Section 1A SUZUKI SWIFT 2004 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2004, Model line: SWIFT, Model: SUZUKI SWIFT 2004 2.GPages: 1496, PDF Size: 34.44 MB

Page 371 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-8

Thermostat Removal and InstallationS7RS0B1606007

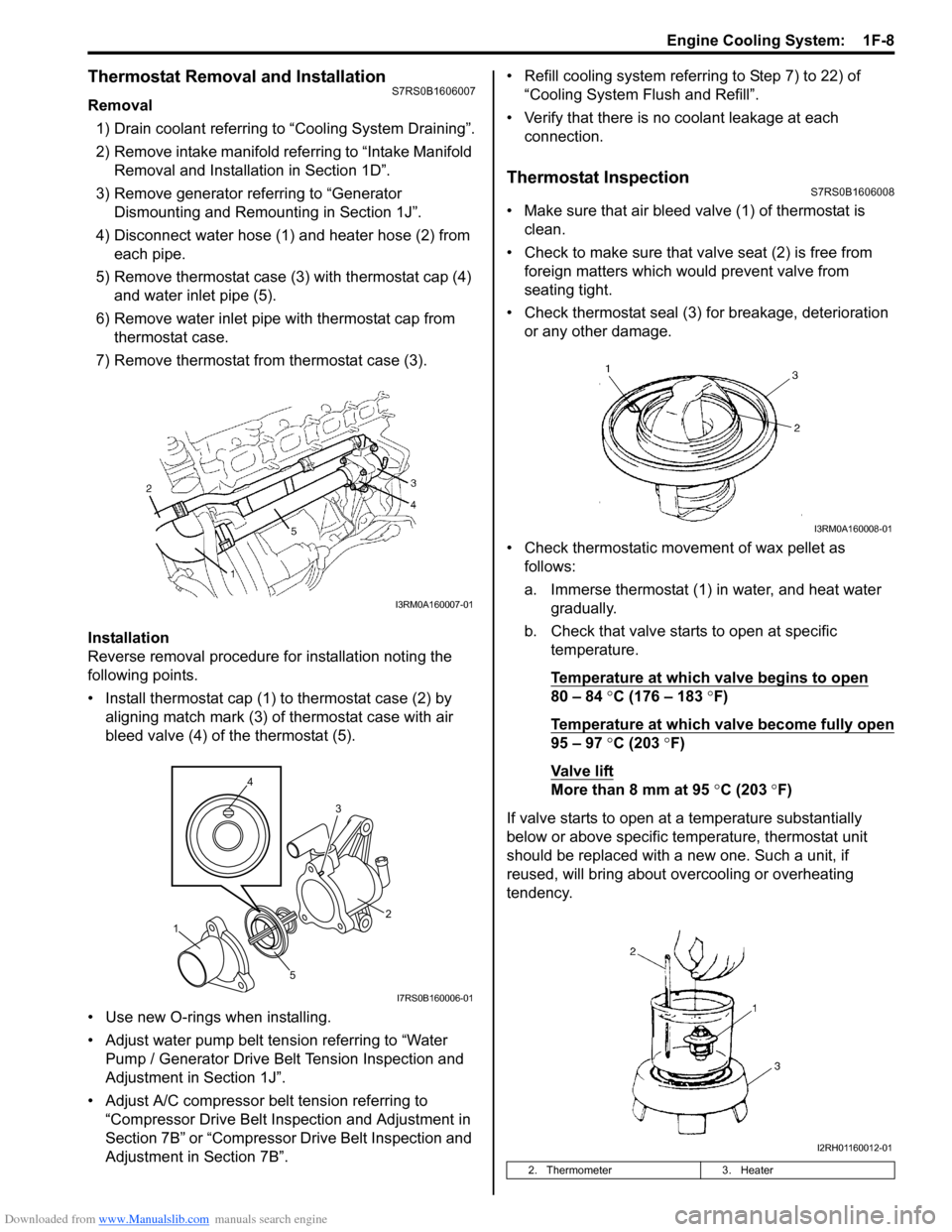

Removal1) Drain coolant referring to “Cooling System Draining”.

2) Remove intake manifold referring to “Intake Manifold Removal and Installa tion in Section 1D”.

3) Remove generator referring to “Generator Dismounting and Remounting in Section 1J”.

4) Disconnect water hose (1) and heater hose (2) from each pipe.

5) Remove thermostat case (3) with thermostat cap (4)

and water inlet pipe (5).

6) Remove water inlet pipe with thermostat cap from thermostat case.

7) Remove thermostat from thermostat case (3).

Installation

Reverse removal procedure for installation noting the

following points.

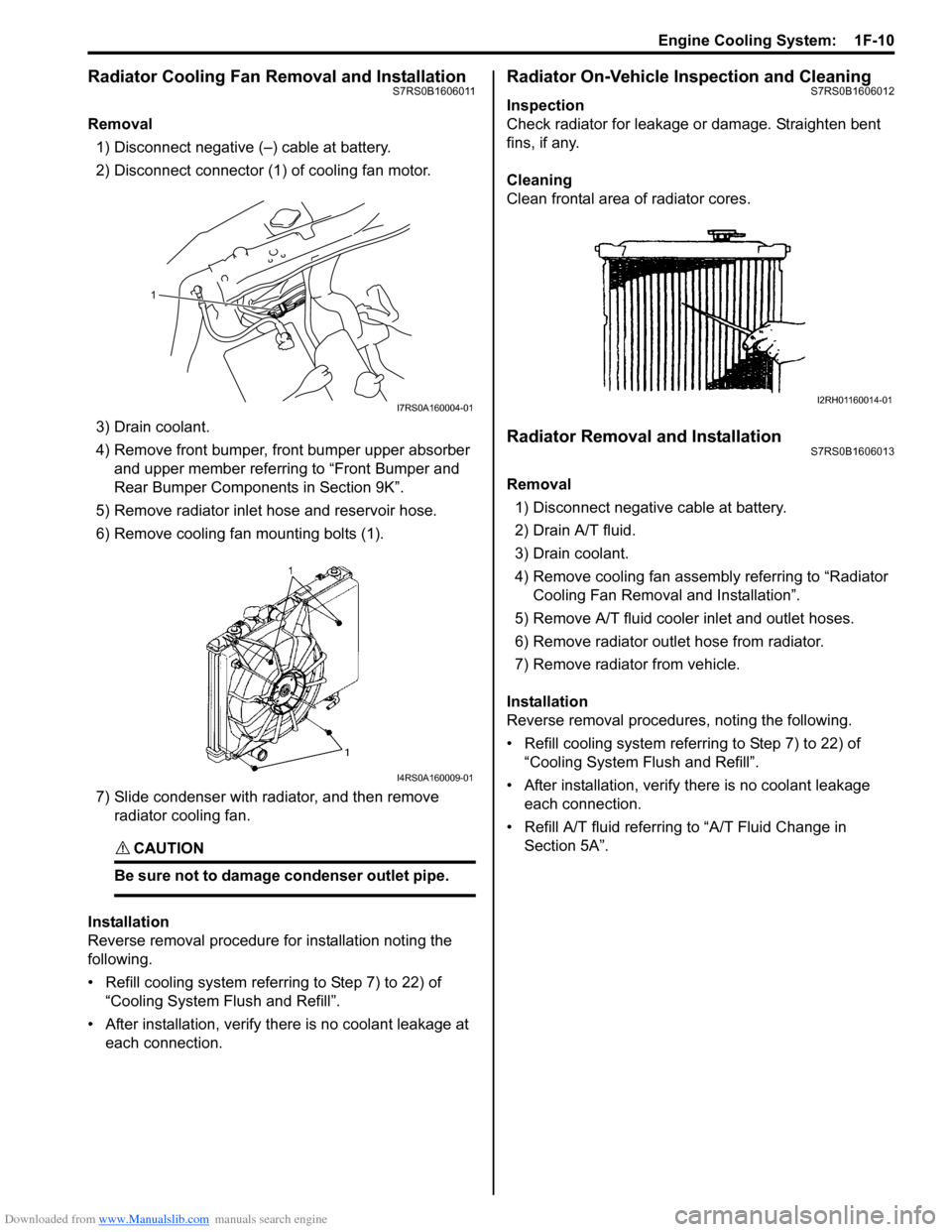

• Install thermostat cap (1) to thermostat case (2) by aligning match mark (3) of thermostat case with air

bleed valve (4) of the thermostat (5).

• Use new O-rings when installing.

• Adjust water pump belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment in Section 1J”.

• Adjust A/C compressor belt tension referring to “Compressor Drive Belt Inspection and Adjustment in

Section 7B” or “Compressor Drive Belt Inspection and

Adjustment in Section 7B”. • Refill cooling system referrin

g to Step 7) to 22) of

“Cooling System Flush and Refill”.

• Verify that there is no coolant leakage at each connection.

Thermostat InspectionS7RS0B1606008

• Make sure that air bleed valve (1) of thermostat is clean.

• Check to make sure that va lve seat (2) is free from

foreign matters which would prevent valve from

seating tight.

• Check thermostat seal (3) for breakage, deterioration or any other damage.

• Check thermostatic movement of wax pellet as follows:

a. Immerse thermostat (1) in water, and heat water gradually.

b. Check that valve starts to open at specific temperature.

Temperature at which valve begins to open

80 – 84 °C (176 – 183 °F)

Temperature at which valve become fully open

95 – 97 °C (203 °F)

Va l v e l i ft

More than 8 mm at 95 °C (203 ° F)

If valve starts to open at a temperature substantially

below or above specific temperature, thermostat unit

should be replaced with a new one. Such a unit, if

reused, will bring about ov ercooling or overheating

tendency.

I3RM0A160007-01

4

5 3

1 2

I7RS0B160006-01

2. Thermometer

3. Heater

I3RM0A160008-01

I2RH01160012-01

Page 373 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-10

Radiator Cooling Fan Removal and InstallationS7RS0B1606011

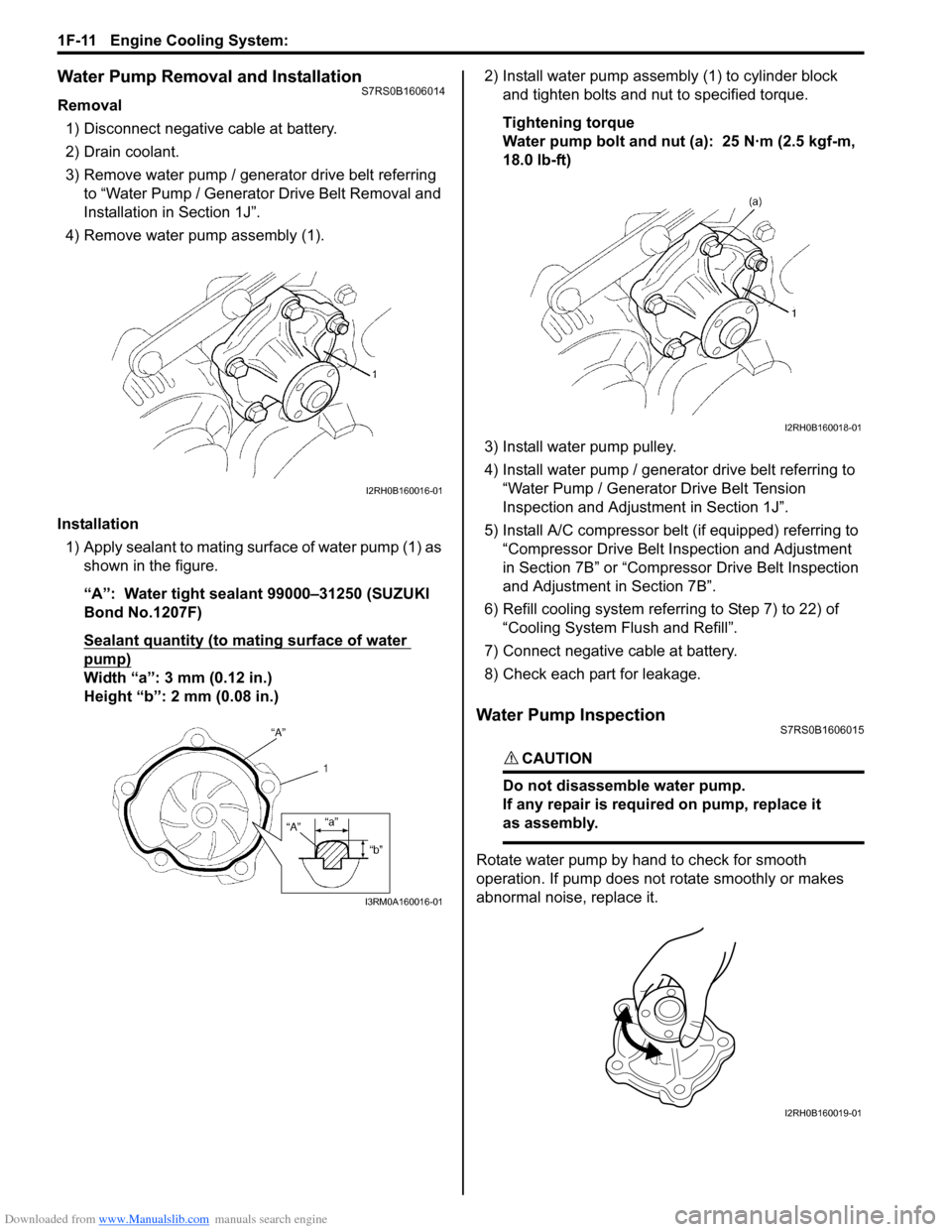

Removal1) Disconnect negative (–) cable at battery.

2) Disconnect connector (1) of cooling fan motor.

3) Drain coolant.

4) Remove front bumper, front bumper upper absorber and upper member referring to “Front Bumper and

Rear Bumper Componen ts in Section 9K”.

5) Remove radiator inlet hose and reservoir hose.

6) Remove cooling fan mounting bolts (1).

7) Slide condenser with radiator, and then remove radiator cooling fan.

CAUTION!

Be sure not to damage condenser outlet pipe.

Installation

Reverse removal procedure for installation noting the

following.

• Refill cooling system referring to Step 7) to 22) of “Cooling System Fl ush and Refill”.

• After installation, verify there is no coolant leakage at each connection.

Radiator On-Vehicle Inspection and CleaningS7RS0B1606012

Inspection

Check radiator for leakage or damage. Straighten bent

fins, if any.

Cleaning

Clean frontal area of radiator cores.

Radiator Removal and InstallationS7RS0B1606013

Removal

1) Disconnect negative cable at battery.

2) Drain A/T fluid.

3) Drain coolant.

4) Remove cooling fan assemb ly referring to “Radiator

Cooling Fan Removal and Installation”.

5) Remove A/T fluid cooler inlet and outlet hoses.

6) Remove radiator outlet hose from radiator.

7) Remove radiator from vehicle.

Installation

Reverse removal procedures, noting the following.

• Refill cooling system referrin g to Step 7) to 22) of

“Cooling System Flush and Refill”.

• After installation, verify there is no coolant leakage each connection.

• Refill A/T fluid referring to “A/T Fluid Change in

Section 5A”.

1

I7RS0A160004-01

I4RS0A160009-01

I2RH01160014-01

Page 374 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-11 Engine Cooling System:

Water Pump Removal and InstallationS7RS0B1606014

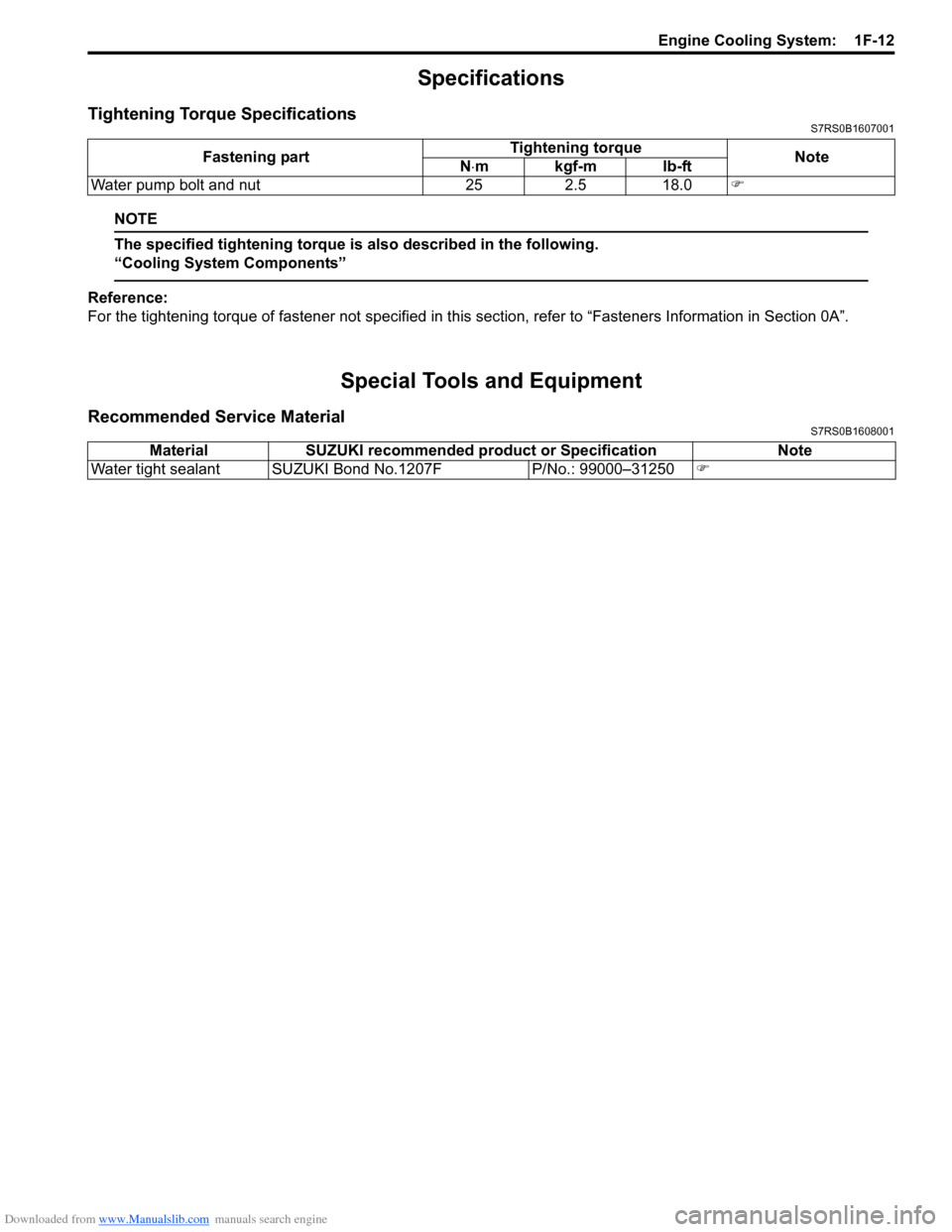

Removal1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

4) Remove water pump assembly (1).

Installation 1) Apply sealant to mating surface of water pump (1) as shown in the figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.) 2) Install water pump assemb

ly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

5) Install A/C compressor belt (if equipped) referring to “Compressor Drive Belt Inspection and Adjustment

in Section 7B” or “Compressor Drive Belt Inspection

and Adjustment in Section 7B”.

6) Refill cooling system referri ng to Step 7) to 22) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

Water Pump InspectionS7RS0B1606015

CAUTION!

Do not disassemble water pump.

If any repair is requir ed on pump, replace it

as assembly.

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

I2RH0B160016-01

I3RM0A160016-01

I2RH0B160018-01

I2RH0B160019-01

Page 375 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-12

Specifications

Tightening Torque SpecificationsS7RS0B1607001

NOTE

The specified tightening torque is also described in the following.

“Cooling System Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B1608001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Water pump bolt and nut 25 2.5 18.0 �)

MaterialSUZUKI recommended product or Specification Note

Water tight sealant SUZUKI Bond No.1207F P/No.: 99000–31250�)

Page 378 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-3 Fuel System:

4) Check that battery voltage is 11 V or more.

5) Measure fuel pressure at each condition.If measured pressure is out of specification, refer to

“Fuel Pressure Check in Section 1A” and check each

possibly defective part. Replace if found defective.

a) Turn ignition switch ON to operate fuel pump and after 2 seconds turn it OFF. Repeat this 3 or 4

times and then check fuel pressure.

Fuel pressure specification

With fuel pump operating and engine

stopped: 270 – 310 kPa (2.7 – 3.1 kg/cm2, 38.4

– 44.0 psi)

b) Start engine and warm it up to normal operating temperature, and measure fuel pressure at

idling.

Fuel pressure specification

At specified idle speed: 270 – 310 kPa (2.7 –

3.1 kg/cm2, 38.4 – 44.0 psi)

c) Stop engine, and measure fuel pressure at one minute after stopping.

Fuel pressure specification

With 1 min. after engine (fuel pump) stop

(Pressure reduces as time passes): Over 300

kPa (3.0 kg/cm

2, 42.7 psi)

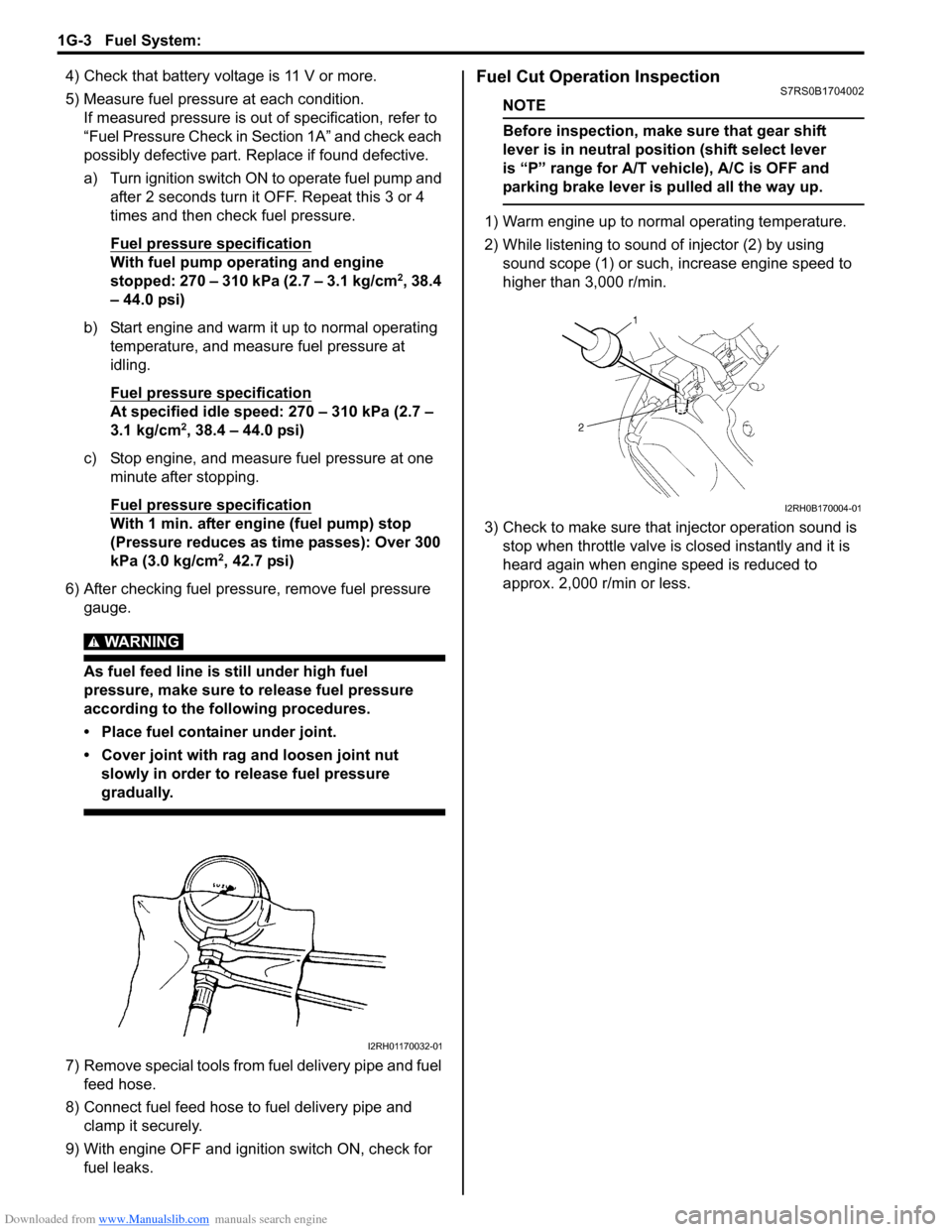

6) After checking fuel pressure, remove fuel pressure gauge.

WARNING!

As fuel feed line is still under high fuel

pressure, make sure to release fuel pressure

according to the following procedures.

• Place fuel container under joint.

• Cover joint with rag and loosen joint nut slowly in order to release fuel pressure

gradually.

7) Remove special tools from fuel delivery pipe and fuel feed hose.

8) Connect fuel feed hose to fuel delivery pipe and clamp it securely.

9) With engine OFF and ignition switch ON, check for fuel leaks.

Fuel Cut Operation InspectionS7RS0B1704002

NOTE

Before inspection, make sure that gear shift

lever is in neutral positi on (shift select lever

is “P” range for A/T vehicle), A/C is OFF and

parking brake lever is pulled all the way up.

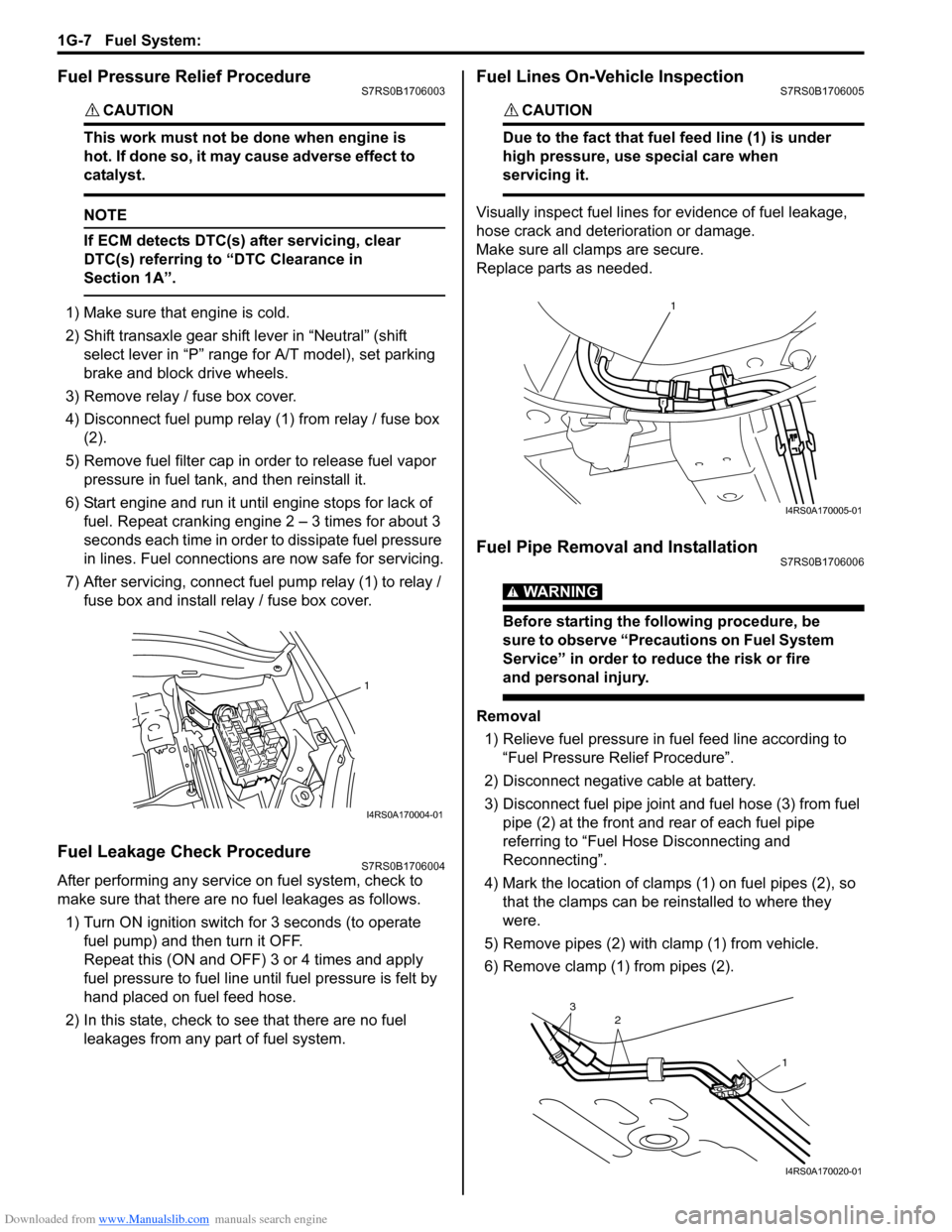

1) Warm engine up to normal operating temperature.

2) While listening to sound of injector (2) by using sound scope (1) or such, increase engine speed to

higher than 3,000 r/min.

3) Check to make sure that injector operation sound is stop when throttle valve is closed instantly and it is

heard again when engine speed is reduced to

approx. 2,000 r/min or less.

I2RH01170032-01

I2RH0B170004-01

Page 382 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

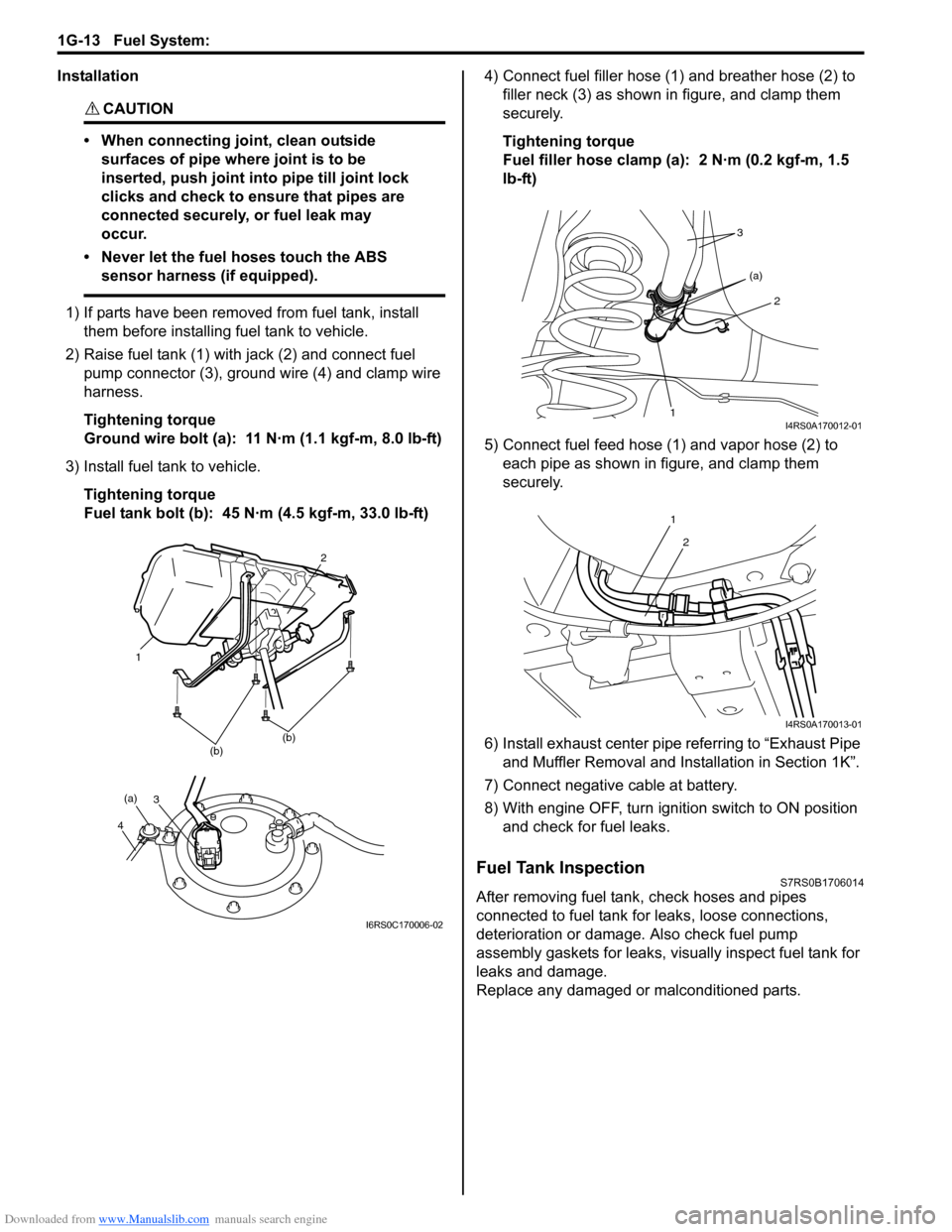

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

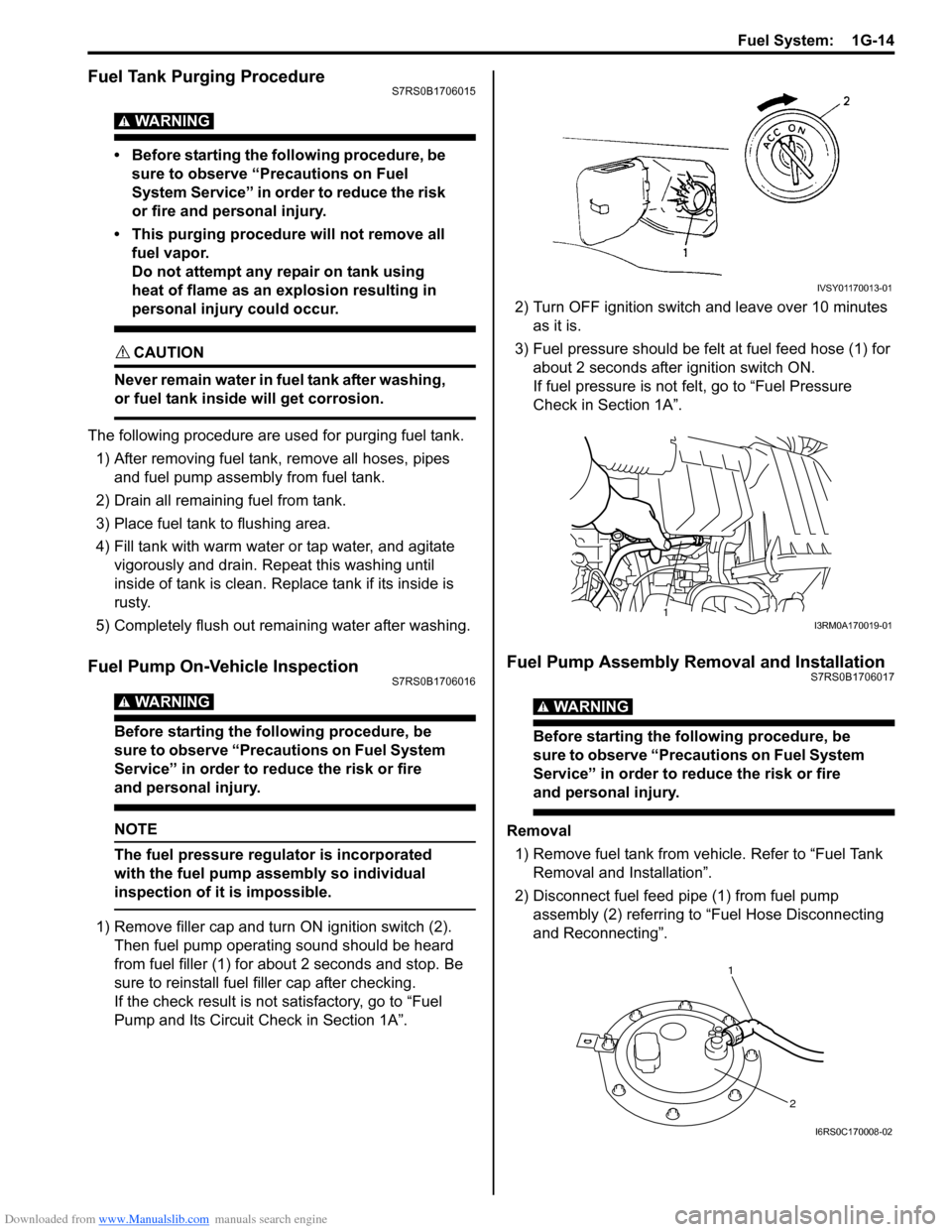

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 389 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

Fuel Tank Purging ProcedureS7RS0B1706015

WARNING!

• Before starting the following procedure, be sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

or fire and personal injury.

• This purging procedure will not remove all fuel vapor.

Do not attempt any repair on tank using

heat of flame as an explosion resulting in

personal injury could occur.

CAUTION!

Never remain water in fu el tank after washing,

or fuel tank inside will get corrosion.

The following procedure are used for purging fuel tank.

1) After removing fuel tank, remove all hoses, pipes and fuel pump assembly from fuel tank.

2) Drain all remaining fuel from tank.

3) Place fuel tank to flushing area.

4) Fill tank with warm water or tap water, and agitate

vigorously and drain. Repeat this washing until

inside of tank is clean. Replace tank if its inside is

rusty.

5) Completely flush out rema ining water after washing.

Fuel Pump On-Vehicle InspectionS7RS0B1706016

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

NOTE

The fuel pressure regulator is incorporated

with the fuel pump assembly so individual

inspection of it is impossible.

1) Remove filler cap and turn ON ignition switch (2).

Then fuel pump operating sound should be heard

from fuel filler (1) for about 2 seconds and stop. Be

sure to reinstall fuel filler cap after checking.

If the check result is not satisfactory, go to “Fuel

Pump and Its Circuit Check in Section 1A”. 2) Turn OFF ignition switch and leave over 10 minutes

as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for about 2 seconds after ignition switch ON.

If fuel pressure is not felt, go to “Fuel Pressure

Check in Section 1A”.

Fuel Pump Assembly Removal and InstallationS7RS0B1706017

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Remove fuel tank from vehicle. Refer to “Fuel Tank Removal and Installation”.

2) Disconnect fuel feed pipe (1) from fuel pump assembly (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

IVSY01170013-01

1I3RM0A170019-01

1

2

I6RS0C170008-02

Page 390 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

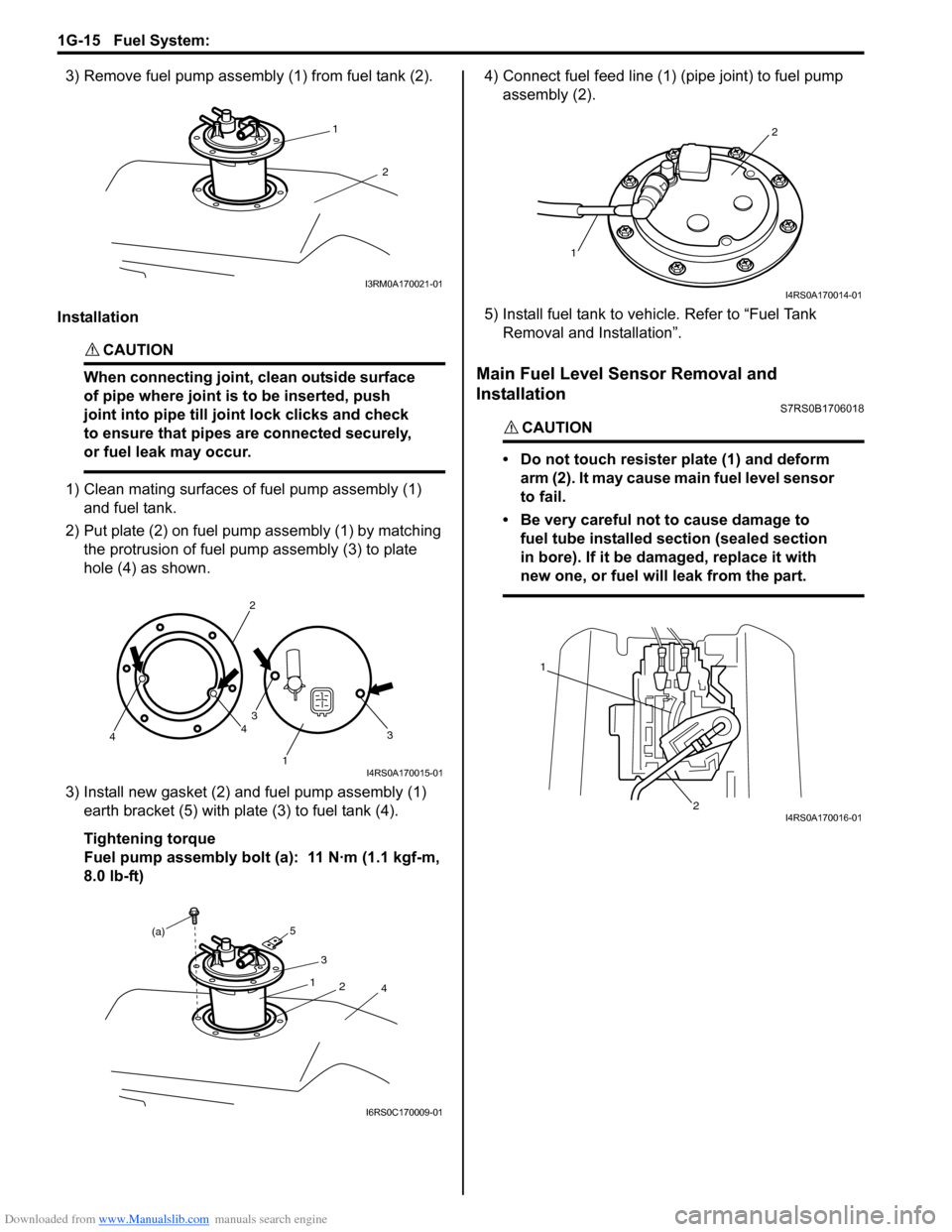

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01

Page 391 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-16

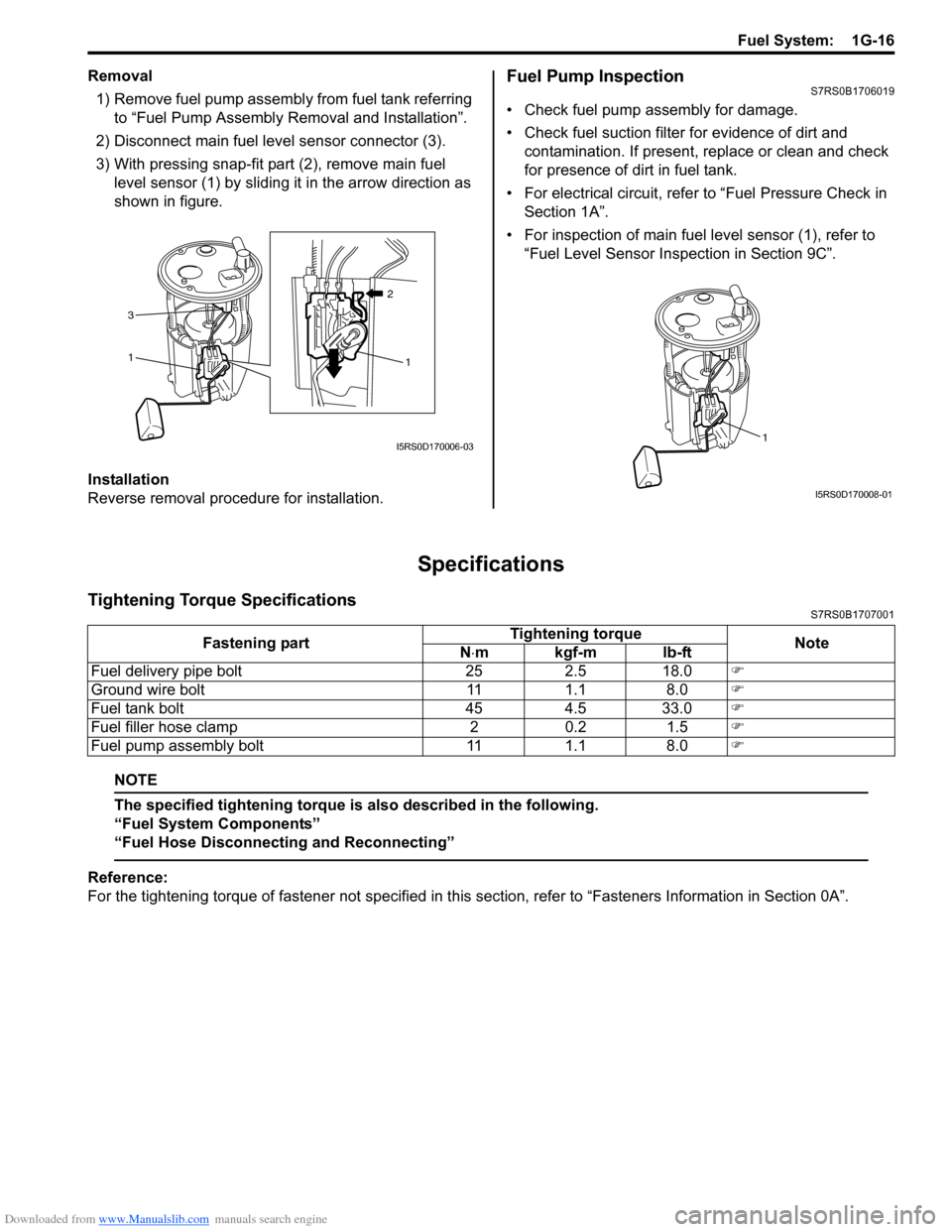

Removal1) Remove fuel pump assembly from fuel tank referring to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.Fuel Pump InspectionS7RS0B1706019

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and contamination. If present, replace or clean and check

for presence of dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pressure Check in Section 1A”.

• For inspection of main fuel level sensor (1), refer to “Fuel Level Sensor Inspection in Section 9C”.

Specifications

Tightening Torque SpecificationsS7RS0B1707001

NOTE

The specified tightening torque is also described in the following.

“Fuel System Components”

“Fuel Hose Disconnecting and Reconnecting”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1

21

3

I5RS0D170006-031

I5RS0D170008-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Fuel delivery pipe bolt 25 2.5 18.0 �)

Ground wire bolt 11 1.1 8.0 �)

Fuel tank bolt 45 4.5 33.0 �)

Fuel filler hose clamp 2 0.2 1.5 �)

Fuel pump assembly bolt 11 1.1 8.0 �)