oil filter SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 9 of 698

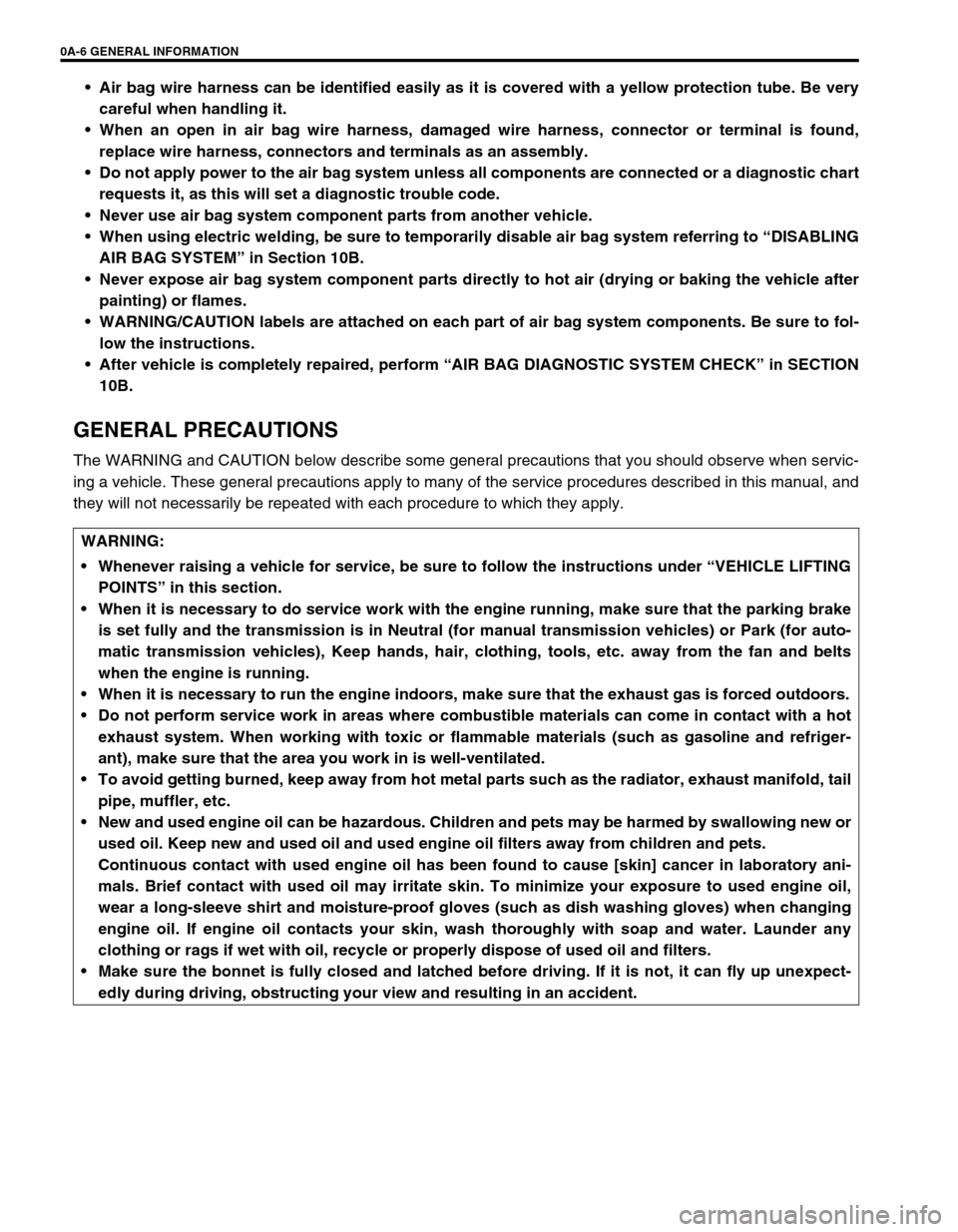

0A-6 GENERAL INFORMATION

Air bag wire harness can be identified easily as it is covered with a yellow protection tube. Be very

careful when handling it.

When an open in air bag wire harness, damaged wire harness, connector or terminal is found,

replace wire harness, connectors and terminals as an assembly.

Do not apply power to the air bag system unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble code.

Never use air bag system component parts from another vehicle.

When using electric welding, be sure to temporarily disable air bag system referring to “DISABLING

AIR BAG SYSTEM” in Section 10B.

Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING/CAUTION labels are attached on each part of air bag system components. Be sure to fol-

low the instructions.

After vehicle is completely repaired, perform “AIR BAG DIAGNOSTIC SYSTEM CHECK” in SECTION

10B.

GENERAL PRECAUTIONS

The WARNING and CAUTION below describe some general precautions that you should observe when servic-

ing a vehicle. These general precautions apply to many of the service procedures described in this manual, and

they will not necessarily be repeated with each procedure to which they apply.

WARNING:

Whenever raising a vehicle for service, be sure to follow the instructions under “VEHICLE LIFTING

POINTS” in this section.

When it is necessary to do service work with the engine running, make sure that the parking brake

is set fully and the transmission is in Neutral (for manual transmission vehicles) or Park (for auto-

matic transmission vehicles), Keep hands, hair, clothing, tools, etc. away from the fan and belts

when the engine is running.

When it is necessary to run the engine indoors, make sure that the exhaust gas is forced outdoors.

Do not perform service work in areas where combustible materials can come in contact with a hot

exhaust system. When working with toxic or flammable materials (such as gasoline and refriger-

ant), make sure that the area you work in is well-ventilated.

To avoid getting burned, keep away from hot metal parts such as the radiator, exhaust manifold, tail

pipe, muffler, etc.

New and used engine oil can be hazardous. Children and pets may be harmed by swallowing new or

used oil. Keep new and used oil and used engine oil filters away from children and pets.

Continuous contact with used engine oil has been found to cause [skin] cancer in laboratory ani-

mals. Brief contact with used oil may irritate skin. To minimize your exposure to used engine oil,

wear a long-sleeve shirt and moisture-proof gloves (such as dish washing gloves) when changing

engine oil. If engine oil contacts your skin, wash thoroughly with soap and water. Launder any

clothing or rags if wet with oil, recycle or properly dispose of used oil and filters.

Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly up unexpect-

edly during driving, obstructing your view and resulting in an accident.

Page 30 of 698

MAINTENANCE AND LUBRICATION 0B-1

0A 6F1

0B

0B

6G

1A 6H

1B 6K

37A

3A 7A1

3B1 7B1

3C1 7C1

3D 7D

3E 7E

3F 7F

4A2 8A

4B 8B

8C

58D

5A 8E

5B

5C 9

5E

5E1 10

10A

610B

6-1

6A1

6A2

6A4

6B

6C

6E1

6E2

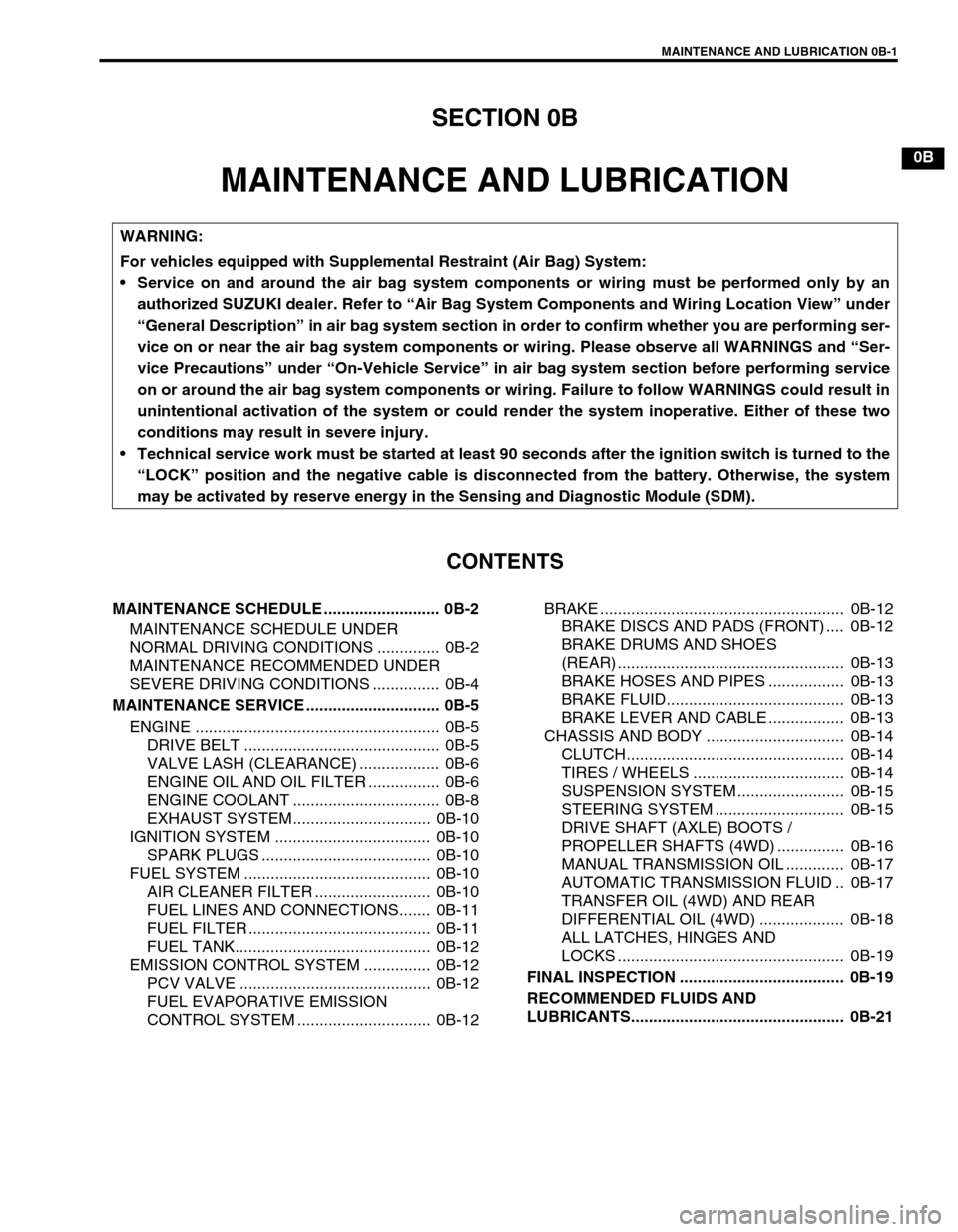

SECTION 0B

MAINTENANCE AND LUBRICATION

CONTENTS

MAINTENANCE SCHEDULE .......................... 0B-2

MAINTENANCE SCHEDULE UNDER

NORMAL DRIVING CONDITIONS .............. 0B-2

MAINTENANCE RECOMMENDED UNDER

SEVERE DRIVING CONDITIONS ............... 0B-4

MAINTENANCE SERVICE .............................. 0B-5

ENGINE ....................................................... 0B-5

DRIVE BELT ............................................ 0B-5

VALVE LASH (CLEARANCE) .................. 0B-6

ENGINE OIL AND OIL FILTER ................ 0B-6

ENGINE COOLANT ................................. 0B-8

EXHAUST SYSTEM............................... 0B-10

IGNITION SYSTEM ................................... 0B-10

SPARK PLUGS ...................................... 0B-10

FUEL SYSTEM .......................................... 0B-10

AIR CLEANER FILTER .......................... 0B-10

FUEL LINES AND CONNECTIONS....... 0B-11

FUEL FILTER ......................................... 0B-11

FUEL TANK............................................ 0B-12

EMISSION CONTROL SYSTEM ............... 0B-12

PCV VALVE ........................................... 0B-12

FUEL EVAPORATIVE EMISSION

CONTROL SYSTEM .............................. 0B-12BRAKE ....................................................... 0B-12

BRAKE DISCS AND PADS (FRONT) .... 0B-12

BRAKE DRUMS AND SHOES

(REAR) ................................................... 0B-13

BRAKE HOSES AND PIPES ................. 0B-13

BRAKE FLUID........................................ 0B-13

BRAKE LEVER AND CABLE ................. 0B-13

CHASSIS AND BODY ............................... 0B-14

CLUTCH................................................. 0B-14

TIRES / WHEELS .................................. 0B-14

SUSPENSION SYSTEM ........................ 0B-15

STEERING SYSTEM ............................. 0B-15

DRIVE SHAFT (AXLE) BOOTS /

PROPELLER SHAFTS (4WD) ............... 0B-16

MANUAL TRANSMISSION OIL ............. 0B-17

AUTOMATIC TRANSMISSION FLUID .. 0B-17

TRANSFER OIL (4WD) AND REAR

DIFFERENTIAL OIL (4WD) ................... 0B-18

ALL LATCHES, HINGES AND

LOCKS ................................................... 0B-19

FINAL INSPECTION ..................................... 0B-19

RECOMMENDED FLUIDS AND

LUBRICANTS................................................ 0B-21

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 31 of 698

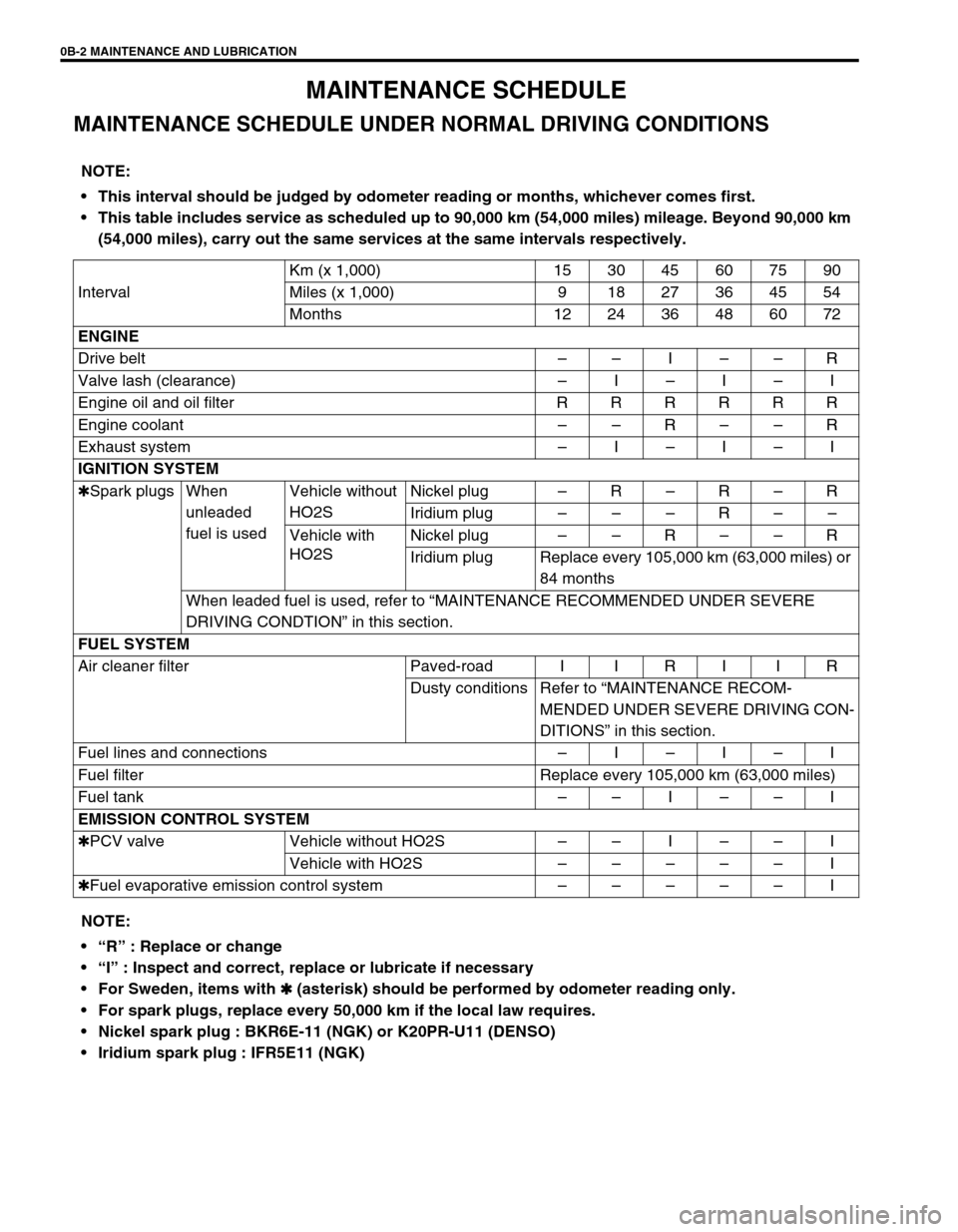

0B-2 MAINTENANCE AND LUBRICATION

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE UNDER NORMAL DRIVING CONDITIONS

NOTE:

This interval should be judged by odometer reading or months, whichever comes first.

This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

IntervalKm (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 1827364554

Months 12 24 36 48 60 72

ENGINE

Drive belt––I––R

Valve lash (clearance) –I–I–I

Engine oil and oil filter R R R R R R

Engine coolant––R––R

Exhaust system–I–I–I

IGNITION SYSTEM

✱Spark plugs When

unleaded

fuel is usedVehicle without

HO2SNickel plug–R–R–R

Iridium plug–––R––

Vehicle with

HO2SNickel plug––R––R

Iridium plug Replace every 105,000 km (63,000 miles) or

84 months

When leaded fuel is used, refer to “MAINTENANCE RECOMMENDED UNDER SEVERE

DRIVING CONDTION” in this section.

FUEL SYSTEM

Air cleaner filter Paved-road I I R I I R

Dusty conditions Refer to “MAINTENANCE RECOM-

MENDED UNDER SEVERE DRIVING CON-

DITIONS” in this section.

Fuel lines and connections–I–I–I

Fuel filter Replace every 105,000 km (63,000 miles)

Fuel tank––I––I

EMISSION CONTROL SYSTEM

✱PCV valve Vehicle without HO2S––I––I

Vehicle with HO2S–––––I

✱Fuel evaporative emission control system–––––I

NOTE:

“R” : Replace or change

“I” : Inspect and correct, replace or lubricate if necessary

For Sweden, items with

✱

✱✱ ✱ (asterisk) should be performed by odometer reading only.

For spark plugs, replace every 50,000 km if the local law requires.

Nickel spark plug : BKR6E-11 (NGK) or K20PR-U11 (DENSO)

Iridium spark plug : IFR5E11 (NGK)

Page 33 of 698

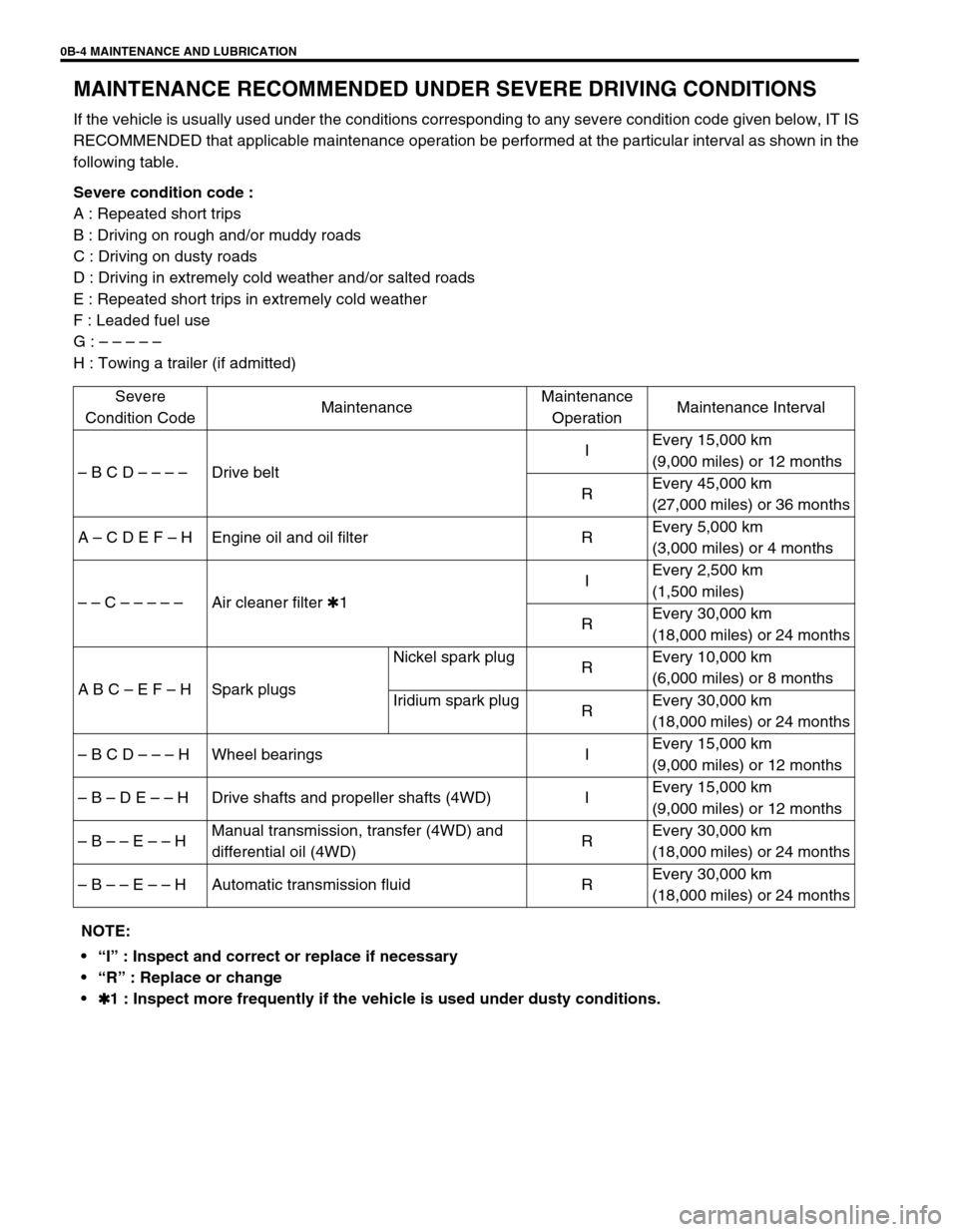

0B-4 MAINTENANCE AND LUBRICATION

MAINTENANCE RECOMMENDED UNDER SEVERE DRIVING CONDITIONS

If the vehicle is usually used under the conditions corresponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be performed at the particular interval as shown in the

following table.

Severe condition code :

A : Repeated short trips

B : Driving on rough and/or muddy roads

C : Driving on dusty roads

D : Driving in extremely cold weather and/or salted roads

E : Repeated short trips in extremely cold weather

F : Leaded fuel use

G : – – – – –

H : Towing a trailer (if admitted)

Severe

Condition CodeMaintenanceMaintenance

OperationMaintenance Interval

– B C D – – – –Drive beltIEvery 15,000 km

(9,000 miles) or 12 months

REvery 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter REvery 5,000 km

(3,000 miles) or 4 months

– – C – – – – –Air cleaner filter ✱1IEvery 2,500 km

(1,500 miles)

REvery 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugsNickel spark plug

REvery 10,000 km

(6,000 miles) or 8 months

Iridium spark plug

REvery 30,000 km

(18,000 miles) or 24 months

– B C D – – – H Wheel bearings IEvery 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Drive shafts and propeller shafts (4WD) IEvery 15,000 km

(9,000 miles) or 12 months

– B – – E – – HManual transmission, transfer (4WD) and

differential oil (4WD)REvery 30,000 km

(18,000 miles) or 24 months

– B – – E – – H Automatic transmission fluid REvery 30,000 km

(18,000 miles) or 24 months

NOTE:

“I” : Inspect and correct or replace if necessary

“R” : Replace or change

✱

✱✱ ✱1 : Inspect more frequently if the vehicle is used under dusty conditions.

Page 35 of 698

0B-6 MAINTENANCE AND LUBRICATION

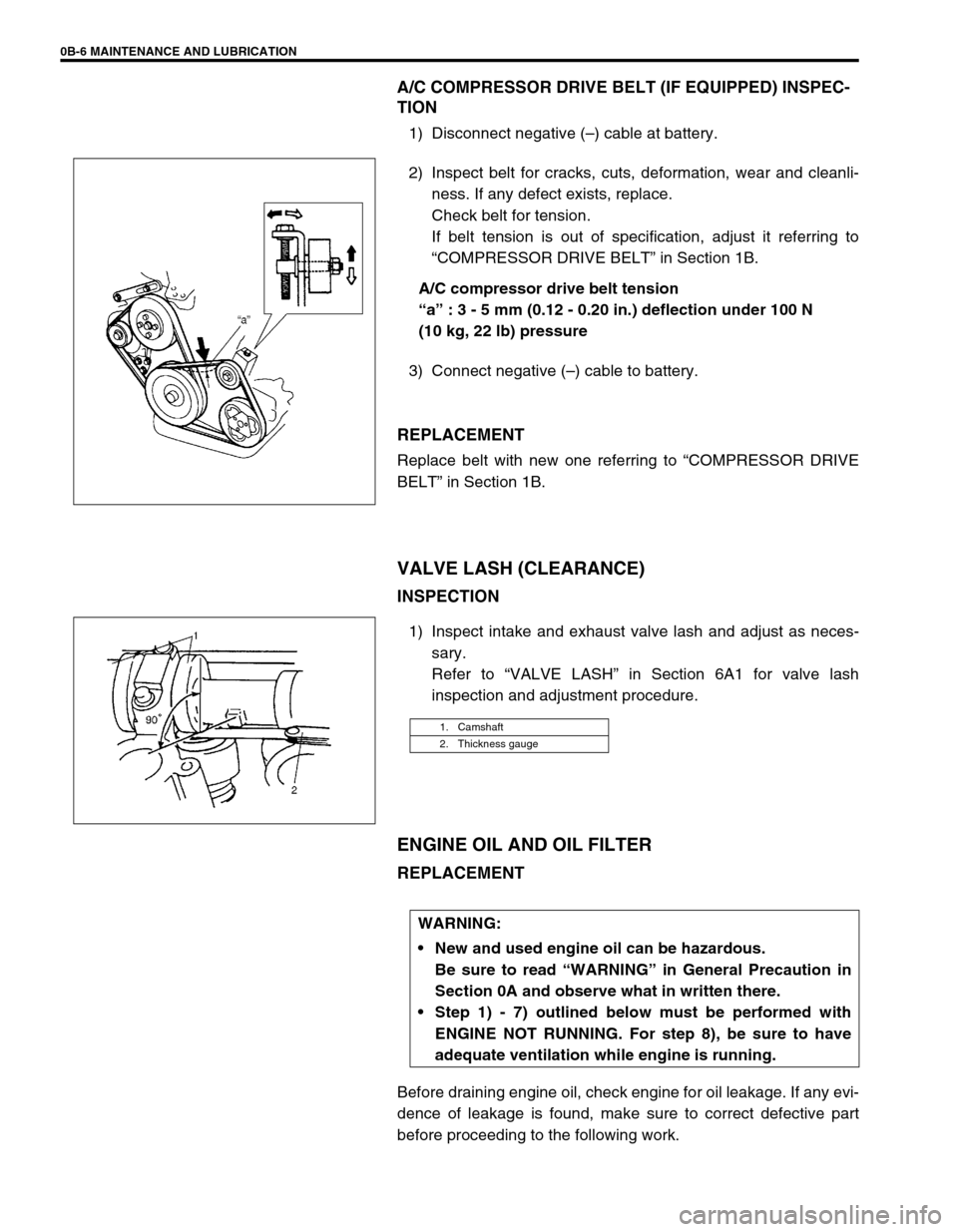

A/C COMPRESSOR DRIVE BELT (IF EQUIPPED) INSPEC-

TION

1) Disconnect negative (–) cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanli-

ness. If any defect exists, replace.

Check belt for tension.

If belt tension is out of specification, adjust it referring to

“COMPRESSOR DRIVE BELT” in Section 1B.

A/C compressor drive belt tension

“a” : 3 - 5 mm (0.12 - 0.20 in.) deflection under 100 N

(10 kg, 22 lb) pressure

3) Connect negative (–) cable to battery.

REPLACEMENT

Replace belt with new one referring to “COMPRESSOR DRIVE

BELT” in Section 1B.

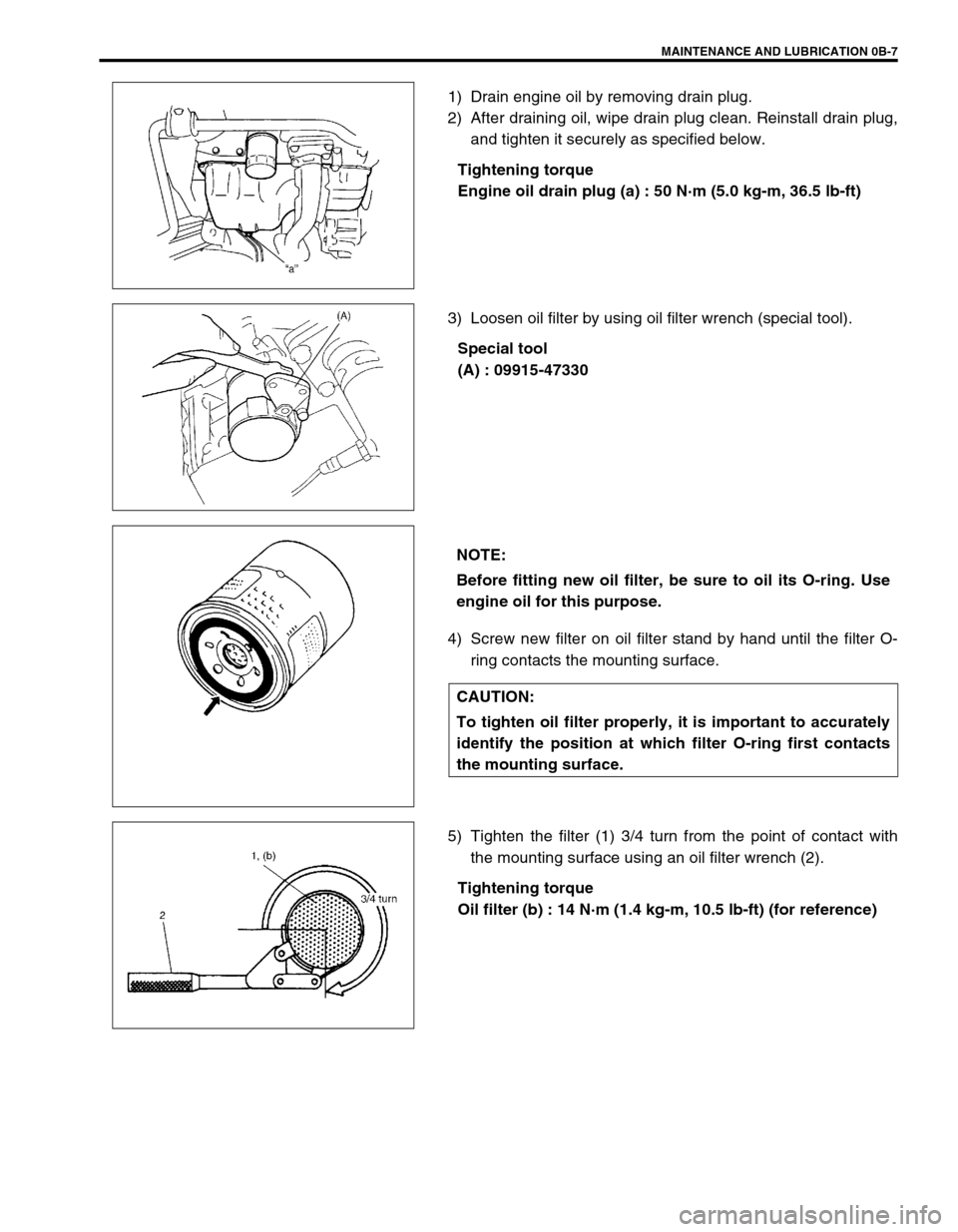

VALVE LASH (CLEARANCE)

INSPECTION

1) Inspect intake and exhaust valve lash and adjust as neces-

sary.

Refer to “VALVE LASH” in Section 6A1 for valve lash

inspection and adjustment procedure.

ENGINE OIL AND OIL FILTER

REPLACEMENT

Before draining engine oil, check engine for oil leakage. If any evi-

dence of leakage is found, make sure to correct defective part

before proceeding to the following work.

1. Camshaft

2. Thickness gauge

WARNING:

New and used engine oil can be hazardous.

Be sure to read “WARNING” in General Precaution in

Section 0A and observe what in written there.

Step 1) - 7) outlined below must be performed with

ENGINE NOT RUNNING. For step 8), be sure to have

adequate ventilation while engine is running.

Page 36 of 698

MAINTENANCE AND LUBRICATION 0B-7

1) Drain engine oil by removing drain plug.

2) After draining oil, wipe drain plug clean. Reinstall drain plug,

and tighten it securely as specified below.

Tightening torque

Engine oil drain plug (a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

3) Loosen oil filter by using oil filter wrench (special tool).

Special tool

(A) : 09915-47330

4) Screw new filter on oil filter stand by hand until the filter O-

ring contacts the mounting surface.

5) Tighten the filter (1) 3/4 turn from the point of contact with

the mounting surface using an oil filter wrench (2).

Tightening torque

Oil filter (b) : 14 N·m (1.4 kg-m, 10.5 lb-ft) (for reference)

NOTE:

Before fitting new oil filter, be sure to oil its O-ring. Use

engine oil for this purpose.

CAUTION:

To tighten oil filter properly, it is important to accurately

identify the position at which filter O-ring first contacts

the mounting surface.

Page 37 of 698

0B-8 MAINTENANCE AND LUBRICATION

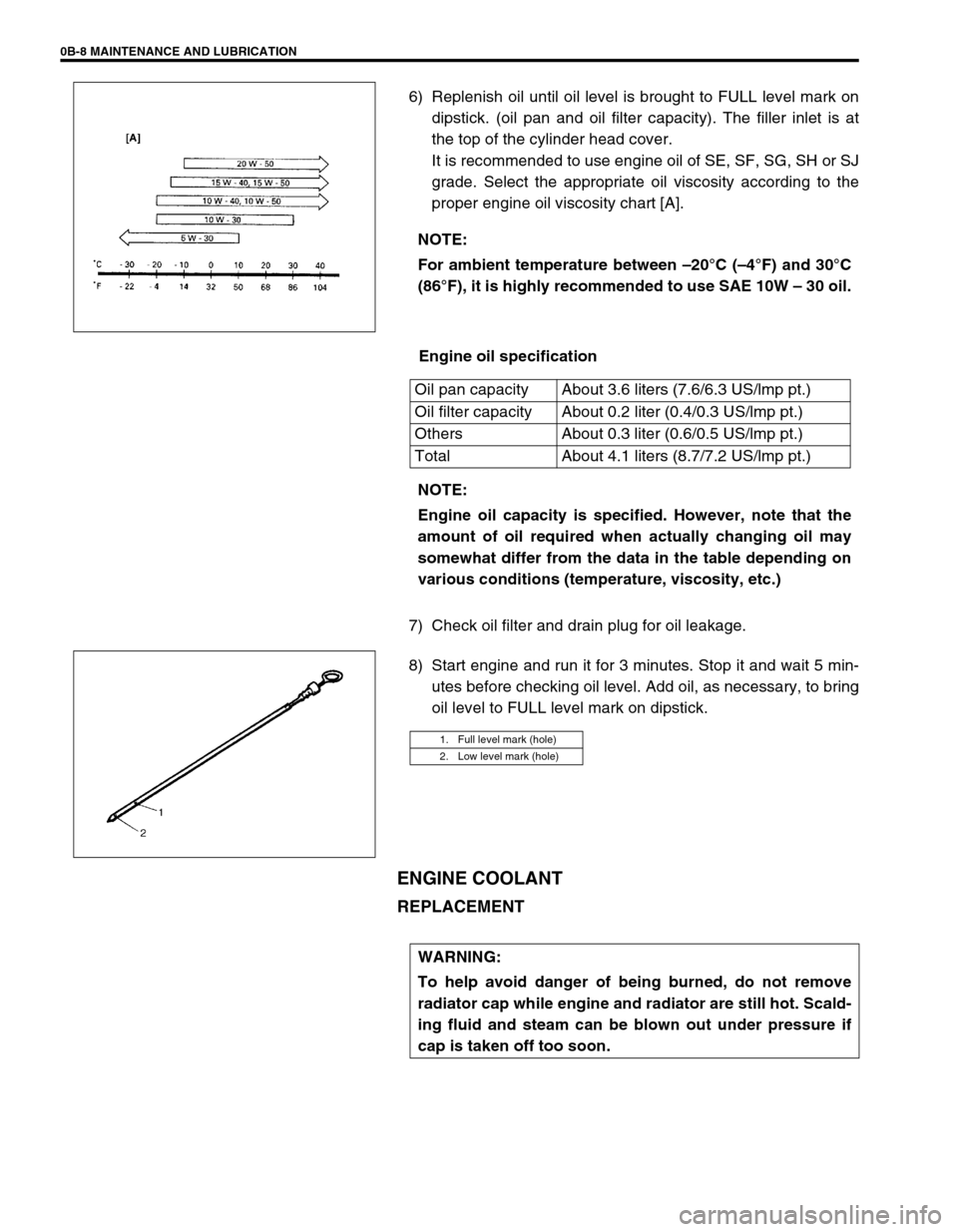

6) Replenish oil until oil level is brought to FULL level mark on

dipstick. (oil pan and oil filter capacity). The filler inlet is at

the top of the cylinder head cover.

It is recommended to use engine oil of SE, SF, SG, SH or SJ

grade. Select the appropriate oil viscosity according to the

proper engine oil viscosity chart [A].

Engine oil specification

7) Check oil filter and drain plug for oil leakage.

8) Start engine and run it for 3 minutes. Stop it and wait 5 min-

utes before checking oil level. Add oil, as necessary, to bring

oil level to FULL level mark on dipstick.

ENGINE COOLANT

REPLACEMENT

NOTE:

For ambient temperature between –20°C (–4°F) and 30°C

(86°F), it is highly recommended to use SAE 10W – 30 oil.

Oil pan capacity About 3.6 liters (7.6/6.3 US/lmp pt.)

Oil filter capacity About 0.2 liter (0.4/0.3 US/lmp pt.)

Others About 0.3 liter (0.6/0.5 US/lmp pt.)

Total About 4.1 liters (8.7/7.2 US/lmp pt.)

NOTE:

Engine oil capacity is specified. However, note that the

amount of oil required when actually changing oil may

somewhat differ from the data in the table depending on

various conditions (temperature, viscosity, etc.)

1. Full level mark (hole)

2. Low level mark (hole)

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot. Scald-

ing fluid and steam can be blown out under pressure if

cap is taken off too soon.

Page 39 of 698

0B-10 MAINTENANCE AND LUBRICATION

EXHAUST SYSTEM

INSPECTION

When carrying out periodic maintenance, or the vehicle is raised

for other service, check exhaust system as follows:

Check rubber mountings for damage, deterioration, and out

of position.

Check exhaust system for leakage, loose connections, dents

and damages.

If bolts or nuts are loose, tighten them to specification.

Check nearby body areas for damaged, missing, or misposi-

tioned parts, open seams, holes, loose connections or other

defects which could permit exhaust fumes to seep into the

vehicle.

Make sure that exhaust system components have enough

clearance from the underbody to avoid overheating and pos-

sible damage to the floor carpet.

Any defects should be fixed at once.

IGNITION SYSTEM

SPARK PLUGS

REPLACEMENT

Replace spark plugs with new ones referring to “SPARK PLUG”

in Section 6F1.

FUEL SYSTEM

AIR CLEANER FILTER

INSPECTION

1) Remove air cleaner case clamps.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or oily,

clean filter with compressed air from air outlet side of filter. WARNING:

To avoid danger of being burned, do not touch exhaust

system when it is still hot. Any service on exhaust sys-

tem should be performed when it is cool.

Page 50 of 698

MAINTENANCE AND LUBRICATION 0B-21

STEERING

Check to ensure that steering wheel is free from instability, or abnormally heavy feeling.

Check that the vehicle does not wander or pull to one side.

ENGINE

Check that engine responds readily at all speeds.

Check that engine is free from abnormal noise and abnormal vibration.

BODY, WHEELS AND POWER TRANSMITTING SYSTEM

Check that body, wheels and power transmitting system are free from abnormal noise and abnormal vibration or

any other abnormal condition.

METERS AND GAUGE

Check that speedometer, odometer, fuel meter, temperature gauge, etc. are operating accurately.

LIGHTS

Check that all lights operate properly.

WINDSHIELD DEFROSTER

Periodically check that air comes out from defroster outlet when operating heater or air conditioning.

Set mode control lever to defroster position and fan switch lever to “HI” position for this check.

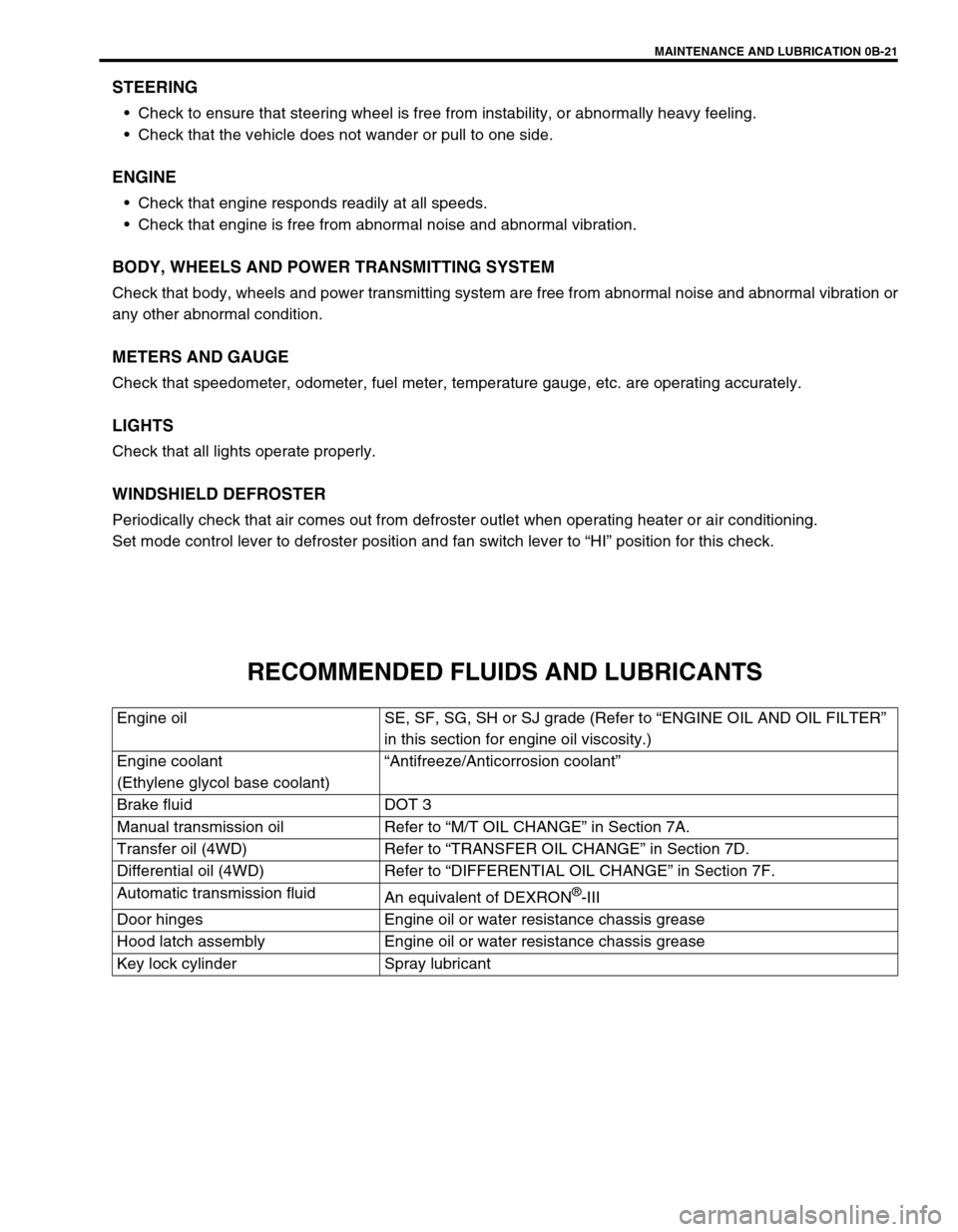

RECOMMENDED FLUIDS AND LUBRICANTS

Engine oil SE, SF, SG, SH or SJ grade (Refer to “ENGINE OIL AND OIL FILTER”

in this section for engine oil viscosity.)

Engine coolant

(Ethylene glycol base coolant)“Antifreeze/Anticorrosion coolant”

Brake fluid DOT 3

Manual transmission oil Refer to “M/T OIL CHANGE” in Section 7A.

Transfer oil (4WD) Refer to “TRANSFER OIL CHANGE” in Section 7D.

Differential oil (4WD) Refer to “DIFFERENTIAL OIL CHANGE” in Section 7F.

Automatic transmission fluid

An equivalent of DEXRON

®-III

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

Page 395 of 698

6-26 ENGINE GENERAL INFORMATION AND DIAGNOSIS

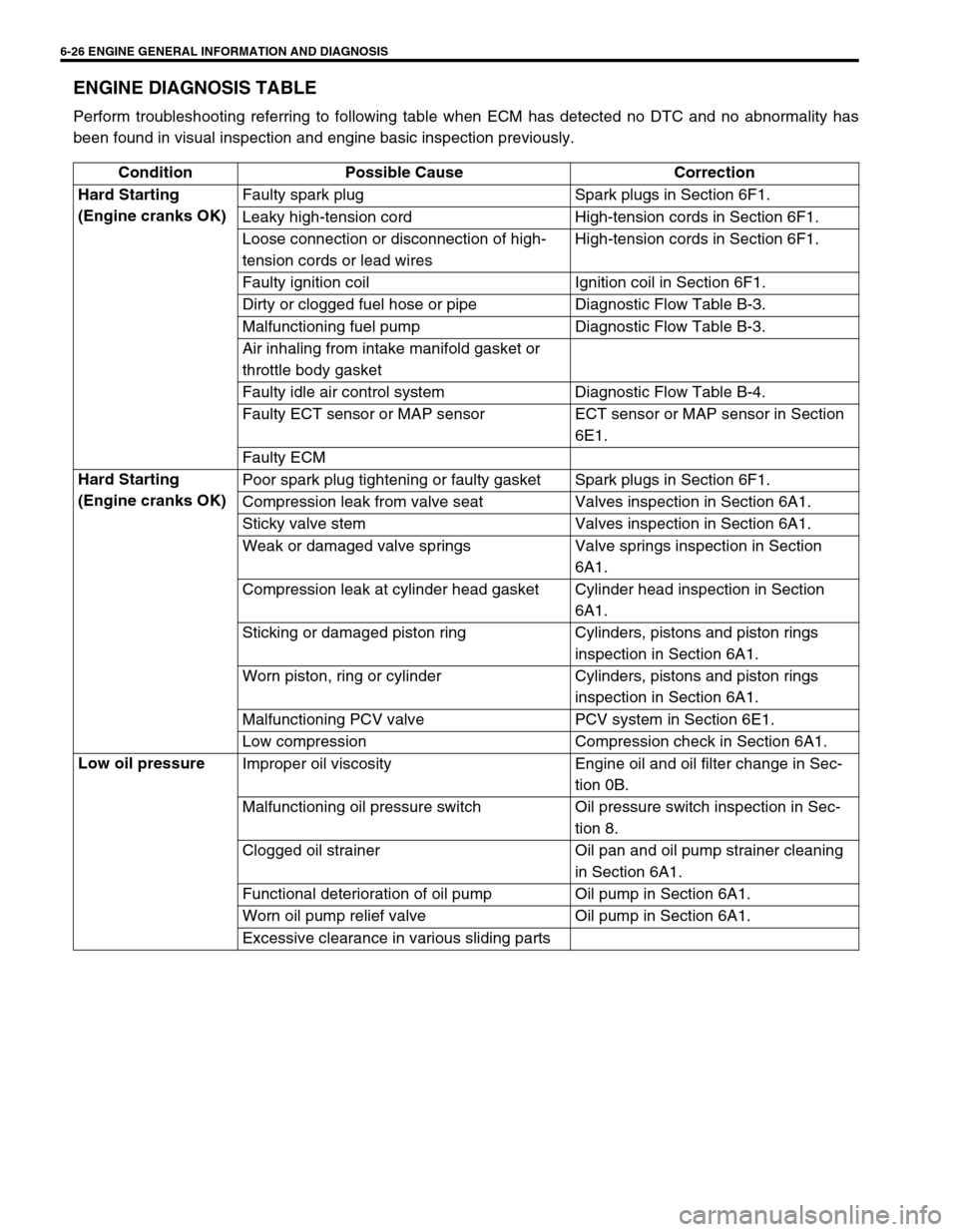

ENGINE DIAGNOSIS TABLE

Perform troubleshooting referring to following table when ECM has detected no DTC and no abnormality has

been found in visual inspection and engine basic inspection previously.

Condition Possible Cause Correction

Hard Starting

(Engine cranks OK) Faulty spark plug Spark plugs in Section 6F1.

Leaky high-tension cord High-tension cords in Section 6F1.

Loose connection or disconnection of high-

tension cords or lead wiresHigh-tension cords in Section 6F1.

Faulty ignition coil Ignition coil in Section 6F1.

Dirty or clogged fuel hose or pipe Diagnostic Flow Table B-3.

Malfunctioning fuel pump Diagnostic Flow Table B-3.

Air inhaling from intake manifold gasket or

throttle body gasket

Faulty idle air control system Diagnostic Flow Table B-4.

Faulty ECT sensor or MAP sensor ECT sensor or MAP sensor in Section

6E1.

Faulty ECM

Hard Starting

(Engine cranks OK) Poor spark plug tightening or faulty gasket Spark plugs in Section 6F1.

Compression leak from valve seat Valves inspection in Section 6A1.

Sticky valve stem Valves inspection in Section 6A1.

Weak or damaged valve springs Valve springs inspection in Section

6A1.

Compression leak at cylinder head gasket Cylinder head inspection in Section

6A1.

Sticking or damaged piston ring Cylinders, pistons and piston rings

inspection in Section 6A1.

Worn piston, ring or cylinder Cylinders, pistons and piston rings

inspection in Section 6A1.

Malfunctioning PCV valve PCV system in Section 6E1.

Low compression Compression check in Section 6A1.

Low oil pressure

Improper oil viscosity Engine oil and oil filter change in Sec-

tion 0B.

Malfunctioning oil pressure switch Oil pressure switch inspection in Sec-

tion 8.

Clogged oil strainer Oil pan and oil pump strainer cleaning

in Section 6A1.

Functional deterioration of oil pump Oil pump in Section 6A1.

Worn oil pump relief valve Oil pump in Section 6A1.

Excessive clearance in various sliding parts