Spark plugs SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 666 of 698

6F1-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” in Section 6 per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in Sec-

tion 6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” in this section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check Is DTC stored

in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” in this section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” in this section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

3 and 4 of “DTC P0335 (No.23) Diag. Flow Table”

in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” in this sec-

tion.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.

Page 667 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F1-5

ON-VEHICLE SERVICE

IGNITION SPARK TEST

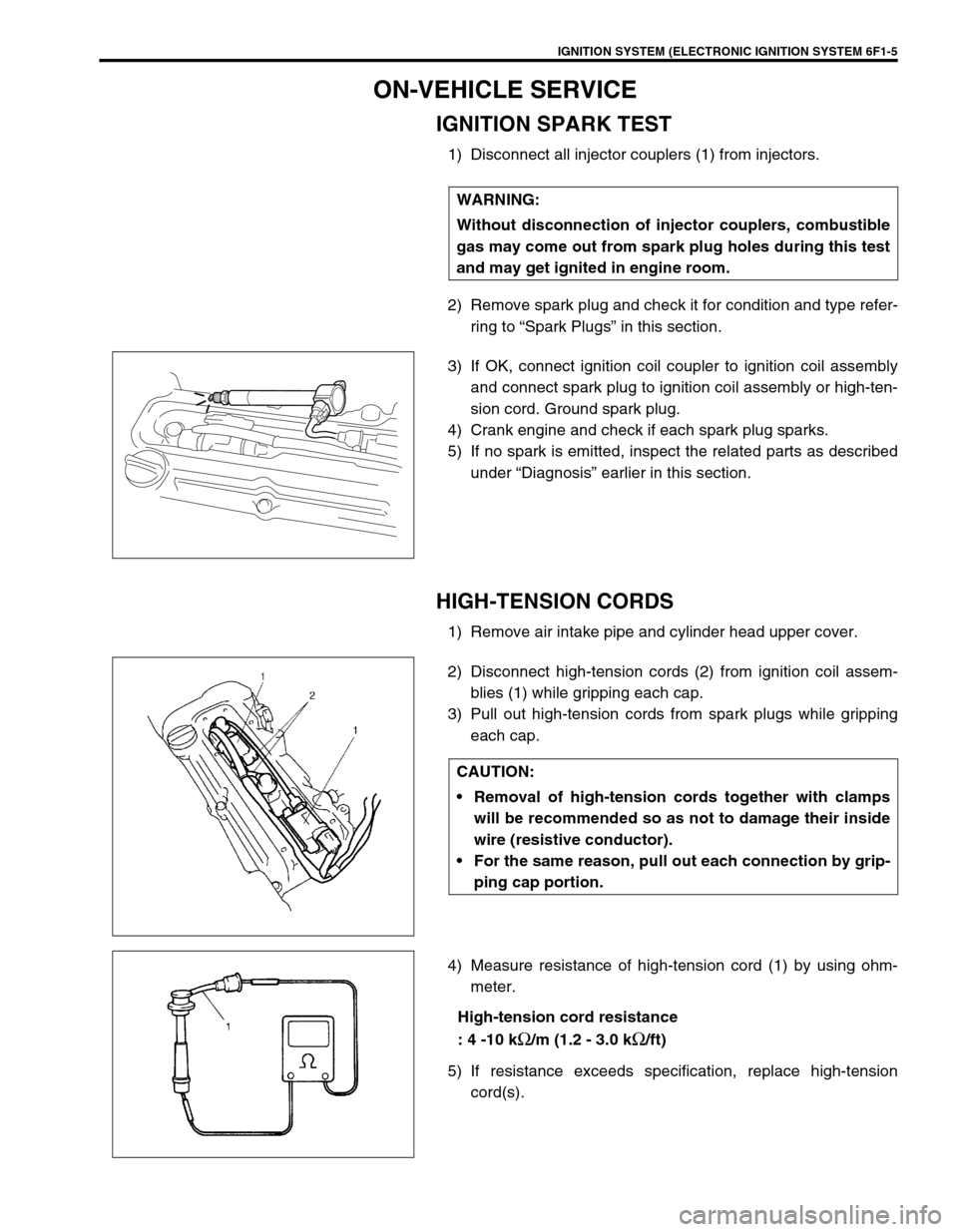

1) Disconnect all injector couplers (1) from injectors.

2) Remove spark plug and check it for condition and type refer-

ring to “Spark Plugs” in this section.

3) If OK, connect ignition coil coupler to ignition coil assembly

and connect spark plug to ignition coil assembly or high-ten-

sion cord. Ground spark plug.

4) Crank engine and check if each spark plug sparks.

5) If no spark is emitted, inspect the related parts as described

under “Diagnosis” earlier in this section.

HIGH-TENSION CORDS

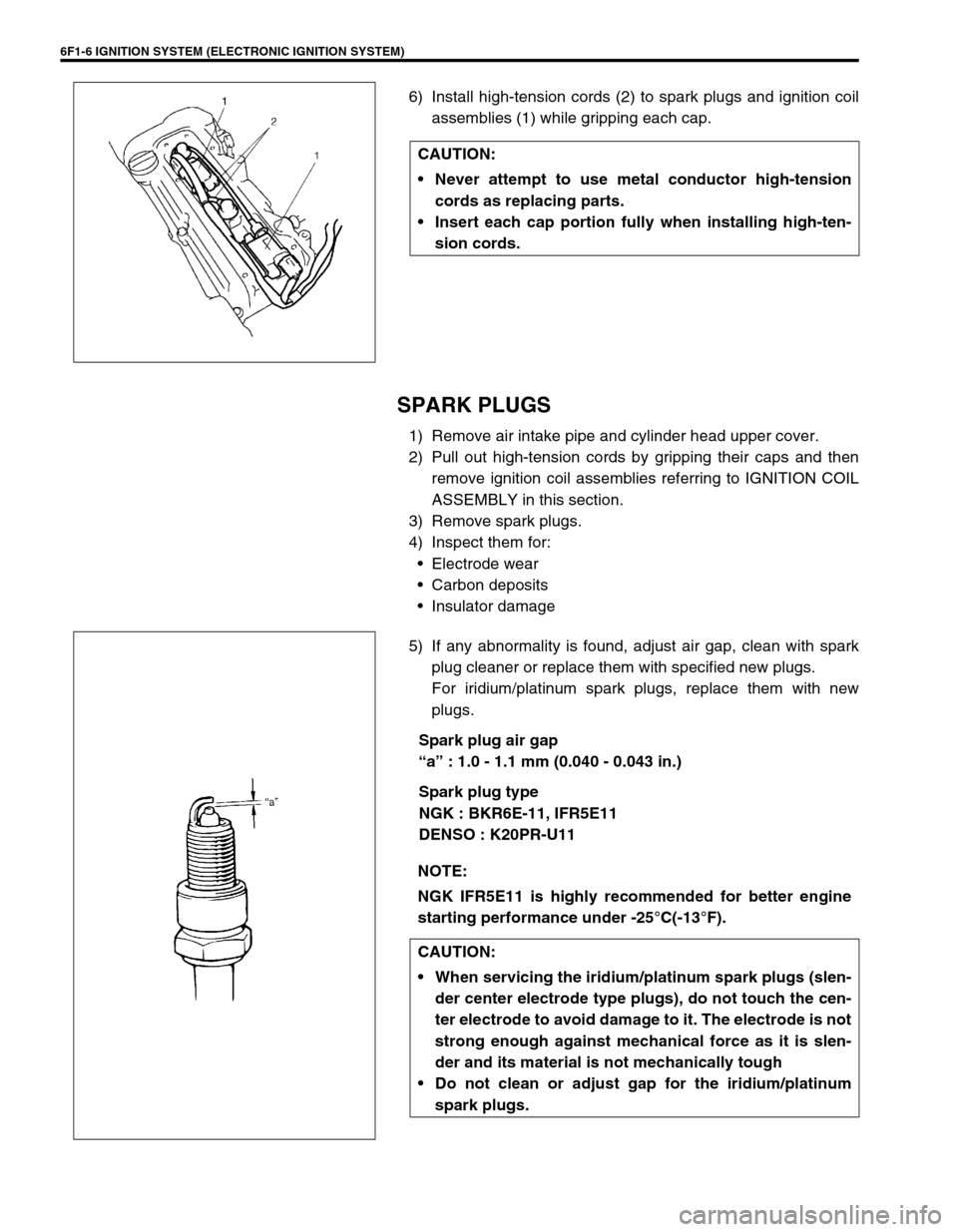

1) Remove air intake pipe and cylinder head upper cover.

2) Disconnect high-tension cords (2) from ignition coil assem-

blies (1) while gripping each cap.

3) Pull out high-tension cords from spark plugs while gripping

each cap.

4) Measure resistance of high-tension cord (1) by using ohm-

meter.

High-tension cord resistance

: 4 -10 k

Ω/m (1.2 - 3.0 kΩ/ft)

5) If resistance exceeds specification, replace high-tension

cord(s). WARNING:

Without disconnection of injector couplers, combustible

gas may come out from spark plug holes during this test

and may get ignited in engine room.

CAUTION:

Removal of high-tension cords together with clamps

will be recommended so as not to damage their inside

wire (resistive conductor).

For the same reason, pull out each connection by grip-

ping cap portion.

Page 668 of 698

6F1-6 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

6) Install high-tension cords (2) to spark plugs and ignition coil

assemblies (1) while gripping each cap.

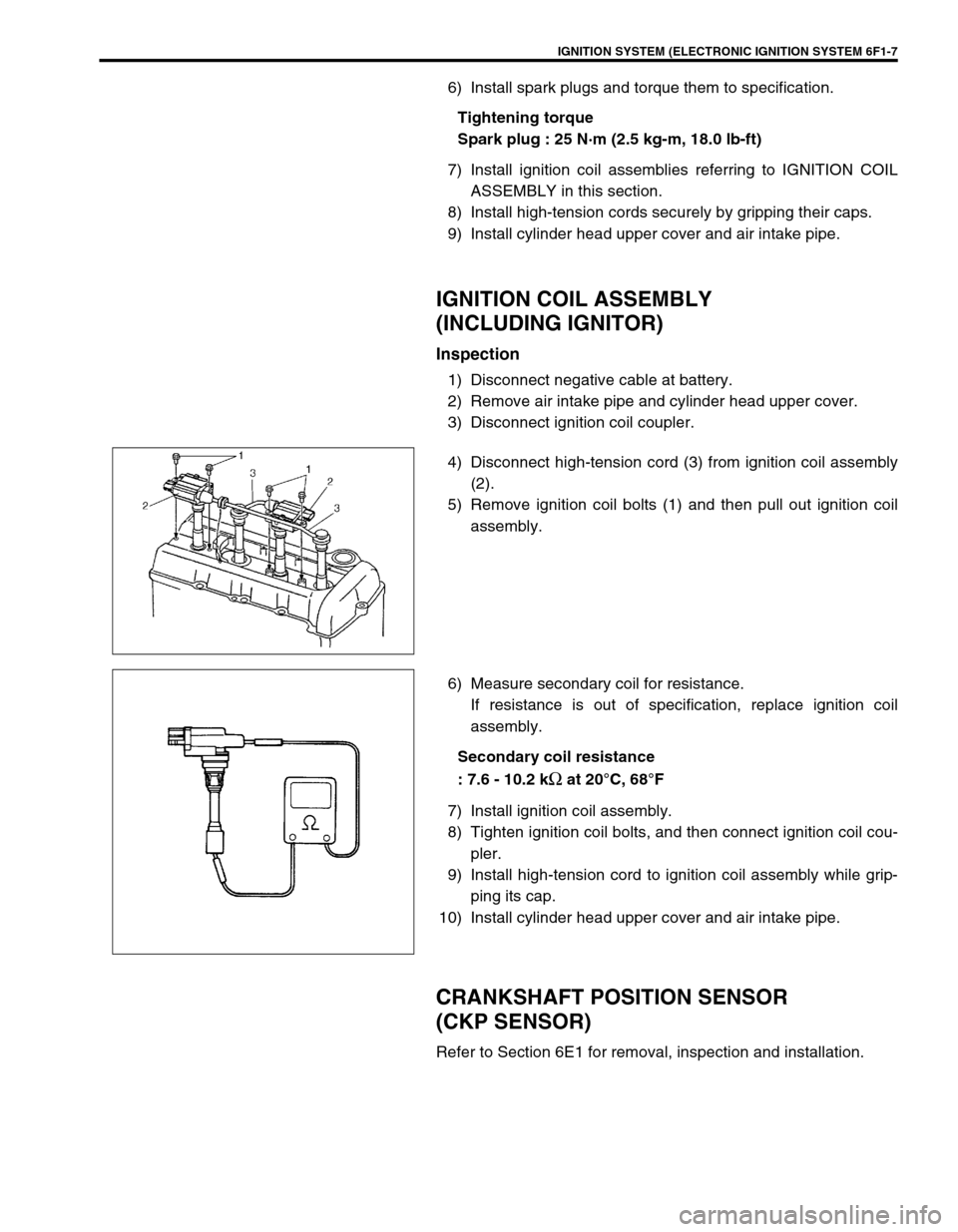

SPARK PLUGS

1) Remove air intake pipe and cylinder head upper cover.

2) Pull out high-tension cords by gripping their caps and then

remove ignition coil assemblies referring to IGNITION COIL

ASSEMBLY in this section.

3) Remove spark plugs.

4) Inspect them for:

Electrode wear

Carbon deposits

Insulator damage

5) If any abnormality is found, adjust air gap, clean with spark

plug cleaner or replace them with specified new plugs.

For iridium/platinum spark plugs, replace them with new

plugs.

Spark plug air gap

“a” : 1.0 - 1.1 mm (0.040 - 0.043 in.)

Spark plug type

NGK : BKR6E-11, IFR5E11

DENSO : K20PR-U11 CAUTION:

Never attempt to use metal conductor high-tension

cords as replacing parts.

Insert each cap portion fully when installing high-ten-

sion cords.

NOTE:

NGK IFR5E11 is highly recommended for better engine

starting performance under -25°C(-13°F).

CAUTION:

When servicing the iridium/platinum spark plugs (slen-

der center electrode type plugs), do not touch the cen-

ter electrode to avoid damage to it. The electrode is not

strong enough against mechanical force as it is slen-

der and its material is not mechanically tough

Do not clean or adjust gap for the iridium/platinum

spark plugs.

Page 669 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F1-7

6) Install spark plugs and torque them to specification.

Tightening torque

Spark plug : 25 N·m (2.5 kg-m, 18.0 lb-ft)

7) Install ignition coil assemblies referring to IGNITION COIL

ASSEMBLY in this section.

8) Install high-tension cords securely by gripping their caps.

9) Install cylinder head upper cover and air intake pipe.

IGNITION COIL ASSEMBLY

(INCLUDING IGNITOR)

Inspection

1) Disconnect negative cable at battery.

2) Remove air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly

(2).

5) Remove ignition coil bolts (1) and then pull out ignition coil

assembly.

6) Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

: 7.6 - 10.2 k

Ω at 20°C, 68°F

7) Install ignition coil assembly.

8) Tighten ignition coil bolts, and then connect ignition coil cou-

pler.

9) Install high-tension cord to ignition coil assembly while grip-

ping its cap.

10) Install cylinder head upper cover and air intake pipe.

CRANKSHAFT POSITION SENSOR

(CKP SENSOR)

Refer to Section 6E1 for removal, inspection and installation.