oil change SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 398 of 698

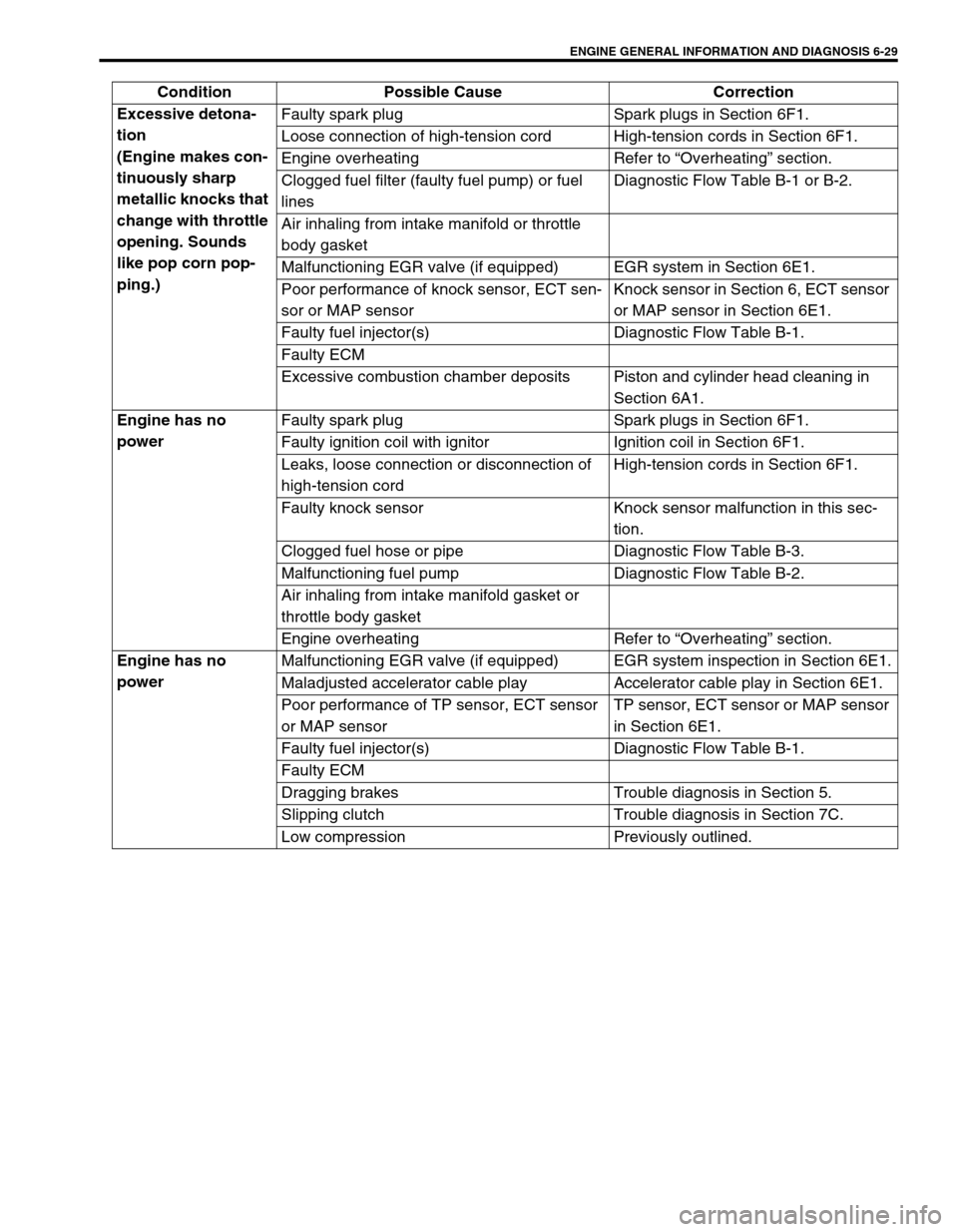

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-29

Excessive detona-

tion

(Engine makes con-

tinuously sharp

metallic knocks that

change with throttle

opening. Sounds

like pop corn pop-

ping.)Faulty spark plug Spark plugs in Section 6F1.

Loose connection of high-tension cord High-tension cords in Section 6F1.

Engine overheating Refer to “Overheating” section.

Clogged fuel filter (faulty fuel pump) or fuel

linesDiagnostic Flow Table B-1 or B-2.

Air inhaling from intake manifold or throttle

body gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Poor performance of knock sensor, ECT sen-

sor or MAP sensorKnock sensor in Section 6, ECT sensor

or MAP sensor in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Excessive combustion chamber deposits Piston and cylinder head cleaning in

Section 6A1.

Engine has no

powerFaulty spark plug Spark plugs in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Leaks, loose connection or disconnection of

high-tension cordHigh-tension cords in Section 6F1.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Clogged fuel hose or pipe Diagnostic Flow Table B-3.

Malfunctioning fuel pump Diagnostic Flow Table B-2.

Air inhaling from intake manifold gasket or

throttle body gasket

Engine overheating Refer to “Overheating” section.

Engine has no

powerMalfunctioning EGR valve (if equipped) EGR system inspection in Section 6E1.

Maladjusted accelerator cable play Accelerator cable play in Section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Low compression Previously outlined. Condition Possible Cause Correction

Page 450 of 698

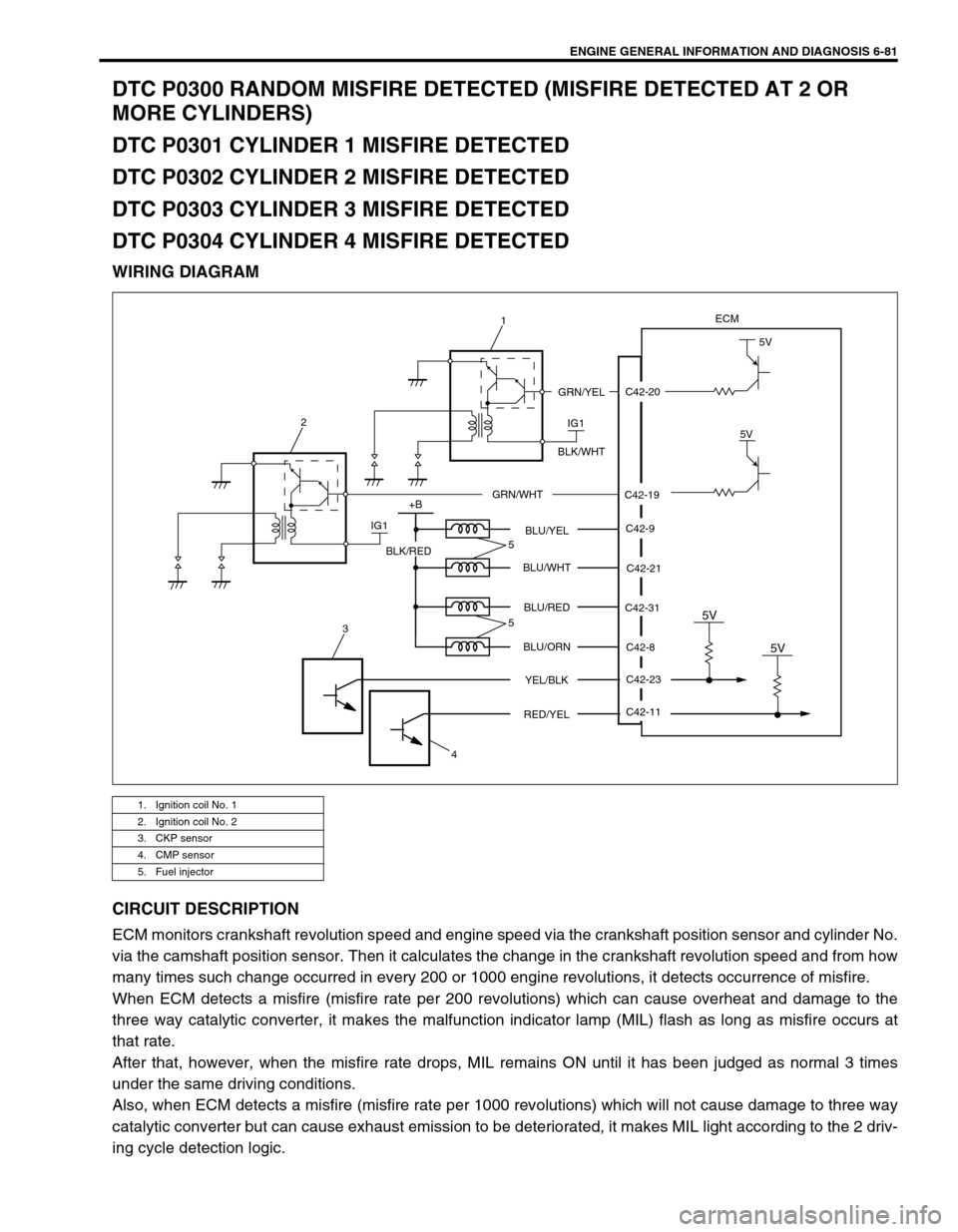

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-81

DTC P0300 RANDOM MISFIRE DETECTED (MISFIRE DETECTED AT 2 OR

MORE CYLINDERS)

DTC P0301 CYLINDER 1 MISFIRE DETECTED

DTC P0302 CYLINDER 2 MISFIRE DETECTED

DTC P0303 CYLINDER 3 MISFIRE DETECTED

DTC P0304 CYLINDER 4 MISFIRE DETECTED

WIRING DIAGRAM

CIRCUIT DESCRIPTION

ECM monitors crankshaft revolution speed and engine speed via the crankshaft position sensor and cylinder No.

via the camshaft position sensor. Then it calculates the change in the crankshaft revolution speed and from how

many times such change occurred in every 200 or 1000 engine revolutions, it detects occurrence of misfire.

When ECM detects a misfire (misfire rate per 200 revolutions) which can cause overheat and damage to the

three way catalytic converter, it makes the malfunction indicator lamp (MIL) flash as long as misfire occurs at

that rate.

After that, however, when the misfire rate drops, MIL remains ON until it has been judged as normal 3 times

under the same driving conditions.

Also, when ECM detects a misfire (misfire rate per 1000 revolutions) which will not cause damage to three way

catalytic converter but can cause exhaust emission to be deteriorated, it makes MIL light according to the 2 driv-

ing cycle detection logic.

1. Ignition coil No. 1

2. Ignition coil No. 2

3. CKP sensor

4. CMP sensor

5. Fuel injector

C42-20

C42-19

ECM

IG1

5V

5V

GRN/YEL

BLK/WHT

GRN/WHT

IG1 2

+B

C42-9

C42-21

C42-8

C42-23 C42-31 BLU/YEL

BLU/WHT

BLU/RED

BLU/ORN

YEL/BLK

5V

C42-11

RED/YEL

5V

BLK/RED

3

45

5

1

Page 451 of 698

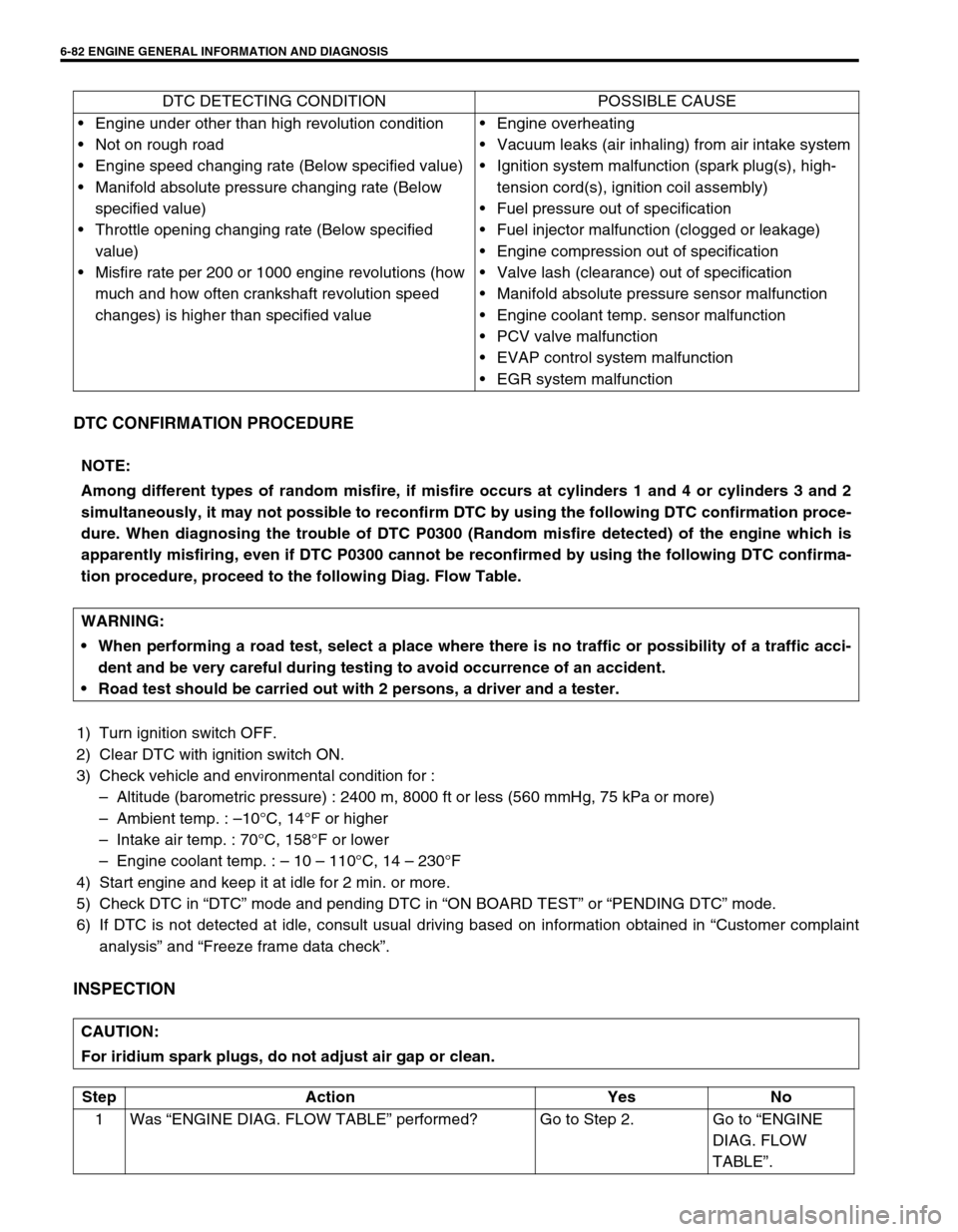

6-82 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 158°F or lower

–Engine coolant temp. : – 10 – 110°C, 14 – 230°F

4) Start engine and keep it at idle for 2 min. or more.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

6) If DTC is not detected at idle, consult usual driving based on information obtained in “Customer complaint

analysis” and “Freeze frame data check”.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine under other than high revolution condition

Not on rough road

Engine speed changing rate (Below specified value)

Manifold absolute pressure changing rate (Below

specified value)

Throttle opening changing rate (Below specified

value)

Misfire rate per 200 or 1000 engine revolutions (how

much and how often crankshaft revolution speed

changes) is higher than specified valueEngine overheating

Vacuum leaks (air inhaling) from air intake system

Ignition system malfunction (spark plug(s), high-

tension cord(s), ignition coil assembly)

Fuel pressure out of specification

Fuel injector malfunction (clogged or leakage)

Engine compression out of specification

Valve lash (clearance) out of specification

Manifold absolute pressure sensor malfunction

Engine coolant temp. sensor malfunction

PCV valve malfunction

EVAP control system malfunction

EGR system malfunction

NOTE:

Among different types of random misfire, if misfire occurs at cylinders 1 and 4 or cylinders 3 and 2

simultaneously, it may not possible to reconfirm DTC by using the following DTC confirmation proce-

dure. When diagnosing the trouble of DTC P0300 (Random misfire detected) of the engine which is

apparently misfiring, even if DTC P0300 cannot be reconfirmed by using the following DTC confirma-

tion procedure, proceed to the following Diag. Flow Table.

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

CAUTION:

For iridium spark plugs, do not adjust air gap or clean.

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE

DIAG. FLOW

TABLE”.

Page 508 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-7

4) Connect special tool (Vacuum gauge) to intake manifold.

Special tool

(A) : 09915-67310

5) Run engine at specified idle speed and read vacuum gauge.

Vacuum should be within specification.

Vacuum specification (at sea level)

: 59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 inHg)

at specified idle speed

6) After checking, disconnect special tool (Vacuum gauge) from

intake manifold.

7) Install cap to intake manifold.

OIL PRESSURE CHECK

Oil level in oil pan

If oil level is low, add oil up to Full level mark (hole) on oil

level gauge.

Oil quality

If oil is discolored, or deteriorated, change it.

For particular oil to be used referring to the table in Section

0B.

Oil leaks

If leak is found, repair it.

1) Disconnect oil pressure switch coupler (1) and remove oil

pressure switch (2) from cylinder block.

NOTE:

Prior to checking oil pressure, check the following items.

1. Full level mark (hole)

2. Low level mark (hole)

Page 525 of 698

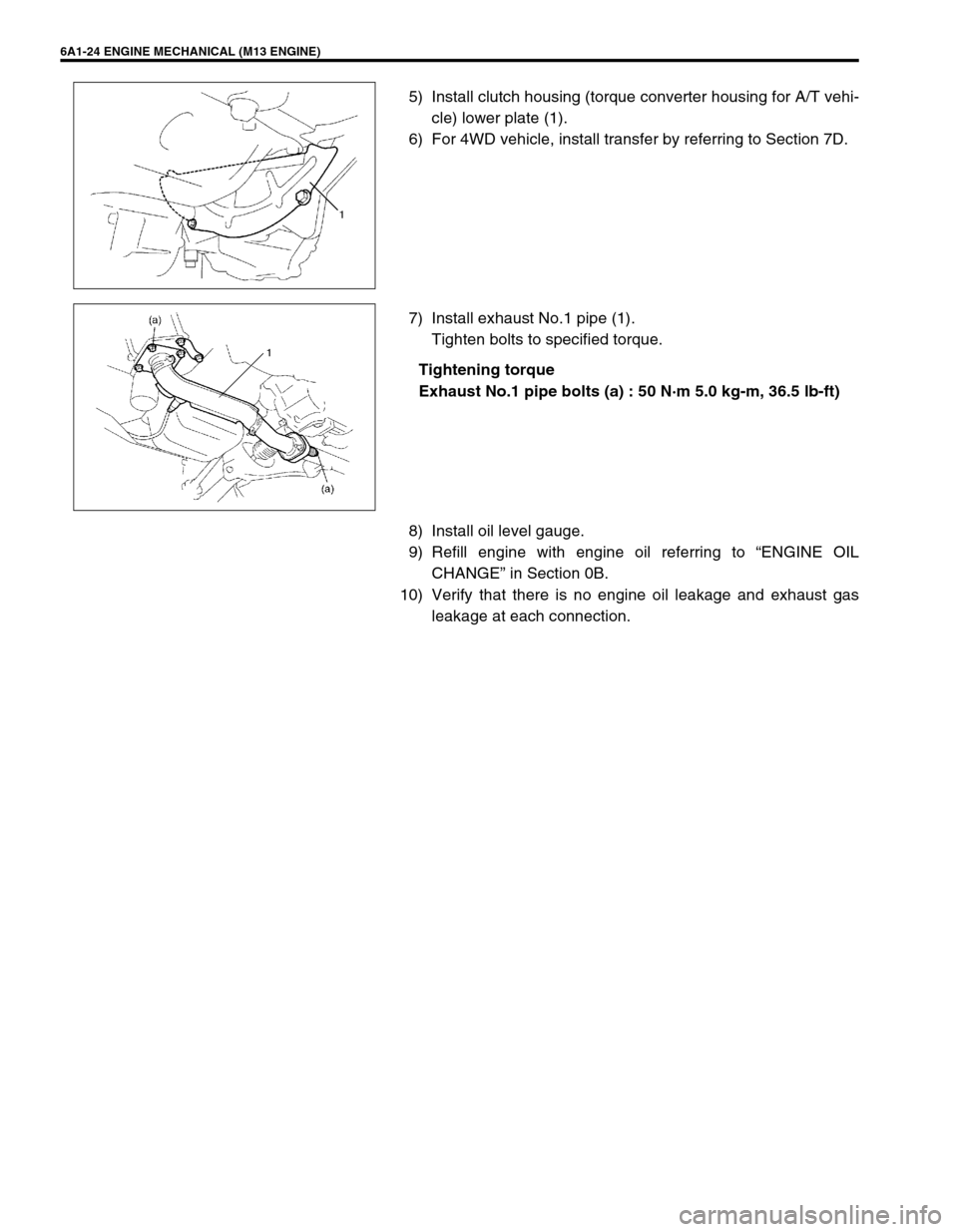

6A1-24 ENGINE MECHANICAL (M13 ENGINE)

5) Install clutch housing (torque converter housing for A/T vehi-

cle) lower plate (1).

6) For 4WD vehicle, install transfer by referring to Section 7D.

7) Install exhaust No.1 pipe (1).

Tighten bolts to specified torque.

Tightening torque

Exhaust No.1 pipe bolts (a) : 50 N·m 5.0 kg-m, 36.5 lb-ft)

8) Install oil level gauge.

9) Refill engine with engine oil referring to “ENGINE OIL

CHANGE” in Section 0B.

10) Verify that there is no engine oil leakage and exhaust gas

leakage at each connection.