fluid level SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 21 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Abbreviations ...................................................... 0A-1

Symbols .............................................................. 0A-2

Wire Color Symbols ............................................ 0A-2

Fasteners Information ......................................... 0A-3

Vehicle Lifting Points ........................................... 0A-5

Engine Supporting Points ................................... 0A-7

Vehicle Identification Number ............................. 0A-7

Engine Identification Number .............................. 0A-7

Transmission Identification Number .................... 0A-7

Component Locatio n ........................................... 0A-8

Warning, Caution and Information Labels Location ............................................................ 0A-8

Maintenance and Lubricat ion ................. 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance and Lubrication ..... 0B-1

Scheduled Maintenance ...................................... 0B-1 Maintenance Schedule under Normal Driving Conditions ......................................................... 0B-1

Maintenance Recommended under Severe Driving Conditions ............................................. 0B-2

Repair Instructions .............................................. 0B-3 Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Repl acement ..................... 0B-4

Valve Lash (Clearance) Inspection ..................... 0B-4

Engine Oil and Filter Change .............................. 0B-4

Engine Coolant Change ...... ................................ 0B-5

Exhaust System Inspection ................................. 0B-6

Spark Plug Replacement .................................... 0B-6

Air Cleaner Filter Inspection ................................ 0B-6

Air Cleaner Filter Replac ement ........................... 0B-6 Fuel Lines and Connections Inspection .............. 0B-6

Fuel Filter Replacement ...................................... 0B-7

Fuel Tank Inspection ........................................... 0B-7

PCV Valve Inspection ......................................... 0B-7

Fuel Evaporative Emission Control System

Inspection .......................................................... 0B-7

Brake Discs and Pads Inspection ....................... 0B-7

Brake Hoses and Pipes Inspection ..................... 0B-7

Brake Fluid Inspection......................................... 0B-8

Brake Fluid Replacement .................................... 0B-8

Brake Lever and Cable Inspection ...................... 0B-8

Clutch Fluid Inspection ........................................ 0B-8

Tires Inspection ................................................... 0B-9

Wheel Discs Inspection ....................................... 0B-9

Wheel Bearing Inspection ................................... 0B-9

Suspension System Inspection ........................... 0B-9

Steering System Inspection .............................. 0B-10

Drive Shaft (Axle) Boots Inspection .................. 0B-10

Manual Transaxle Oil Inspection ....................... 0B-10

Manual Transaxle Oil Replacement .................. 0B-10

Automatic Transaxle Fluid Level Inspection...... 0B-11

Automatic Transaxle Fluid Replacement .......... 0B-11

Automatic Transaxle Fluid Cooler Hose Inspection ........................................................ 0B-11

All Latches, Hinges and Locks Inspection......... 0B-11

HVAC Air Filter (If Equipped) Inspection ........... 0B-12

HVAC Air Filter (If Equipped) Replacement ...... 0B-12

Final Inspection for Maint enance Service ......... 0B-12

Specifications .................... .................................0B-13

Tightening Torque Specifications ...................... 0B-13

Special Tools and Equipmen t ...........................0B-13

Recommended Fluids and Lubricants............... 0B-13

Special Tool ...................................................... 0B-14

Page 31 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-1

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance and LubricationS7RS0B0200001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Scheduled Maintenance

Maintenance Schedule under Normal Driving ConditionsS7RS0B0205001

NOTE

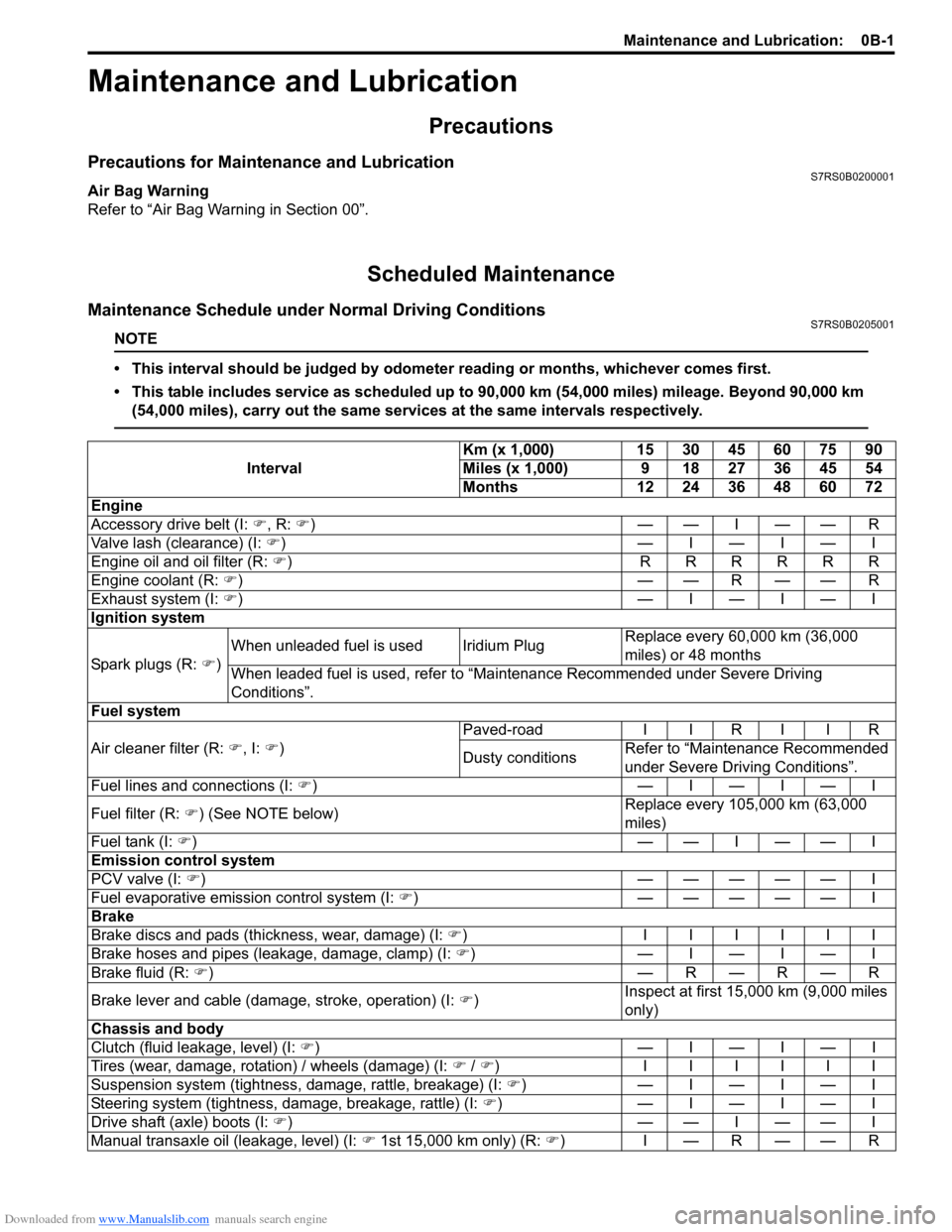

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

Interval Km (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Engine

Accessory drive belt (I: �), R: �))——I——R

Valve lash (clearance) (I: �)) —I—I—I

Engine oil and oil filter (R: �)) RRRRRR

Engine coolant (R: �))— —R— — R

Exhaust system (I: �)) —I—I—I

Ignition system

Spark plugs (R: �) )When unleaded fuel is used Iridium Plug

Replace every 60,000 km (36,000

miles) or 48 months

When leaded fuel is used, refer to “Maintenance Recommended under Severe Driving

Conditions”.

Fuel system

Air cleaner filter (R: �), I: �)) Paved-road

I I R I I R

Dusty conditions Refer to “Maintenance Recommended

under Severe Driv

ing Conditions”.

Fuel lines and connections (I: �)) —I—I—I

Fuel filter (R: �)) (See NOTE below) Replace every 105,000 km (63,000

miles)

Fuel tank (I: �))— —I— — I

Emission control system

PCV valve (I: �)) ————— I

Fuel evaporative emission control system (I: �)) ————— I

Brake

Brake discs and pads (thickness, wear, damage) (I: �)) IIIIII

Brake hoses and pipes (leakage, damage, clamp) (I: �)) —I—I—I

Brake fluid (R: �)) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: �)) Inspect at first 15,000 km (9,000 miles

only)

Chassis and body

Clutch (fluid leakage, level) (I: �)) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: �) / �) ) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: �)) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: �)) —I—I—I

Drive shaft (axle) boots (I: �))— —I— — I

Manual transaxle oil (leakage, level) (I: �) 1st 15,000 km only) (R: �))I—R——R

Page 32 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-2 Maintenance and Lubrication:

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

• For spark plugs, replace every 50,000 km if the local law requires.

• Periodic replacement of fuel filter is not necessary if it is not instructed in “Periodic Maintenance Schedule” section of the Owner’s manual. The scheduled maintenance varies depending on the

vehicle specification.

Maintenance Recommended under Severe Driving ConditionsS7RS0B0205002

If the vehicle is usually used under the conditions corres ponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be per formed at the particular interval as shown in the

following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: – – – – –

H: Towing a trailer (if admitted) Automatic transaxle fluid

Fluid level (I:

�)) —I—I—I

Fluid change (R: �)) Replace every 165,000 km (99,000

miles)

Fluid hose (I: �))———I——

All latches, hinges and locks (I: �)) —I—I—I

HVAC air filter (if equipped) (I: �) ) (R: �))— IR — IR

Interval

Km (x 1,000)

15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

– B C D – – – – Accessory drive belt �)

I Every 15,000 km

(9,000 miles) or 12 months

�) R Every 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter �) R Every 7,500 km

(4,500 miles) or 6 months

– – C – – – – – Air cleaner filter *1 �)

I Every 2,500 km

(1,500 miles)

�) R Every 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugs Iridium plug �) R Every 30,000 km (18,000 miles) or

24 months

– B C D – – – H Wheel bearings �) I Every 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Drive shaft (axle) boots �) I Every 15,000 km

(9,000 miles) or 12 months

– B – – E – – H Manual transaxle oil �) R First time only:

15,000 km (9,000 miles) or 12

months

Second time and after:

Every 30,000 km (18,000 miles) or

24 months reckoning from 0 km (0

mile) or 0 month

Page 35 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-5

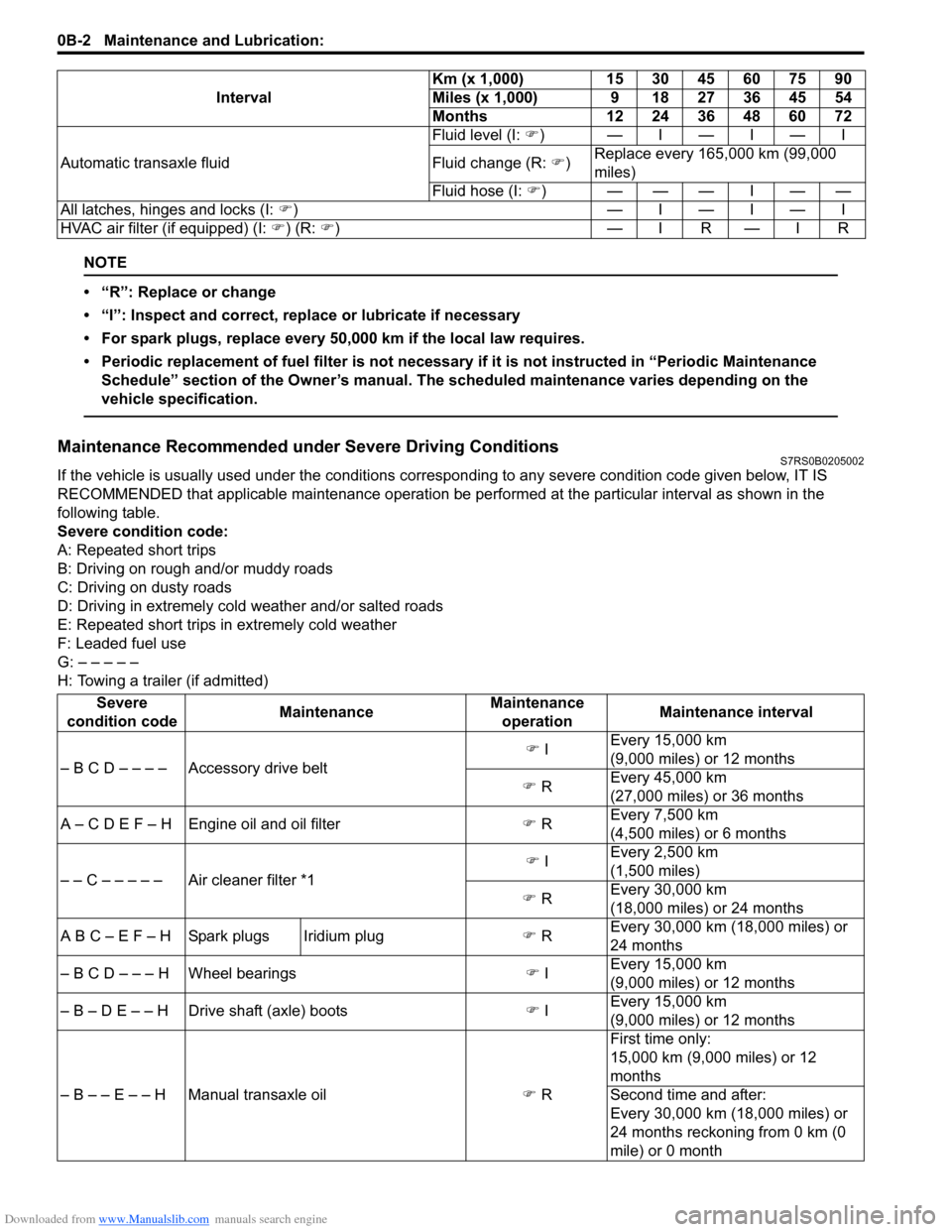

4) Screw new filter on oil filter stand by hand until the filter O-ring contacts mounting surface.

CAUTION!

To tighten oil filter prop erly, it is important to

accurately identify the position at which filter

O-ring first contacts mounting surface.

5) Tighten the filter (1) 3/4 tu rn from the point of contact

with the mounting surface using an oil filter wrench

(2).

Tightening torque

Oil filter (b): 14 N·m (1 .4 kgf-m, 10.5 lb-ft) for

reference

6) Replenish oil until oil leve l is brought to FULL level

mark on dipstick (oil pan and oil filter capacity). The

filler inlet is at the top of the cylinder head cover. It is

recommended to use engine oil of SG, SH, SJ, SL or

SM grade. Select the appropriate oil viscosity

according to the proper engine oil viscosity chart [A].

NOTE

Engine oil capacity is specified as the

following.

However, note that the amount of oil required

when actually changing oil may somewhat

differ from the data depending on various

conditions (temperature, viscosity, etc.).

Engine oil specification

Oil pan capacity: About 3.7 liters (7.8 / 6.5 US /

lmp pt.)

Oil filter capacity: About 0.2 liter (0.4 / 0.3 US /

lmp pt.)

Others: About 0.3 liter (0 .6 / 0.5 US / lmp pt.)

Total: About 4.2 liters (8.9 / 7.4 US / lmp pt.) 7) Check oil filter and drain plug for oil leakage.

8) Start engine and run it for 3 minutes. Stop it and wait

another 5 minutes before checking oil level. Add oil,

as necessary, to bring oil le vel to FULL level mark (1)

on dipstick.

Engine Coolant ChangeS7RS0B0206005

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

CAUTION!

When changing engine coolant, use mixture

of 50% specified water and 50% ANTIFREEZE

/ ANTICORROSION COOLANT for the

purpose of corrosion protection and

lubrication.

Change engine coolant with new one referring to

“Cooling System Flush and Refill in Section 1F”.

IYSQ01020010-01

Co

Fo-30

-22 -20

-4 -10

14 32 50 68 86 104 010203040

5W-30

20W-40

15W-40

10W-30, 10W-40

[A]

I7RS0B020001-02

2. Low level mark (hole)

IYSQ01020012-01

Page 38 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-8 Maintenance and Lubrication:

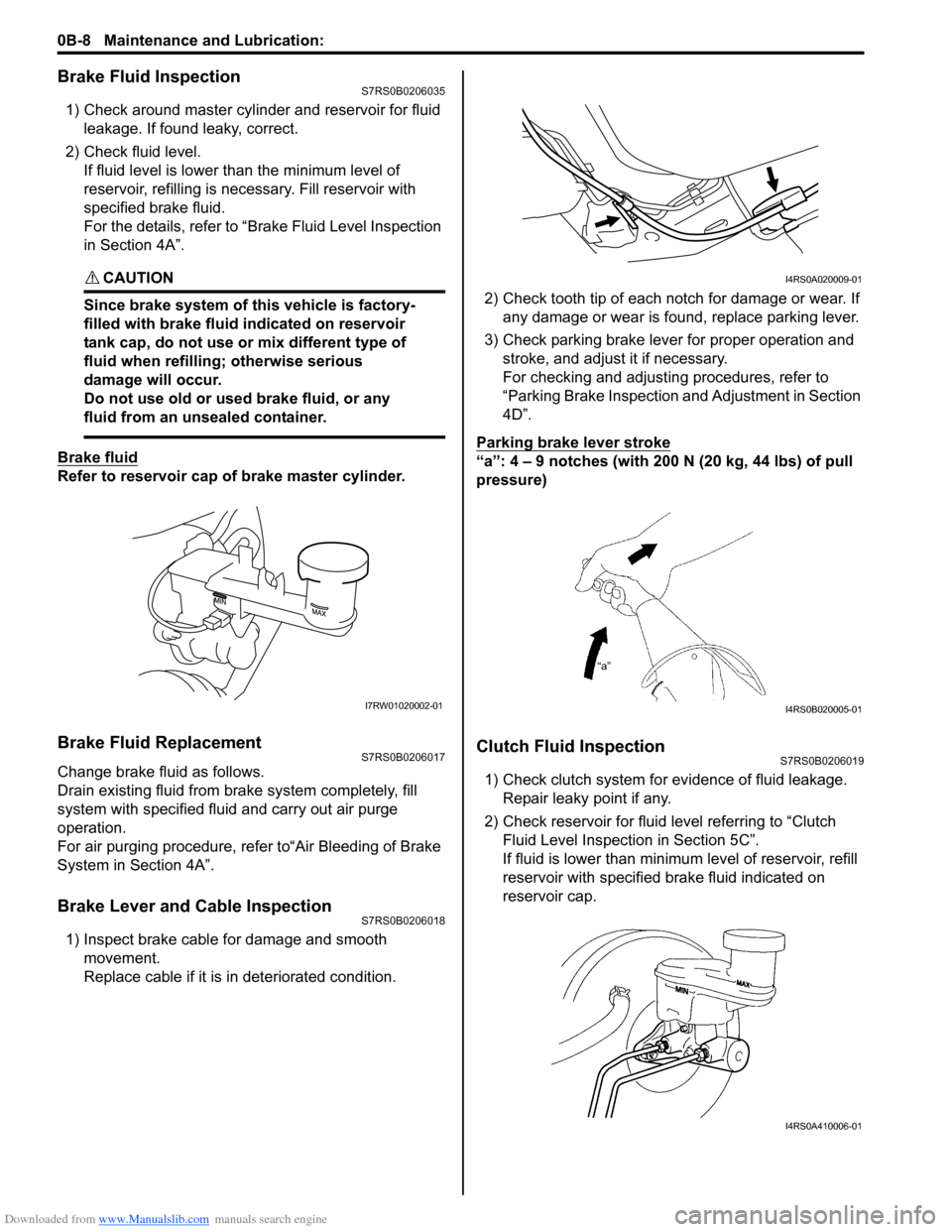

Brake Fluid InspectionS7RS0B0206035

1) Check around master cylinder and reservoir for fluid leakage. If found leaky, correct.

2) Check fluid level. If fluid level is lower than the minimum level of

reservoir, refilling is necessary. Fill reservoir with

specified brake fluid.

For the details, refer to “Brake Fluid Level Inspection

in Section 4A”.

CAUTION!

Since brake system of this vehicle is factory-

filled with brake fluid indicated on reservoir

tank cap, do not use or mix different type of

fluid when refilling; otherwise serious

damage will occur.

Do not use old or used brake fluid, or any

fluid from an unsealed container.

Brake fluid

Refer to reservoir cap of brake master cylinder.

Brake Fluid ReplacementS7RS0B0206017

Change brake fluid as follows.

Drain existing fluid from brake system completely, fill

system with specified fluid and carry out air purge

operation.

For air purging procedure, refer to“Air Bleeding of Brake

System in Section 4A”.

Brake Lever and Cable InspectionS7RS0B0206018

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition. 2) Check tooth tip of each notch for damage or wear. If

any damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and stroke, and adjust it if necessary.

For checking and adjusting procedures, refer to

“Parking Brake Inspection and Adjustment in Section

4D”.

Parking brake lever stroke

“a”: 4 – 9 notches (with 200 N (20 kg, 44 lbs) of pull

pressure)

Clutch Fluid InspectionS7RS0B0206019

1) Check clutch system for evidence of fluid leakage. Repair leaky point if any.

2) Check reservoir for fluid level referring to “Clutch

Fluid Level Inspection in Section 5C”.

If fluid is lower than minimum level of reservoir, refill

reservoir with specified brake fluid indicated on

reservoir cap.

I7RW01020002-01

I4RS0A020009-01

I4RS0B020005-01

I4RS0A410006-01

Page 41 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-11

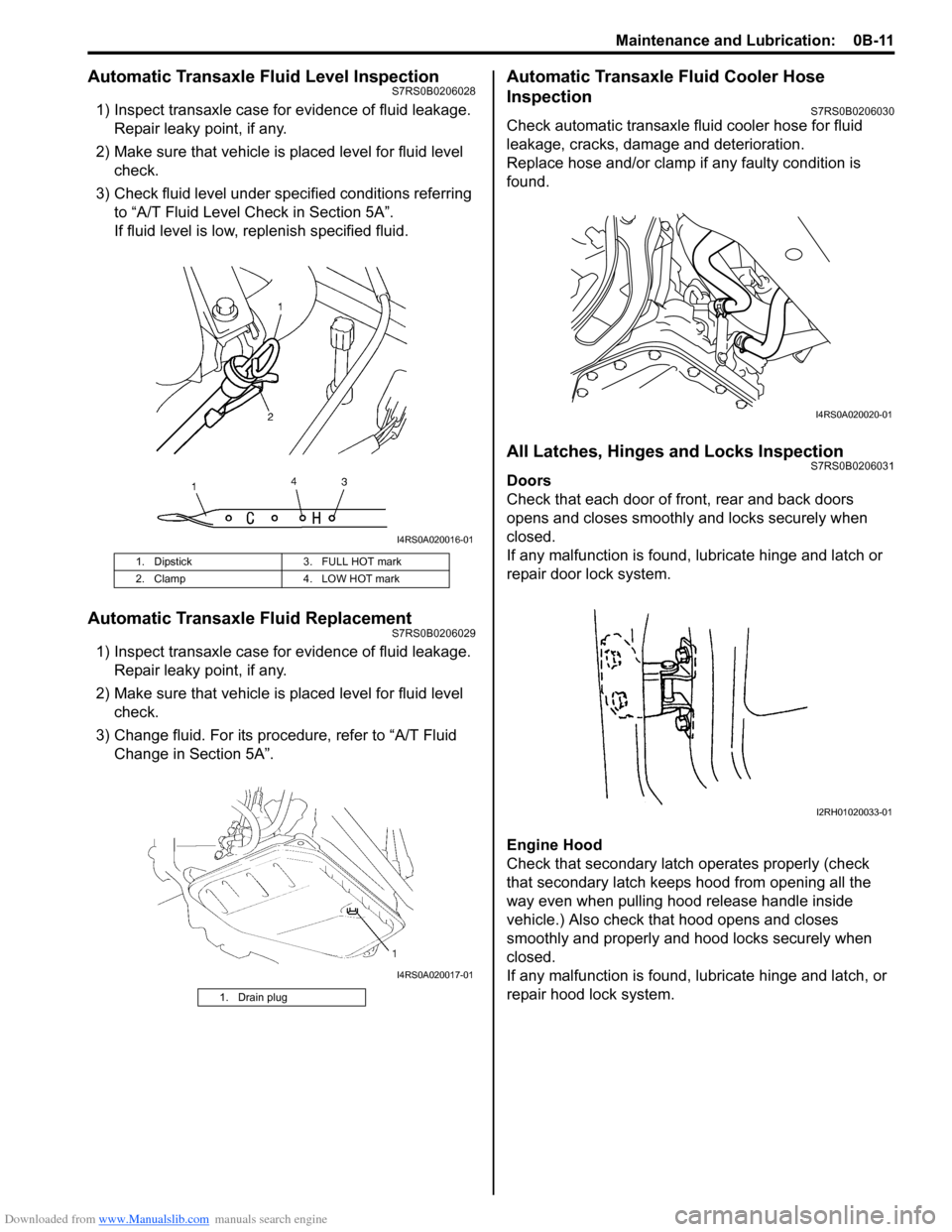

Automatic Transaxle Fluid Level InspectionS7RS0B0206028

1) Inspect transaxle case for evidence of fluid leakage.Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Check fluid level under spec ified conditions referring

to “A/T Fluid Level Check in Section 5A”.

If fluid level is low, replenish specified fluid.

Automatic Transaxle Fluid ReplacementS7RS0B0206029

1) Inspect transaxle case for evidence of fluid leakage. Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Change fluid. For its procedure, refer to “A/T Fluid Change in Section 5A”.

Automatic Transaxle Fluid Cooler Hose

Inspection

S7RS0B0206030

Check automatic transaxle fluid cooler hose for fluid

leakage, cracks, damage and deterioration.

Replace hose and/or clamp if any faulty condition is

found.

All Latches, Hinges and Locks InspectionS7RS0B0206031

Doors

Check that each door of front, rear and back doors

opens and closes smoothly and locks securely when

closed.

If any malfunction is found, lubricate hinge and latch or

repair door lock system.

Engine Hood

Check that secondary latch operates properly (check

that secondary latch keeps hood from opening all the

way even when pulling hood release handle inside

vehicle.) Also check that hood opens and closes

smoothly and properly and hood locks securely when

closed.

If any malfunction is found, l ubricate hinge and latch, or

repair hood lock system.

1. Dipstick 3. FULL HOT mark

2. Clamp 4. LOW HOT mark

1. Drain plug

I4RS0A020016-01

I4RS0A020017-01

I4RS0A020020-01

I2RH01020033-01

Page 87 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-37

TP SENSOR 2 VOLT (THROTTLE POSITION SENSOR

(SUB) OUTPUT VOLTAGE, V)

The TP sensor (sub) reading provides throttle valve

opening information in the form of voltage.

APP SENSOR 1 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (MAIN) OUTPUT

VOLTAGE, V)

The APP sensor (main) read ing provides accelerator

pedal opening information in the form of voltage.

APP SENSOR 2 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (S UB) OUTPUT VOLTAGE,

V)

The APP sensor (sub) reading provides accelerator

pedal opening information in the form of voltage.

ACCEL POSITION (ABSOLUTE ACCELERATOR

PEDAL POSITION, %)

When accelerator pedal is at fully released position,

accelerator pedal is indicated as 0 – 5% and 90 – 100%

fully depressed position. THROTTLE TARGET POSI (TARGET THROTTLE

VALVE POSITION, %)

Target throttle valve position is ECM internal parameter

which indicates the ECM requested throttle valve

position.

BATTERY CURRENT (A)

This parameter indicates elec

tric load value (current

consumption) that detected by electric load current

sensor.

GENERATOR CONT DUTY (GENERATOR CONTROL

DUTY, %)

This parameter indicates generator control duty ratio that

controls production electricity of generator by ECM.

100%: No limitation for the generating

0%: Maximum limitation for the generating

GENERATOR FIELD DUTY (GENERATOR FIELD

COIL DUTY, %)

This parameter indicates ope rating rate (status of

production electricity) for gen erator by field coil duty

ratio.

100%: maximum operation.

0%: minimum operation.

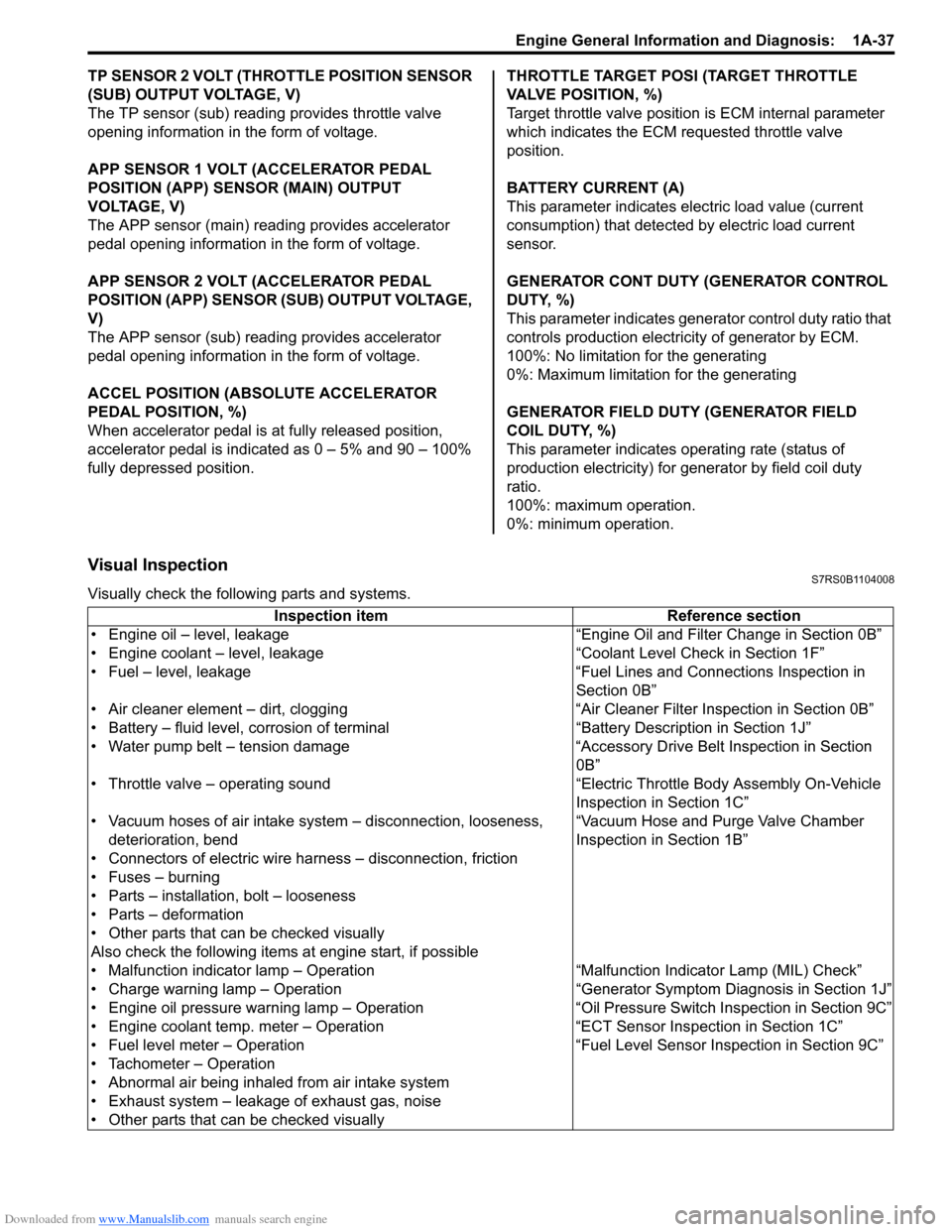

Visual InspectionS7RS0B1104008

Visually check the following parts and systems.

Inspection item Reference section

• Engine oil – level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant – level, leakage “Co olant Level Check in Section 1F”

• Fuel – level, leakage “Fuel Lines and Connections Inspection in Section 0B”

• Air cleaner element – dirt, clogging “Air Cleaner Filter Inspection in Section 0B”

• Battery – fluid level, corrosion of terminal “Battery Description in Section 1J”

• Water pump belt – tension damage “Accessory Drive Belt Inspection in Section 0B”

• Throttle valve – operating sound “Electric Throttle Body Assembly On-Vehicle Inspection in Section 1C”

• Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend “Vacuum Hose and Purge Valve Chamber

Inspection in Section 1B”

• Connectors of electric wire harness – disconnection, friction

• Fuses – burning

• Parts – installation, bolt – looseness

• Parts – deformation

• Other parts that can be checked visually

Also check the following items at engine start, if possible

• Malfunction indicator lamp – Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp – Operation “Genera tor Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp – Operation “O il Pressure Switch Inspection in Section 9C”

• Engine coolant temp. meter – Operation “ECT Sensor Inspection in Section 1C”

• Fuel level meter – Operation “Fuel Level Sensor Inspection in Section 9C”

• Tachometer – Operation

• Abnormal air being inhaled from air intake system

• Exhaust system – leakage of exhaust gas, noise

• Other parts that can be checked visually

Page 369 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-6

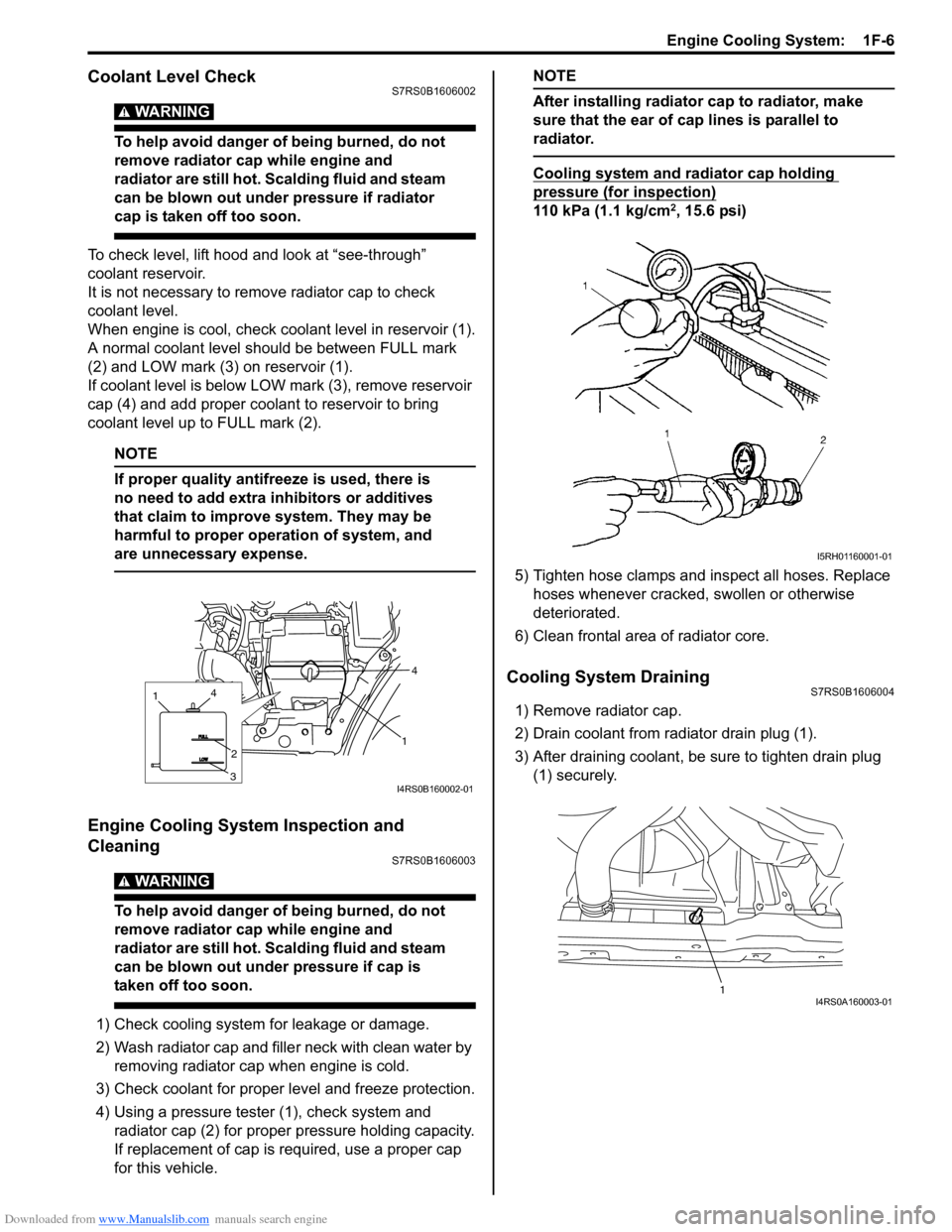

Coolant Level CheckS7RS0B1606002

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if radiator

cap is taken off too soon.

To check level, lift hood and look at “see-through”

coolant reservoir.

It is not necessary to remove radiator cap to check

coolant level.

When engine is cool, check coolant level in reservoir (1).

A normal coolant level should be between FULL mark

(2) and LOW mark (3) on reservoir (1).

If coolant level is below LOW mark (3), remove reservoir

cap (4) and add proper coolant to reservoir to bring

coolant level up to FULL mark (2).

NOTE

If proper quality antifreeze is used, there is

no need to add extra inhibitors or additives

that claim to improve system. They may be

harmful to proper operation of system, and

are unnecessary expense.

Engine Cooling System Inspection and

Cleaning

S7RS0B1606003

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

1) Check cooling system for leakage or damage.

2) Wash radiator cap and fille r neck with clean water by

removing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

4) Using a pressure tester (1), check system and radiator cap (2) for proper pressure holding capacity.

If replacement of cap is required, use a proper cap

for this vehicle.

NOTE

After installing radiator cap to radiator, make

sure that the ear of cap lines is parallel to

radiator.

Cooling system and radiator cap holding

pressure (for inspection)

110 kPa (1.1 kg/cm2, 15.6 psi)

5) Tighten hose clamps and inspect all hoses. Replace hoses whenever cracked, swollen or otherwise

deteriorated.

6) Clean frontal area of radiator core.

Cooling System DrainingS7RS0B1606004

1) Remove radiator cap.

2) Drain coolant from radiator drain plug (1).

3) After draining coolant, be sure to tighten drain plug (1) securely.

1

4

1

3

2

4

I4RS0B160002-01

I5RH01160001-01

1I4RS0A160003-01

Page 370 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-7 Engine Cooling System:

Cooling System Flush and RefillS7RS0B1606005

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

NOTE

For detail of coolant specification, refer to

“Coolant Description”.

1) Remove radiator cap when engine is cool as follows.a) Turn cap counterclockwise slowly until it reaches a “stop” (Do not press down while turning it).

b) Wait until pressure is relieved (indicated by a hissing sound) then press down on cap and

continue to turn it counterclockwise.

2) With radiator cap removed, run engine until upper radiator hose is hot (this shows that thermostat is

open and coolant is flowing through system).

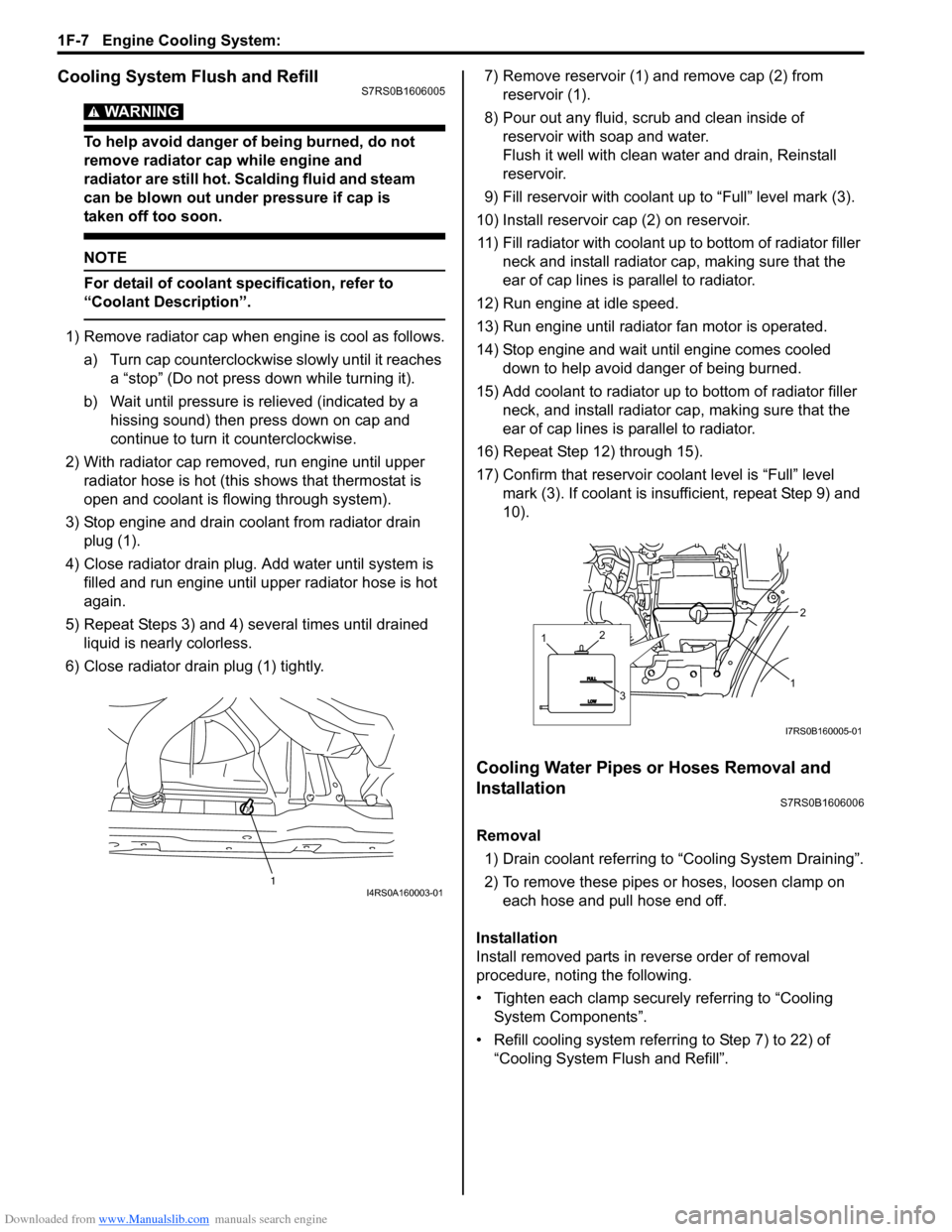

3) Stop engine and drain coolant from radiator drain plug (1).

4) Close radiator drain plug. Add water until system is filled and run engine until up per radiator hose is hot

again.

5) Repeat Steps 3) and 4) several times until drained liquid is nearly colorless.

6) Close radiator drain plug (1) tightly. 7) Remove reservoir (1) and remove cap (2) from

reservoir (1).

8) Pour out any fluid, scrub and clean inside of reservoir with soap and water.

Flush it well with clean water and drain, Reinstall

reservoir.

9) Fill reservoir with coolant up to “Full” level mark (3).

10) Install reservoir cap (2) on reservoir. 11) Fill radiator with coolant up to bottom of radiator filler neck and install radiator cap, making sure that the

ear of cap lines is parallel to radiator.

12) Run engine at idle speed.

13) Run engine until radiator fan motor is operated.

14) Stop engine and wait until engine comes cooled down to help avoid danger of being burned.

15) Add coolant to radiator up to bottom of radiator filler

neck, and install radiator ca p, making sure that the

ear of cap lines is parallel to radiator.

16) Repeat Step 12) through 15).

17) Confirm that reservoir cool ant level is “Full” level

mark (3). If coolant is insu fficient, repeat Step 9) and

10).

Cooling Water Pipes or Hoses Removal and

Installation

S7RS0B1606006

Removal

1) Drain coolant referring to “Cooling System Draining”.

2) To remove these pipes or hoses, loosen clamp on each hose and pull hose end off.

Installation

Install removed parts in reverse order of removal

procedure, noting the following.

• Tighten each clamp securely referring to “Cooling System Components”.

• Refill cooling system referrin g to Step 7) to 22) of

“Cooling System Flush and Refill”.

1I4RS0A160003-01

1

2

1

3

2

I7RS0B160005-01

Page 411 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-1

Engine

Charging System

General Description

Battery DescriptionS7RS0B1A01001

The battery has three major functions in the electrical

system.

• It is a source of electrical energy for cranking the engine.

• It acts as a voltage stabilizer for the electrical system.

• It can, for a limited time, provide energy when the electrical load exceeds the output of the generator.

Carrier and Hold-Down

The battery carrier should be in good condition so that it

will support the battery securely and keep it level. Before

installing the battery, the ba ttery carrier and hold-down

clamp should be clean and free from corrosion and

make certain there are no parts in carrier.

To prevent the battery from shaking in its carrier, the

hold-down bolts should be tight enough but not over-

tightened.

Electrolyte Freezing

The freezing point of electrolyte depends on its specific

gravity. Since freezing may ruin a battery, it should be

protected against freezing by keeping it in a fully

charged condition. If a battery is frozen accidentally, it

should not be charged until it is warmed.

Sulfation

If the battery is allowed to stand for a long period in

discharged condition, the lead sulfate becomes

converted into a hard, cryst alline substance, which will

not easily turn back to the active material again during

the subsequent recharging. “Sulfation” means the result

as well as the process of that reaction. Such a battery

can be revived by very slow charging and may be

restored to usable condition but its capacity is lower than

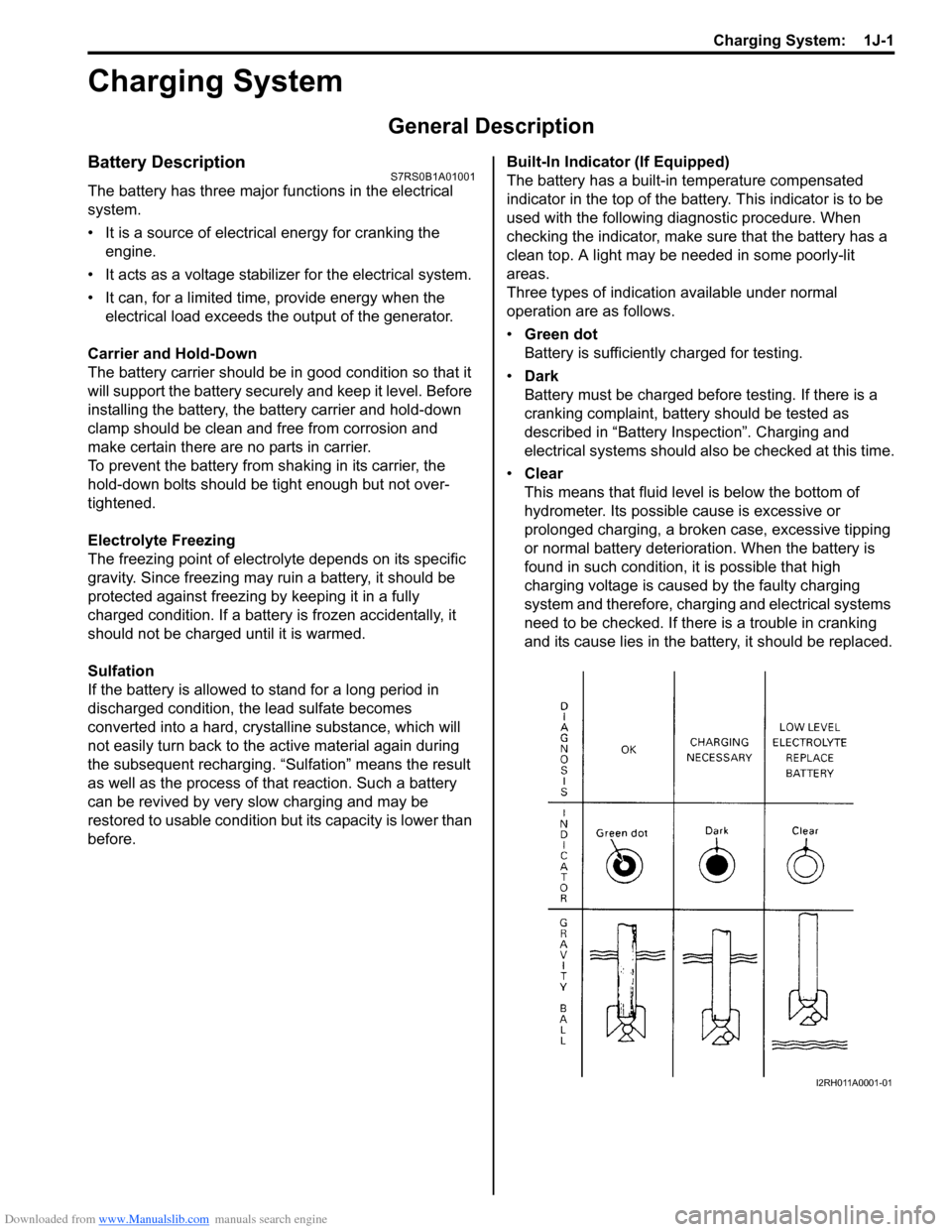

before. Built-In Indicator (If Equipped)

The battery has a built-in temperature compensated

indicator in the top of the battery. This indicator is to be

used with the following diagnostic procedure. When

checking the indicator, make sure that the battery has a

clean top. A light may be needed in some poorly-lit

areas.

Three types of indication available under normal

operation are as follows.

•

Green dot

Battery is sufficiently charged for testing.

• Dark

Battery must be charged before testing. If there is a

cranking complaint, battery should be tested as

described in “Battery Inspection”. Charging and

electrical systems should also be checked at this time.

• Clear

This means that fluid level is below the bottom of

hydrometer. Its possible cause is excessive or

prolonged charging, a broken case, excessive tipping

or normal battery deteriorat ion. When the battery is

found in such condition, it is possible that high

charging voltage is caused by the faulty charging

system and therefore, charging and electrical systems

need to be checked. If there is a trouble in cranking

and its cause lies in the battery, it should be replaced.

I2RH011A0001-01