bulb SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 245 of 447

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8

8D

8E

9

10

10A

10B

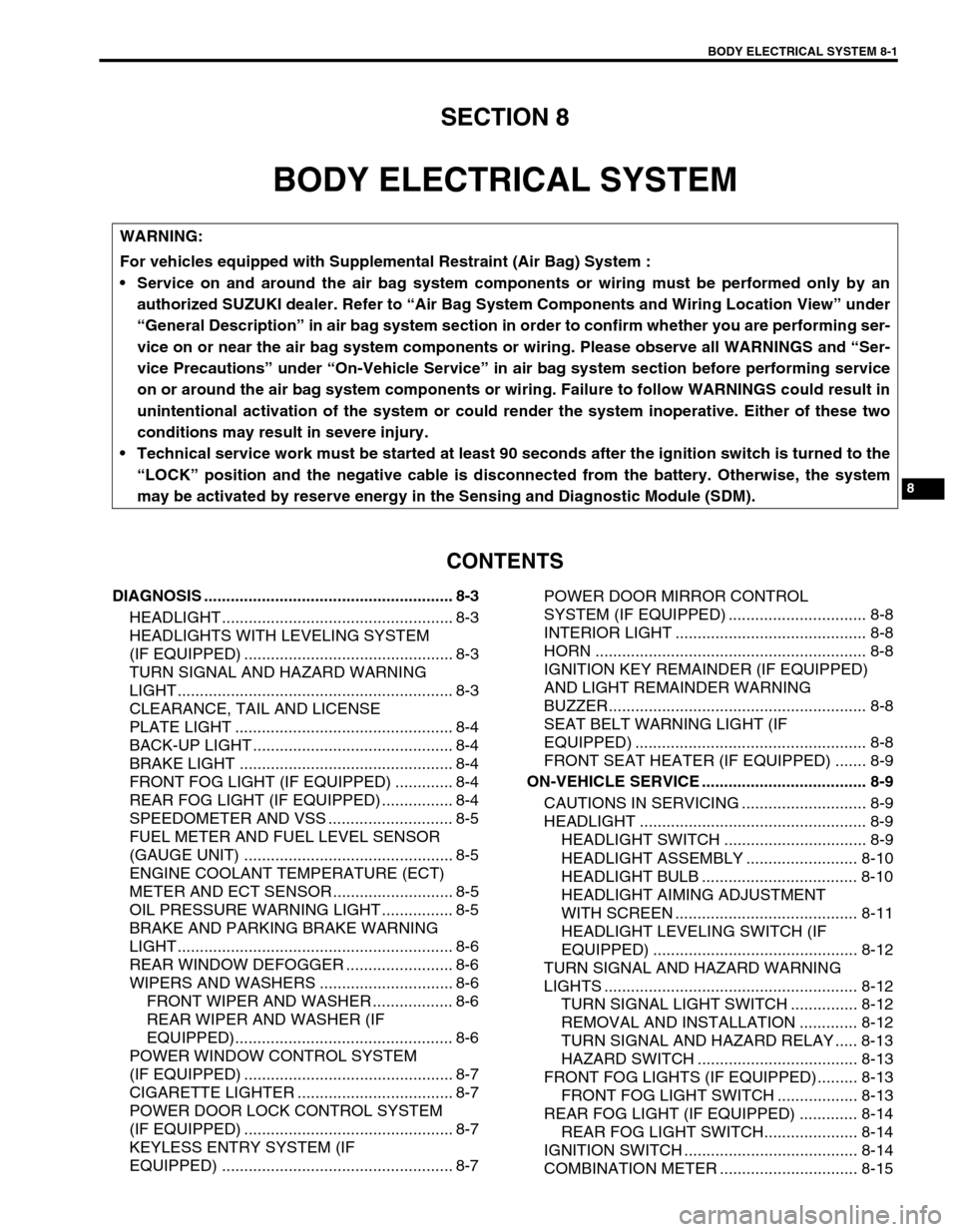

SECTION 8

BODY ELECTRICAL SYSTEM

CONTENTS

DIAGNOSIS ........................................................ 8-3

HEADLIGHT .................................................... 8-3

HEADLIGHTS WITH LEVELING SYSTEM

(IF EQUIPPED) ............................................... 8-3

TURN SIGNAL AND HAZARD WARNING

LIGHT .............................................................. 8-3

CLEARANCE, TAIL AND LICENSE

PLATE LIGHT ................................................. 8-4

BACK-UP LIGHT ............................................. 8-4

BRAKE LIGHT ................................................ 8-4

FRONT FOG LIGHT (IF EQUIPPED) ............. 8-4

REAR FOG LIGHT (IF EQUIPPED) ................ 8-4

SPEEDOMETER AND VSS ............................ 8-5

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT) ............................................... 8-5

ENGINE COOLANT TEMPERATURE (ECT)

METER AND ECT SENSOR ........................... 8-5

OIL PRESSURE WARNING LIGHT ................ 8-5

BRAKE AND PARKING BRAKE WARNING

LIGHT .............................................................. 8-6

REAR WINDOW DEFOGGER ........................ 8-6

WIPERS AND WASHERS .............................. 8-6

FRONT WIPER AND WASHER .................. 8-6

REAR WIPER AND WASHER (IF

EQUIPPED)................................................. 8-6

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

CIGARETTE LIGHTER ................................... 8-7

POWER DOOR LOCK CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) .................................................... 8-7POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) ............................... 8-8

INTERIOR LIGHT ........................................... 8-8

HORN ............................................................. 8-8

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER.......................................................... 8-8

SEAT BELT WARNING LIGHT (IF

EQUIPPED) .................................................... 8-8

FRONT SEAT HEATER (IF EQUIPPED) ....... 8-9

ON-VEHICLE SERVICE ..................................... 8-9

CAUTIONS IN SERVICING ............................ 8-9

HEADLIGHT ................................................... 8-9

HEADLIGHT SWITCH ................................ 8-9

HEADLIGHT ASSEMBLY ......................... 8-10

HEADLIGHT BULB ................................... 8-10

HEADLIGHT AIMING ADJUSTMENT

WITH SCREEN ......................................... 8-11

HEADLIGHT LEVELING SWITCH (IF

EQUIPPED) .............................................. 8-12

TURN SIGNAL AND HAZARD WARNING

LIGHTS ......................................................... 8-12

TURN SIGNAL LIGHT SWITCH ............... 8-12

REMOVAL AND INSTALLATION ............. 8-12

TURN SIGNAL AND HAZARD RELAY ..... 8-13

HAZARD SWITCH .................................... 8-13

FRONT FOG LIGHTS (IF EQUIPPED)......... 8-13

FRONT FOG LIGHT SWITCH .................. 8-13

REAR FOG LIGHT (IF EQUIPPED) ............. 8-14

REAR FOG LIGHT SWITCH..................... 8-14

IGNITION SWITCH ....................................... 8-14

COMBINATION METER ............................... 8-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 247 of 447

BODY ELECTRICAL SYSTEM 8-3

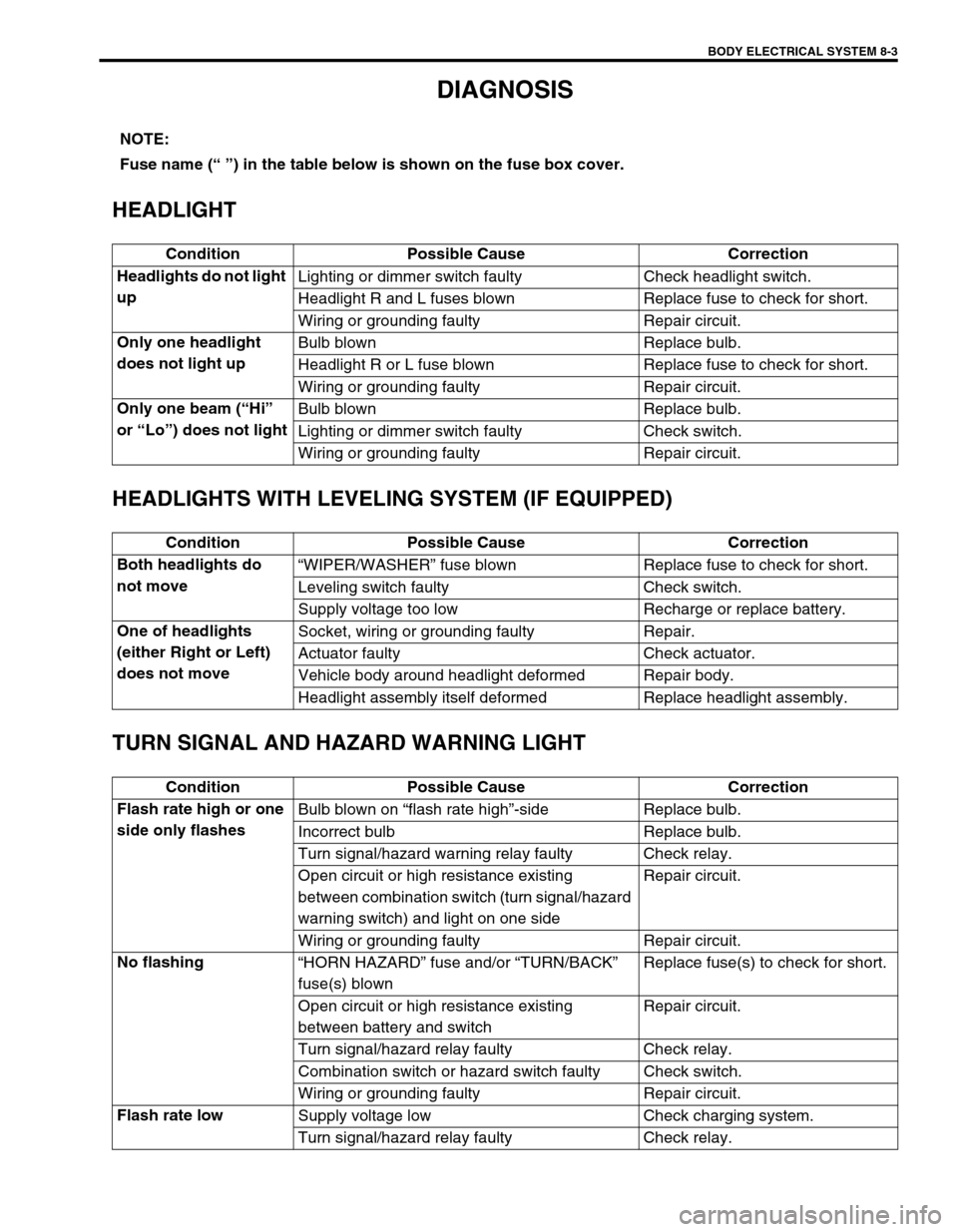

DIAGNOSIS

HEADLIGHT

HEADLIGHTS WITH LEVELING SYSTEM (IF EQUIPPED)

TURN SIGNAL AND HAZARD WARNING LIGHT

NOTE:

Fuse name (“ ”) in the table below is shown on the fuse box cover.

Condition Possible Cause Correction

Headlights do not light

upLighting or dimmer switch faulty Check headlight switch.

Headlight R and L fuses blown Replace fuse to check for short.

Wiring or grounding faulty Repair circuit.

Only one headlight

does not light upBulb blown Replace bulb.

Headlight R or L fuse blown Replace fuse to check for short.

Wiring or grounding faulty Repair circuit.

Only one beam (“Hi”

or “Lo”) does not lightBulb blown Replace bulb.

Lighting or dimmer switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Both headlights do

not move“WIPER/WASHER” fuse blown Replace fuse to check for short.

Leveling switch faulty Check switch.

Supply voltage too low Recharge or replace battery.

One of headlights

(either Right or Left)

does not moveSocket, wiring or grounding faulty Repair.

Actuator faulty Check actuator.

Vehicle body around headlight deformed Repair body.

Headlight assembly itself deformed Replace headlight assembly.

Condition Possible Cause Correction

Flash rate high or one

side only flashesBulb blown on “flash rate high”-side Replace bulb.

Incorrect bulb Replace bulb.

Turn signal/hazard warning relay faulty Check relay.

Open circuit or high resistance existing

between combination switch (turn signal/hazard

warning switch) and light on one sideRepair circuit.

Wiring or grounding faulty Repair circuit.

No flashing

“HORN HAZARD” fuse and/or “TURN/BACK”

fuse(s) blownReplace fuse(s) to check for short.

Open circuit or high resistance existing

between battery and switchRepair circuit.

Turn signal/hazard relay faulty Check relay.

Combination switch or hazard switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Flash rate low

Supply voltage low Check charging system.

Turn signal/hazard relay faulty Check relay.

Page 248 of 447

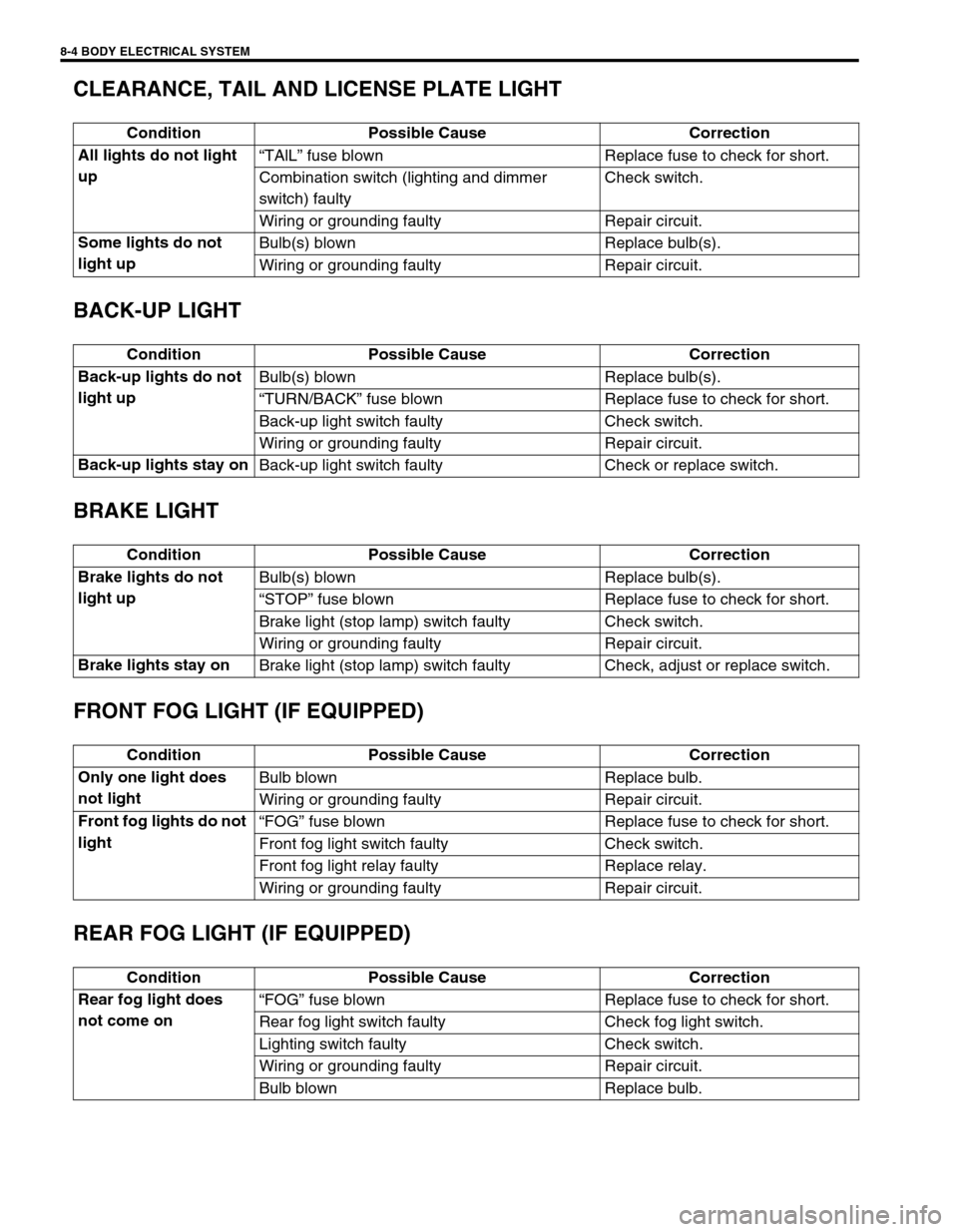

8-4 BODY ELECTRICAL SYSTEM

CLEARANCE, TAIL AND LICENSE PLATE LIGHT

BACK-UP LIGHT

BRAKE LIGHT

FRONT FOG LIGHT (IF EQUIPPED)

REAR FOG LIGHT (IF EQUIPPED)

Condition Possible Cause Correction

All lights do not light

up“TAlL” fuse blown Replace fuse to check for short.

Combination switch (lighting and dimmer

switch) faultyCheck switch.

Wiring or grounding faulty Repair circuit.

Some lights do not

light upBulb(s) blown Replace bulb(s).

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Back-up lights do not

light upBulb(s) blown Replace bulb(s).

“TURN/BACK” fuse blown Replace fuse to check for short.

Back-up light switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Back-up lights stay on

Back-up light switch faulty Check or replace switch.

Condition Possible Cause Correction

Brake lights do not

light upBulb(s) blown Replace bulb(s).

“STOP” fuse blown Replace fuse to check for short.

Brake light (stop lamp) switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Brake lights stay on

Brake light (stop lamp) switch faulty Check, adjust or replace switch.

Condition Possible Cause Correction

Only one light does

not lightBulb blown Replace bulb.

Wiring or grounding faulty Repair circuit.

Front fog lights do not

light“FOG” fuse blown Replace fuse to check for short.

Front fog light switch faulty Check switch.

Front fog light relay faulty Replace relay.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Rear fog light does

not come on“FOG” fuse blown Replace fuse to check for short.

Rear fog light switch faulty Check fog light switch.

Lighting switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Bulb blown Replace bulb.

Page 249 of 447

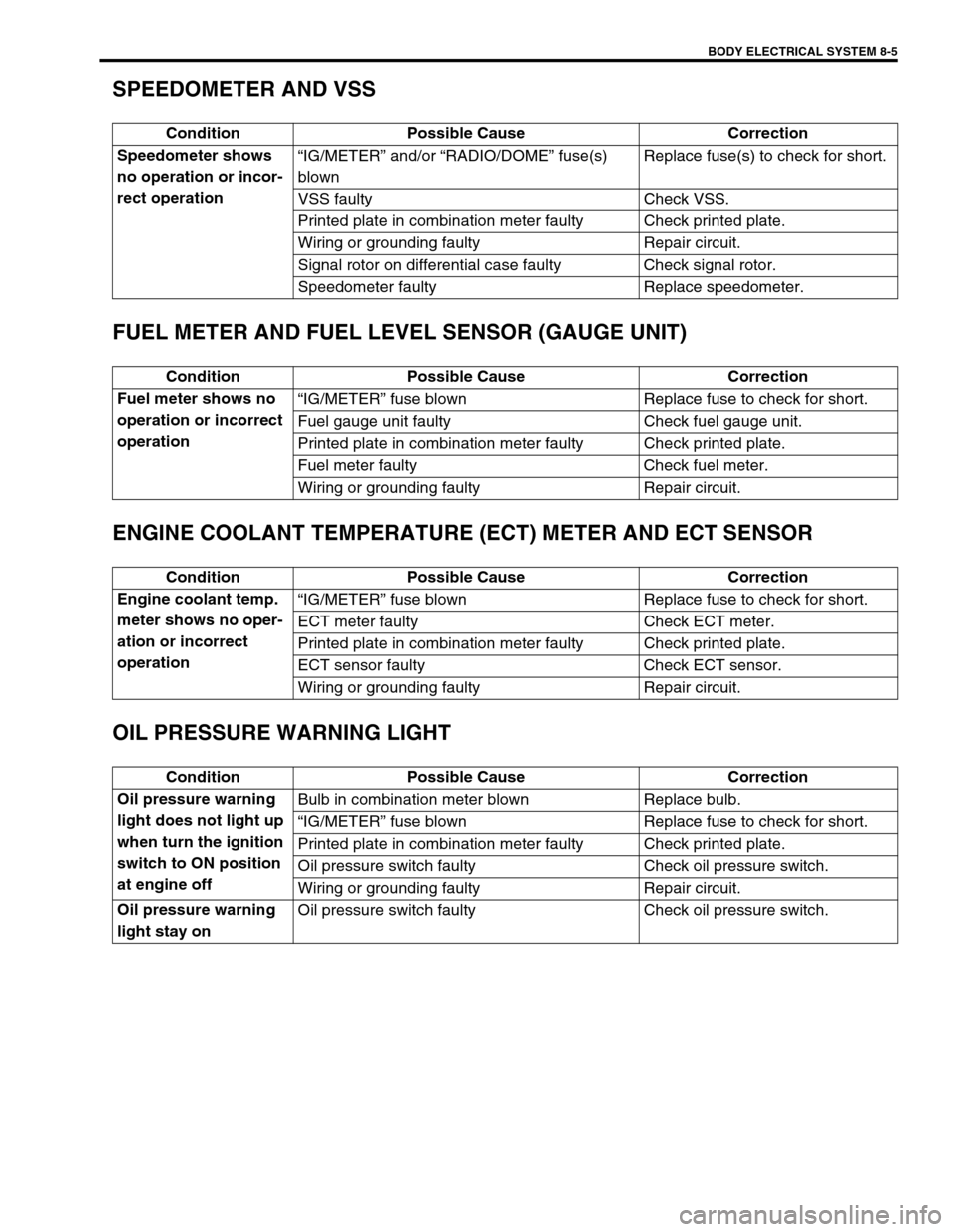

BODY ELECTRICAL SYSTEM 8-5

SPEEDOMETER AND VSS

FUEL METER AND FUEL LEVEL SENSOR (GAUGE UNIT)

ENGINE COOLANT TEMPERATURE (ECT) METER AND ECT SENSOR

OIL PRESSURE WARNING LIGHT

Condition Possible Cause Correction

Speedometer shows

no operation or incor-

rect operation“IG/METER” and/or “RADIO/DOME” fuse(s)

blownReplace fuse(s) to check for short.

VSS faulty Check VSS.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Signal rotor on differential case faulty Check signal rotor.

Speedometer faulty Replace speedometer.

Condition Possible Cause Correction

Fuel meter shows no

operation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

Fuel gauge unit faulty Check fuel gauge unit.

Printed plate in combination meter faulty Check printed plate.

Fuel meter faulty Check fuel meter.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Engine coolant temp.

meter shows no oper-

ation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

ECT meter faulty Check ECT meter.

Printed plate in combination meter faulty Check printed plate.

ECT sensor faulty Check ECT sensor.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Oil pressure warning

light does not light up

when turn the ignition

switch to ON position

at engine offBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Printed plate in combination meter faulty Check printed plate.

Oil pressure switch faulty Check oil pressure switch.

Wiring or grounding faulty Repair circuit.

Oil pressure warning

light stay onOil pressure switch faulty Check oil pressure switch.

Page 250 of 447

8-6 BODY ELECTRICAL SYSTEM

BRAKE AND PARKING BRAKE WARNING LIGHT

REAR WINDOW DEFOGGER

WIPERS AND WASHERS

FRONT WIPER AND WASHER

REAR WIPER AND WASHER (IF EQUIPPED)

Condition Possible Cause Correction

Brake warning light

does not light up

(when fluid low level

and/or parking brake

pull up)Bulb in combination meter blown Replace bulb.

Printed plate in combination meter faulty Check printed plate.

“IG/METER” fuse blown Replace fuse to check for short.

Brake fluid level switch faulty Check brake fluid level switch.

Parking brake switch faulty Check parking brake switch.

Wiring or grounding faulty Repair circuit.

Brake warning light

does not light up

when cranking (when

turned ignition switch

to ST position)Ignition switch faulty Check ignition switch.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Brake warning light

stay onBrake fluid level switch and/or parking brake

switch faultyCheck switch.

Condition Possible Cause Correction

Defogger does not

operate“REAR DEFG” fuse blown Replace fuse to check for short.

Heat wire faulty Repair heat wire.

Rear window defogger switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Wiper malfunctions

“WIPER/WASHER” fuse blown Replace fuse to check for short.

Wiper motor faulty Check wiper motor.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty Repair circuit.

Washer malfunctions

Washer hose or nozzle clogged Clean or repair clogged hose or

nozzle.

“WIPER/WASHER” fuse blown Replace fuse to check for short.

Washer motor faulty Check washer motor.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty Repair circuit.

Page 252 of 447

8-8 BODY ELECTRICAL SYSTEM

POWER DOOR MIRROR CONTROL SYSTEM (IF EQUIPPED)

INTERIOR LIGHT

HORN

IGNITION KEY REMAINDER (IF EQUIPPED) AND LIGHT REMAINDER WARN-

ING BUZZER

SEAT BELT WARNING LIGHT (IF EQUIPPED)

Condition Possible Cause Correction

All power mirrors do

not operate“CIGAR” fuse blown Replace fuse to check for short.

Power door mirror switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

One power mirror

does not operatePower door mirror switch faulty Check switch.

Actuator (power door mirror motor) faulty Check actuator.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Interior lights do not

light upBulbs blown Replace bulbs.

“RADIO/DOME” fuse blown Replace fuse to check for short.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

One of interior light

does not light upBulb blown Replace bulb.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

Condition Possible Cause Correction

Horn does not operate

“HORN/HAZARD” fuse blown Replace fuse to check for short.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay.

Horn faulty Replace horn.

Condition Possible Cause Correction

Ignition key remain-

der and light remain-

der warning buzzer

shows no soundingBuzzer faulty Replace buzzer.

Wiring or grounding faulty Repair circuit.

Driver side door switch faulty Check door switch.

Ignition switch faulty Check ignition switch.

Condition Possible Cause Correction

Seat belt warning light

does not light upBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Seat belt switch faulty Check seat belt switch.

Wiring or grounding faulty Repair circuit.

Page 254 of 447

8-10 BODY ELECTRICAL SYSTEM

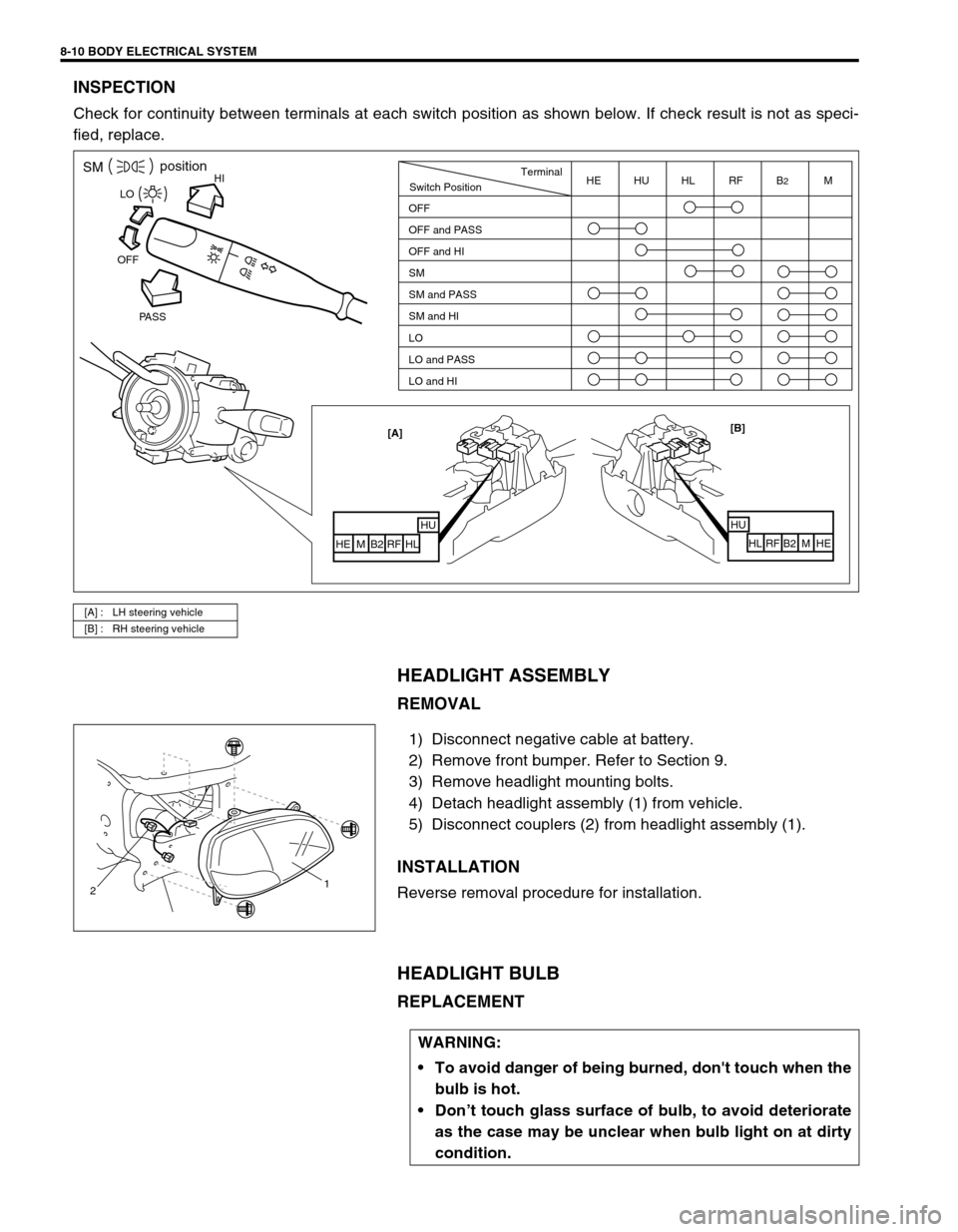

INSPECTION

Check for continuity between terminals at each switch position as shown below. If check result is not as speci-

fied, replace.

HEADLIGHT ASSEMBLY

REMOVAL

1) Disconnect negative cable at battery.

2) Remove front bumper. Refer to Section 9.

3) Remove headlight mounting bolts.

4) Detach headlight assembly (1) from vehicle.

5) Disconnect couplers (2) from headlight assembly (1).

INSTALLATION

Reverse removal procedure for installation.

HEADLIGHT BULB

REPLACEMENT

[A] : LH steering vehicle

[B] : RH steering vehicle

HISMposition

PASS OFFLO

[B]

HU

HL RF B2 M HE [A]

HUHL

RF B2 M HE

Switch PositionTerminal

OFF

OFF and PASS

OFF and HI

SM

SM and PASS

SM and HI

LO

LO and PASS

LO and HIHE HU HL RF B2M

21

WARNING:

To avoid danger of being burned, don't touch when the

bulb is hot.

Don’t touch glass surface of bulb, to avoid deteriorate

as the case may be unclear when bulb light on at dirty

condition.

Page 255 of 447

BODY ELECTRICAL SYSTEM 8-11

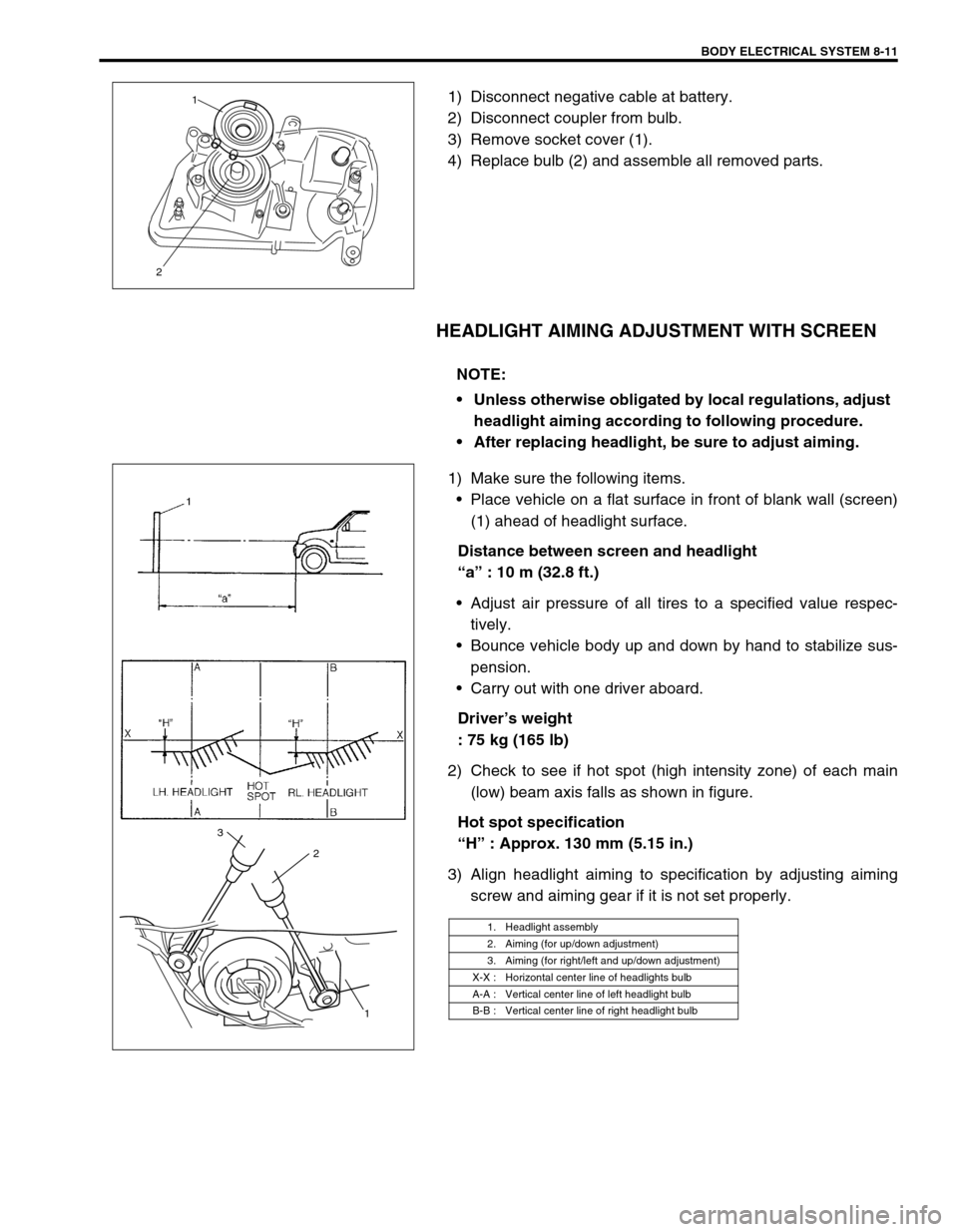

1) Disconnect negative cable at battery.

2) Disconnect coupler from bulb.

3) Remove socket cover (1).

4) Replace bulb (2) and assemble all removed parts.

HEADLIGHT AIMING ADJUSTMENT WITH SCREEN

1) Make sure the following items.

Place vehicle on a flat surface in front of blank wall (screen)

(1) ahead of headlight surface.

Distance between screen and headlight

“a” : 10 m (32.8 ft.)

Adjust air pressure of all tires to a specified value respec-

tively.

Bounce vehicle body up and down by hand to stabilize sus-

pension.

Carry out with one driver aboard.

Driver’s weight

: 75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each main

(low) beam axis falls as shown in figure.

Hot spot specification

“H” : Approx. 130 mm (5.15 in.)

3) Align headlight aiming to specification by adjusting aiming

screw and aiming gear if it is not set properly.

21

NOTE:

Unless otherwise obligated by local regulations, adjust

headlight aiming according to following procedure.

After replacing headlight, be sure to adjust aiming.

1. Headlight assembly

2. Aiming (for up/down adjustment)

3. Aiming (for right/left and up/down adjustment)

X-X : Horizontal center line of headlights bulb

A-A : Vertical center line of left headlight bulb

B-B : Vertical center line of right headlight bulb

1 2 3

Page 257 of 447

BODY ELECTRICAL SYSTEM 8-13

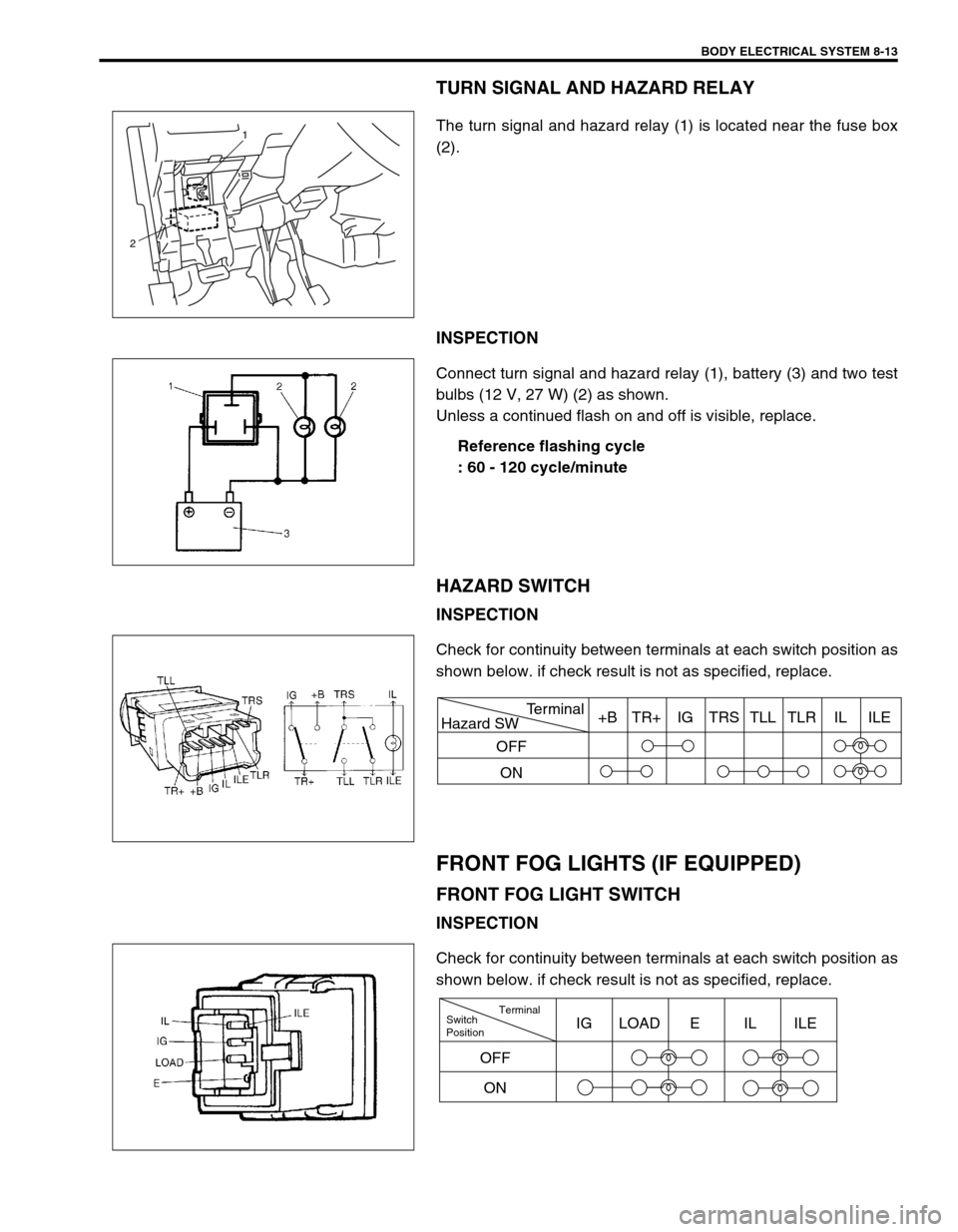

TURN SIGNAL AND HAZARD RELAY

The turn signal and hazard relay (1) is located near the fuse box

(2).

INSPECTION

Connect turn signal and hazard relay (1), battery (3) and two test

bulbs (12 V, 27 W) (2) as shown.

Unless a continued flash on and off is visible, replace.

Reference flashing cycle

: 60 - 120 cycle/minute

HAZARD SWITCH

INSPECTION

Check for continuity between terminals at each switch position as

shown below. if check result is not as specified, replace.

FRONT FOG LIGHTS (IF EQUIPPED)

FRONT FOG LIGHT SWITCH

INSPECTION

Check for continuity between terminals at each switch position as

shown below. if check result is not as specified, replace.

1

2

Hazard SWTerminal

OFF

ON+B TR+ IG TRS TLL TLR IL ILE

Switch

PositionTerminal

ONIG LOAD E IL ILE

OFF

Page 260 of 447

8-16 BODY ELECTRICAL SYSTEM

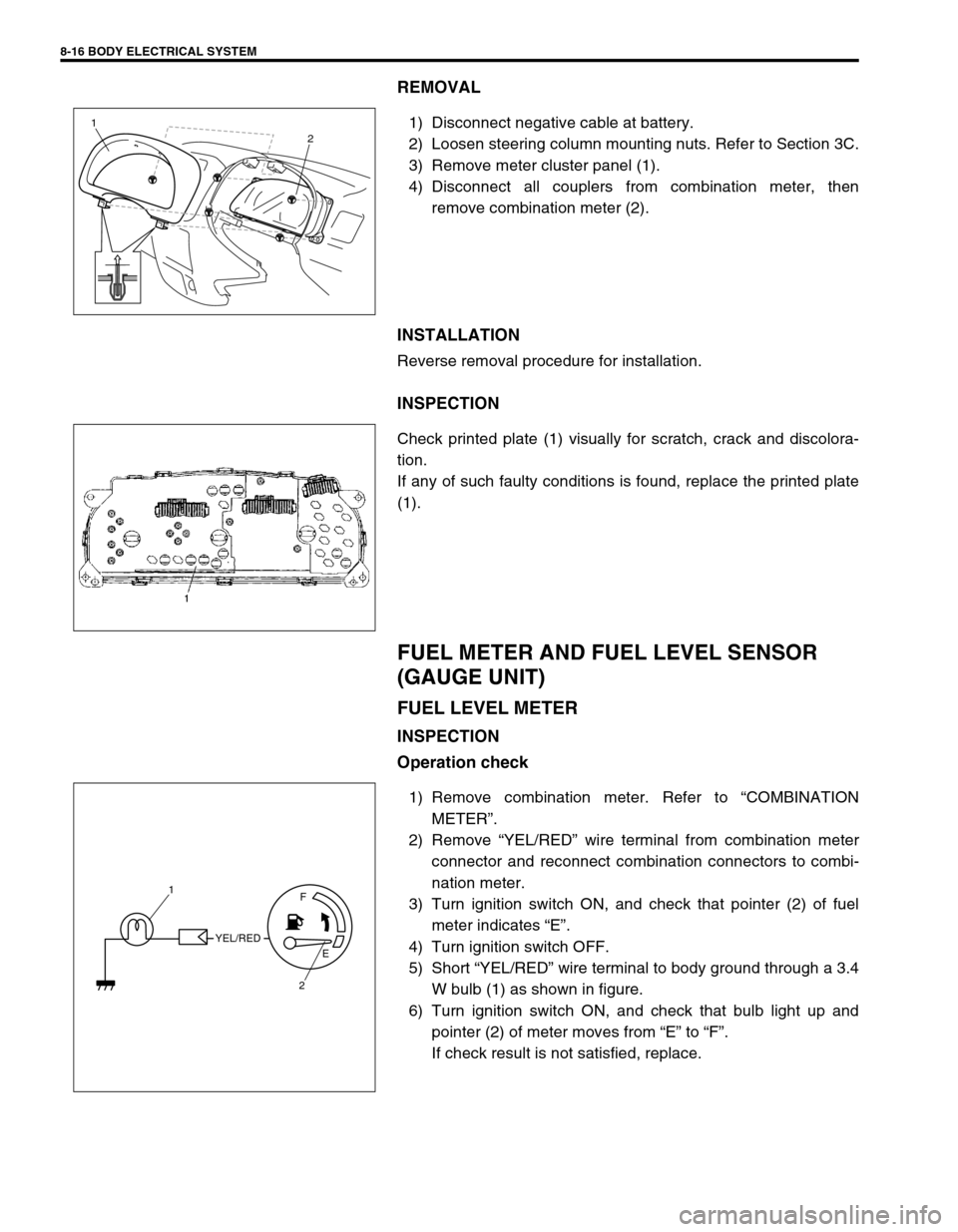

REMOVAL

1) Disconnect negative cable at battery.

2) Loosen steering column mounting nuts. Refer to Section 3C.

3) Remove meter cluster panel (1).

4) Disconnect all couplers from combination meter, then

remove combination meter (2).

INSTALLATION

Reverse removal procedure for installation.

INSPECTION

Check printed plate (1) visually for scratch, crack and discolora-

tion.

If any of such faulty conditions is found, replace the printed plate

(1).

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT)

FUEL LEVEL METER

INSPECTION

Operation check

1) Remove combination meter. Refer to “COMBINATION

METER”.

2) Remove “YEL/RED” wire terminal from combination meter

connector and reconnect combination connectors to combi-

nation meter.

3) Turn ignition switch ON, and check that pointer (2) of fuel

meter indicates “E”.

4) Turn ignition switch OFF.

5) Short “YEL/RED” wire terminal to body ground through a 3.4

W bulb (1) as shown in figure.

6) Turn ignition switch ON, and check that bulb light up and

pointer (2) of meter moves from “E” to “F”.

If check result is not satisfied, replace.

1

2

YEL/REDF

E

2 1