Wheel bearing SUZUKI SWIFT 2000 1.G RG413 Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 261 of 698

4A-8 FRONT DRIVE SHAFT

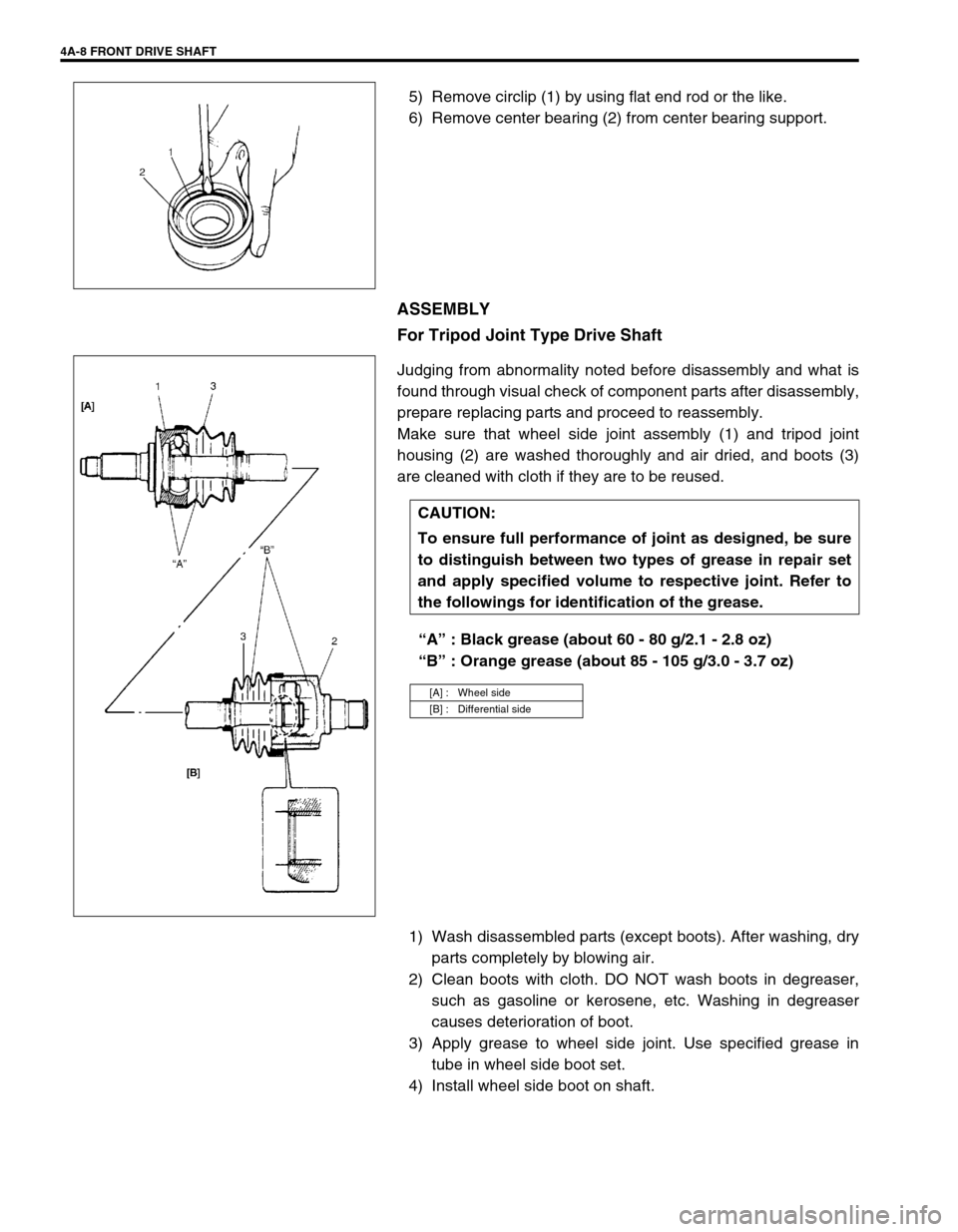

5) Remove circlip (1) by using flat end rod or the like.

6) Remove center bearing (2) from center bearing support.

ASSEMBLY

For Tripod Joint Type Drive Shaft

Judging from abnormality noted before disassembly and what is

found through visual check of component parts after disassembly,

prepare replacing parts and proceed to reassembly.

Make sure that wheel side joint assembly (1) and tripod joint

housing (2) are washed thoroughly and air dried, and boots (3)

are cleaned with cloth if they are to be reused.

“A” : Black grease (about 60 - 80 g/2.1 - 2.8 oz)

“B” : Orange grease (about 85 - 105 g/3.0 - 3.7 oz)

1) Wash disassembled parts (except boots). After washing, dry

parts completely by blowing air.

2) Clean boots with cloth. DO NOT wash boots in degreaser,

such as gasoline or kerosene, etc. Washing in degreaser

causes deterioration of boot.

3) Apply grease to wheel side joint. Use specified grease in

tube in wheel side boot set.

4) Install wheel side boot on shaft.

CAUTION:

To ensure full performance of joint as designed, be sure

to distinguish between two types of grease in repair set

and apply specified volume to respective joint. Refer to

the followings for identification of the grease.

[A] : Wheel side

[B] : Differential side

Page 267 of 698

4A-14 FRONT DRIVE SHAFT

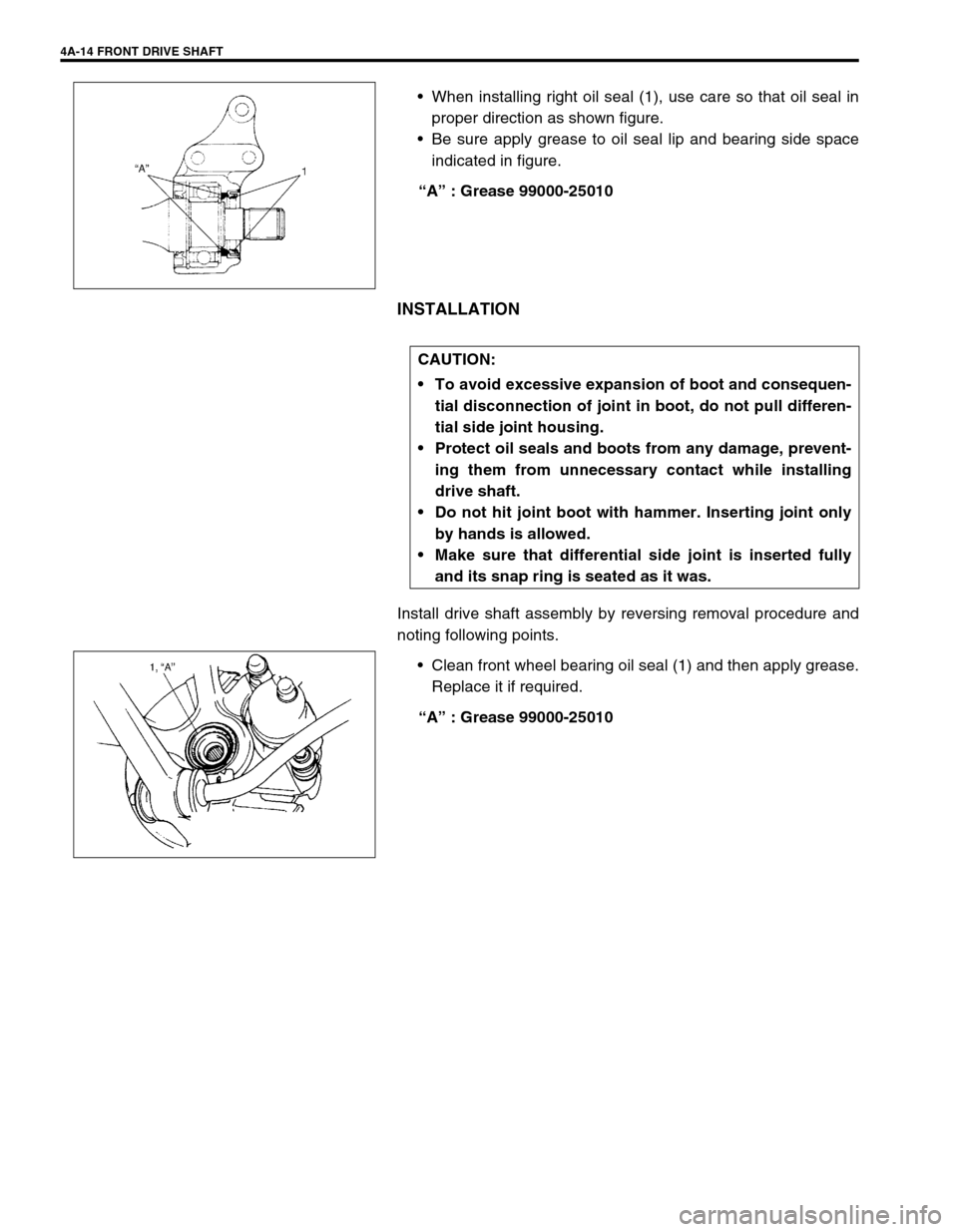

When installing right oil seal (1), use care so that oil seal in

proper direction as shown figure.

Be sure apply grease to oil seal lip and bearing side space

indicated in figure.

“A” : Grease 99000-25010

INSTALLATION

Install drive shaft assembly by reversing removal procedure and

noting following points.

Clean front wheel bearing oil seal (1) and then apply grease.

Replace it if required.

“A” : Grease 99000-25010

CAUTION:

To avoid excessive expansion of boot and consequen-

tial disconnection of joint in boot, do not pull differen-

tial side joint housing.

Protect oil seals and boots from any damage, prevent-

ing them from unnecessary contact while installing

drive shaft.

Do not hit joint boot with hammer. Inserting joint only

by hands is allowed.

Make sure that differential side joint is inserted fully

and its snap ring is seated as it was.

Page 268 of 698

FRONT DRIVE SHAFT 4A-15

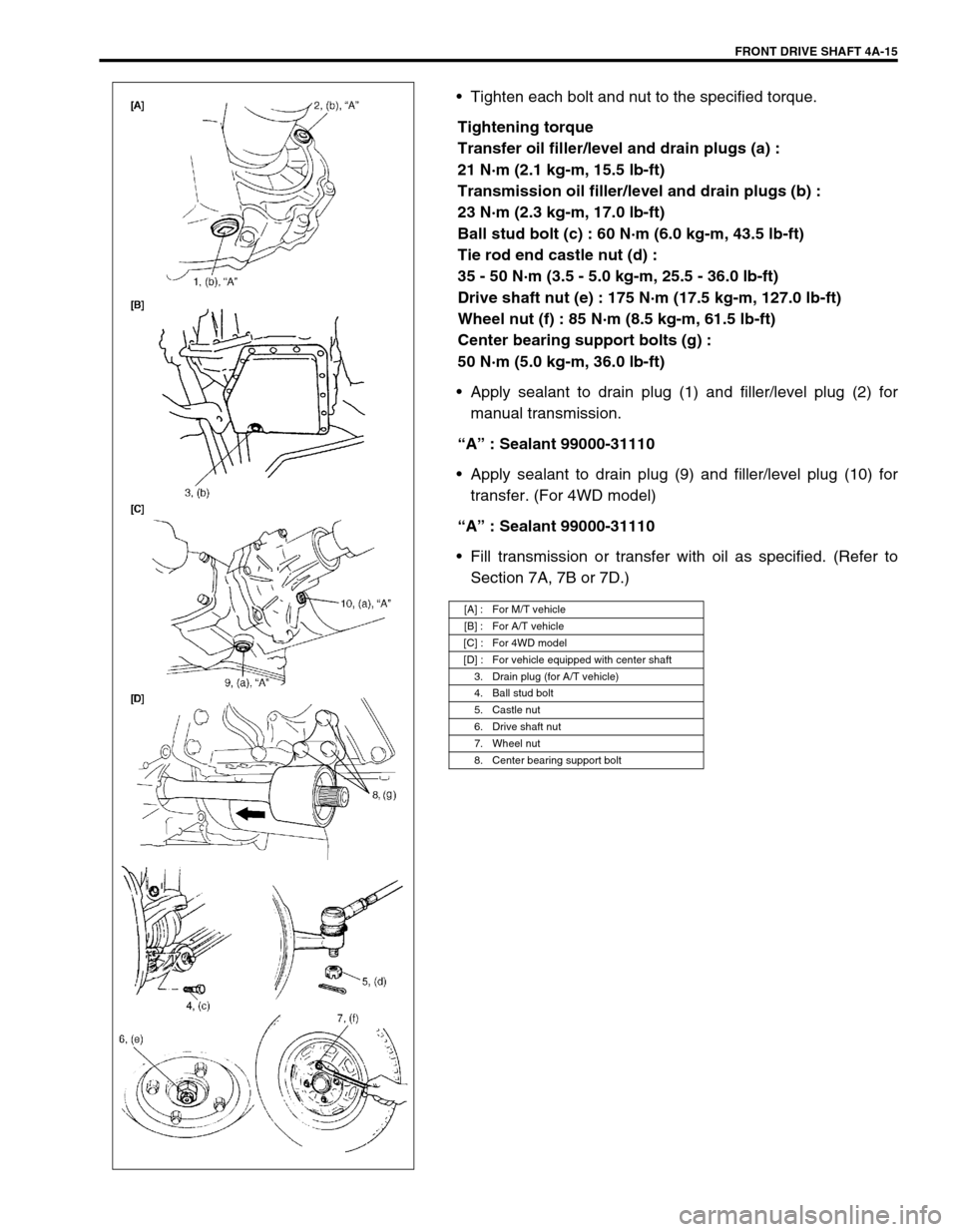

Tighten each bolt and nut to the specified torque.

Tightening torque

Transfer oil filler/level and drain plugs (a) :

21 N·m (2.1 kg-m, 15.5 lb-ft)

Transmission oil filler/level and drain plugs (b) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

Ball stud bolt (c) : 60 N·m (6.0 kg-m, 43.5 lb-ft)

Tie rod end castle nut (d) :

35 - 50 N·m (3.5 - 5.0 kg-m, 25.5 - 36.0 lb-ft)

Drive shaft nut (e) : 175 N·m (17.5 kg-m, 127.0 lb-ft)

Wheel nut (f) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

Center bearing support bolts (g) :

50 N·m (5.0 kg-m, 36.0 lb-ft)

Apply sealant to drain plug (1) and filler/level plug (2) for

manual transmission.

“A” : Sealant 99000-31110

Apply sealant to drain plug (9) and filler/level plug (10) for

transfer. (For 4WD model)

“A” : Sealant 99000-31110

Fill transmission or transfer with oil as specified. (Refer to

Section 7A, 7B or 7D.)

[A] : For M/T vehicle

[B] : For A/T vehicle

[C] : For 4WD model

[D] : For vehicle equipped with center shaft

3. Drain plug (for A/T vehicle)

4. Ball stud bolt

5. Castle nut

6. Drive shaft nut

7. Wheel nut

8. Center bearing support bolt

Page 269 of 698

4A-16 FRONT DRIVE SHAFT

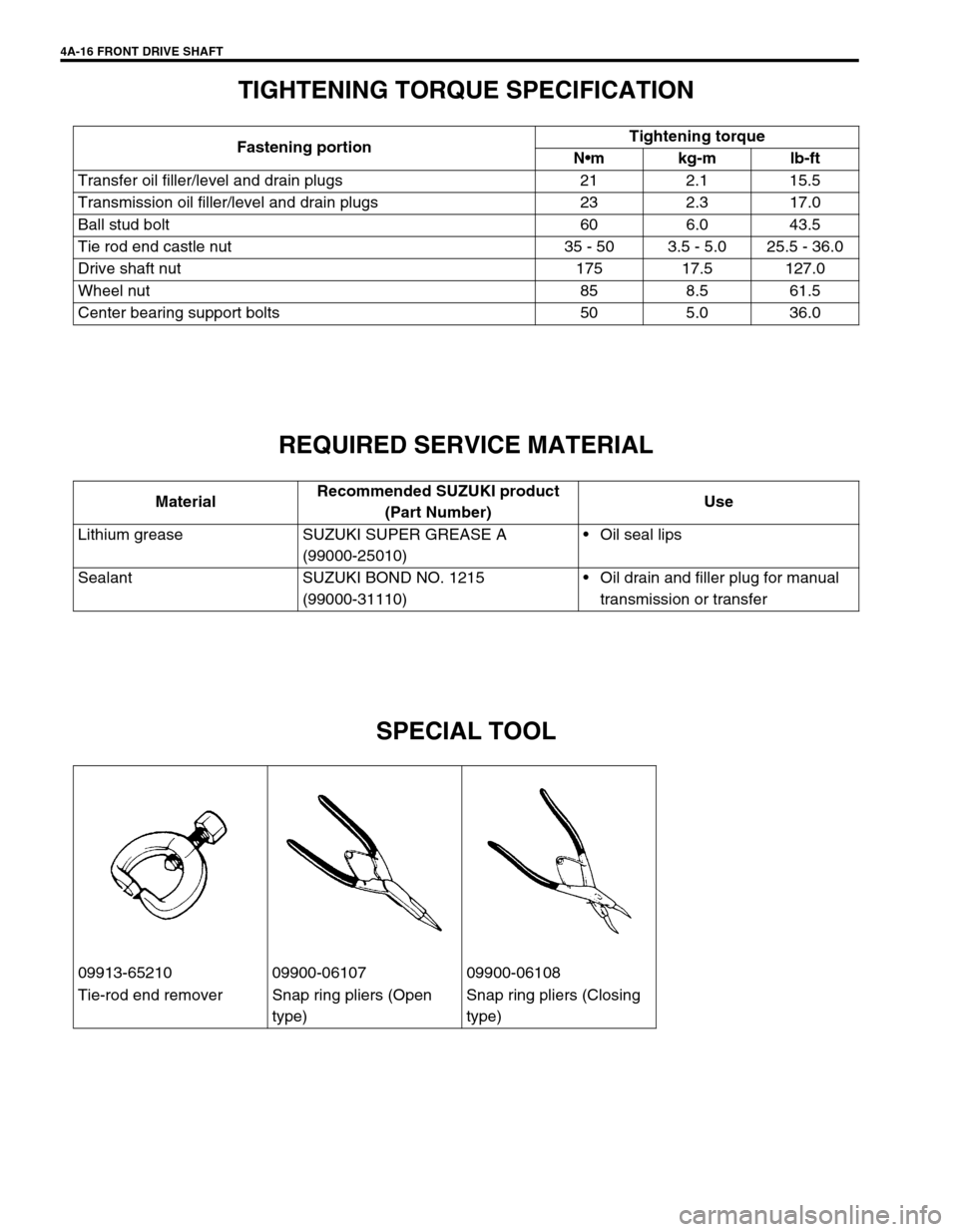

TIGHTENING TORQUE SPECIFICATION

REQUIRED SERVICE MATERIAL

SPECIAL TOOL

Fastening portionTightening torque

Nm kg-m lb-ft

Transfer oil filler/level and drain plugs 21 2.1 15.5

Transmission oil filler/level and drain plugs 23 2.3 17.0

Ball stud bolt 60 6.0 43.5

Tie rod end castle nut 35 - 50 3.5 - 5.0 25.5 - 36.0

Drive shaft nut 175 17.5 127.0

Wheel nut 85 8.5 61.5

Center bearing support bolts 50 5.0 36.0

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Oil seal lips

Sealant SUZUKI BOND NO. 1215

(99000-31110)Oil drain and filler plug for manual

transmission or transfer

09913-65210 09900-06107 09900-06108

Tie-rod end remover Snap ring pliers (Open

type)Snap ring pliers (Closing

type)

Page 279 of 698

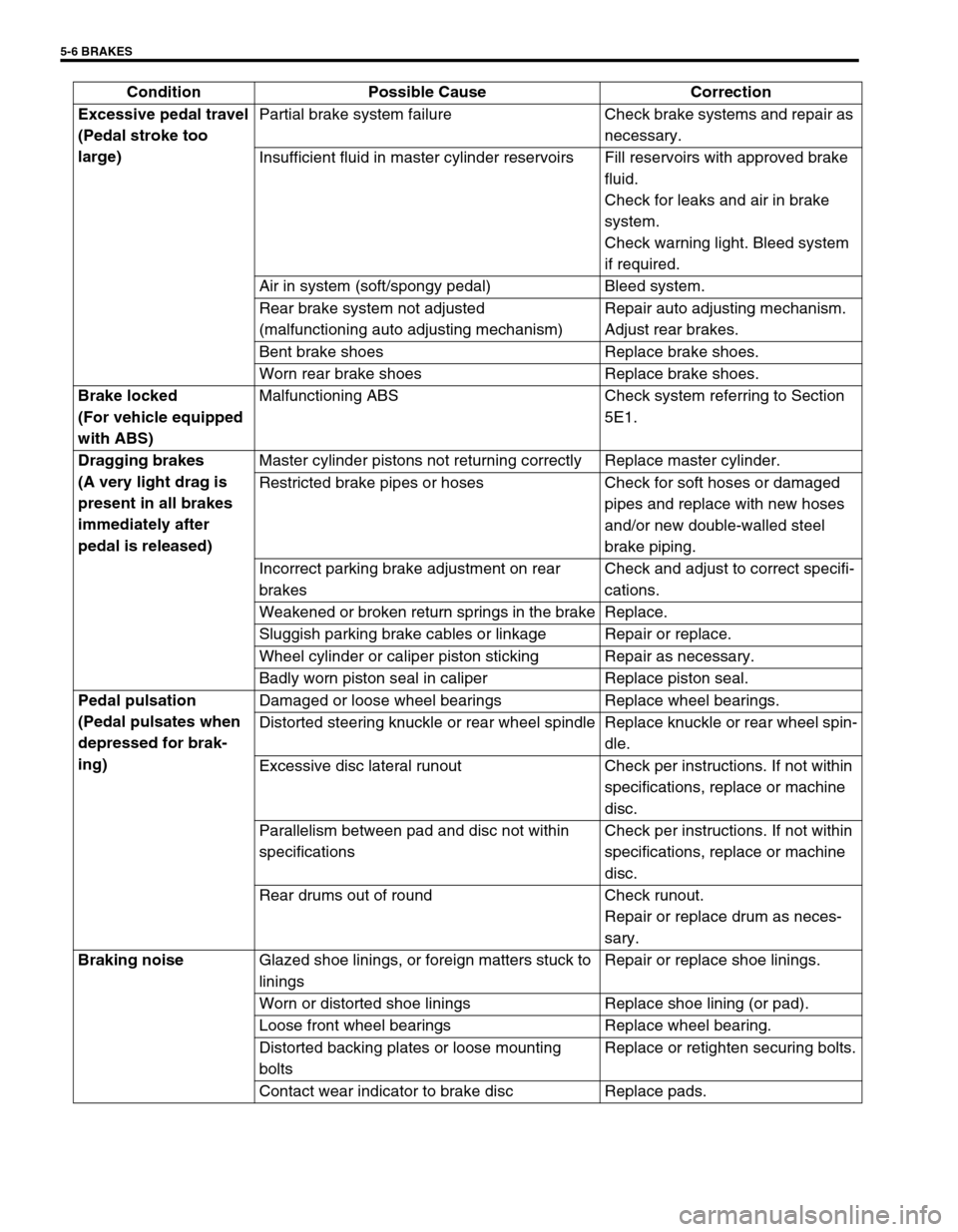

5-6 BRAKES

Excessive pedal travel

(Pedal stroke too

large)Partial brake system failure Check brake systems and repair as

necessary.

Insufficient fluid in master cylinder reservoirs Fill reservoirs with approved brake

fluid.

Check for leaks and air in brake

system.

Check warning light. Bleed system

if required.

Air in system (soft/spongy pedal) Bleed system.

Rear brake system not adjusted

(malfunctioning auto adjusting mechanism)Repair auto adjusting mechanism.

Adjust rear brakes.

Bent brake shoes Replace brake shoes.

Worn rear brake shoes Replace brake shoes.

Brake locked

(For vehicle equipped

with ABS)Malfunctioning ABS Check system referring to Section

5E1.

Dragging brakes

(A very light drag is

present in all brakes

immediately after

pedal is released)Master cylinder pistons not returning correctly Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged

pipes and replace with new hoses

and/or new double-walled steel

brake piping.

Incorrect parking brake adjustment on rear

brakesCheck and adjust to correct specifi-

cations.

Weakened or broken return springs in the brake Replace.

Sluggish parking brake cables or linkage Repair or replace.

Wheel cylinder or caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Pedal pulsation

(Pedal pulsates when

depressed for brak-

ing)Damaged or loose wheel bearings Replace wheel bearings.

Distorted steering knuckle or rear wheel spindle Replace knuckle or rear wheel spin-

dle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine

disc.

Parallelism between pad and disc not within

specificationsCheck per instructions. If not within

specifications, replace or machine

disc.

Rear drums out of round Check runout.

Repair or replace drum as neces-

sary.

Braking noise

Glazed shoe linings, or foreign matters stuck to

liningsRepair or replace shoe linings.

Worn or distorted shoe linings Replace shoe lining (or pad).

Loose front wheel bearings Replace wheel bearing.

Distorted backing plates or loose mounting

boltsReplace or retighten securing bolts.

Contact wear indicator to brake disc Replace pads. Condition Possible Cause Correction

Page 306 of 698

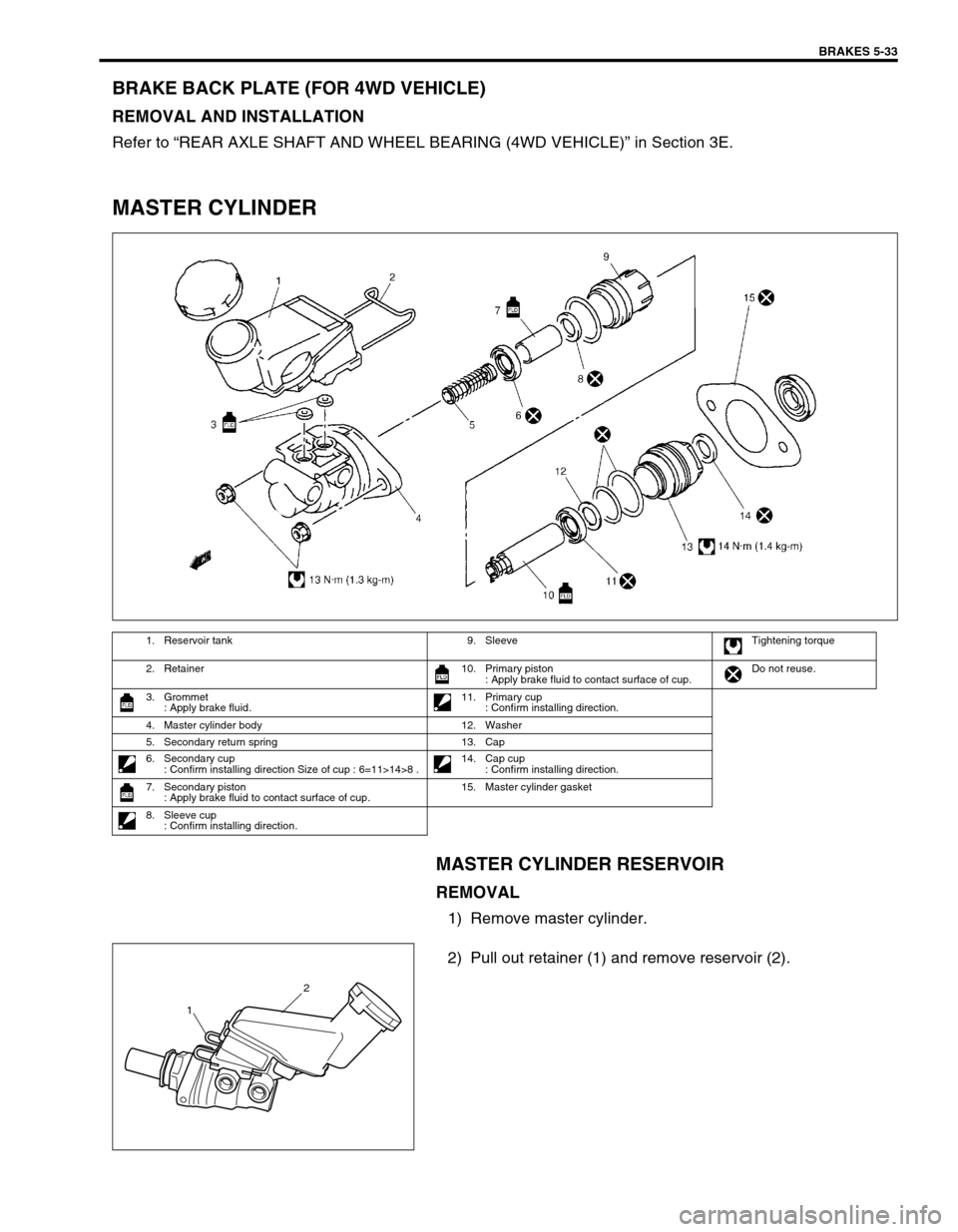

BRAKES 5-33

BRAKE BACK PLATE (FOR 4WD VEHICLE)

REMOVAL AND INSTALLATION

Refer to “REAR AXLE SHAFT AND WHEEL BEARING (4WD VEHICLE)” in Section 3E.

MASTER CYLINDER

MASTER CYLINDER RESERVOIR

REMOVAL

1) Remove master cylinder.

2) Pull out retainer (1) and remove reservoir (2).

1. Reservoir tank 9. Sleeve Tightening torque

2. Retainer 10. Primary piston

: Apply brake fluid to contact surface of cup.Do not reuse.

3. Grommet

: Apply brake fluid.11. Primary cup

: Confirm installing direction.

4. Master cylinder body 12. Washer

5. Secondary return spring 13. Cap

6. Secondary cup

: Confirm installing direction Size of cup : 6=11>14>8 .14. Cap cup

: Confirm installing direction.

7. Secondary piston

: Apply brake fluid to contact surface of cup.15. Master cylinder gasket

8. Sleeve cup

: Confirm installing direction.

2

1

Page 350 of 698

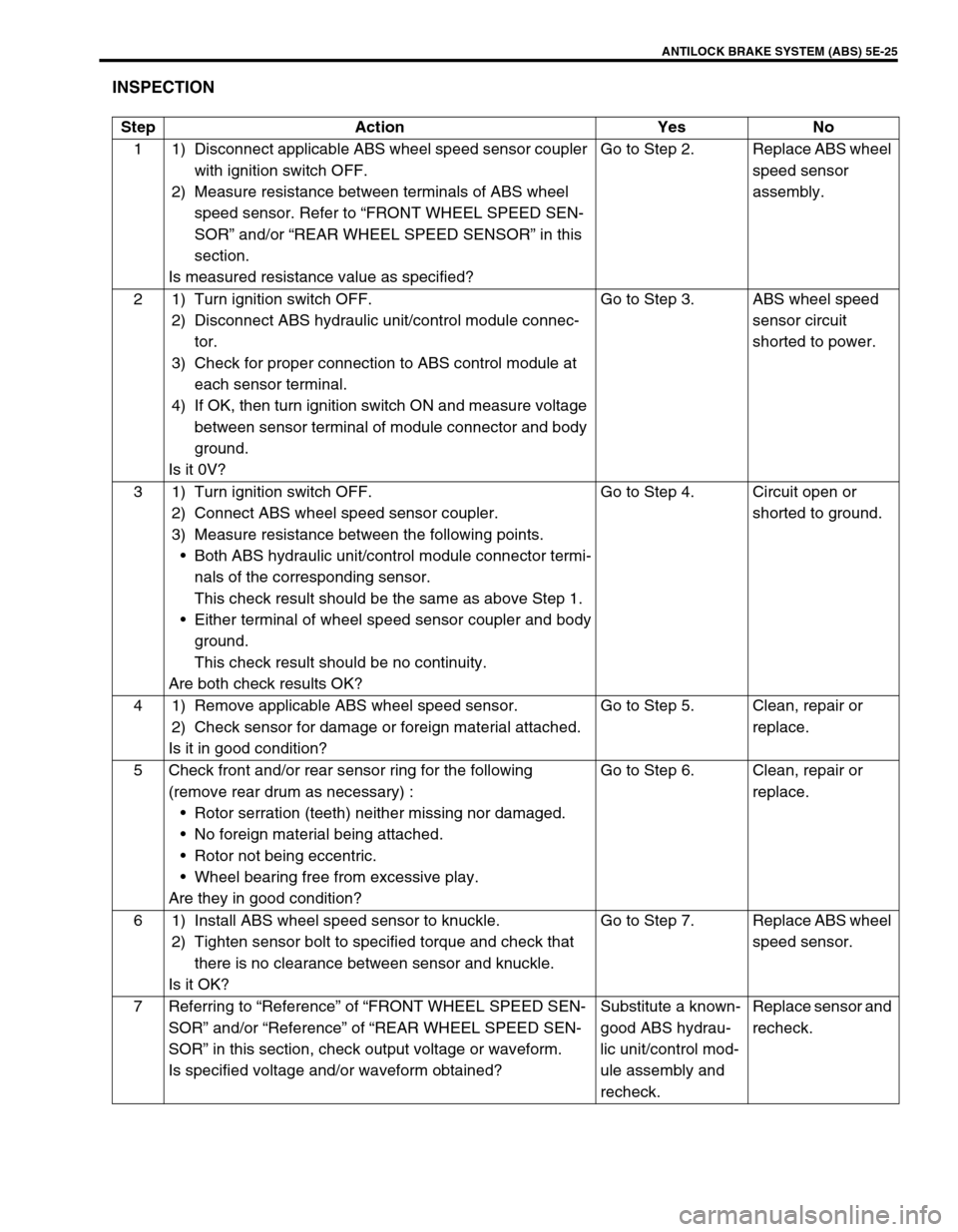

ANTILOCK BRAKE SYSTEM (ABS) 5E-25

INSPECTION

Step Action Yes No

1 1) Disconnect applicable ABS wheel speed sensor coupler

with ignition switch OFF.

2) Measure resistance between terminals of ABS wheel

speed sensor. Refer to “FRONT WHEEL SPEED SEN-

SOR” and/or “REAR WHEEL SPEED SENSOR” in this

section.

Is measured resistance value as specified?Go to Step 2. Replace ABS wheel

speed sensor

assembly.

2 1) Turn ignition switch OFF.

2) Disconnect ABS hydraulic unit/control module connec-

tor.

3) Check for proper connection to ABS control module at

each sensor terminal.

4) If OK, then turn ignition switch ON and measure voltage

between sensor terminal of module connector and body

ground.

Is it 0V?Go to Step 3. ABS wheel speed

sensor circuit

shorted to power.

3 1) Turn ignition switch OFF.

2) Connect ABS wheel speed sensor coupler.

3) Measure resistance between the following points.

Both ABS hydraulic unit/control module connector termi-

nals of the corresponding sensor.

This check result should be the same as above Step 1.

Either terminal of wheel speed sensor coupler and body

ground.

This check result should be no continuity.

Are both check results OK?Go to Step 4. Circuit open or

shorted to ground.

4 1) Remove applicable ABS wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition?Go to Step 5. Clean, repair or

replace.

5 Check front and/or rear sensor ring for the following

(remove rear drum as necessary) :

Rotor serration (teeth) neither missing nor damaged.

No foreign material being attached.

Rotor not being eccentric.

Wheel bearing free from excessive play.

Are they in good condition?Go to Step 6. Clean, repair or

replace.

6 1) Install ABS wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK?Go to Step 7. Replace ABS wheel

speed sensor.

7 Referring to “Reference” of “FRONT WHEEL SPEED SEN-

SOR” and/or “Reference” of “REAR WHEEL SPEED SEN-

SOR” in this section, check output voltage or waveform.

Is specified voltage and/or waveform obtained?Substitute a known-

good ABS hydrau-

lic unit/control mod-

ule assembly and

recheck.Replace sensor and

recheck.

Page 373 of 698

6-4 ENGINE GENERAL INFORMATION AND DIAGNOSIS

GENERAL INFORMATION

STATEMENT ON CLEANLINESS AND CARE

An automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances

that are measured in the thousands of an millimeter (ten thousands of an inch).

Accordingly, when any internal engine parts are serviced, care and cleanliness are important.

Throughout this section, it should be understood that proper cleaning and protection of machined surfaces and

friction areas is part of the repair procedure. This is considered standard shop practice even if not specifically

stated.

A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate the

surfaces on initial operation.

Whenever valve train components, pistons, piston rings, connecting rods, rod bearings, and crankshaft jour-

nal bearings are removed for service, they should be retained in order.

At the time of installation, they should be installed in the same locations and with the same mating surfaces

as when removed.

Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to wire harness or other electrical parts.

Throughout this manual, the four cylinders of the engine are

identified by numbers; No.1 (1), No.2 (2), No.3 (3) and No.4

(4) counted from crankshaft pulley side to flywheel side.

GENERAL INFORMATION ON ENGINE SERVICE

THE FOLLOWING INFORMATION ON ENGINE SERVICE SHOULD BE NOTED CAREFULLY, AS IT IS

IMPORTANT IN PREVENTING DAMAGE, AND IN CONTRIBUTING TO RELIABLE ENGINE PERFOR-

MANCE.

When raising or supporting engine for any reason, do not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against oil pan may cause it to be bent against strainer result-

ing in damaged oil pick-up unit.

It should be kept in mind, while working on engine, that 12-volt electrical system is capable of violent and

damaging short circuits.

When performing any work where electrical terminals can be grounded, ground cable of the battery should

be disconnected at battery.

Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be covered.

This will protect against accidental entrance of foreign material which could follow intake passage into cylin-

der and cause extensive damage when engine is started.

1

2

3

4

Page 566 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-65

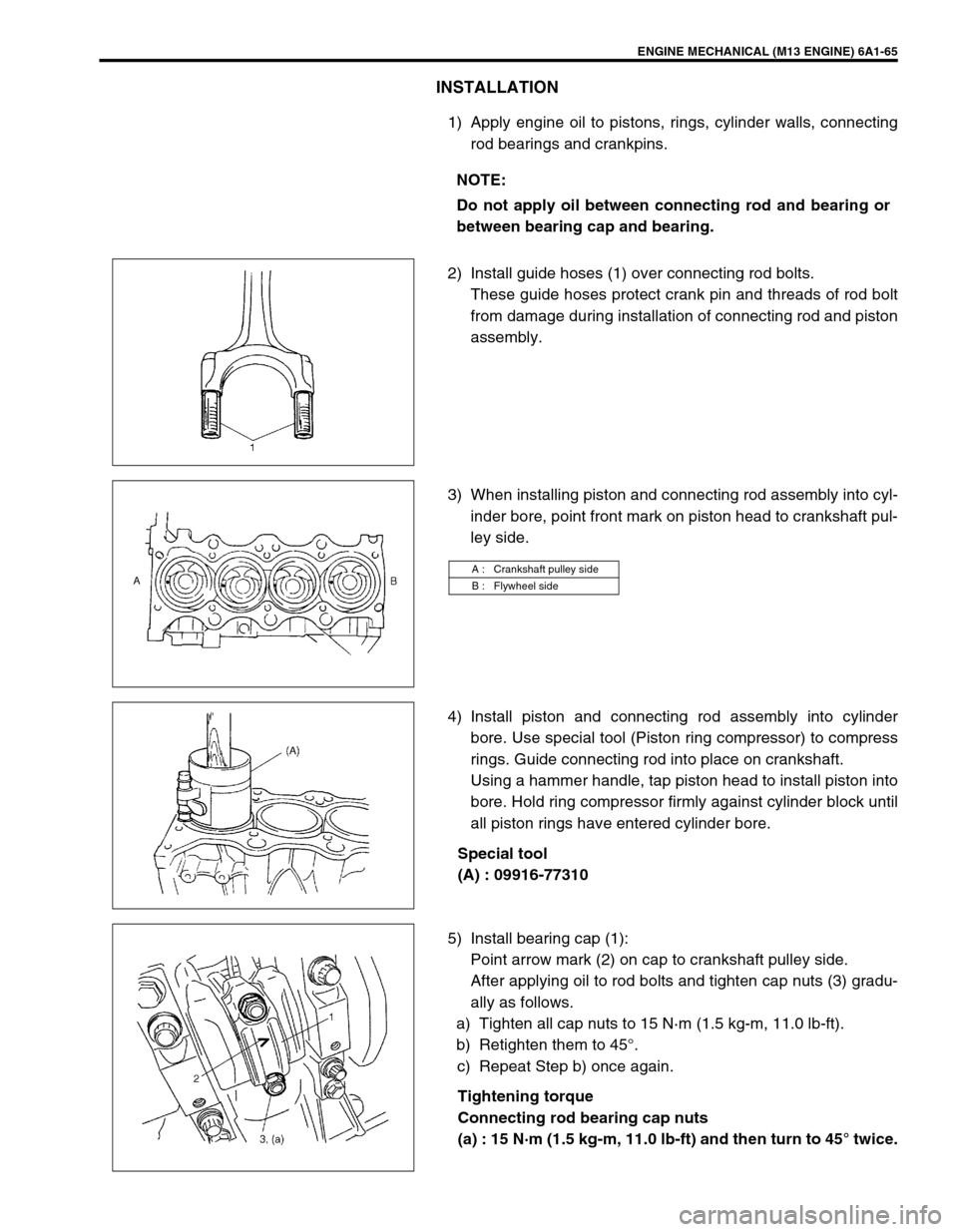

INSTALLATION

1) Apply engine oil to pistons, rings, cylinder walls, connecting

rod bearings and crankpins.

2) Install guide hoses (1) over connecting rod bolts.

These guide hoses protect crank pin and threads of rod bolt

from damage during installation of connecting rod and piston

assembly.

3) When installing piston and connecting rod assembly into cyl-

inder bore, point front mark on piston head to crankshaft pul-

ley side.

4) Install piston and connecting rod assembly into cylinder

bore. Use special tool (Piston ring compressor) to compress

rings. Guide connecting rod into place on crankshaft.

Using a hammer handle, tap piston head to install piston into

bore. Hold ring compressor firmly against cylinder block until

all piston rings have entered cylinder bore.

Special tool

(A) : 09916-77310

5) Install bearing cap (1):

Point arrow mark (2) on cap to crankshaft pulley side.

After applying oil to rod bolts and tighten cap nuts (3) gradu-

ally as follows.

a) Tighten all cap nuts to 15 N·m (1.5 kg-m, 11.0 lb-ft).

b) Retighten them to 45°.

c) Repeat Step b) once again.

Tightening torque

Connecting rod bearing cap nuts

(a) : 15 N·m (1.5 kg-m, 11.0 lb-ft) and then turn to 45° twice. NOTE:

Do not apply oil between connecting rod and bearing or

between bearing cap and bearing.

A : Crankshaft pulley side

B : Flywheel side

Page 575 of 698

6A1-74 ENGINE MECHANICAL (M13 ENGINE)

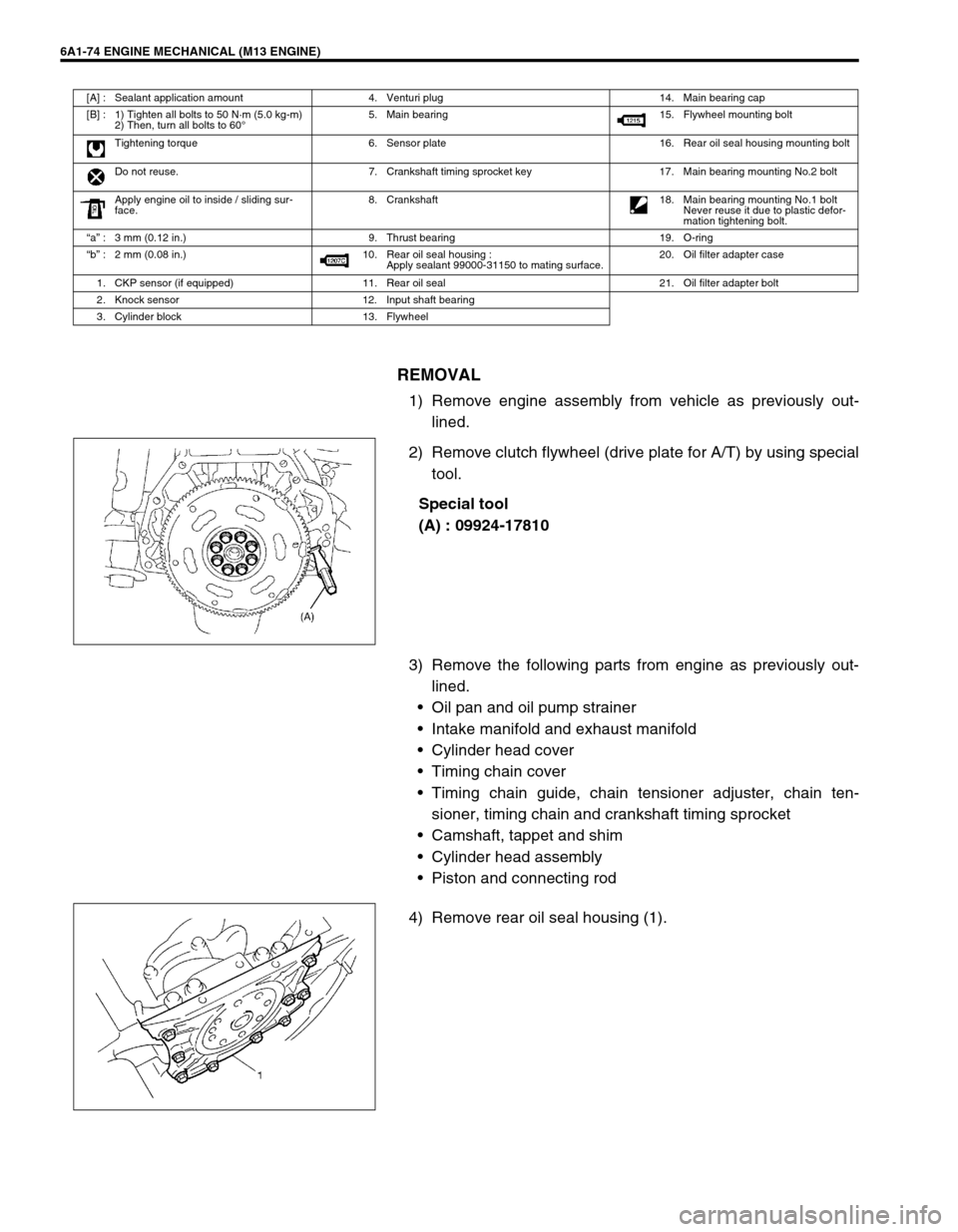

REMOVAL

1) Remove engine assembly from vehicle as previously out-

lined.

2) Remove clutch flywheel (drive plate for A/T) by using special

tool.

Special tool

(A) : 09924-17810

3) Remove the following parts from engine as previously out-

lined.

Oil pan and oil pump strainer

Intake manifold and exhaust manifold

Cylinder head cover

Timing chain cover

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Camshaft, tappet and shim

Cylinder head assembly

Piston and connecting rod

4) Remove rear oil seal housing (1).

[A] : Sealant application amount 4. Venturi plug 14. Main bearing cap

[B] : 1) Tighten all bolts to 50 N·m (5.0 kg-m)

2) Then, turn all bolts to 60°5. Main bearing 15. Flywheel mounting bolt

Tightening torque 6. Sensor plate 16. Rear oil seal housing mounting bolt

Do not reuse. 7. Crankshaft timing sprocket key 17. Main bearing mounting No.2 bolt

Apply engine oil to inside / sliding sur-

face.8. Crankshaft

18. Main bearing mounting No.1 bolt

Never reuse it due to plastic defor-

mation tightening bolt.

“a” : 3 mm (0.12 in.) 9. Thrust bearing 19. O-ring

“b” : 2 mm (0.08 in.) 10. Rear oil seal housing :

Apply sealant 99000-31150 to mating surface.20. Oil filter adapter case

1. CKP sensor (if equipped) 11. Rear oil seal 21. Oil filter adapter bolt

2. Knock sensor 12. Input shaft bearing

3. Cylinder block 13. Flywheel