oil level SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 202 of 447

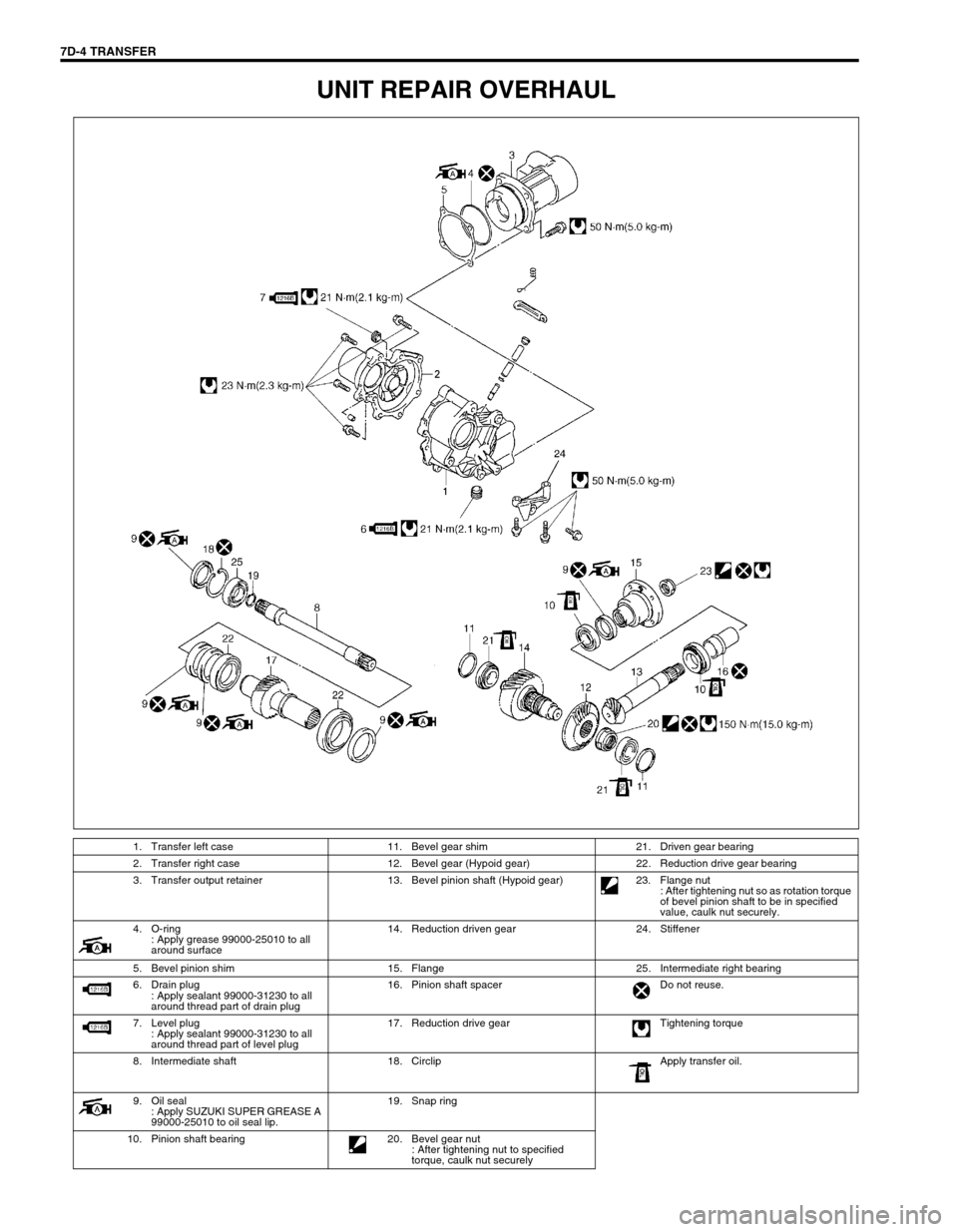

7D-4 TRANSFER

UNIT REPAIR OVERHAUL

1. Transfer left case 11. Bevel gear shim 21. Driven gear bearing

2. Transfer right case 12. Bevel gear (Hypoid gear) 22. Reduction drive gear bearing

3. Transfer output retainer 13. Bevel pinion shaft (Hypoid gear) 23. Flange nut

: After tightening nut so as rotation torque

of bevel pinion shaft to be in specified

value, caulk nut securely.

4. O-ring

: Apply grease 99000-25010 to all

around surface14. Reduction driven gear 24. Stiffener

5. Bevel pinion shim 15. Flange 25. Intermediate right bearing

6. Drain plug

: Apply sealant 99000-31230 to all

around thread part of drain plug16. Pinion shaft spacer Do not reuse.

7. Level plug

: Apply sealant 99000-31230 to all

around thread part of level plug17. Reduction drive gear Tightening torque

8. Intermediate shaft 18. Circlip Apply transfer oil.

9. Oil seal

: Apply SUZUKI SUPER GREASE A

99000-25010 to oil seal lip.19. Snap ring

10. Pinion shaft bearing 20. Bevel gear nut

: After tightening nut to specified

torque, caulk nut securely

Page 219 of 447

TRANSFER 7D-21

Tighten mounting bolt and mounting bracket bolts and nuts

to specified torque.

Tightening torque

Transfer rear mounting bracket nuts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Transfer mounting bolt

(b) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

Transfer rear mounting bracket No.2 bolts

(c) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

Tighten transfer stiffener bolts (4) to specified torque.

Tightening torque

Transfer stiffener bolts (a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Tighten exhaust pipe bolts.

Tightening torque

Exhaust pipe bolts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Install right side drive shaft, refer to Section 4A.

Install propeller shaft and tighten propeller shaft bolts and

center support bolts to specified torque (refer to Section 4B).

Fill gear oil to transfer as specified, refer to OIL CHANGE of

ON-VEHICLE SERVICE.

Check oil level and leakage.

(a)

(b)

(c)

1. Transmission

2. Transfer

3. Stiffener

1. Exhaust No.1 pipe

2. Exhaust No.2 pipe

1

(a)(a)2

Page 220 of 447

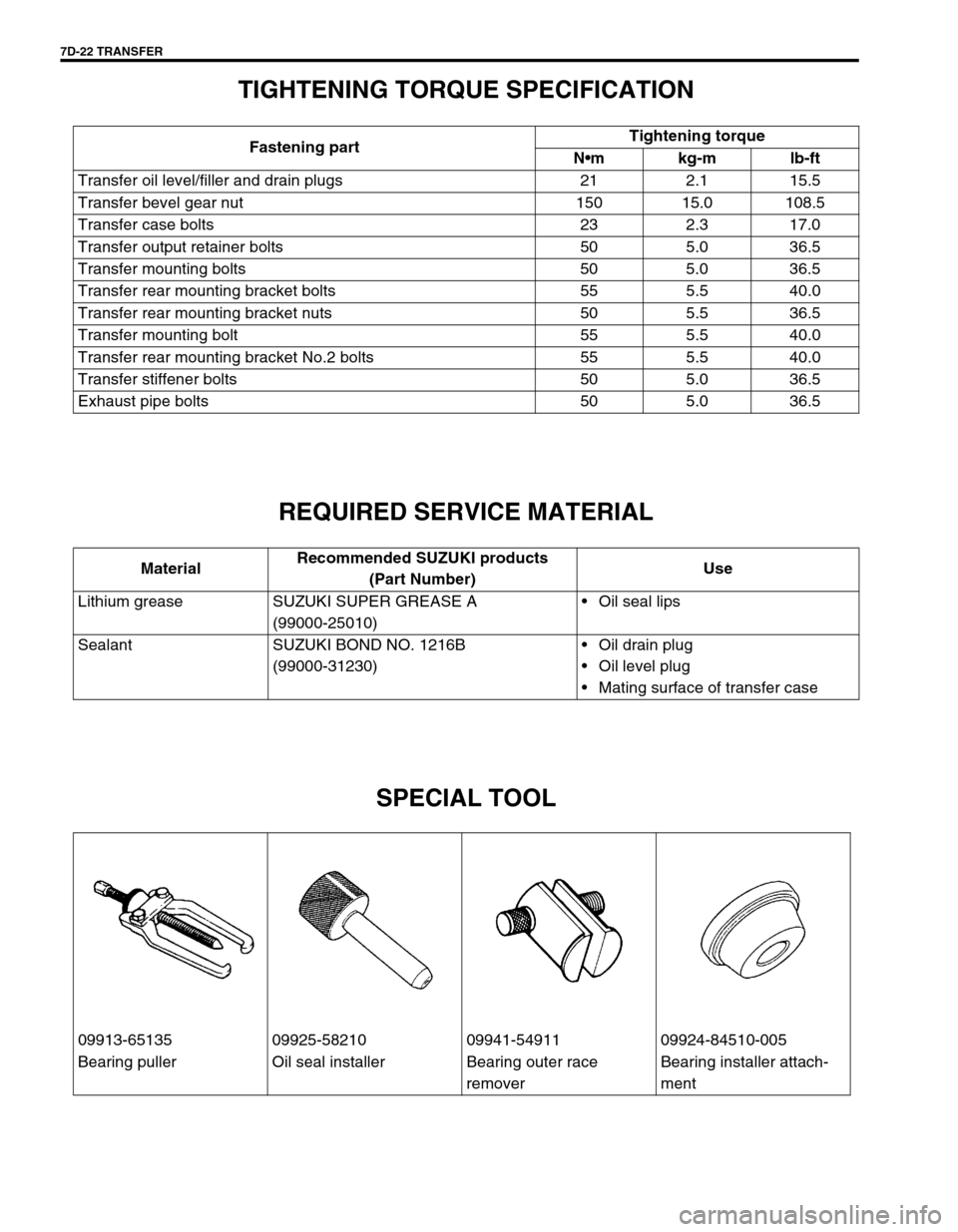

7D-22 TRANSFER

TIGHTENING TORQUE SPECIFICATION

REQUIRED SERVICE MATERIAL

SPECIAL TOOL

Fastening partTightening torque

Nm kg-m lb-ft

Transfer oil level/filler and drain plugs 21 2.1 15.5

Transfer bevel gear nut 150 15.0 108.5

Transfer case bolts 23 2.3 17.0

Transfer output retainer bolts 50 5.0 36.5

Transfer mounting bolts 50 5.0 36.5

Transfer rear mounting bracket bolts 55 5.5 40.0

Transfer rear mounting bracket nuts 50 5.5 36.5

Transfer mounting bolt 55 5.5 40.0

Transfer rear mounting bracket No.2 bolts 55 5.5 40.0

Transfer stiffener bolts 50 5.0 36.5

Exhaust pipe bolts 50 5.0 36.5

MaterialRecommended SUZUKI products

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Oil seal lips

Sealant SUZUKI BOND NO. 1216B

(99000-31230)Oil drain plug

Oil level plug

Mating surface of transfer case

09913-65135 09925-58210 09941-54911 09924-84510-005

Bearing puller Oil seal installer Bearing outer race

removerBearing installer attach-

ment

Page 225 of 447

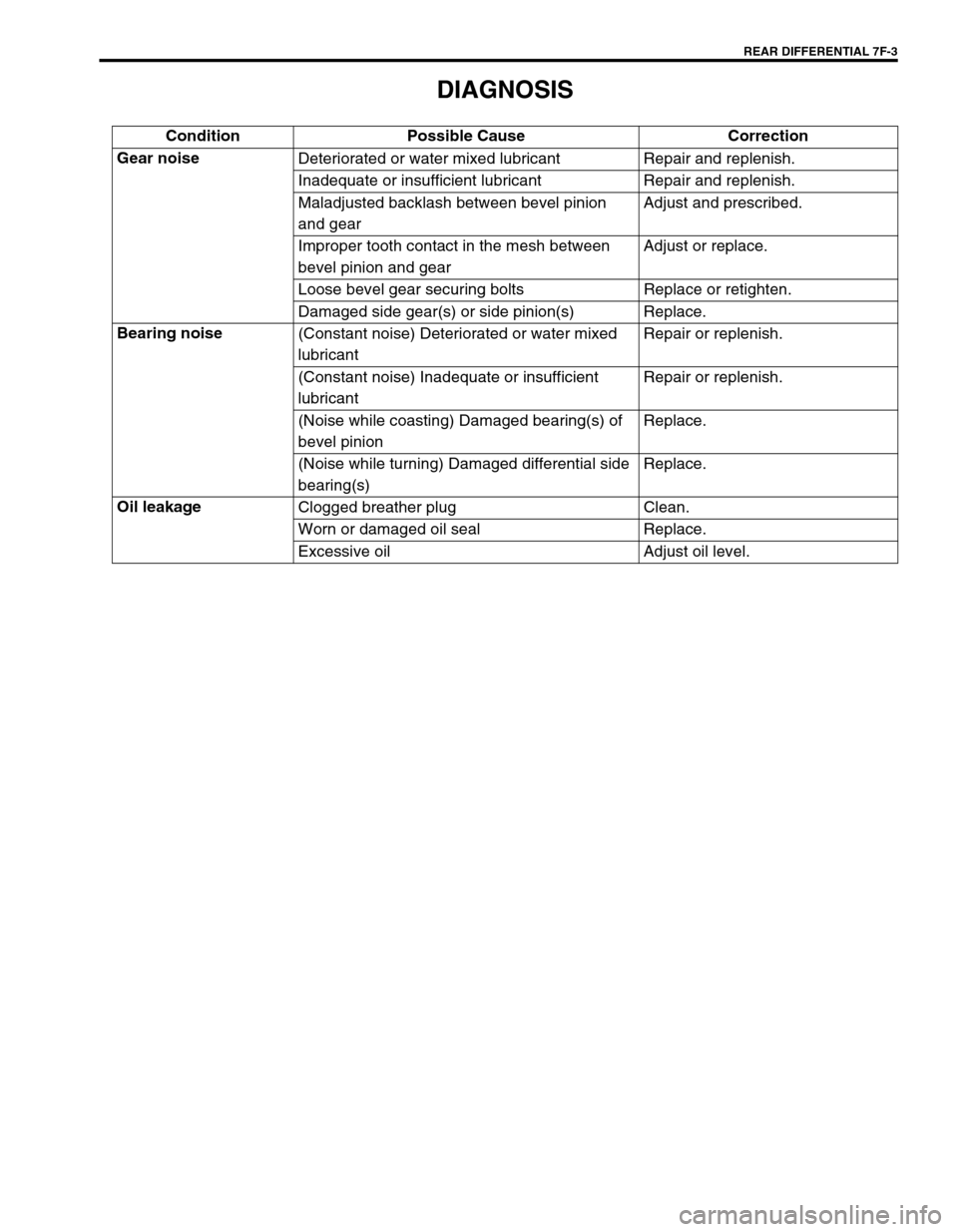

REAR DIFFERENTIAL 7F-3

DIAGNOSIS

Condition Possible Cause Correction

Gear noise

Deteriorated or water mixed lubricant Repair and replenish.

Inadequate or insufficient lubricant Repair and replenish.

Maladjusted backlash between bevel pinion

and gearAdjust and prescribed.

Improper tooth contact in the mesh between

bevel pinion and gearAdjust or replace.

Loose bevel gear securing bolts Replace or retighten.

Damaged side gear(s) or side pinion(s) Replace.

Bearing noise

(Constant noise) Deteriorated or water mixed

lubricantRepair or replenish.

(Constant noise) Inadequate or insufficient

lubricantRepair or replenish.

(Noise while coasting) Damaged bearing(s) of

bevel pinionReplace.

(Noise while turning) Damaged differential side

bearing(s)Replace.

Oil leakage

Clogged breather plug Clean.

Worn or damaged oil seal Replace.

Excessive oil Adjust oil level.

Page 226 of 447

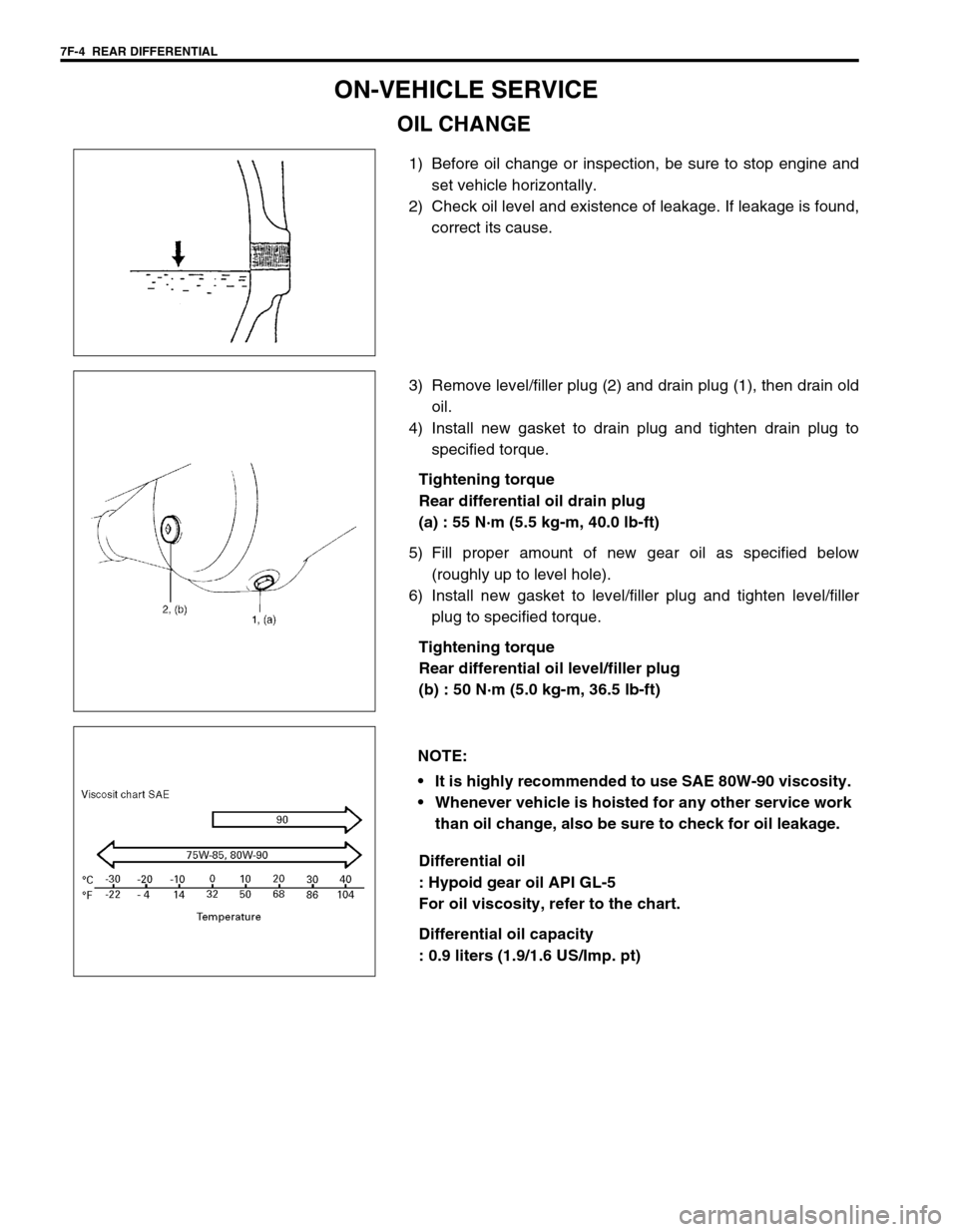

7F-4 REAR DIFFERENTIAL

ON-VEHICLE SERVICE

OIL CHANGE

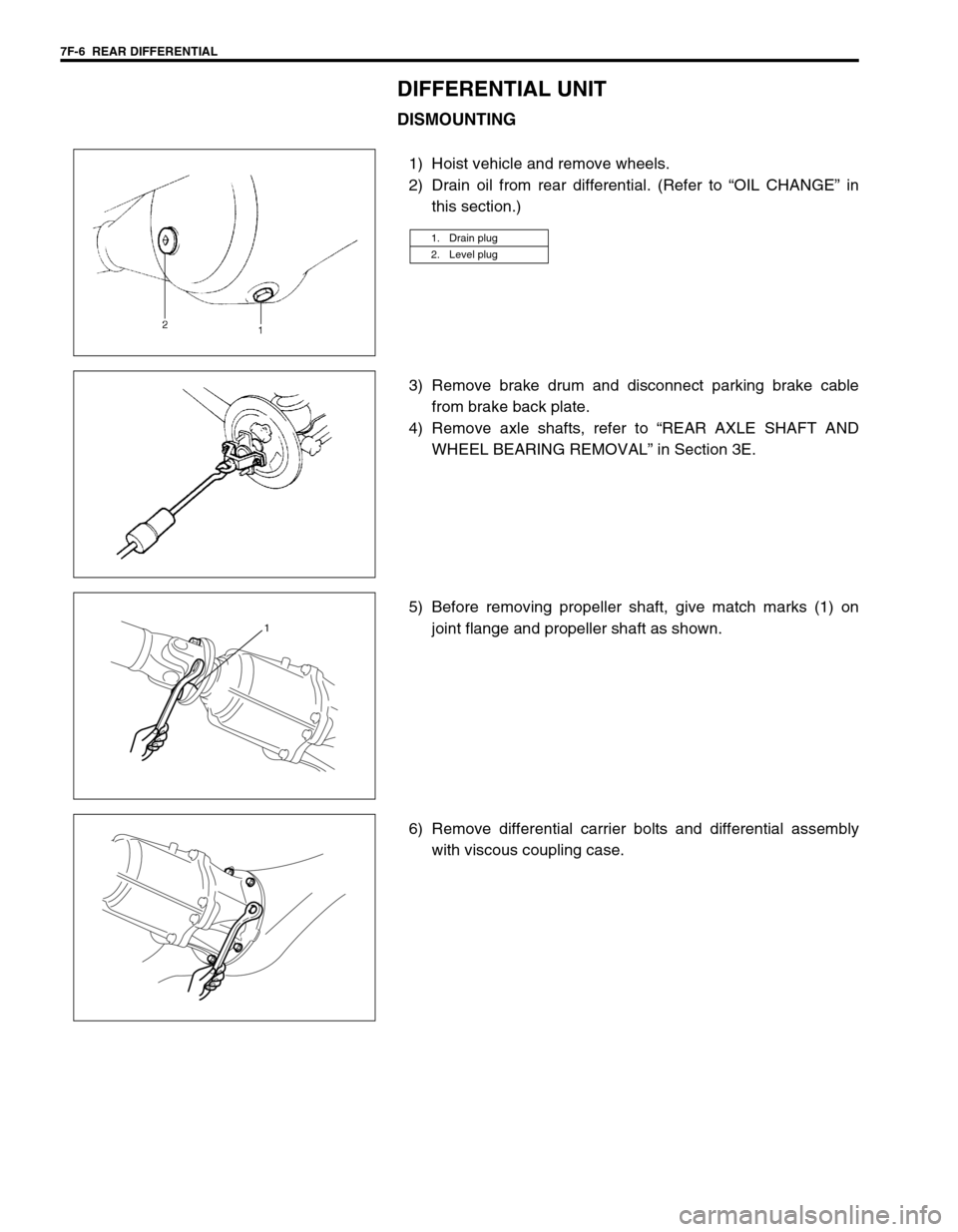

1) Before oil change or inspection, be sure to stop engine and

set vehicle horizontally.

2) Check oil level and existence of leakage. If leakage is found,

correct its cause.

3) Remove level/filler plug (2) and drain plug (1), then drain old

oil.

4) Install new gasket to drain plug and tighten drain plug to

specified torque.

Tightening torque

Rear differential oil drain plug

(a) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

5) Fill proper amount of new gear oil as specified below

(roughly up to level hole).

6) Install new gasket to level/filler plug and tighten level/filler

plug to specified torque.

Tightening torque

Rear differential oil level/filler plug

(b) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Differential oil

: Hypoid gear oil API GL-5

For oil viscosity, refer to the chart.

Differential oil capacity

: 0.9 liters (1.9/1.6 US/Imp. pt)

NOTE:

It is highly recommended to use SAE 80W-90 viscosity.

Whenever vehicle is hoisted for any other service work

than oil change, also be sure to check for oil leakage.

Page 228 of 447

7F-6 REAR DIFFERENTIAL

DIFFERENTIAL UNIT

DISMOUNTING

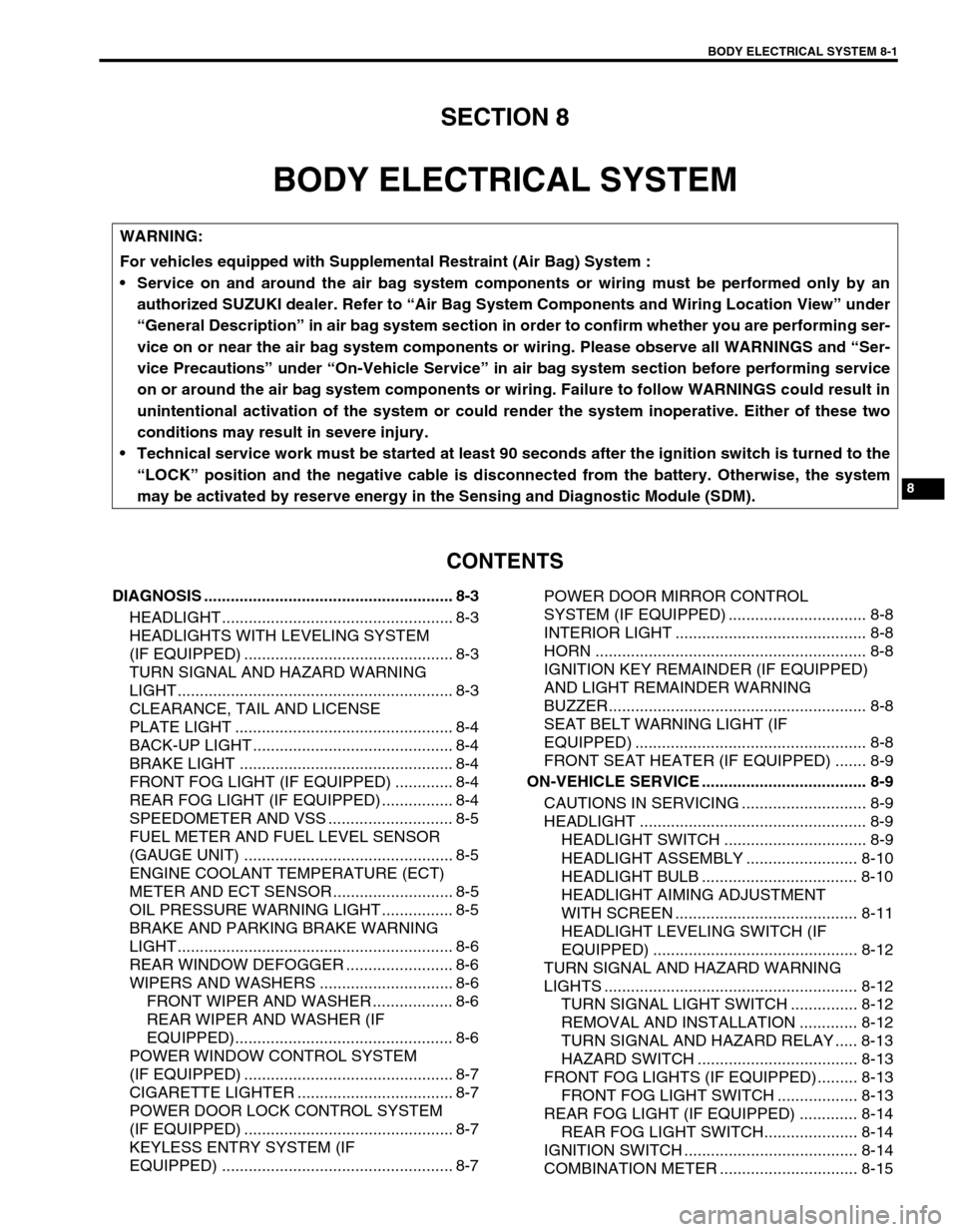

1) Hoist vehicle and remove wheels.

2) Drain oil from rear differential. (Refer to “OIL CHANGE” in

this section.)

3) Remove brake drum and disconnect parking brake cable

from brake back plate.

4) Remove axle shafts, refer to “REAR AXLE SHAFT AND

WHEEL BEARING REMOVAL” in Section 3E.

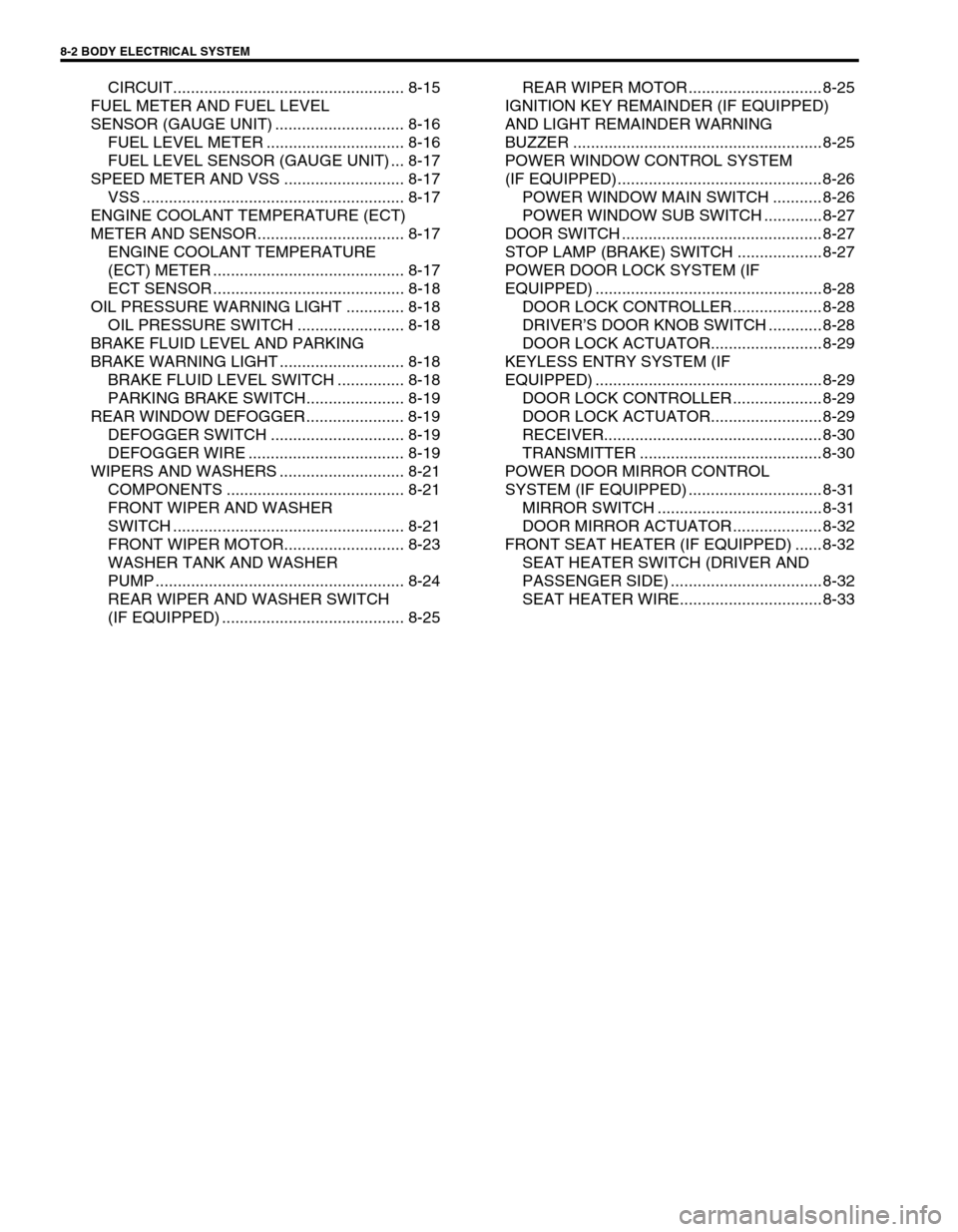

5) Before removing propeller shaft, give match marks (1) on

joint flange and propeller shaft as shown.

6) Remove differential carrier bolts and differential assembly

with viscous coupling case.

1. Drain plug

2. Level plug

1

Page 242 of 447

7F-20 REAR DIFFERENTIAL

UNIT ASSEMBLY

Before installing viscous coupling case (1) to differential carrier

(2), clean mating surfaces of viscous coupling case and differen-

tial carrier, then apply sealant to differential carrier (2) by using a

nozzle as shown in figure by such amount that its section is

1.5mm (0.059 in.) in diameter.

“A” : Sealant 99000-31110

Tightening torque

Coupling case bolts (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

TIGHTENING TORQUE SPECIFICATION

Irregular patterns: If the pattern is not oval, it means

that bevel gear is defective. High or low spots on tooth

surfaces or on the seat of bevel gear are the cause of

irregular patterns appearing on some teeth. The rem-

edy is to replace the pinion and-gear set and, if the

seat is defective, so is transfer case. TOOTH CONTACT PATTERN DIAGNOSIS AND REMEDY

Fastening partTightening torque

Nm kg-m lb-ft

Rear differential oil drain plug 55 5.5 40.0

Rear differential oil level/filler plug 50 5.0 36.5

Rear differential companion flange nut 130 13.0 94.0

Rear differential input flange bolts 23 2.3 17.0

Drive bevel gear bolts 80 8.0 58.0

Differential side bearing cap bolts 23 2.3 17.0

Coupling case bolts 25 2.5 18.0

Differential carrier bolts 23 2.3 17.0

Propeller shaft bolts 23 2.3 17.0

Page 245 of 447

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8

8D

8E

9

10

10A

10B

SECTION 8

BODY ELECTRICAL SYSTEM

CONTENTS

DIAGNOSIS ........................................................ 8-3

HEADLIGHT .................................................... 8-3

HEADLIGHTS WITH LEVELING SYSTEM

(IF EQUIPPED) ............................................... 8-3

TURN SIGNAL AND HAZARD WARNING

LIGHT .............................................................. 8-3

CLEARANCE, TAIL AND LICENSE

PLATE LIGHT ................................................. 8-4

BACK-UP LIGHT ............................................. 8-4

BRAKE LIGHT ................................................ 8-4

FRONT FOG LIGHT (IF EQUIPPED) ............. 8-4

REAR FOG LIGHT (IF EQUIPPED) ................ 8-4

SPEEDOMETER AND VSS ............................ 8-5

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT) ............................................... 8-5

ENGINE COOLANT TEMPERATURE (ECT)

METER AND ECT SENSOR ........................... 8-5

OIL PRESSURE WARNING LIGHT ................ 8-5

BRAKE AND PARKING BRAKE WARNING

LIGHT .............................................................. 8-6

REAR WINDOW DEFOGGER ........................ 8-6

WIPERS AND WASHERS .............................. 8-6

FRONT WIPER AND WASHER .................. 8-6

REAR WIPER AND WASHER (IF

EQUIPPED)................................................. 8-6

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

CIGARETTE LIGHTER ................................... 8-7

POWER DOOR LOCK CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) .................................................... 8-7POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) ............................... 8-8

INTERIOR LIGHT ........................................... 8-8

HORN ............................................................. 8-8

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER.......................................................... 8-8

SEAT BELT WARNING LIGHT (IF

EQUIPPED) .................................................... 8-8

FRONT SEAT HEATER (IF EQUIPPED) ....... 8-9

ON-VEHICLE SERVICE ..................................... 8-9

CAUTIONS IN SERVICING ............................ 8-9

HEADLIGHT ................................................... 8-9

HEADLIGHT SWITCH ................................ 8-9

HEADLIGHT ASSEMBLY ......................... 8-10

HEADLIGHT BULB ................................... 8-10

HEADLIGHT AIMING ADJUSTMENT

WITH SCREEN ......................................... 8-11

HEADLIGHT LEVELING SWITCH (IF

EQUIPPED) .............................................. 8-12

TURN SIGNAL AND HAZARD WARNING

LIGHTS ......................................................... 8-12

TURN SIGNAL LIGHT SWITCH ............... 8-12

REMOVAL AND INSTALLATION ............. 8-12

TURN SIGNAL AND HAZARD RELAY ..... 8-13

HAZARD SWITCH .................................... 8-13

FRONT FOG LIGHTS (IF EQUIPPED)......... 8-13

FRONT FOG LIGHT SWITCH .................. 8-13

REAR FOG LIGHT (IF EQUIPPED) ............. 8-14

REAR FOG LIGHT SWITCH..................... 8-14

IGNITION SWITCH ....................................... 8-14

COMBINATION METER ............................... 8-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 246 of 447

8-2 BODY ELECTRICAL SYSTEM

CIRCUIT.................................................... 8-15

FUEL METER AND FUEL LEVEL

SENSOR (GAUGE UNIT) ............................. 8-16

FUEL LEVEL METER ............................... 8-16

FUEL LEVEL SENSOR (GAUGE UNIT) ... 8-17

SPEED METER AND VSS ........................... 8-17

VSS ........................................................... 8-17

ENGINE COOLANT TEMPERATURE (ECT)

METER AND SENSOR................................. 8-17

ENGINE COOLANT TEMPERATURE

(ECT) METER ........................................... 8-17

ECT SENSOR ........................................... 8-18

OIL PRESSURE WARNING LIGHT ............. 8-18

OIL PRESSURE SWITCH ........................ 8-18

BRAKE FLUID LEVEL AND PARKING

BRAKE WARNING LIGHT ............................ 8-18

BRAKE FLUID LEVEL SWITCH ............... 8-18

PARKING BRAKE SWITCH...................... 8-19

REAR WINDOW DEFOGGER...................... 8-19

DEFOGGER SWITCH .............................. 8-19

DEFOGGER WIRE ................................... 8-19

WIPERS AND WASHERS ............................ 8-21

COMPONENTS ........................................ 8-21

FRONT WIPER AND WASHER

SWITCH .................................................... 8-21

FRONT WIPER MOTOR........................... 8-23

WASHER TANK AND WASHER

PUMP ........................................................ 8-24

REAR WIPER AND WASHER SWITCH

(IF EQUIPPED) ......................................... 8-25REAR WIPER MOTOR .............................. 8-25

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER ........................................................ 8-25

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED).............................................. 8-26

POWER WINDOW MAIN SWITCH ........... 8-26

POWER WINDOW SUB SWITCH ............. 8-27

DOOR SWITCH ............................................. 8-27

STOP LAMP (BRAKE) SWITCH ................... 8-27

POWER DOOR LOCK SYSTEM (IF

EQUIPPED) ................................................... 8-28

DOOR LOCK CONTROLLER .................... 8-28

DRIVER’S DOOR KNOB SWITCH ............ 8-28

DOOR LOCK ACTUATOR......................... 8-29

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) ................................................... 8-29

DOOR LOCK CONTROLLER .................... 8-29

DOOR LOCK ACTUATOR......................... 8-29

RECEIVER................................................. 8-30

TRANSMITTER ......................................... 8-30

POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) .............................. 8-31

MIRROR SWITCH ..................................... 8-31

DOOR MIRROR ACTUATOR .................... 8-32

FRONT SEAT HEATER (IF EQUIPPED) ...... 8-32

SEAT HEATER SWITCH (DRIVER AND

PASSENGER SIDE) .................................. 8-32

SEAT HEATER WIRE................................ 8-33

Page 249 of 447

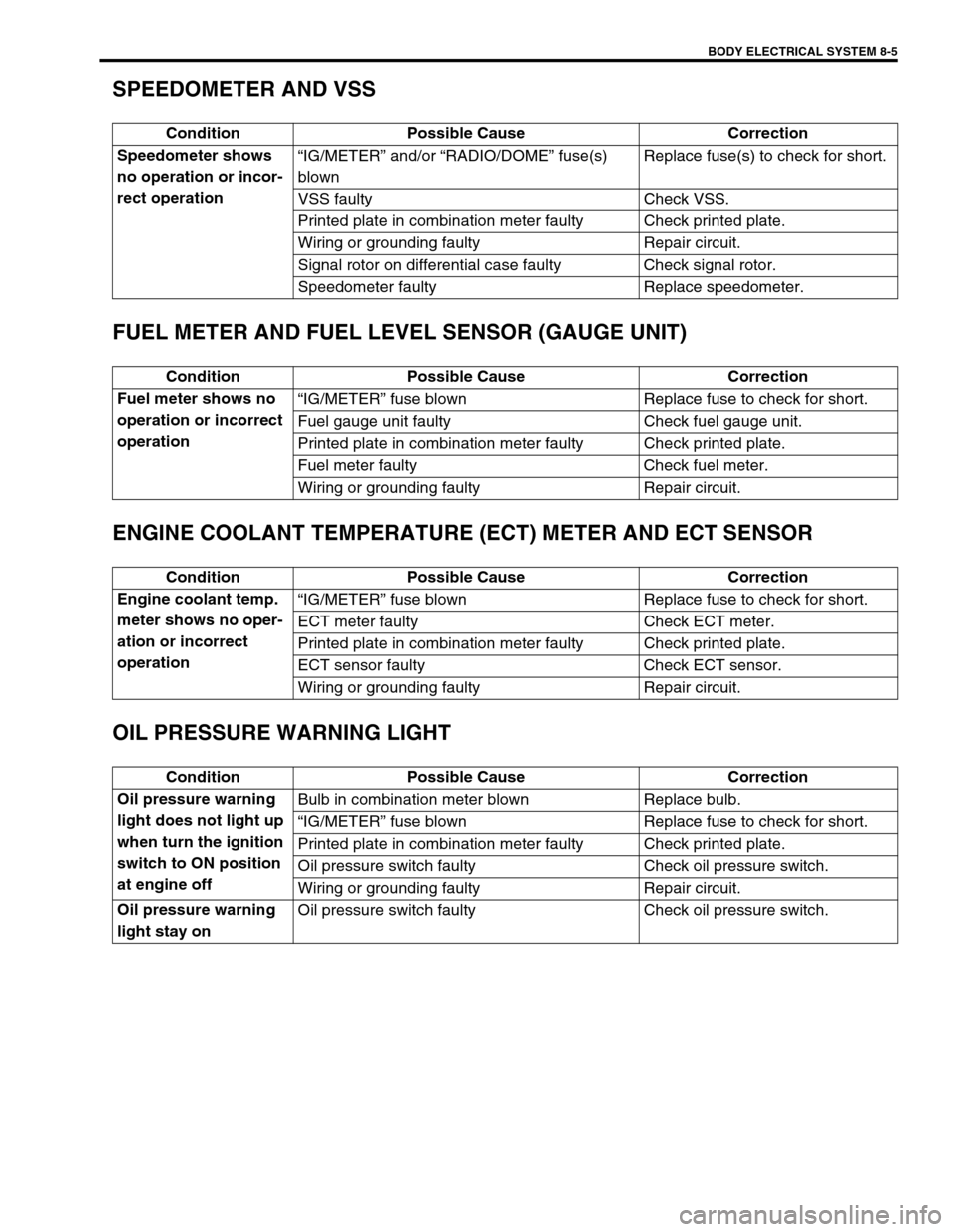

BODY ELECTRICAL SYSTEM 8-5

SPEEDOMETER AND VSS

FUEL METER AND FUEL LEVEL SENSOR (GAUGE UNIT)

ENGINE COOLANT TEMPERATURE (ECT) METER AND ECT SENSOR

OIL PRESSURE WARNING LIGHT

Condition Possible Cause Correction

Speedometer shows

no operation or incor-

rect operation“IG/METER” and/or “RADIO/DOME” fuse(s)

blownReplace fuse(s) to check for short.

VSS faulty Check VSS.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Signal rotor on differential case faulty Check signal rotor.

Speedometer faulty Replace speedometer.

Condition Possible Cause Correction

Fuel meter shows no

operation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

Fuel gauge unit faulty Check fuel gauge unit.

Printed plate in combination meter faulty Check printed plate.

Fuel meter faulty Check fuel meter.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Engine coolant temp.

meter shows no oper-

ation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

ECT meter faulty Check ECT meter.

Printed plate in combination meter faulty Check printed plate.

ECT sensor faulty Check ECT sensor.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Oil pressure warning

light does not light up

when turn the ignition

switch to ON position

at engine offBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Printed plate in combination meter faulty Check printed plate.

Oil pressure switch faulty Check oil pressure switch.

Wiring or grounding faulty Repair circuit.

Oil pressure warning

light stay onOil pressure switch faulty Check oil pressure switch.