5A- SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 773 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-129

Forward and Reverse Clutch Assembly

Preliminary Check

S7RS0B5106042

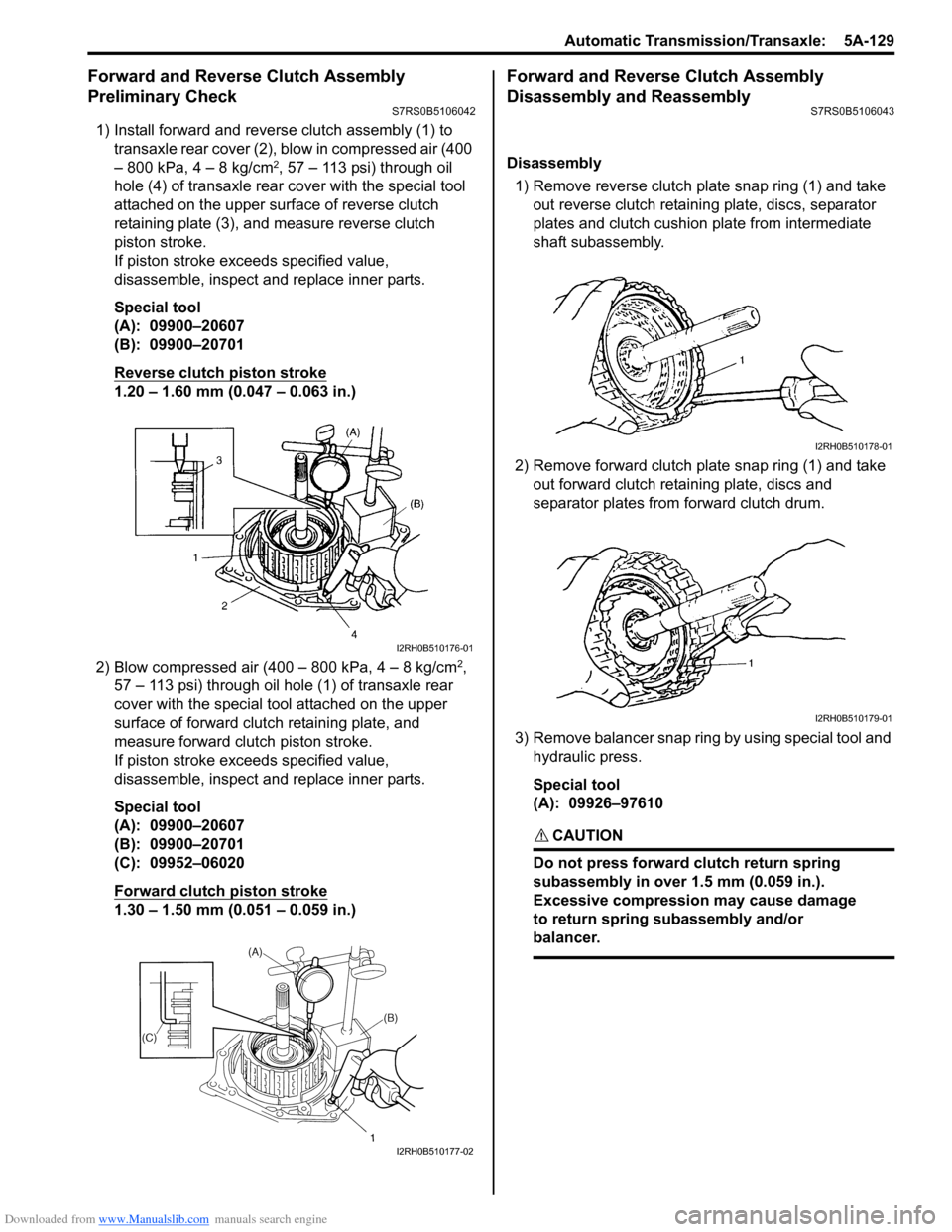

1) Install forward and reverse clutch assembly (1) to

transaxle rear cover (2), blow in compressed air (400

– 800 kPa, 4 – 8 kg/cm

2, 57 – 113 psi) through oil

hole (4) of transaxle rear cover with the special tool

attached on the upper surf ace of reverse clutch

retaining plate (3), and measure reverse clutch

piston stroke.

If piston stroke exce eds specified value,

disassemble, inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701

Reverse clutch piston stroke

1.20 – 1.60 mm (0.047 – 0.063 in.)

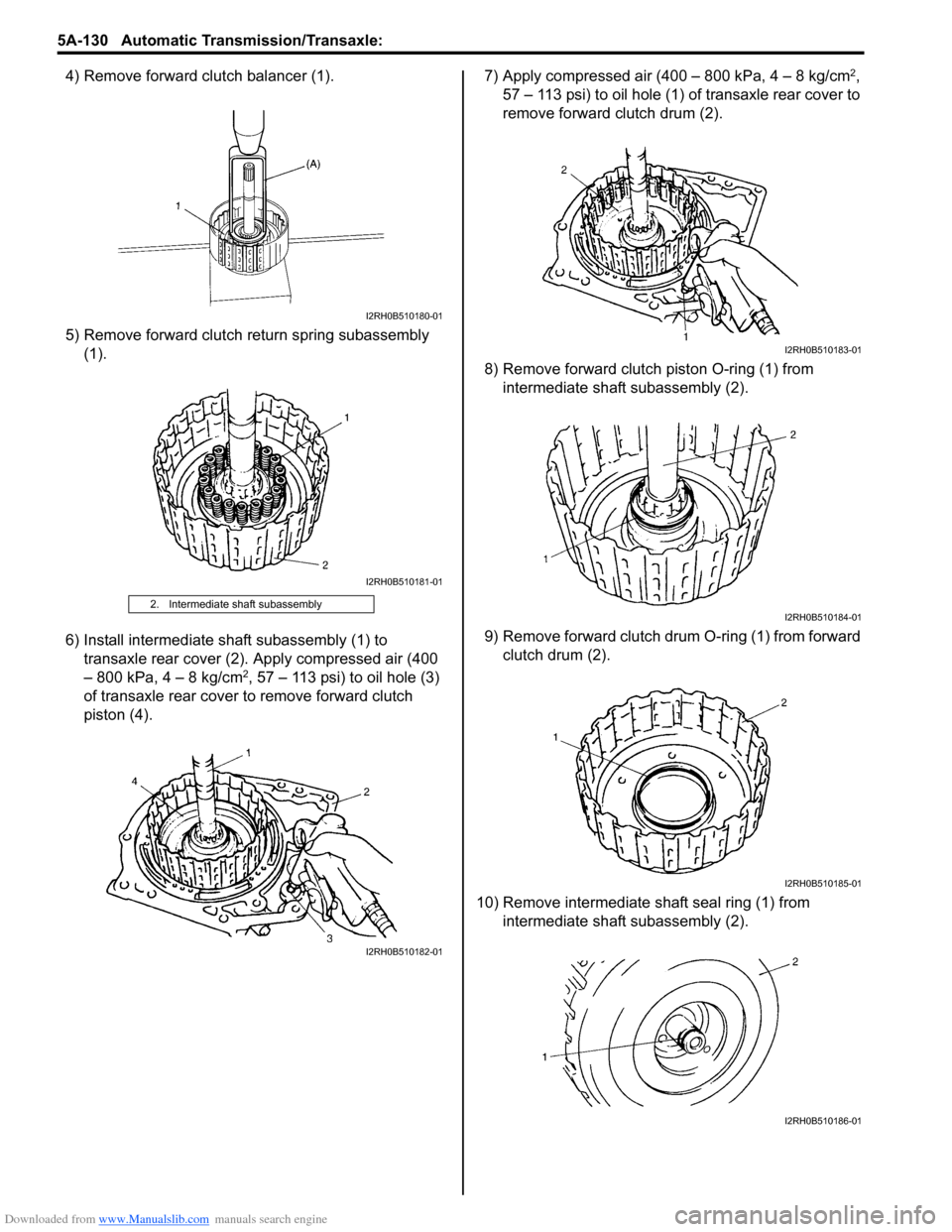

2) Blow compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) through oil hole (1) of transaxle rear

cover with the special tool attached on the upper

surface of forward clutch retaining plate, and

measure forward clutch piston stroke.

If piston stroke exce eds specified value,

disassemble, inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

Forward clutch piston stroke

1.30 – 1.50 mm (0.051 – 0.059 in.)

Forward and Reverse Clutch Assembly

Disassembly and Reassembly

S7RS0B5106043

Disassembly

1) Remove reverse clutch plate snap ring (1) and take out reverse clutch retaini ng plate, discs, separator

plates and clutch cushion plate from intermediate

shaft subassembly.

2) Remove forward clutch plate snap ring (1) and take out forward clutch retaining plate, discs and

separator plates from forward clutch drum.

3) Remove balancer snap ring by using special tool and hydraulic press.

Special tool

(A): 09926–97610

CAUTION!

Do not press forward clutch return spring

subassembly in over 1.5 mm (0.059 in.).

Excessive compression may cause damage

to return spring subassembly and/or

balancer.

I2RH0B510176-01

I2RH0B510177-02

I2RH0B510178-01

I2RH0B510179-01

Page 774 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-130 Automatic Transmission/Transaxle:

4) Remove forward clutch balancer (1).

5) Remove forward clutch return spring subassembly

(1).

6) Install intermed iate shaft subassembly (1) to

transaxle rear cover (2). Apply compressed air (400

– 800 kPa, 4 – 8 kg/cm

2, 57 – 113 psi) to oil hole (3)

of transaxle rear cover to remove forward clutch

piston (4). 7) Apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) to oil hole (1) of transaxle rear cover to

remove forward clutch drum (2).

8) Remove forward clutch piston O-ring (1) from intermediate shaft subassembly (2).

9) Remove forward clutch drum O-ring (1) from forward clutch drum (2).

10) Remove intermediate shaft seal ring (1) from intermediate shaft subassembly (2).

2. Intermediate shaft subassembly

I2RH0B510180-01

I2RH0B510181-01

I2RH0B510182-01

I2RH0B510183-01

I2RH0B510184-01

I2RH0B510185-01

I2RH0B510186-01

Page 775 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-131

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Before assembling, apply automatic transaxle fluid to component parts.

• Replace O-rings and seal ring with new ones.

• Do not damage forward clutch return spring subassembly and balancer (1) by pressing forward

clutch return spring subassembly passing through its

original installing position over 1.5 mm (0.059 in.).

Special tool

(A): 09926–97610

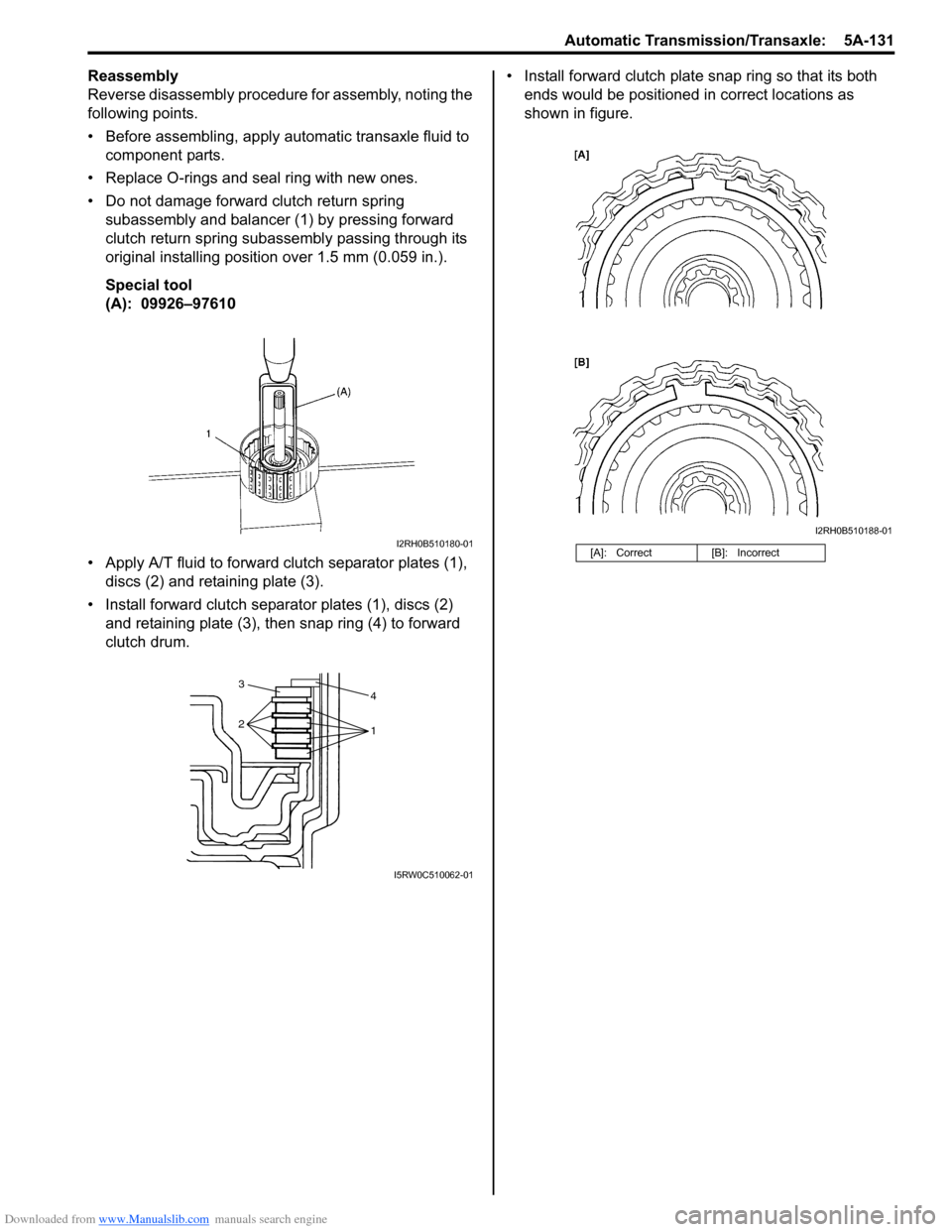

• Apply A/T fluid to forward clutch separator plates (1), discs (2) and retaining plate (3).

• Install forward clutch separator plates (1), discs (2) and retaining plate (3), then snap ring (4) to forward

clutch drum. • Install forward clutch plate snap ring so that its both

ends would be positioned in correct locations as

shown in figure.

I2RH0B510180-01

4

1

2 3

I5RW0C510062-01

[A]: Correct

[B]: Incorrect

I2RH0B510188-01

Page 776 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-132 Automatic Transmission/Transaxle:

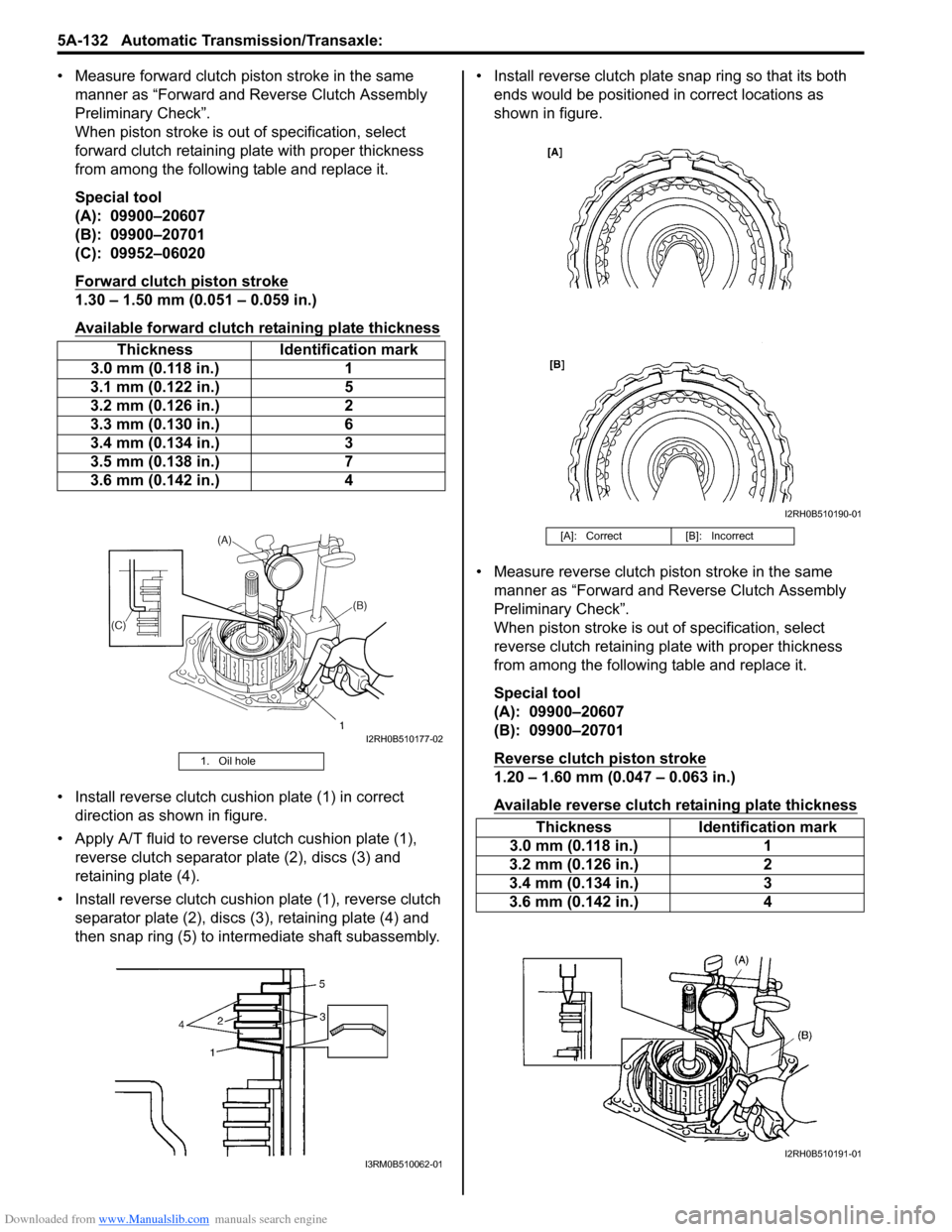

• Measure forward clutch piston stroke in the same manner as “Forward and Reverse Clutch Assembly

Preliminary Check”.

When piston stroke is out of specification, select

forward clutch retaining plate with proper thickness

from among the following table and replace it.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

Forward clutch piston stroke

1.30 – 1.50 mm (0.051 – 0.059 in.)

Available forward clutch retaining plate thickness

• Install reverse clutch cushion plate (1) in correct direction as shown in figure.

• Apply A/T fluid to reverse clutch cushion plate (1),

reverse clutch separator plate (2), discs (3) and

retaining plate (4).

• Install reverse clutch cushio n plate (1), reverse clutch

separator plate (2), discs (3), retaining plate (4) and

then snap ring (5) to inte rmediate shaft subassembly. • Install reverse clutch plate snap ring so that its both

ends would be positioned in correct locations as

shown in figure.

• Measure reverse clutch piston stroke in the same manner as “Forward and Reverse Clutch Assembly

Preliminary Check”.

When piston stroke is out of specification, select

reverse clutch retaining plate with proper thickness

from among the following table and replace it.

Special tool

(A): 09900–20607

(B): 09900–20701

Reverse clutch piston stroke

1.20 – 1.60 mm (0.047 – 0.063 in.)

Available reverse clutch retaining plate thickness

Thickness Identification mark

3.0 mm (0.118 in.) 1

3.1 mm (0.122 in.) 5

3.2 mm (0.126 in.) 2

3.3 mm (0.130 in.) 6

3.4 mm (0.134 in.) 3

3.5 mm (0.138 in.) 7

3.6 mm (0.142 in.) 4

1. Oil hole

I2RH0B510177-02

I3RM0B510062-01

[A]: Correct[B]: Incorrect

ThicknessIdentification mark

3.0 mm (0.118 in.) 1

3.2 mm (0.126 in.) 2

3.4 mm (0.134 in.) 3

3.6 mm (0.142 in.) 4

I2RH0B510190-01

I2RH0B510191-01

Page 777 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-133

Forward and Reverse Clutch Assembly

Inspection

S7RS0B5106044

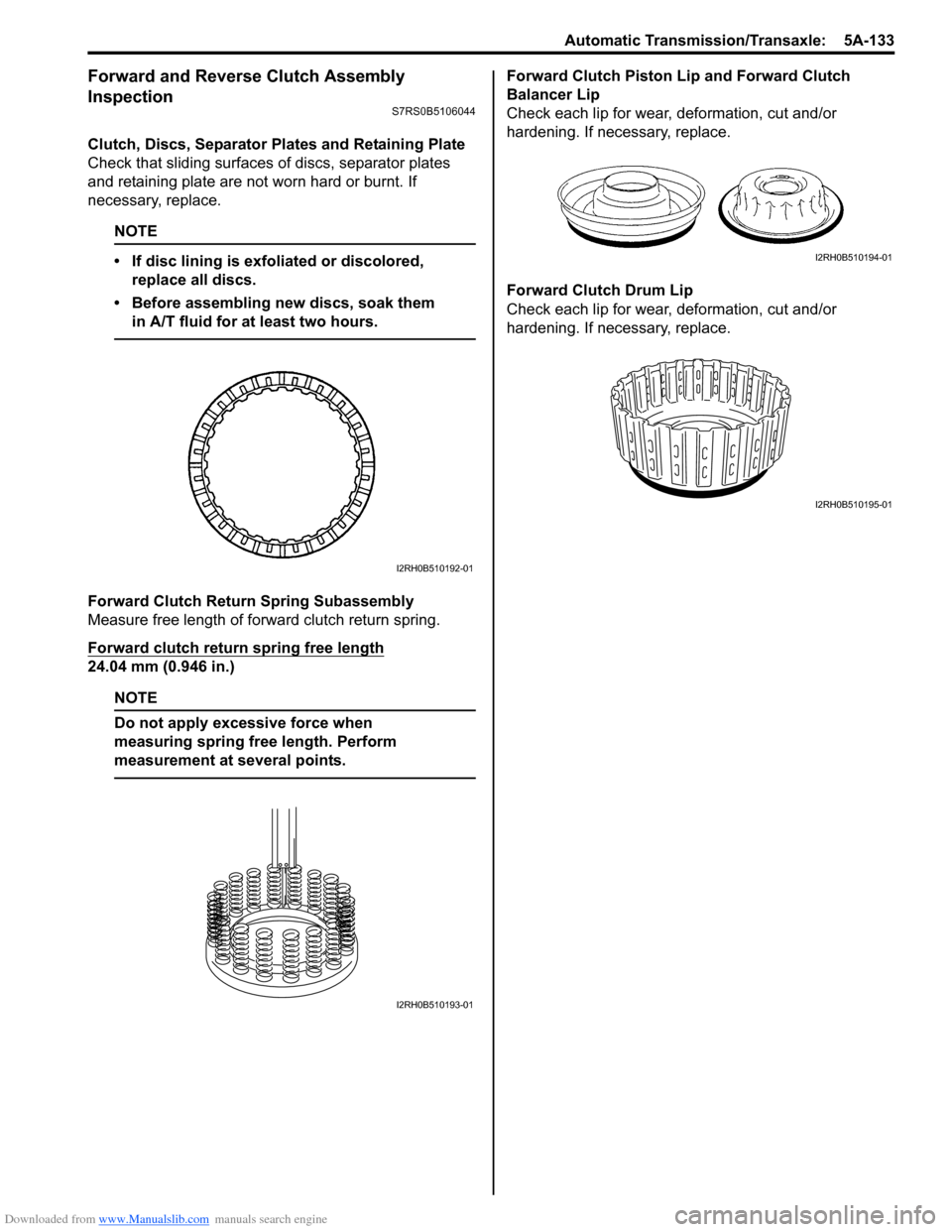

Clutch, Discs, Separator Plates and Retaining Plate

Check that sliding surfaces of discs, separator plates

and retaining plate are not worn hard or burnt. If

necessary, replace.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

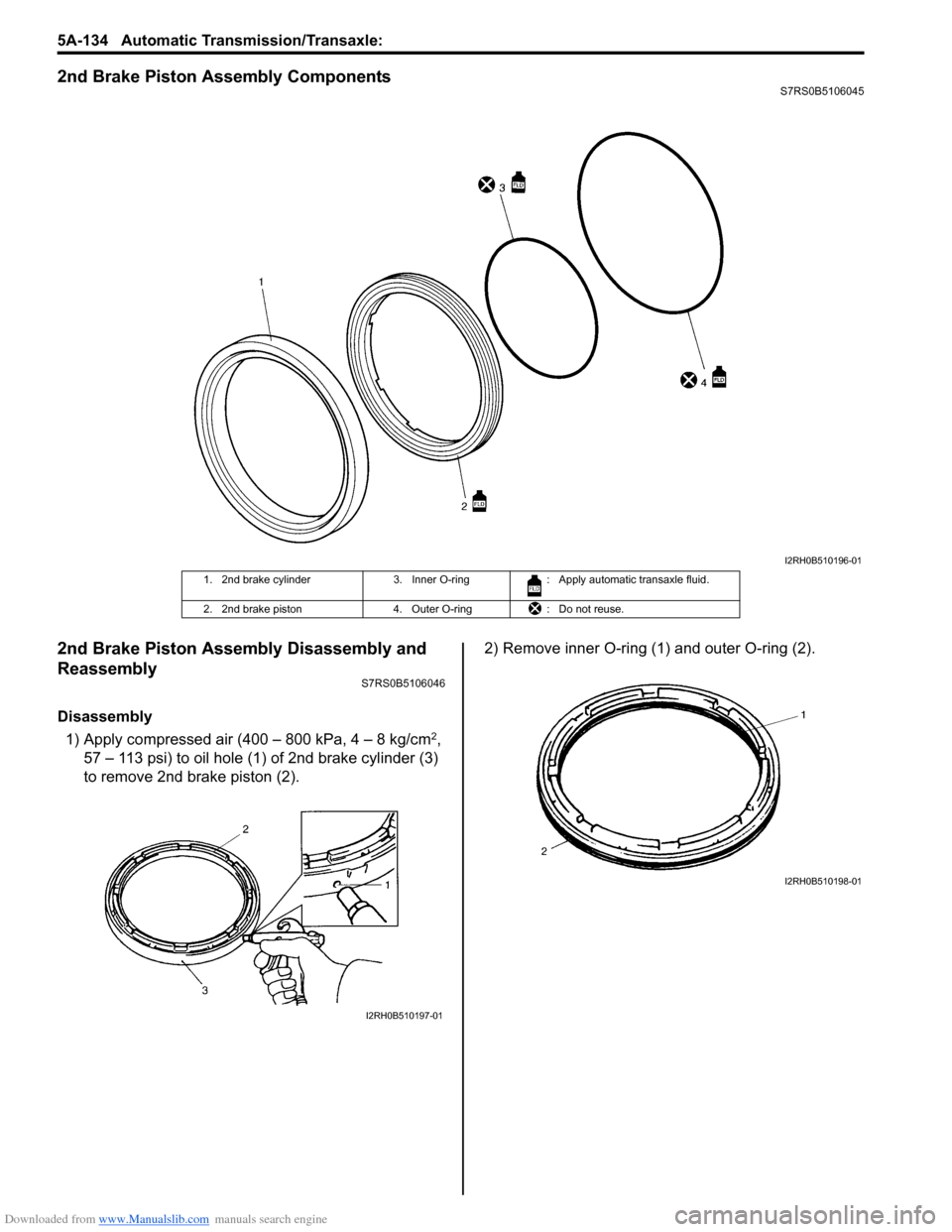

Forward Clutch Return Spring Subassembly

Measure free length of fo rward clutch return spring.

Forward clutch return spring free length

24.04 mm (0.946 in.)

NOTE

Do not apply excessive force when

measuring spring free length. Perform

measurement at several points.

Forward Clutch Piston Lip and Forward Clutch

Balancer Lip

Check each lip for wear, deformation, cut and/or

hardening. If necessary, replace.

Forward Clutch Drum Lip

Check each lip for wear, deformation, cut and/or

hardening. If necessary, replace.

I2RH0B510192-01

I2RH0B510193-01

I2RH0B510194-01

I2RH0B510195-01

Page 778 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-134 Automatic Transmission/Transaxle:

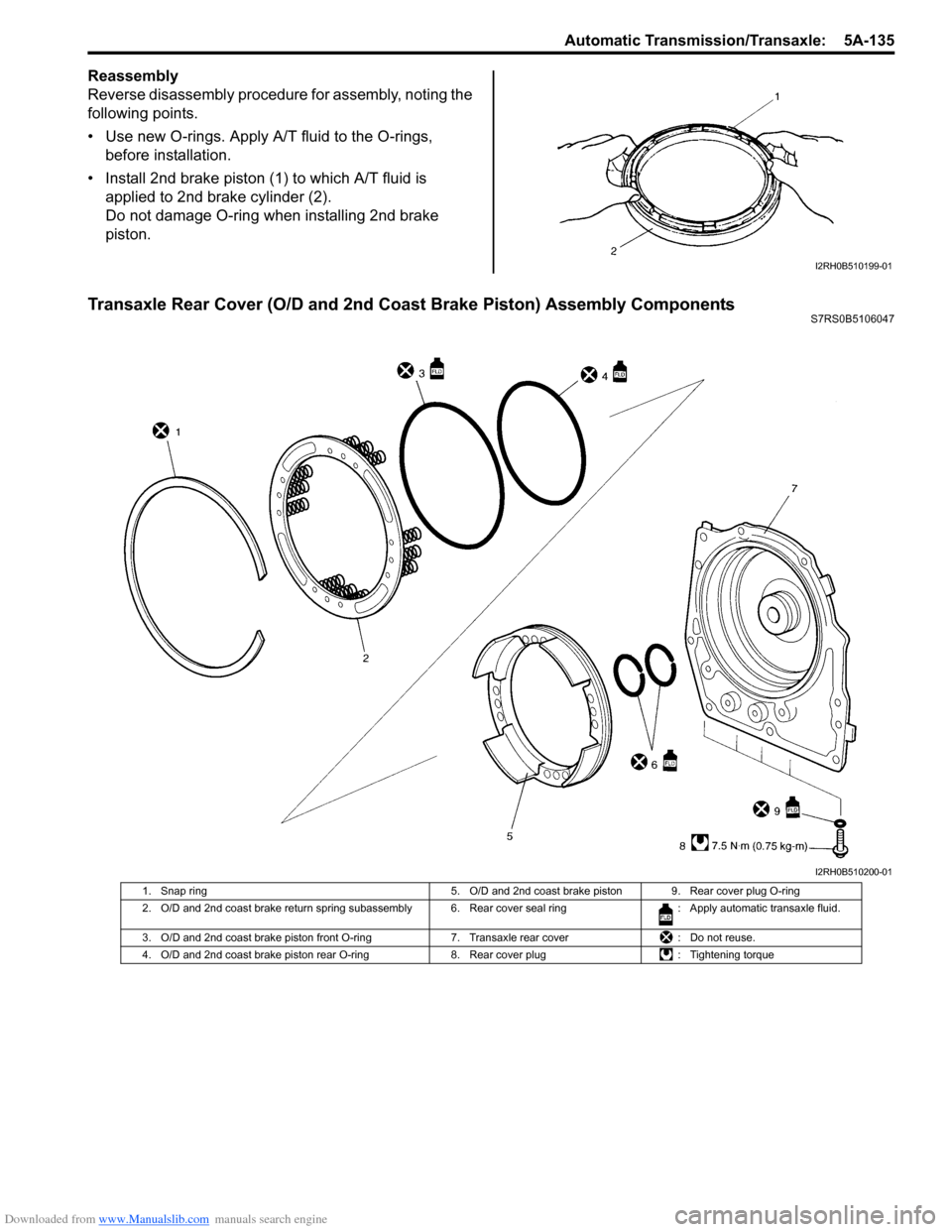

2nd Brake Piston Assembly ComponentsS7RS0B5106045

2nd Brake Piston Assembly Disassembly and

Reassembly

S7RS0B5106046

Disassembly1) Apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) to oil hole (1) of 2nd brake cylinder (3)

to remove 2nd brake piston (2). 2) Remove inner O-ring (1) and outer O-ring (2).

I2RH0B510196-01

1. 2nd brake cylinder

3. Inner O-ring: Apply automatic transaxle fluid.

2. 2nd brake piston 4. Outer O-ring: Do not reuse.

I2RH0B510197-01

I2RH0B510198-01

Page 779 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-135

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new O-rings. Apply A/T fluid to the O-rings, before installation.

• Install 2nd brake piston (1) to which A/T fluid is applied to 2nd brake cylinder (2).

Do not damage O-ring wh en installing 2nd brake

piston.

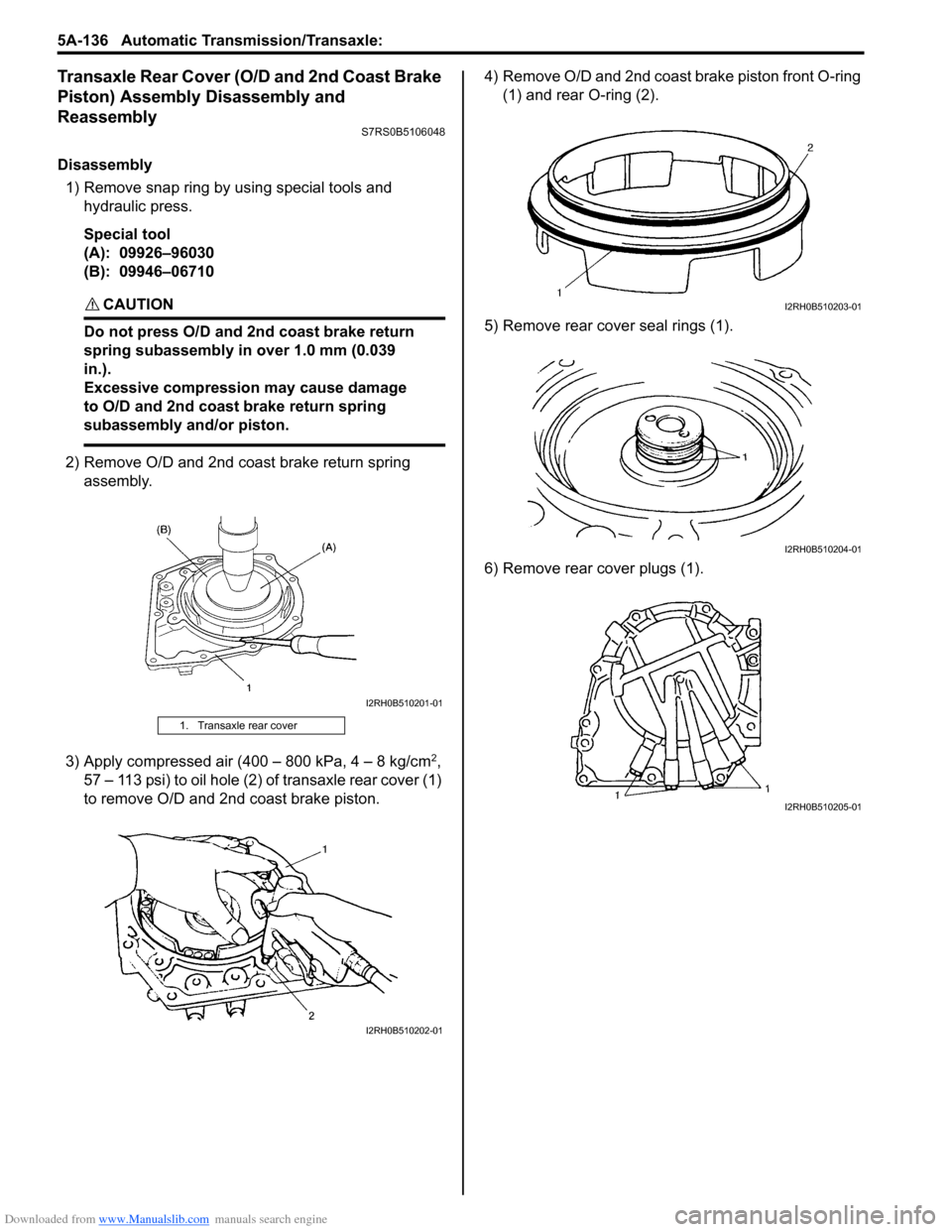

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly ComponentsS7RS0B5106047

I2RH0B510199-01

I2RH0B510200-01

1. Snap ring 5. O/D and 2nd coast brake piston 9. Rear cover plug O-ring

2. O/D and 2nd coast brake return spring subassembly 6. R ear cover seal ring: Apply automatic transaxle fluid.

3. O/D and 2nd coast brake piston front O- ring7. Transaxle rear cover : Do not reuse.

4. O/D and 2nd coast brake piston rear O- ring8. Rear cover plug : Tightening torque

Page 780 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-136 Automatic Transmission/Transaxle:

Transaxle Rear Cover (O/D and 2nd Coast Brake

Piston) Assembly Disassembly and

Reassembly

S7RS0B5106048

Disassembly1) Remove snap ring by using special tools and hydraulic press.

Special tool

(A): 09926–96030

(B): 09946–06710

CAUTION!

Do not press O/D and 2nd coast brake return

spring subassembly in over 1.0 mm (0.039

in.).

Excessive compression may cause damage

to O/D and 2nd coast brake return spring

subassembly and/or piston.

2) Remove O/D and 2nd coast brake return spring assembly.

3) Apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) to oil hole (2) of transaxle rear cover (1)

to remove O/D and 2nd coast brake piston. 4) Remove O/D and 2nd coast brake piston front O-ring

(1) and rear O-ring (2).

5) Remove rear cove r seal rings (1).

6) Remove rear cover plugs (1).

1. Transaxle rear cover

I2RH0B510201-01

I2RH0B510202-01

I2RH0B510203-01

I2RH0B510204-01

I2RH0B510205-01

Page 781 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-137

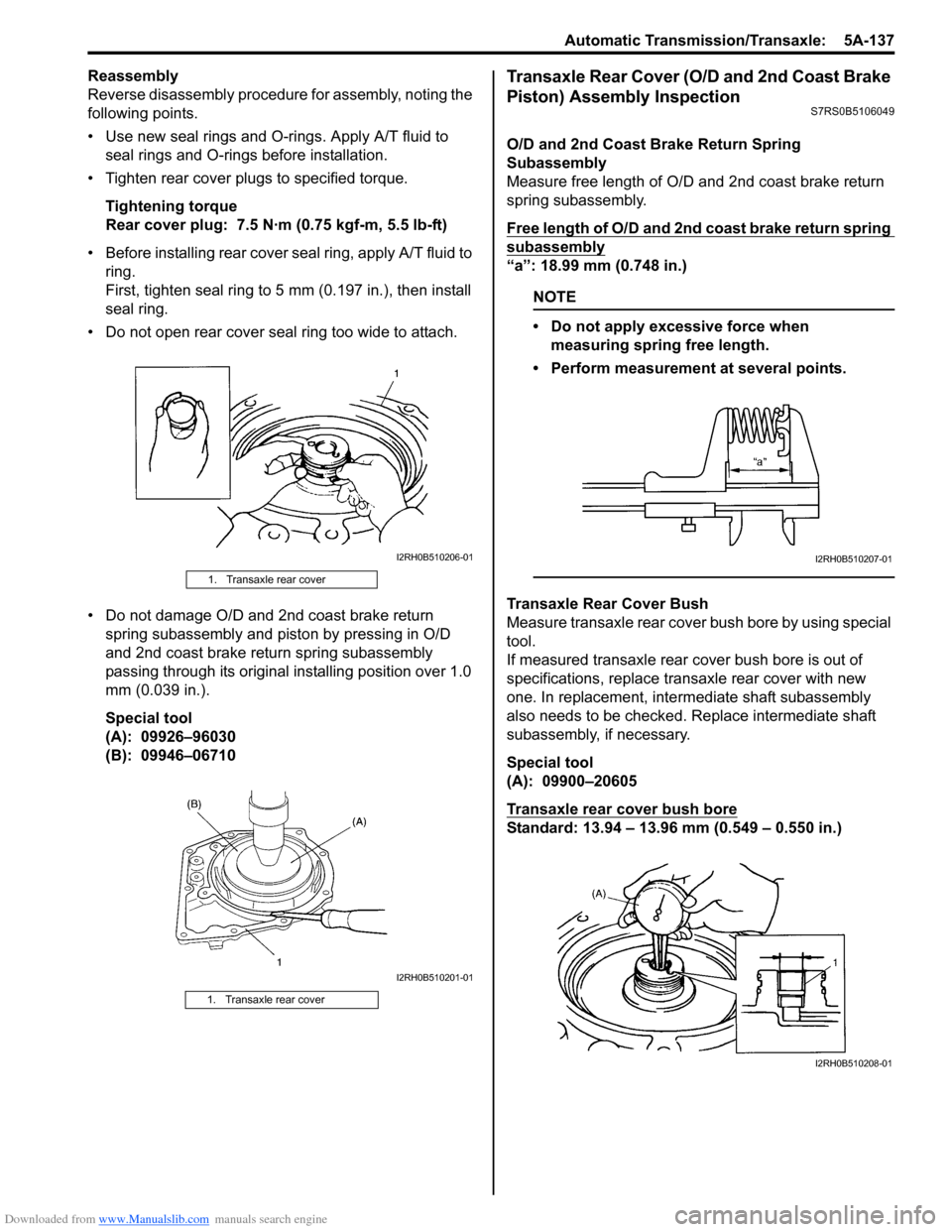

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new seal rings and O-rings. Apply A/T fluid to seal rings and O-rings before installation.

• Tighten rear cover plugs to specified torque.

Tightening torque

Rear cover plug: 7.5 N·m (0.75 kgf-m, 5.5 lb-ft)

• Before installing rear cover seal ring, apply A/T fluid to ring.

First, tighten seal ring to 5 mm (0.197 in.), then install

seal ring.

• Do not open rear cover seal ring too wide to attach.

• Do not damage O/D and 2nd coast brake return spring subassembly and piston by pressing in O/D

and 2nd coast brake return spring subassembly

passing through its original installing position over 1.0

mm (0.039 in.).

Special tool

(A): 09926–96030

(B): 09946–06710Transaxle Rear Cover (O/D and 2nd Coast Brake

Piston) Assembly Inspection

S7RS0B5106049

O/D and 2nd Coast Brake Return Spring

Subassembly

Measure free length of O/D and 2nd coast brake return

spring subassembly.

Free length of O/D and 2nd coast brake return spring

subassembly

“a”: 18.99 mm (0.748 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

Transaxle Rear Cover Bush

Measure transaxle rear cover bush bore by using special

tool.

If measured transaxle rear cover bush bore is out of

specifications, replace transaxle rear cover with new

one. In replacement, inte rmediate shaft subassembly

also needs to be checked. Replace intermediate shaft

subassembly, if necessary.

Special tool

(A): 09900–20605

Transaxle rear cover bush bore

Standard: 13.94 – 13.96 mm (0.549 – 0.550 in.)

1. Transaxle rear cover

1. Transaxle rear cover

I2RH0B510206-01

I2RH0B510201-01

I2RH0B510207-01

I2RH0B510208-01

Page 782 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-138 Automatic Transmission/Transaxle:

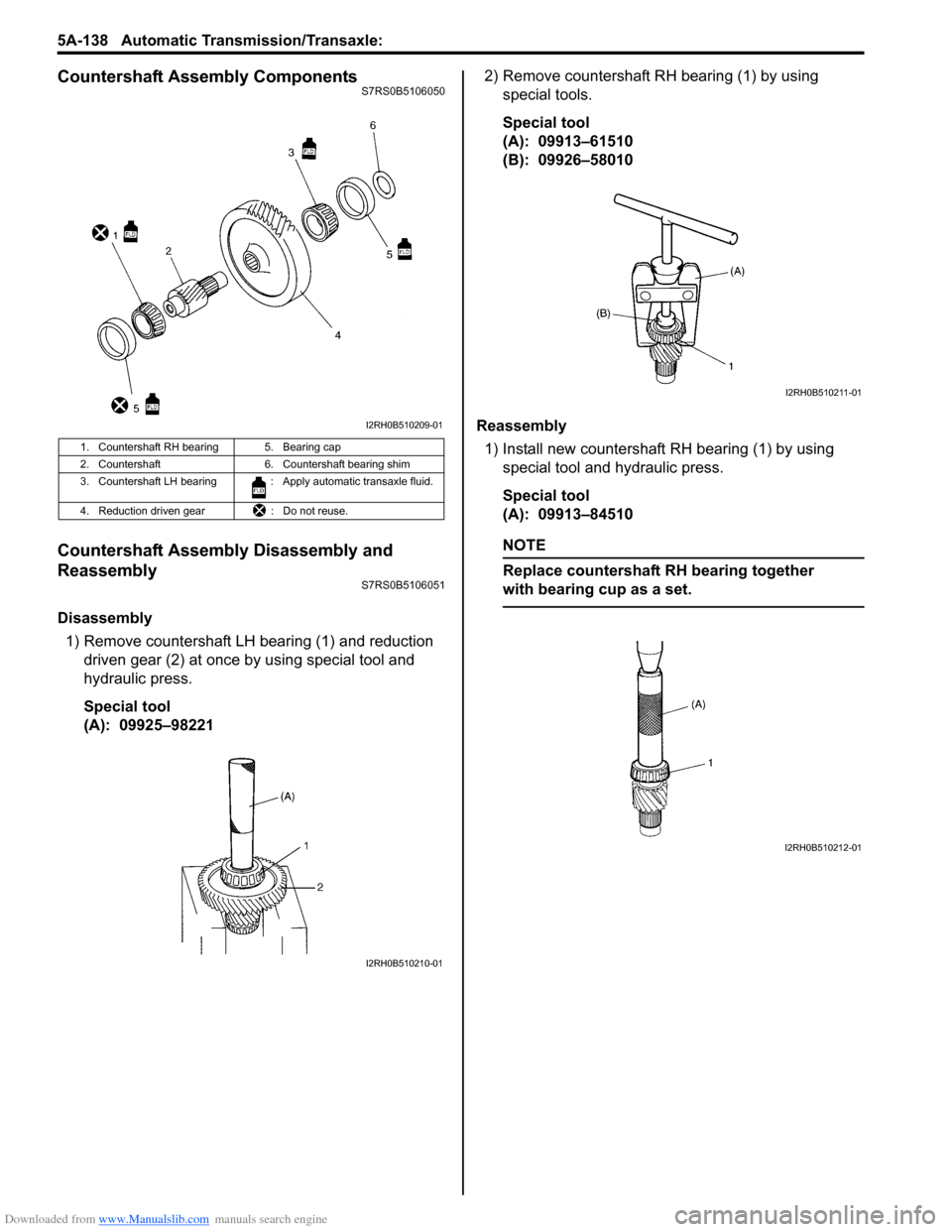

Countershaft Assembly ComponentsS7RS0B5106050

Countershaft Assembly Disassembly and

Reassembly

S7RS0B5106051

Disassembly1) Remove countershaft LH bearing (1) and reduction driven gear (2) at once by using special tool and

hydraulic press.

Special tool

(A): 09925–98221 2) Remove countershaft RH bearing (1) by using

special tools.

Special tool

(A): 09913–61510

(B): 09926–58010

Reassembly 1) Install new countershaft RH bearing (1) by using special tool and hydraulic press.

Special tool

(A): 09913–84510

NOTE

Replace countershaft RH bearing together

with bearing cup as a set.

1. Countershaft RH bearing 5. Bearing cap

2. Countershaft 6. Countershaft bearing shim

3. Countershaft LH bearing : Apply automatic transaxle fluid.

4. Reduction driven gear : Do not reuse.

I2RH0B510209-01

I2RH0B510210-01

I2RH0B510211-01

I2RH0B510212-01