battery replacement SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 66 of 447

7B-24 AUTOMATIC TRANSMISSION (4 A/T)

ELECTRONIC CONTROL SYSTEM DIAGNO-

SIS

TCM has on-board diagnostic system (a system self-diagnosis

function). Investigate where the trouble is by referring to “DIAG-

NOSTIC FLOW TABLE” and “DTC TABLE” in this section.

PRECAUTIONS IN DIAGNOSING TROUBLES

[PRECAUTIONS IN IDENTIFYING DTC]

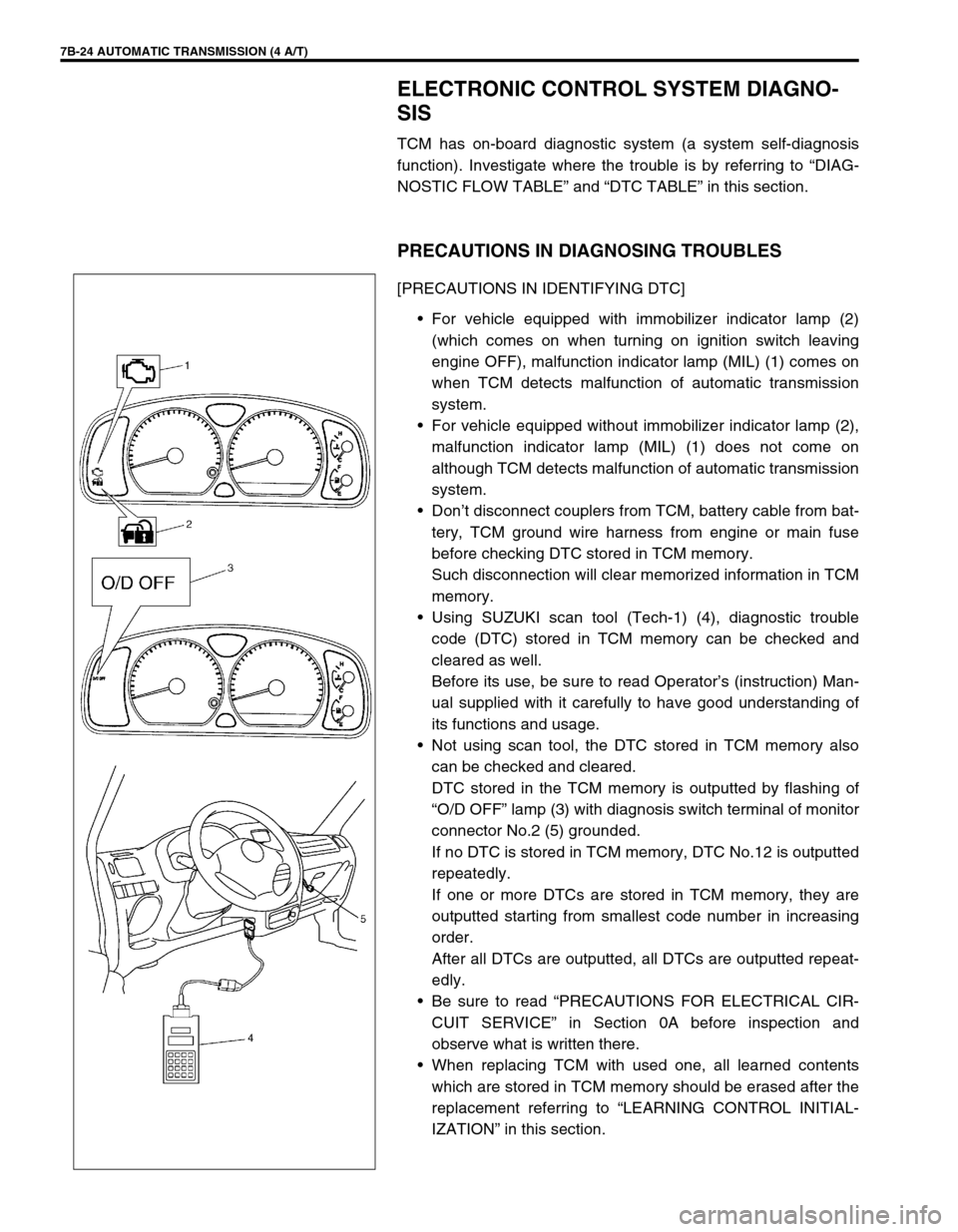

For vehicle equipped with immobilizer indicator lamp (2)

(which comes on when turning on ignition switch leaving

engine OFF), malfunction indicator lamp (MIL) (1) comes on

when TCM detects malfunction of automatic transmission

system.

For vehicle equipped without immobilizer indicator lamp (2),

malfunction indicator lamp (MIL) (1) does not come on

although TCM detects malfunction of automatic transmission

system.

Don’t disconnect couplers from TCM, battery cable from bat-

tery, TCM ground wire harness from engine or main fuse

before checking DTC stored in TCM memory.

Such disconnection will clear memorized information in TCM

memory.

Using SUZUKI scan tool (Tech-1) (4), diagnostic trouble

code (DTC) stored in TCM memory can be checked and

cleared as well.

Before its use, be sure to read Operator’s (instruction) Man-

ual supplied with it carefully to have good understanding of

its functions and usage.

Not using scan tool, the DTC stored in TCM memory also

can be checked and cleared.

DTC stored in the TCM memory is outputted by flashing of

“O/D OFF” lamp (3) with diagnosis switch terminal of monitor

connector No.2 (5) grounded.

If no DTC is stored in TCM memory, DTC No.12 is outputted

repeatedly.

If one or more DTCs are stored in TCM memory, they are

outputted starting from smallest code number in increasing

order.

After all DTCs are outputted, all DTCs are outputted repeat-

edly.

Be sure to read “PRECAUTIONS FOR ELECTRICAL CIR-

CUIT SERVICE” in Section 0A before inspection and

observe what is written there.

When replacing TCM with used one, all learned contents

which are stored in TCM memory should be erased after the

replacement referring to “LEARNING CONTROL INITIAL-

IZATION” in this section.

Page 254 of 447

8-10 BODY ELECTRICAL SYSTEM

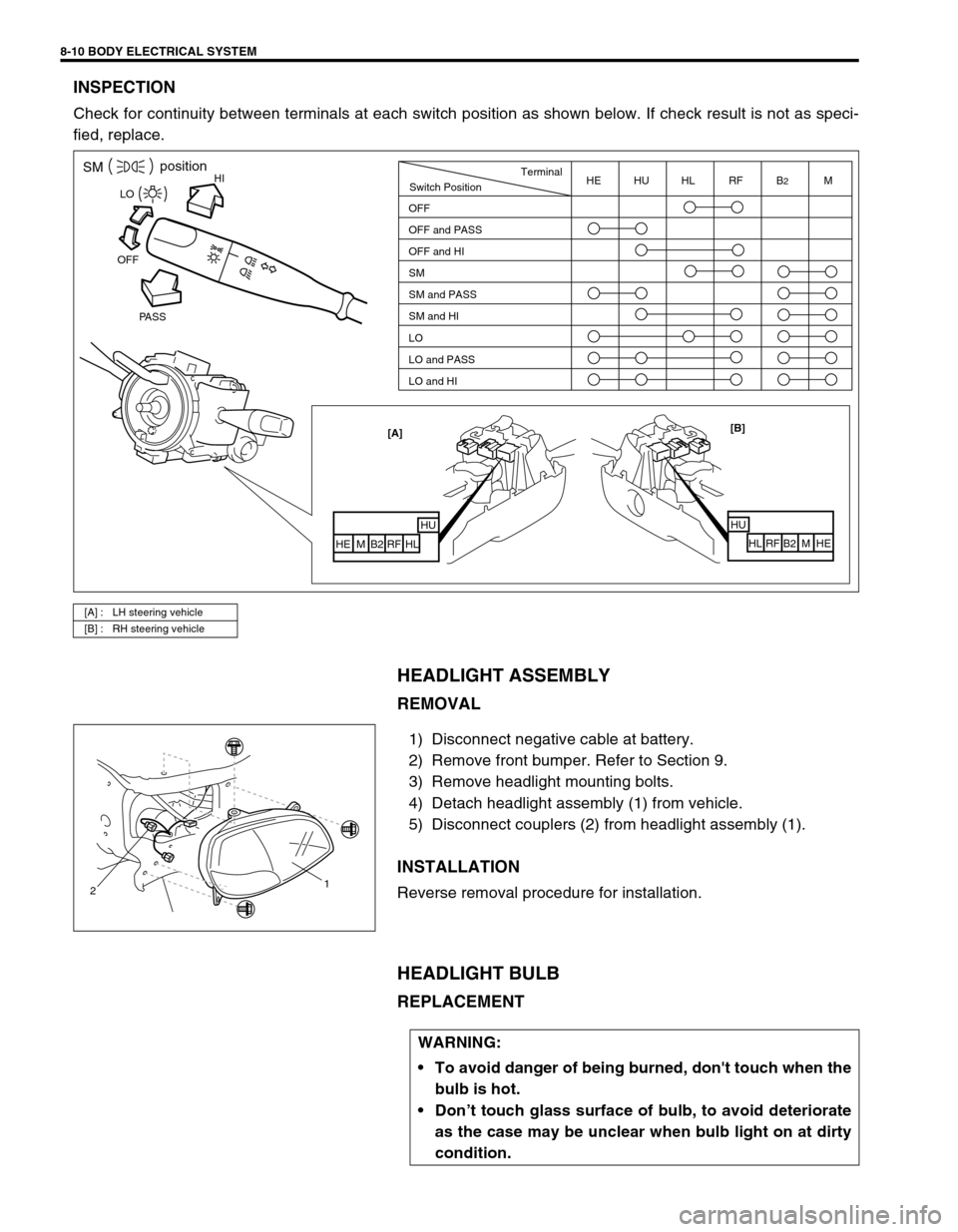

INSPECTION

Check for continuity between terminals at each switch position as shown below. If check result is not as speci-

fied, replace.

HEADLIGHT ASSEMBLY

REMOVAL

1) Disconnect negative cable at battery.

2) Remove front bumper. Refer to Section 9.

3) Remove headlight mounting bolts.

4) Detach headlight assembly (1) from vehicle.

5) Disconnect couplers (2) from headlight assembly (1).

INSTALLATION

Reverse removal procedure for installation.

HEADLIGHT BULB

REPLACEMENT

[A] : LH steering vehicle

[B] : RH steering vehicle

HISMposition

PASS OFFLO

[B]

HU

HL RF B2 M HE [A]

HUHL

RF B2 M HE

Switch PositionTerminal

OFF

OFF and PASS

OFF and HI

SM

SM and PASS

SM and HI

LO

LO and PASS

LO and HIHE HU HL RF B2M

21

WARNING:

To avoid danger of being burned, don't touch when the

bulb is hot.

Don’t touch glass surface of bulb, to avoid deteriorate

as the case may be unclear when bulb light on at dirty

condition.

Page 274 of 447

8-30 BODY ELECTRICAL SYSTEM

RECEIVER

INSPECTION

Check voltage between each terminal and body ground with con-

necting controller coupler. If check result is not as specified,

replace.

Receiver specification

Reference :

TRANSMITTER

REPLACEMEMT OF THE BATTERY

If the transmitter becomes unreliable, replace the battery.

As the battery power is consumed, the operation distance will be

shorter.

1) Remove screw.

2) Use a small coin or flat blade screwdriver to separate the

bottom half from the top half of the transmitter.

3) Replace the battery with the new one. Make sure the posi-

tive (+) side of battery faces up. For battery replacement,

use type CR2032 or equivalent.

4) Put the two halves back together and install a screw.

5) Make sure the door locks can be operated with the transmit-

ter. Terminal Voltage (V) Condition

B10 - 14Always

SIG“A”

(Refer to the figure)Approx. 75 ms while trans-

mitter signal received

5Other condition than above

mentioned

GND 0 Always

1. Receiver

2. Receiver coupler (receiver side)

Page 300 of 447

8G-22 IMMOBILIZER CONTROL SYSTEM

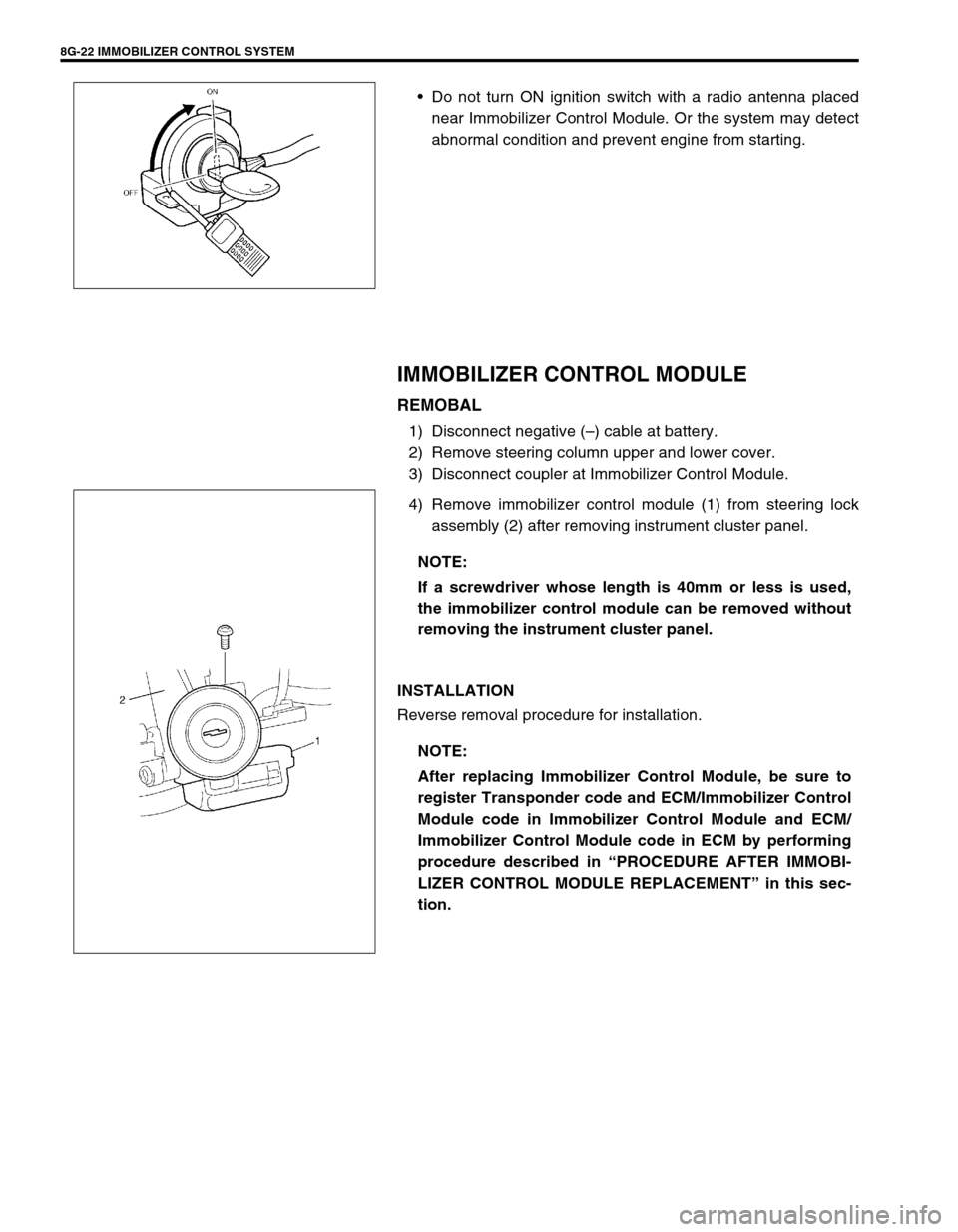

Do not turn ON ignition switch with a radio antenna placed

near Immobilizer Control Module. Or the system may detect

abnormal condition and prevent engine from starting.

IMMOBILIZER CONTROL MODULE

REMOBAL

1) Disconnect negative (–) cable at battery.

2) Remove steering column upper and lower cover.

3) Disconnect coupler at Immobilizer Control Module.

4) Remove immobilizer control module (1) from steering lock

assembly (2) after removing instrument cluster panel.

INSTALLATION

Reverse removal procedure for installation.

NOTE:

If a screwdriver whose length is 40mm or less is used,

the immobilizer control module can be removed without

removing the instrument cluster panel.

NOTE:

After replacing Immobilizer Control Module, be sure to

register Transponder code and ECM/Immobilizer Control

Module code in Immobilizer Control Module and ECM/

Immobilizer Control Module code in ECM by performing

procedure described in “PROCEDURE AFTER IMMOBI-

LIZER CONTROL MODULE REPLACEMENT” in this sec-

tion.

Page 305 of 447

BODY SERVICE 9-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 9

BODY SERVICE

CONTENTS

GLASS, WINDOWS AND MIRRORS ................. 9-2

FRONT DOOR GLASS ................................... 9-2

FRONT DOOR WINDOW REGULATOR ........ 9-6

DOOR MIRROR .......................................... 9-7

REAR DOOR GLASS (IF EQUIPPED) ....... 9-8

REAR DOOR WINDOW REGULATOR ........ 9-11

WINDOW SHIELD ........................................ 9-12

QUARTER WINDOW .................................... 9-17

BACK DOOR GLASS .................................... 9-18

BODY STRUCTURE......................................... 9-19

FRONT DOOR ASSEMBLY .......................... 9-19

REAR DOOR ASSEMBLY ............................ 9-22

BACK DOOR ASSEMBLY ............................ 9-23

HOOD ........................................................... 9-25

FRONT FENDER .......................................... 9-26

FRONT BUMPER AND REAR BUMPER...... 9-27

ROOF RAIL (IF EQUIPPED) ......................... 9-28

BODY DIMENSIONS .................................... 9-29

ENGINE ROOM ........................................ 9-29

BACK DOOR ............................................. 9-30

SIDE BODY ............................................... 9-31UNDER BODY .......................................... 9-34

PANEL CLEARANCE ................................... 9-36

INSTRUMENTATION AND DRIVER

INFORMATION................................................. 9-38

INSTRUMENT PANEL .................................. 9-38

SEATS .............................................................. 9-40

FRONT SEAT ............................................... 9-40

REAR SEAT.................................................. 9-41

SECURITY AND LOCKS ................................. 9-42

FRONT DOOR LOCK ASSEMBLY............... 9-42

REAR DOOR LOCK ASSEMBLY (IF

EQUIPPED) .................................................. 9-44

BACK DOOR LOCK ASSEMBLY ................. 9-45

KEY CODING ............................................... 9-46

KEY USAGE AND IDENTIFICATION ....... 9-46

IGNITION SWITCH LOCK CYLINDER ..... 9-47

EXTERIOR AND INTERIOR TRIM ................... 9-47

FLOOR CARPET .......................................... 9-47

HEAD LINING ............................................... 9-48

PAINT AND COATINGS .................................. 9-50 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

When body servicing, if shock may be applied to air bag system component parts, remove those

parts beforehand. (Refer to Section 10B.)

NOTE:

Fasteners are important attaching parts in that they could affect the performance of vital components

and systems, and / or could result in major repair expense. They must be replaced with one of the

same part number of with an equivalent part if replacement becomes necessary.

Do not use a replacement part of lesser quality or substitute a design. Torque values must be used as

specified during reassembly to assure proper retention of these parts.

Page 383 of 447

AIR BAG SYSTEM 10B-9

AIR BAG DIAGNOSTIC SYSTEM CHECK

The diagnostic procedures used in this section are designed to find and repair air bag system malfunctions.

To get the best results, it is important to use the diagnostic flow tables and follow the sequence listed below.

1) Perform the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE.

(The AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE must be the starting point of any air bag sys-

tem diagnosis.

The AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE checks for proper “AIR BAG” warning lamp

operation through “AIR BAG” warning lamp and whether air bag diagnostic trouble codes exist.)

2) Refer to the proper diagnostic table as directed by the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW

TABLE.

(The AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE will lead you to the correct table to diagnose

any air bag system malfunctions. Bypassing these procedures may result in extended diagnostic time, incor-

rect diagnosis and incorrect parts replacement.)

3) Repeat the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE after any repair or diagnostic proce-

dures have been performed.

(Performing the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE after all repair or diagnostic pro-

cedures will ensure that the repair has been made correctly and that no other malfunctions exist.)

FLOW TABLE TEST DESCRIPTION

STEP 1 : Check that “AIR BAG” warning lamp lights.

STEP 2 : Check that “AIR BAG” warning lamp lights.

STEP 3 : Check diagnosis switch circuit.

STEP 4 : Check that “AIR BAG” warning lamp flashes 6 times after ignition switch is turned ON.

STEP 6 : Check that history codes are in SDM memory. (using SUZUKI scan tool)

STEP 7 : Check that history codes are in SDM memory. (using monitor coupler)

STEP 9 : Check that current code is in SDM memory. (using SUZUKI scan tool)

STEP 10 : Check that current code is in SDM memory. (using monitor coupler)WARNING:

To avoid deployment when troubleshooting the air bag system, do not use electrical test equipment

such as a battery powered or AC powered voltmeter, ohmmeter, etc., or any type of electrical equip-

ment other than that specified in this manual. Do not use a non-powered probe type tester.

Instructions in this manual must be followed carefully, otherwise personal injury may result.

CAUTION:

The order in which diagnostic trouble codes are diagnosed is very important. Failure to diagnose the

diagnostic trouble codes in the order specified may result in extended diagnostic time, incorrect diag-

nosis and incorrect parts replacement.