ECM input SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 477 of 698

6-108 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P1450 BAROMETRIC PRESSURE SENSOR LOW/HIGH INPUT

DTC P1451 BAROMETRIC PRESSURE SENSOR PERFORMANCE PROBLEM

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Barometric pressure sensor is installed in ECM.

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Turn ignition switch ON for 2 sec., crank engine for 2 sec. and run it at idle for 1 min.

4) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

INSPECTION

DTC P1450 :

Substitute a known-good ECM and recheck.

DTC P1451 :

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC P1450 :

Barometric pressure : Sensor voltage is 4.7 V or higher, or

1.6 V or lowerECM (barometric pressure sensor) malfunc-

tion

DTC P1451 :

Vehicle stopped

Engine cranking

Difference between barometric pressure and intake mani-

fold absolute pressure is 26 kPa, 200 mmHg or more

Difference between intake manifold absolute pressure at

engine start and the pressure after engine start is 1.3 kPa,

10 mmHg or less.

✱2 driving cycle detection logic, monitoring once/1 driving.Manifold absolute pressure sensor and its

circuit malfunction

ECM (barometric pressure sensor) malfunc-

tion

NOTE:

Note that atmospheric pressure varies depending on weather conditions as well as altitude.

Take that into consideration when performing these check.

Step Action Yes No

1 Check Barometric Pressure Valve.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON and select “DATA

LIST” mode on scan tool.

3) Check manifold absolute pressure. See Fig.

1.

Is it barometric pressure (approx. 100 kPa, 760

mmHg) at sea level?Substitute a known-good

ECM and recheck.Go to Step 2.

Page 481 of 698

6-112 ENGINE GENERAL INFORMATION AND DIAGNOSIS

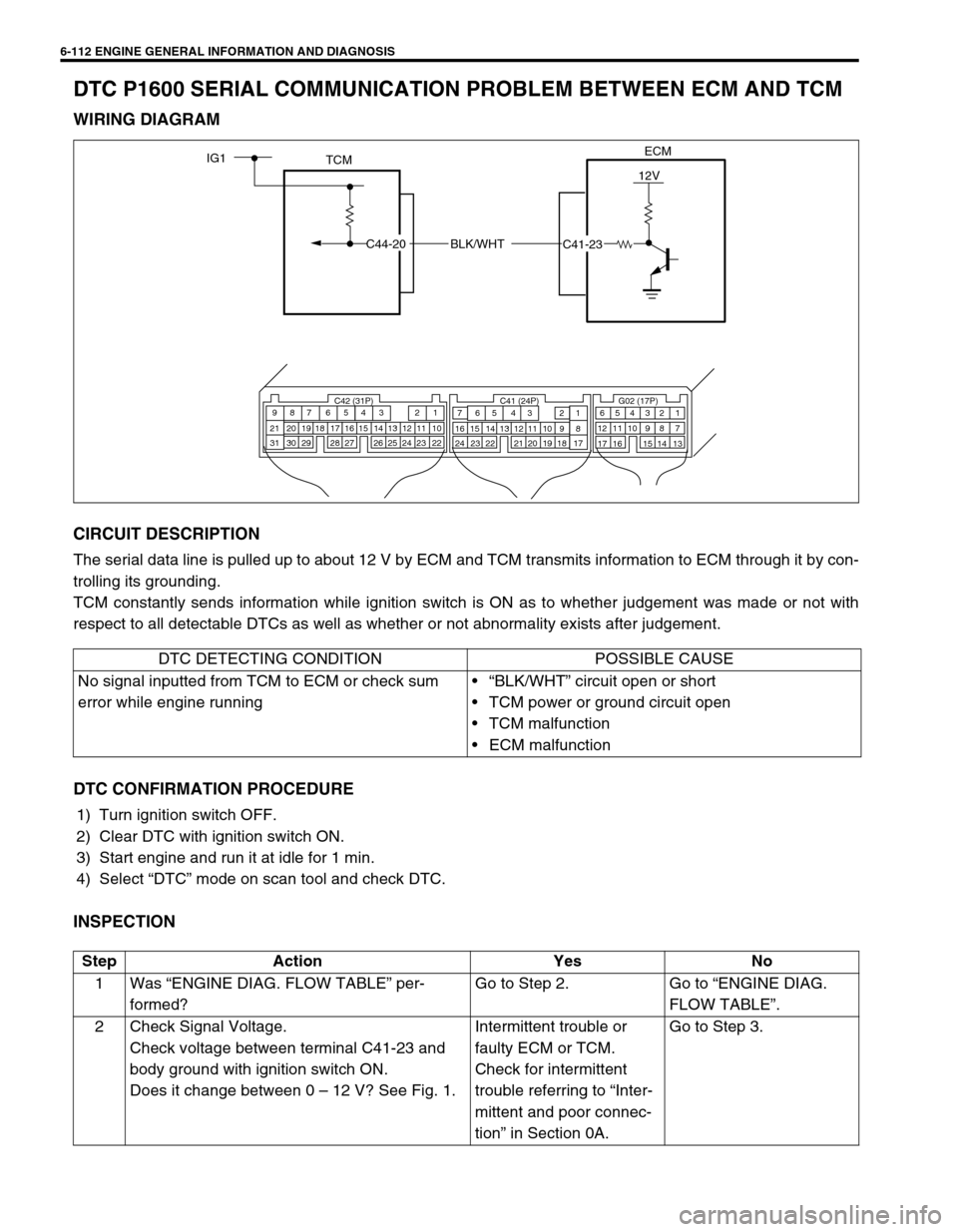

DTC P1600 SERIAL COMMUNICATION PROBLEM BETWEEN ECM AND TCM

WIRING DIAGRAM

CIRCUIT DESCRIPTION

The serial data line is pulled up to about 12 V by ECM and TCM transmits information to ECM through it by con-

trolling its grounding.

TCM constantly sends information while ignition switch is ON as to whether judgement was made or not with

respect to all detectable DTCs as well as whether or not abnormality exists after judgement.

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Start engine and run it at idle for 1 min.

4) Select “DTC” mode on scan tool and check DTC.

INSPECTION

ECM

TCMIG1

BLK/WHT

12V

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C44-20

C41-23

DTC DETECTING CONDITION POSSIBLE CAUSE

No signal inputted from TCM to ECM or check sum

error while engine running“BLK/WHT” circuit open or short

TCM power or ground circuit open

TCM malfunction

ECM malfunction

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check Signal Voltage.

Check voltage between terminal C41-23 and

body ground with ignition switch ON.

Does it change between 0 – 12 V? See Fig. 1.Intermittent trouble or

faulty ECM or TCM.

Check for intermittent

trouble referring to “Inter-

mittent and poor connec-

tion” in Section 0A.Go to Step 3.

Page 483 of 698

6-114 ENGINE GENERAL INFORMATION AND DIAGNOSIS

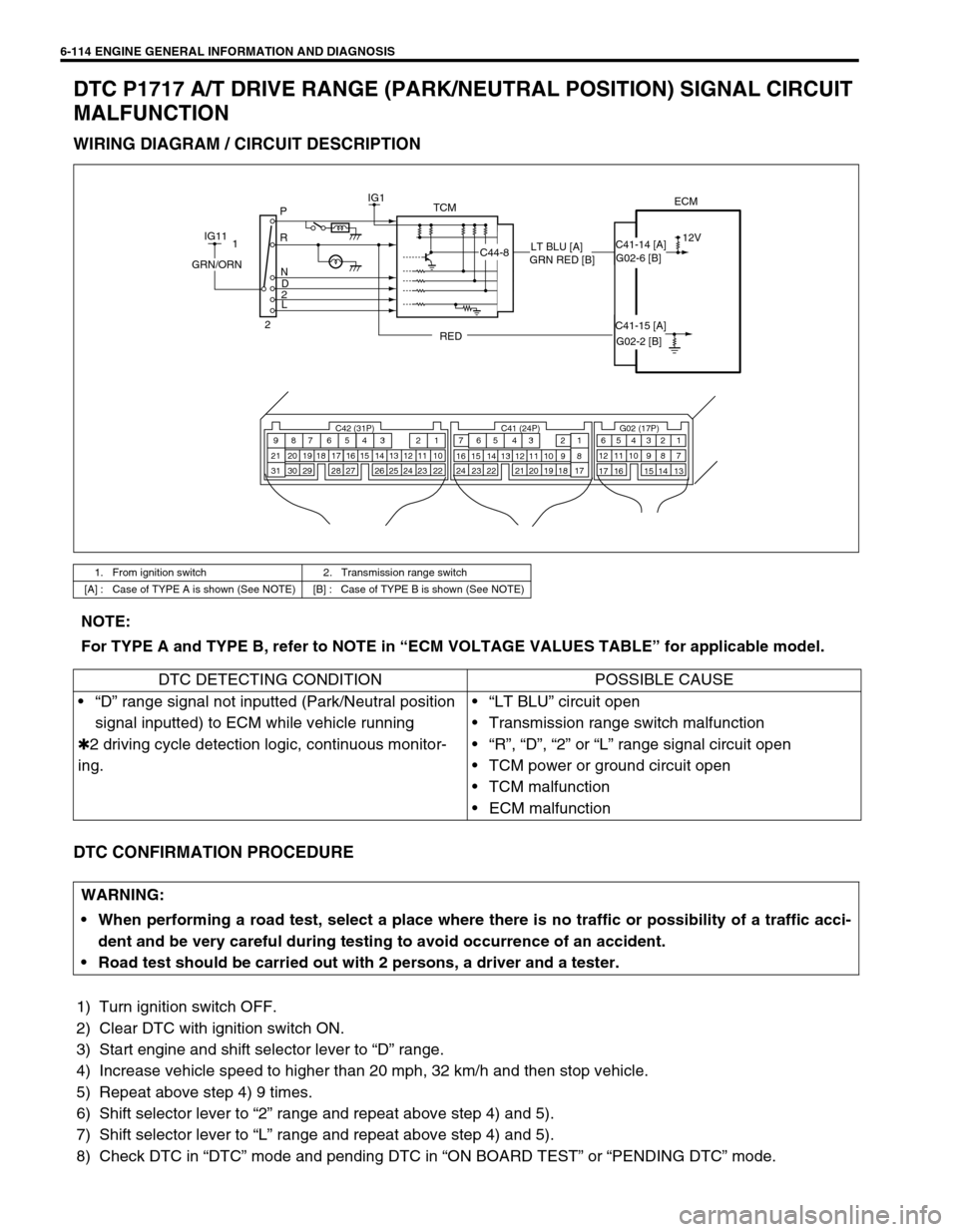

DTC P1717 A/T DRIVE RANGE (PARK/NEUTRAL POSITION) SIGNAL CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Start engine and shift selector lever to “D” range.

4) Increase vehicle speed to higher than 20 mph, 32 km/h and then stop vehicle.

5) Repeat above step 4) 9 times.

6) Shift selector lever to “2” range and repeat above step 4) and 5).

7) Shift selector lever to “L” range and repeat above step 4) and 5).

8) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

1. From ignition switch 2. Transmission range switch

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

TCMECMIG1

12V P

R

N

D

2

L

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

IG11

C44-8

REDGRN/ORN1

2G02-6 [B] C41-14 [A]

C41-15 [A]

G02-2 [B] GRN RED [B]LT BLU [A]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

DTC DETECTING CONDITION POSSIBLE CAUSE

“D” range signal not inputted (Park/Neutral position

signal inputted) to ECM while vehicle running

✱2 driving cycle detection logic, continuous monitor-

ing.“LT BLU” circuit open

Transmission range switch malfunction

“R”, “D”, “2” or “L” range signal circuit open

TCM power or ground circuit open

TCM malfunction

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 492 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-123

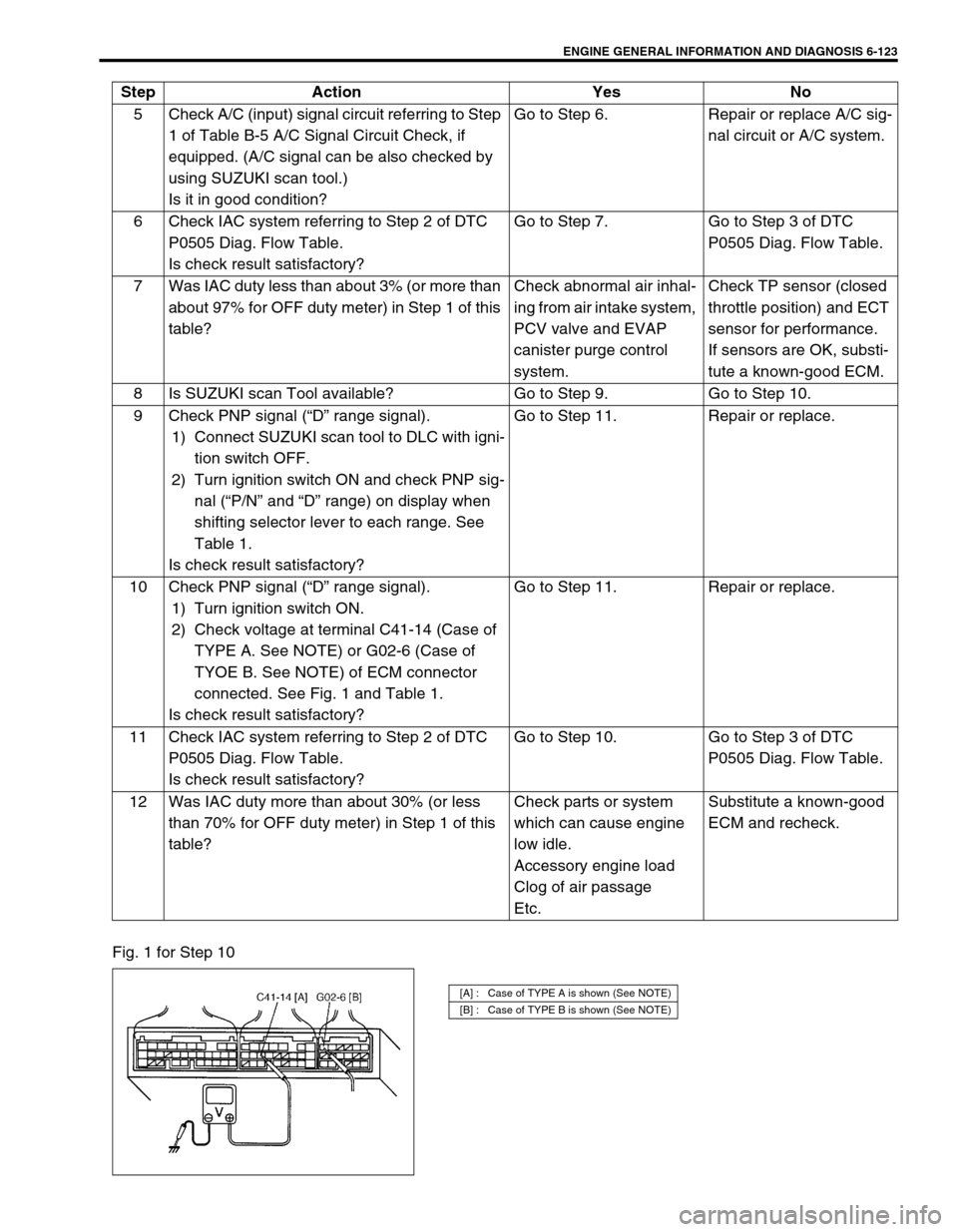

Fig. 1 for Step 105 Check A/C (input) signal circuit referring to Step

1 of Table B-5 A/C Signal Circuit Check, if

equipped. (A/C signal can be also checked by

using SUZUKI scan tool.)

Is it in good condition?Go to Step 6. Repair or replace A/C sig-

nal circuit or A/C system.

6 Check IAC system referring to Step 2 of DTC

P0505 Diag. Flow Table.

Is check result satisfactory?Go to Step 7. Go to Step 3 of DTC

P0505 Diag. Flow Table.

7 Was IAC duty less than about 3% (or more than

about 97% for OFF duty meter) in Step 1 of this

table?Check abnormal air inhal-

ing from air intake system,

PCV valve and EVAP

canister purge control

system.Check TP sensor (closed

throttle position) and ECT

sensor for performance.

If sensors are OK, substi-

tute a known-good ECM.

8 Is SUZUKI scan Tool available? Go to Step 9. Go to Step 10.

9 Check PNP signal (“D” range signal).

1) Connect SUZUKI scan tool to DLC with igni-

tion switch OFF.

2) Turn ignition switch ON and check PNP sig-

nal (“P/N” and “D” range) on display when

shifting selector lever to each range. See

Table 1.

Is check result satisfactory?Go to Step 11. Repair or replace.

10 Check PNP signal (“D” range signal).

1) Turn ignition switch ON.

2) Check voltage at terminal C41-14 (Case of

TYPE A. See NOTE) or G02-6 (Case of

TYOE B. See NOTE) of ECM connector

connected. See Fig. 1 and Table 1.

Is check result satisfactory?Go to Step 11. Repair or replace.

11 Check IAC system referring to Step 2 of DTC

P0505 Diag. Flow Table.

Is check result satisfactory?Go to Step 10. Go to Step 3 of DTC

P0505 Diag. Flow Table.

12 Was IAC duty more than about 30% (or less

than 70% for OFF duty meter) in Step 1 of this

table?Check parts or system

which can cause engine

low idle.

Accessory engine load

Clog of air passage

Etc.Substitute a known-good

ECM and recheck. Step Action Yes No

[A] : Case of TYPE A is shown (See NOTE)

[B] : Case of TYPE B is shown (See NOTE)

Page 622 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-1

6F1

6F2

6G

6H

6E1

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6E1

ENGINE AND EMISSION CONTROL SYSTEM

CONTENTS

GENERAL DESCRIPTION ............................ 6E1-2

AIR INTAKE SYSTEM ............................... 6E1-5

FUEL DELIVERY SYSTEM ....................... 6E1-6

FUEL PUMP ........................................... 6E1-6

ELECTRONIC CONTROL SYSTEM .......... 6E1-7

ENGINE & EMISSION CONTROL

INPUT/OUTPUT TABLE ........................ 6E1-8

ECM INPUT/OUTPUT CIRCUIT

DIAGRAM............................................... 6E1-9

ECM TERMINAL ARRANGEMENT

TABLE .................................................. 6E1-13

ON-VEHICLE SERVICE .............................. 6E1-15

ACCELERATOR CABLE

ADJUSTMENT ..................................... 6E1-15

IDLE SPEED/IDLE AIR CONTROL

(IAC) DUTY INSPECTION ................... 6E1-15

IDLE MIXTURE INSPECTION /

ADJUSTMENT (VEHICLE WITHOUT

HEATED OXYGEN SENSOR) ............. 6E1-17

AIR INTAKE SYSTEM ............................. 6E1-18

THROTTLE BODY ............................... 6E1-18IDLE AIR CONTROL VALVE (IAC

VALVE) ................................................ 6E1-20

FUEL DELIVERY SYSTEM ..................... 6E1-21

FUEL PRESSURE INSPECTION ........ 6E1-21

FUEL PUMP WITH PRESSURE

REGULATOR ....................................... 6E1-22

FUEL INJECTOR ................................. 6E1-23

ELECTRONIC CONTROL SYSTEM ....... 6E1-27

ENGINE CONTROL MODULE

(ECM) ................................................... 6E1-27

MANIFOLD ABSOLUTE PRESSURE

SENSOR (MAP SENSOR)................... 6E1-27

THROTTLE POSITION SENSOR (TP

SENSOR) ............................................. 6E1-28

INTAKE AIR TEMPERATURE

SENSOR (IAT SENSOR) ..................... 6E1-29

ENGINE COOLANT TEMPERATURE

SENSOR (ECT SENSOR) ................... 6E1-30

HEATED OXYGEN SENSOR (HO2S-1

AND HO2S-2) ...................................... 6E1-31

CAMSHAFT POSITION SENSOR ....... 6E1-32 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether the following system (parts) are used in the particular vehicle or not depends on vehicle

specifications. Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor(s) or CO adjusting resistor

Three way catalytic converter

Immobilizer indicator lamp

Knock sensor

Page 630 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-9

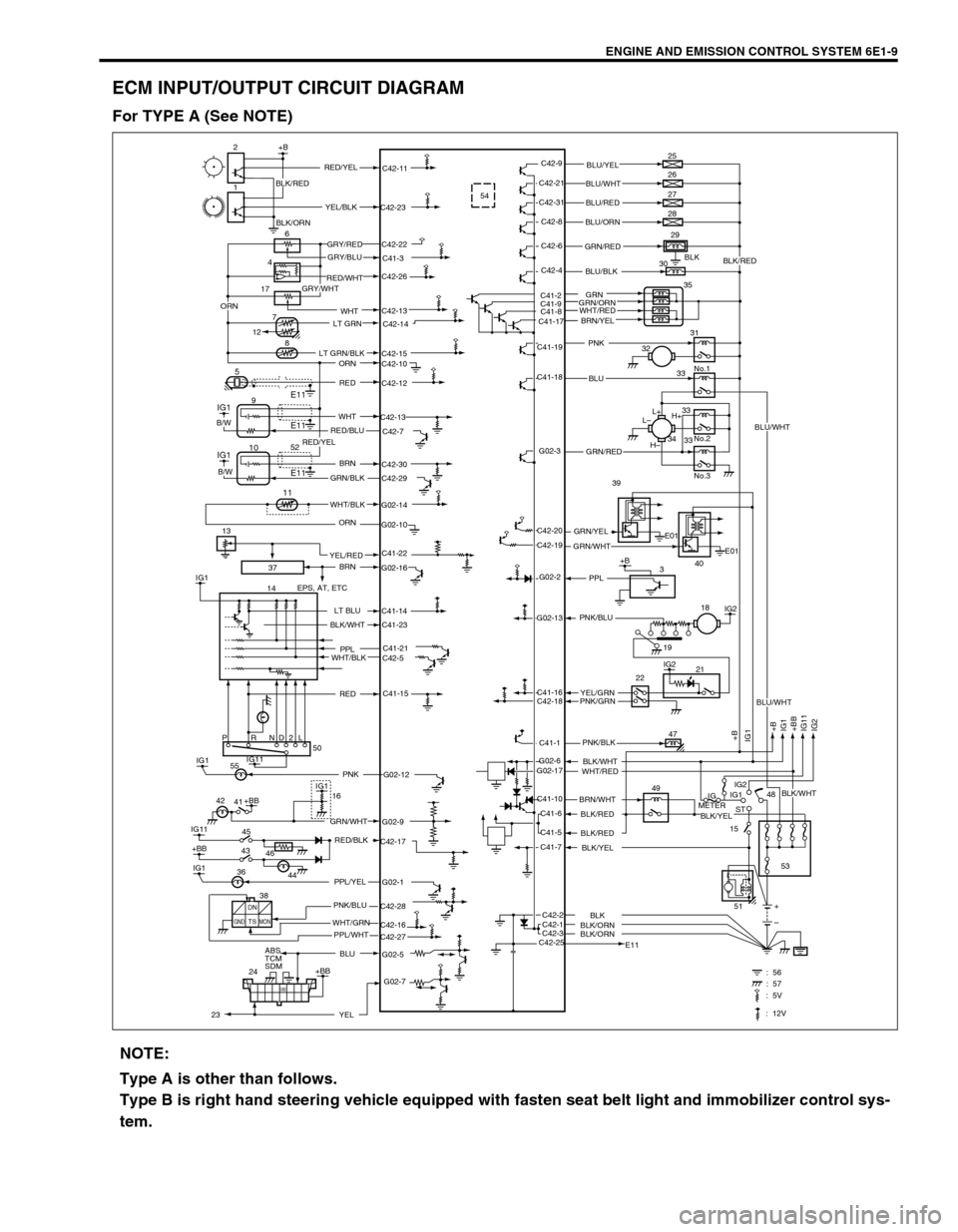

ECM INPUT/OUTPUT CIRCUIT DIAGRAM

For TYPE A (See NOTE)

37

C41-23

G02-12 IG1PNK 5554

BLK

C41-2

C41-9

C41-8

C41-17C42-13

17

2+B

1

6

8

5

IG1

IG1

14C42-9

C42-11

C42-23

C42-22

C41-3

C42-26

C42-14

C42-15

C42-10

C42-12

C42-13

C42-7

C42-30

C42-29

G02-14

G02-10

G02-16

C41-14

C41-21

C42-5

C41-15

G02-9

C42-17

G02-1

C42-28

C42-27 C42-16

G02-5C42-21

C42-31

C42-8

C42-6

C42-4

C41-19

C41-18

G02-3

G02-2

G02-13

C41-16

C42-18

C41-1

C41-10

C41-6

C41-5

C41-7

C42-1 C42-2

C42-3

C42-25G02-6

G02-173E01

E01 C42-20

C42-19L+

L–

H–H+ 25

26

27

28

29

30

35

31

No.1

No.2

No.3 32

33

33

33 34

IG2

IG2

+B

+B

IG1

+BB

IG11

IG2 IG1

21

47

49

IG

METERIG1

ST

15IG2

48

53

E11+

– 2218

PRND2L

IG11

IG11

+BB

IG145 41

ABS

TCM

SDM

24IG1

+BB50

16

E11

E1194

7

12

+BB

GND

: 56 : 57

IG1

E11 10

11

+B RED/YELBLU/YEL

BLU/WHT

BLU/RED

BLU/ORN

GRN/RED

BLU/BLK

PNK

BLU

GRN/RED

GRN/YEL39

40 GRN/WHT

PPL

YEL/GRN PNK/BLU

PNK/GRN

PNK/BLK

BLK/WHT

WHT/RED

BRN/WHT

BLK/RED

BLK/RED

BLK/YEL

BLK/ORNBLK

BLK/ORN YEL/BLK

GRY/RED

GRY/BLU

RED/WHT

GRY/WHT

LT GRN

LT GRN/BLK

ORN

RED

WHT

RED/BLU

BRN

GRN/BLK

WHT/BLK

ORN

BRN

EPS, AT, ETC

LT BLU

PPL

WHT/BLK

GRN/WHT

RED/BLK

PPL/YEL

PNK/BLU

WHT/GRN

BLU

B/W

B/W

BLK/WHT

RED

42

46 43

44 36

DN

TSGND MONPPL/WHT 38

G02-7

YEL

BLK/RED

GRN

GRN/ORN

BRN/YEL

51

2352

C41-22YEL/RED 13WHT

19

ORN

: 5V

: 12V

BLU/WHT

BLK/WHT

BLU/WHT

BLK/YEL

BLK/RED

BLK/ORN

WHT/RED

RED/YEL

NOTE:

Type A is other than follows.

Type B is right hand steering vehicle equipped with fasten seat belt light and immobilizer control sys-

tem.

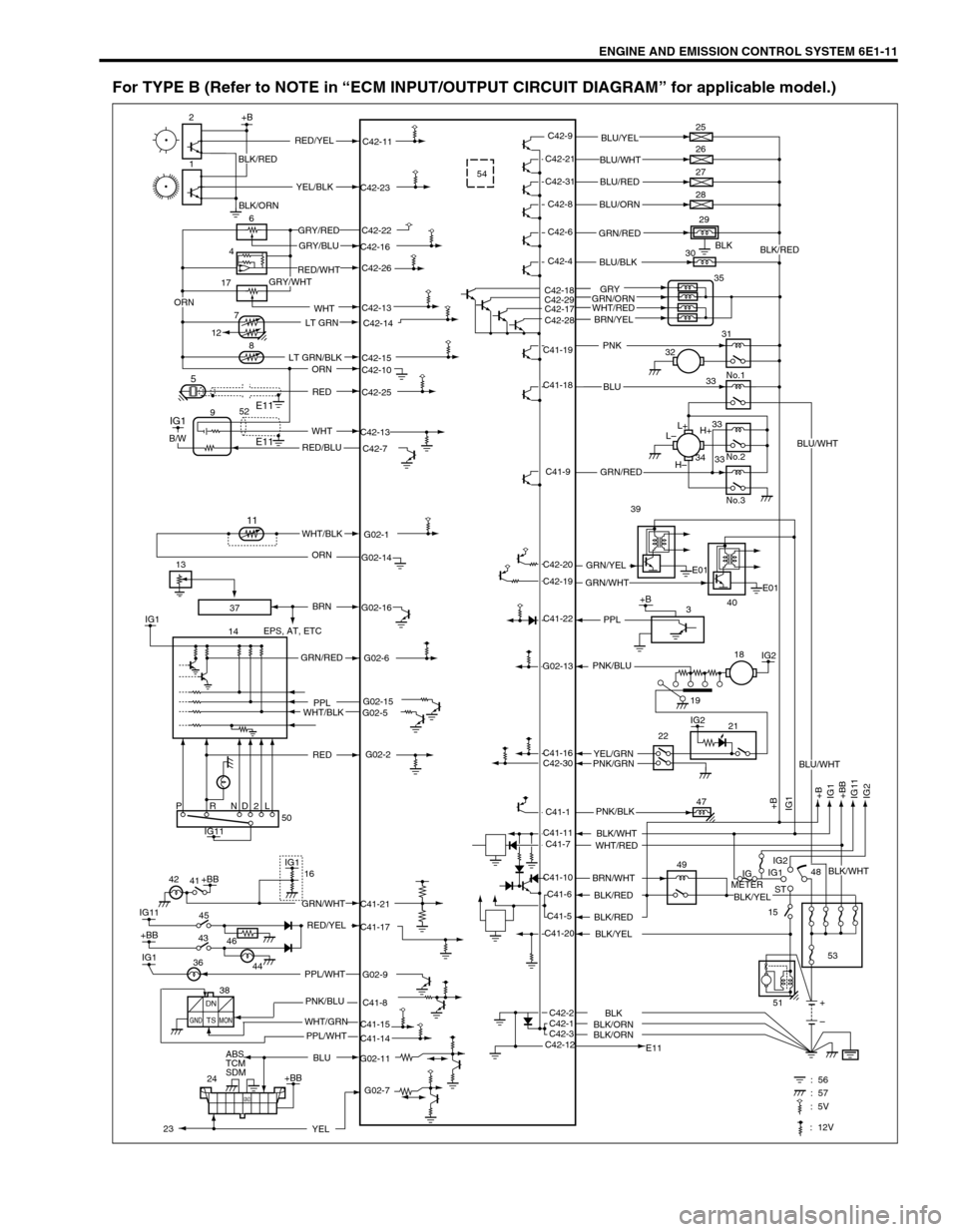

Page 632 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-11

For TYPE B (Refer to NOTE in “ECM INPUT/OUTPUT CIRCUIT DIAGRAM” for applicable model.)

37

54

BLK

C42-18

C42-29

C42-17

C42-28

C42-13

17

2+B

1

6

8

5

IG1

IG1

14C42-9

C42-11

C42-23

C42-22

C42-16

C42-26

C42-14

C42-15

C42-10

C42-25

C42-13

C42-7

G02-1

G02-14

G02-16

G02-6

G02-15

G02-5

G02-2

C41-21

C41-17

G02-9

C41-8

C41-14 C41-15

G02-11C42-21

C42-31

C42-8

C42-6

C42-4

C41-19

C41-18

C41-9

C41-22

G02-13

C41-16

C42-30

C41-1

C41-10

C41-6

C41-5

C41-20

C42-1 C42-2

C42-3

C42-12 C41-11

C41-73E01

E01 C42-20

C42-19L+

L–

H–H+ 25

26

27

28

29

30

35

31

No.1

No.2

No.3 32

33

33

33 34

IG2

IG2

+B

+B

IG1

+BB

IG11

IG2 IG1

21

47

49

IG

METERIG1

ST

15IG2

48

53

E11+

– 2218

PRND2L

IG11

IG11

+BB

IG145 41

ABS

TCM

SDM

24IG1

+BB50

16

E11

E1194

7

12

52

+BB

GND

: 56 : 57

11

+B RED/YELBLU/YEL

BLU/WHT

BLU/RED

BLU/ORN

GRN/RED

BLU/BLK

PNK

BLU

GRN/RED

GRN/YEL39

40 GRN/WHT

PPL

YEL/GRN PNK/BLU

PNK/GRN

PNK/BLK

BLK/WHT

WHT/RED

BRN/WHT

BLK/RED

BLK/RED

BLK/YEL

BLK/ORNBLK

BLK/ORN YEL/BLK

GRY/RED

GRY/BLU

RED/WHT

GRY/WHT

LT GRN

LT GRN/BLK

ORN

RED

WHT

RED/BLU

WHT/BLK

ORN

BRN

EPS, AT, ETC

GRN/RED

PPL

WHT/BLK

GRN/WHT

RED/YEL

PPL/WHT

PNK/BLU

WHT/GRN

BLU

B/W

RED

42

46 43

44 36

DN

TS

GND MON

PPL/WHT 38

G02-7

YEL

BLK/RED

GRY

GRN/ORN

BRN/YEL

51

23

13WHT

19

ORN

: 5V

: 12V

BLU/WHT

BLK/WHT

BLU/WHT

BLK/YEL

BLK/RED

BLK/ORN

WHT/RED

Page 634 of 698

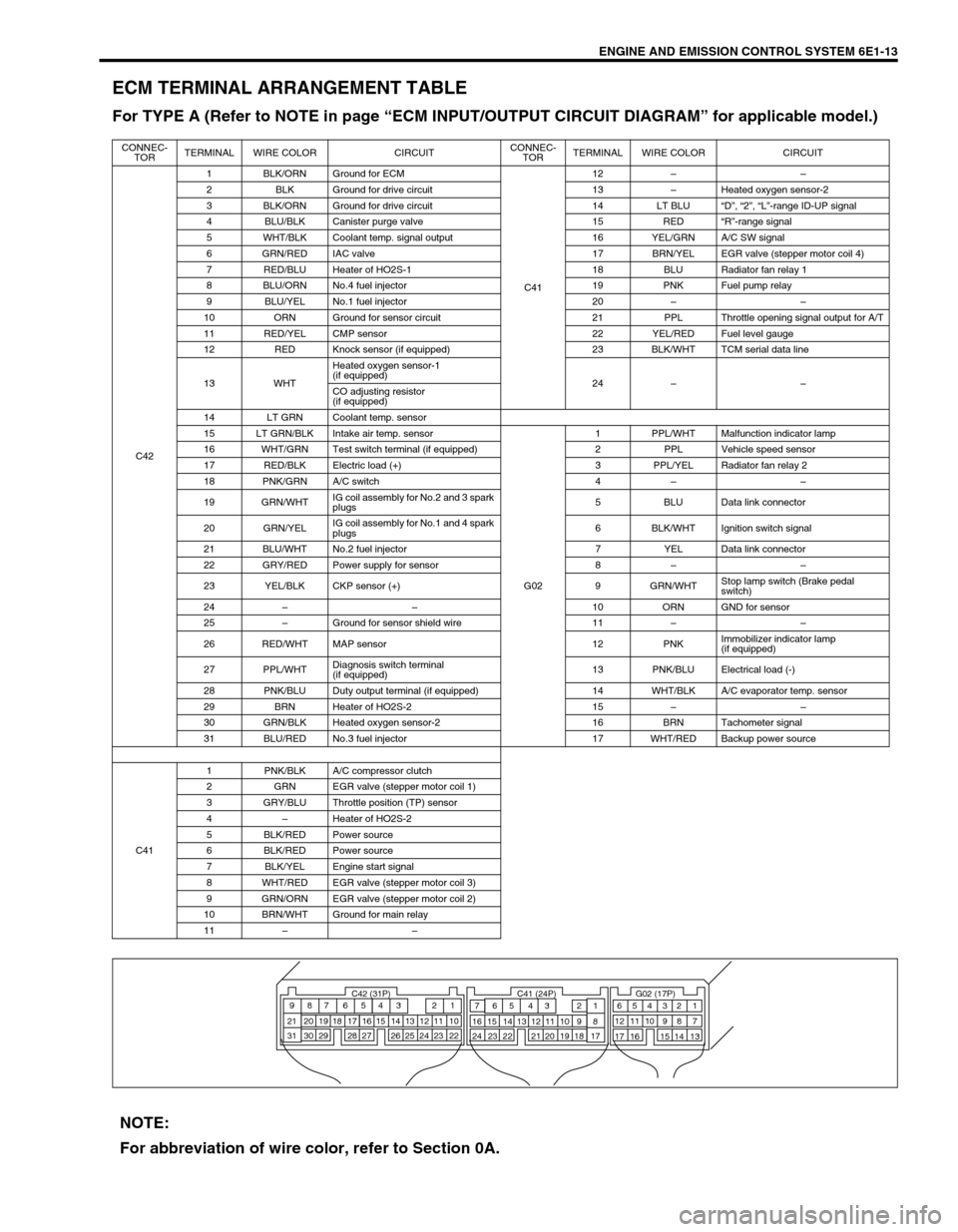

ENGINE AND EMISSION CONTROL SYSTEM 6E1-13

ECM TERMINAL ARRANGEMENT TABLE

For TYPE A (Refer to NOTE in page “ECM INPUT/OUTPUT CIRCUIT DIAGRAM” for applicable model.)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

C421 BLK/ORN Ground for ECM

C4112––

2 BLK Ground for drive circuit 13–Heated oxygen sensor-2

3 BLK/ORN Ground for drive circuit 14 LT BLU“D”, “2”, “L”-range ID-UP signal

4 BLU/BLK Canister purge valve 15 RED“R”-range signal

5 WHT/BLK Coolant temp. signal output 16 YEL/GRN A/C SW signal

6 GRN/RED IAC valve 17 BRN/YEL EGR valve (stepper motor coil 4)

7 RED/BLU Heater of HO2S-1 18 BLU Radiator fan relay 1

8 BLU/ORN No.4 fuel injector 19 PNK Fuel pump relay

9 BLU/YEL No.1 fuel injector 20––

10 ORN Ground for sensor circuit 21 PPL Throttle opening signal output for A/T

11 RED/YEL CMP sensor 22 YEL/RED Fuel level gauge

12 RED Knock sensor (if equipped) 23 BLK/WHT TCM serial data line

13 WHTHeated oxygen sensor-1

(if equipped)

24––

CO adjusting resistor

(if equipped)

14 LT GRN Coolant temp. sensor

15 LT GRN/BLK Intake air temp. sensor

G021 PPL/WHT Malfunction indicator lamp

16 WHT/GRN Test switch terminal (if equipped) 2 PPL Vehicle speed sensor

17 RED/BLK Electric load (+) 3 PPL/YEL Radiator fan relay 2

18 PNK/GRN A/C switch 4––

19 GRN/WHTIG coil assembly for No.2 and 3 spark

plugs5 BLU Data link connector

20 GRN/YELIG coil assembly for No.1 and 4 spark

plugs6 BLK/WHT Ignition switch signal

21 BLU/WHT No.2 fuel injector 7 YEL Data link connector

22 GRY/RED Power supply for sensor 8––

23 YEL/BLK CKP sensor (+) 9 GRN/WHTStop lamp switch (Brake pedal

switch)

24––10 ORN GND for sensor

25–Ground for sensor shield wire 11––

26 RED/WHT MAP sensor 12 PNKImmobilizer indicator lamp

(if equipped)

27 PPL/WHTDiagnosis switch terminal

(if equipped)13 PNK/BLU Electrical load (-)

28 PNK/BLU Duty output terminal (if equipped) 14 WHT/BLK A/C evaporator temp. sensor

29 BRN Heater of HO2S-2 15––

30 GRN/BLK Heated oxygen sensor-2 16 BRN Tachometer signal

31 BLU/RED No.3 fuel injector 17 WHT/RED Backup power source

C411 PNK/BLK A/C compressor clutch

2 GRN EGR valve (stepper motor coil 1)

3 GRY/BLU Throttle position (TP) sensor

4–Heater of HO2S-2

5 BLK/RED Power source

6 BLK/RED Power source

7 BLK/YEL Engine start signal

8 WHT/RED EGR valve (stepper motor coil 3)

9 GRN/ORN EGR valve (stepper motor coil 2)

10 BRN/WHT Ground for main relay

11––

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

NOTE:

For abbreviation of wire color, refer to Section 0A.

Page 635 of 698

6E1-14 ENGINE AND EMISSION CONTROL SYSTEM

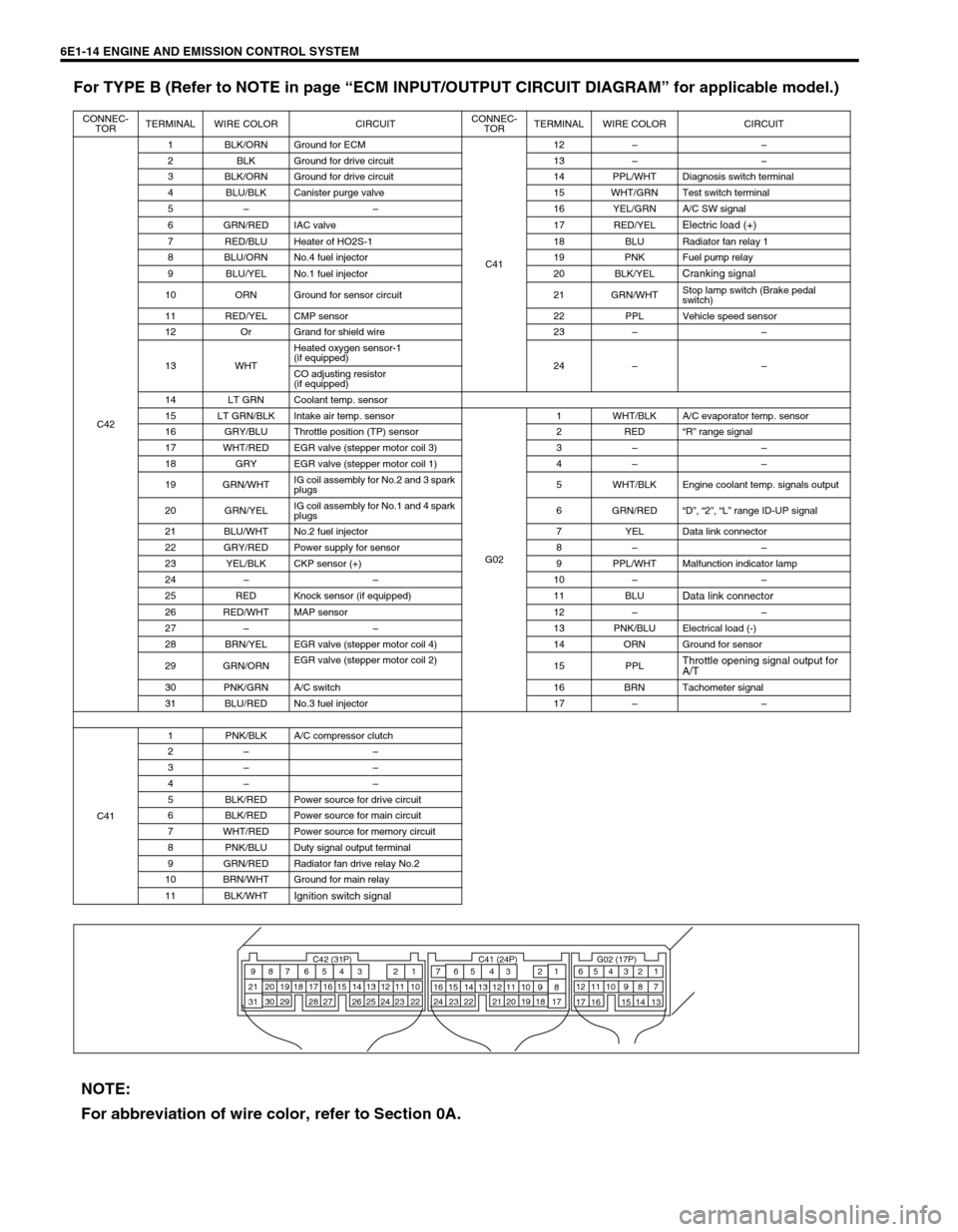

For TYPE B (Refer to NOTE in page “ECM INPUT/OUTPUT CIRCUIT DIAGRAM” for applicable model.)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

C421 BLK/ORN Ground for ECM

C4112––

2 BLK Ground for drive circuit 13––

3 BLK/ORN Ground for drive circuit 14 PPL/WHT Diagnosis switch terminal

4 BLU/BLK Canister purge valve 15 WHT/GRN Test switch terminal

5––16 YEL/GRN A/C SW signal

6 GRN/RED IAC valve 17 RED/YEL

Electric load (+)

7 RED/BLU Heater of HO2S-1 18 BLU Radiator fan relay 1

8 BLU/ORN No.4 fuel injector 19 PNK Fuel pump relay

9 BLU/YEL No.1 fuel injector 20 BLK/YEL

Cranking signal

10 ORN Ground for sensor circuit 21 GRN/WHTStop lamp switch (Brake pedal

switch)

11 RED/YEL CMP sensor 22 PPL Vehicle speed sensor

12 Or Grand for shield wire 23––

13 WHTHeated oxygen sensor-1

(if equipped)

24––

CO adjusting resistor

(if equipped)

14 LT GRN Coolant temp. sensor

15 LT GRN/BLK Intake air temp. sensor

G021 WHT/BLK A/C evaporator temp. sensor

16 GRY/BLU Throttle position (TP) sensor 2 RED“R” range signal

17 WHT/RED EGR valve (stepper motor coil 3) 3––

18 GRY EGR valve (stepper motor coil 1) 4––

19 GRN/WHTIG coil assembly for No.2 and 3 spark

plugs5 WHT/BLK Engine coolant temp. signals output

20 GRN/YELIG coil assembly for No.1 and 4 spark

plugs6 GRN/RED“D”, “2”, “L” range ID-UP signal

21 BLU/WHT No.2 fuel injector 7 YEL Data link connector

22 GRY/RED Power supply for sensor 8––

23 YEL/BLK CKP sensor (+) 9 PPL/WHT Malfunction indicator lamp

24––10––

25 RED Knock sensor (if equipped) 11 BLU

Data link connector

26 RED/WHT MAP sensor 12––

27––13 PNK/BLU Electrical load (-)

28 BRN/YEL EGR valve (stepper motor coil 4) 14 ORN Ground for sensor

29 GRN/ORNEGR valve (stepper motor coil 2)

15 PPL

Throttle opening signal output for

A/T

30 PNK/GRN A/C switch 16 BRN Tachometer signal

31 BLU/RED No.3 fuel injector 17––

C411 PNK/BLK A/C compressor clutch

2––

3––

4––

5 BLK/RED Power source for drive circuit

6 BLK/RED Power source for main circuit

7 WHT/RED Power source for memory circuit

8 PNK/BLU Duty signal output terminal

9 GRN/RED Radiator fan drive relay No.2

10 BRN/WHT Ground for main relay

11 BLK/WHT

Ignition switch signal

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

NOTE:

For abbreviation of wire color, refer to Section 0A.

Page 666 of 698

6F1-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” in Section 6 per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in Sec-

tion 6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” in this section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check Is DTC stored

in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” in this section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” in this section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

3 and 4 of “DTC P0335 (No.23) Diag. Flow Table”

in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” in this sec-

tion.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.