manual transmission SUZUKI SWIFT 2000 1.G Transmission Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 148 of 447

7B-106 AUTOMATIC TRANSMISSION (4 A/T)

VALVE BODY

1. Upper valve body 12. Lock-up control valve 23. Fail valve No.1

2. Upper valve body gasket 13. Lock-up control valve spring 24. Fail valve No.1 sleeve

3. Valve body plate 14. Lock-up signal valve plug 25. Key (short)

4. Lower valve body gasket 15. Lock-up signal valve 26. Key (long)

5. Lower valve body 16. Lock-up signal valve spring 27. Oil strainer

6. Primary regulator valve sleeve 17. Fail valve No.2 sleeve 28. Cooler by-pass valve

7. Primary regulator valve plunger 18. Fail valve No.2 29. Cooler by-pass valve spring

8. Primary regulator valve spring 19. Secondary regulator valve plug 30. Steel ball

9. Washer 20. Secondary regulator valve spring 31. Lock-up control valve

10. Primary regulator valve 21. Secondary regulator valve Apply automatic transmission fluid.

11. Lock-up control valve sleeve 22. Manual valve Do not reuse.

Page 149 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-107

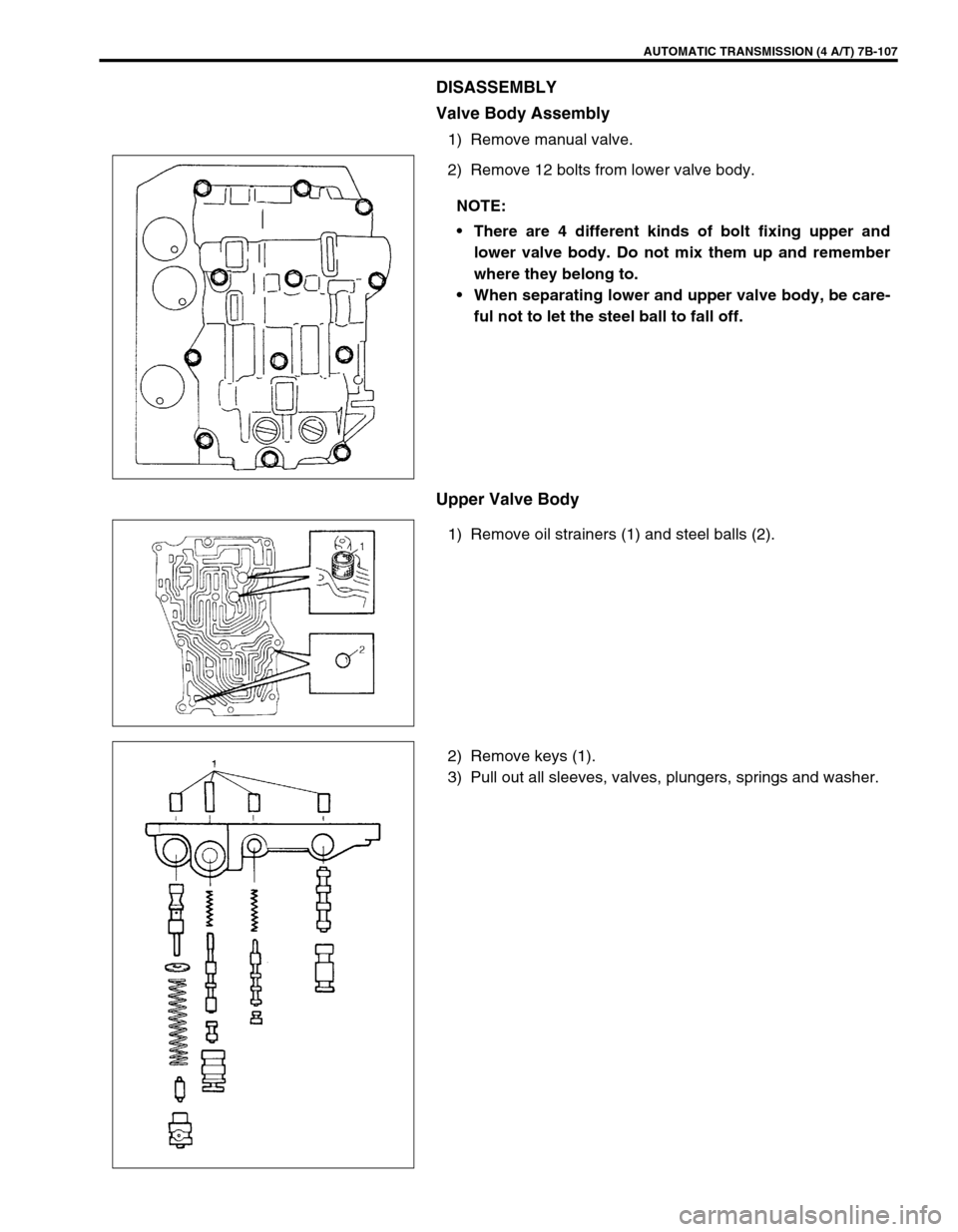

DISASSEMBLY

Valve Body Assembly

1) Remove manual valve.

2) Remove 12 bolts from lower valve body.

Upper Valve Body

1) Remove oil strainers (1) and steel balls (2).

2) Remove keys (1).

3) Pull out all sleeves, valves, plungers, springs and washer.NOTE:

There are 4 different kinds of bolt fixing upper and

lower valve body. Do not mix them up and remember

where they belong to.

When separating lower and upper valve body, be care-

ful not to let the steel ball to fall off.

Page 150 of 447

7B-108 AUTOMATIC TRANSMISSION (4 A/T)

Valve spring dimensions (Reference)

Lower Valve Body

1) Remove oil strainers (1).

2) Remove solenoid valves, if still attached.

3) Remove keys (2) and pull out all sleeve, plug, spring and

valves.

Valve spring dimensions (Reference)Spring Free length

“a” (mm)Outside diameter

“b” (mm)

Primary regula-

tor valve spring79.2 18.0

Lock-up control

valve spring31.1 8.5

Lock-up signal

valve spring36.1 8.5

3. Fail valve No.1 sleeve

4. Fail valve No.1

5. Cooler by-pass valve

6. Cooler by-pass valve spring

7. Manual valve

8. Secondary regulator valve

9. Secondary regulator valve spring

10. Secondary regulator valve plug

Spring Free length

“a” (mm)Outside diame-

ter “b” (mm)

Secondary regula-

tor valve spring38.7 8.8

Cooler by-pass

valve spring22.8 8.0

Page 152 of 447

7B-110 AUTOMATIC TRANSMISSION (4 A/T)

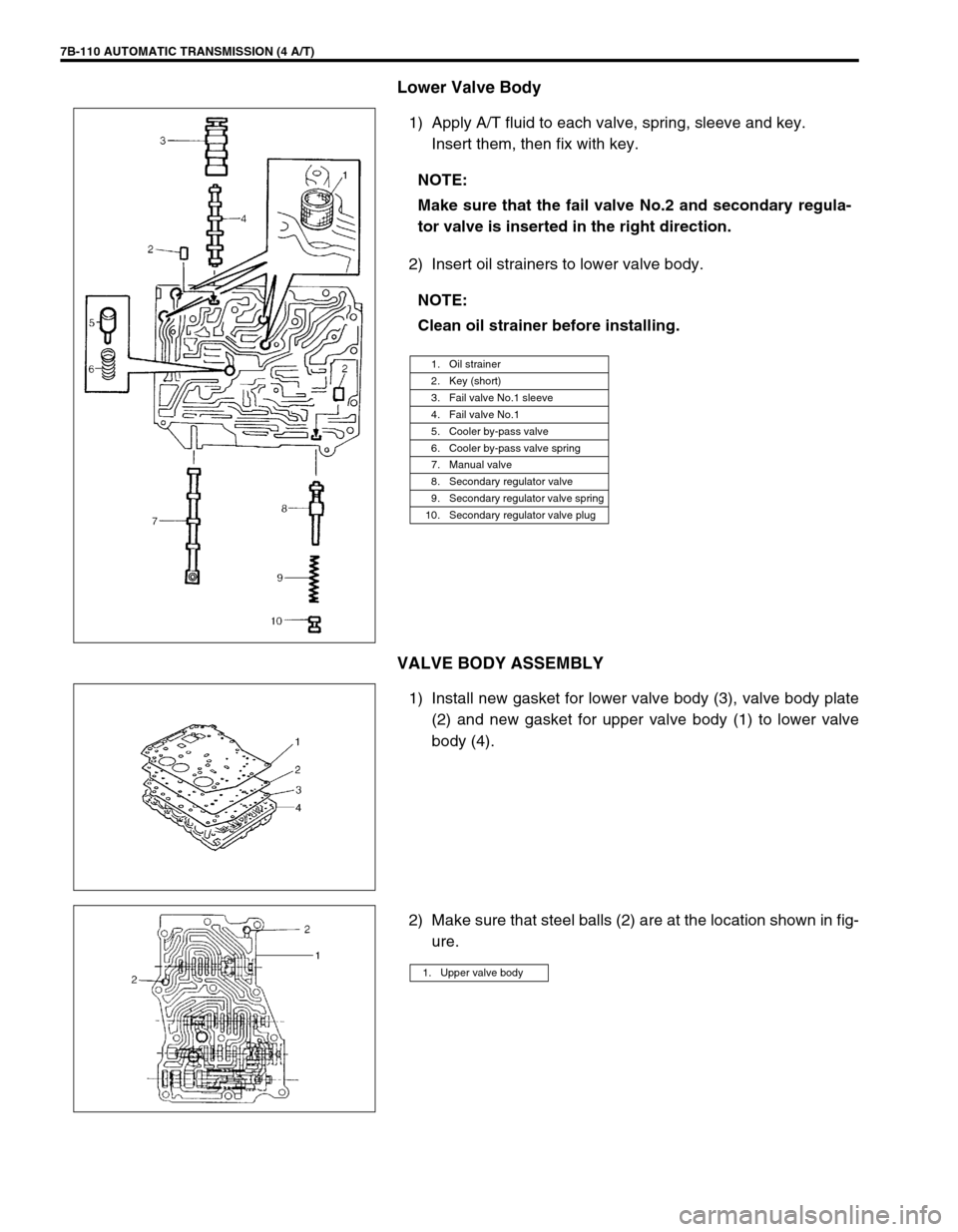

Lower Valve Body

1) Apply A/T fluid to each valve, spring, sleeve and key.

Insert them, then fix with key.

2) Insert oil strainers to lower valve body.

VALVE BODY ASSEMBLY

1) Install new gasket for lower valve body (3), valve body plate

(2) and new gasket for upper valve body (1) to lower valve

body (4).

2) Make sure that steel balls (2) are at the location shown in fig-

ure. NOTE:

Make sure that the fail valve No.2 and secondary regula-

tor valve is inserted in the right direction.

NOTE:

Clean oil strainer before installing.

1. Oil strainer

2. Key (short)

3. Fail valve No.1 sleeve

4. Fail valve No.1

5. Cooler by-pass valve

6. Cooler by-pass valve spring

7. Manual valve

8. Secondary regulator valve

9. Secondary regulator valve spring

10. Secondary regulator valve plug

1. Upper valve body

Page 153 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-111

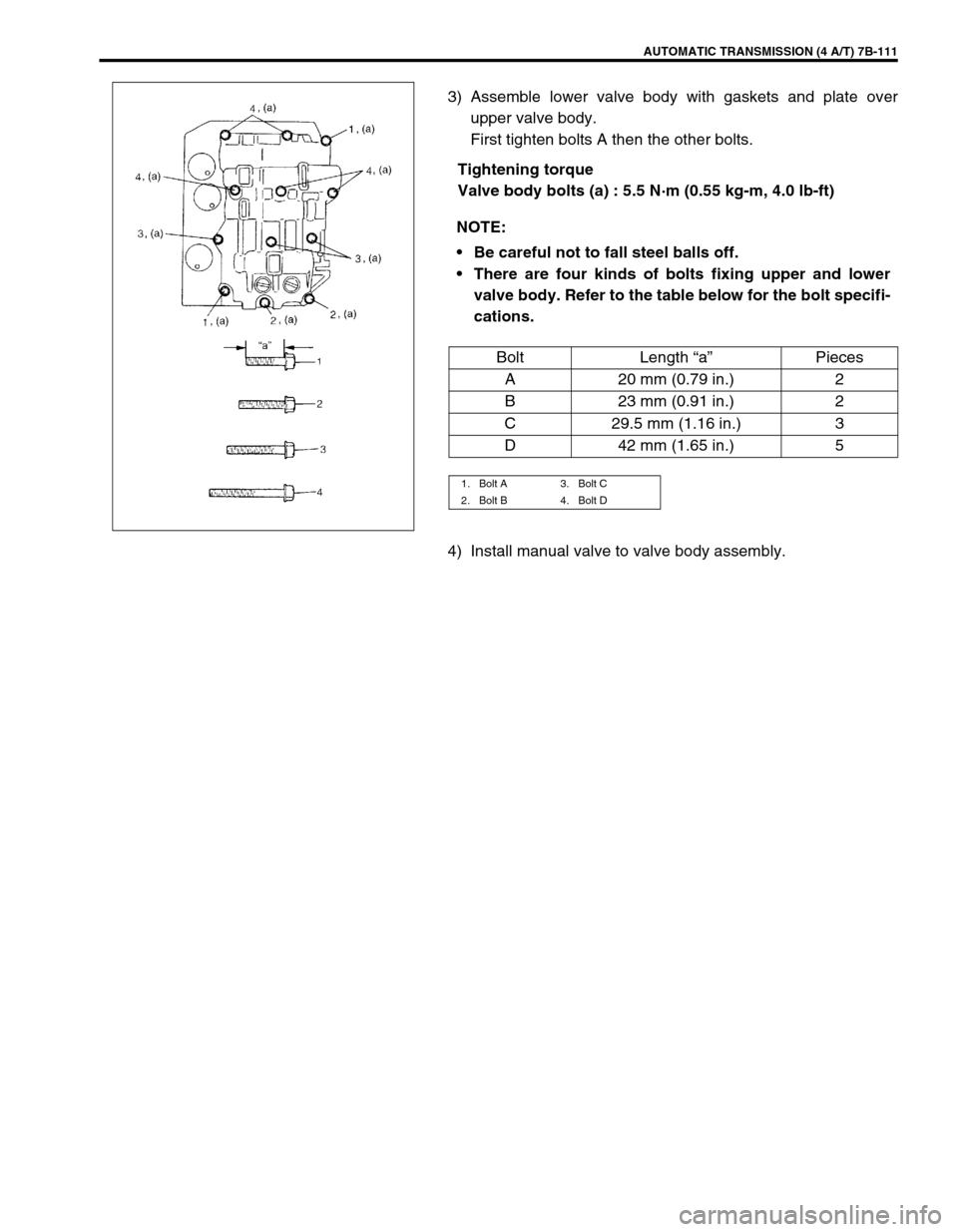

3) Assemble lower valve body with gaskets and plate over

upper valve body.

First tighten bolts A then the other bolts.

Tightening torque

Valve body bolts (a) : 5.5 N·m (0.55 kg-m, 4.0 lb-ft)

4) Install manual valve to valve body assembly.NOTE:

Be careful not to fall steel balls off.

There are four kinds of bolts fixing upper and lower

valve body. Refer to the table below for the bolt specifi-

cations.

Bolt Length “a”Pieces

A 20 mm (0.79 in.) 2

B 23 mm (0.91 in.) 2

C 29.5 mm (1.16 in.) 3

D 42 mm (1.65 in.) 5

1. Bolt A 3. Bolt C

2. Bolt B 4. Bolt D

Page 154 of 447

7B-112 AUTOMATIC TRANSMISSION (4 A/T)

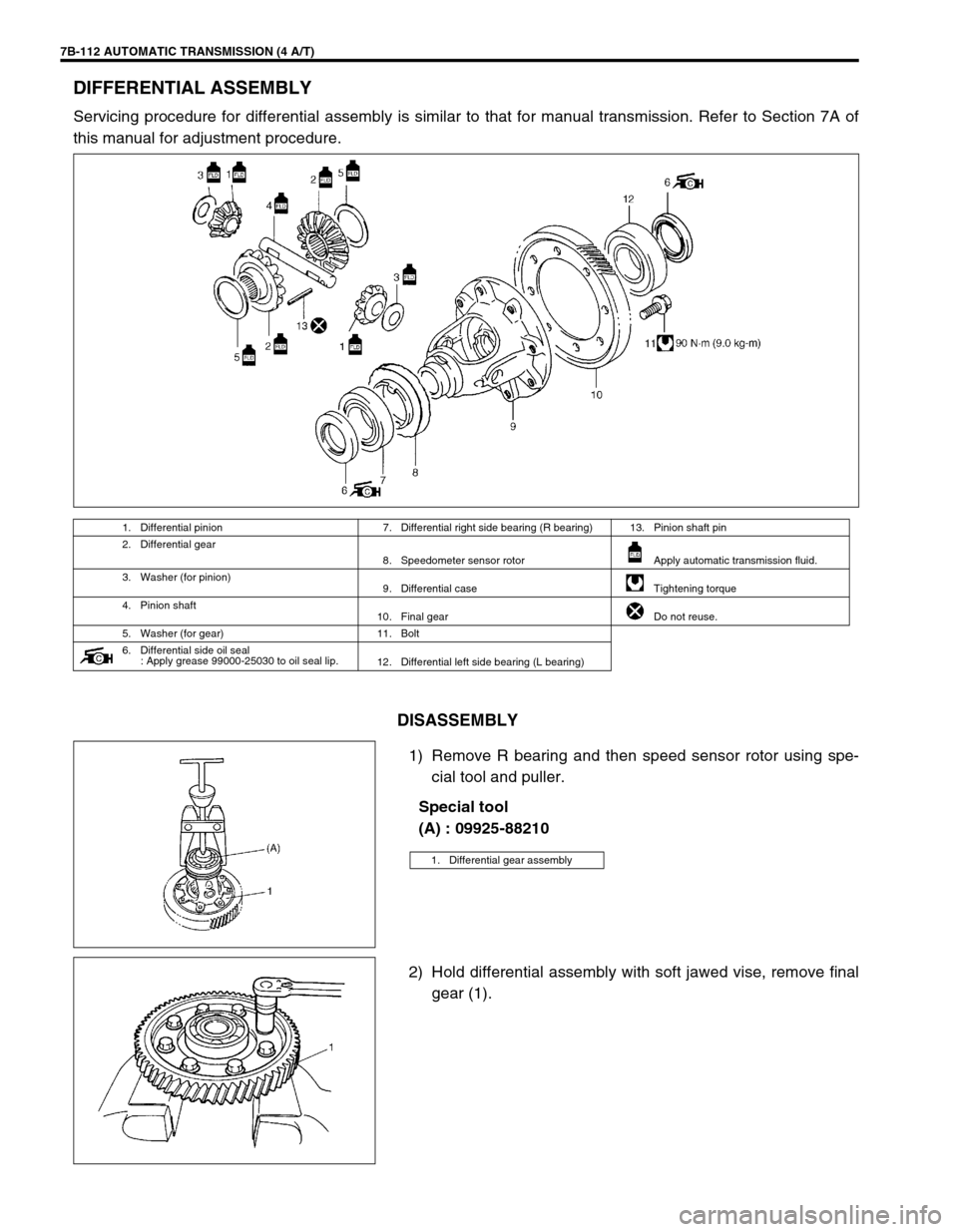

DIFFERENTIAL ASSEMBLY

Servicing procedure for differential assembly is similar to that for manual transmission. Refer to Section 7A of

this manual for adjustment procedure.

DISASSEMBLY

1) Remove R bearing and then speed sensor rotor using spe-

cial tool and puller.

Special tool

(A) : 09925-88210

2) Hold differential assembly with soft jawed vise, remove final

gear (1).

1. Differential pinion 7. Differential right side bearing (R bearing) 13. Pinion shaft pin

2. Differential gear

8. Speedometer sensor rotor Apply automatic transmission fluid.

3. Washer (for pinion)

9. Differential case Tightening torque

4. Pinion shaft

10. Final gear Do not reuse.

5. Washer (for gear) 11. Bolt

6. Differential side oil seal

: Apply grease 99000-25030 to oil seal lip.

12. Differential left side bearing (L bearing)

1. Differential gear assembly

Page 167 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-125

26) Attach parking lock rod (2) to manual shift shaft (1).

27) Install manual shift shaft and washer (3) to transmission

case. Fix manual shift shaft with washer, control shift lever

(4) and two nuts (5).

Apply grease to the washers.

Tightening torque

Control shift lever nuts

(a) : 30 N·m (3.0 kg-m, 22.0 lb-ft)

“A” : Grease 99000-25030

28) Install detent spring (1) to transmission case.

Tightening torque

Detent spring bolt (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

29) Install thrust needle roller bearing (2) on counter bearing (3).

30) Install counter driven gear (1).

31) Install parking lock pawl sleeve (1) and oil plate (not shown

in figure).

Tightening torque

Parking lock pawl sleeve bolt

(a) : 19 N·m (1.9 kg-m, 14.0 lb-ft)

Page 174 of 447

7B-132 AUTOMATIC TRANSMISSION (4 A/T)

56) Install valve body assembly (1) to transmission case.

First match the pin of the manual valve to the slot of the

manual shift shaft.

To fix valve body assembly (1) to transmission case, first

tighten bolt B (3), then tighten other bolts.

Tightening torque

Valve body to transmission case bolts

: 10 N·m (1.0 kg-m, 7.5 lb-ft)

57) Connect couplers of wire-to-solenoid to solenoid valves.Bolt Length “a”Pieces

A 30 mm (1.20 in.) 7

B 31 mm (1.22 in.) 2

C 25 mm (0.98 in.) 2

2. Bolt A

4. Bolt C

5. Manual valve pin

6. Slot of manual shift shaft

Solenoid Valve Wire Color

A (No.1) White

B (No.2) Black

C (No.3) Red

D (No.4) Yellow

E (No.5) Brown

TCC (Lock-up) Orange

1. Solenoid valve No.1

2. Solenoid valve No.2

3. Solenoid valve No.3

4. Solenoid valve No.4

5. Solenoid valve No.5

6. Lock-up solenoid

Page 181 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-139

REQUIRED SERVICE MATERIAL

NOTE:

This kit includes the following items.

1. Storage case, 2. Operator’s manual, 3. SUZUKI scan tool (Tech-1A), 4. DLC cable,

5. Test lead / probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

MaterialRecommended SUZUKI product

(Part Number)Use

Automatic transmission fluid

An equivalent of DEXRON

®-III or

DEXRONR

®-IIEAutomatic transmission

Parts lubrication when installing

Sealant SUZUKI BOND No. 1215

(99000-31110)Case housing star-shaped recess

bolts

(3 pcs only)

Lithium grease SUZUKI SUPER GREASE C

(99000-25030)Retaining parts in place when

assembling

Oil seal lips

D-rings

O-rings

SUZUKI SUPER GREASE A

(99000-25010)Cable ends

Converter center cup

Thread lock cement THREAD LOCK 1322

(99000-32110)Final gear bolts

Torque converter housing bolts