ring SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 317 of 447

BODY SERVICE 9-13

REMOVAL

1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and garnish.

3) Using tape, cover body surface around glass to prevent any

damage.

4) Remove rear view mirror, sunvisor, and front pillar trims (right

& left).

5) If necessary, remove instrument panel. Refer to “INSTRU-

MENT PANEL” in this section.

6) If necessary, remove head lining. Refer to “HEAD LINING” in

this section.

7) Remove (or cut) windshield molding.

8) Drill hole with eyeleteer (1) through adhesive and let piano

string through it.

9) Cut adhesive all around windshield (1) with piano string (2).

When using tool, windshield knife (3), to cut adhesive, be

careful not to cause damage to windshield. Use wire to cut

adhesive along lower part of windshield.

10) Using knife (1), smoothen adhesive (2) remaining on body

side (3) so that it is 1 to 2 mm thick all around.

NOTE:

Use piano string (2) as close to glass as possible so as to

prevent damage to body and instrument panel.

NOTE:

Before using knife (1), clean it with alcohol or the like to

remove oil from it.

Page 320 of 447

9-16 BODY SERVICE

9) Apply primer for molding along molding surface all around.

10) Apply adhesive (1) referring to figure.

Adhesive amount specifications and position for wind-

shield

Width “a” : Approx. 7 mm (0.27 in.)

Height “b” : Approx. 15 mm (0.59 in.)

Position “c” : Approx. 10 mm (0.39 in.) for front, rear and

upper sections

Position “d” : Approx. 17 mm (0.67 in.) for bottom section.

11) Holding rubber sucker grips (1), place glass onto body by

aligning mating marks marked in step 3) and press it.

12) Check for water leakage by pouring water over windshield

through hose. If leakage is found, dry windshield and fill

leaky point with adhesive. If water still leaks even after that,

remove glass and start installation procedure all over again. NOTE:

Press glass (2) against fittings surface of body panel

quickly after adhesive (1) is applied.

Use of rubber sucker grip is helpful to hold and carry

glass after adhesive (1) is applied.

Perform steps 8) to 9) within 10 min. to ensure suffi-

cient adhesion.

Be sure to refer to adhesive maker’s instruction for

proper handling and drying time.

Start from bottom side of glass (2).

Be careful not to damage primer.

3. Molding

3

2

1

1“b”

“b”“b” “a”

“c”

“d”“c”

2

2

2

3

3

1

“a”“a”

NOTE:

Do not use high pressure water.

Do not blow compressed air directly at adhesive

applied part when drying.

Do not use infrared lamp or like for drying.

Page 325 of 447

BODY SERVICE 9-21

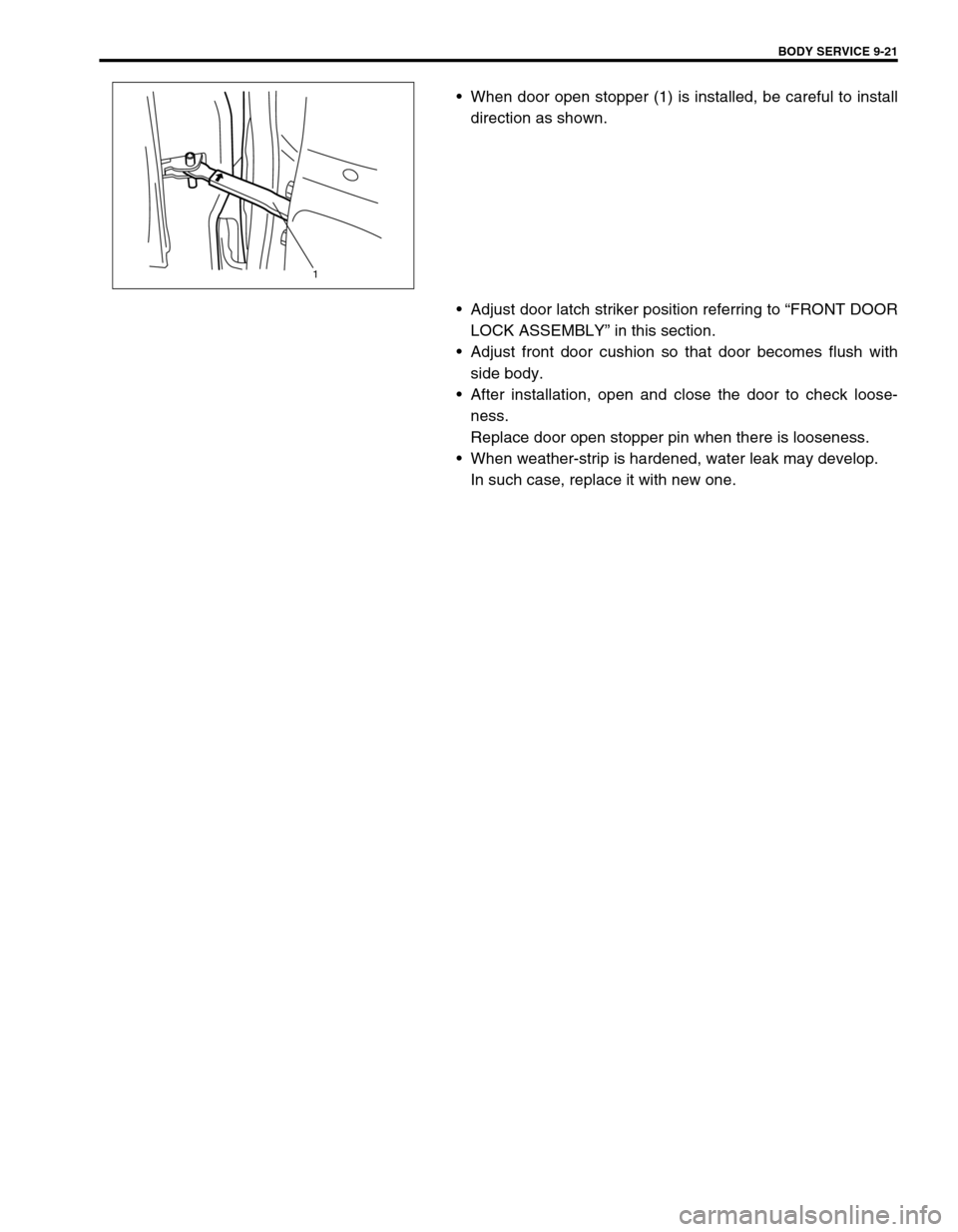

When door open stopper (1) is installed, be careful to install

direction as shown.

Adjust door latch striker position referring to “FRONT DOOR

LOCK ASSEMBLY” in this section.

Adjust front door cushion so that door becomes flush with

side body.

After installation, open and close the door to check loose-

ness.

Replace door open stopper pin when there is looseness.

When weather-strip is hardened, water leak may develop.

In such case, replace it with new one.

1

Page 328 of 447

9-24 BODY SERVICE

INSTALLATION

Reverse removal procedure to install back door noting the follow-

ing instructions.

Secure wiring harness.

Adjust door latch striker position by referring “BACK DOOR

LOCK ASSEMBLY” in this section.

Adjust door cushion so that door contacts body when closed.

Adjust door clearance by loosening door hinge mounting

bolts and nuts referring to “PANEL CLEARANCE” in this sec-

tion.

Apply sealant to contact face “A” of door hinge (1) and apply

grease to rotating part “B” of hinge (1).

“A” : Sealant 99000-31110

“B” : Lithium grease 99000-25010 WARNING:

Handling of Back Door Balancer (Damper)

Do not disassemble balancer (1) because its cylinder is

filled with gas.

Handle balancer carefully. Do not scar or scratch

exposed surface of its piston rod, and never allow any

paint or oil to stick to its surface.

Do not turn piston rod with balancer fully extended.

When discarding removed back door balancer

(damper), use a 2 – 3 mm (0.08 – 0.12 in.) drill (2) to

make a hole as shown.

The gas itself is harmless but it may issue out of the

hole together with chips generated by the drill (2).

Therefore, be sure to wear goggle.

Page 329 of 447

BODY SERVICE 9-25

HOOD

REMOVAL

1) Remove window washer hose (1) from hood (2).

2) Remove 4 mounting bolts (3) to detach hood (2).

INSTALLATION

Reverse removal procedure to install hood noting the following

instruction.

Apply sealant to contact face “B” of hood hinge (4).

“B” : Sealant 99000-3110

ADJUSTMENT

Adjust the following point :

Hood position adjustment.

Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting bolts,

refer to “PANEL CLEARANCE” in this section.

Vertical adjustment

If only one side (right or left) of hood is not level with front

fender, make it level by tightening or loosening hood cushion

(1).

Hood lock position adjustment

When installing hood lock (1), bring bolt at highest position

and move it in vertical direction for adjustment free from

loose to hood striker.

Tightening torque

Hood latch bolts (a) : 10 N·m (1.0 kg-m, 7.0 lb-ft) CAUTION:

Place cloth on “A” in figure to prevent from any damage.

33

4

“B”

“B”

1 2

“A”“A”

Page 330 of 447

9-26 BODY SERVICE

INSPECTION

Check that hood opens and closes smoothly and properly. Lubri-

cate if necessary. Also check that secondary latch operates prop-

erly (check that secondary latch keeps hood from opening all the

way) and hood locks securely when closed.

Adjust hood locks position if necessary.

FRONT FENDER

REMOVAL

1) Remove front fender side moulding.

2) Remove front bumper.

3) Disconnect connector of side turn signal (or side marker)

lamp.

4) Remove front fender lining.

5) Remove front fender.

INSTALLATION

Reverse removal procedure to install front fender noting the fol-

lowing instructions.

If paint on fender bolt is peeled off, be sure to apply paint

again.

Adjust panel clearance referring to “PANEL CLEARANCE” in

this section.

1. Front fender lining 2. Front fender 3. Front fender side moulding

“A”“A”

2

3

1

“A”

Page 336 of 447

![SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual 9-32 BODY SERVICE

Hole to hole distance

[B] : 5 door model f. Side sill scuff installation rear hole l. Rear door rear notch

a. Front door upper hinge installation hole g. Front shoulder adjuster inst SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual 9-32 BODY SERVICE

Hole to hole distance

[B] : 5 door model f. Side sill scuff installation rear hole l. Rear door rear notch

a. Front door upper hinge installation hole g. Front shoulder adjuster inst](/img/20/7605/w960_7605-335.png)

9-32 BODY SERVICE

Hole to hole distance

[B] : 5 door model f. Side sill scuff installation rear hole l. Rear door rear notch

a. Front door upper hinge installation hole g. Front shoulder adjuster installation upper

holem. Rear door switch installation hole

b. Front door lower hinge installation hole h. Rear door upper hinge installation hole n. Side soil scuff installation rear hole

c. Front pillar inner trim installation lower hole i. Front door switch installation hole o. Parking brake cable bracket installation rear

hole

d. Front pillar inner trim installation upper hole j. Rear door lower hinge installation hole p. Steering support member installation hole

e. Assistant grip installation front hole k. Assistant grip installation hole

a-g : 1166 mm (45.90 in.) d-i : 820 mm (32.28 in.) i-o : 742 mm (29.21 in.)

a-h : 942 mm (37.09 in.) d-o : 1252 mm (49.29 in.) j-m : 895 mm (35.24 in.)

a-i : 901 mm (35.47 in.) e- f : 1077 mm (42.40 in.) k-n : 1089 mm (42.87 in.)

b-i : 891 mm (35.08 in.) e-o : 1244 mm (48.98 in.) k-o : 1321 mm (52.01 in.)

b-j : 902 mm (35.51 in.) f-g: 1048 mm (41.26 in.) l-n : 948 mm (37.32 in.)

b-o : 1222 mm (48.11 in.) f-o 785 mm (30.91 in.) l-o : 1323 mm (52.09 in.)

c-f : 884 mm (34.80 in.) g-l : 621 mm (24.45 in.) m-o : 1111 mm (43.74 in.)

c-o: 1282 mm (50.47 in.) g-o : 1147 mm (45.16 in.) n-o : 813 mm (32.00 in.)

d-f : 993 mm (39.09 in.) h-l : 846 mm (33.31 in.) o-p : 1229 mm (48.39 in.)

d-g : 580 mm (22.83 in.) h-m : 813 mm (32.01 in.)

a

c

gd

ek

l

m

n

i

h

bf

j

a

c

dl

k

g

e

n

m

i

f

b o

o [B]

Page 342 of 447

9-38 BODY SERVICE

INSTRUMENTATION AND DRIVER INFORMATION

INSTRUMENT PANEL

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system, if equipped. Refer to “DISABLE AIR

BAG SYSTEM” in Section 10B.

3) Remove steering column hole cover (1).

4) Remove glove box (1) and food latch release lever (2).

5) Disconnect instrument panel harness connectors, antenna

and heater control cables which need to be disconnected for

removal for instrument panel.

6) Remove instrument panel ground wire.

7) Remove steering column assembly referring to “STEERING

COLUMN ASSEMBLY” in Section 3C.

8) Remove front pillar trims (1) and dash side trims (2).

9) Remove speaker covers (3).WARNING:

See WARNING at the beginning of this section.

“A”

“A”“A”

“A”

“A”

1

2“A” 1

3

“A”

Page 343 of 447

BODY SERVICE 9-39

10) Remove instrument panel mounting bolts (2).

11) Remove instrument panel (1) with steering support member

and instrument panel harness.

INSTALLATION

Reverse removal procedure to install instrument panel noting the

following instructions.

When installing each part, be careful not to catch any cable

or wiring harness.

Tighten instrument panel mounting bolts (1) to specified

torque

Tightening torque

Instrument panel mounting bolts (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

When installing steering column assembly, refer to “STEER-

ING COLUMN ASSEMBLY” in Section 3C.

Adjust control cables. Refer to “HEATER CONTROL

ASSEMBLY” in Section 1A.

Enable air bag system if equipped. Refer to “ENABLING AIR

BAG SYSTEM” in Section 10B.

2

2

22 2

1

1, (a)1, (a)

Page 348 of 447

9-44 BODY SERVICE

REAR DOOR LOCK ASSEMBLY (IF EQUIPPED)

REMOVAL

1) Remove door trim and door sealing cover, refer to steps 1) to

7) of “REMOVAL” under “REAR DOOR GLASS (IF

EQUIPPED)” in this section.

2) Disconnect door opening control rod (1) and door latch con-

trol rod (2).

3) Loosen door latch mounting screw (3), door latch actuator

screw (5) (if equipped power door lock) and remove door

lock assembly (4).

INSTALLATION

Reverse removal procedure to install rear door lock assembly

referring to “FRONT DOOR LOCK ASSEMBLY” in this section.

1. Outside handle 4. Latch striker 7. Shim

2. Inside handle bezel 5. Door latch screw 8. Door latch actuator screw

3. Rear door latch assembly

: Apply lithium grease 99000-25010 to sliding part6. Door latch striker screw 9. Door lock control rod

4

7

6 5

5 3

3

8 1

9

2

2

1

3

4 5