maintenance SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 47 of 698

0B-18 MAINTENANCE AND LUBRICATION

REPLACEMENT

1) Inspect transmission case for evidence of fluid leakage.

Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Change fluid. For its procedure, refer to “CHANGING A/T

FLUID” in Section 7B.

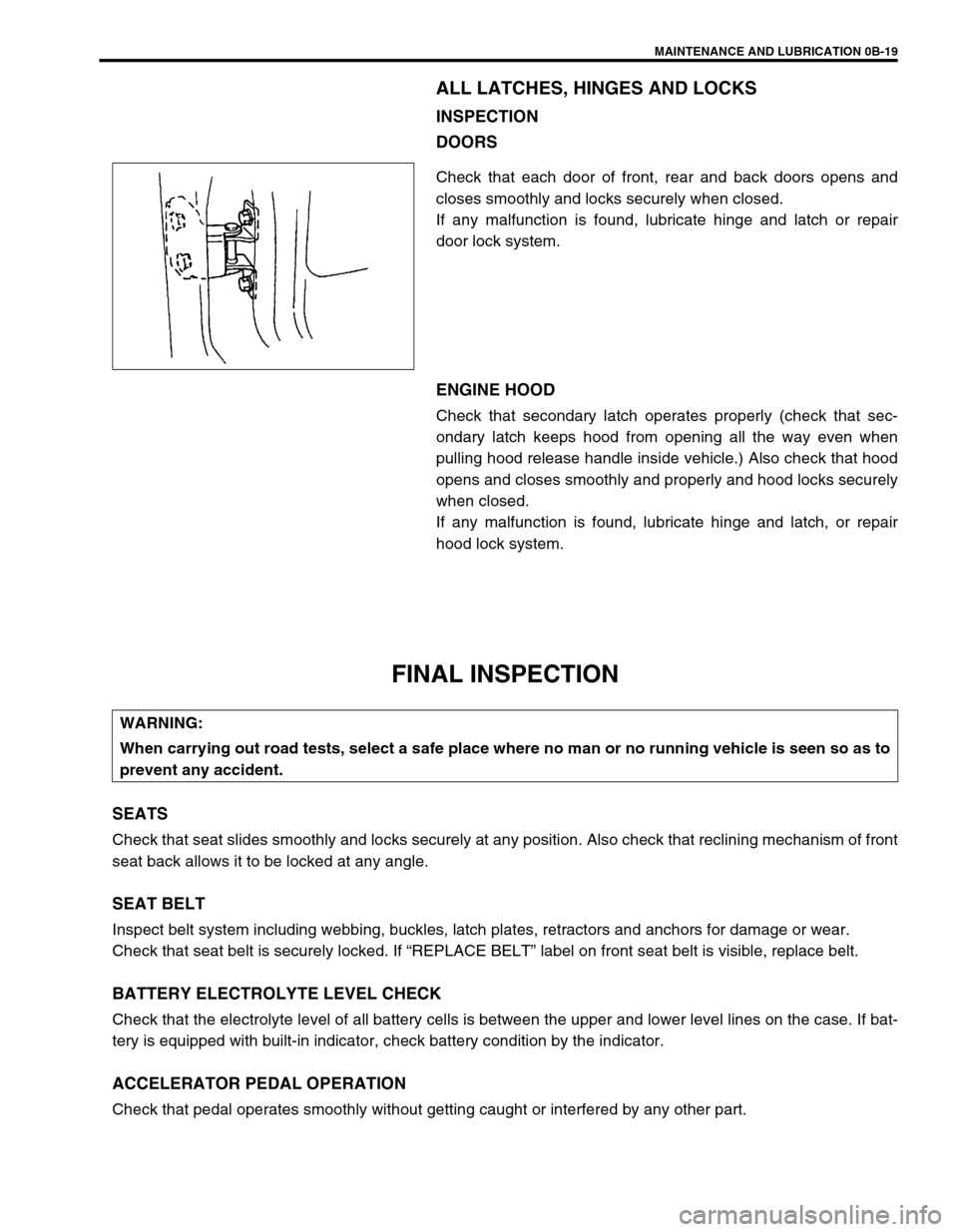

TRANSFER OIL (4WD) AND REAR DIFFERENTIAL

OIL (4WD)

INSPECTION

1) Check transfer case or differential for evidence of oil leak-

age.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level check.

3) Remove level plug of transfer or differential and check oil

level.

Oil level can be checked roughly by means of level plug

hole. That is, if oil flows out of level plug hole or if oil level is

found up to hole when level plug is removed, oil is properly

filled.

If oil is found insufficient, pour specified amount of specified

oil referring to “TRANSFER OIL CHANGE” in Section 7D or

“DIFFERENTIAL OIL CHANGE” in Section 7F.

4) Tighten level plug to specified torque referring to “TRANS-

FER OIL CHANGE” in Section 7D or “CHANGING DIFFER-

ENTIAL OIL” in Section 7F.

REPLACEMENT

Change transfer oil and differential oil with new specified oil refer-

ring to “TRANSFER OIL CHANGE” in Section 7D or “DIFFEREN-

TIAL OIL CHANGE” in Section 7F.

1. Drain plug

[A] : Transfer

[B] : Rear differential

1. Oil level/filler plug

2. Drain plug

Page 48 of 698

MAINTENANCE AND LUBRICATION 0B-19

ALL LATCHES, HINGES AND LOCKS

INSPECTION

DOORS

Check that each door of front, rear and back doors opens and

closes smoothly and locks securely when closed.

If any malfunction is found, lubricate hinge and latch or repair

door lock system.

ENGINE HOOD

Check that secondary latch operates properly (check that sec-

ondary latch keeps hood from opening all the way even when

pulling hood release handle inside vehicle.) Also check that hood

opens and closes smoothly and properly and hood locks securely

when closed.

If any malfunction is found, lubricate hinge and latch, or repair

hood lock system.

FINAL INSPECTION

SEATS

Check that seat slides smoothly and locks securely at any position. Also check that reclining mechanism of front

seat back allows it to be locked at any angle.

SEAT BELT

Inspect belt system including webbing, buckles, latch plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked. If “REPLACE BELT” label on front seat belt is visible, replace belt.

BATTERY ELECTROLYTE LEVEL CHECK

Check that the electrolyte level of all battery cells is between the upper and lower level lines on the case. If bat-

tery is equipped with built-in indicator, check battery condition by the indicator.

ACCELERATOR PEDAL OPERATION

Check that pedal operates smoothly without getting caught or interfered by any other part.

WARNING:

When carrying out road tests, select a safe place where no man or no running vehicle is seen so as to

prevent any accident.

Page 49 of 698

0B-20 MAINTENANCE AND LUBRICATION

ENGINE START

Check engine start for readiness.

On automatic transmission vehicles, try to start the engine in each select lever position. The starting motor

should crank only in “P” (Park) or “N” (Neutral).

On manual transmission vehicles, place the shift lever in “Neutral,” depress clutch pedal fully any try to start.

EXHAUST SYSTEM CHECK

Check for leakage, cracks or loose supports.

CLUTCH (FOR MANUAL TRANSMISSION)

Check for the following.

Clutch is completely released when depressing clutch pedal,

No slipping clutch occurs when releasing pedal and accelerating.

Clutch itself is free from any abnormal condition.

GEARSHIFT OR SELECT LEVER (TRANSMISSION)

Check gear shift or select lever for smooth shifting to all positions and for good performance of transmission in

any position.

With automatic transmission equipped vehicle, also check that shift indicator indicates properly according to

which position select lever is shifted to.

With automatic transmission equipped vehicle, make sure that vehicle is at complete stop when shifting select

lever to “P” range position and release all brakes.

BRAKE

Foot Brake

Check the followings:

that brake pedal has proper travel,

that brake works properly,

that it is free from noise,

that vehicle does not pull to one side when brake is applied.

and that brake do not drag.

Parking Brake

Check that lever has proper travel.

Check to ensure that parking brake is fully effective when the vehicle is stopped on the safe slope and brake

lever is pulled all the way.WARNING:

Before performing the following check, be sure to have enough room around the vehicle. Then, firmly

apply both the parking brake and the regular brakes. Do not use the accelerator pedal. If the engine

starts, be ready to turn off the ignition promptly. Take these precautions because the vehicle could

move without warning and possibly cause personal injury or property damage.

WARNING:

With vehicle parked on a fairly steep slope, make sure nothing is in the way downhill to avoid any per-

sonal injury or property damage. Be prepared to apply regular brake quickly even if vehicle should

start to move.

Page 50 of 698

MAINTENANCE AND LUBRICATION 0B-21

STEERING

Check to ensure that steering wheel is free from instability, or abnormally heavy feeling.

Check that the vehicle does not wander or pull to one side.

ENGINE

Check that engine responds readily at all speeds.

Check that engine is free from abnormal noise and abnormal vibration.

BODY, WHEELS AND POWER TRANSMITTING SYSTEM

Check that body, wheels and power transmitting system are free from abnormal noise and abnormal vibration or

any other abnormal condition.

METERS AND GAUGE

Check that speedometer, odometer, fuel meter, temperature gauge, etc. are operating accurately.

LIGHTS

Check that all lights operate properly.

WINDSHIELD DEFROSTER

Periodically check that air comes out from defroster outlet when operating heater or air conditioning.

Set mode control lever to defroster position and fan switch lever to “HI” position for this check.

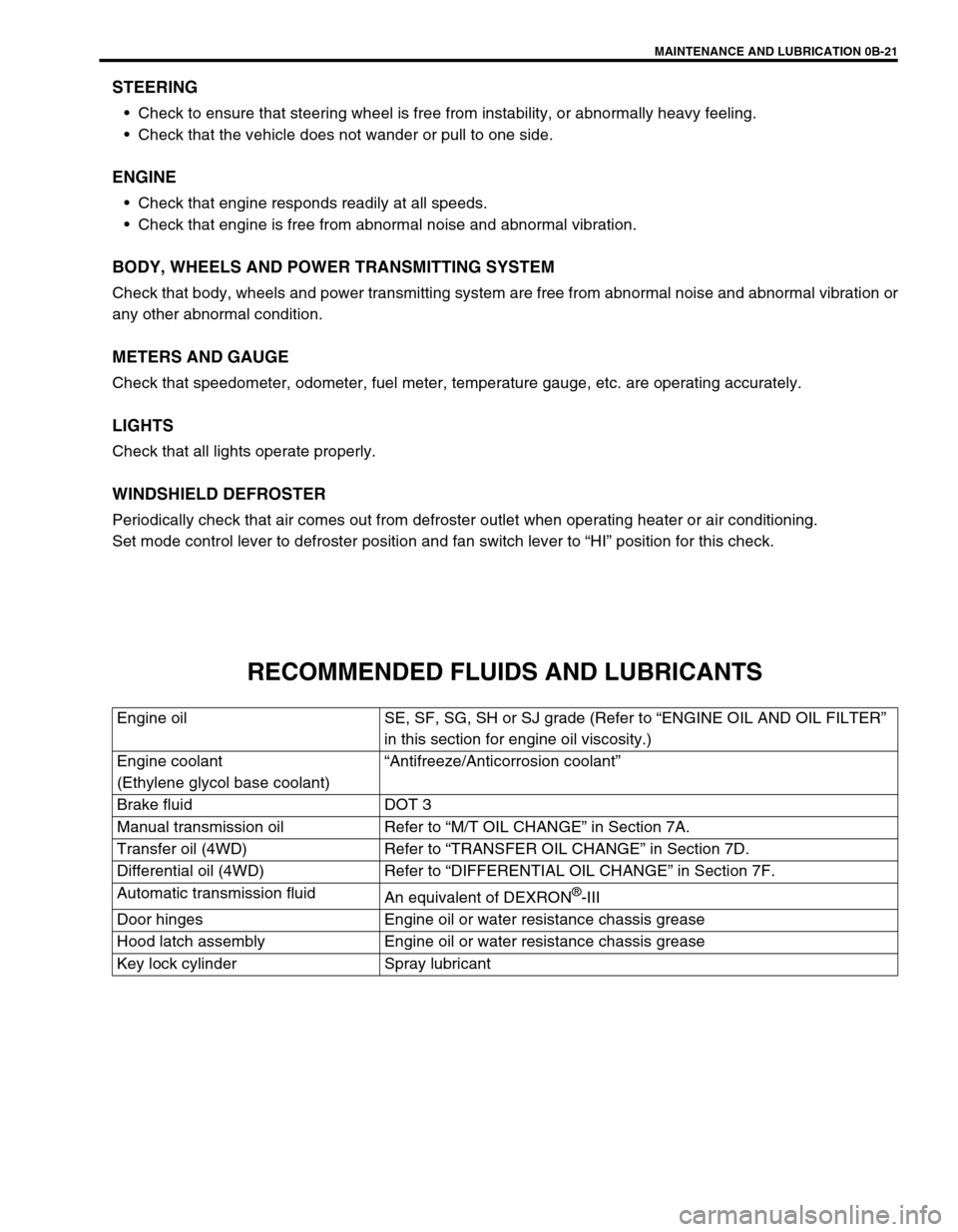

RECOMMENDED FLUIDS AND LUBRICANTS

Engine oil SE, SF, SG, SH or SJ grade (Refer to “ENGINE OIL AND OIL FILTER”

in this section for engine oil viscosity.)

Engine coolant

(Ethylene glycol base coolant)“Antifreeze/Anticorrosion coolant”

Brake fluid DOT 3

Manual transmission oil Refer to “M/T OIL CHANGE” in Section 7A.

Transfer oil (4WD) Refer to “TRANSFER OIL CHANGE” in Section 7D.

Differential oil (4WD) Refer to “DIFFERENTIAL OIL CHANGE” in Section 7F.

Automatic transmission fluid

An equivalent of DEXRON

®-III

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

Page 51 of 698

0B-22 MAINTENANCE AND LUBRICATION

Page 175 of 698

3C-2 STEERING WHEEL AND COLUMN

GENERAL DESCRIPTION

STEERING COLUMN

This double tube type steering column has following three important features in addition to the steering function

:

The column is energy absorbing, designed to compress in a front-end collision.

The ignition switch and lock are mounted conveniently on this column.

With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the vehi-

cle.

To insure the energy absorbing action, it is important that only the specified screws, bolts, and nuts be used as

designated and that they are tightened to the specified torque.

When the column assembly is removed from the vehicle, special care must be taken in handling it. Use of a

steering wheel puller other than the one recommended in this manual or a sharp blow on the end of the steering

shaft, leaning on the assembly, or dropping the assembly could shear the plastic shear pins which maintain col-

umn length and position.

STEERING WHEEL AND DRIVER AIR BAG (INFLATOR) MODULE

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is

mounted to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the

restraint of the driver’s and passenger’s seat belts by deploying the air bags.

The air bag (inflator) module should be handled with care to prevent accidental deployment. When servicing, be

sure to observe all WARNINGS and CAUTIONS and “SERVICE PRECAUTIONS” under “ON-VEHICLE SER-

VICE” in Section 10B.

DIAGNOSIS

For maintenance service of the steering wheel and column, refer to Section 0B.

For diagnosis of the steering wheel and column, refer to Section 3.

For diagnosis of the air bag system, refer to Section 10B.

INSPECTION AND REPAIR REQUIRED AFTER ACCIDENT

After an accident, whether the air bag has been deployed or not, be sure to perform checks, inspections and

repairs described under “CHECKING STEERING COLUMN ASSEMBLY AND LOWER SHAFT FOR ACCI-

DENT DAMAGE” as well as “REPAIRS AND INSPECTIONS REQUIRED AFTER ACCIDENT” under “DIAGNO-

SIS” in Section 10B.

Page 246 of 698

WHEELS AND TIRES 3F-1

6F1

6F2

6G

3F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3F

WHEELS AND TIRES

CONTENTS

GENERAL DESCRIPTION ............................... 3F-2

TIRES ............................................................ 3F-2

WHEELS ....................................................... 3F-2

REPLACEMENT TIRES ................................ 3F-2

REPLACEMENT WHEELS ........................... 3F-2

HOW TO MEASURE WHEEL RUNOUT... 3F-3

METRIC LUG NUTS AND WHEEL

STUDS ...................................................... 3F-3

DIAGNOSIS ...................................................... 3F-3

DIAGNOSIS TABLE ...................................... 3F-3

BALANCING WHEELS ................................. 3F-3

GENERAL BALANCE PROCEDURES ......... 3F-4

OFF-VEHICLE BALANCING ..................... 3F-4

ON-VEHICLE BALANCING....................... 3F-4MAINTENANCE AND MINOR

ADJUSTMENTS ............................................... 3F-5

WHEEL MAINTENANCE .............................. 3F-5

WHEEL ATTACHING STUDS .................. 3F-5

MATCHED TIRES AND WHEELS ............ 3F-5

TIRE MAINTENANCE................................... 3F-5

TIRE PLACARD ........................................ 3F-5

INFLATION OF TIRES .............................. 3F-6

TIRE ROTATION ...................................... 3F-6

ON-VEHICLE SERVICE ................................... 3F-7

WHEEL ......................................................... 3F-7

TIRE .............................................................. 3F-8

MOUNTING AND DISMOUNTING ........... 3F-8

REPAIR ..................................................... 3F-8

NOTE:

All wheel fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of the

same part number or with an equivalent part if replacement becomes necessary. Do not use a replace-

ment part of lesser quality or substitute design. Torque values must be used as specified during reas-

sembly to assure proper retention of all parts.

There is to be no welding as it may result in extensive damage and weakening of the metal.

Page 250 of 698

WHEELS AND TIRES 3F-5

MAINTENANCE AND MINOR ADJUSTMENTS

WHEEL MAINTENANCE

Wheel repairs that use welding, heating, or peening are not approved. All damaged wheels should be replaced.

WHEEL ATTACHING STUDS

If a broken stud is found, see Section 3E (rear) or Section 3D (front) for Note and Replacement procedure.

MATCHED TIRES AND WHEELS

Tires and wheels are match mounted at the assembly plant.

This means that the radially stiffest part of the tire, or “high spot”,

is matched to the smallest radius or “low spot” of the wheel.

This is done to provide the smoothest possible ride.

The “high spot” of the tire is originally marked by paint dot (1) on

the outboard sidewall. This paint dot will eventually wash off the

tire.

The “ow spot” of the wheel is originally marked by paint dot (2) on

the wheel rim-flange. Properly assembled, the wheel rims’ paint

dot should be aligned with the tires’ paint dot as shown in left fig-

ure.

Whenever a tire is dismounted from its wheel, it should be

remounted so that the tire and wheel are matched. If the tire’s

paint dot cannot be located, a line should be scribed on the tire

and wheel before dismounting to assure that it is remounted in

the same position.

TIRE MAINTENANCE

TIRE PLACARD

The “Tire Placard” is located on the left door (right door for right-hand side steering vehicle) lock pillar and

should be referred to tire information.

The placard lists the maximum load, tire size and cold tire pressure where applicable.

NOTE:

Whether rim size and/or maximum load are listed or not depends on regulations of each country.

Page 270 of 698

PROPELLER SHAFTS 4B-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

4B

8D

8E

9

10

10A

10B

SECTION 4B

PROPELLER SHAFTS

CONTENTS

GENERAL DESCRIPTION .............................. 4B-1

DIAGNOSIS ..................................................... 4B-1

DIAGNOSIS TABLE ..................................... 4B-1PROPELLER SHAFT JOINT CHECK.......... 4B-2

ON-VEHICLE SERVICE .................................. 4B-2

TIGHTENING TORQUE SPECIFICATION...... 4B-4

GENERAL DESCRIPTION

Most universal and constant velocity joints require no maintenance. They are lubricated for life and can not be

lubricated on the vehicle. If universal and constant velocity joints becomes noisy or worn, it must be replace.

The propeller shaft is a balanced unit. Handle it carefully so that balance can be maintained.

DIAGNOSIS

DIAGNOSIS TABLE

Condition Possible Cause Correction

Abnormal noise

Loose universal joint bolt Tighten universal joint bolt.

Spider bearing worn out or stuck Replace.

Wear spider Replace propeller shaft.

Vibration

Performed propeller shaft Replace.

Page 282 of 698

BRAKES 5-9

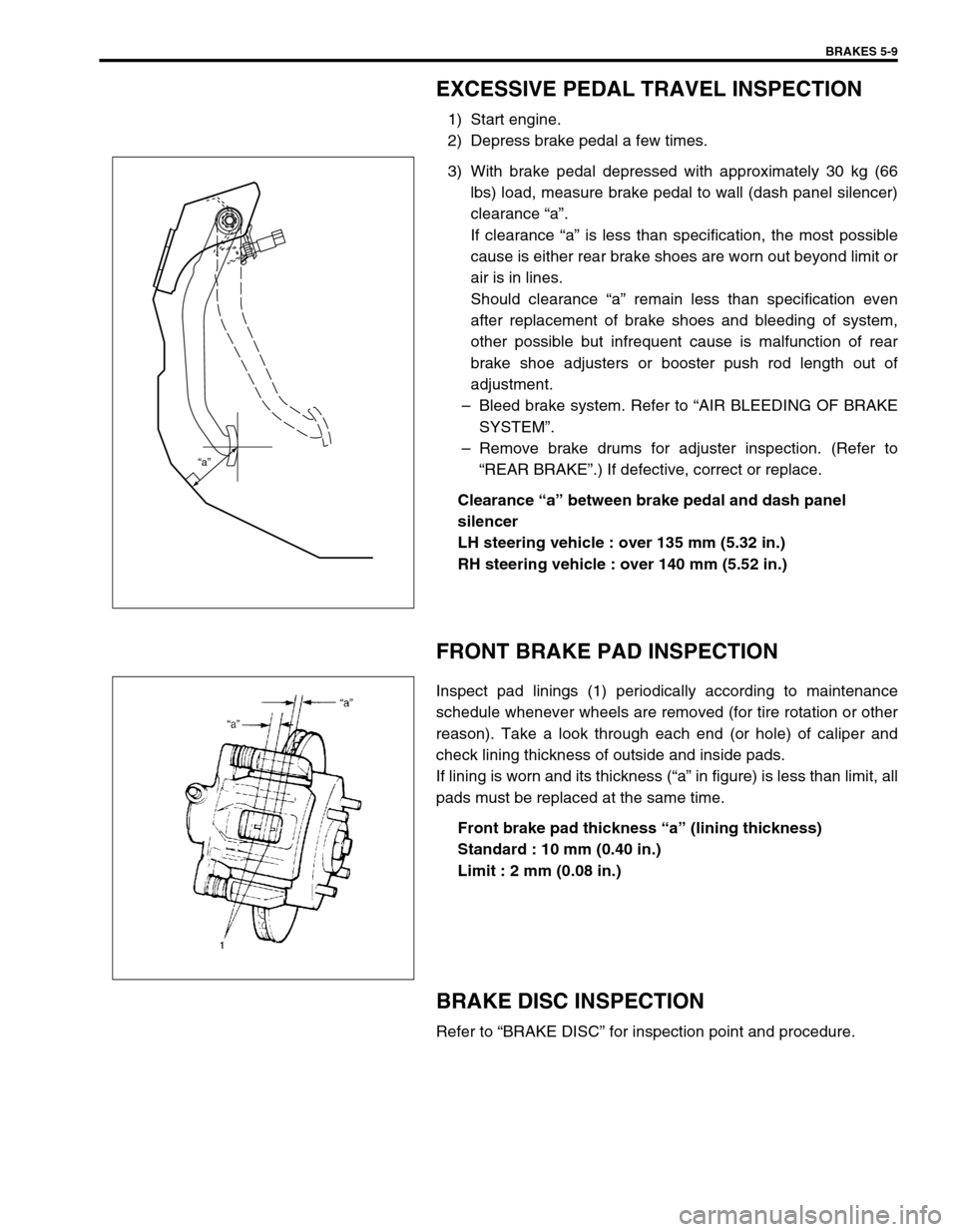

EXCESSIVE PEDAL TRAVEL INSPECTION

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 30 kg (66

lbs) load, measure brake pedal to wall (dash panel silencer)

clearance “a”.

If clearance “a” is less than specification, the most possible

cause is either rear brake shoes are worn out beyond limit or

air is in lines.

Should clearance “a” remain less than specification even

after replacement of brake shoes and bleeding of system,

other possible but infrequent cause is malfunction of rear

brake shoe adjusters or booster push rod length out of

adjustment.

–Bleed brake system. Refer to “AIR BLEEDING OF BRAKE

SYSTEM”.

–Remove brake drums for adjuster inspection. (Refer to

“REAR BRAKE”.) If defective, correct or replace.

Clearance “a” between brake pedal and dash panel

silencer

LH steering vehicle : over 135 mm (5.32 in.)

RH steering vehicle : over 140 mm (5.52 in.)

FRONT BRAKE PAD INSPECTION

Inspect pad linings (1) periodically according to maintenance

schedule whenever wheels are removed (for tire rotation or other

reason). Take a look through each end (or hole) of caliper and

check lining thickness of outside and inside pads.

If lining is worn and its thickness (“a” in figure) is less than limit, all

pads must be replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Standard : 10 mm (0.40 in.)

Limit : 2 mm (0.08 in.)

BRAKE DISC INSPECTION

Refer to “BRAKE DISC” for inspection point and procedure.

“a”