brake fluid SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 235 of 698

3E-22 REAR SUSPENSION

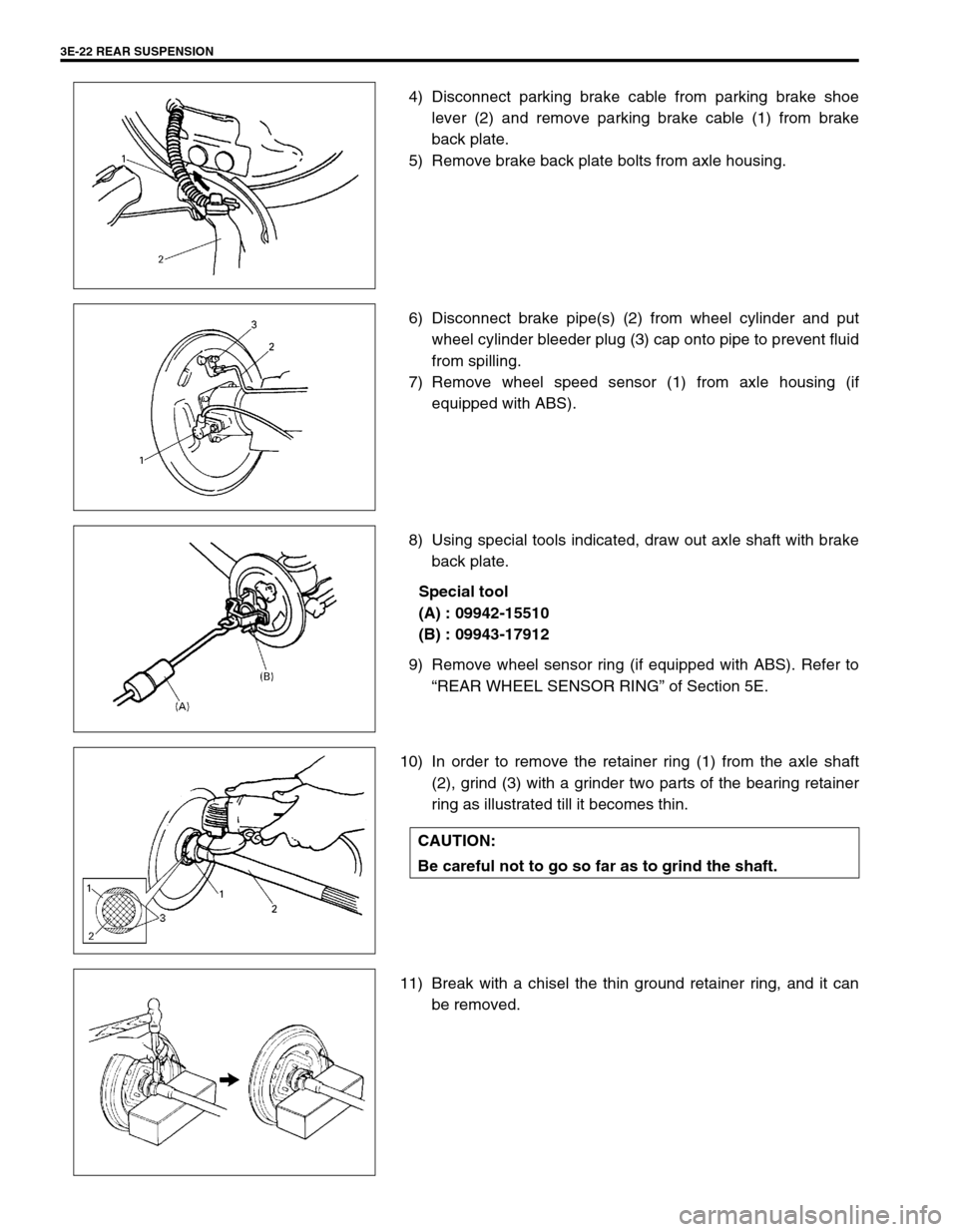

4) Disconnect parking brake cable from parking brake shoe

lever (2) and remove parking brake cable (1) from brake

back plate.

5) Remove brake back plate bolts from axle housing.

6) Disconnect brake pipe(s) (2) from wheel cylinder and put

wheel cylinder bleeder plug (3) cap onto pipe to prevent fluid

from spilling.

7) Remove wheel speed sensor (1) from axle housing (if

equipped with ABS).

8) Using special tools indicated, draw out axle shaft with brake

back plate.

Special tool

(A) : 09942-15510

(B) : 09943-17912

9) Remove wheel sensor ring (if equipped with ABS). Refer to

“REAR WHEEL SENSOR RING” of Section 5E.

10) In order to remove the retainer ring (1) from the axle shaft

(2), grind (3) with a grinder two parts of the bearing retainer

ring as illustrated till it becomes thin.

11) Break with a chisel the thin ground retainer ring, and it can

be removed.

CAUTION:

Be careful not to go so far as to grind the shaft.

Page 238 of 698

REAR SUSPENSION 3E-25

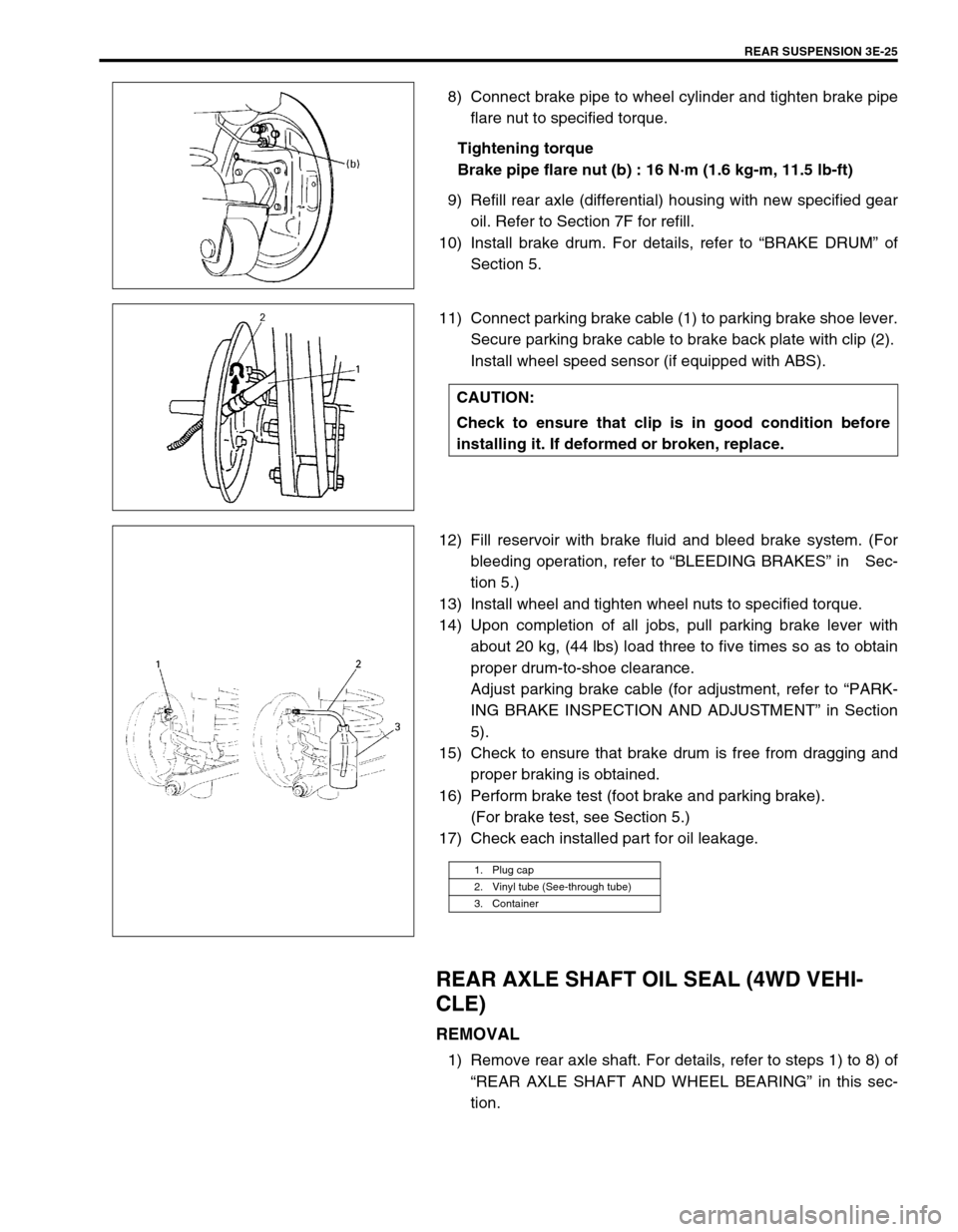

8) Connect brake pipe to wheel cylinder and tighten brake pipe

flare nut to specified torque.

Tightening torque

Brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

9) Refill rear axle (differential) housing with new specified gear

oil. Refer to Section 7F for refill.

10) Install brake drum. For details, refer to “BRAKE DRUM” of

Section 5.

11) Connect parking brake cable (1) to parking brake shoe lever.

Secure parking brake cable to brake back plate with clip (2).

Install wheel speed sensor (if equipped with ABS).

12) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, refer to “BLEEDING BRAKES” in Sec-

tion 5.)

13) Install wheel and tighten wheel nuts to specified torque.

14) Upon completion of all jobs, pull parking brake lever with

about 20 kg, (44 lbs) load three to five times so as to obtain

proper drum-to-shoe clearance.

Adjust parking brake cable (for adjustment, refer to “PARK-

ING BRAKE INSPECTION AND ADJUSTMENT” in Section

5).

15) Check to ensure that brake drum is free from dragging and

proper braking is obtained.

16) Perform brake test (foot brake and parking brake).

(For brake test, see Section 5.)

17) Check each installed part for oil leakage.

REAR AXLE SHAFT OIL SEAL (4WD VEHI-

CLE)

REMOVAL

1) Remove rear axle shaft. For details, refer to steps 1) to 8) of

“REAR AXLE SHAFT AND WHEEL BEARING” in this sec-

tion.

CAUTION:

Check to ensure that clip is in good condition before

installing it. If deformed or broken, replace.

1. Plug cap

2. Vinyl tube (See-through tube)

3. Container

Page 243 of 698

3E-30 REAR SUSPENSION

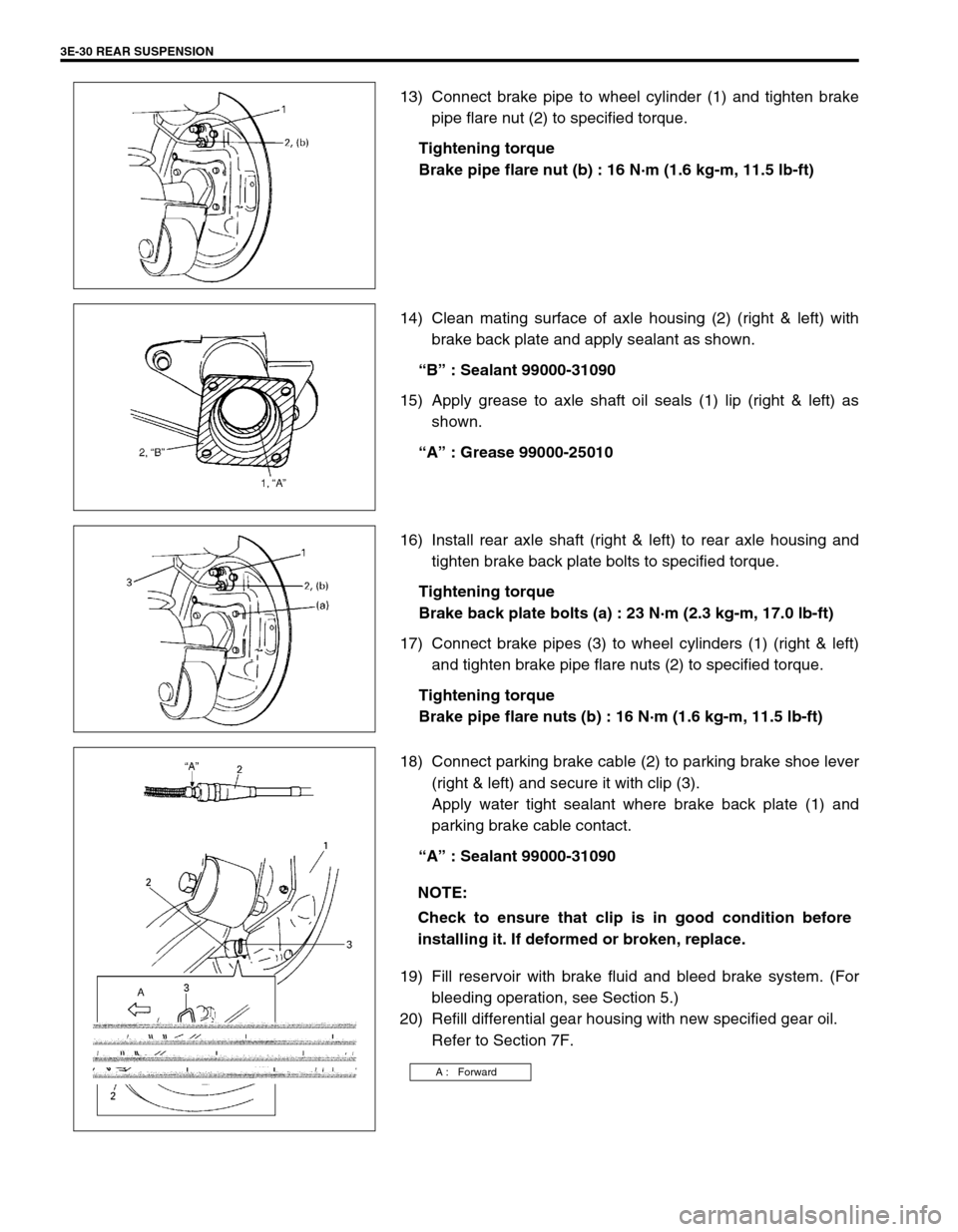

13) Connect brake pipe to wheel cylinder (1) and tighten brake

pipe flare nut (2) to specified torque.

Tightening torque

Brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

14) Clean mating surface of axle housing (2) (right & left) with

brake back plate and apply sealant as shown.

“B” : Sealant 99000-31090

15) Apply grease to axle shaft oil seals (1) lip (right & left) as

shown.

“A” : Grease 99000-25010

16) Install rear axle shaft (right & left) to rear axle housing and

tighten brake back plate bolts to specified torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

17) Connect brake pipes (3) to wheel cylinders (1) (right & left)

and tighten brake pipe flare nuts (2) to specified torque.

Tightening torque

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

18) Connect parking brake cable (2) to parking brake shoe lever

(right & left) and secure it with clip (3).

Apply water tight sealant where brake back plate (1) and

parking brake cable contact.

“A” : Sealant 99000-31090

19) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, see Section 5.)

20) Refill differential gear housing with new specified gear oil.

Refer to Section 7F.

NOTE:

Check to ensure that clip is in good condition before

installing it. If deformed or broken, replace.

A : Forward

Page 244 of 698

REAR SUSPENSION 3E-31

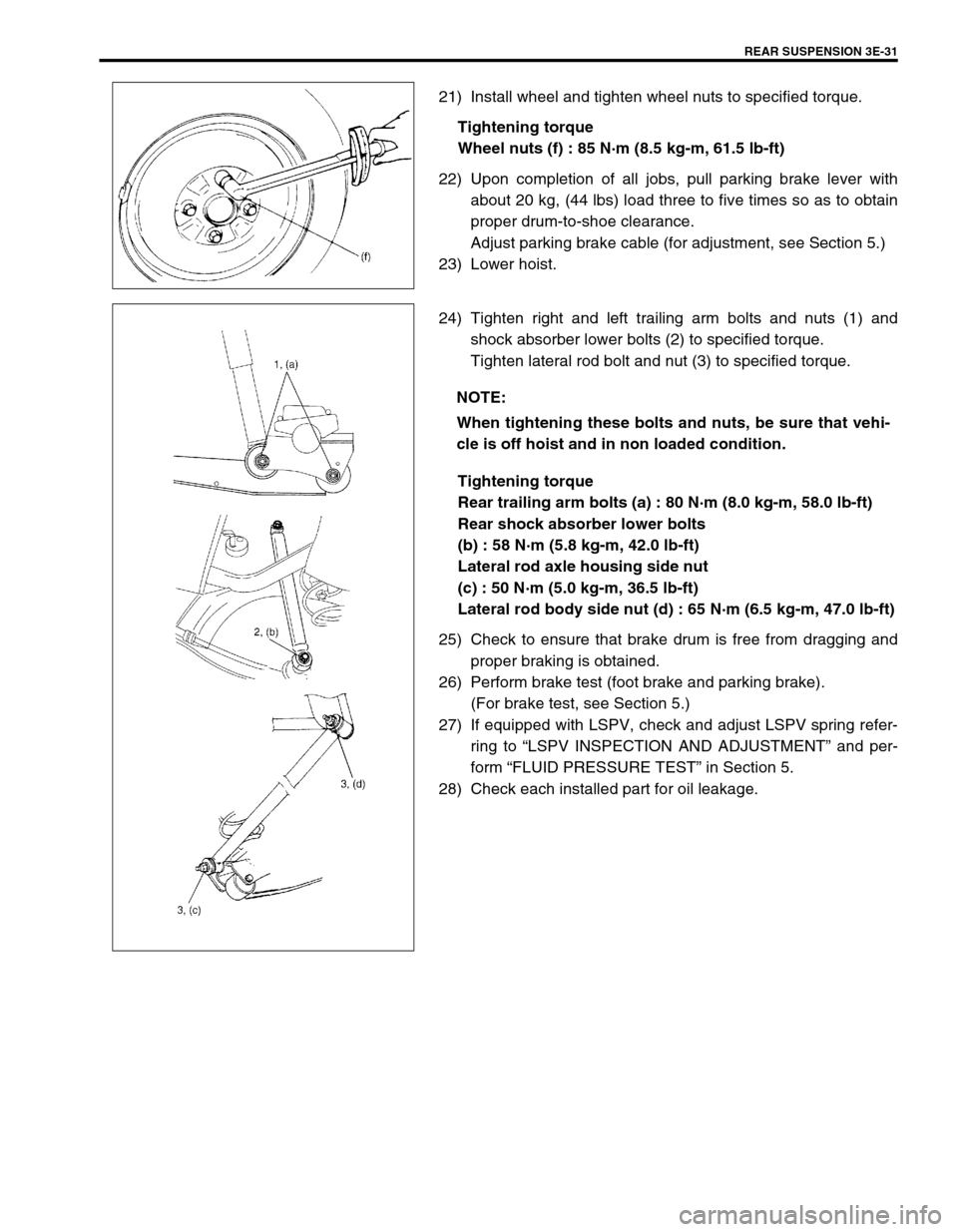

21) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts (f) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

22) Upon completion of all jobs, pull parking brake lever with

about 20 kg, (44 lbs) load three to five times so as to obtain

proper drum-to-shoe clearance.

Adjust parking brake cable (for adjustment, see Section 5.)

23) Lower hoist.

24) Tighten right and left trailing arm bolts and nuts (1) and

shock absorber lower bolts (2) to specified torque.

Tighten lateral rod bolt and nut (3) to specified torque.

Tightening torque

Rear trailing arm bolts (a) : 80 N·m (8.0 kg-m, 58.0 lb-ft)

Rear shock absorber lower bolts

(b) : 58 N·m (5.8 kg-m, 42.0 lb-ft)

Lateral rod axle housing side nut

(c) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Lateral rod body side nut (d) : 65 N·m (6.5 kg-m, 47.0 lb-ft)

25) Check to ensure that brake drum is free from dragging and

proper braking is obtained.

26) Perform brake test (foot brake and parking brake).

(For brake test, see Section 5.)

27) If equipped with LSPV, check and adjust LSPV spring refer-

ring to “LSPV INSPECTION AND ADJUSTMENT” and per-

form “FLUID PRESSURE TEST” in Section 5.

28) Check each installed part for oil leakage.

NOTE:

When tightening these bolts and nuts, be sure that vehi-

cle is off hoist and in non loaded condition.

Page 274 of 698

BRAKES 5-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

5

9

10

10A

10B

SECTION 5

BRAKES

CONTENTS

GENERAL DESCRIPTION ................................ 5-2

DIAGNOSIS ....................................................... 5-4

ROAD TESTING BRAKES ............................. 5-4

BRAKE FLUID LEAKS ................................... 5-4

SUBSTANDARD OR CONTAMINATED

BRAKE FLUID ................................................ 5-4

DIAGNOSIS TABLE ....................................... 5-5

BRAKE PEDAL FREE HEIGHT

ADJUSTMENT ............................................... 5-8

BRAKE PEDAL PLAY INSPECTION ............. 5-8

STOP LIGHT SWITCH ADJUSTMENT.......... 5-8

EXCESSIVE PEDAL TRAVEL

INSPECTION ................................................. 5-9

FRONT BRAKE PAD INSPECTION .............. 5-9

BRAKE DISC INSPECTION........................... 5-9

PARKING BRAKE INSPECTION AND

ADJUSTMENT ............................................. 5-10

BOOSTER OPERATION INSPECTION....... 5-11

FLUID PRESSURE TEST (IF EQUIPPED

WITH LSPV) ................................................ 5-12

MASTER CYLINDER AND BRAKE FLUID

LEVEL INSPECTION ................................... 5-14

BRAKE HOSE AND PIPE INSPECTION ..... 5-15

HOSE ....................................................... 5-15

PIPE ......................................................... 5-15

ON-VEHICLE SERVICE .................................. 5-15AIR BLEEDING OF BRAKE SYSTEM ......... 5-15

FRONT BRAKE ........................................... 5-17

BRAKE PAD............................................. 5-17

CALIPER ASSEMBLY ............................. 5-19

BRAKE DISC ........................................... 5-23

REAR BRAKE .............................................. 5-25

BRAKE DRUM ......................................... 5-26

BRAKE SHOE .......................................... 5-29

WHEEL CYLINDER ................................. 5-30

BRAKE BACK PLATE (FOR 2WD

VEHICLE)................................................. 5-31

BRAKE BACK PLATE (FOR 4WD

VEHICLE)................................................. 5-33

MASTER CYLINDER ................................... 5-33

MASTER CYLINDER RESERVOIR ......... 5-33

MASTER CYLINDER ASSEMBLY........... 5-34

BRAKE BOOSTER ...................................... 5-38

BRAKE HOSE/PIPE .................................... 5-41

FRONT BRAKE HOSE/PIPE ................... 5-41

REAR BRAKE HOSE/PIPE...................... 5-44

PARKING BRAKE CABLE ........................... 5-46

LSPV (LOAD SENSING PROPORTIONING

VALVE) ASSEMBLY (IF EQUIPPED).......... 5-48

REQUIRED SERVICE MATERIAL.................. 5-50

SPECIAL TOOL .............................................. 5-50

NOTE:

All front fasteners are important attaching parts in that they could affect the performance of vital parts

and systems, and/or could result in major repair expense. They must be replaced with one of same

part number or with an equivalent part if replacement becomes necessary. Do not use a replacement

part of lesser quality or substitute design. Torque values must be used as specified during reassem-

bly to assure proper retention of all parts. There is to be no welding as it may result in extensive dam-

age and weakening of the metal.

Page 277 of 698

5-4 BRAKES

DIAGNOSIS

ROAD TESTING BRAKES

Brakes should be tested on dry, clean, smooth and reasonably level roadway which is not crowned. Road test

brakes by making brake applications with both light and heavy pedal forces at various speeds to determine if the

vehicle stops evenly and effectively. Also drive vehicle to see if it leads to one side or the other without brake

application. If it does, check the tire pressure, front end alignment and front suspension attachments for loose-

ness. See diagnosis table for other causes.

BRAKE FLUID LEAKS

Check the master cylinder fluid levels. While a slight drop in reservoir level does result from normal lining wear,

an abnormally low level indicates a leak in the system. In such a case, check the entire brake system for leak-

age. If even a slight evidence of leakage is noted, the cause should be corrected or defective parts should be

replaced.

SUBSTANDARD OR CONTAMINATED BRAKE FLUID

Improper brake fluid, mineral oil or water in the fluid may cause the brake fluid to boil or the rubber components

in the hydraulic system to deteriorate.

If primary piston cups are swollen, then rubber parts have deteriorated. This deterioration may also be evi-

denced by swollen wheel cylinder piston cups on the drum brake wheels.

If deterioration of rubber is evident, disassemble all hydraulic parts and wash with alcohol. Dry these parts with

compressed air before assembly to keep alcohol out of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads.

If master cylinder piston seals are satisfactory, check for leakage or excessive heat conditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed system.

The system must be flushed if there is any doubt as to the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to contaminated fluid.

Page 279 of 698

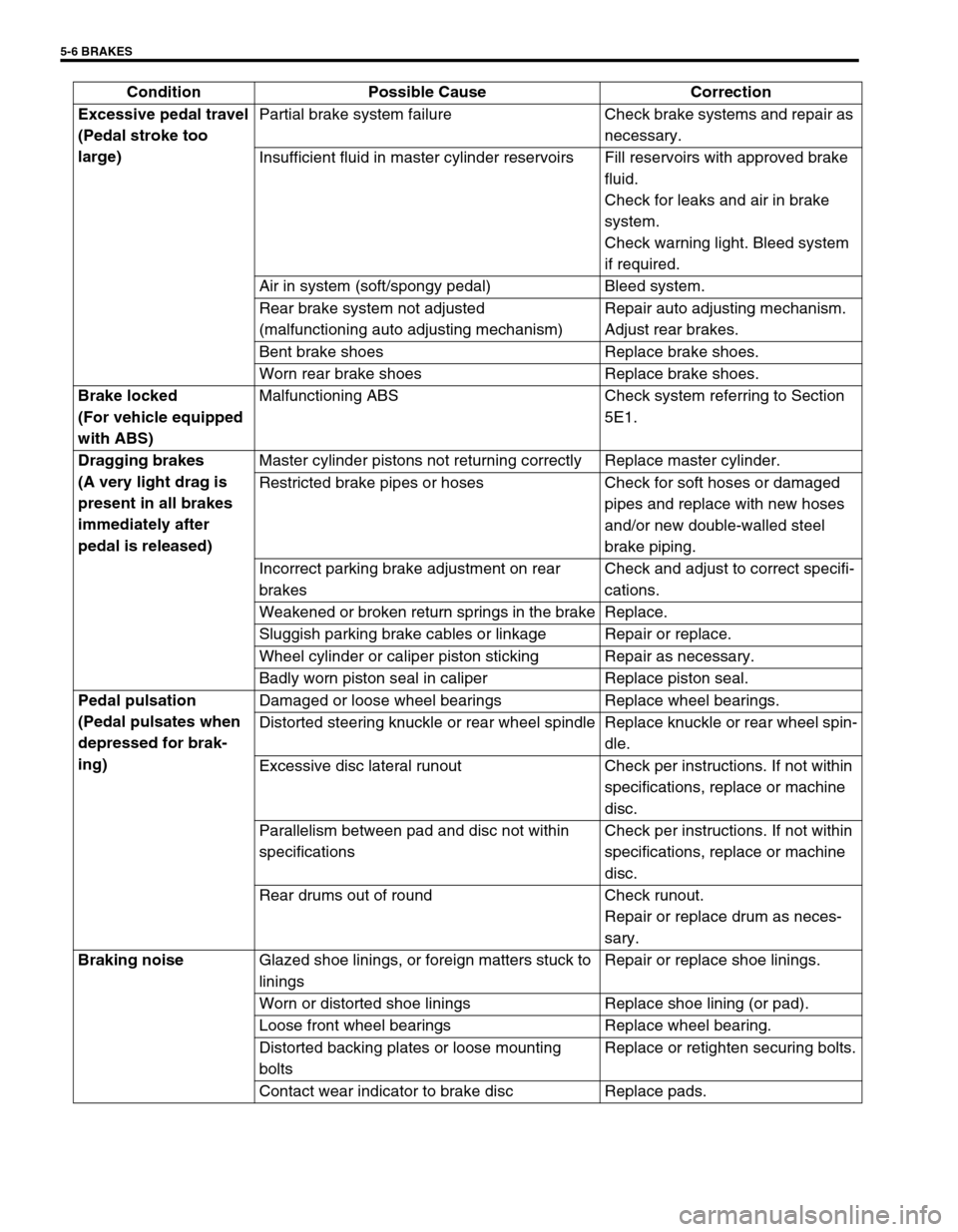

5-6 BRAKES

Excessive pedal travel

(Pedal stroke too

large)Partial brake system failure Check brake systems and repair as

necessary.

Insufficient fluid in master cylinder reservoirs Fill reservoirs with approved brake

fluid.

Check for leaks and air in brake

system.

Check warning light. Bleed system

if required.

Air in system (soft/spongy pedal) Bleed system.

Rear brake system not adjusted

(malfunctioning auto adjusting mechanism)Repair auto adjusting mechanism.

Adjust rear brakes.

Bent brake shoes Replace brake shoes.

Worn rear brake shoes Replace brake shoes.

Brake locked

(For vehicle equipped

with ABS)Malfunctioning ABS Check system referring to Section

5E1.

Dragging brakes

(A very light drag is

present in all brakes

immediately after

pedal is released)Master cylinder pistons not returning correctly Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged

pipes and replace with new hoses

and/or new double-walled steel

brake piping.

Incorrect parking brake adjustment on rear

brakesCheck and adjust to correct specifi-

cations.

Weakened or broken return springs in the brake Replace.

Sluggish parking brake cables or linkage Repair or replace.

Wheel cylinder or caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Pedal pulsation

(Pedal pulsates when

depressed for brak-

ing)Damaged or loose wheel bearings Replace wheel bearings.

Distorted steering knuckle or rear wheel spindle Replace knuckle or rear wheel spin-

dle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine

disc.

Parallelism between pad and disc not within

specificationsCheck per instructions. If not within

specifications, replace or machine

disc.

Rear drums out of round Check runout.

Repair or replace drum as neces-

sary.

Braking noise

Glazed shoe linings, or foreign matters stuck to

liningsRepair or replace shoe linings.

Worn or distorted shoe linings Replace shoe lining (or pad).

Loose front wheel bearings Replace wheel bearing.

Distorted backing plates or loose mounting

boltsReplace or retighten securing bolts.

Contact wear indicator to brake disc Replace pads. Condition Possible Cause Correction

Page 280 of 698

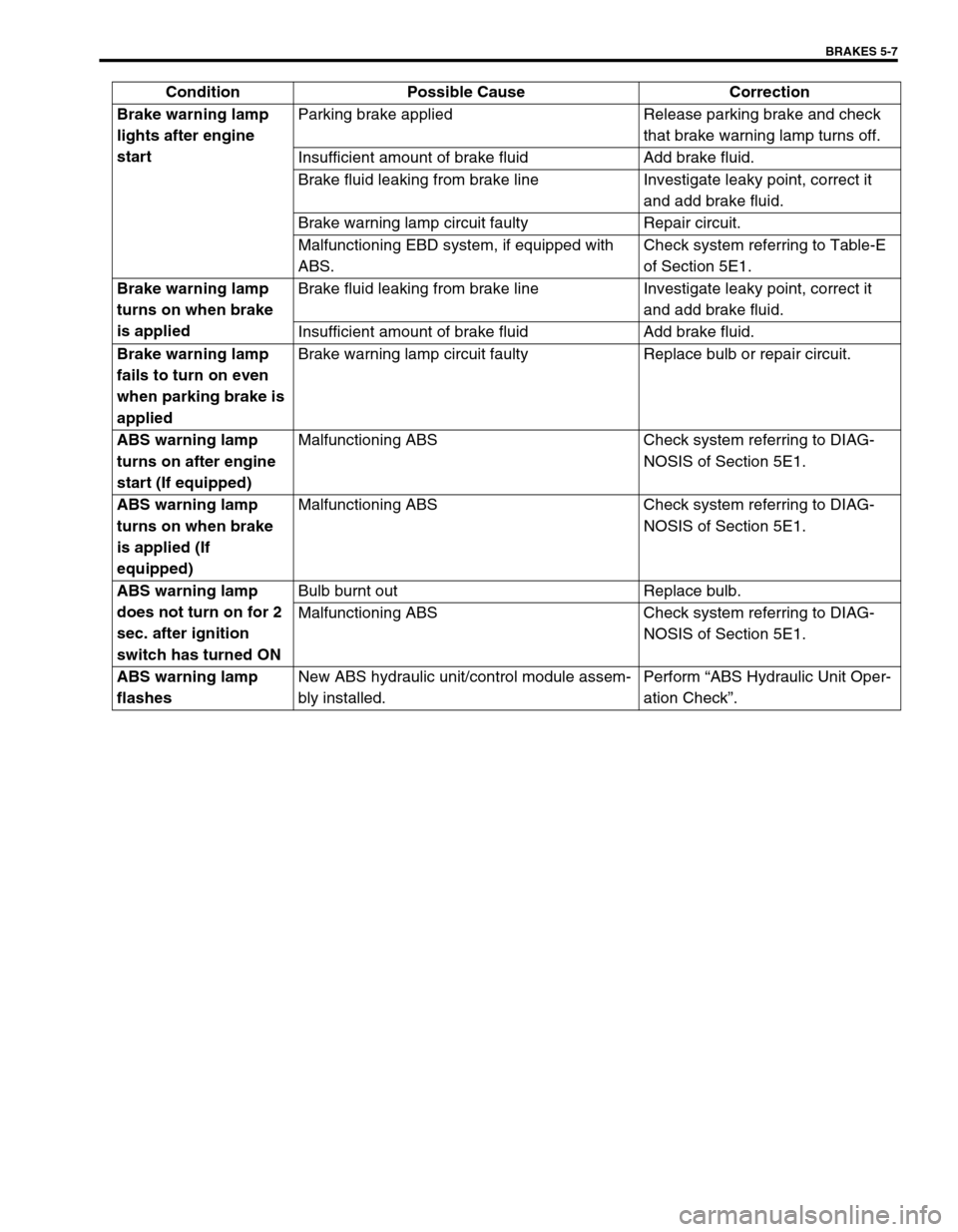

BRAKES 5-7

Brake warning lamp

lights after engine

startParking brake applied Release parking brake and check

that brake warning lamp turns off.

Insufficient amount of brake fluid Add brake fluid.

Brake fluid leaking from brake line Investigate leaky point, correct it

and add brake fluid.

Brake warning lamp circuit faulty Repair circuit.

Malfunctioning EBD system, if equipped with

ABS.Check system referring to Table-E

of Section 5E1.

Brake warning lamp

turns on when brake

is appliedBrake fluid leaking from brake line Investigate leaky point, correct it

and add brake fluid.

Insufficient amount of brake fluid Add brake fluid.

Brake warning lamp

fails to turn on even

when parking brake is

appliedBrake warning lamp circuit faulty Replace bulb or repair circuit.

ABS warning lamp

turns on after engine

start (If equipped)Malfunctioning ABS Check system referring to DIAG-

NOSIS of Section 5E1.

ABS warning lamp

turns on when brake

is applied (If

equipped)Malfunctioning ABS Check system referring to DIAG-

NOSIS of Section 5E1.

ABS warning lamp

does not turn on for 2

sec. after ignition

switch has turned ONBulb burnt out Replace bulb.

Malfunctioning ABS Check system referring to DIAG-

NOSIS of Section 5E1.

ABS warning lamp

flashesNew ABS hydraulic unit/control module assem-

bly installed.Perform “ABS Hydraulic Unit Oper-

ation Check”. Condition Possible Cause Correction

Page 285 of 698

5-12 BRAKES

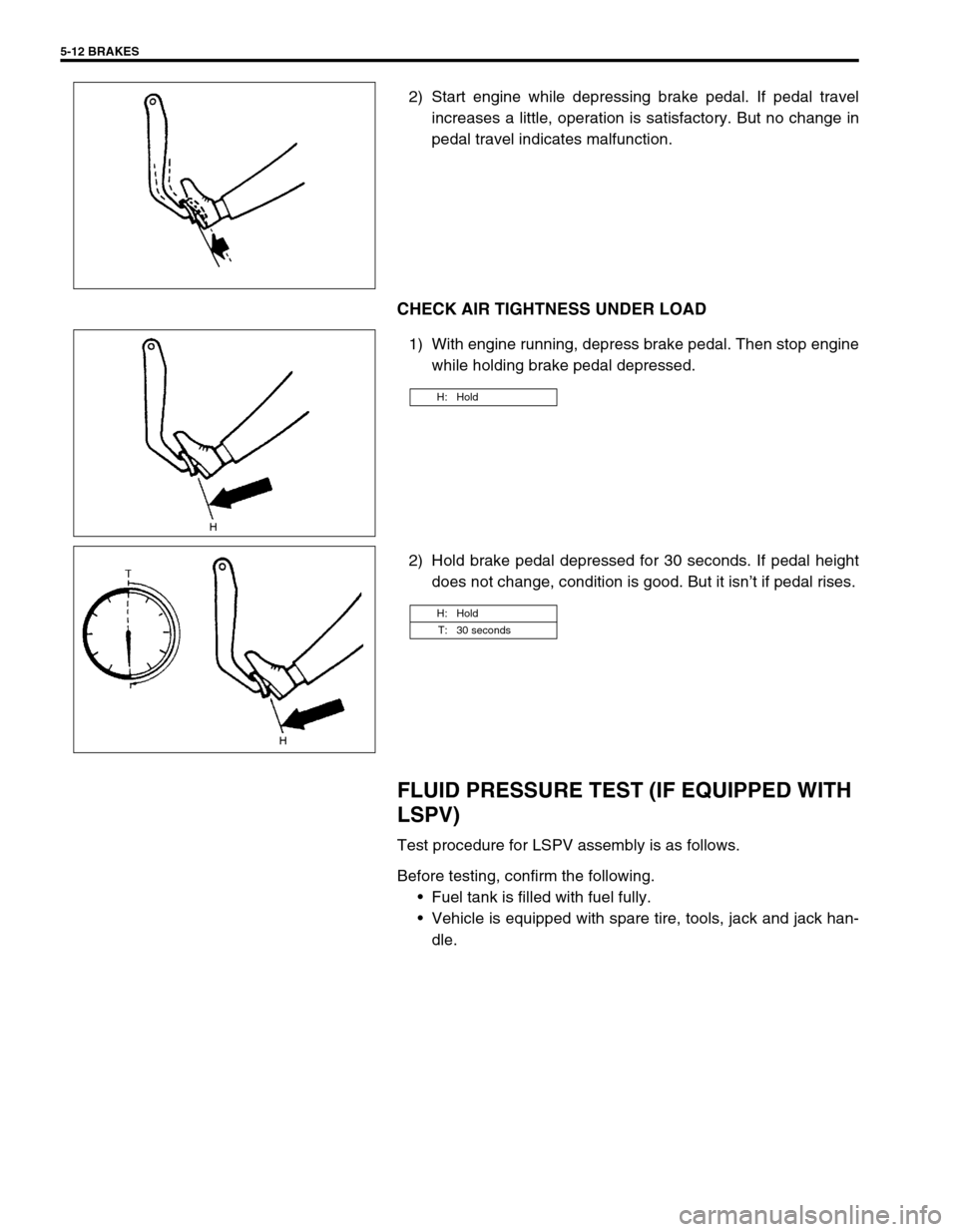

2) Start engine while depressing brake pedal. If pedal travel

increases a little, operation is satisfactory. But no change in

pedal travel indicates malfunction.

CHECK AIR TIGHTNESS UNDER LOAD

1) With engine running, depress brake pedal. Then stop engine

while holding brake pedal depressed.

2) Hold brake pedal depressed for 30 seconds. If pedal height

does not change, condition is good. But it isn’t if pedal rises.

FLUID PRESSURE TEST (IF EQUIPPED WITH

LSPV)

Test procedure for LSPV assembly is as follows.

Before testing, confirm the following.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

H: Hold

H: Hold

T: 30 seconds

Page 286 of 698

BRAKES 5-13

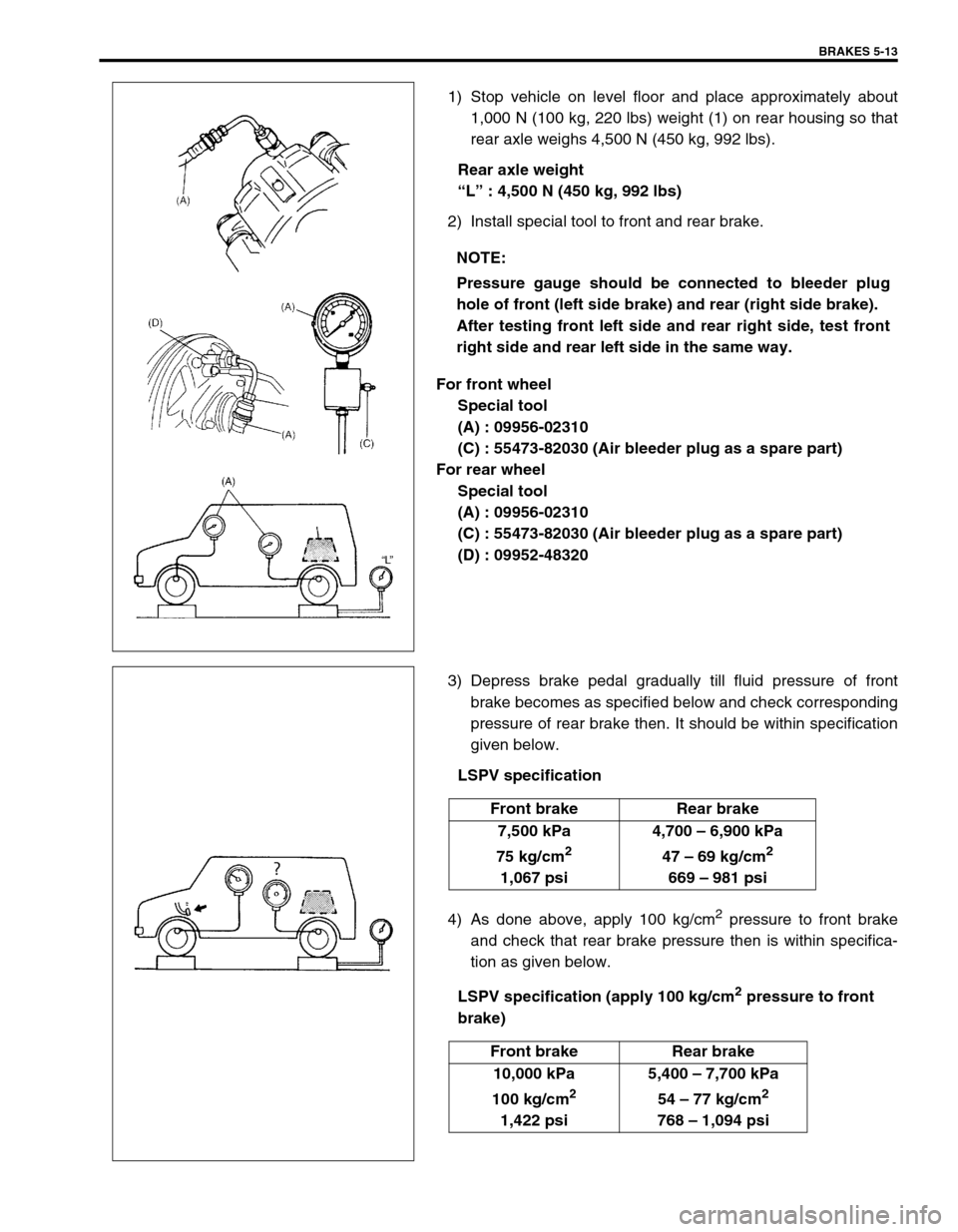

1) Stop vehicle on level floor and place approximately about

1,000 N (100 kg, 220 lbs) weight (1) on rear housing so that

rear axle weighs 4,500 N (450 kg, 992 lbs).

Rear axle weight

“L” : 4,500 N (450 kg, 992 lbs)

2) Install special tool to front and rear brake.

For front wheel

Special tool

(A) : 09956-02310

(C) : 55473-82030 (Air bleeder plug as a spare part)

For rear wheel

Special tool

(A) : 09956-02310

(C) : 55473-82030 (Air bleeder plug as a spare part)

(D) : 09952-48320

3) Depress brake pedal gradually till fluid pressure of front

brake becomes as specified below and check corresponding

pressure of rear brake then. It should be within specification

given below.

LSPV specification

4) As done above, apply 100 kg/cm

2 pressure to front brake

and check that rear brake pressure then is within specifica-

tion as given below.

LSPV specification (apply 100 kg/cm

2 pressure to front

brake) NOTE:

Pressure gauge should be connected to bleeder plug

hole of front (left side brake) and rear (right side brake).

After testing front left side and rear right side, test front

right side and rear left side in the same way.

Front brake Rear brake

7,500 kPa

75 kg/cm

2

1,067 psi4,700 – 6,900 kPa

47 – 69 kg/cm

2

669 – 981 psi

Front brake Rear brake

10,000 kPa

100 kg/cm

2

1,422 psi5,400 – 7,700 kPa

54 – 77 kg/cm

2

768 – 1,094 psi