Precautions SUZUKI SWIFT 2005 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1145 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-107

Side-Air Bag (Inflator) InspectionS7RS0B8206010

WARNING!

• Never attempt to disassemble or repair the side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System” before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

undeployment of the air bag when

necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

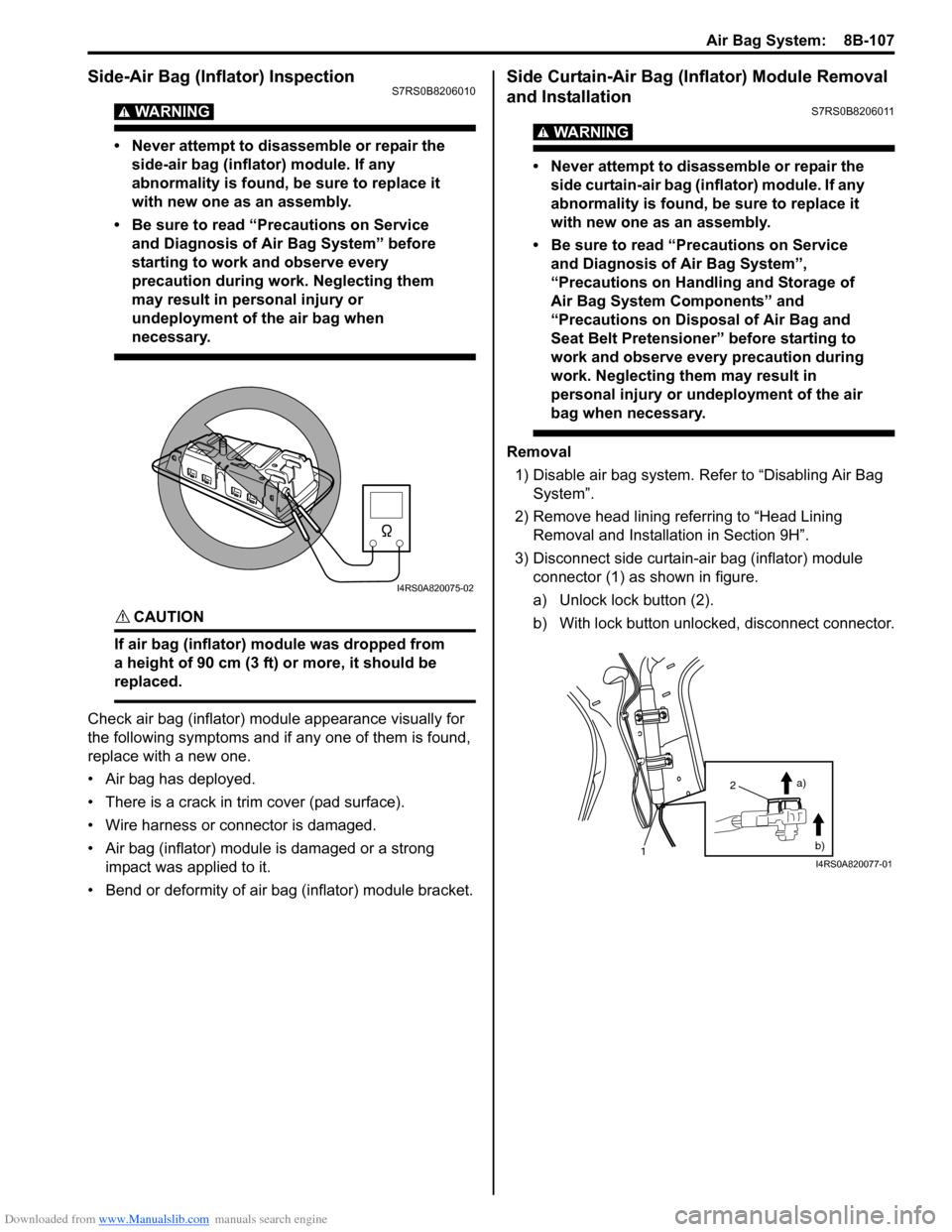

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• There is a crack in trim cover (pad surface).

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

Side Curtain-Air Bag (Inflator) Module Removal

and Installation

S7RS0B8206011

WARNING!

• Never attempt to disassemble or repair the side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

Removal

1) Disable air bag system. Re fer to “Disabling Air Bag

System”.

2) Remove head lining referring to “Head Lining Removal and Installati on in Section 9H”.

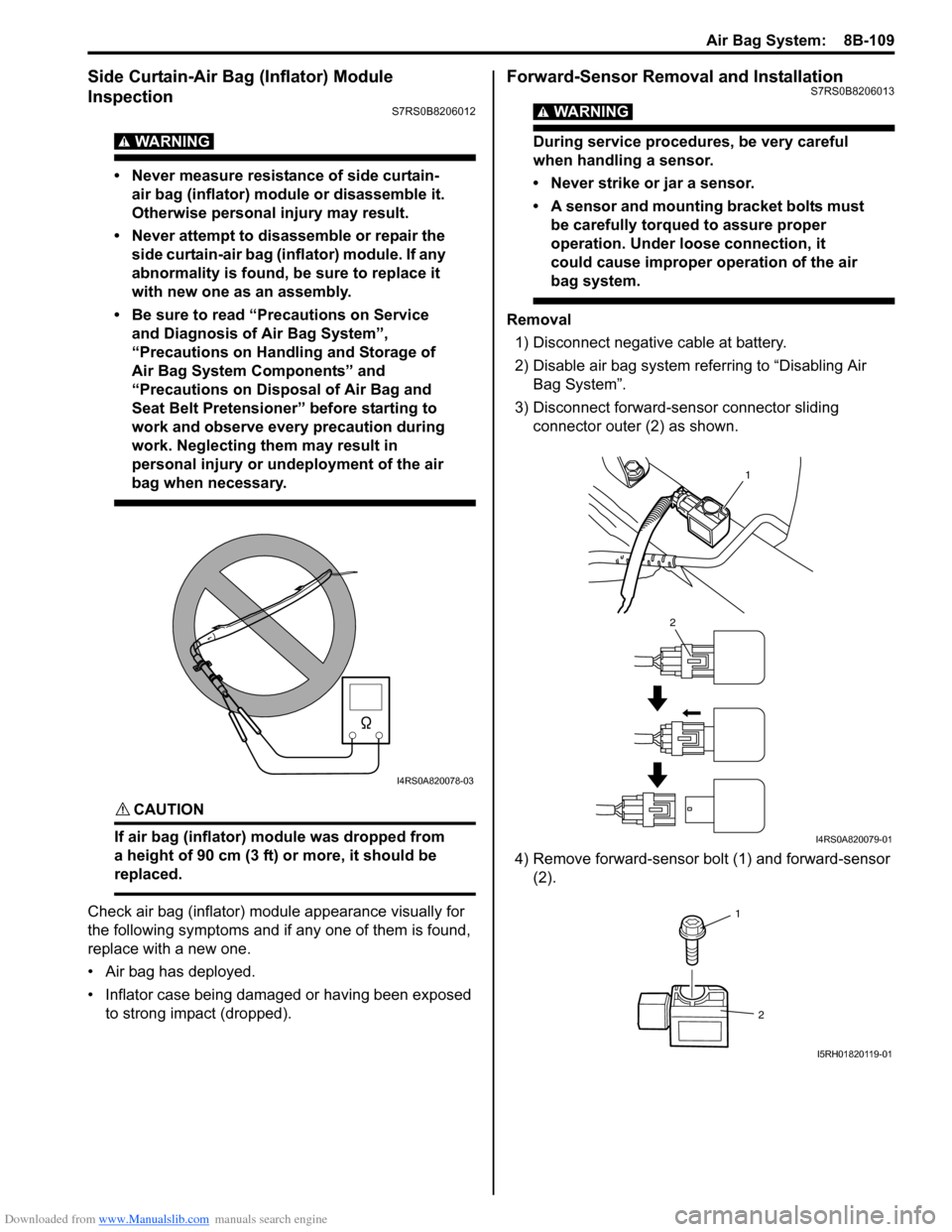

3) Disconnect side curtain-air bag (inflator) module connector (1) as shown in figure.

a) Unlock lock button (2).

b) With lock button unlocked, disconnect connector.

I4RS0A820075-02

2

1 a)

b)

I4RS0A820077-01

Page 1146 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-108 Air Bag System:

4) Remove side curtain-air bag (inflator) module fixing bolts (1) and clips (2).

5) Remove side curtain-air bag (inflator) module.

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live curtain air bag (inflator) module must be kept with it s bag facing up while

being stored or left standing. This is

necessary so that a free space is provided

to allow the air bag to expand in the

unlikely event of accidental deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

WARNING!

Do not install side curtain-air bag (inflator)

module while twisted or bended. Otherwise,

side curtain-air bag (inflator) module may not

deploy and injury may result.

1) Install side curtain-air bag (inflator) module (1) with

clips and new bolts.

2) Tighten side curtain-air bag (inflator) module attaching bolts (1) to specified torque.

Tightening torque

Side curtain-air bag (inflator) module attaching

bolts (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Connect side curtain-air bag (inflator) module connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector wi th lock button (2).

4) Install head lining referring to “Head Lining Removal and Installation in Section 9H”.

5) Enable air bag system. Refer to “Enabling Air Bag System”.1 2

2

22

1

I4RS0A820076-01

1,(a) 1,(a)

I4RS0A820110-01

1

2

a)

b)

I4RS0A820055-01

Page 1147 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-109

Side Curtain-Air Bag (Inflator) Module

Inspection

S7RS0B8206012

WARNING!

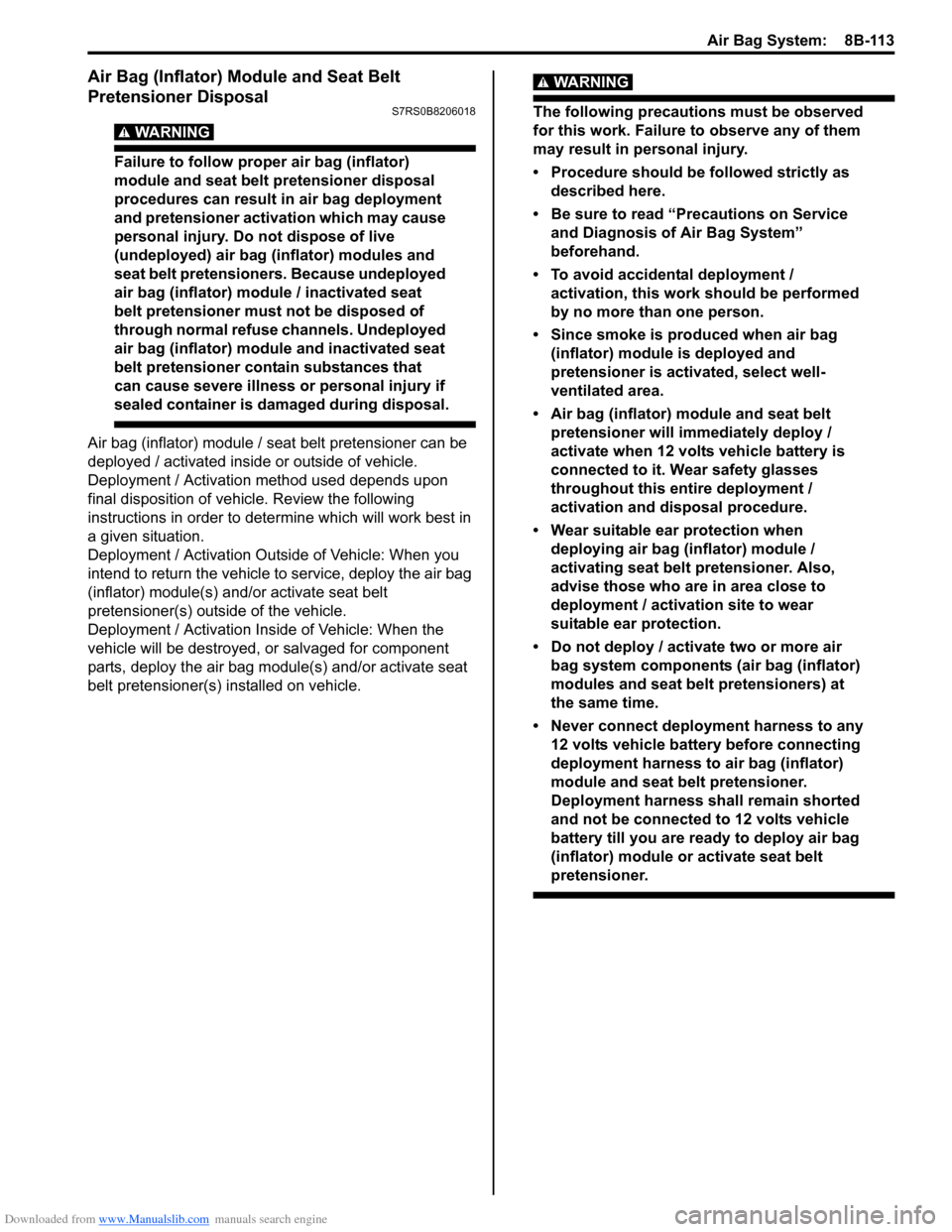

• Never measure resistance of side curtain-air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Inflator case being damaged or having been exposed to strong impact (dropped).

Forward-Sensor Removal and InstallationS7RS0B8206013

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System”.

3) Disconnect forward-sensor connector sliding connector outer (2) as shown.

4) Remove forward-sensor bolt (1) and forward-sensor (2).

I4RS0A820078-03

1

2

I4RS0A820079-01

1

2

I5RH01820119-01

Page 1151 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-113

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal

S7RS0B8206018

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. Do not dispose of live

(undeployed) air bag (inflator) modules and

seat belt pretensioners. Because undeployed

air bag (inflator) module / inactivated seat

belt pretensioner must not be disposed of

through normal refuse channels. Undeployed

air bag (inflator) module and inactivated seat

belt pretensioner contain substances that

can cause severe illness or personal injury if

sealed container is damaged during disposal.

Air bag (inflator) module / seat belt pretensioner can be

deployed / activated inside or outside of vehicle.

Deployment / Activation method used depends upon

final disposition of vehicle. Review the following

instructions in order to deter mine which will work best in

a given situation.

Deployment / Activation Ou tside of Vehicle: When you

intend to return the vehicle to service, deploy the air bag

(inflator) module(s) and/or activate seat belt

pretensioner(s) outside of the vehicle.

Deployment / Activation Insi de of Vehicle: When the

vehicle will be destroyed, or salvaged for component

parts, deploy the air bag module(s) and/or activate seat

belt pretensioner(s) installed on vehicle.

WARNING!

The following precautions must be observed

for this work. Failure to observe any of them

may result in personal injury.

• Procedure should be followed strictly as described here.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”

beforehand.

• To avoid accidental deployment / activation, this work should be performed

by no more than one person.

• Since smoke is produced when air bag (inflator) module is deployed and

pretensioner is activated, select well-

ventilated area.

• Air bag (inflator) module and seat belt pretensioner will immediately deploy /

activate when 12 volts vehicle battery is

connected to it. Wear safety glasses

throughout this entire deployment /

activation and disposal procedure.

• Wear suitable ear protection when deploying air bag (inflator) module /

activating seat belt pretensioner. Also,

advise those who are in area close to

deployment / activation site to wear

suitable ear protection.

• Do not deploy / activate two or more air bag system components (air bag (inflator)

modules and seat belt pretensioners) at

the same time.

• Never connect deployment harness to any 12 volts vehicle battery before connecting

deployment harness to air bag (inflator)

module and seat belt pretensioner.

Deployment harness sh all remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.

Page 1157 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-119

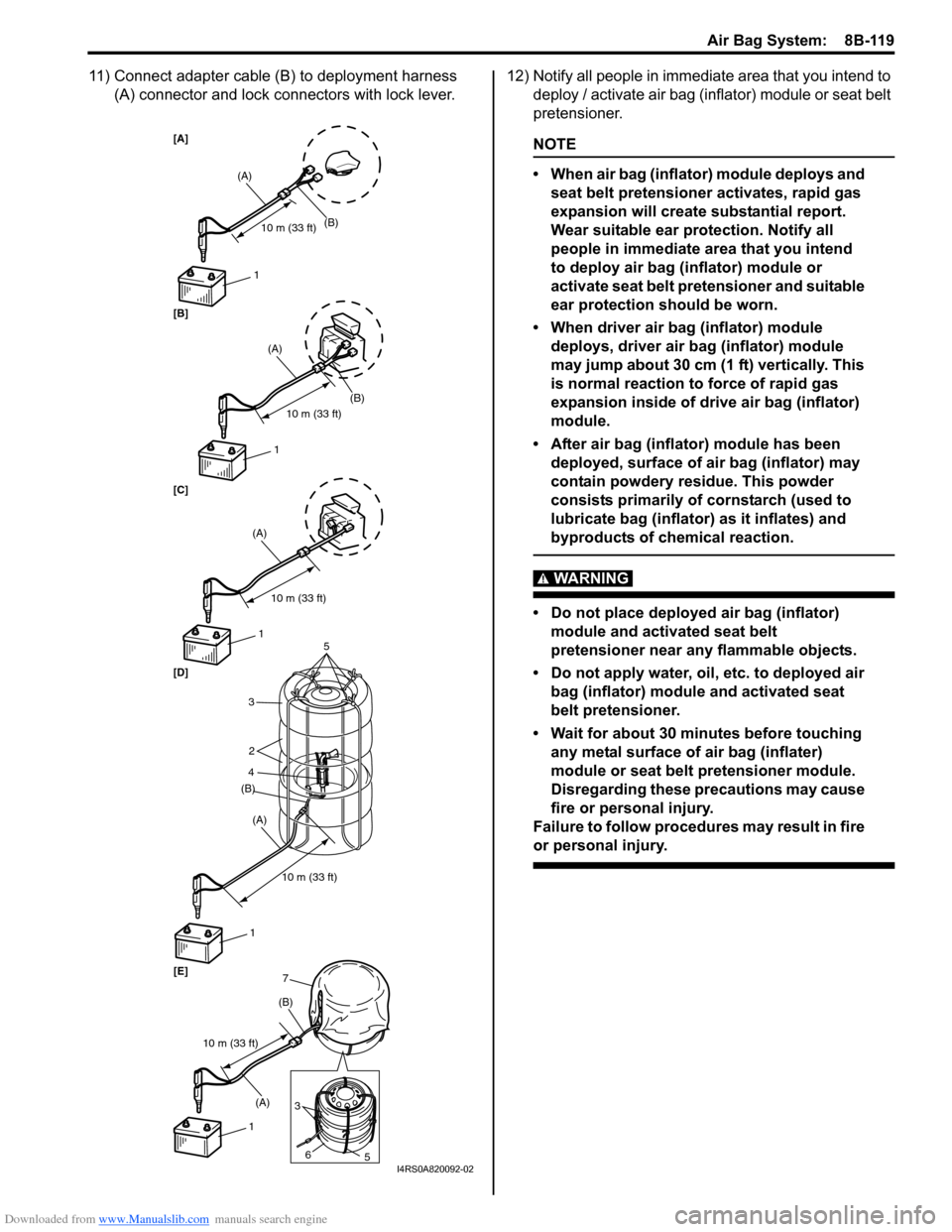

11) Connect adapter cable (B) to deployment harness (A) connector and lock connectors with lock lever. 12) Notify all people in immediate area that you intend to

deploy / activate air bag (inflator) module or seat belt

pretensioner.

NOTE

• When air bag (inflator) module deploys and seat belt pretensioner activates, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or

activate seat belt pretensioner and suitable

ear protection should be worn.

• When driver air bag (inflator) module deploys, driver air bag (inflator) module

may jump about 30 cm (1 ft) vertically. This

is normal reaction to force of rapid gas

expansion inside of drive air bag (inflator)

module.

• After air bag (inflator) module has been deployed, surface of air bag (inflator) may

contain powdery residue. This powder

consists primarily of cornstarch (used to

lubricate bag (inflator) as it inflates) and

byproducts of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator) module and activated seat belt

pretensioner near any flammable objects.

• Do not apply water, oil, etc. to deployed air bag (inflator) module and activated seat

belt pretensioner.

• Wait for about 30 minutes before touching any metal surface of air bag (inflater)

module or seat belt pretensioner module.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

[A]

10 m (33 ft)

(A)

(B)

1

10 m (33 ft)

(A)

(B) 1

5

3 2

4

(A)

[B]

[C]

[D]

[E]

7

3

6 5

(A) (B)

1

10 m (33 ft)

10 m (33 ft)

(A)

(B)

1

1

10 m (33 ft)

I4RS0A820092-02

Page 1158 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-120 Air Bag System:

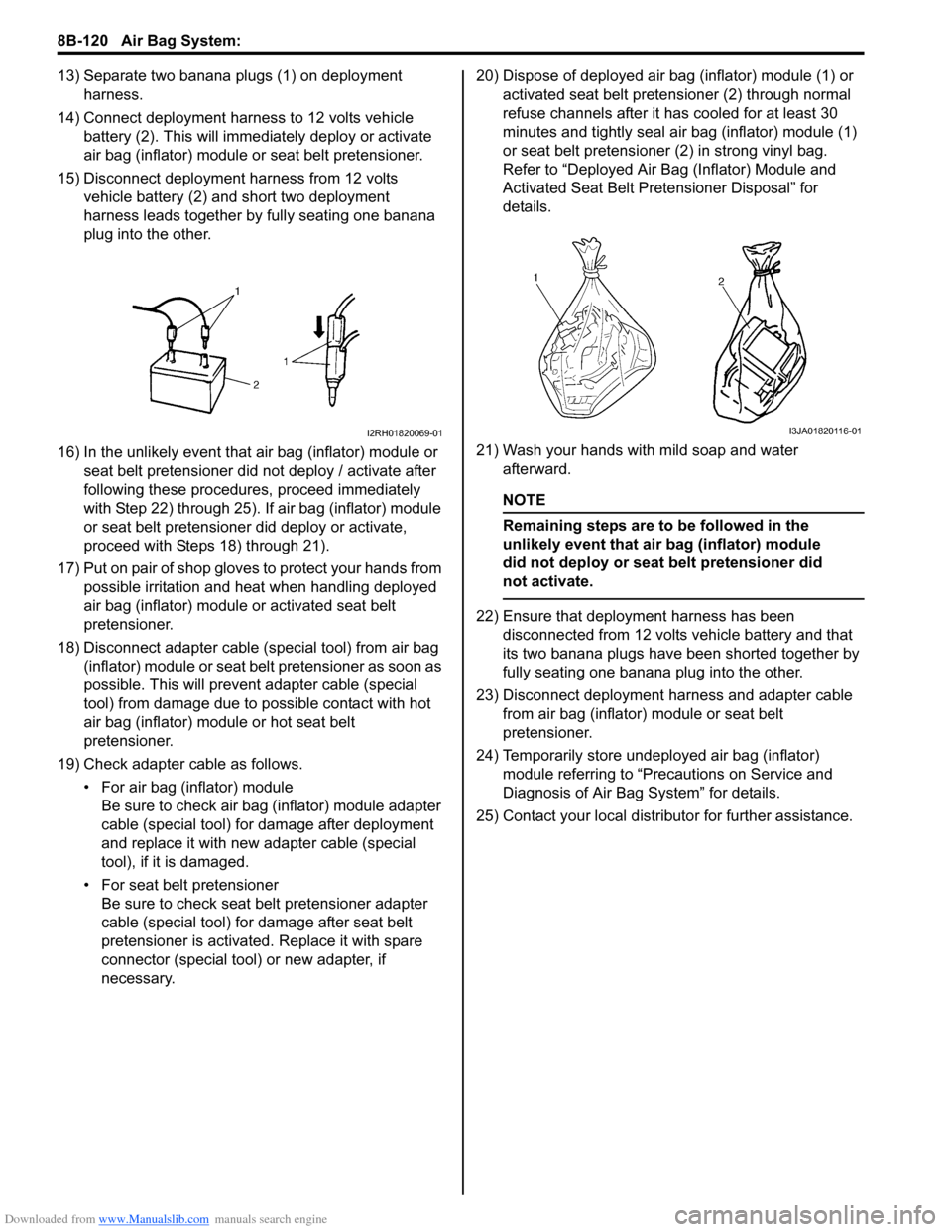

13) Separate two banana plugs (1) on deployment harness.

14) Connect deployment harness to 12 volts vehicle battery (2). This will immedi ately deploy or activate

air bag (inflator) module or seat belt pretensioner.

15) Disconnect deployment harness from 12 volts vehicle battery (2) and short two deployment

harness leads together by fully seating one banana

plug into the other.

16) In the unlikely event that air bag (inflator) module or seat belt pretensioner did not deploy / activate after

following these procedur es, proceed immediately

with Step 22) through 25). If air bag (inflator) module

or seat belt pretensioner did deploy or activate,

proceed with Steps 18) through 21).

17) Put on pair of shop gloves to protect your hands from possible irritation and heat when handling deployed

air bag (inflator) module or activated seat belt

pretensioner.

18) Disconnect adapter cable (special tool) from air bag (inflator) module or seat belt pretensioner as soon as

possible. This will preven t adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

19) Check adapter cable as follows. • For air bag (inflator) moduleBe sure to check air bag (inflator) module adapter

cable (special tool) for damage after deployment

and replace it with new adapter cable (special

tool), if it is damaged.

• For seat belt pretensioner Be sure to check seat belt pretensioner adapter

cable (special tool) for damage after seat belt

pretensioner is activated. Replace it with spare

connector (special tool) or new adapter, if

necessary. 20) Dispose of deployed air bag (inflator) module (1) or

activated seat belt preten sioner (2) through normal

refuse channels after it has cooled for at least 30

minutes and tightly seal air bag (inflator) module (1)

or seat belt pretensioner (2) in strong vinyl bag.

Refer to “Deployed Air B ag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal” for

details.

21) Wash your hands with mild soap and water afterward.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

22) Ensure that deployment harness has been disconnected from 12 volts vehicle battery and that

its two banana plugs have been shorted together by

fully seating one banana plug into the other.

23) Disconnect deployment harness and adapter cable from air bag (inflator) module or seat belt

pretensioner.

24) Temporarily store undeployed air bag (inflator) module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

25) Contact your local distributor for further assistance.

I2RH01820069-01I3JA01820116-01

Page 1161 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-123

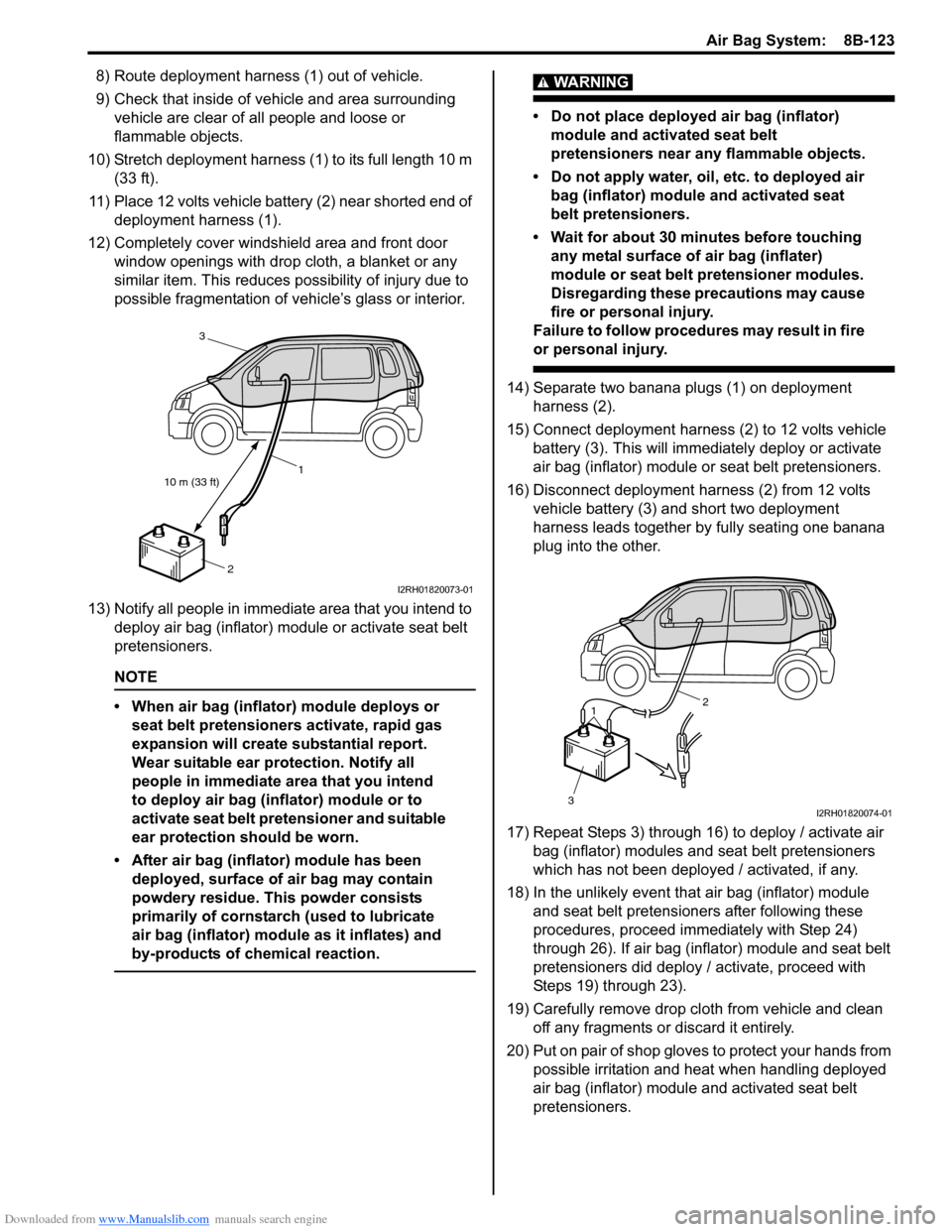

8) Route deployment harness (1) out of vehicle.

9) Check that inside of vehicle and area surrounding vehicle are clear of all people and loose or

flammable objects.

10) Stretch deployment harness (1) to its full length 10 m (33 ft).

11) Place 12 volts vehicle battery (2) near shorted end of deployment harness (1).

12) Completely cover windshield area and front door window openings with drop cloth, a blanket or any

similar item. This reduces possibility of injury due to

possible fragmentation of vehicle’s glass or interior.

13) Notify all people in immediate area that you intend to deploy air bag (inflator) module or activate seat belt

pretensioners.

NOTE

• When air bag (inflator) module deploys or seat belt pretensioners activate, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or to

activate seat belt pretensioner and suitable

ear protection should be worn.

• After air bag (inflator) module has been deployed, surface of air bag may contain

powdery residue. This powder consists

primarily of cornstarch (used to lubricate

air bag (inflator) module as it inflates) and

by-products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator) module and activated seat belt

pretensioners near any flammable objects.

• Do not apply water, oil, etc. to deployed air bag (inflator) module and activated seat

belt pretensioners.

• Wait for about 30 minutes before touching any metal surface of air bag (inflater)

module or seat belt pretensioner modules.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

14) Separate two banana plugs (1) on deployment harness (2).

15) Connect deployment harness (2) to 12 volts vehicle battery (3). This will immedi ately deploy or activate

air bag (inflator) module or seat belt pretensioners.

16) Disconnect deployment harness (2) from 12 volts vehicle battery (3) and short two deployment

harness leads together by fully seating one banana

plug into the other.

17) Repeat Steps 3) through 16) to deploy / activate air bag (inflator) modules and seat belt pretensioners

which has not been deployed / activated, if any.

18) In the unlikely event that air bag (inflator) module and seat belt pretensioners after following these

procedures, proceed immediately with Step 24)

through 26). If air bag (inflator) module and seat belt

pretensioners did deploy / activate, proceed with

Steps 19) through 23).

19) Carefully remove drop cloth from vehicle and clean off any fragments or discard it entirely.

20) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module and activated seat belt

pretensioners.

10 m (33 ft) 1

2

3

I2RH01820073-01

1

3 2

I2RH01820074-01

Page 1162 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-124 Air Bag System:

21) Disconnect adapter cable (special tool) from air bag (inflator) module or seat belt pretensioner as soon as

possible. This will preven t adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

22) Check adapter cable connector as follows. Adapter cable connector (special tool) is designed to

be reused. However it should be inspected for

damage after deployment and replaced if necessary.

23) With air bag (inflator) modules deployed and seat belt pretensioners acti vated, vehicle may be

scrapped in the same manner as non-air bag system

/ seat belt pretensioner equipped vehicle.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

24) Remove undeployed air bag (inflator) module(s) and/ or inactivated seat belt pretensioner(s) from vehicle.

For driver air bag (inflator) module, refer to “Driver

Air Bag (Inflator) Module Removal and Installation”.

For passenger air bag (inflator) module, refer to

“Passenger Air Bag (Inflator) Module Removal and

Installation”. For seat belt pretensioner, refer to

“Front Seat Belt Removal an d Installation in Section

8A”.

25) Temporarily store undeployed air bag (inflator) module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

26) Contact your local distribu tor for further assistance.

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal

S7RS0B8206019

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. The undeployed air bag

(inflator) module and the inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

the inactivated seat belt pretensioner

contains substances that can cause severe

illness or personal injury if the sealed

container is damaged during disposal.

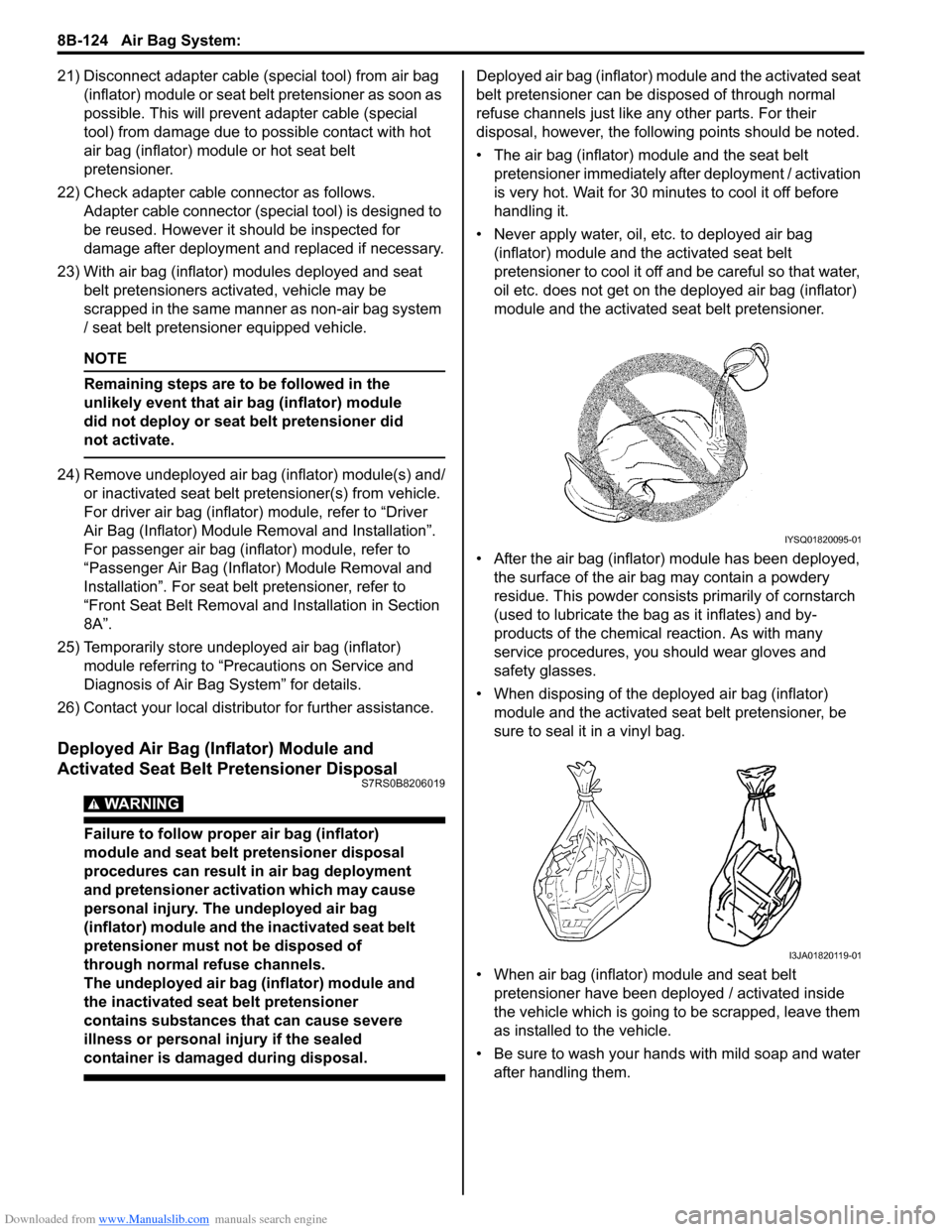

Deployed air bag (inflator) module and the activated seat

belt pretensioner can be disposed of through normal

refuse channels just like any other parts. For their

disposal, however, the following points should be noted.

• The air bag (inflator) module and the seat belt

pretensioner immediately after deployment / activation

is very hot. Wait for 30 minu tes to cool it off before

handling it.

• Never apply water, oil, etc. to deployed air bag (inflator) module and the activated seat belt

pretensioner to cool it off and be careful so that water,

oil etc. does not get on the deployed air bag (inflator)

module and the activated seat belt pretensioner.

• After the air bag (inflator) module has been deployed, the surface of the air bag may contain a powdery

residue. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-

products of the chemical reaction. As with many

service procedures, you should wear gloves and

safety glasses.

• When disposing of the deployed air bag (inflator) module and the activated seat belt pretensioner, be

sure to seal it in a vinyl bag.

• When air bag (inflator) module and seat belt pretensioner have been deployed / activated inside

the vehicle which is going to be scrapped, leave them

as installed to the vehicle.

• Be sure to wash your hand s with mild soap and water

after handling them.

IYSQ01820095-01

I3JA01820119-01

Page 1167 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems............... ......................... 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1 Abbreviations ...................................................... 9A-1

Wire / Connector Color Sy mbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-7

How to Read Power Supply Diagram.................. 9A-8

How to Read System Circuit Diagram................. 9A-8

Connector Layout Diagram . .............................. 9A-10

Connector Layout Diagram ............................... 9A-10

Engine Compartment .......... .............................. 9A-10

Instrument Panel ............................................... 9A-16

Door, Roof......................................................... 9A-20

Floor .................................................................. 9A-23

Rear .................................................................. 9A-29

Ground Point ...................................................... 9A-30 Ground (earth) Point ......................................... 9A-30

Power Supply Diagram ........ .............................. 9A-31

Power Supply Diagram ....... .............................. 9A-31

Fuses and the Protected Parts ......................... 9A-33

Fuses in Main Fuse Box (RHD) ........................ 9A-33

Fuses in Main Fuse Box (LHD) ......................... 9A-33

Individual Circuit Fuse Box No. 1 ...................... 9A-34

Individual Circuit Fuse Box No. 2 (In J/B) ......... 9A-35

Junction Block (J/B) Connector / Fuse Layout .. 9A-37

Junction Block Inner Circuit (Overview) ............ 9A-38

Junction Block Inner Circuit (Detail) .................. 9A-40

System Circuit Diagram... .................................. 9A-45

System Circuit Diagram .. .................................. 9A-45

A-1 Cranking System Circ uit Diagram .............. 9A-46

A-2 Charging System Circu it Diagram .............. 9A-47

A-3 Ignition System Circu it Diagram ................. 9A-48

A-4 Cooling System Circuit Diagram................. 9A-49 A-5 Engine and A/C Control System Circuit

Diagram........................................................... 9A-50

A-6 A/T Control System Circuit Diagram........... 9A-55

A-7 Immobilizer System Circuit Diagram .......... 9A-57

A-8 Body Control System Circuit Diagram ........ 9A-58

B-1 Windshield Wiper and Washer Circuit Diagram........................................................... 9A-62

B-2 Rear Wiper and Washer Circuit Diagram ... 9A-63

B-3 Rear Defogger Circuit Diagram .................. 9A-64

B-4 Power Window Circuit Diagram .................. 9A-65

B-5 Power Door Lock Circu it Diagram .............. 9A-67

B-6 Power Mirror Circuit Diagram ..................... 9A-69

B-7 Horn Circuit Diagram .................................. 9A-70

B-8 Seat Heater Circuit Diagram....................... 9A-71

B-9 Keyless Start System Circuit Diagram........ 9A-72

C-1 Combination Mete r Circuit Diagram

(Meter)............................................................. 9A-73

C-2 Combination Mete r Circuit Diagram

(Indicator) ........................................................ 9A-74

C-3 Combination Mete r Circuit Diagram

(Warning Light)................................................ 9A-75

D-1 Headlight System Circuit Diagram ............. 9A-77

D-2 Position, Tail and Licence Plate Light System Circuit Diagram .................................. 9A-79

D-3 Front Fog Light System Circuit Diagram .... 9A-80

D-4 Illumination Light System Circuit Diagram .. 9A-81

D-5 Interior Light System Circuit Diagram......... 9A-82

D-6 Turn Signal and Hazard Warning Light System Circuit Diagram .................................. 9A-83

D-7 Brake Light System Circuit Diagram .......... 9A-85

D-8 Back-Up Light System Circuit Diagram ...... 9A-86

D-9 Headlight Beam Leveling System Circuit Diagram........................................................... 9A-87

D-10 Rear Fog Light Circuit Diagram ................ 9A-88

E-1 Heater System Circuit Diagram .................. 9A-89

E-2 Auto A/C System Circuit Diagram .............. 9A-91

F-1 Air-Bag System Circuit Diagram ................. 9A-93

F-2 Anti-Lock Brake System Circuit Diagram.... 9A-95

F-3 Electronic Stab ility Program System

Circuit Diagram .................. ............................. 9A-97

F-4 Power Steering System Circuit Diagram .... 9A-99

G-1 Audio System Circuit Diagram ................. 9A-101

G-2 Multi Information Display / Accessory Socket System Circuit Diagram .................... 9A-102

List of Connector .............................................9A-103

Page 1168 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-ii Table of Contents

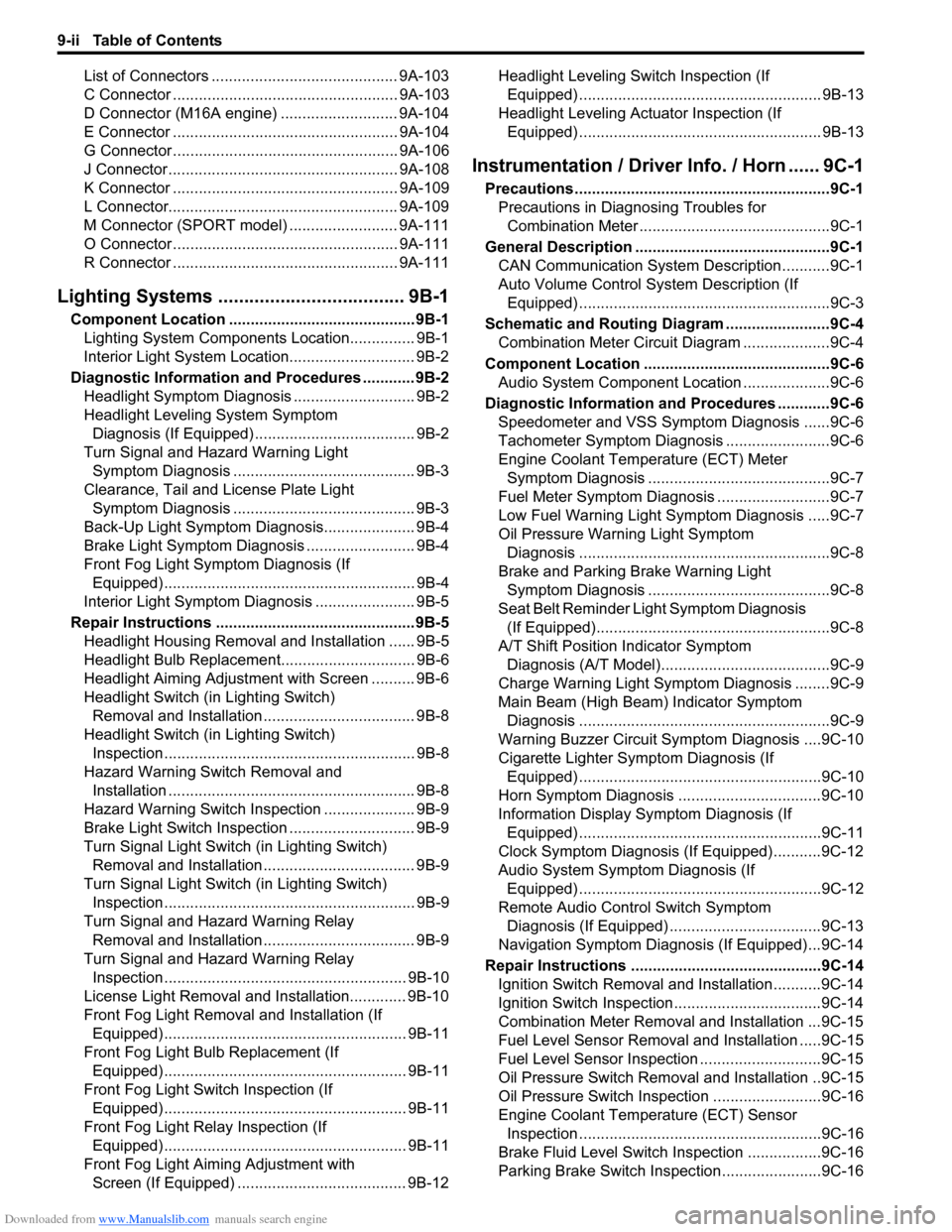

List of Connectors ........................................... 9A-103

C Connector .................................................... 9A-103

D Connector (M16A engine) ........................... 9A-104

E Connector .................................................... 9A-104

G Connector .................................................... 9A-106

J Connector ..................................................... 9A-108

K Connector .................................................... 9A-109

L Connector..................................................... 9A-109

M Connector (SPORT model) ......................... 9A-111

O Connector .................................................... 9A-111

R Connector .................................................... 9A-111

Lighting Systems .................................... 9B-1

Component Location ........... ................................9B-1

Lighting System Component s Location............... 9B-1

Interior Light System Location............................. 9B-2

Diagnostic Information and Procedures ............ 9B-2 Headlight Symptom Diagnosis ............................ 9B-2

Headlight Leveling System Symptom Diagnosis (If Equipped) ..................................... 9B-2

Turn Signal and Hazard Warning Light Symptom Diagnosis .......................................... 9B-3

Clearance, Tail and License Plate Light Symptom Diagnosis .......................................... 9B-3

Back-Up Light Symptom Diagnosis..................... 9B-4

Brake Light Symptom Diagnosis ......................... 9B-4

Front Fog Light Symptom Diagnosis (If Equipped) .......................................................... 9B-4

Interior Light Symptom Diagnosis ....................... 9B-5

Repair Instructions ..............................................9B-5 Headlight Housing Removal and Installation ...... 9B-5

Headlight Bulb Replacemen t............................... 9B-6

Headlight Aiming Adjustment with Screen .......... 9B-6

Headlight Switch (in Lighting Switch) Removal and Installation ................................... 9B-8

Headlight Switch (in Lighting Switch) Inspection .......................................................... 9B-8

Hazard Warning Switch Removal and Installation ......................................................... 9B-8

Hazard Warning Switch Inspection ..................... 9B-9

Brake Light Switch Inspection ............................. 9B-9

Turn Signal Light Switch (in Lighting Switch) Removal and Installation ................................... 9B-9

Turn Signal Light Switch (in Lighting Switch) Inspection .......................................................... 9B-9

Turn Signal and Hazard Warning Relay Removal and Installation ................................... 9B-9

Turn Signal and Hazard Warning Relay Inspection ........................................................ 9B-10

License Light Removal and Installation............. 9B-10

Front Fog Light Removal and Installation (If Equipped) ........................................................ 9B-11

Front Fog Light Bulb Replacement (If Equipped) ........................................................ 9B-11

Front Fog Light Switch Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Relay Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Aiming Adjustment with Screen (If Equipped) ....................................... 9B-12 Headlight Leveling Switch Inspection (If

Equipped) ........................................................ 9B-13

Headlight Leveling Actuator Inspection (If Equipped) ........................................................ 9B-13

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions ...........................................................9C-1 Precautions in Diagnosing Troubles for Combination Meter ............................................9C-1

General Description .............................................9C-1 CAN Communication System Description...........9C-1

Auto Volume Co ntrol System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4 Combination Meter Circuit Diagram ....................9C-4

Component Location ............ ...............................9C-6

Audio System Component Location ....................9C-6

Diagnostic Information and Procedures ............9C-6 Speedometer and VSS Symp tom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter Symptom Diagnosis ..........................................9C-7

Fuel Meter Symptom Diagnosis ..........................9C-7

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom Diagnosis ..........................................................9C-8

Brake and Parking Brake Warning Light Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis (If Equipped)......................................................9C-8

A/T Shift Position Indicator Symptom Diagnosis (A/T Model).......................................9C-9

Charge Warning Light Sy mptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Sy mptom Diagnosis ....9C-10

Cigarette Lighter Symptom Diagnosis (If Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If Equipped) ........................................................9C-11

Clock Symptom Diagnosis (If Equipped)...........9C-12

Audio System Symptom Diagnosis (If Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-14

Repair Instructions ............ ................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-15

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Remova l and Installation ..9C-15

Oil Pressure Switch Inspec tion .........................9C-16

Engine Coolant Temperature (ECT) Sensor Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspec tion.......................9C-16