oil SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 425 of 447

AIR BAG SYSTEM 10B-51

DEPLOYED AIR BAG (INFLATOR) MODULE AND ACTI-

VATED SEAT BELT PRETENSIONER

Refer to the procedure described under “DEPLOYED AIR BAG

(INFLATOR) MODULE AND ACTIVATED SEAT BELT PRETEN-

SIONER DISPOSAL”. WARNING:

For handling and storage of a live seat belt preten-

sioner, select a place where the ambient temperature

below 65

°

°° °C (150

°

°° °F), without high humidity and away

from electric noise.

Never carry the seat belt pretensioner by the wire or

connector of the pretensioner.

When placing a live seat belt pretensioner on the work-

bench or other surface, be sure not to lay it with its

exhaust hole (1) provided side facing down. It is also

prohibited to put something on its face with an exhaust

hole (1) or to put a seat belt pretensioner on top of

another.

Otherwise, personal injury may result.

WARNING:

The air bag (inflator) module and seat belt pretensioner

immediately after deployment/activation is very hot.

Wait for at least 30 minutes to cool it off before pro-

ceeding the work.

Do not apply water, oil, etc. to deployed air bag (infla-

tor) module and to activate seat belt pretensioner.

After an air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery resi-

due. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-prod-

ucts of the chemical reaction. As with many service

procedures, gloves and safety glasses should be

worn.

Wash your hands with mild soap and water after com-

pleting the work.

Page 427 of 447

AIR BAG SYSTEM 10B-53

REPAIRS AND INSPECTIONS REQUIRED AFTER AN ACCIDENT

ACCIDENT WITH DEPLOYMENT/ACTIVA-

TION - COMPONENT REPLACEMENT

The following components must be replaced.

Driver and passenger air bag (inflator) modules

Driver and passenger seat belt pretensioners

SDM

–Replace with new one as an assembly.

ACCIDENT WITH OR WITHOUT DEPLOY-

MENT/ACTIVATION - COMPONENT INSPEC-

TIONS

Certain air bag system components must be inspected after any

crash, whether the air bag system activated or not.

Those components are :

Steering column (1) and shaft joints

–Check for length, damage and bend according to “CHECK-

ING STEERING COLUMN FOR ACCIDENT DAMAGE” in

SECTION 3C.

If any faulty condition is found in above checks, replace faulty

part.

Steering column bracket (2) and capsules (3)

–Check for damage and bent.

If any faulty condition is found in above checks, replace faulty

part. CAUTION:

All air bag system components, including the electrical harness (component mounting points),

must be inspected after an accident. If any components are damaged or bent, they must be

replaced even if air bag system activation did not occur.

Never use air bag system parts from another vehicle.

Do not attempt to service the parts below. Service of these parts is by replacement only.

–Driver/Passenger air bag (inflator) module, Driver/Passenger seat belt pretensioner

–SDM

–Contact coil and combination switch assembly

–Air bag wire harness

Proper operation of the air bag system requires that any repairs to the vehicle structure return it to

its original production configuration.

CAUTION:

After detecting one time of such collision as to meet deployment conditions, the SDM must not be

used. Refer to “AIR BAG DIAGNOSTIC SYSTEM CHECK” when checking the SDM.

Page 428 of 447

10B-54 AIR BAG SYSTEM

Steering wheel and driver air bag (inflator) module

–Check for damage or air bag (inflator) module fitness.

–Check trim cover (pad surface) for cracks.

–Check wire harness and connector for damage or tight-

ness.

If any faulty condition is found in above checks, replace faulty

part.

Contact coil and combination switch assembly

–Check wire harness and connectors for damage or tight-

ness.

–Check contact coil case for damage.

If any faulty condition is found in above checks, replace.

SDM and SDM plate

–Check for external damage such as deformation, scratch,

crack, peeled paint, etc.

–Check that SDM cannot be installed properly due to a

cause in itself. (There is a gap between SDM and SDM

plate, or it cannot be fixed securely.)

–Check that connector or lead wire of SDM has a scorching,

melting or damage.

–Check SDM connector and terminals for tightness.

–Check SDM sets a diagnostic trouble code (Refer to “DTC

CHECK”.) and the diagnostic table leads to a malfunction-

ing SDM.

If any faulty condition is found in above checks, replace.

Instrument panel member and reinforcement

–Check for any distortion, bending, cracking or other dam-

age.

If any faulty condition is found in above checks, replace.

Passenger air bag (inflator) module

–Check for dents, cracks, damage or fitness.

–Check trim cover for cracks or deformities.

–Check harness and connector for damage or tightness.

If any faulty condition is found in above checks, replace.

Page 433 of 447

AIR BAG SYSTEM 10B-59

INSTALLATION

1) Install passenger air bag (inflator) module (1) to instrument

panel (2).

2) Tighten passenger air bag (inflator) module attaching bolts

to specified torque.

Tightening torque

Passenger air bag (inflator) module mounting bolt

(a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

3) Connect negative cable to battery.

4) Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM”.

DRIVER AIR BAG (INFLATOR) MODULE

Refer to “DRIVER AIR BAG (INFLATOR) MODULE” in SECTION

3C for removal, inspection and installation.

CONTACT COIL AND COMBINATION SWITCH

ASSEMBLY

Refer to “CONTACT COIL AND COMBINATION SWITCH

ASSEMBLY” in SECTION 3C for removal, inspection and installa-

tion.

SEAT BELT PRETENSIONER (IF EQUIPPED)

Refer to “FRONT SEAT BELT WITH PRETENSIONER” in SEC-

TION 10 for removal, inspection and installation.

1

2

(a)

Page 439 of 447

AIR BAG SYSTEM 10B-65

12) Separate (1) the two banana plugs on the deployment har-

ness.

13) Connect the deployment harness to the power source (12V

vehicle battery) (2) to immediately deploy/activate the air

bag or seat belt pretensioner.

14) Disconnect the deployment harness from power source (12V

vehicle battery) (2) and short (3) the two deployment har-

ness leads together by fully seating one banana plug into the

other.

15) In the unlikely event that the air bag (inflator) module or seat

belt pretensioner did not deploy/activate after following these

procedures, proceed immediately with Steps 20) through

23). If the air bag (inflator) module or the seat belt preten-

sioner did deploy/activate, proceed with Steps 16) through

19).

16) Put on a pair of shop gloves to protect your hands from pos-

sible irritation and heat when handling the deployed air bag

(inflator) module and the activated seat belt pretensioner.

17) Disconnect the deployment harness from the air bag (infla-

tor) module and the seat belt pretensioner as soon after

deployment/activation as possible.

This will prevent damage to the deployment harness due to

possible contact with the hot air bag (inflator) module and

seat belt pretentioner. The deployment harness are

designed to be reused. They should, however, be inspected

for damage after each deployment/activation and replaced it

if necessary. WARNING:

After deployment/activation, the metal surfaces of the

air bag (inflator) module and the seat belt pretensioner

will be very hot. Do not touch the metal areas of them

for about 30 minutes after deployment/activation.

Do not place the deployed air bag (inflator) module and

the activated seat belt pretensioner near any flamma-

ble objects.

Do not apply water, oil, etc. to deployed air bag (infla-

tor) module and activated seat belt pretensioner.

If the deployed air bag (inflator) module and the acti-

vated seat belt pretensioner must be moved before it is

cool, wear gloves and handle it by using nonmetal

material such as the air bag, webbing and vinyl trim.

Failure to follow procedures may result in fire or per-

sonal injury.

1

2

3

Page 441 of 447

AIR BAG SYSTEM 10B-67

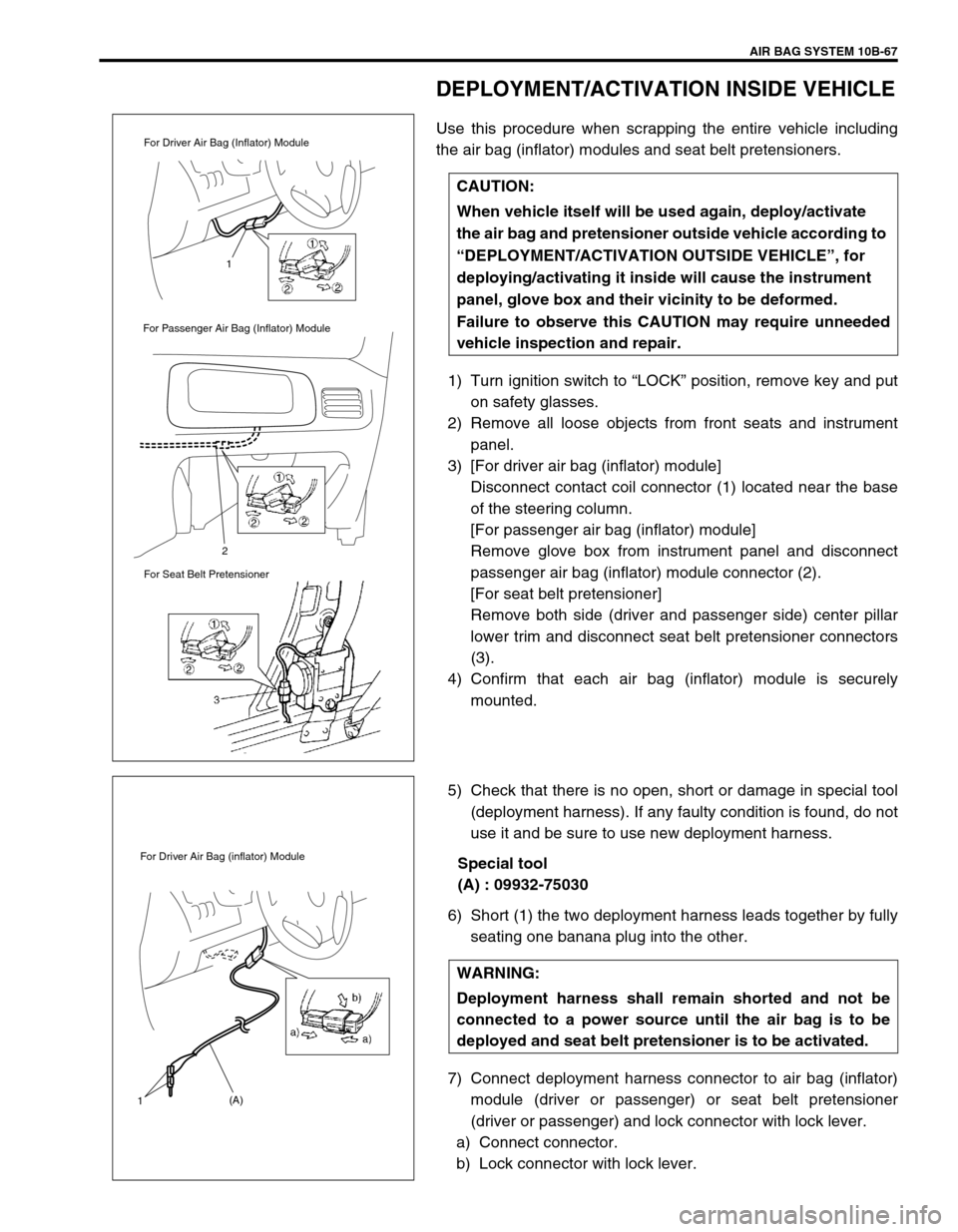

DEPLOYMENT/ACTIVATION INSIDE VEHICLE

Use this procedure when scrapping the entire vehicle including

the air bag (inflator) modules and seat belt pretensioners.

1) Turn ignition switch to “LOCK” position, remove key and put

on safety glasses.

2) Remove all loose objects from front seats and instrument

panel.

3) [For driver air bag (inflator) module]

Disconnect contact coil connector (1) located near the base

of the steering column.

[For passenger air bag (inflator) module]

Remove glove box from instrument panel and disconnect

passenger air bag (inflator) module connector (2).

[For seat belt pretensioner]

Remove both side (driver and passenger side) center pillar

lower trim and disconnect seat belt pretensioner connectors

(3).

4) Confirm that each air bag (inflator) module is securely

mounted.

5) Check that there is no open, short or damage in special tool

(deployment harness). If any faulty condition is found, do not

use it and be sure to use new deployment harness.

Special tool

(A) : 09932-75030

6) Short (1) the two deployment harness leads together by fully

seating one banana plug into the other.

7) Connect deployment harness connector to air bag (inflator)

module (driver or passenger) or seat belt pretensioner

(driver or passenger) and lock connector with lock lever.

a) Connect connector.

b) Lock connector with lock lever.CAUTION:

When vehicle itself will be used again, deploy/activate

the air bag and pretensioner outside vehicle according to

“DEPLOYMENT/ACTIVATION OUTSIDE VEHICLE”, for

deploying/activating it inside will cause the instrument

panel, glove box and their vicinity to be deformed.

Failure to observe this CAUTION may require unneeded

vehicle inspection and repair.

1

2

For Driver Air Bag (Inflator) Module

For Passenger Air Bag (Inflator) Module

For Seat Belt Pretensioner

WARNING:

Deployment harness shall remain shorted and not be

connected to a power source until the air bag is to be

deployed and seat belt pretensioner is to be activated.

(A)

1

For Driver Air Bag (inflator) Module

Page 442 of 447

10B-68 AIR BAG SYSTEM

8) Route deployment harness out the vehicle.

9) Verify that the inside of the vehicle and the area surrounding

the vehicle are clear of all people and loose or flammable

objects.

10) Stretch the deployment harness to its full length 10 m (33 ft)

(1).

Special tool

(A) : 09932-75030

11) Place a power source near the shorted end (3) of the deploy-

ment harness. Recommended application: 12 Volts mini-

mum, 2 amps minimum. A vehicle battery is suggested.

12) Completely cover windshield area and front door window

openings with a drop cloth, blanket to similar item (2). This

reduces the possibility of injury due to possible fragmenta-

tion of the vehicle’s glass or interior.

13) Notify all people in the immediate area that you intend to

deploy the air bag (inflator) module or activate the seat belt

pretensioner.

.

NOTE:

When the air bag deploys and the pretensioner acti-

vates, the rapid gas expansion will create a substantial

report. Wear suitable ear protection. Notify all people

in the immediate area that you intend to deploy the air

bag (inflator) module or to activate the seat belt preten-

sioner and suitable ear protection should be worn.

After the air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery resi-

due. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-prod-

ucts of the chemical reaction.

WARNING:

After deployment/activation, the metal surfaces of the

air bag (inflator) module and the seat belt pretensioner

will be very hot. Do not touch the metal areas of them

for about 30 minutes after deployment/activation.

Do not apply water, oil, etc. to deployed air bag (infla-

tor) module and activated seat belt pretensioner. Fail-

ure to follow procedures may result in fire or personal

injury.

1

3 2

1

32

Driver side for left hand steering vehicle

Driver side for right hand steering vehicle

Page 444 of 447

10B-70 AIR BAG SYSTEM

DEPLOYED AIR BAG (INFLATOR) MODULE

AND ACTIVATED SEAT BELT PRETEN-

SIONER DISPOSAL

Deployed air bag (inflator) module and the activated seat belt pre-

tensioner can be disposed of through normal refuse channels just

like any other parts. For their disposal, however, following points

should be noted.

The air bag (inflator) module and the seat belt pretensioner

immediately after deployment/activation is very hot. Wait for

30 minutes to cool it off before handling it.

Never apply water, oil, etc. to deployed air bag (inflator)

module and the activated seat belt pretensioner to cool it off

and be careful so that water, oil etc. does not get on the

deployed air bag (inflator) module and the activated seat belt

pretensioner.

After the air bag (inflator) module has been deployed, the

surface of the air bag may contain a powdery residue. This

powder consists primarily of cornstarch (used to lubricate the

bag as it inflates) and by-products of the chemical reaction.

As with many service procedures, you should wear gloves

and safety glasses.

When disposing of the deployed air bag (inflator) module

and the activated seat belt pretensioner, be sure to seal it in

a vinyl bag.

When air bag (inflator) module and seat belt pretensioner

have been deployed/activated inside the vehicle which is

going to be scrapped, leave them as installed to the vehicle.

Be sure to wash your hands with mild soap and water after

handling it. WARNING:

Failure to follow proper air bag (inflator) module and seat

belt pretensioner disposal procedures can result in air

bag deployment and pretensioner activation which may

cause personal injury. The undeployed air bag (inflator)

module and the inactivated seat belt pretensioner must

not be disposed of through normal refuse channels.

The undeployed air bag (inflator) module and the inacti-

vated seat belt pretensioner contains substances that

can cause severe illness or personal injury if the sealed

container is damaged during disposal.