BCM SUZUKI SWIFT 2004 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2004, Model line: SWIFT, Model: SUZUKI SWIFT 2004 2.GPages: 1496, PDF Size: 34.44 MB

Page 230 of 1496

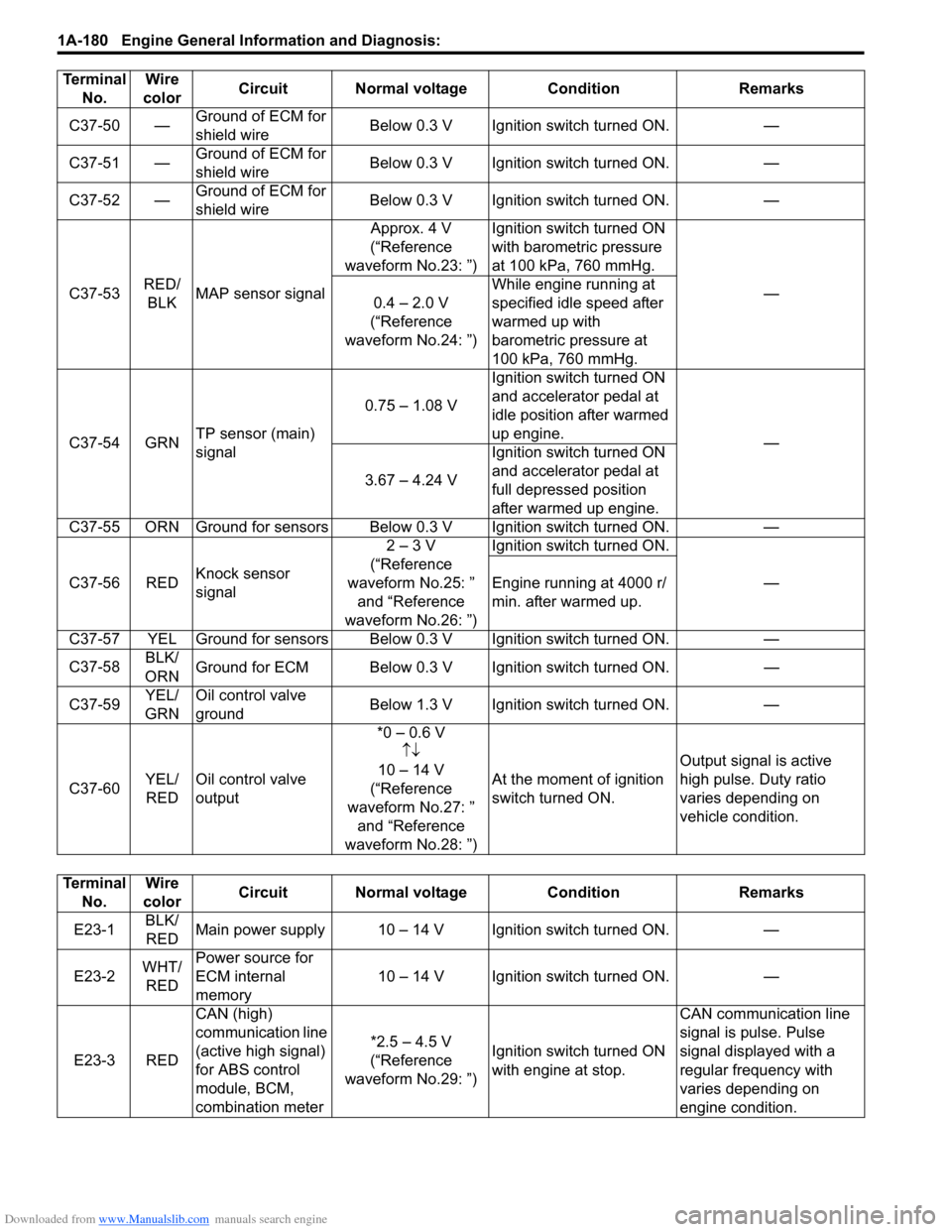

Downloaded from www.Manualslib.com manuals search engine 1A-180 Engine General Information and Diagnosis:

C37-50 —Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-51 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-52 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-53 RED/

BLK MAP sensor signal Approx. 4 V

(“Reference

waveform No.23: ”) Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

—

0.4 – 2.0 V

(“Reference

waveform No.24: ”) While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C37-54 GRN TP sensor (main)

signal 0.75 – 1.08 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.67 – 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-56 RED Knock sensor

signal 2 – 3 V

(“Reference

waveform No.25: ” and “Reference

waveform No.26: ”) Ignition switch turned ON.

—

Engine running at 4000 r/

min. after warmed up.

C37-57 YEL Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-58 BLK/

ORN Ground for ECM Below 0.3 V Ignition switch turned ON.

—

C37-59 YEL/

GRN Oil control valve

ground

Below 1.3 V Ignition switch turned ON.

—

C37-60 YEL/

RED Oil control valve

output *0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.27: ” and “Reference

waveform No.28: ”) At the moment of ignition

switch turned ON.

Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

E23-1 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-2 WHT/

RED Power source for

ECM internal

memory

10 – 14 V Ignition switch turned ON. —

E23-3 RED CAN (high)

communication line

(active high signal)

for ABS control

module, BCM,

combination meter *2.5 – 4.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

Page 231 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

E23-4 BRNEngine revolution

signal output for P/

S control module 0 – 0.8 V

Ignition switch turned ON

with engine at stop. —

*0 – 1 V ↑↓

8 – 14 V

(“Reference

waveform No.30: ” and “Reference

waveform No.31: ”) While engine running. Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E23-5 PPL/

WHT Serial

communication line

of DLC 12 V

8 – 14 V Ignition switch turned ON. —

E23-6 — — — — —

E23-7 — — — — —

E23-8 — — — — —

E23-9 — — — — —

E23-10 — — — — — E23-11 — — — — —

E23-12 BLU Diagnosis switch

terminal (Hong

Kong model) 4 – 5 V Ignition switch turned ON. —

E23-13 YEL/

RED Clock signal for

immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-14 — — — — —

E23-15 GRN/

WHT Fuel pump relay

output 0 – 2.5 V

For 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 V On and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E23-16 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-17 — — — — —

E23-18 WHT CAN (low)

communication line

(active low signal)

for ABS control

module, BCM,

combination meter *0.5 – 2.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E23-19 BLU/

WHT Electric load signal

for heater blower

motor 10 – 14 V

Ignition switch turned ON,

blower fan selector at OFF

position.

—

0 – 1 V Ignition switch turned ON,

blower fan selector at 2nd

speed position or more.

E23-20 GRN/

WHT Stop lamp switch

signal 0 – 1 V

Ignition switch turned ON,

stop lamp not lit up.

—

10 – 14 V Ignition switch turned ON,

stop lamp lit up.

E23-21 — — — — —

E23-22 — — — — —

E23-23 — — — — —

E23-24 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 244 of 1496

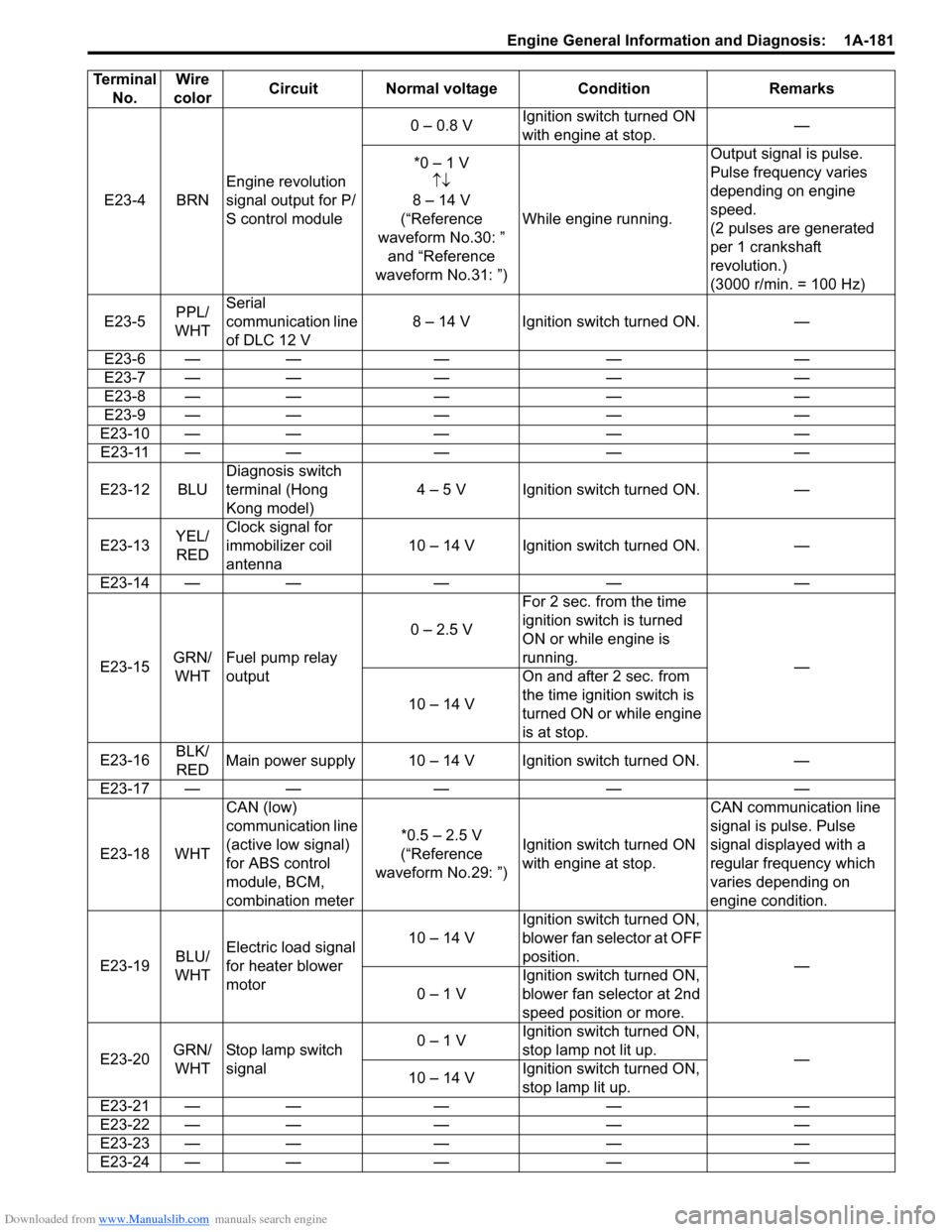

Downloaded from www.Manualslib.com manuals search engine 1A-194 Engine General Information and Diagnosis:

ECM Power and Ground Circuit CheckS7RS0B1104080

Wiring DiagramC37-3 to E23-1/16 EGR valve

(stepping motor No.2 coil)

20 – 31 Ω —

C37-18 to E23-1/16 EGR valv e (stepping motor No.4 coil)

C37-19 to E23-1/16 EGR valv e (stepping motor No.3 coil)

C37-46 to E23-29 Heater of HO2S-1 2 – 11 Ω—

C37-1 to E23-1/16 No.1 fuel injector 10.8 – 18.2 Ω —

E23-47 to E23-1/16 A/C compressor relay 160 – 240 Ω —

C37-60 to C37-59 Oil control valve 6 – 15 Ω —

E23-45 to E23-1/16 Throttle actuator control relay 160 – 240 Ω —

Terminals

CircuitStandard resistance Condition

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/RED

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V

5VE23-1

E23-60

E23-16

WHT 2

4

11

6

3

12

13 14

7

1

16

17

89

15

10

5

WHT/REDE23-2

C37-58

C37-15C37-30

BLK/ORN

BLKBLKE23-31BLK

WHT

GRY/REDRED/BLK

ORN

C37-14C37-53

C37-55E23-54

REDE23-55

GRNBRN

BLU

REDYELWHT

E23-35E23-37E23-52

E23-51

E23-34E23-36

E23-50

LT GRN/REDLT GRN/BLKC37-45C37-44

C37-43

C37-54C37-40C37-42C37-41

RED

GRN

WHTBLK

ORN

BLK/WHTE23-29

I6RS0C110039-01

1. Main fuse box 7. Individual circuit fuse box No.1 13. A/C refrigerant pressure sensor (if equipped with A/C)

2. Ignition switch 8. “IG ACC” fuse14. APP sensor (main)

3. Main relay 9. “FI” fuse15. APP sensor (sub)

4. BCM (included in junction block assembly) 10. “RADIO” fuse 16. TP sensor (main)

5. “IG COIL” fuse 11. DLC17. TP sensor (sub)

6. ECM 12. MAP sensor

Page 255 of 1496

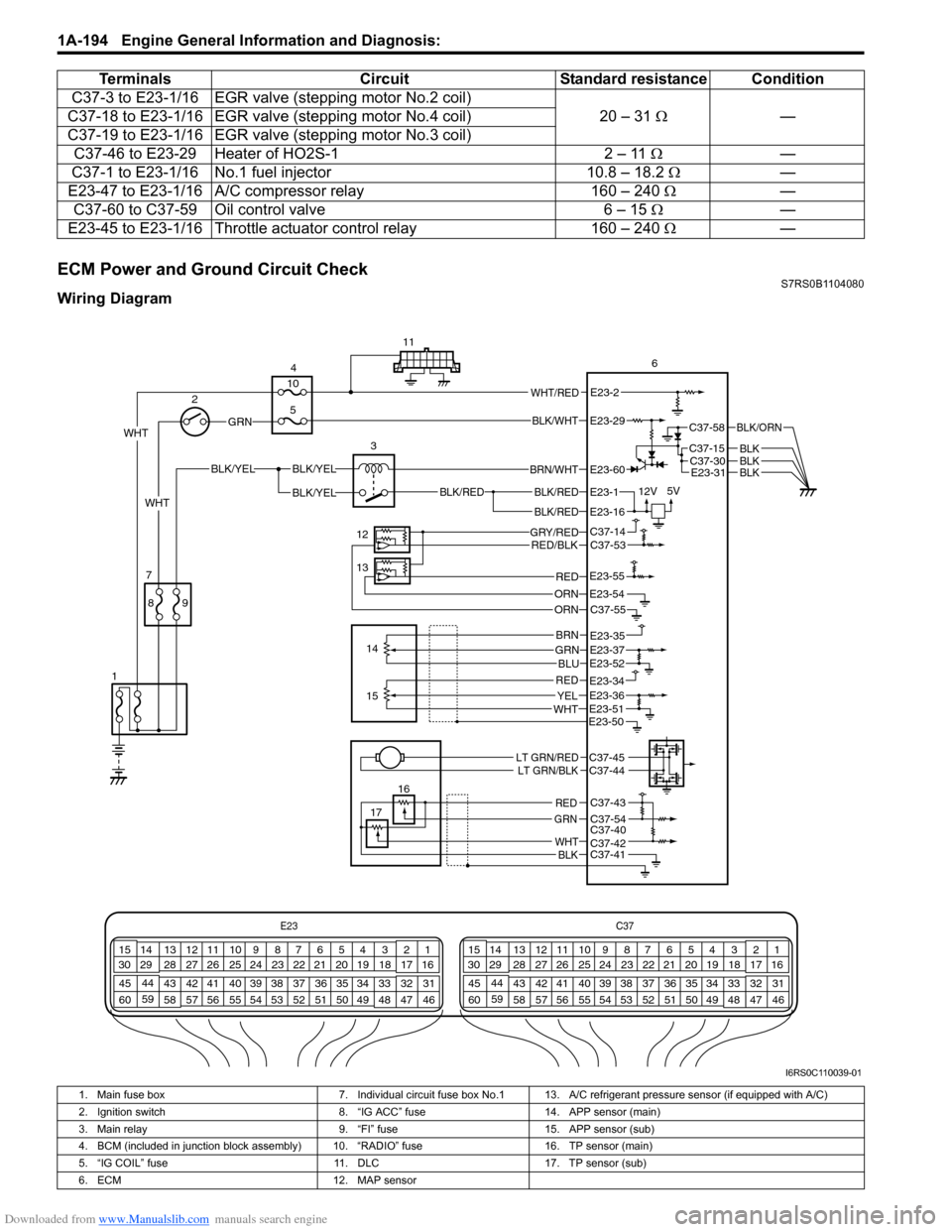

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-205

A/C System Circuits CheckS7RS0B1104084

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V

12

E23-1

E23-60

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

GRN

GRY

E23-48

8

11

2

3BLU/WHT

REDWHTREDWHTE23-3E23-18

E23-19

6

BLK

WHT

BLK 12V

E23-47 GRY

WHT

YELBLU

WHT

BLK/YEL

RED/BLK

GRN/WHT

WHT/BLU1

713

14

5V

5V

4

E23-55C37-14GRY/REDRED

E23-54ORN 5V

E23-57WHT/BLK16

9

10

25

17

5

24

15

22

BLU/YEL

23212019

GRN

BLK

18

26

28

27

I6RS0C110042-01

1. Blower fan motor 11. Radiator cooling fan motor 21. “A/C COMP” fuse

2. Blower fan switch 12. Main relay 22. “IG ACC” fuse

3. A/C switch 13. ECM 23. “RDTR FAN” fuse

4. A/C refrigerant pressure sensor 14. Ignition switch 24. Junction block assembly

5. Blower motor relay 15. BCM 25. “IG2 SIG” fuse

6. Compressor relay 16. Evaporator outlet air temp. sensor 26. HVAC control module

7. A/C compressor 17. “BACK” fuse 27. For manual A/C

8. Radiator cooling fan relay No.1 18. Individual circuit fuse box No.1 28. For automatic A/C

9. Radiator cooling fan relay No.2 19. “HTR FAN” fuse

10. Radiator cooling fan relay No.3 20. “FI” fuse

Page 256 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-206 Engine General Information and Diagnosis:

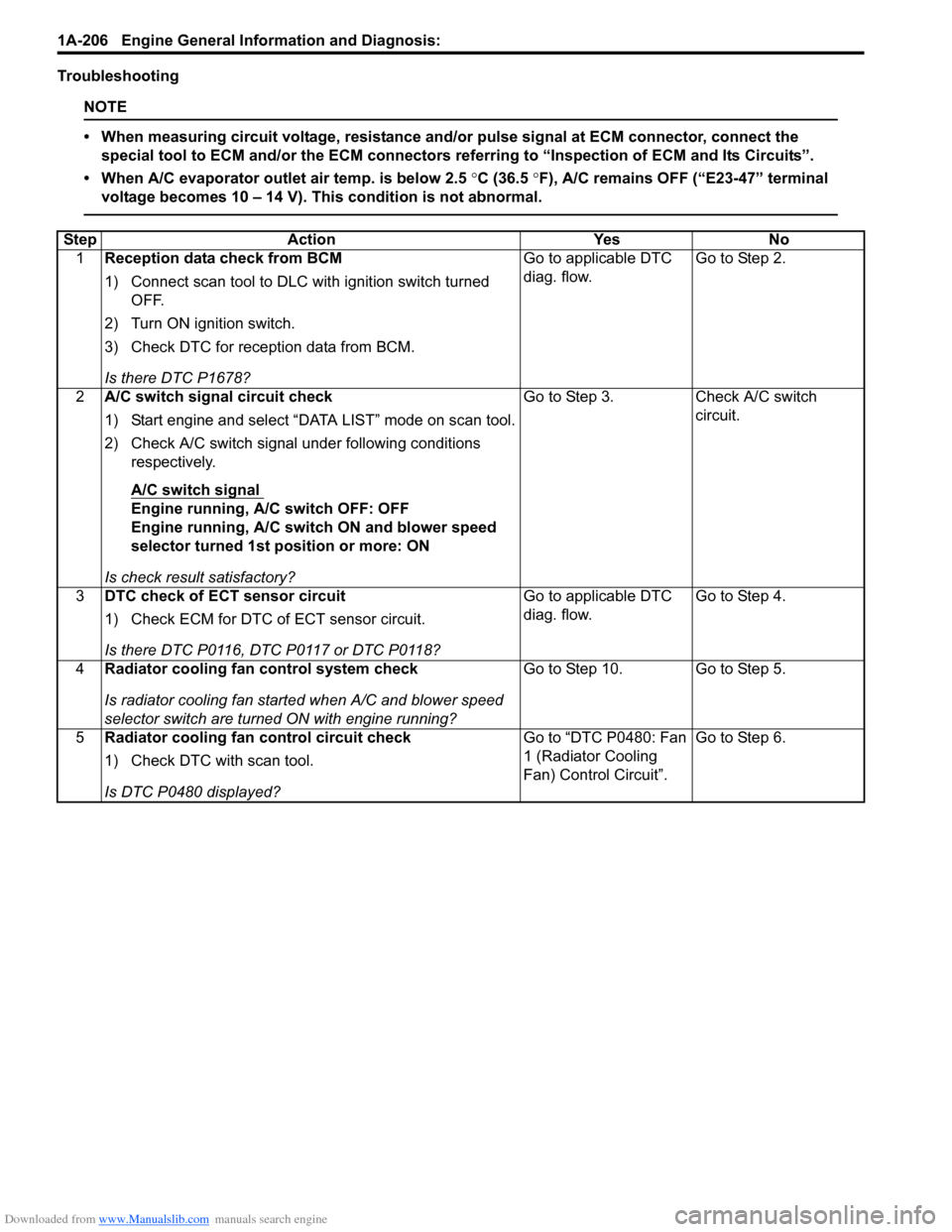

Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• When A/C evaporator outlet air temp. is below 2.5 °C (36.5 °F), A/C remains OFF (“E23-47” terminal

voltage becomes 10 – 14 V). This condition is not abnormal.

Step Action YesNo

1 Reception data check from BCM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC for reception data from BCM.

Is there DTC P1678? Go to applicable DTC

diag. flow.

Go to Step 2.

2 A/C switch signal circuit check

1) Start engine and select “DATA LIST” mode on scan tool.

2) Check A/C switch signal under following conditions

respectively.

A/C switch signal

Engine running, A/C switch OFF: OFF

Engine running, A/C switch ON and blower speed

selector turned 1st position or more: ON

Is check result satisfactory? Go to Step 3. Check A/C switch

circuit.

3 DTC check of ECT sensor circuit

1) Check ECM for DTC of ECT sensor circuit.

Is there DTC P0116, DTC P0117 or DTC P0118? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Radiator cooling fan control system check

Is radiator cooling fan started when A/C and blower speed

selector switch are turned ON with engine running? Go to Step 10. Go to Step 5.

5 Radiator cooling fan control circuit check

1) Check DTC with scan tool.

Is DTC P0480 displayed? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit”.

Go to Step 6.

Page 259 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-209

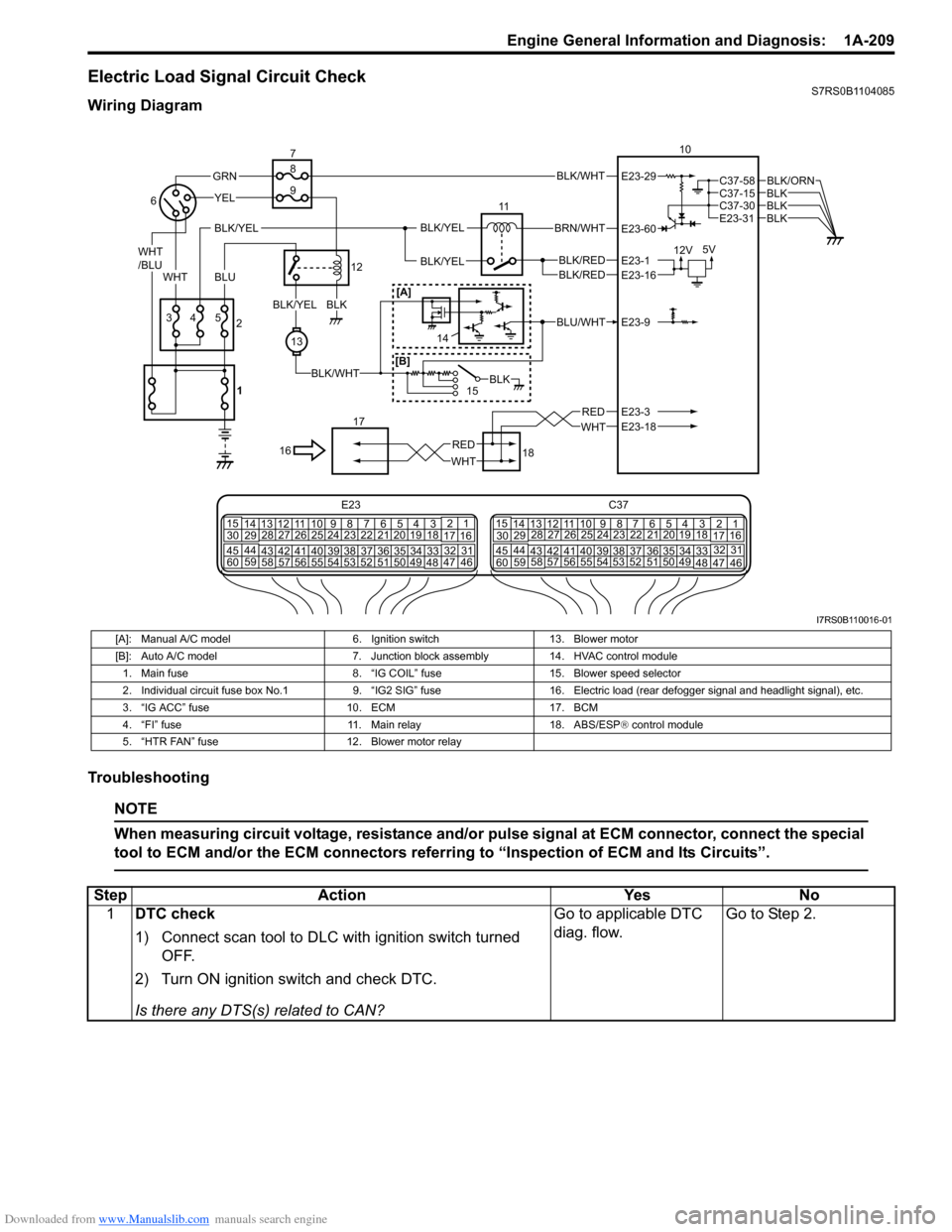

Electric Load Signal Circuit CheckS7RS0B1104085

Wiring Diagram

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

BLK/WHT

BLK/RED

WHT

BRN/WHT

12V5V

11

BLK/YELBLK/YEL

BLK/YEL

BLKBLKBLK

BLK/ORN

10

18

17

BLU/WHT

15

WHTRED

43

YEL

5

13

BLK/WHT

BLKBLK/YEL

GRN

WHT

/BLU

BLU

16

2

6

7

12

8

9

BLK

WHT

RED

E23-29

E23-60

E23-1E23-16

E23-9

E23-3E23-18

C37-58C37-15

E23-31C37-30

BLK/RED

[A]

[B]

E23 C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

1

14

I7RS0B110016-01

[A]: Manual A/C model

6. Ignition switch13. Blower motor

[B]: Auto A/C model 7. Junction block assembly14. HVAC control module

1. Main fuse 8. “IG COIL” fuse15. Blower speed selector

2. Individual circuit fuse box No.1 9. “IG2 SIG” fuse16. Electric load (rear defogger signal and headlight signal), etc.

3. “IG ACC” fuse 10. ECM17. BCM

4. “FI” fuse 11. Main relay18. ABS/ESP® control module

5. “HTR FAN” fuse 12. Blower motor relay

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there any DTS(s) related to CAN? Go to applicable DTC

diag. flow.

Go to Step 2.

Page 497 of 1496

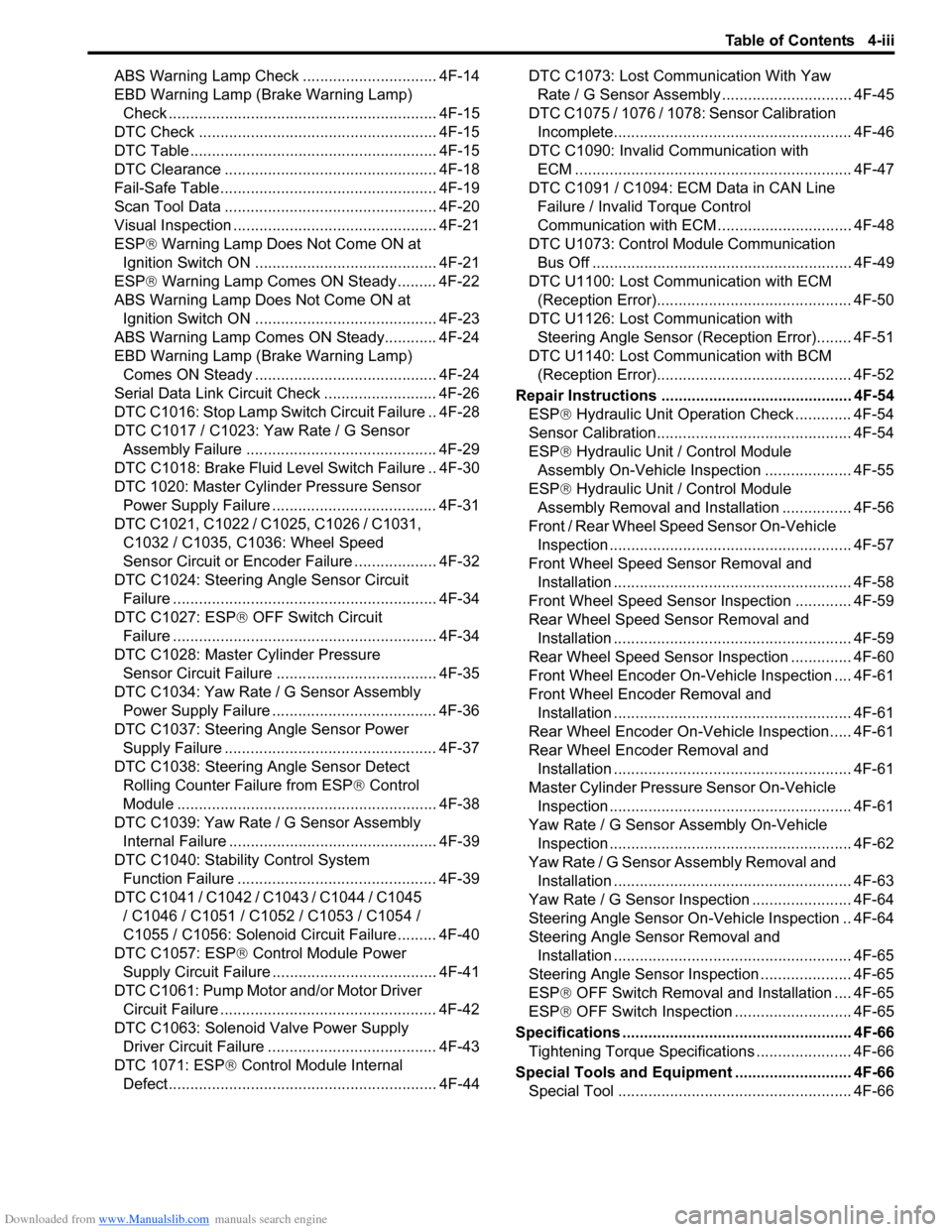

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

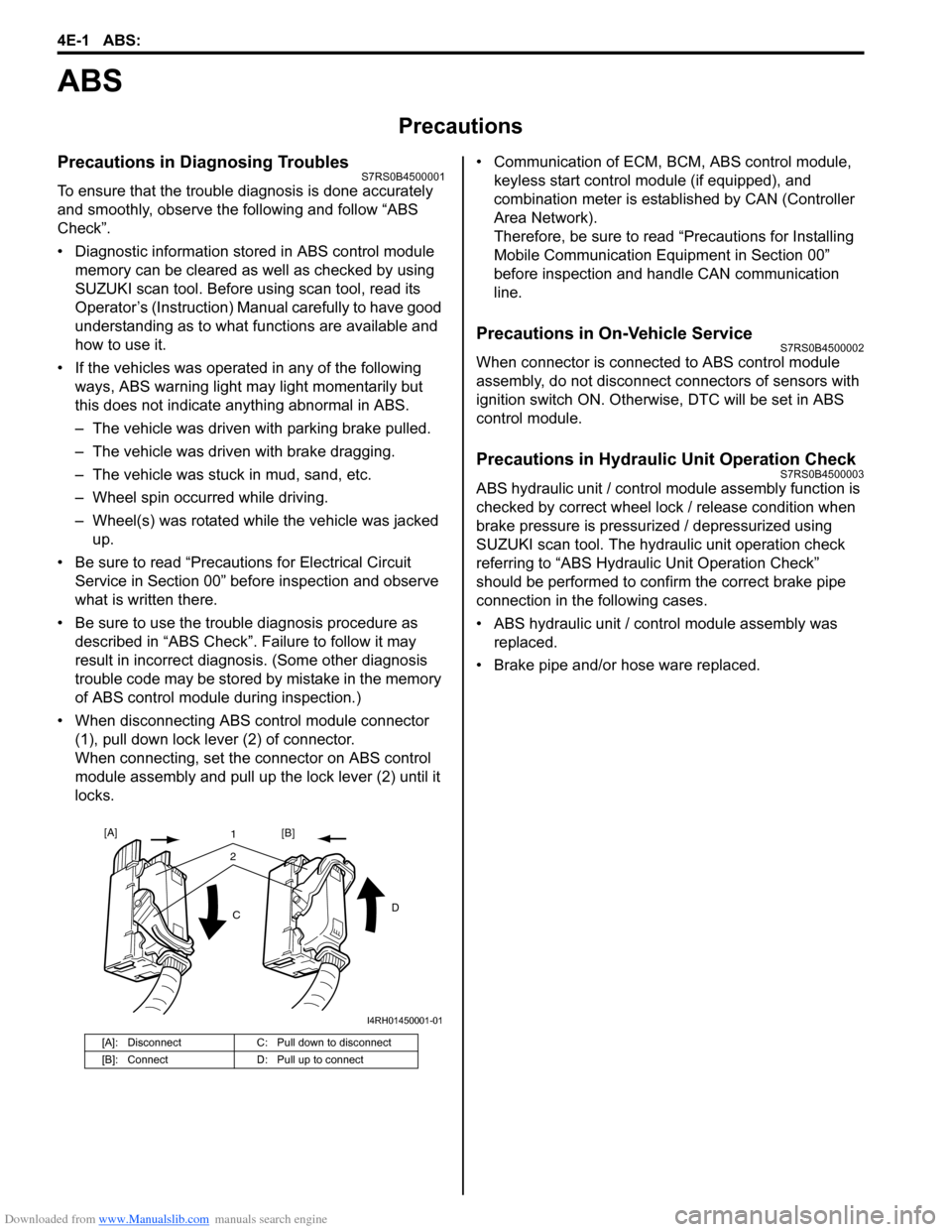

Precautions

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 545 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

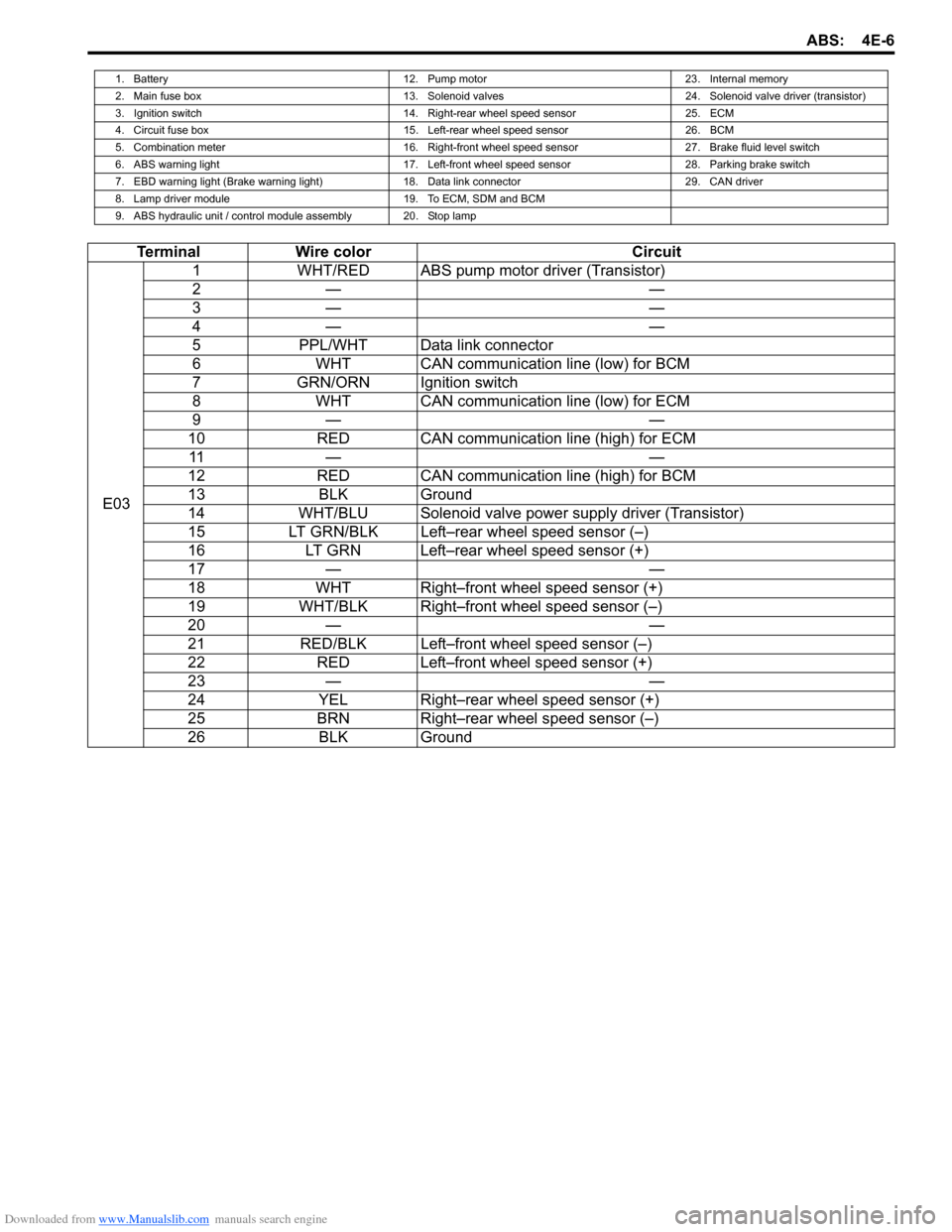

1. Battery12. Pump motor23. Internal memory

2. Main fuse box 13. Solenoid valves24. Solenoid valve driver (transistor)

3. Ignition switch 14. Right-rear wheel speed sensor25. ECM

4. Circuit fuse box 15. Left-rear wheel speed sensor26. BCM

5. Combination meter 16. Right-front wheel speed sensor27. Brake fluid level switch

6. ABS warning light 17. Left-front wheel speed sensor28. Parking brake switch

7. EBD warning light (Brake warning light) 18. Data link connector29. CAN driver

8. Lamp driver module 19. To ECM, SDM and BCM

9. ABS hydraulic unit / control module assembly 20. Stop lamp

Terminal Wire color Circuit

E03 1

WHT/RED ABS pump motor driver (Transistor)

2— —

3— —

4— —

5 PPL/WHT Data link connector

6 WHT CAN communication line (low) for BCM

7 GRN/ORN Ignition switch

8 WHT CAN communication line (low) for ECM

9— —

10 RED CAN communication line (high) for ECM

11 — —

12 RED CAN communication line (high) for BCM

13 BLK Ground

14 WHT/BLU Solenoid valve power supply driver (Transistor)

15 LT GRN/BLK Left–rear wheel speed sensor (–)

16 LT GRN Left–rear wheel speed sensor (+)

17 — —

18 WHT Right–front wheel speed sensor (+)

19 WHT/BLK Right–front wheel speed sensor (–)

20 — —

21 RED/BLK Left–front wheel speed sensor (–)

22 RED Left–front wheel speed sensor (+)

23 — —

24 YEL Right–rear wheel speed sensor (+)

25 BRN Right–rear wheel speed sensor (–)

26 BLK Ground

Page 552 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-13 ABS:

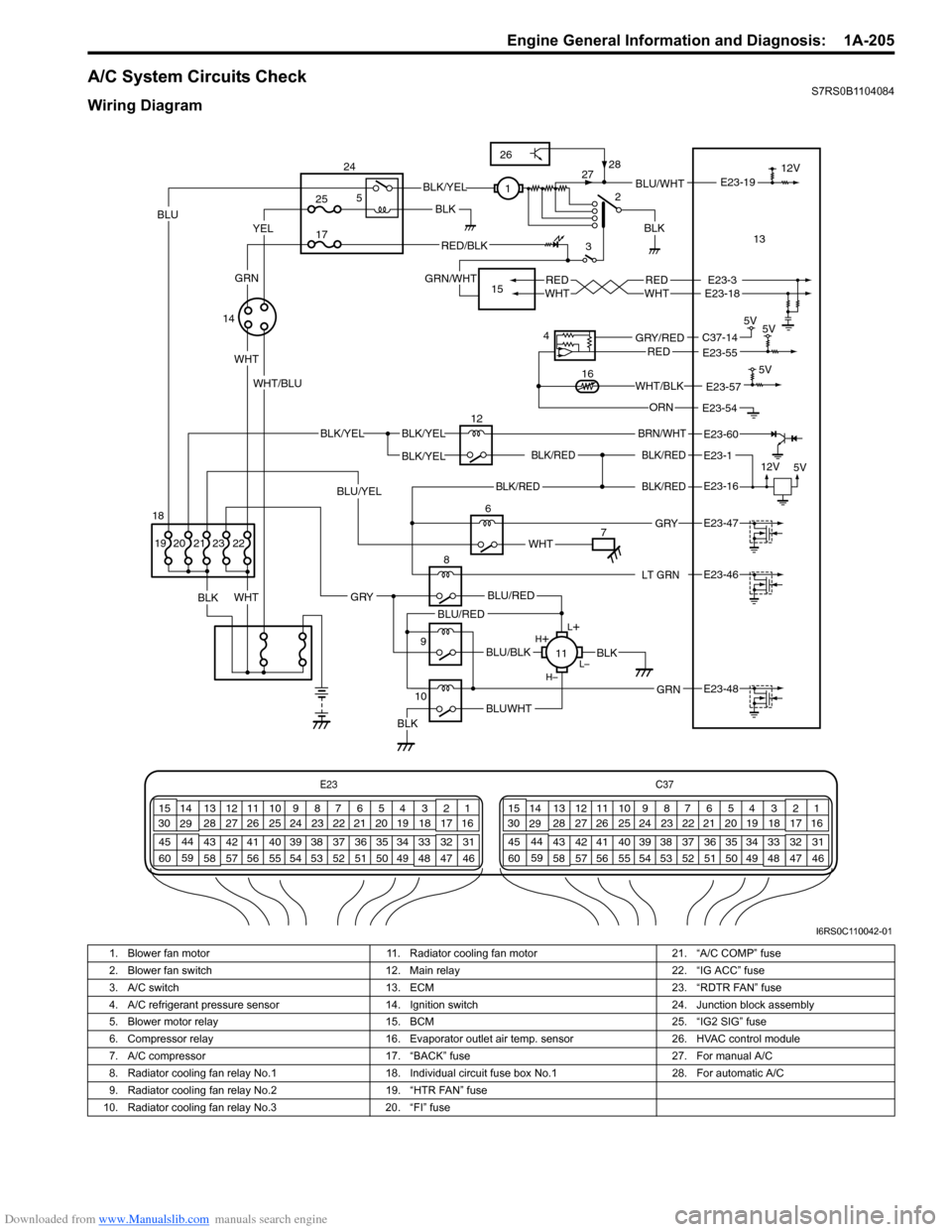

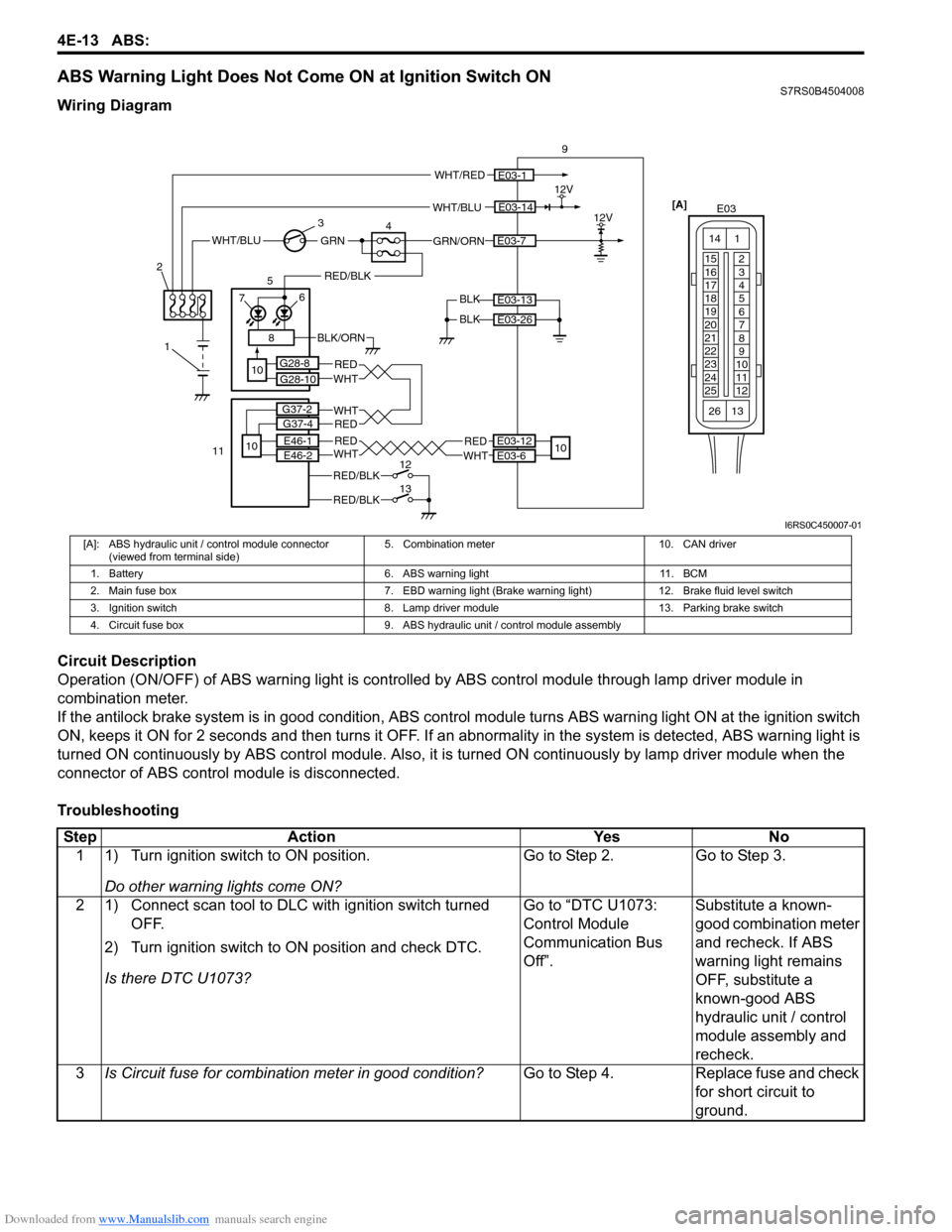

ABS Warning Light Does Not Come ON at Ignition Switch ONS7RS0B4504008

Wiring Diagram

Circuit Description

Operation (ON/OFF) of ABS warning light is controlled by ABS contro l module through lamp driver module in

combination meter.

If the antilock brake system is in good condition, ABS control module turns ABS warning light ON at the ignition switch

ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ABS warning light is

turned ON continuously by ABS control module. Also, it is turned ON continuously by la mp driver module when the

connector of ABS control module is disconnected.

Troubleshooting

WHT/BLU

BLK 12V

9

BLK

E03-14

E03-13

E03-26

WHT/RED

GRN/ORNE03-7WHT/BLUGRN

1

2

3

48

RED/BLK

76

5

10

E03-112V[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

BLK/ORN

E03-12

E03-6

REDWHT

10

G28-8

G28-10

REDWHTE46-1

E46-2

RED/BLK

RED/BLK

RED

RED

WHT

WHT

12

13

11

10

G37-2

G37-4

I6RS0C450007-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 5. Combination meter 10. CAN driver

1. Battery 6. ABS warning light 11. BCM

2. Main fuse box 7. EBD warning light (Brake warning light) 12. Brake fluid level switch

3. Ignition switch 8. Lamp driver module 13. Parking brake switch

4. Circuit fuse box 9. ABS hydraulic unit / control module assembly

Step Action YesNo

1 1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ignition switch to ON position and check DTC.

Is there DTC U1073? Go to “DTC U1073:

Control Module

Communication Bus

Off”.

Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

OFF, substitute a

known-good ABS

hydraulic unit / control

module assembly and

recheck.

3 Is Circuit fuse fo r combination meter in good condition? Go to Step 4.Replace fuse and check

for short circuit to

ground.