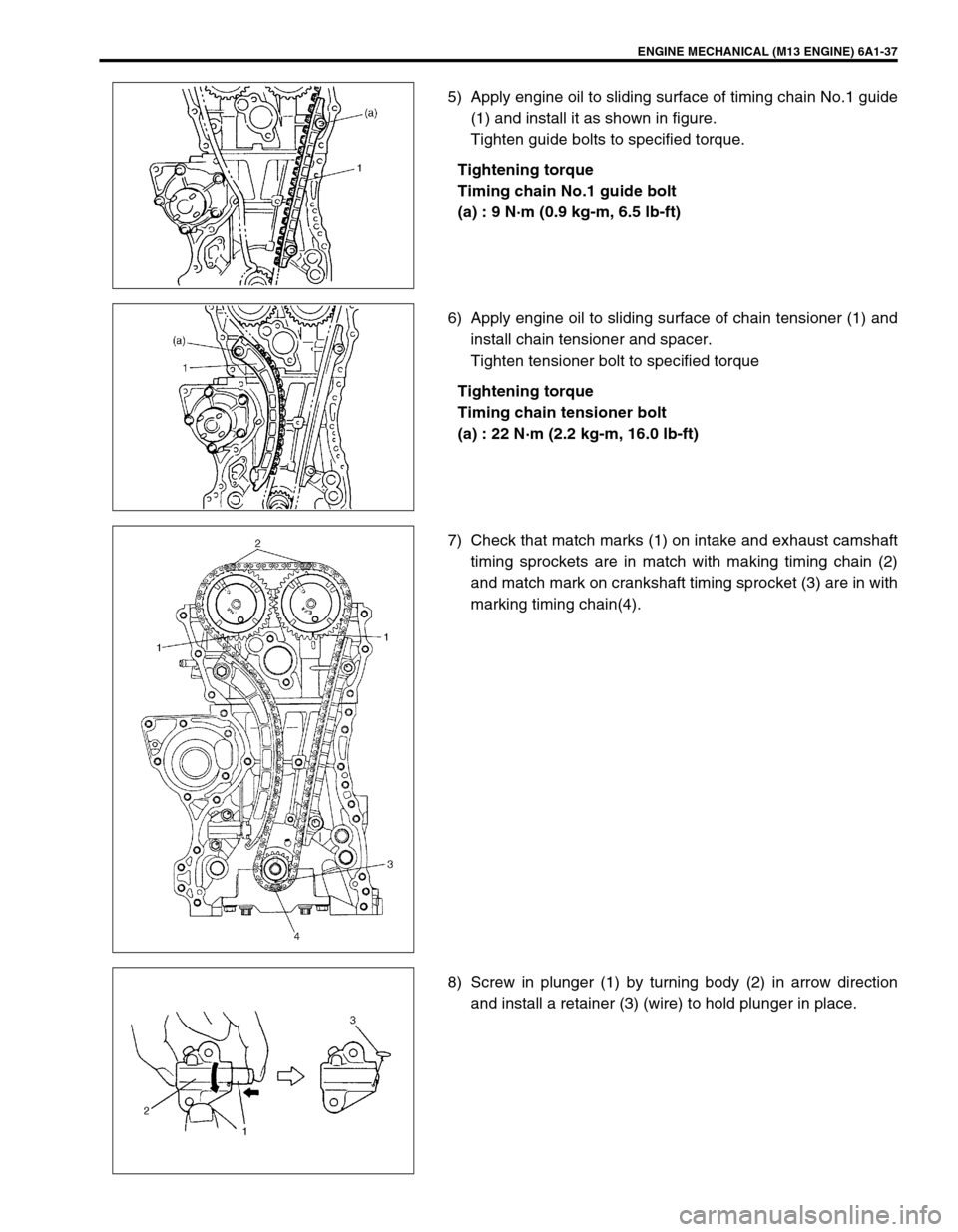

5) Apply engine oil to sliding surface of timing chain No.1 guide

(1) and install it as shown in figure.

Tighten guide bolts to specified torque.

Tightening torque

Timing chain No.1 guide bolt

(a) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

6) Apply engine oil to sliding surface of chain tensioner (1) and

install chain tensioner and spacer.

Tighten tensioner bolt to specified torque

Tightening torque

Timing chain tensioner bolt

(a) : 22 N·m (2.2 kg-m, 16.0 lb-ft)

7) Check that match marks (1) on intake and exhaust camshaft

timing sprockets are in match with making timing chain (2)

and match mark on crankshaft timing sprocket (3) are in with

marking timing chain(4).

8) Screw in plunger (1) by turning body (2) in arrow direction

and install a retainer (3) (wire) to hold plunger in place.

Page 539 of 698

6A1-38 ENGINE MECHANICAL (M13 ENGINE)

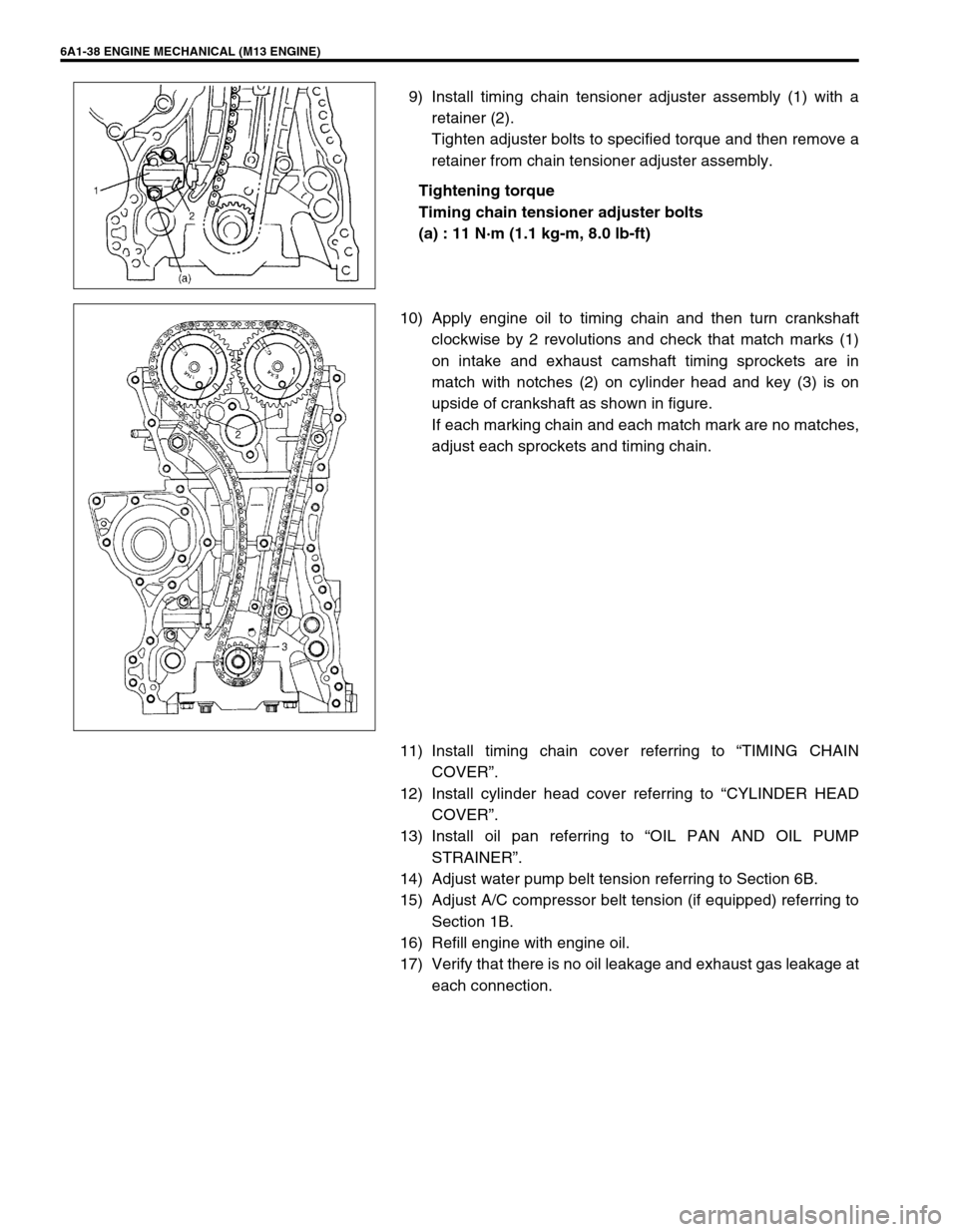

9) Install timing chain tensioner adjuster assembly (1) with a

retainer (2).

Tighten adjuster bolts to specified torque and then remove a

retainer from chain tensioner adjuster assembly.

Tightening torque

Timing chain tensioner adjuster bolts

(a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

10) Apply engine oil to timing chain and then turn crankshaft

clockwise by 2 revolutions and check that match marks (1)

on intake and exhaust camshaft timing sprockets are in

match with notches (2) on cylinder head and key (3) is on

upside of crankshaft as shown in figure.

If each marking chain and each match mark are no matches,

adjust each sprockets and timing chain.

11) Install timing chain cover referring to “TIMING CHAIN

COVER”.

12) Install cylinder head cover referring to “CYLINDER HEAD

COVER”.

13) Install oil pan referring to “OIL PAN AND OIL PUMP

STRAINER”.

14) Adjust water pump belt tension referring to Section 6B.

15) Adjust A/C compressor belt tension (if equipped) referring to

Section 1B.

16) Refill engine with engine oil.

17) Verify that there is no oil leakage and exhaust gas leakage at

each connection.

Page 541 of 698

6A1-40 ENGINE MECHANICAL (M13 ENGINE)

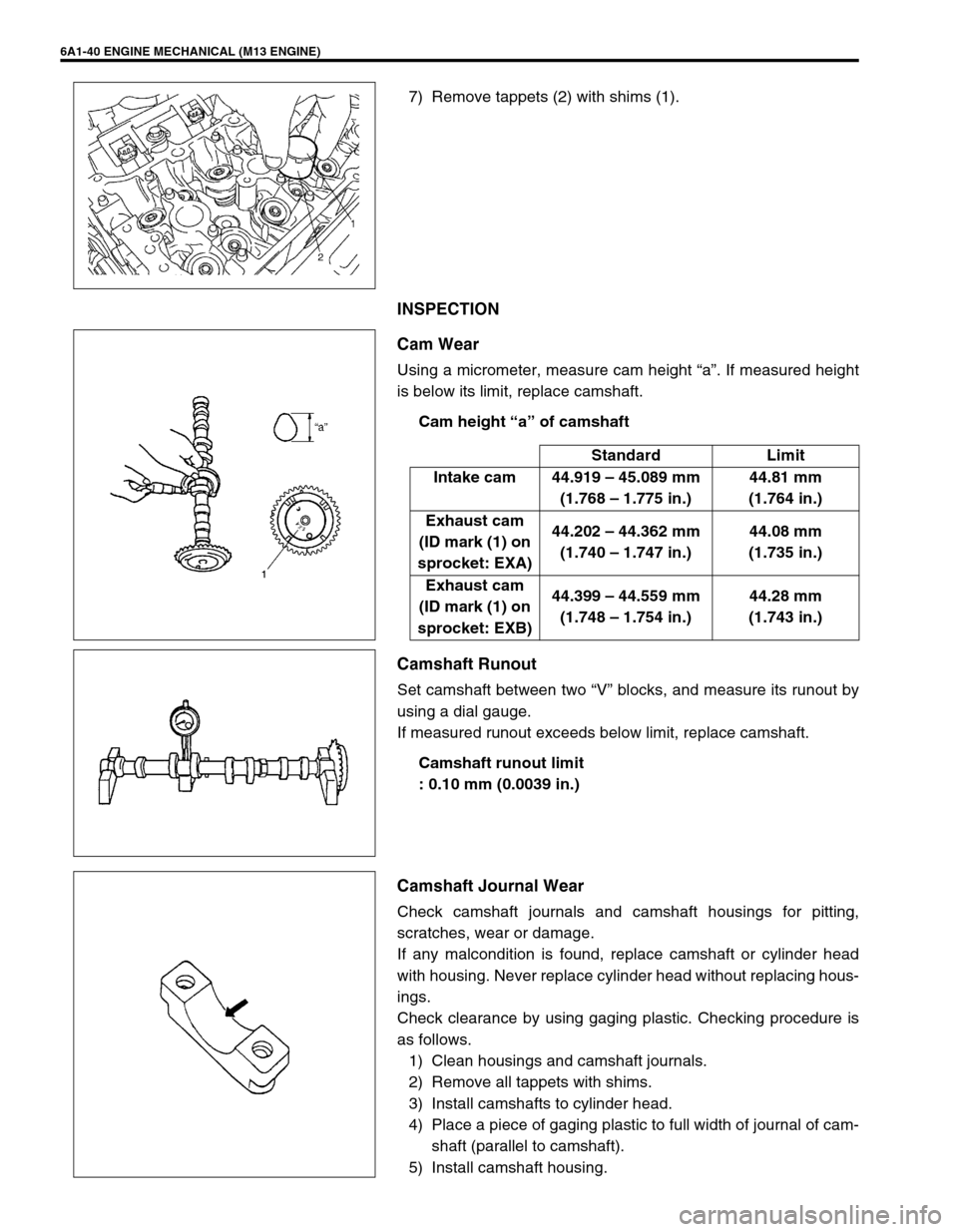

7) Remove tappets (2) with shims (1).

INSPECTION

Cam Wear

Using a micrometer, measure cam height “a”. If measured height

is below its limit, replace camshaft.

Cam height “a” of camshaft

Camshaft Runout

Set camshaft between two “V” blocks, and measure its runout by

using a dial gauge.

If measured runout exceeds below limit, replace camshaft.

Camshaft runout limit

: 0.10 mm (0.0039 in.)

Camshaft Journal Wear

Check camshaft journals and camshaft housings for pitting,

scratches, wear or damage.

If any malcondition is found, replace camshaft or cylinder head

with housing. Never replace cylinder head without replacing hous-

ings.

Check clearance by using gaging plastic. Checking procedure is

as follows.

1) Clean housings and camshaft journals.

2) Remove all tappets with shims.

3) Install camshafts to cylinder head.

4) Place a piece of gaging plastic to full width of journal of cam-

shaft (parallel to camshaft).

5) Install camshaft housing.

Standard Limit

Intake cam 44.919 – 45.089 mm

(1.768 – 1.775 in.)44.81 mm

(1.764 in.)

Exhaust cam

(ID mark (1) on

sprocket: EXA)44.202 – 44.362 mm

(1.740 – 1.747 in.)44.08 mm

(1.735 in.)

Exhaust cam

(ID mark (1) on

sprocket: EXB)44.399 – 44.559 mm

(1.748 – 1.754 in.)44.28 mm

(1.743 in.)

Page 543 of 698

6A1-42 ENGINE MECHANICAL (M13 ENGINE)

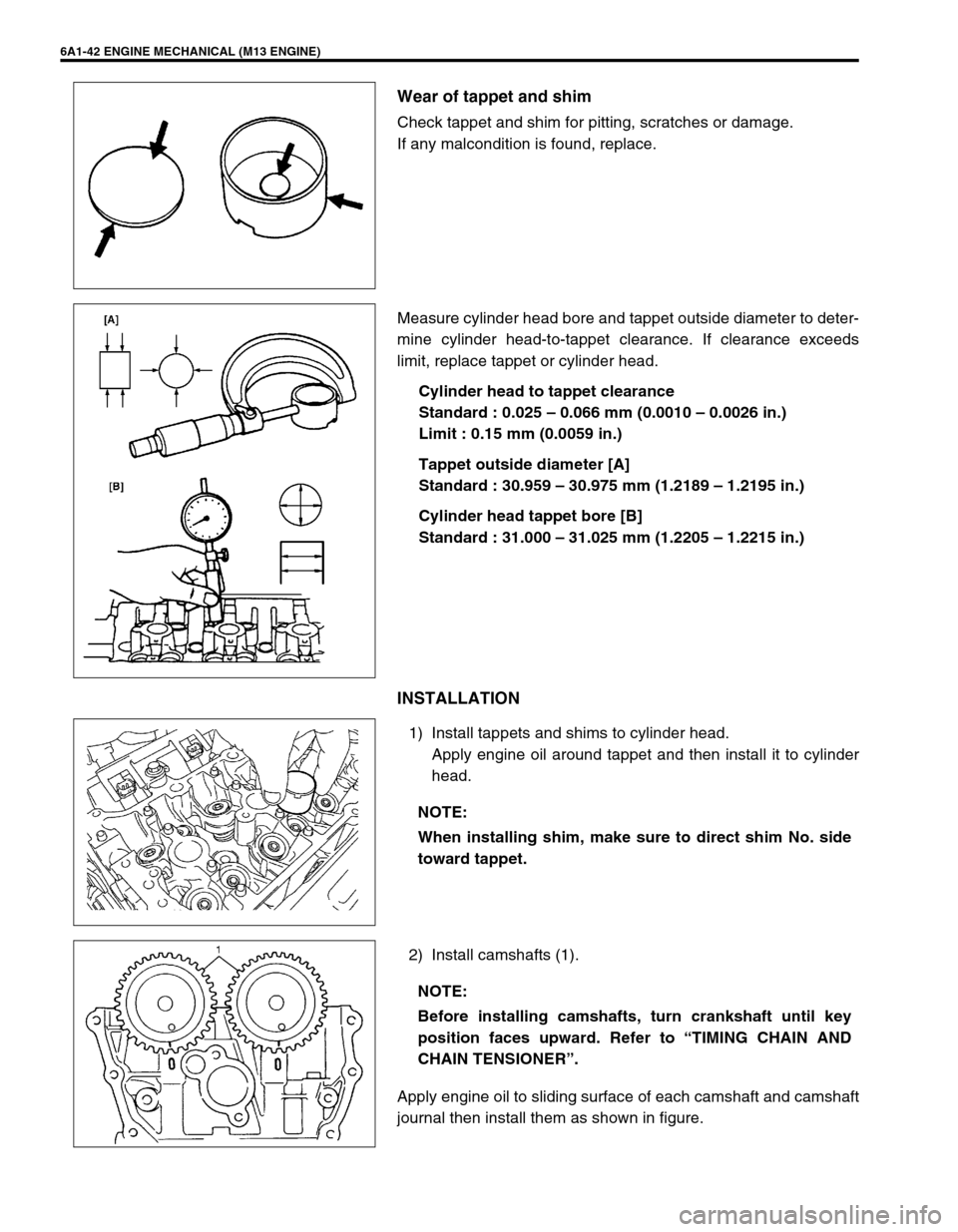

Wear of tappet and shim

Check tappet and shim for pitting, scratches or damage.

If any malcondition is found, replace.

Measure cylinder head bore and tappet outside diameter to deter-

mine cylinder head-to-tappet clearance. If clearance exceeds

limit, replace tappet or cylinder head.

Cylinder head to tappet clearance

Standard : 0.025 – 0.066 mm (0.0010 – 0.0026 in.)

Limit : 0.15 mm (0.0059 in.)

Tappet outside diameter [A]

Standard : 30.959 – 30.975 mm (1.2189 – 1.2195 in.)

Cylinder head tappet bore [B]

Standard : 31.000 – 31.025 mm (1.2205 – 1.2215 in.)

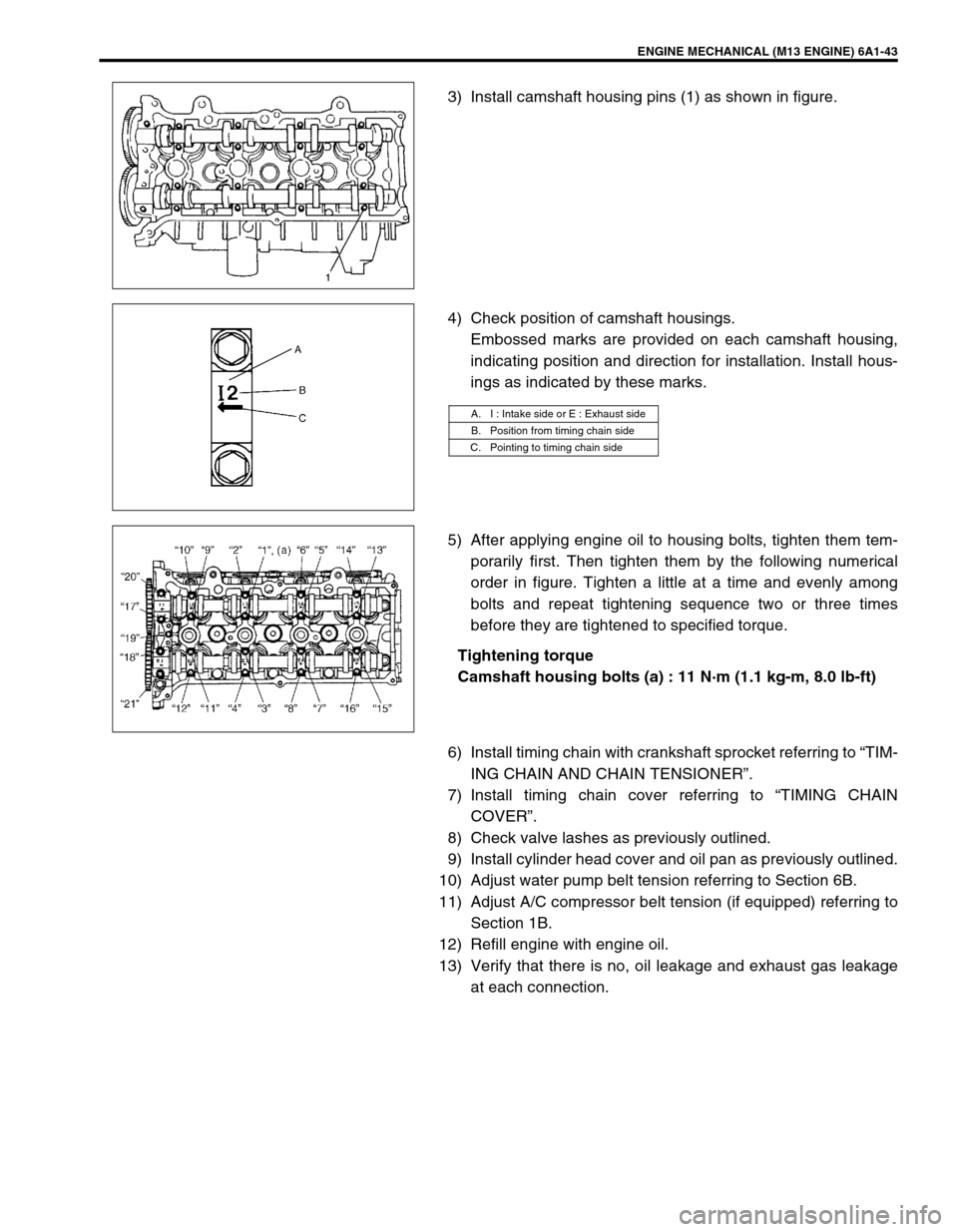

INSTALLATION

1) Install tappets and shims to cylinder head.

Apply engine oil around tappet and then install it to cylinder

head.

2) Install camshafts (1).

Apply engine oil to sliding surface of each camshaft and camshaft

journal then install them as shown in figure.

NOTE:

When installing shim, make sure to direct shim No. side

toward tappet.

NOTE:

Before installing camshafts, turn crankshaft until key

position faces upward. Refer to “TIMING CHAIN AND

CHAIN TENSIONER”.

Page 544 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-43

3) Install camshaft housing pins (1) as shown in figure.

4) Check position of camshaft housings.

Embossed marks are provided on each camshaft housing,

indicating position and direction for installation. Install hous-

ings as indicated by these marks.

5) After applying engine oil to housing bolts, tighten them tem-

porarily first. Then tighten them by the following numerical

order in figure. Tighten a little at a time and evenly among

bolts and repeat tightening sequence two or three times

before they are tightened to specified torque.

Tightening torque

Camshaft housing bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

6) Install timing chain with crankshaft sprocket referring to “TIM-

ING CHAIN AND CHAIN TENSIONER”.

7) Install timing chain cover referring to “TIMING CHAIN

COVER”.

8) Check valve lashes as previously outlined.

9) Install cylinder head cover and oil pan as previously outlined.

10) Adjust water pump belt tension referring to Section 6B.

11) Adjust A/C compressor belt tension (if equipped) referring to

Section 1B.

12) Refill engine with engine oil.

13) Verify that there is no, oil leakage and exhaust gas leakage

at each connection.

A. I : Intake side or E : Exhaust side

B. Position from timing chain side

C. Pointing to timing chain side

Page 547 of 698

6A1-46 ENGINE MECHANICAL (M13 ENGINE)

10) Remove intake manifold stiffener (1).

11) Remove oil pan referring to “OIL PAN AND OIL PUMP

STRAINER”.

12) Remove cylinder head cover referring to “CYLINDER HEAD

COVER”.

13) Remove timing chain cover referring to “TIMING CHAIN

COVER”.

14) Remove timing chain referring to “TIMING CHAIN AND

CHAIN TENSIONER”.

15) Remove intake and exhaust camshafts referring to “CAM-

SHAFT, TAPPET AND SHIM”.

16) Loosen cylinder head bolts in such order as indicated in fig-

ure by using a 12 corner socket wrenches and remove them.

17) Check all around cylinder head for any other parts required

to be removed or disconnected and remove or disconnect

whatever necessary.

18) Remove exhaust manifold, if necessary, referring to

“EXHAUST MANIFOLD”.

19) Remove cylinder head with intake manifold and exhaust

manifold. Use lifting device, if necessary.

NOTE:

Don’t forget to remove bolt (M8) (1) as shown in figure.

Never reuse cylinder head bolts once disassembled it

due to plastic deformation tightening. Be sure to use

new cylinder head bolts when installing.

Page 549 of 698

6A1-48 ENGINE MECHANICAL (M13 ENGINE)

INSPECTION

Valve Guides

Using a micrometer and bore gauge, take diameter readings on

valve stems and guides to check stem-to-guide clearance. Be

sure to take reading at more than one place along the length of

each stem and guide.

If clearance exceeds limit, replace valve and valve guide.

Valve stem-to-guide clearance

Valve stem diameter [A]

Valve guide bore [B] standard

In and Ex : 6.000 – 6.012 mm (0.2362 – 0.2367 in.) for 69G

type valve

In and Ex : 5.485 – 5.510 mm (0.2159 – 0.2169 in.) for 54G

type valve

If bore gauge is not available, check end deflection of valve stem

with a dial gauge instead.

Move stem end in directions (1) and (2) to measure end deflec-

tion.

If deflection exceeds its limit, replace valve stem and valve guide.

Valve stem end deflection limit

In : 0.14 mm (0.005 in.)

Ex : 0.18 mm (0.007 in.)Valve type Standard Limit

69GIn0.020 – 0.047 mm

(0.0008 – 0.0019 in.)0.07 mm

(0.0028 in.)

Ex0.045 – 0.072 mm

(0.0018 – 0.0028 in.)0.09 mm

(0.0035 in.)

54GIn0.020 – 0.030 mm

(0.0008 – 0.0012 in.)0.05 mm

(0.0017 in.)

Ex0.045 – 0.055 mm

(0.0018 – 0.0022 in.)0.07 mm

(0.0028 in.)

Valve type Standard

69GIn5.965 – 5.980 mm

(0.2348 – 0.2354 in.)

Ex5.940 – 5.955 mm

(0.2339 – 0.2344 in.)

54GIn5.465 – 5.480 mm

(0.2152 – 0.2157 in.)

Ex5.440 – 5.455 mm

(0.2142 – 0.2148 in.)

1. Emboss mark 54G or 69G

Page 550 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-49

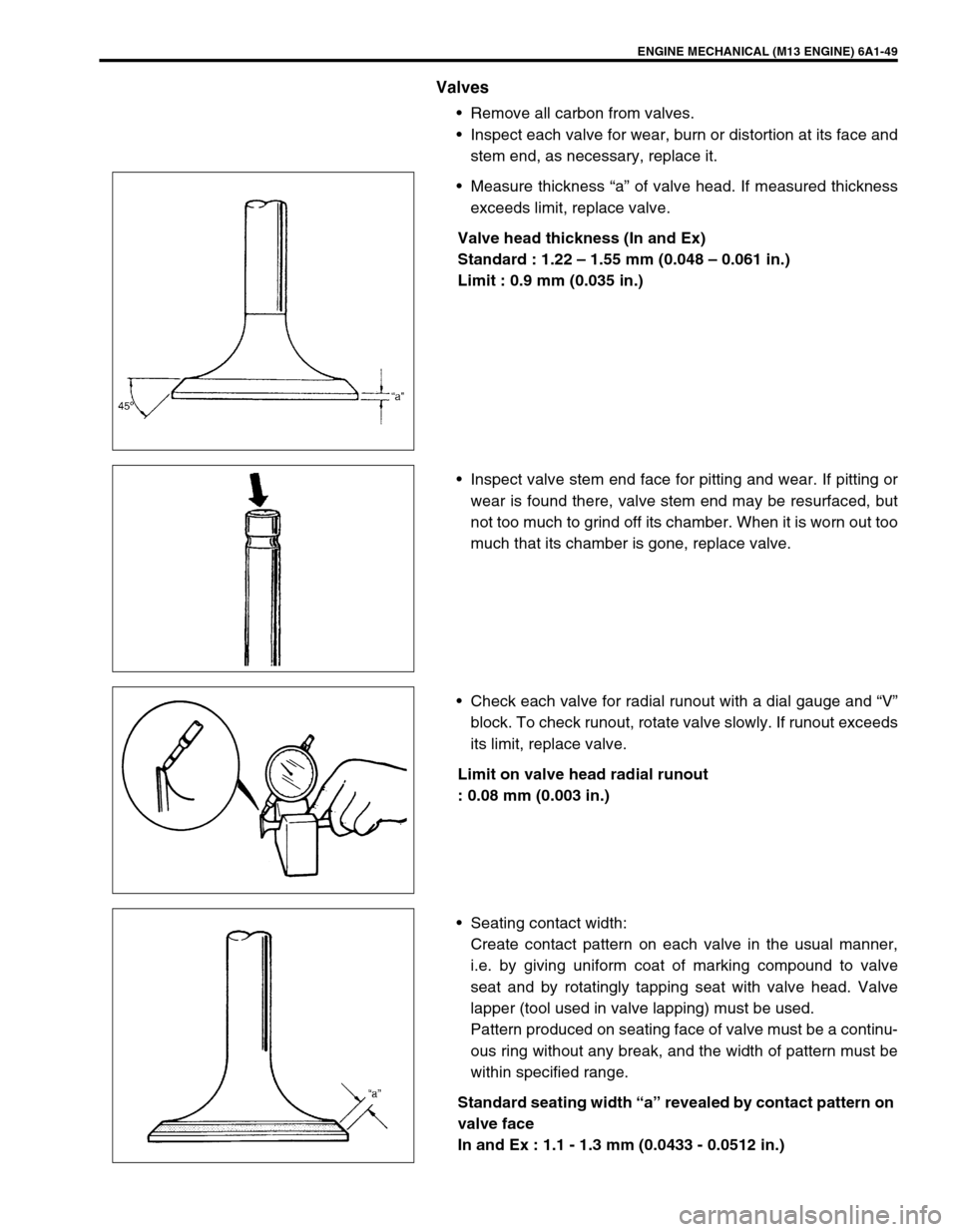

Valves

Remove all carbon from valves.

Inspect each valve for wear, burn or distortion at its face and

stem end, as necessary, replace it.

Measure thickness “a” of valve head. If measured thickness

exceeds limit, replace valve.

Valve head thickness (In and Ex)

Standard : 1.22 – 1.55 mm (0.048 – 0.061 in.)

Limit : 0.9 mm (0.035 in.)

Inspect valve stem end face for pitting and wear. If pitting or

wear is found there, valve stem end may be resurfaced, but

not too much to grind off its chamber. When it is worn out too

much that its chamber is gone, replace valve.

Check each valve for radial runout with a dial gauge and “V”

block. To check runout, rotate valve slowly. If runout exceeds

its limit, replace valve.

Limit on valve head radial runout

: 0.08 mm (0.003 in.)

Seating contact width:

Create contact pattern on each valve in the usual manner,

i.e. by giving uniform coat of marking compound to valve

seat and by rotatingly tapping seat with valve head. Valve

lapper (tool used in valve lapping) must be used.

Pattern produced on seating face of valve must be a continu-

ous ring without any break, and the width of pattern must be

within specified range.

Standard seating width “a” revealed by contact pattern on

valve face

In and Ex : 1.1 - 1.3 mm (0.0433 - 0.0512 in.)

Page 552 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-51

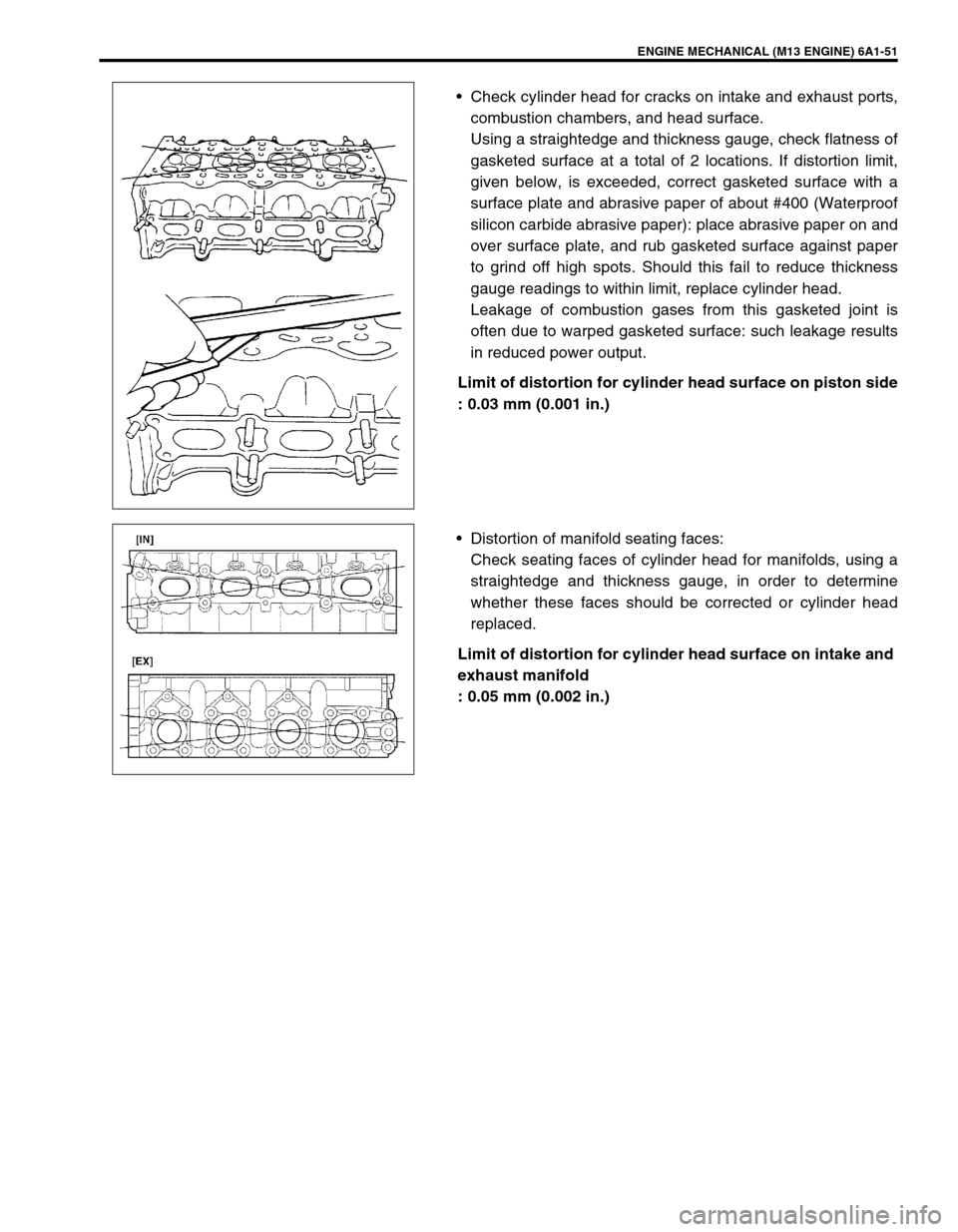

Check cylinder head for cracks on intake and exhaust ports,

combustion chambers, and head surface.

Using a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 2 locations. If distortion limit,

given below, is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400 (Waterproof

silicon carbide abrasive paper): place abrasive paper on and

over surface plate, and rub gasketed surface against paper

to grind off high spots. Should this fail to reduce thickness

gauge readings to within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint is

often due to warped gasketed surface: such leakage results

in reduced power output.

Limit of distortion for cylinder head surface on piston side

: 0.03 mm (0.001 in.)

Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds, using a

straightedge and thickness gauge, in order to determine

whether these faces should be corrected or cylinder head

replaced.

Limit of distortion for cylinder head surface on intake and

exhaust manifold

: 0.05 mm (0.002 in.)