dead battery SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 25 of 698

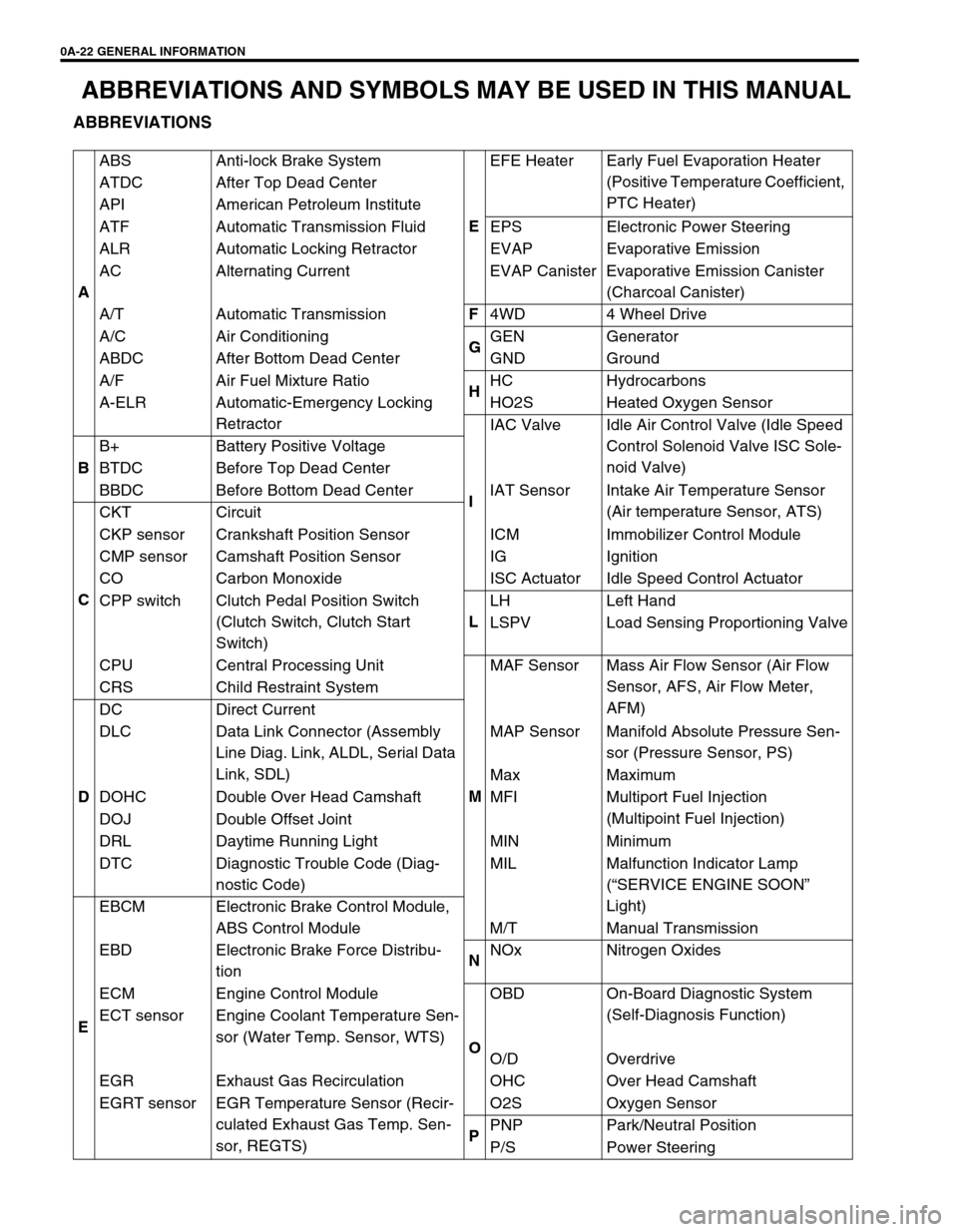

0A-22 GENERAL INFORMATION

ABBREVIATIONS AND SYMBOLS MAY BE USED IN THIS MANUAL

ABBREVIATIONS

AABS Anti-lock Brake System

EEFE Heater Early Fuel Evaporation Heater

(Positive Temperature Coefficient,

PTC Heater) ATDC After Top Dead Center

API American Petroleum Institute

ATF Automatic Transmission Fluid EPS Electronic Power Steering

ALR Automatic Locking Retractor EVAP Evaporative Emission

AC Alternating Current EVAP Canister Evaporative Emission Canister

(Charcoal Canister)

A/T Automatic TransmissionF

4WD 4 Wheel Drive

A/C Air Conditioning

GGEN Generator

ABDC After Bottom Dead Center GND Ground

A/F Air Fuel Mixture Ratio

HHC Hydrocarbons

A-ELR Automatic-Emergency Locking

RetractorHO2S Heated Oxygen Sensor

IIAC Valve Idle Air Control Valve (Idle Speed

Control Solenoid Valve ISC Sole-

noid Valve)

BB+ Battery Positive Voltage

BTDC Before Top Dead Center

BBDC Before Bottom Dead Center IAT Sensor Intake Air Temperature Sensor

(Air temperature Sensor, ATS)

CCKT Circuit

CKP sensor Crankshaft Position Sensor ICM Immobilizer Control Module

CMP sensor Camshaft Position Sensor IG Ignition

CO Carbon Monoxide ISC Actuator Idle Speed Control Actuator

CPP switch Clutch Pedal Position Switch

(Clutch Switch, Clutch Start

Switch)LLH Left Hand

LSPV Load Sensing Proportioning Valve

CPU Central Processing Unit

MMAF Sensor Mass Air Flow Sensor (Air Flow

Sensor, AFS, Air Flow Meter,

AFM) CRS Child Restraint System

DDC Direct Current

DLC Data Link Connector (Assembly

Line Diag. Link, ALDL, Serial Data

Link, SDL)MAP Sensor Manifold Absolute Pressure Sen-

sor (Pressure Sensor, PS)

Max Maximum

DOHC Double Over Head Camshaft MFI Multiport Fuel Injection

(Multipoint Fuel Injection)

DOJ Double Offset Joint

DRL Daytime Running Light MIN Minimum

DTC Diagnostic Trouble Code (Diag-

nostic Code)MIL Malfunction Indicator Lamp

(“SERVICE ENGINE SOON”

Light)

EEBCM Electronic Brake Control Module,

ABS Control Module M/T Manual Transmission

EBD Electronic Brake Force Distribu-

tionNNOx Nitrogen Oxides

ECM Engine Control Module

OOBD On-Board Diagnostic System

(Self-Diagnosis Function)

ECT sensor Engine Coolant Temperature Sen-

sor (Water Temp. Sensor, WTS)

O/D Overdrive

EGR Exhaust Gas Recirculation OHC Over Head Camshaft

EGRT sensor EGR Temperature Sensor (Recir-

culated Exhaust Gas Temp. Sen-

sor, REGTS)O2S Oxygen Sensor

PPNP Park/Neutral Position

P/S Power Steering

Page 689 of 698

CHARGING SYSTEM 6H-9

ON-VEHICLE SERVICE

BATTERY

JUMP STARTING IN CASE OF EMERGENCY

WITH AUXILIARY (BOOSTER) BATTERY

Both booster and discharged battery should be treated carefully when using jumper cables. Follow procedure

outlined below, being careful not to cause sparks.

1) Set parking brake and place automatic transmission in PARK (NEUTRAL on manual transmission). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same cable to

positive terminal of discharged battery. (Use 12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other end to

a solid engine ground (such as exhaust manifold) at least 45 cm (18 in.) away from battery of vehicle being

started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then Start engine of the vehi-

cle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

WITH CHARGING EQUIPMENT

CAUTION:

If vehicle is manual transmission model and has a catalytic converter, do not push or tow it to start.

Damage to its emission system and/or to other parts may result.

WARNING:

Departure from these conditions or procedure described below could result in:

–Serious personal injury (particularly to eyes) or property damage from such causes as battery

explosion, battery acid, or electrical burns.

–Damage to electronic components of either vehicle.

Remove rings, watches, and other jewelry. Wear approved eye protection.

Be careful so that metal tools or jumper cables do not contact positive battery terminal (or metal in

contact with it) and any other metal on vehicle, because a short circuit could occur.

WARNING:

Do not connect negative cable directly to negative terminal of dead battery.

CAUTION:

When jump starting engine with charging equipment, be sure equipment used is 12-volt and negative

ground. Do not use 24-volt charging equipment. Using such equipment can cause serious damage to

electrical system or electronic parts.