bolts SUZUKI SWIFT 2005 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 742 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-98 Automatic Transmission/Transaxle:

Transmission Fluid Temperature Sensor

Inspection

S7RS0B5106021

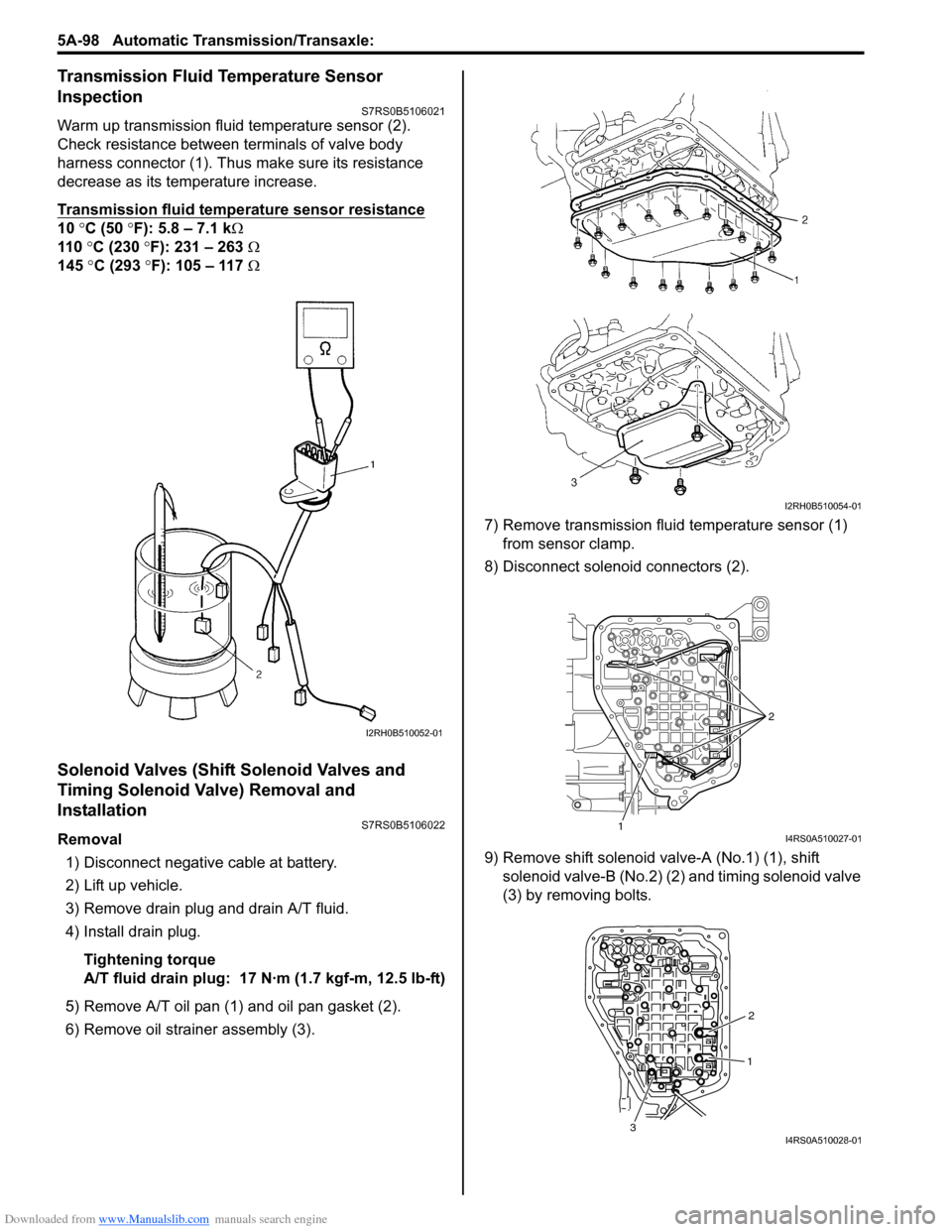

Warm up transmission fluid temperature sensor (2).

Check resistance between terminals of valve body

harness connector (1). Thus make sure its resistance

decrease as its temperature increase.

Transmission fluid temperature sensor resistance

10 °C (50 °F): 5.8 – 7.1 k Ω

110 °C (230 °F): 231 – 263 Ω

145 °C (293 °F): 105 – 117 Ω

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation

S7RS0B5106022

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N· m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

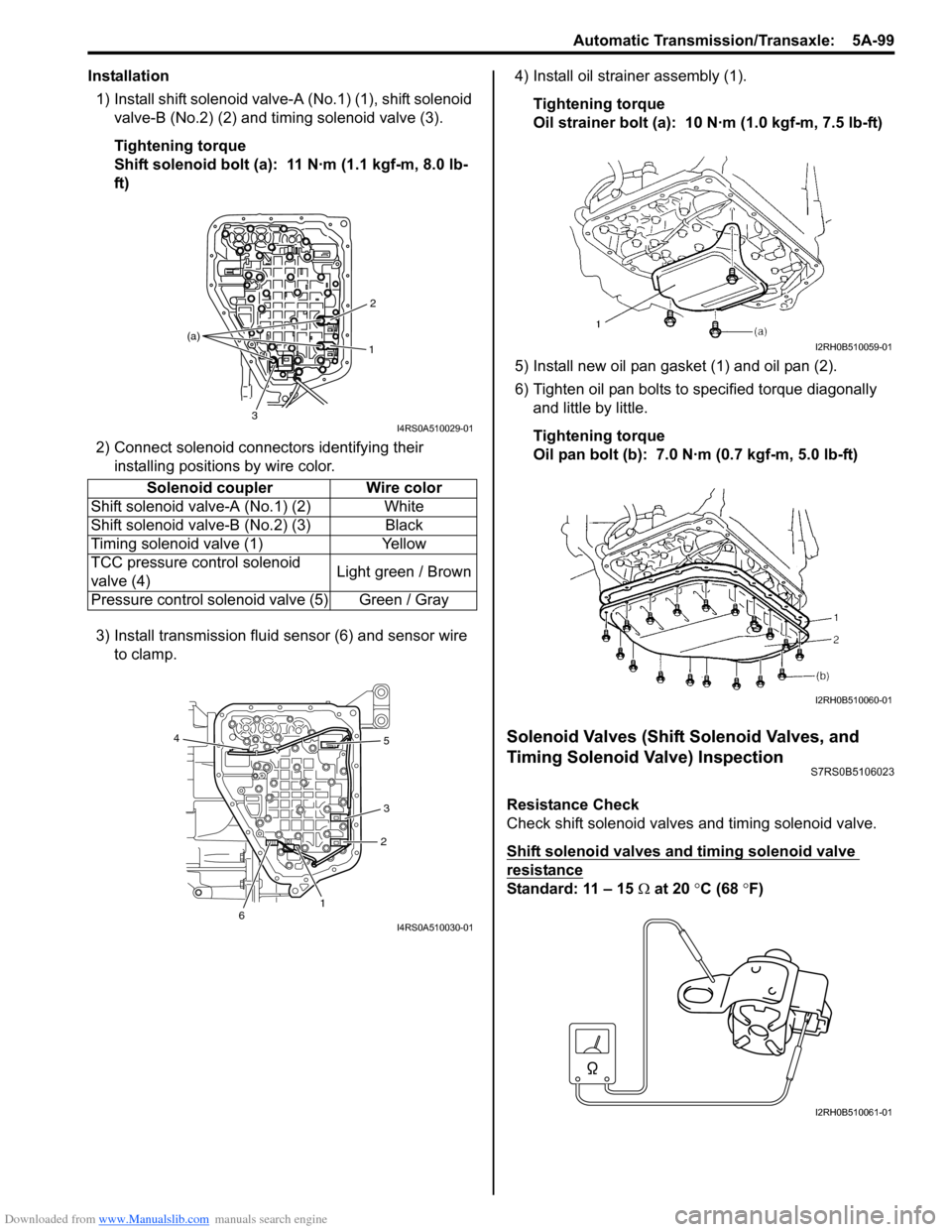

6) Remove oil strain er assembly (3). 7) Remove transmission fluid temperature sensor (1)

from sensor clamp.

8) Disconnect solenoid connectors (2).

9) Remove shift solenoid va lve-A (No.1) (1), shift

solenoid valve-B (No.2) (2) and timing solenoid valve

(3) by removing bolts.

I2RH0B510052-01

I2RH0B510054-01

1 2I4RS0A510027-01

1

2

3

I4RS0A510028-01

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 – 15 Ω at 20 °C (68 ° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01

Page 746 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

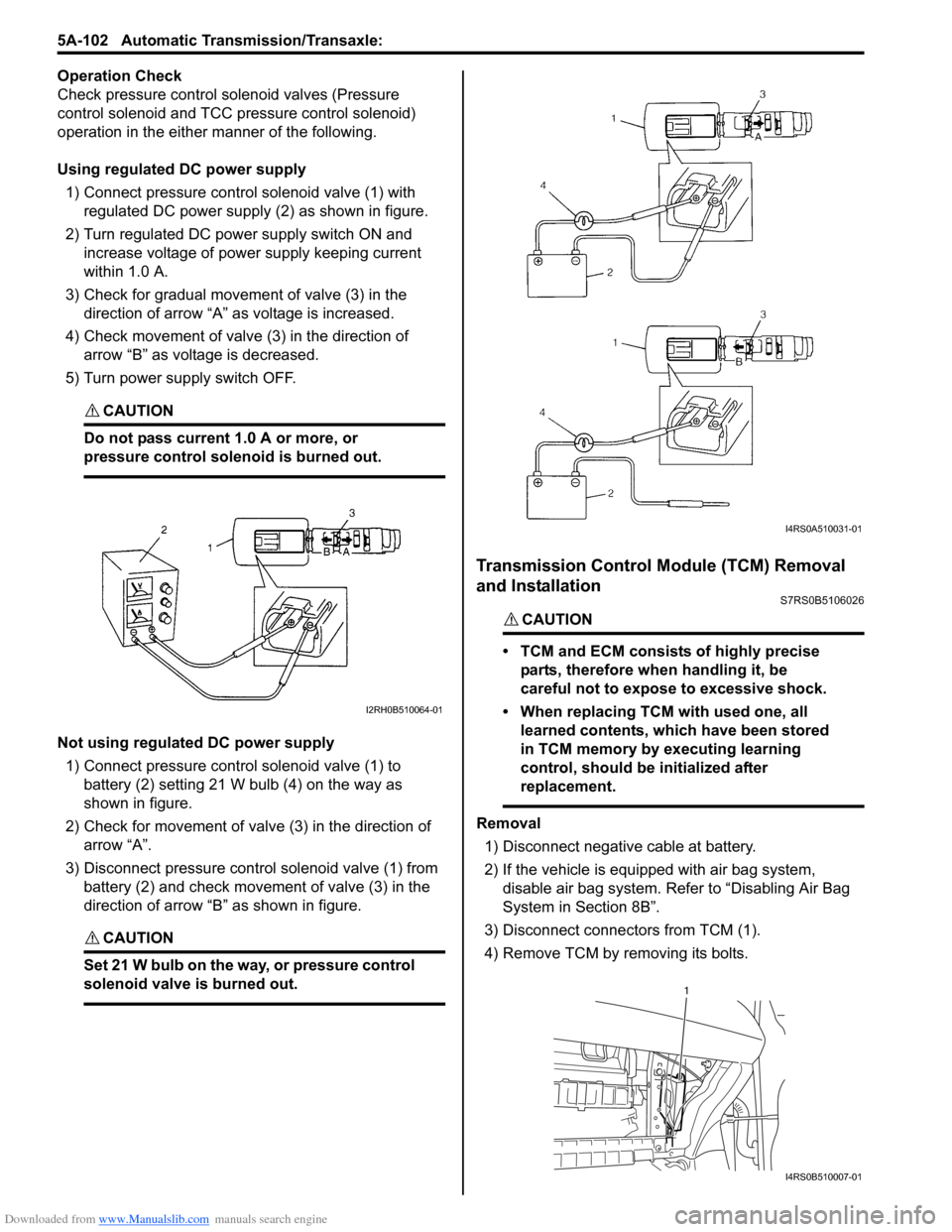

Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

Using regulated DC power supply

1) Connect pressure contro l solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply 1) Connect pressure control solenoid valve (1) to battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of arrow “A”.

3) Disconnect pressure control solenoid valve (1) from battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

Transmission Control Module (TCM) Removal

and Installation

S7RS0B5106026

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its bolts.

I2RH0B510064-01

I4RS0A510031-01

1

I4RS0B510007-01

Page 750 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-106 Automatic Transmission/Transaxle:

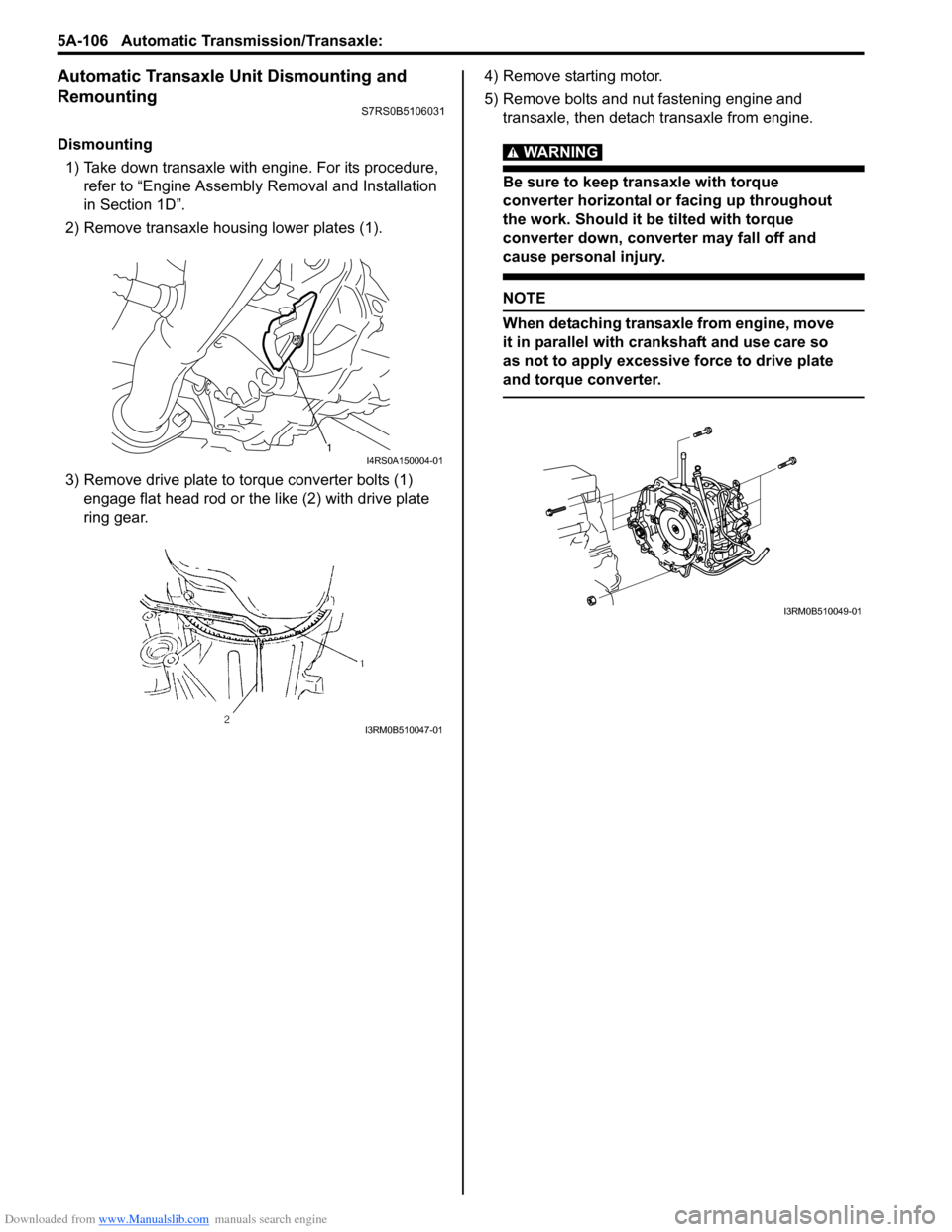

Automatic Transaxle Unit Dismounting and

Remounting

S7RS0B5106031

Dismounting1) Take down transaxle with engine. For its procedure, refer to “Engine Assembly Removal and Installation

in Section 1D”.

2) Remove transaxle housing lower plates (1).

3) Remove drive plate to torque converter bolts (1) engage flat head rod or the like (2) with drive plate

ring gear. 4) Remove starting motor.

5) Remove bolts and nut fastening engine and

transaxle, then detach transaxle from engine.WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

NOTE

When detaching transaxle from engine, move

it in parallel with cranks haft and use care so

as not to apply excessive force to drive plate

and torque converter.

1I4RS0A150004-01

I3RM0B510047-01

I3RM0B510049-01

Page 751 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-107

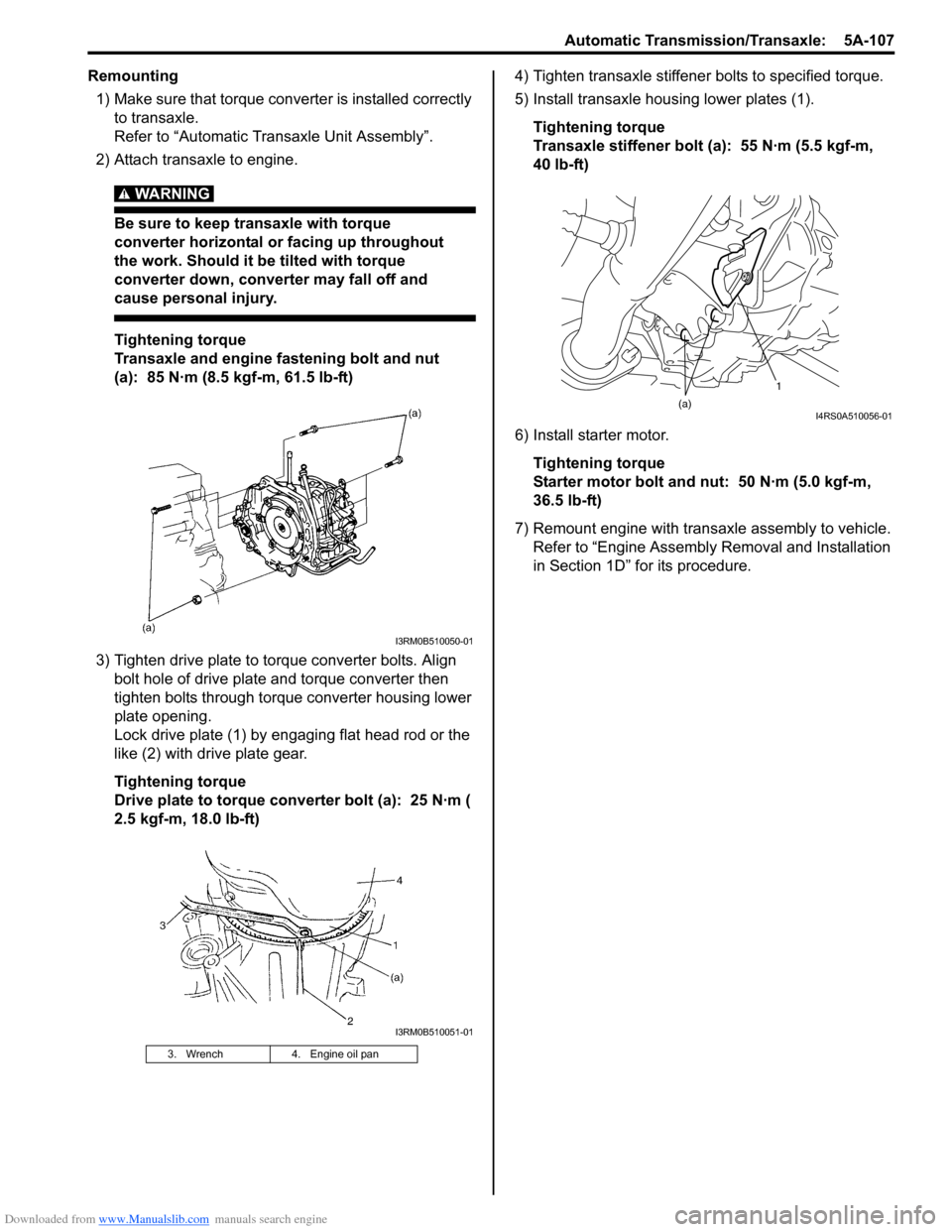

Remounting1) Make sure that torque converter is installed correctly to transaxle.

Refer to “Automatic Transaxle Unit Assembly”.

2) Attach transaxle to engine.

WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

Tightening torque

Transaxle and engine fastening bolt and nut

(a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

3) Tighten drive plate to torque converter bolts. Align bolt hole of drive plate and torque converter then

tighten bolts through torque converter housing lower

plate opening.

Lock drive plate (1) by engaging flat head rod or the

like (2) with drive plate gear.

Tightening torque

Drive plate to torque converter bolt (a): 25 N·m (

2.5 kgf-m, 18.0 lb-ft) 4) Tighten transaxle stiffener bolts to specified torque.

5) Install transaxle housing lower plates (1).

Tightening torque

Transaxle stiffener bolt (a): 55 N·m (5.5 kgf-m,

40 lb-ft)

6) Install starter motor. Tightening torque

Starter motor bolt and nut: 50 N·m (5.0 kgf-m,

36.5 lb-ft)

7) Remount engine with transaxle assembly to vehicle. Refer to “Engine Assembly Removal and Installation

in Section 1D” for its procedure.

3. Wrench 4. Engine oil pan

I3RM0B510050-01

I3RM0B510051-01

1

(a)

I4RS0A510056-01

Page 755 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-111

8) Remove fluid cooler pipes (1) and pipe union (2).

9) Remove fluid level gauge (3) and fluid filler tube (4).

10) Remove oil pan (1) and oil pan gasket (2).

NOTE

• For removal of oil pan, do not turn transaxle over as this will contaminate

valve body with foreign materials in

bottom of oil pan.

• When removing oil pan, tap around it lightly with plastic ha mmer. Do not force it

off by using screwdriver or the like.

11) Remove oil strain er assembly (1). 12) Disconnect connectors (2) from solenoid valves and

transmission fluid temperature sensor (1).

13) Remove valve body assembly bolts.

CAUTION!

Be careful not to let manual valve fall off

when removing valve body assembly.

NOTE

There are five kinds of bolts (bolts A (1), B (2),

C (3), D (4) and E (5)) fixing valve body

assembly.

14) Remove manual valve rod (1) from manual valve lever (2), then remove valve body assembly (3).

1 2

4

3

I3RM0B510059-01

I2RH0B510086-01

I2RH0B510087-01

1 2I4RS0A510027-01

I2RH0B510089-01

I2RH0B510090-01

Page 757 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-113

19) Remove transaxle case plug (1).

20) Remove torque converter housing bolts.

21) Remove torque converter housing (1) while tapping

around it lightly with plastic hammer.

22) Remove breather hose (1).

23) Remove breather union (2).

24) Measure input shaft thrust play. Apply dial gauge onto input shaft end (1) and

measure thrust play of input shaft.

When input shaft thrust play is out of specification,

select input shaft front th rust bearing with proper

thickness from among the list below and replace it.

Special tool

(A): 09900–20607

(B): 09900-20701

Input shaft thrust play

0.3 – 0.9 mm (0.012 – 0.035 in.)

Available input shaft front thrust bearing

thickness

: 3.45, 4.05 mm (0.136, 0.159 in.) 25) Remove oil pump assembly (1).

26) Remove direct clutch assembly (1).

27) Remove input shaft front thrust bearing (1).

NOTE

If input shaft front thrust bearing is not

found, it may have been taken out with oil

pump assembly.

I2RH0B510095-01

I3RM0B510060-01

1

2

I2RH0B510097-01

I2RH0B510098-01

I2RH0B510099-01

I2RH0B510100-01

I2RH0B510101-01

Page 764 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-120 Automatic Transmission/Transaxle:

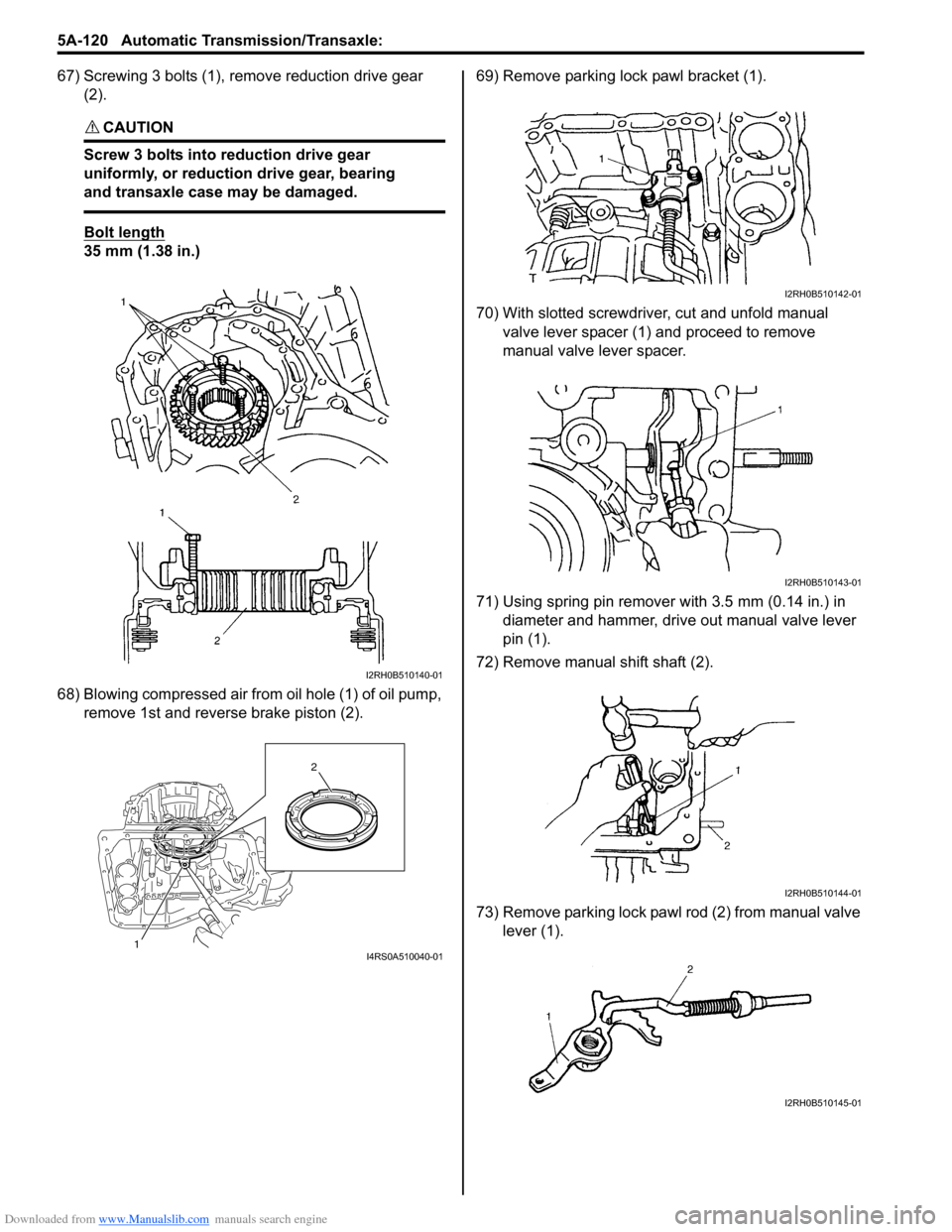

67) Screwing 3 bolts (1), remove reduction drive gear (2).

CAUTION!

Screw 3 bolts into reduction drive gear

uniformly, or reduction drive gear, bearing

and transaxle case may be damaged.

Bolt length

35 mm (1.38 in.)

68) Blowing compressed air from oil hole (1) of oil pump,

remove 1st and reverse brake piston (2). 69) Remove parking lock pawl bracket (1).

70) With slotted screwdriver, cut and unfold manual

valve lever spacer (1) and proceed to remove

manual valve lever spacer.

71) Using spring pin remover with 3.5 mm (0.14 in.) in diameter and hammer, drive out manual valve lever

pin (1).

72) Remove manual shift shaft (2).

73) Remove parking lock pawl rod (2) from manual valve lever (1).

I2RH0B510140-01

1 2I4RS0A510040-01

I2RH0B510142-01

I2RH0B510143-01

I2RH0B510144-01

I2RH0B510145-01

Page 765 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-121

74) Remove manual detent spring (1).75) Remove manual shift shaft oil seal (1).

Oil Pump Assembly ComponentsS7RS0B5106034

I2RH0B510146-01I2RH0B510147-01

I2RH0B510148-01

1. Oil seal

: Apply grease 99000-25030 to oil seal lip. 5. Oil pump drive gear : Apply automatic transaxle fluid.

2. O-ring 6. Stator shaft assembly : Tightening torque

3. Oil pump body 7. Oil pump subassembly bolts : Do not reuse.

4. Oil pump driven gear

Page 766 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-122 Automatic Transmission/Transaxle:

Oil Pump Assembly Disassembly and

Reassembly

S7RS0B5106035

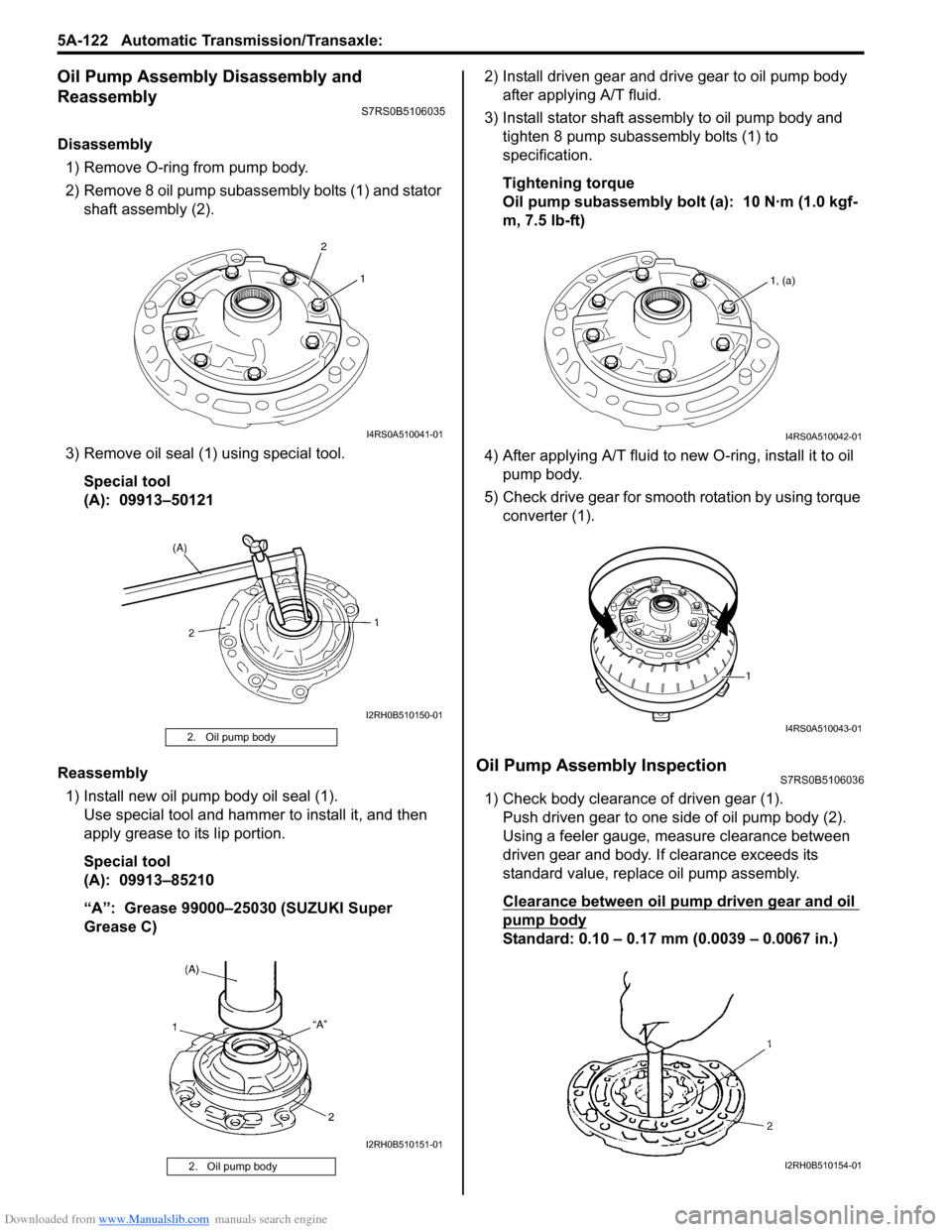

Disassembly1) Remove O-ring from pump body.

2) Remove 8 oil pump subassembly bolts (1) and stator shaft assembly (2).

3) Remove oil seal (1) using special tool. Special tool

(A): 09913–50121

Reassembly 1) Install new oil pump body oil seal (1). Use special tool and hammer to install it, and then

apply grease to its lip portion.

Special tool

(A): 09913–85210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C) 2) Install driven gear and drive gear to oil pump body

after applying A/T fluid.

3) Install stator shaft assembly to oil pump body and tighten 8 pump subassembly bolts (1) to

specification.

Tightening torque

Oil pump subassembly bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

4) After applying A/T fluid to new O-ring, install it to oil pump body.

5) Check drive gear for smooth rotation by using torque converter (1).

Oil Pump Assembly InspectionS7RS0B5106036

1) Check body clearance of driven gear (1).Push driven gear to one side of oil pump body (2).

Using a feeler gauge, m easure clearance between

driven gear and body. If clearance exceeds its

standard value, replace oil pump assembly.

Clearance between oil pump driven gear and oil

pump body

Standard: 0.10 – 0.17 mm (0.0039 – 0.0067 in.)

2. Oil pump body

2. Oil pump body

2 1

I4RS0A510041-01

I2RH0B510150-01

I2RH0B510151-01

1, (a)

I4RS0A510042-01

1

I4RS0A510043-01

I2RH0B510154-01