light SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 888 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-6 Power Assisted Steering System:

NOTE

• As execution of “DTC Clearance” will clear all DTCs, be sure to record all DTCs before service.

• DTC C1122 is indicated when ignition switch is at ON position and engine is not running, it means

that nothing is abnormal.

• Current DTC and history DTC ca n be identified by condition of the “EPS” warning light.

“EPS” warning light operates as follows.

7 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9. Go to Step 10.

8 �) Steering symptom diagnosis and P/S system

symptom diagnosis

1) Check and repair according to “Steering Symptom Diagnosis in Section 6A” and “P/S System Symptom

Diagnosis”.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

9 �) Troubleshooting for DTC

1) Check and repair according to applicable DTC diag. flow.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

10 �) Intermittent problems check

1) Check for intermittent problems referring to “Intermittent Problems Check”.

Is there any faulty condition? Repair or replace

malfunction part(s), and

go to Step 11.

Go to Step 11.

11 �) Final confirmation test

1) Clear DTC if any.

2) Perform final confirmation test referring to “Final Confirmation Test”.

Is there any problem symptom, DTC or abnormal condition? Go to Step 6. End.

Step Action Yes No

Current DTC is set.

(Abnormality exists at

present.)

Only history DTC is set.

(Faulty condition occurred once

in the past, but normal condition

is detected at present.)

Current and history DTC

exist.

“EPS” warning light

after engine started Remains ON. Turns OFF. Remains ON.

Page 890 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 2: DTC Check, Record and Clearance

First, check DTC, referring to “DTC Check”. If DTC is

indicated, print it or write them down and then clear them

by referring to “DTC Clearance”. DTC indicates

malfunction that occurred in the system but does not

indicate whether it exists now or it occurred in the past

and the normal condition has been restored now. To

check which case applies, check the symptom in

question according to Step 5 and recheck DTC

according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the P/S system

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “S tep 2: DTC Check, Record

and Clearance: ”, confirm trouble symptoms. Also,

reconfirm trouble symptom by performing test drive and

turning steering wheel fully to right and left at stopped

vehicle.

Step 6 and 7: Rechecking and Record of DTC

Refer to “DTC Check” for checking procedure.

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2. Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

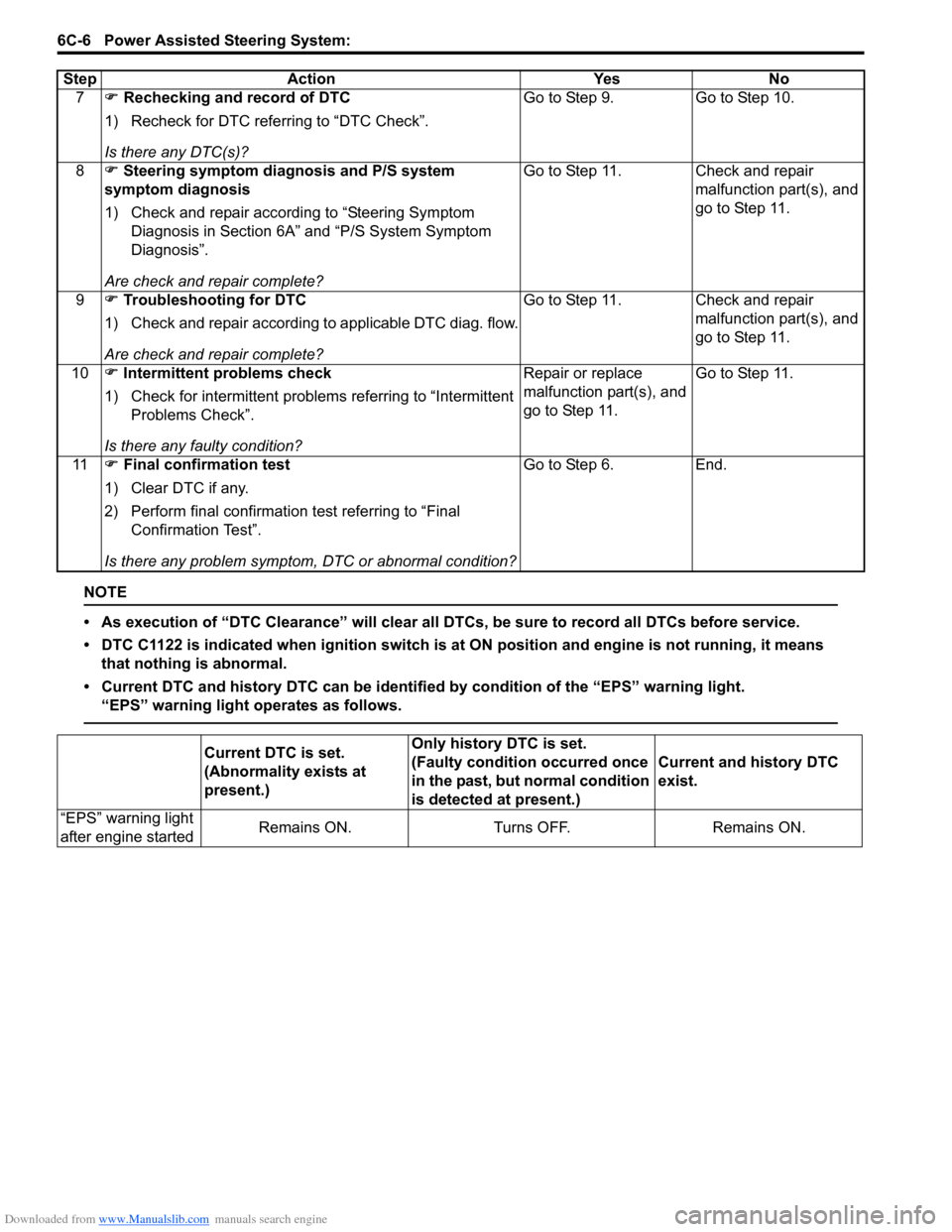

“EPS” Warning Light CheckS7RS0B6304002

1) Turn ignition switch to ON position (without engine

running) and chec k if the “EPS” warning light (1)

lights up. If the light dose not light up, go to ““EPS”

Warning Light Does Not Come ON with Ignition

Switch Turned ON before Engine Starts” of the

diagnostic flows.

2) Start engine and check if the “EPS” warning light turns OFF. If light remains ON and no DTC is stored

in P/S control module, go to ““EPS” Warning Light

Remains ON Steady after Engine Starts” for

troubleshooting.

DTC CheckS7RS0B6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

1

I6RS0C630002-01

(A)

1

I4RS0B450003-01

Page 895 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-13

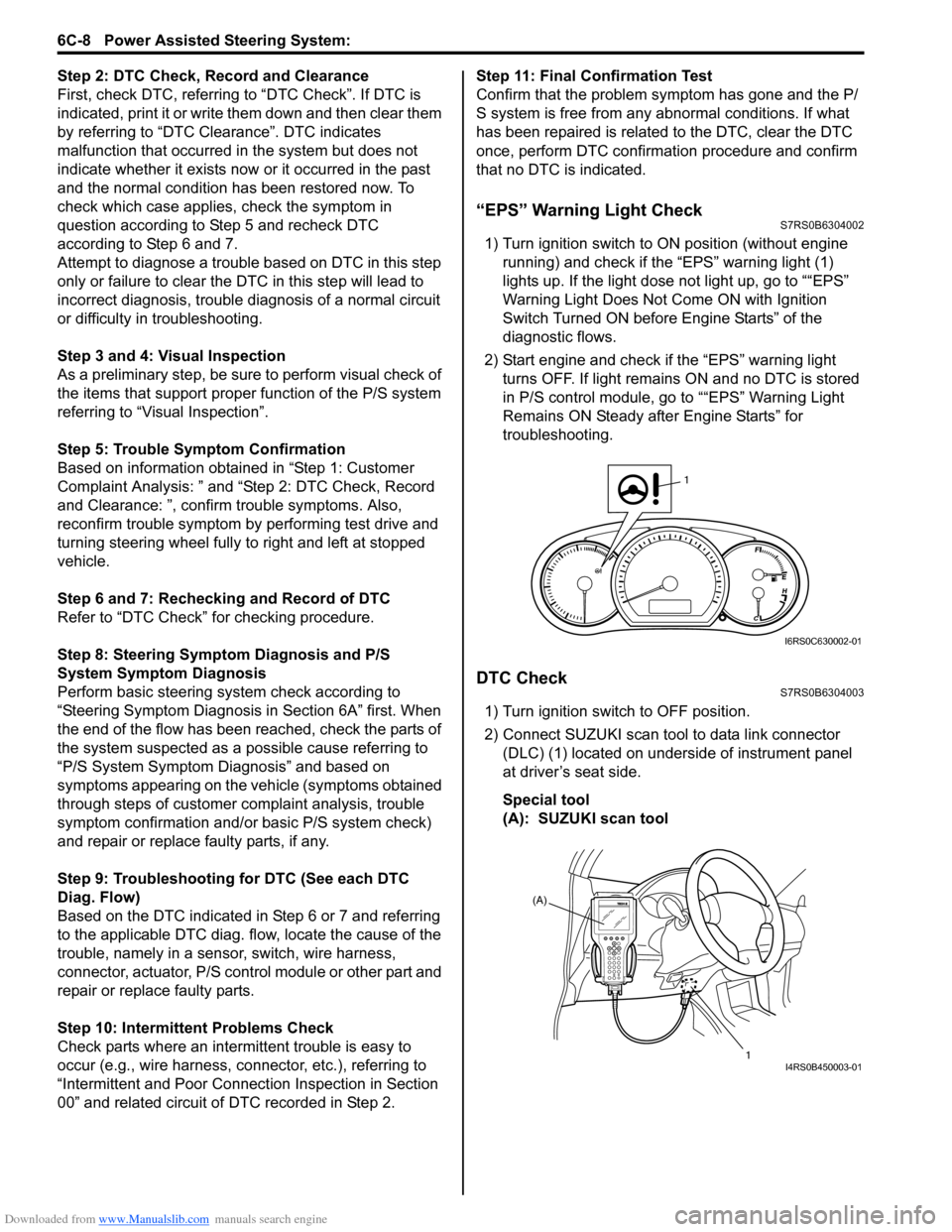

Serial Data Link Circuit CheckS7RS0B6304009

CAUTION!

Be sure to perform “EPS System Check” before starting “Troubleshooting”.

Wiring DiagramVehicle pulls to one side

during straight driving

Poor performance of torque sensor

Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor recovery after turns Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering column faulty Replace.

Abnormal noise P/S motor (built in steering gear case

assembly) malfunction Replace steering gear case assembly.

No idle up P/S control module faulty Check P/S control module referring to

“Inspection of P/S Control Module and Its

Circuits”.

Condition Possible cause Correction / Reference Item

MBLK

RED

E52-11 E51-1

E51-2PPL/WHT

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

8

79

12V

[B ]

11

12

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

10

3

4

4

5 6

4

4

1 2

4

E49-2BLK

I7RS0B630003-01

[A]: Connector “E52” (viewed from harness side) 3. Junction block assembly 8. P/S control module

[B]: Connector “E49” (viewed from harness side) 4. Fuse 9. T o ECM, BCM, Air bag SDM control module and ABS control

module assembly

[C]: Connector “G28” (viewed from harness side) 5. Comb ination meter 10. Individual circuit fuse box No.1

1. Main fuse box 6. “EPS” warning light 11. Serial data circuit

2. Ignition switch 7. Date link connector (DLC)

Page 897 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-15

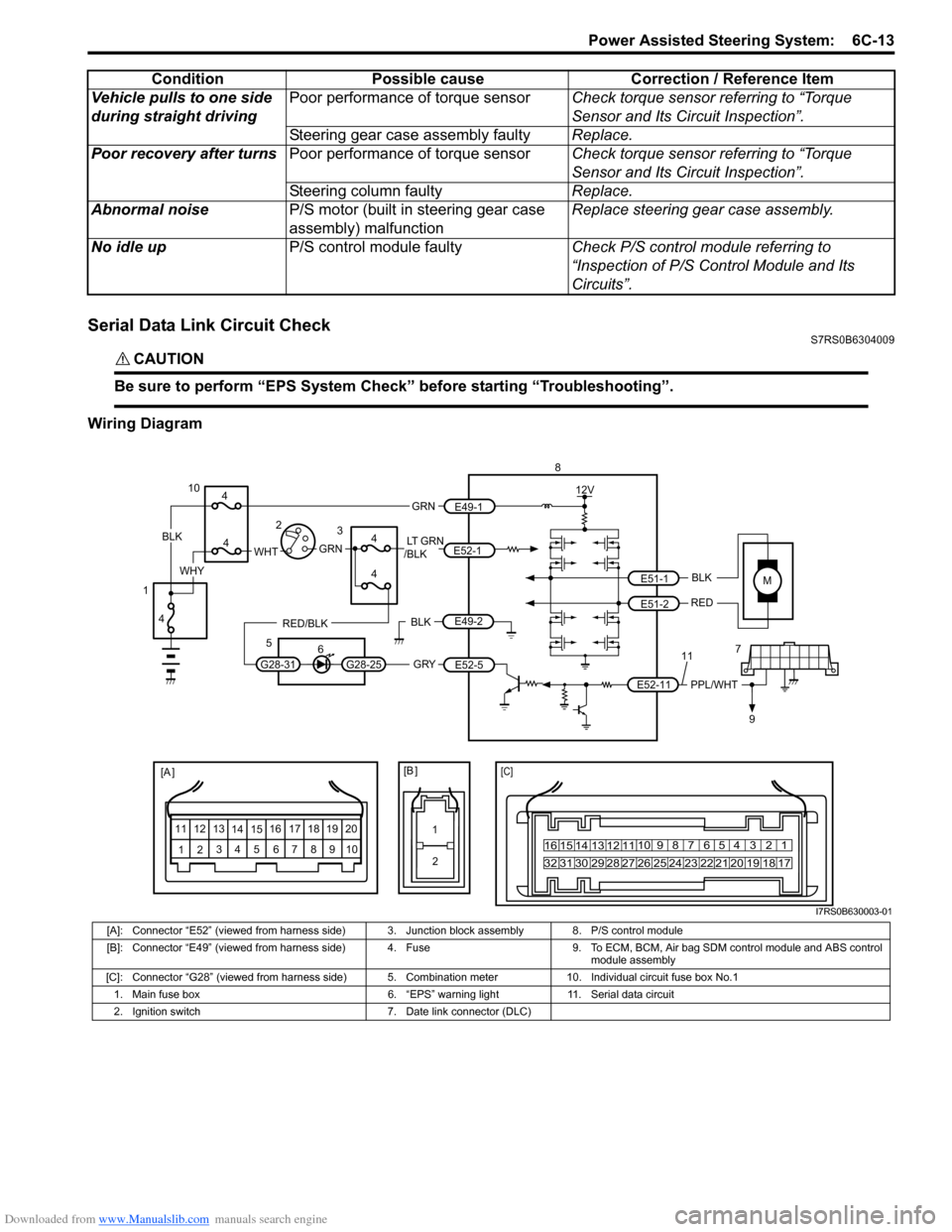

“EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine StartsS7RS0B6304010

Wiring Diagram

Circuit Description

Operation (ON/OFF) of “EPS” warning light is controlled by P/S control module through combination meter.

If the P/S system is in good condition, P/S control module turns “ EPS” warning light ON at the ignition switch ON, and

then turns it OFF at the engine start. If an abnormality in the system is detected, “EPS” warning light is turned ON

continuously by P/S control module. If P/S control module is disconnected, “EPS” warning light is not turned ON.

Troubleshooting

MBLK

REDE51-1

E51-2

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

7

12V

E49-2BLK

[B ]

1 2

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

8

3

4

4

5 6

4

4

1 2

4

9

I7RS0B630004-01

[A]: Connector “E52” (viewed from harness side) 2. Ignition switch6. “EPS” warning light

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. P/S control module

[C]: Connector “G28” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. Combination meter9. “EPS” warning light circuit

StepAction YesNo

1 1) Turn ignition switch ON.

Do the other warning lights come on? Go to Step 2.

“GRN”, “RED/BLK” wire

circuit or circuit fuse for

combination meter open

or short to ground.

2 1) Check power supply circuit and ground circuit for P/S control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 1) Remove combination meter and disconnect combination meter connector (“G28”) with ignition switch turned OFF.

2) Check for proper connection to the combination meter at “G28-31” terminal.

3) If OK, check voltage between “G28-31” (“RED/BLK” wire) terminal and body ground with ignition switch ON.

Is it 10 – 14 V? Go to Step 4.

“RED/BLK” wire circuit

open or short to ground.

Page 898 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-16 Power Assisted Steering System:

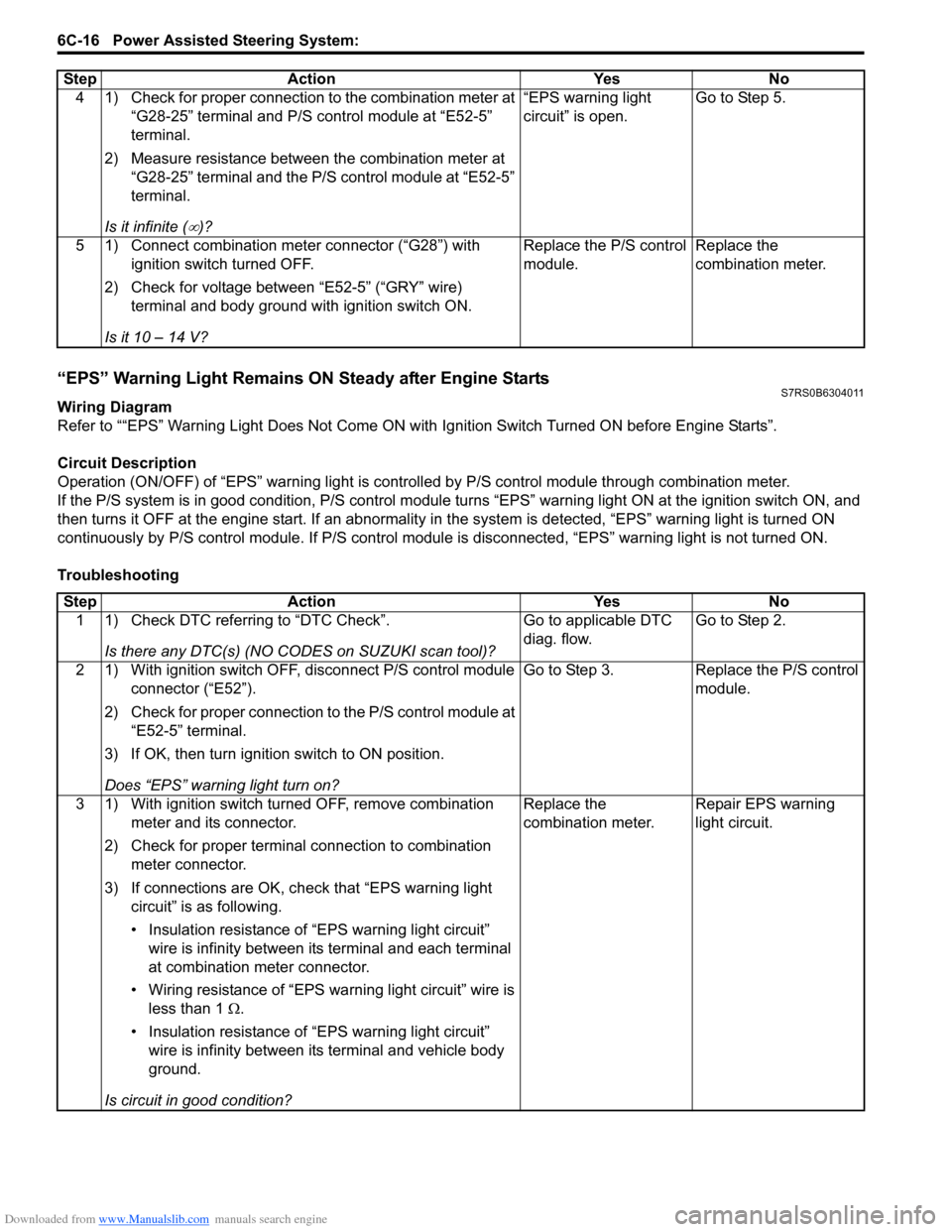

“EPS” Warning Light Remains ON Steady after Engine StartsS7RS0B6304011

Wiring Diagram

Refer to ““EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine Starts”.

Circuit Description

Operation (ON/OFF) of “EPS” warning light is controlled by P/S c ontrol module through combination meter.

If the P/S system is in good condition, P/S control module tu rns “EPS” warning light ON at the ignition switch ON, and

then turns it OFF at the engine start. If an abnormality in the system is detected, “EPS” warning light is turned ON

continuously by P/S control module. If P/S control module is disconnected, “EPS” warning light is not turned ON.

Troubleshooting 4 1) Check for proper connection to the combination meter at

“G28-25” terminal and P/S control module at “E52-5”

terminal.

2) Measure resistance between the combination meter at “G28-25” terminal and the P/S control module at “E52-5”

terminal.

Is it infinite (

∞)? “EPS warning light

circuit” is open.

Go to Step 5.

5 1) Connect combination meter connector (“G28”) with ignition switch turned OFF.

2) Check for voltage between “E52-5” (“GRY” wire) terminal and body ground with ignition switch ON.

Is it 10 – 14 V? Replace the P/S control

module.

Replace the

combination meter.

Step

Action YesNo

Step Action YesNo

1 1) Check DTC referring to “DTC Check”.

Is there any DTC(s) (NO CODES on SUZUKI scan tool)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 1) With ignition switch OFF, disconnect P/S control module connector (“E52”).

2) Check for proper connection to the P/S control module at “E52-5” terminal.

3) If OK, then turn ignition switch to ON position.

Does “EPS” warning light turn on? Go to Step 3.

Replace the P/S control

module.

3 1) With ignition switch turned OFF, remove combination meter and its connector.

2) Check for proper terminal connection to combination meter connector.

3) If connections are OK, ch eck that “EPS warning light

circuit” is as following.

• Insulation resistance of “EPS warning light circuit” wire is infinity between its terminal and each terminal

at combination meter connector.

• Wiring resistance of “EPS wa rning light circuit” wire is

less than 1 Ω.

• Insulation resistance of “EPS warning light circuit” wire is infinity between its terminal and vehicle body

ground.

Is circuit in good condition? Replace the

combination meter.

Repair EPS warning

light circuit.

Page 908 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-26 Power Assisted Steering System:

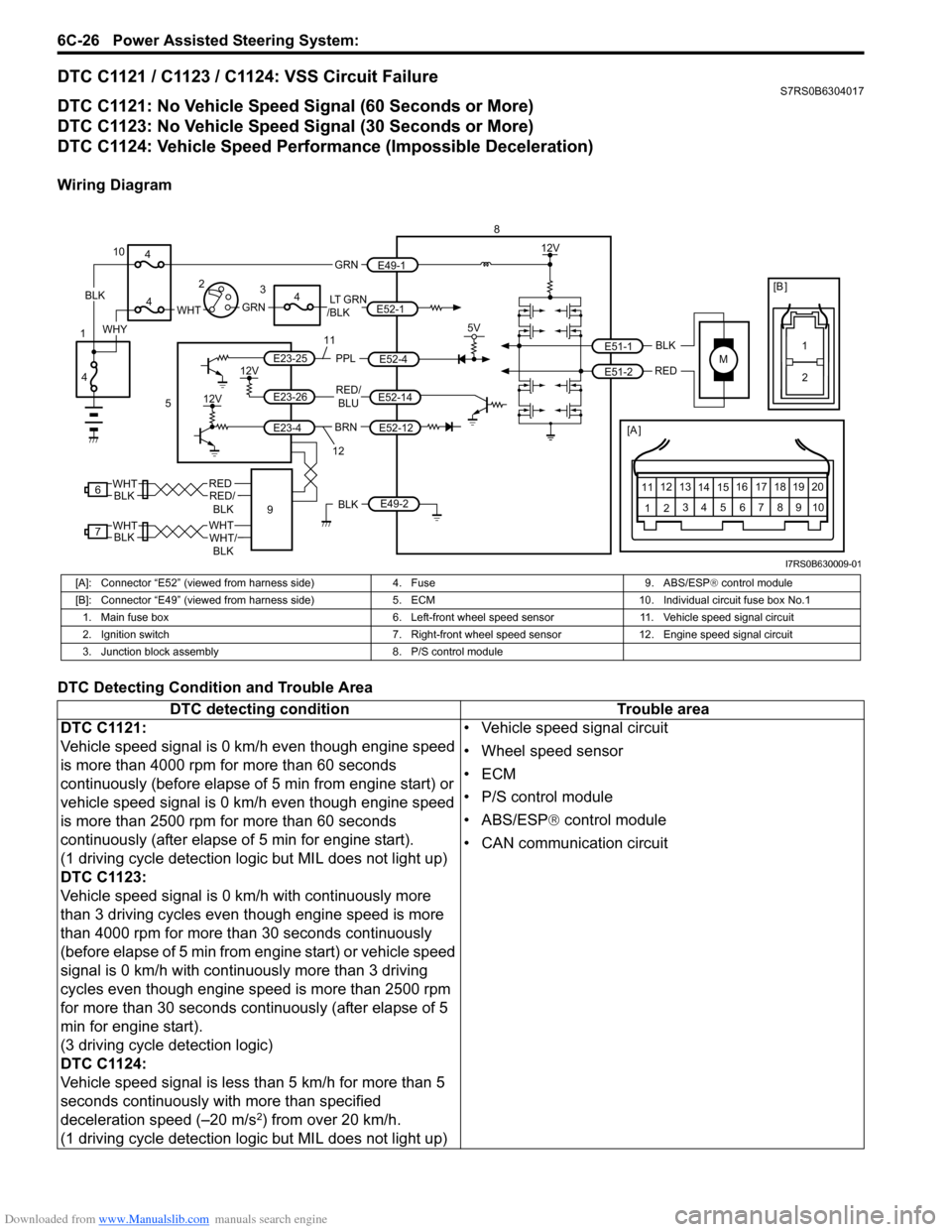

DTC C1121 / C1123 / C1124: VSS Circuit FailureS7RS0B6304017

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

BRNRED/

BLU

BLK

RED

E52-14

E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5V

PPL

E52-4

8

5

12V

E49-2BLK

12V

12V

6REDRED/ BLKWHT

7WHTWHT/BLKWHTBLK BLK

111

2

[B ]

9

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

10

3

4

4

4

4

1 2

12

I7RS0B630009-01

[A]: Connector “E52” (viewed from harness side)

4. Fuse9. ABS/ESP® control module

[B]: Connector “E49” (viewed from harness si de)5. ECM 10. Individual circuit fuse box No.1

1. Main fuse box 6. Left-front wheel speed sensor11. Vehicle speed signal circuit

2. Ignition switch 7. Right-front wheel speed sensor 12. Engine speed signal circuit

3. Junction block assembly 8. P/S control module

DTC detecting condition Trouble area

DTC C1121:

Vehicle speed signal is 0 km/h even though engine speed

is more than 4000 rpm for more than 60 seconds

continuously (before elapse of 5 min from engine start) or

vehicle speed signal is 0 km/h even though engine speed

is more than 2500 rpm for more than 60 seconds

continuously (after elapse of 5 min for engine start).

(1 driving cycle detection logic but MIL does not light up)

DTC C1123:

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 4000 rpm for more than 30 seconds continuously

(before elapse of 5 min from engine start) or vehicle speed

signal is 0 km/h with continuously more than 3 driving

cycles even though engine speed is more than 2500 rpm

for more than 30 seconds continuously (after elapse of 5

min for engine start).

(3 driving cycle detection logic)

DTC C1124:

Vehicle speed signal is less than 5 km/h for more than 5

seconds continuously with more than specified

deceleration speed (–20 m/s

2) from over 20 km/h.

(1 driving cycle detection logic but MIL does not light up) • Vehicle speed signal circuit

• Wheel speed sensor

•ECM

• P/S control module

• ABS/ESP®

control module

• CAN communication circuit

Page 915 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-33

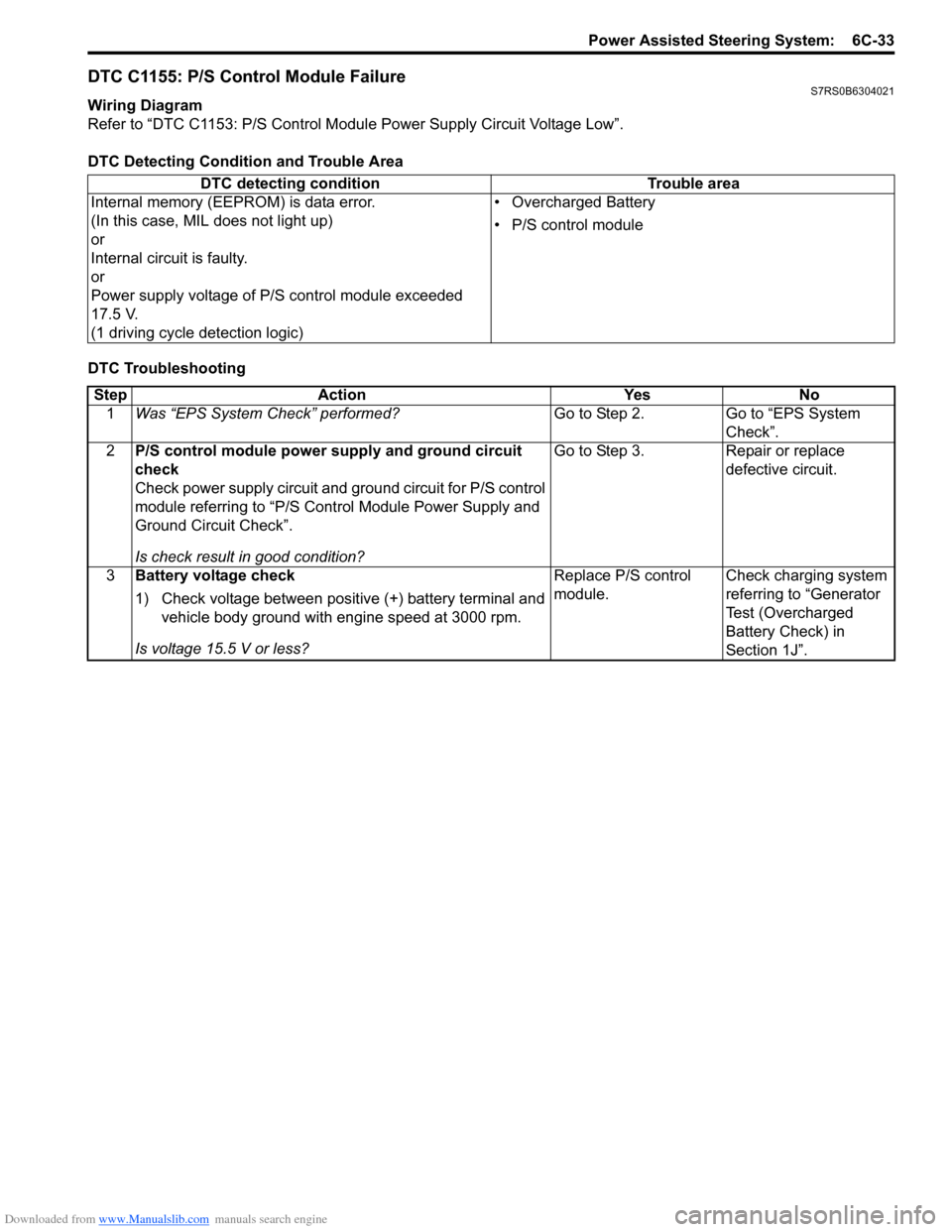

DTC C1155: P/S Control Module FailureS7RS0B6304021

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit Voltage Low”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, MIL does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V.

(1 driving cycle detection logic) • Overcharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less? Replace P/S control

module.

Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Page 918 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-36 Power Assisted Steering System:

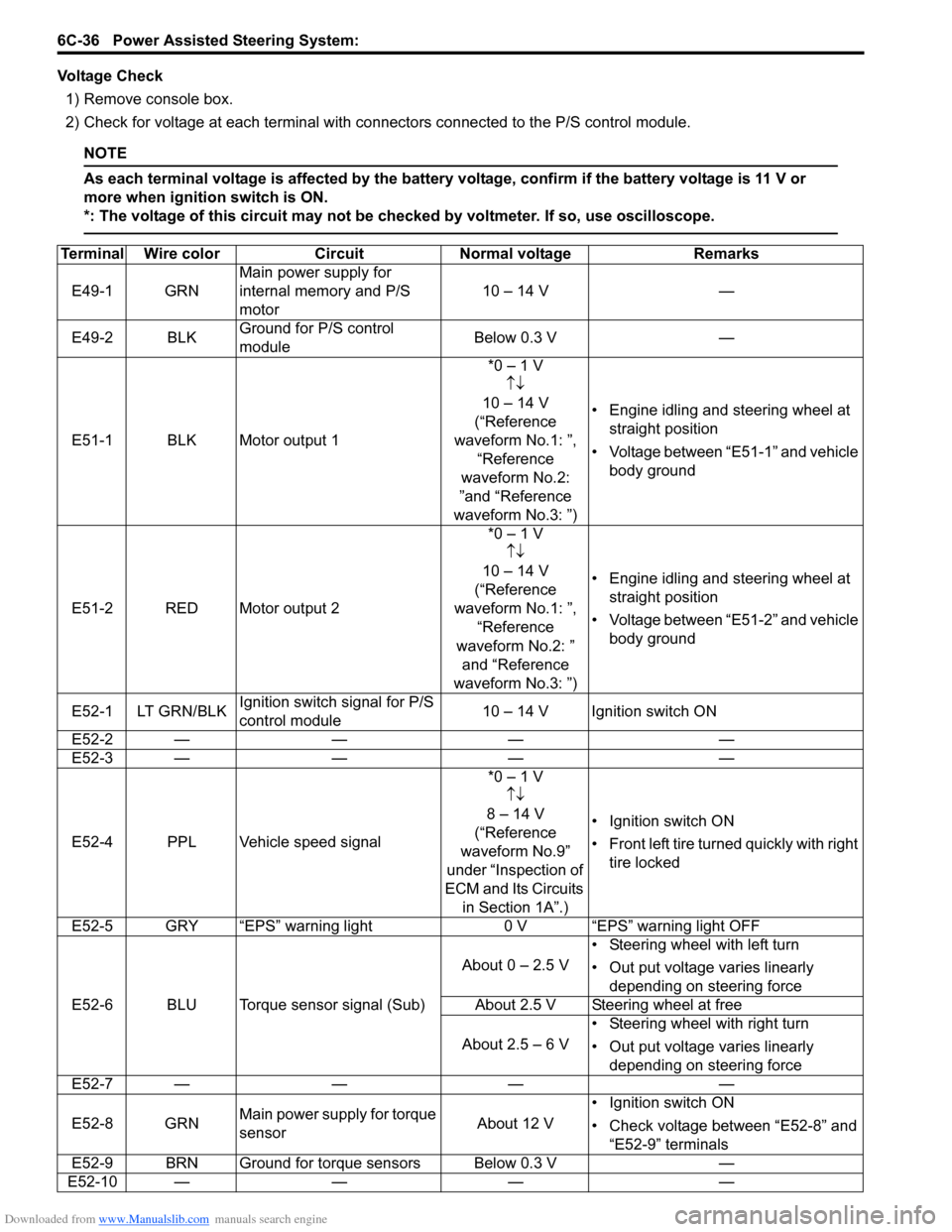

Voltage Check1) Remove console box.

2) Check for voltage at each terminal with co nnectors connected to the P/S control module.

NOTE

As each terminal voltage is affected by the battery voltage, confirm if the battery voltage is 11 V or

more when ignition switch is ON.

*: The voltage of this circuit may not be checked by voltmeter. If so, use oscilloscope.

Terminal Wire colorCircuit Normal voltage Remarks

E49-1 GRN Main power supply for

internal memory and P/S

motor 10 – 14 V

—

E49-2 BLK Ground for P/S control

module Below 0.3 V

—

E51-1 BLK Motor output 1 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2:

”and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-1” and vehicle body ground

E51-2 RED Motor output 2 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2: ” and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-2” and vehicle body ground

E52-1 LT GRN/BLK Ignition switch signal for P/S

control module 10 – 14 V Ignition switch ON

E52-2 — —— —

E52-3 — —— —

E52-4 PPL Vehicle speed signal *0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.9”

under “Inspection of

ECM and Its Circuits in Section 1A”.) • Ignition switch ON

•Front left tire tu

rned quickly with right

tire locked

E52-5 GRY “EPS” warning light 0 V “EPS” warning light OFF

E52-6 BLU Torque sensor signal (Sub) About 0 – 2.5 V

• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 2.5 – 6 V • Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E52-7 — —— —

E52-8 GRN Main power supply for torque

sensor About 12 V• Ignition switch ON

• Check voltage between “E52-8” and

“E52-9” terminals

E52-9 BRN Ground for torque sensors Below 0.3 V —

E52-10 — —— —

Page 927 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-45

8) Install steering gear case assembly referring to “Steering Gear Case Assembly Removal and

Installation”.

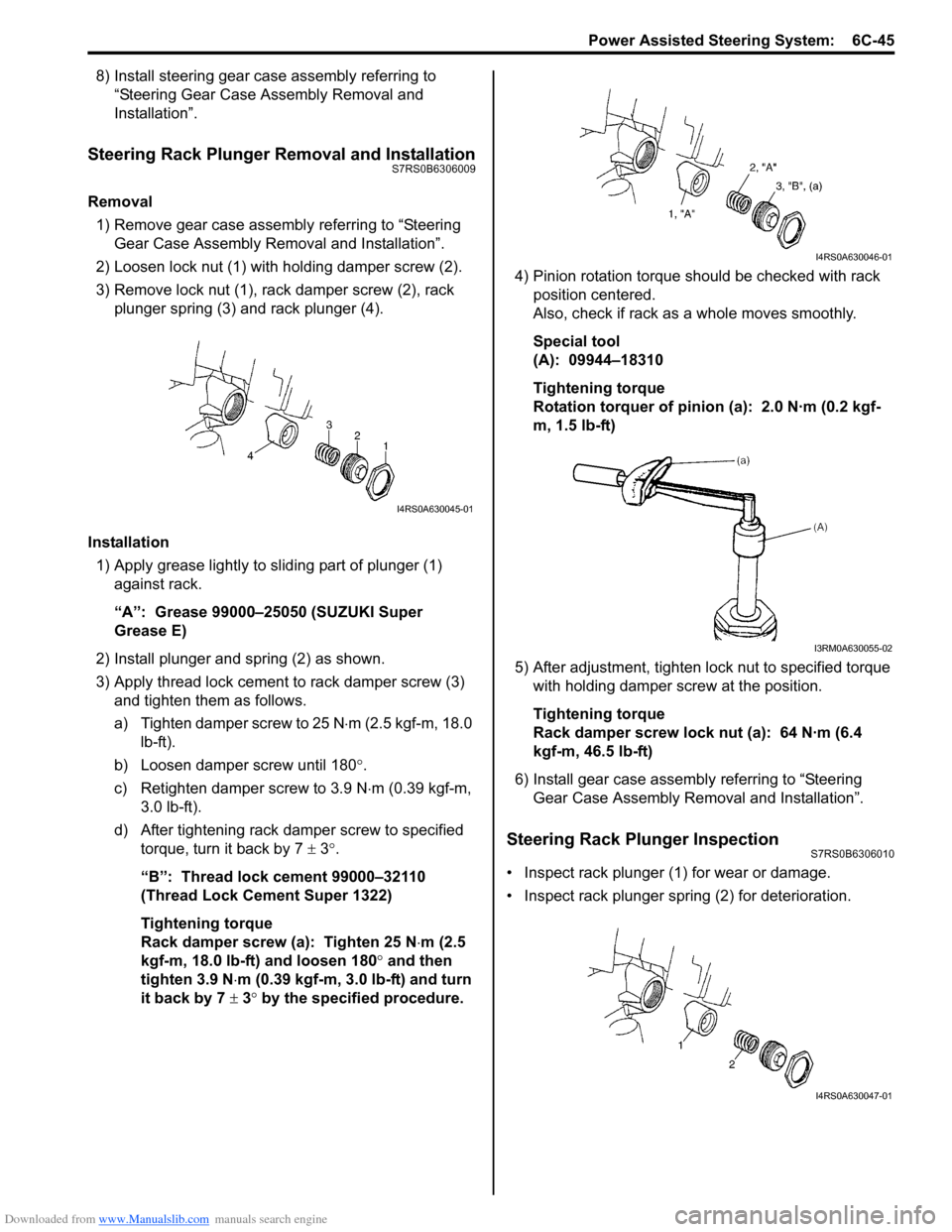

Steering Rack Plunger Removal and InstallationS7RS0B6306009

Removal

1) Remove gear case assembly referring to “Steering

Gear Case Assembly Removal and Installation”.

2) Loosen lock nut (1) with holding damper screw (2).

3) Remove lock nut (1), rack damper screw (2), rack plunger spring (3) and rack plunger (4).

Installation 1) Apply grease lightly to sliding part of plunger (1) against rack.

“A”: Grease 99000–25050 (SUZUKI Super

Grease E)

2) Install plunger and spring (2) as shown.

3) Apply thread lock cement to rack damper screw (3)

and tighten them as follows.

a) Tighten damper screw to 25 N ⋅m (2.5 kgf-m, 18.0

lb-ft).

b) Loosen damper screw until 180 °.

c) Retighten damper screw to 3.9 N ⋅m (0.39 kgf-m,

3.0 lb-ft).

d) After tightening rack damper screw to specified torque, turn it back by 7 ± 3°.

“B”: Thread lock cement 99000–32110

(Thread Lock Cement Super 1322)

Tightening torque

Rack damper screw (a): Tighten 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) and loosen 180° and then

tighten 3.9 N ⋅m (0.39 kgf-m, 3.0 lb-ft) and turn

it back by 7 ± 3° by the specified procedure. 4) Pinion rotation torque should be checked with rack

position centered.

Also, check if rack as a whole moves smoothly.

Special tool

(A): 09944–18310

Tightening torque

Rotation torquer of pinion (a): 2.0 N·m (0.2 kgf-

m, 1.5 lb-ft)

5) After adjustment, tighten lo ck nut to specified torque

with holding damper screw at the position.

Tightening torque

Rack damper screw lock nut (a): 64 N·m (6.4

kgf-m, 46.5 lb-ft)

6) Install gear case assembly referring to “Steering Gear Case Assembly Re moval and Installation”.

Steering Rack Plunger InspectionS7RS0B6306010

• Inspect rack plunger (1) for wear or damage.

• Inspect rack plunger spring (2) for deterioration.

I4RS0A630045-01

I4RS0A630046-01

I3RM0A630055-02

I4RS0A630047-01

Page 938 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-2 Heater and Ventilation:

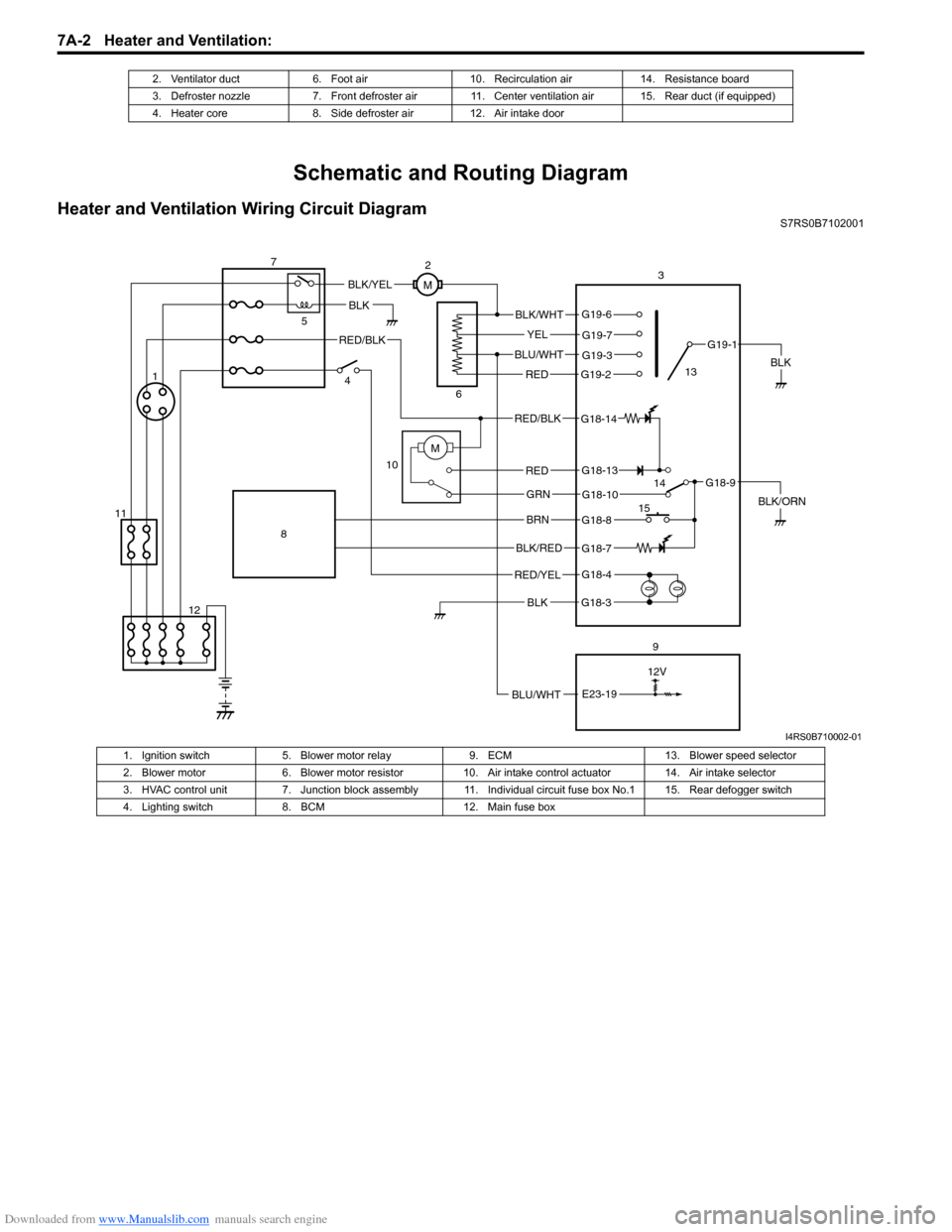

Schematic and Routing Diagram

Heater and Ventilation Wiring Circuit DiagramS7RS0B7102001

2. Ventilator duct 6. Foot air 10. Recirculation air 14. Resistance board

3. Defroster nozzle 7. Front defroster air 11. Center ventilation air 15. Rear duct (if equipped)

4. Heater core 8. Side defroster air 12. Air intake door

BLK

RED/BLK

3

5

7

BLK

2

M

12V

BLU/WHTE23-19

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

10

8

9

M1

12

11 13

14

15

I4RS0B710002-01

1. Ignition switch 5. Blower motor relay 9. ECM 13. Blower speed selector

2. Blower motor 6. Blower motor resistor 10. Air intake control actuator 14. Air intake selector

3. HVAC control unit 7. Junction block assembly 11. Ind ividual circuit fuse box No.1 15. Rear defogger switch

4. Lighting switch 8. BCM 12. Main fuse box