wheel SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 300 of 698

BRAKES 5-27

b) For 4WD vehicle :

Pull brake drum off by using 8 mm bolts.

INSPECTION

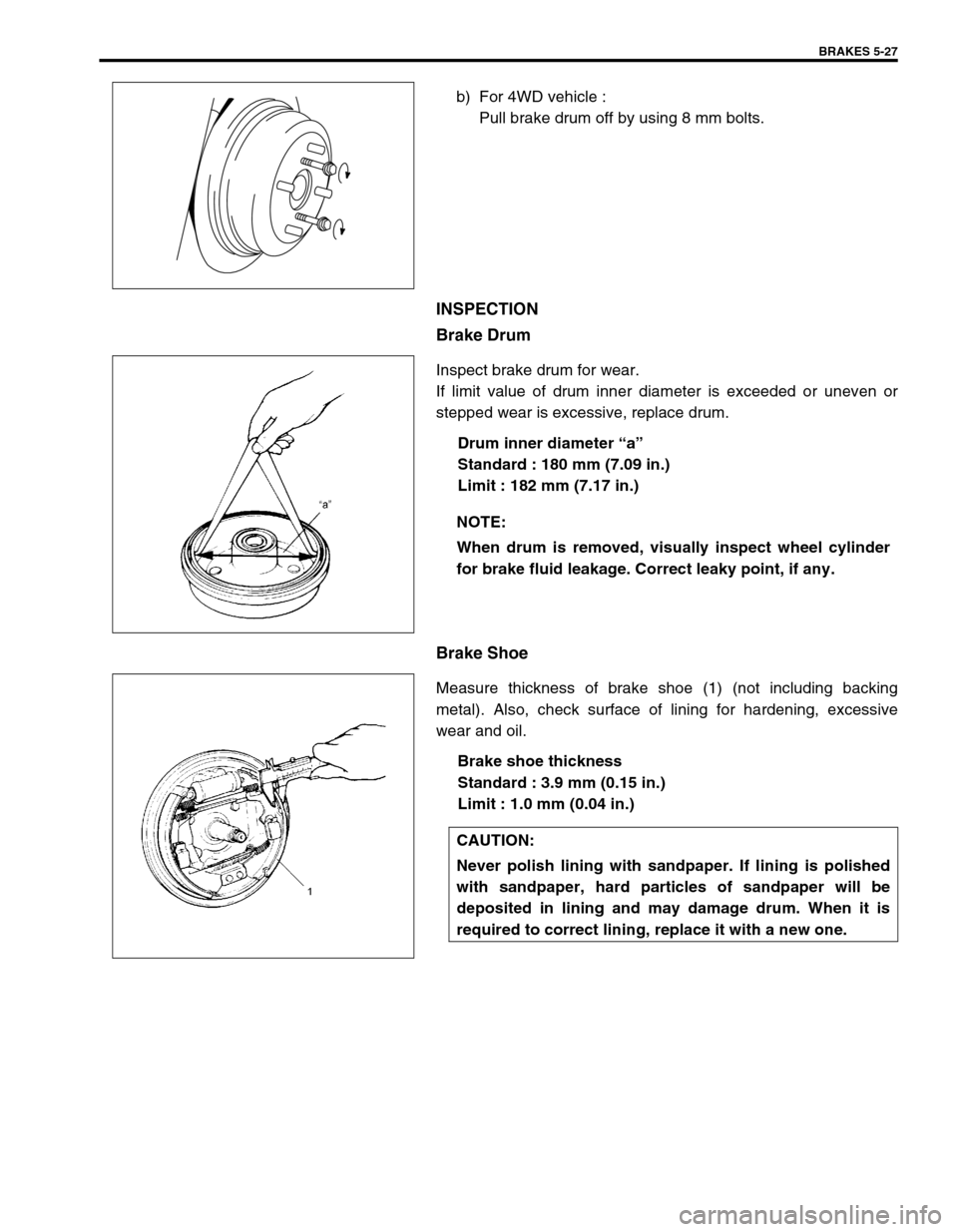

Brake Drum

Inspect brake drum for wear.

If limit value of drum inner diameter is exceeded or uneven or

stepped wear is excessive, replace drum.

Drum inner diameter “a”

Standard : 180 mm (7.09 in.)

Limit : 182 mm (7.17 in.)

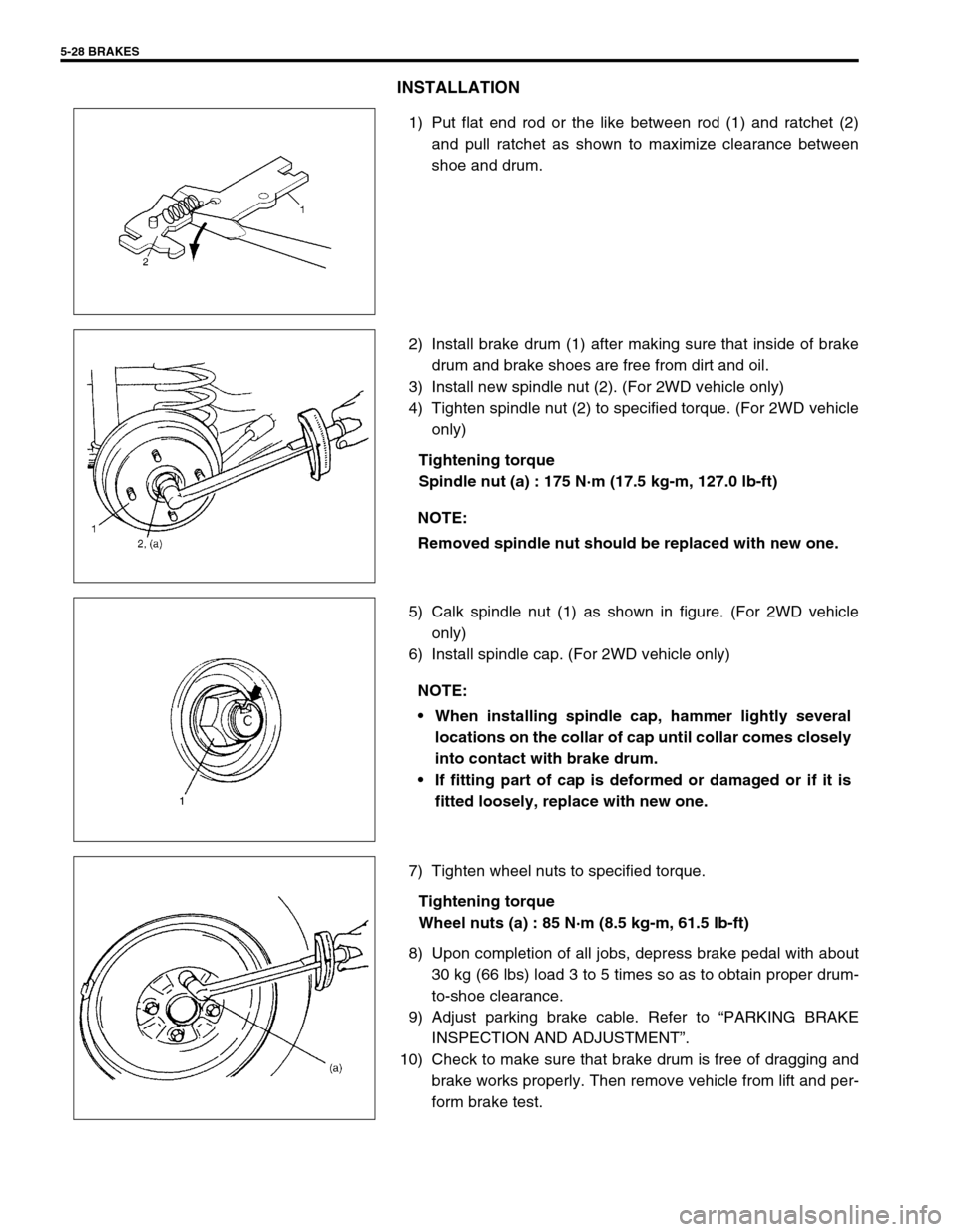

Brake Shoe

Measure thickness of brake shoe (1) (not including backing

metal). Also, check surface of lining for hardening, excessive

wear and oil.

Brake shoe thickness

Standard : 3.9 mm (0.15 in.)

Limit : 1.0 mm (0.04 in.)

NOTE:

When drum is removed, visually inspect wheel cylinder

for brake fluid leakage. Correct leaky point, if any.

CAUTION:

Never polish lining with sandpaper. If lining is polished

with sandpaper, hard particles of sandpaper will be

deposited in lining and may damage drum. When it is

required to correct lining, replace it with a new one.

Page 301 of 698

5-28 BRAKES

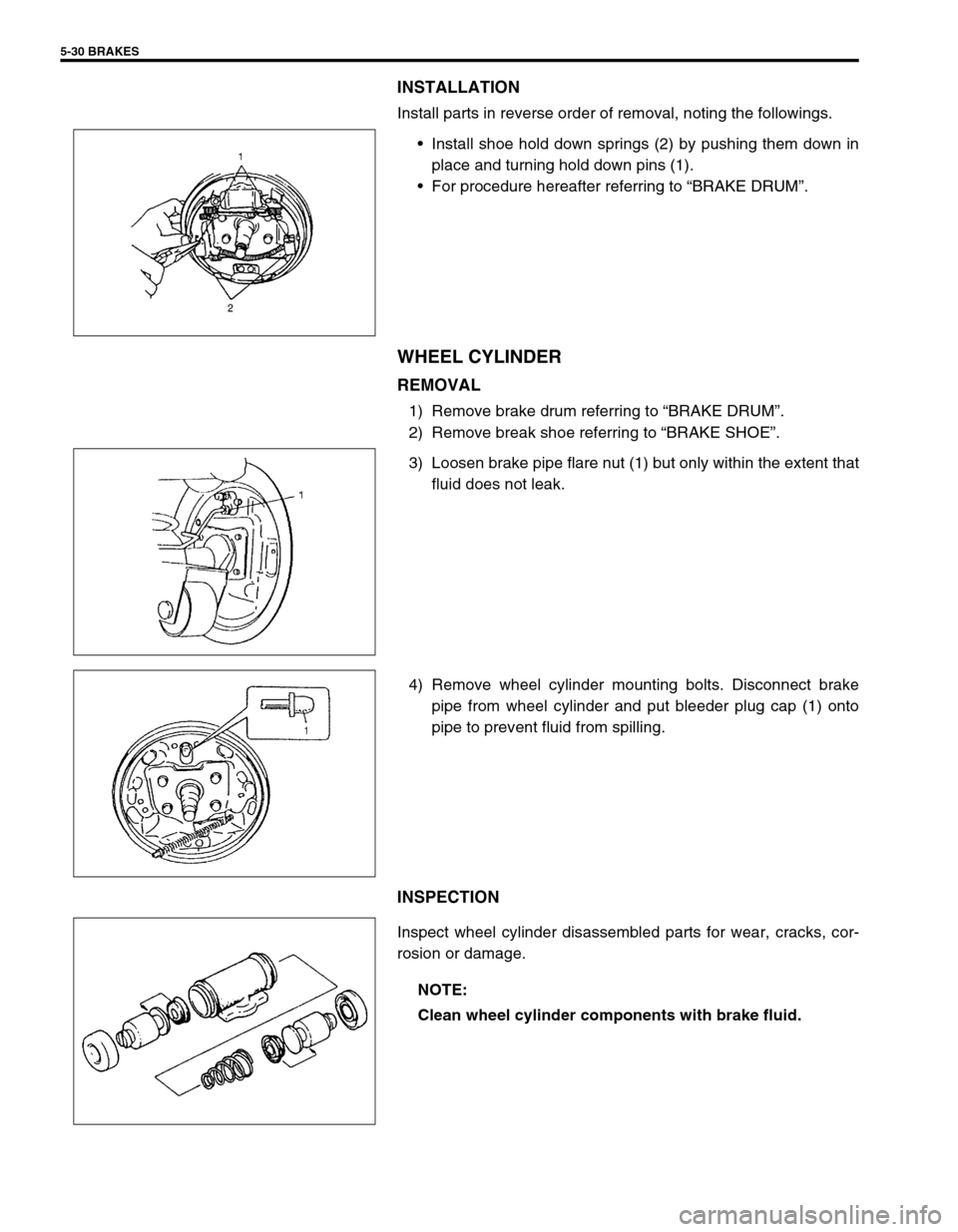

INSTALLATION

1) Put flat end rod or the like between rod (1) and ratchet (2)

and pull ratchet as shown to maximize clearance between

shoe and drum.

2) Install brake drum (1) after making sure that inside of brake

drum and brake shoes are free from dirt and oil.

3) Install new spindle nut (2). (For 2WD vehicle only)

4) Tighten spindle nut (2) to specified torque. (For 2WD vehicle

only)

Tightening torque

Spindle nut (a) : 175 N·m (17.5 kg-m, 127.0 lb-ft)

5) Calk spindle nut (1) as shown in figure. (For 2WD vehicle

only)

6) Install spindle cap. (For 2WD vehicle only)

7) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts (a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

9) Adjust parking brake cable. Refer to “PARKING BRAKE

INSPECTION AND ADJUSTMENT”.

10) Check to make sure that brake drum is free of dragging and

brake works properly. Then remove vehicle from lift and per-

form brake test.

NOTE:

Removed spindle nut should be replaced with new one.

NOTE:

When installing spindle cap, hammer lightly several

locations on the collar of cap until collar comes closely

into contact with brake drum.

If fitting part of cap is deformed or damaged or if it is

fitted loosely, replace with new one.

Page 303 of 698

5-30 BRAKES

INSTALLATION

Install parts in reverse order of removal, noting the followings.

Install shoe hold down springs (2) by pushing them down in

place and turning hold down pins (1).

For procedure hereafter referring to “BRAKE DRUM”.

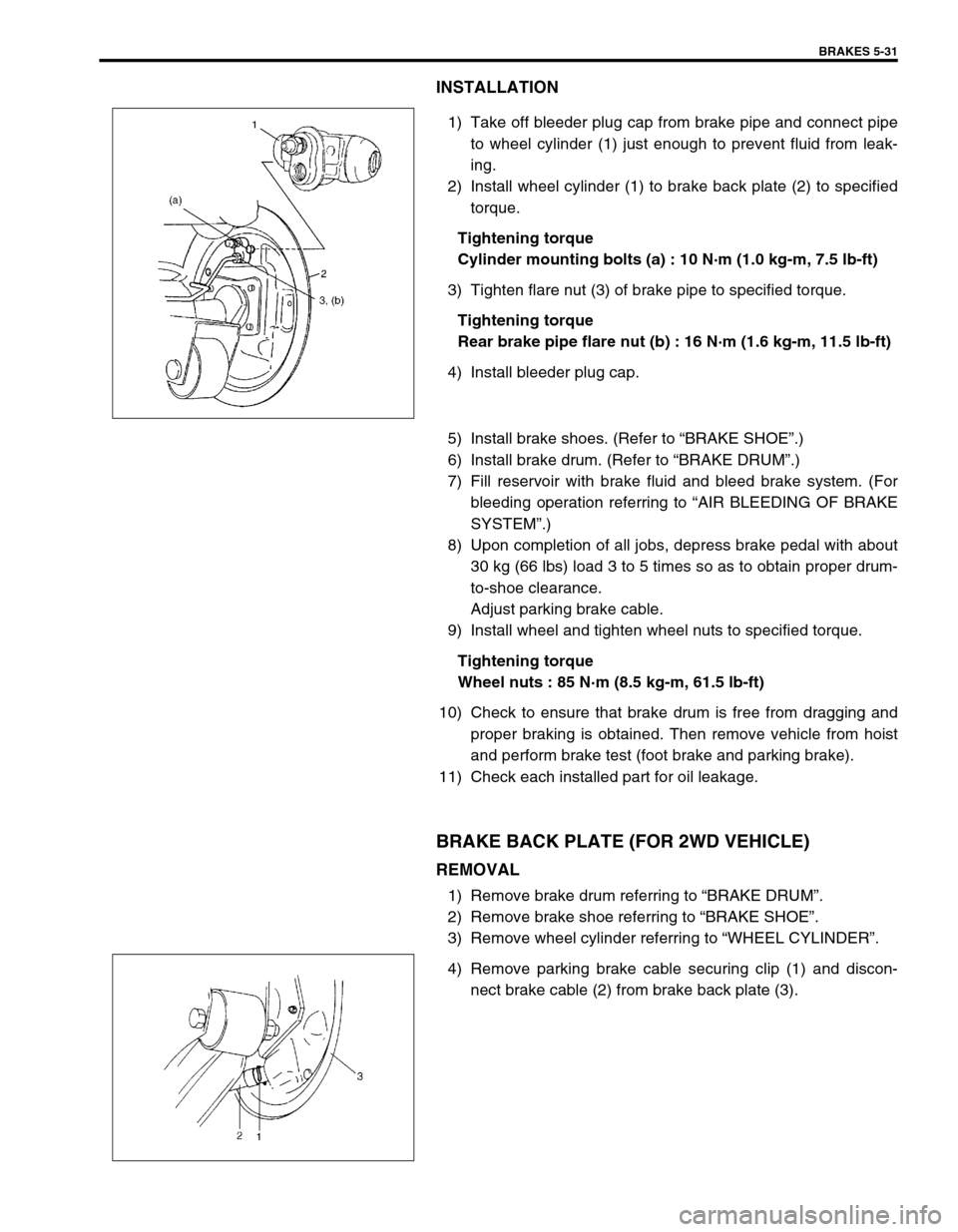

WHEEL CYLINDER

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove break shoe referring to “BRAKE SHOE”.

3) Loosen brake pipe flare nut (1) but only within the extent that

fluid does not leak.

4) Remove wheel cylinder mounting bolts. Disconnect brake

pipe from wheel cylinder and put bleeder plug cap (1) onto

pipe to prevent fluid from spilling.

INSPECTION

Inspect wheel cylinder disassembled parts for wear, cracks, cor-

rosion or damage.

NOTE:

Clean wheel cylinder components with brake fluid.

Page 304 of 698

BRAKES 5-31

INSTALLATION

1) Take off bleeder plug cap from brake pipe and connect pipe

to wheel cylinder (1) just enough to prevent fluid from leak-

ing.

2) Install wheel cylinder (1) to brake back plate (2) to specified

torque.

Tightening torque

Cylinder mounting bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

3) Tighten flare nut (3) of brake pipe to specified torque.

Tightening torque

Rear brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

4) Install bleeder plug cap.

5) Install brake shoes. (Refer to “BRAKE SHOE”.)

6) Install brake drum. (Refer to “BRAKE DRUM”.)

7) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation referring to “AIR BLEEDING OF BRAKE

SYSTEM”.)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

Adjust parking brake cable.

9) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 lb-ft)

10) Check to ensure that brake drum is free from dragging and

proper braking is obtained. Then remove vehicle from hoist

and perform brake test (foot brake and parking brake).

11) Check each installed part for oil leakage.

BRAKE BACK PLATE (FOR 2WD VEHICLE)

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove brake shoe referring to “BRAKE SHOE”.

3) Remove wheel cylinder referring to “WHEEL CYLINDER”.

4) Remove parking brake cable securing clip (1) and discon-

nect brake cable (2) from brake back plate (3).

Page 305 of 698

5-32 BRAKES

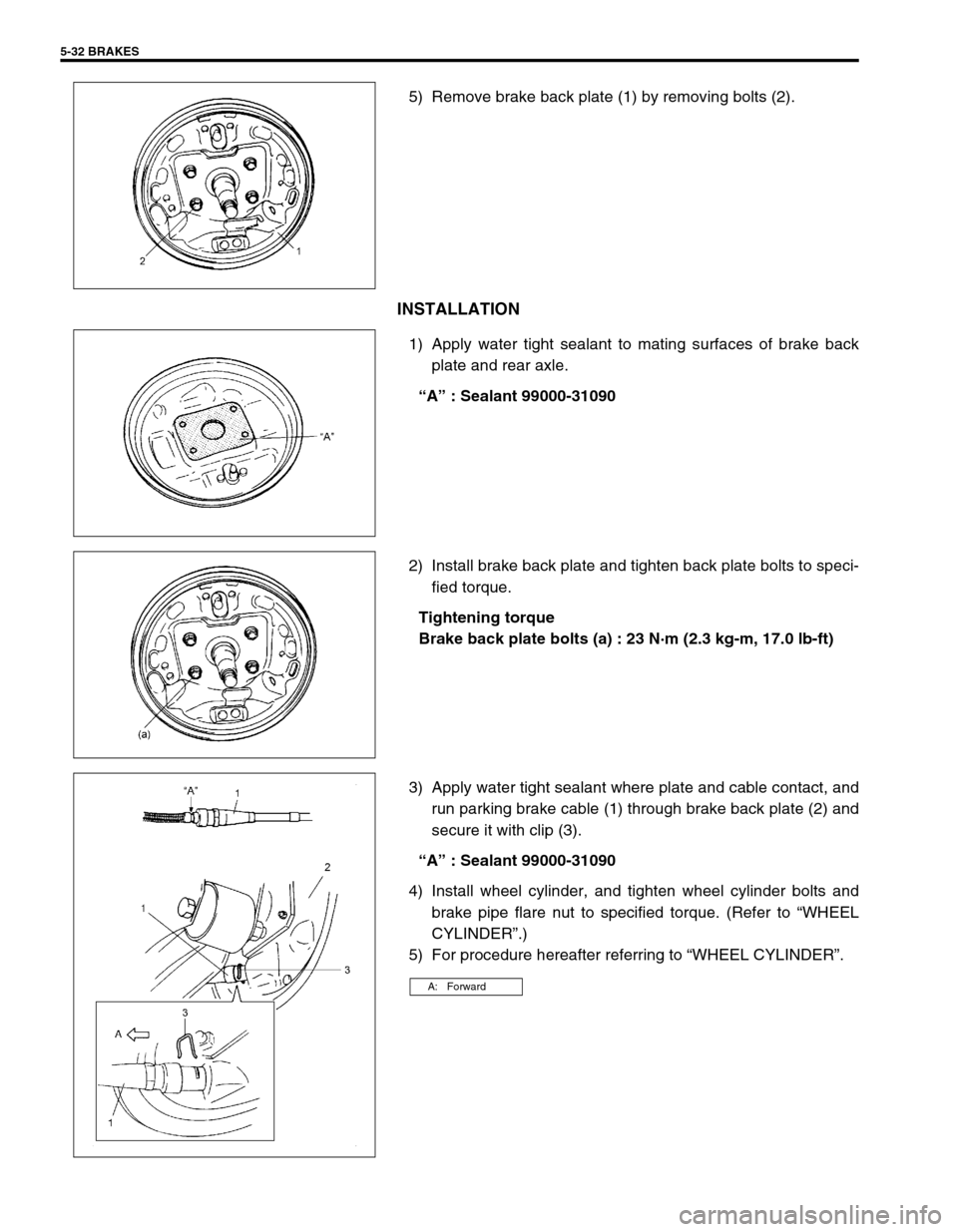

5) Remove brake back plate (1) by removing bolts (2).

INSTALLATION

1) Apply water tight sealant to mating surfaces of brake back

plate and rear axle.

“A” : Sealant 99000-31090

2) Install brake back plate and tighten back plate bolts to speci-

fied torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Apply water tight sealant where plate and cable contact, and

run parking brake cable (1) through brake back plate (2) and

secure it with clip (3).

“A” : Sealant 99000-31090

4) Install wheel cylinder, and tighten wheel cylinder bolts and

brake pipe flare nut to specified torque. (Refer to “WHEEL

CYLINDER”.)

5) For procedure hereafter referring to “WHEEL CYLINDER”.

A: Forward

Page 306 of 698

BRAKES 5-33

BRAKE BACK PLATE (FOR 4WD VEHICLE)

REMOVAL AND INSTALLATION

Refer to “REAR AXLE SHAFT AND WHEEL BEARING (4WD VEHICLE)” in Section 3E.

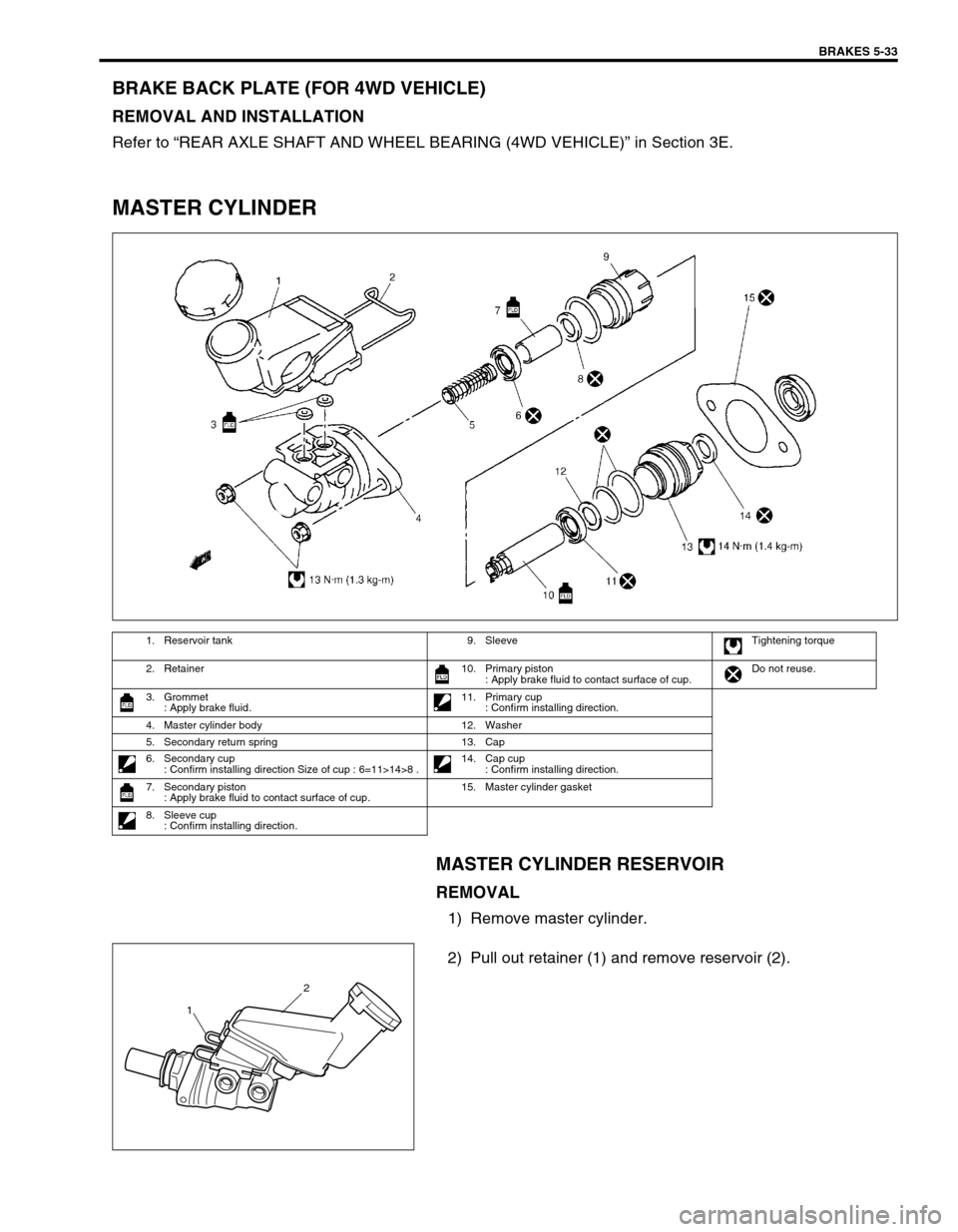

MASTER CYLINDER

MASTER CYLINDER RESERVOIR

REMOVAL

1) Remove master cylinder.

2) Pull out retainer (1) and remove reservoir (2).

1. Reservoir tank 9. Sleeve Tightening torque

2. Retainer 10. Primary piston

: Apply brake fluid to contact surface of cup.Do not reuse.

3. Grommet

: Apply brake fluid.11. Primary cup

: Confirm installing direction.

4. Master cylinder body 12. Washer

5. Secondary return spring 13. Cap

6. Secondary cup

: Confirm installing direction Size of cup : 6=11>14>8 .14. Cap cup

: Confirm installing direction.

7. Secondary piston

: Apply brake fluid to contact surface of cup.15. Master cylinder gasket

8. Sleeve cup

: Confirm installing direction.

2

1

Page 314 of 698

BRAKES 5-41

BRAKE HOSE/PIPE

FRONT BRAKE HOSE/PIPE

REMOVAL

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Remove brake flexible hose or pipe.

INSTALLATION

Reverse brake flexible hose installation procedure, noting the followings.

Make sure that steering wheel is in straight-forward position and flexible hose has not twist or kink.

Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point, remove and correct. Fill and maintain brake fluid level in

reservoir.

Bleed brake system. Refer to “AIR BLEEDING OF BRAKE SYSTEM”.

Perform brake test and check installed part for fluid leakage. NOTE:

This operation is not necessary when removing pipes connecting master cylinder.

Page 317 of 698

5-44 BRAKES

REAR BRAKE HOSE/PIPE

REMOVAL

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Remove brake flexible hose or pipe.

INSTALLATION

Reverse brake flexible hose installation procedure, nothing the followings.

Fill and maintain brake fluid level in reservoir.

Bleed brake system. Refer to “AIR BLEEDING OF BRAKE SYSTEM”.

Perform brake test and check each installed part for fluid leakage.

Never reuse protector nut once removed. Be sure to use a new one.

Install clamps properly referring to figure below and tighten bolts.

When installing hose, make sure that it has no twist or kink.

Page 319 of 698

5-46 BRAKES

PARKING BRAKE CABLE

REMOVAL

1) Raise, suitably support vehicle and remove wheel.

2) Remove parking brake cable.

INSTALLATION

Install it by reversing removal procedure, noting the following points.

Install clamps properly referring to figure below.

Tighten bolts and nuts to specified torque.

Adjust parking brake cable. (Refer to “PARKING BRAKE INSPECTION AND ADJUSTMENT”.)

Check brake drum for dragging and brake system for proper performance. After removing vehicle from hoist,

brake test should be performed.

Page 323 of 698

5-50 BRAKES

REQUIRED SERVICE MATERIAL

SPECIAL TOOL

MaterialRecommended SUZUKI product

(Part Number)Use

Brake fluid DOT 3 or SAE J1703To fill master cylinder reservoir.

To clean and apply to inner parts of master

cylinder caliper and wheel cylinder when they

are disassembled.

Water tight sealant SEALING COMPOUND 366E

(99000-31090)To apply to mating surfaces of brake back

plate and rear axle (2WD vehicle) or rear

axle housing (4WD vehicle).

To apply to mating surfaces of brake back

plate and parking brake cable.

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)To apply to slide pin of brake caliper carrier.

09900-06106 09900-20606 09900-20701 09942-15510

Snap ring remover Dial gauge Dial gauge chuck Sliding hammer

09943-17912 09951-18220 09952-16020 09952-46010

Brake drum remover

(Front wheel hub

remover)Secondary cup installer

setBooster piston rod

adjusterMaster cylinder attach-

ment