mount SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

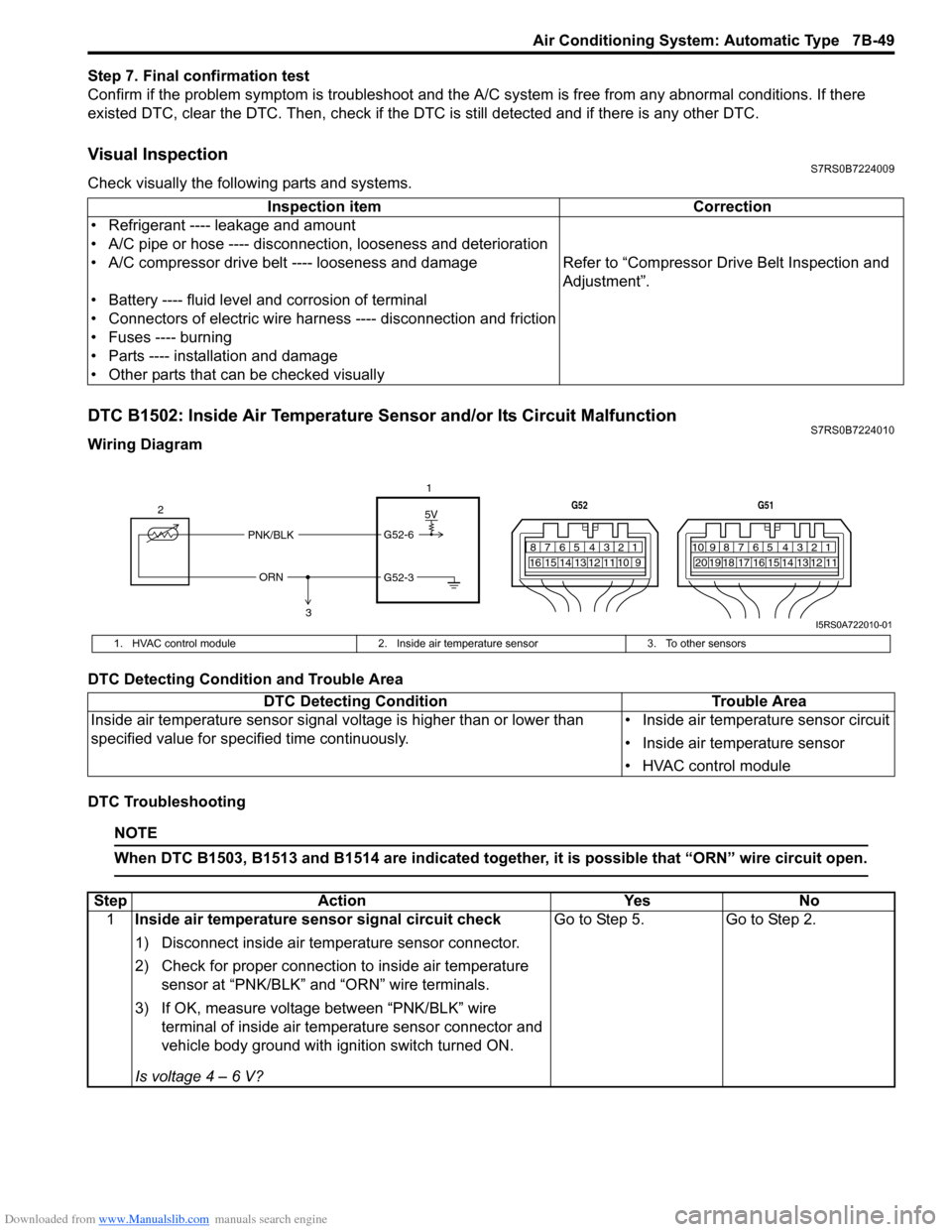

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 1011 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-63

DTC B1546: A/C Refrigerant Pressure MalfunctionS7RS0B7224018

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

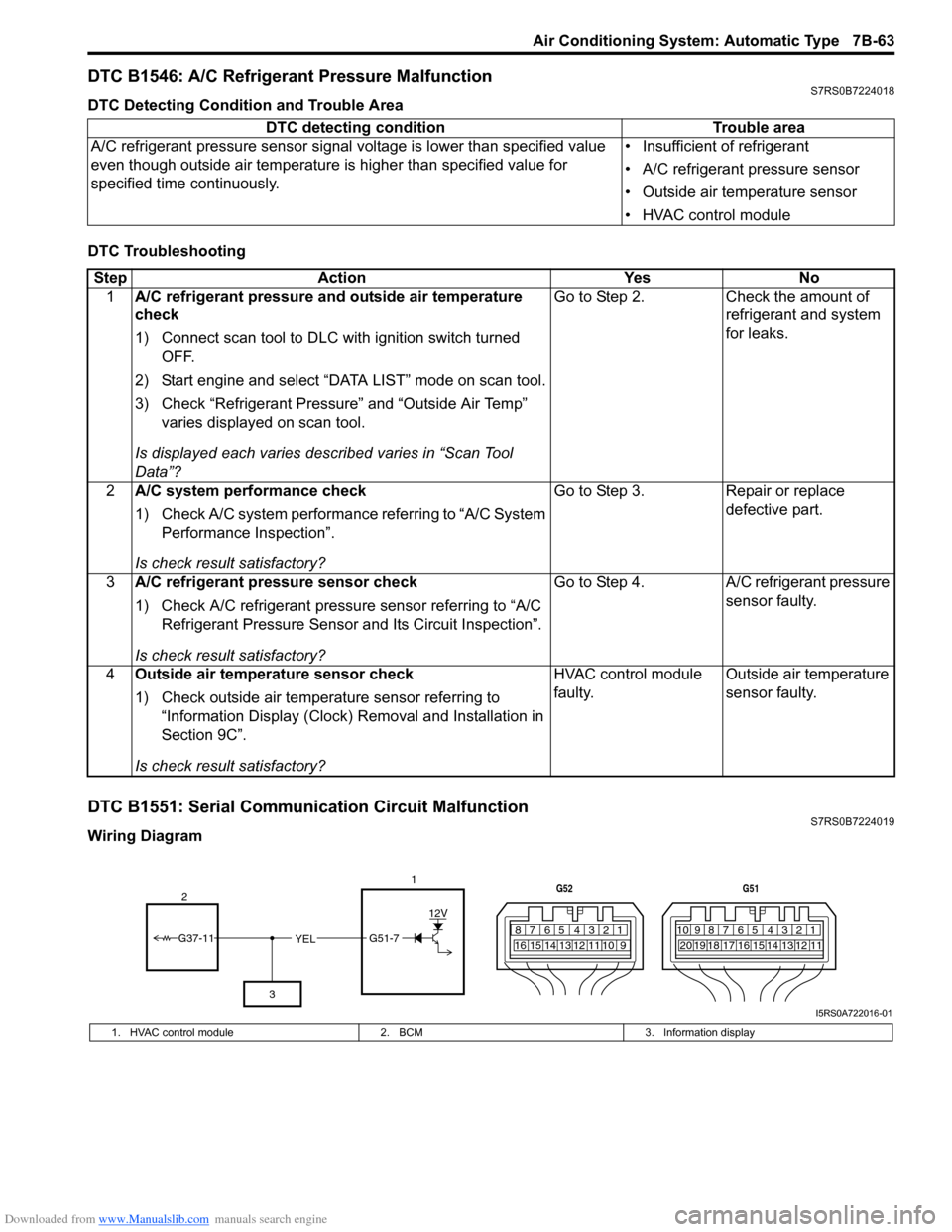

DTC B1551: Serial Communication Circuit MalfunctionS7RS0B7224019

Wiring DiagramDTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is lower t han specified value

even though outside air temperature is higher than specified value for

specified time continuously. • Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step

Action YesNo

1 A/C refrigerant pressure and outside air temperature

check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure” and “Outside Air Temp” varies displayed on scan tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Go to Step 2.

Check the amount of

refrigerant and system

for leaks.

2 A/C system performance check

1) Check A/C system performance referring to “A/C System

Performance Inspection”.

Is check result satisfactory? Go to Step 3.

Repair or replace

defective part.

3 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection”.

Is check result satisfactory? Go to Step 4.

A/C refrigerant pressure

sensor faulty.

4 Outside air temperature sensor check

1) Check outside air temperature sensor referring to

“Information Display (Clock) Removal and Installation in

Section 9C”.

Is check result satisfactory? HVAC control module

faulty.

Outside air temperature

sensor faulty.

YEL17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

G51-7

12V

2

3

G37-11

I5RS0A722016-01

1. HVAC control module 2. BCM3. Information display

Page 1034 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-3 Seat Belts:

Repair Instructions

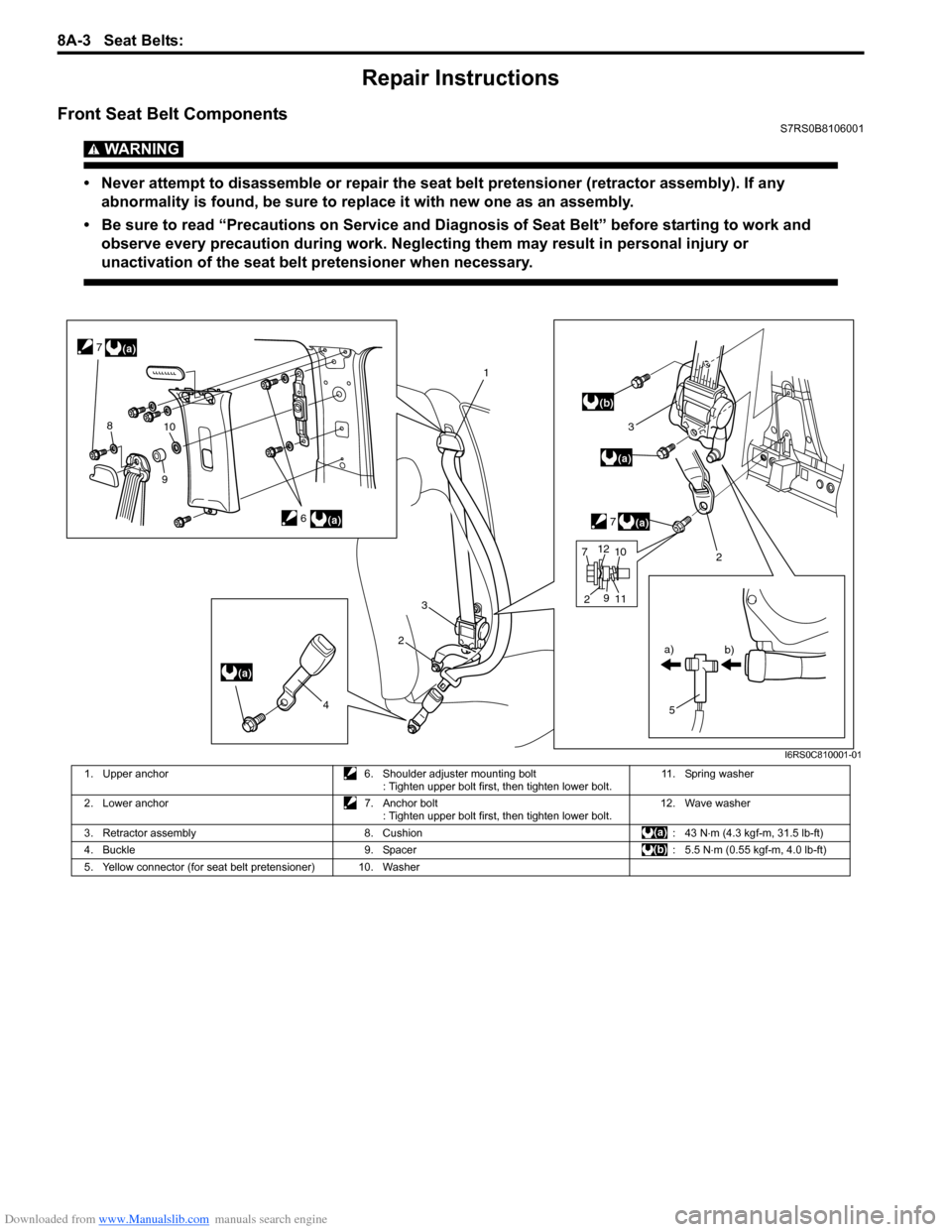

Front Seat Belt ComponentsS7RS0B8106001

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor assembly). If any abnormality is found, be sure to replace it with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting to work and observe every precaution during work. Neglecting them may result in personal injury or

unactivation of the seat belt pretensioner when necessary.

(a)

(a)

(a)

1

2

3

5

a)

b)

(a)

3

7

(b)

6

2

4

(a)

7

810

9

7 2 11

9

1012

I6RS0C810001-01

1. Upper anchor

6. Shoulder adjuster mounting bolt

: Tighten upper bolt first, then tighten lower bolt. 11. Spring washer

2. Lower anchor 7. Anchor bolt

: Tighten upper bolt first, then tighten lower bolt. 12. Wave washer

3. Retractor assembly 8. Cushion : 43 N⋅m (4.3 kgf-m, 31.5 lb-ft)

4. Buckle 9. Spacer : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

5. Yellow connector (for seat belt pretensioner) 10. Washer

Page 1037 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-6

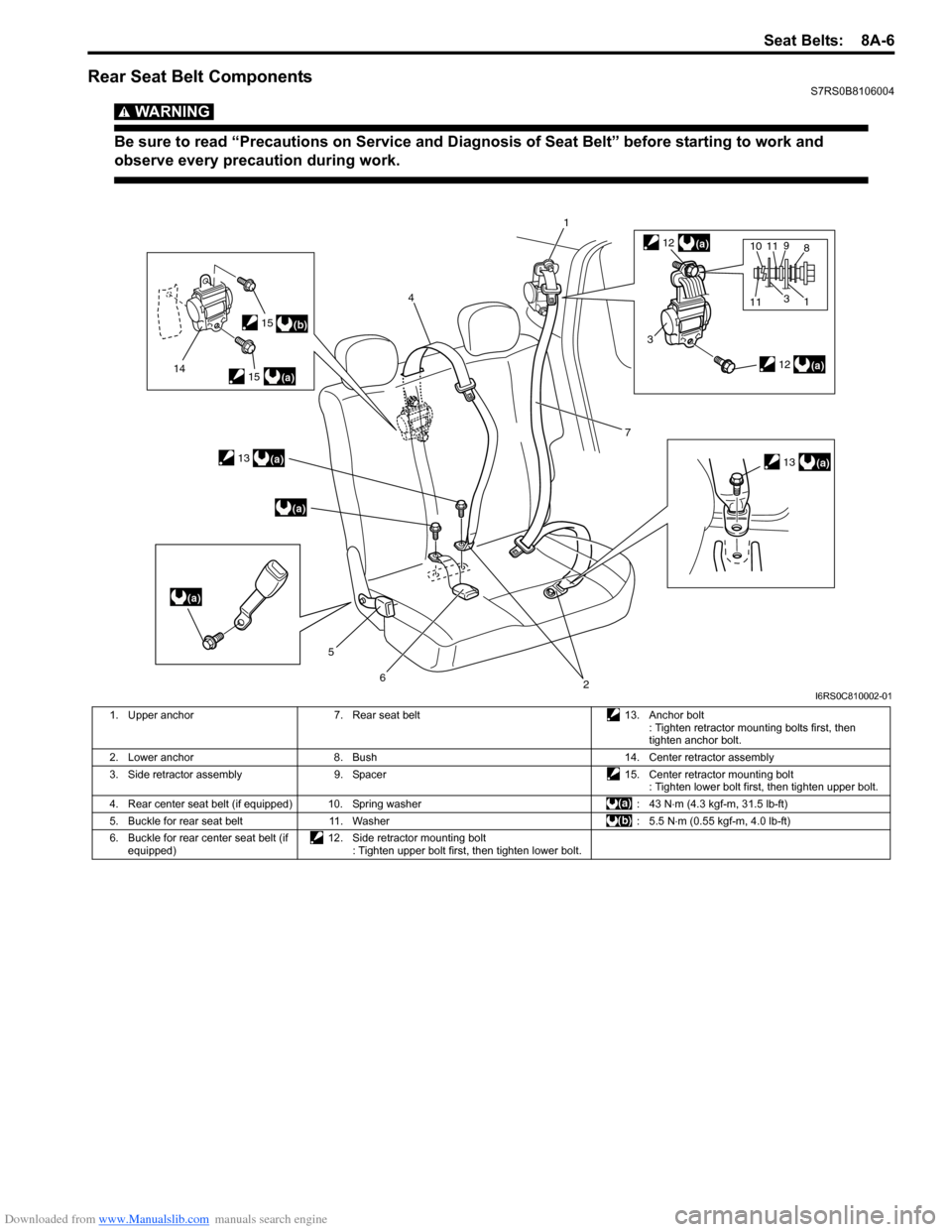

Rear Seat Belt ComponentsS7RS0B8106004

WARNING!

Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting to work and

observe every precaution during work.

(b)

(a)

(a)

(a)

(a)

14

4

5

62

1

7

(a)

(a)

3

8

1

10

3

11911(a)

12

13

12

13

15

15

I6RS0C810002-01

1. Upper anchor 7. Rear seat belt 13. Anchor bolt

: Tighten retractor mounting bolts first, then

tighten anchor bolt.

2. Lower anchor 8. Bush 14. Center retractor assembly

3. Side retractor assembly 9. Spacer 15. Center retractor mounting bolt

: Tighten lower bolt first, then tighten upper bolt.

4. Rear center seat belt (if equipped) 10. Spring washer : 43 N⋅m (4.3 kgf-m, 31.5 lb-ft)

5. Buckle for rear seat belt 11. Washer : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

6. Buckle for rear center seat belt (if equipped) 12. Side retractor mounting bolt

: Tighten upper bolt first, then tighten lower bolt.

Page 1040 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-2 Air Bag System:

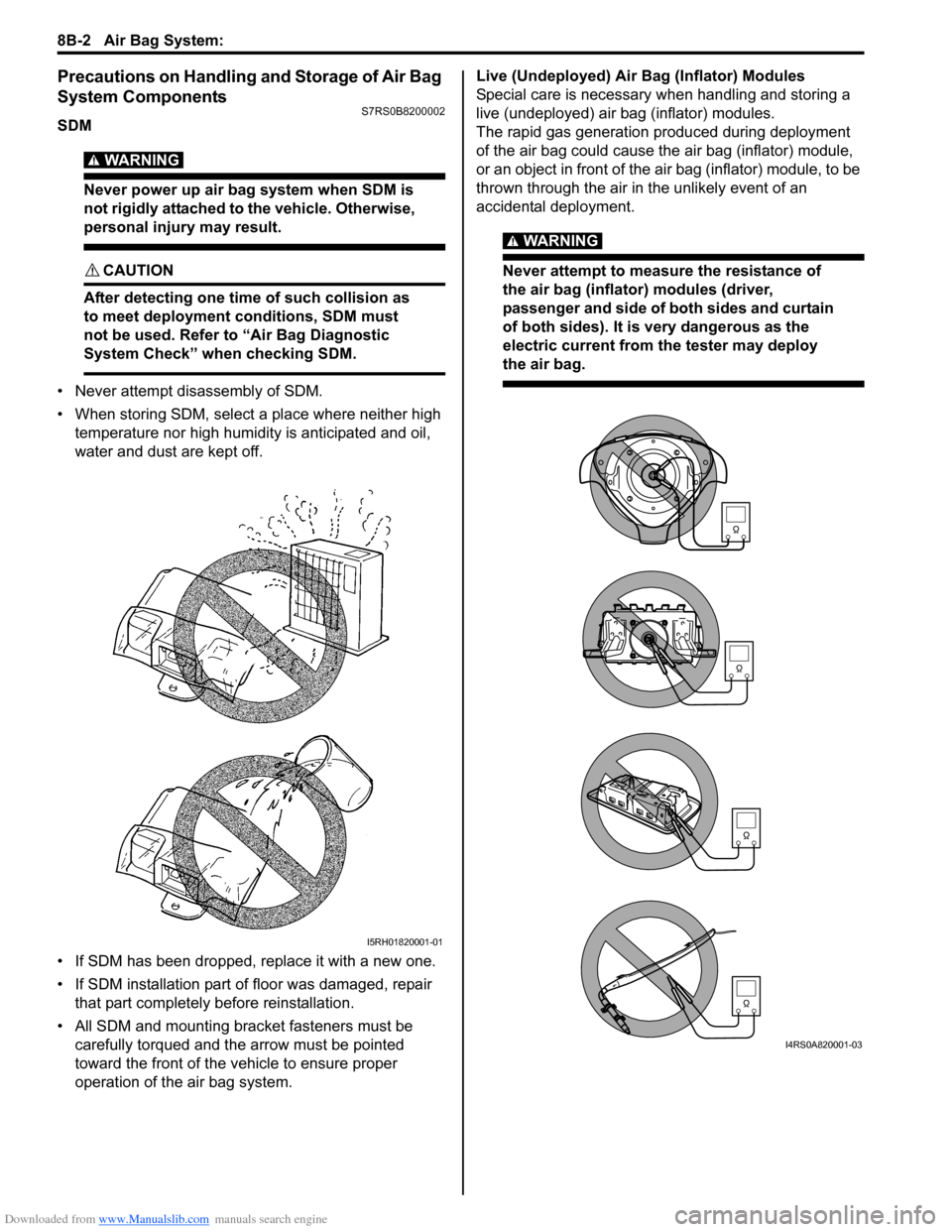

Precautions on Handling and Storage of Air Bag

System Components

S7RS0B8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

• Never attempt disassembly of SDM.

• When storing SDM, select a place where neither high temperature nor high humidity is anticipated and oil,

water and dust are kept off.

• If SDM has been dropped, replace it with a new one.

• If SDM installation part of floor was damaged, repair that part completely before reinstallation.

• All SDM and mounting bracket fasteners must be carefully torqued and the arrow must be pointed

toward the front of the vehicle to ensure proper

operation of the air bag system. Live (Undeployed) Air Bag (Inflator) Modules

Special care is necessary when handling and storing a

live (undeployed) air bag (inflator) modules.

The rapid gas generation produced during deployment

of the air bag could cause the air bag (inflator) module,

or an object in front of the air bag (inflator) module, to be

thrown through the air in the unlikely event of an

accidental deployment.

WARNING!

Never attempt to measure the resistance of

the air bag (inflator) modules (driver,

passenger and side of both sides and curtain

of both sides). It is

very dangerous as the

electric current from the tester may deploy

the air bag.

I5RH01820001-01

I4RS0A820001-03

Page 1041 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-3

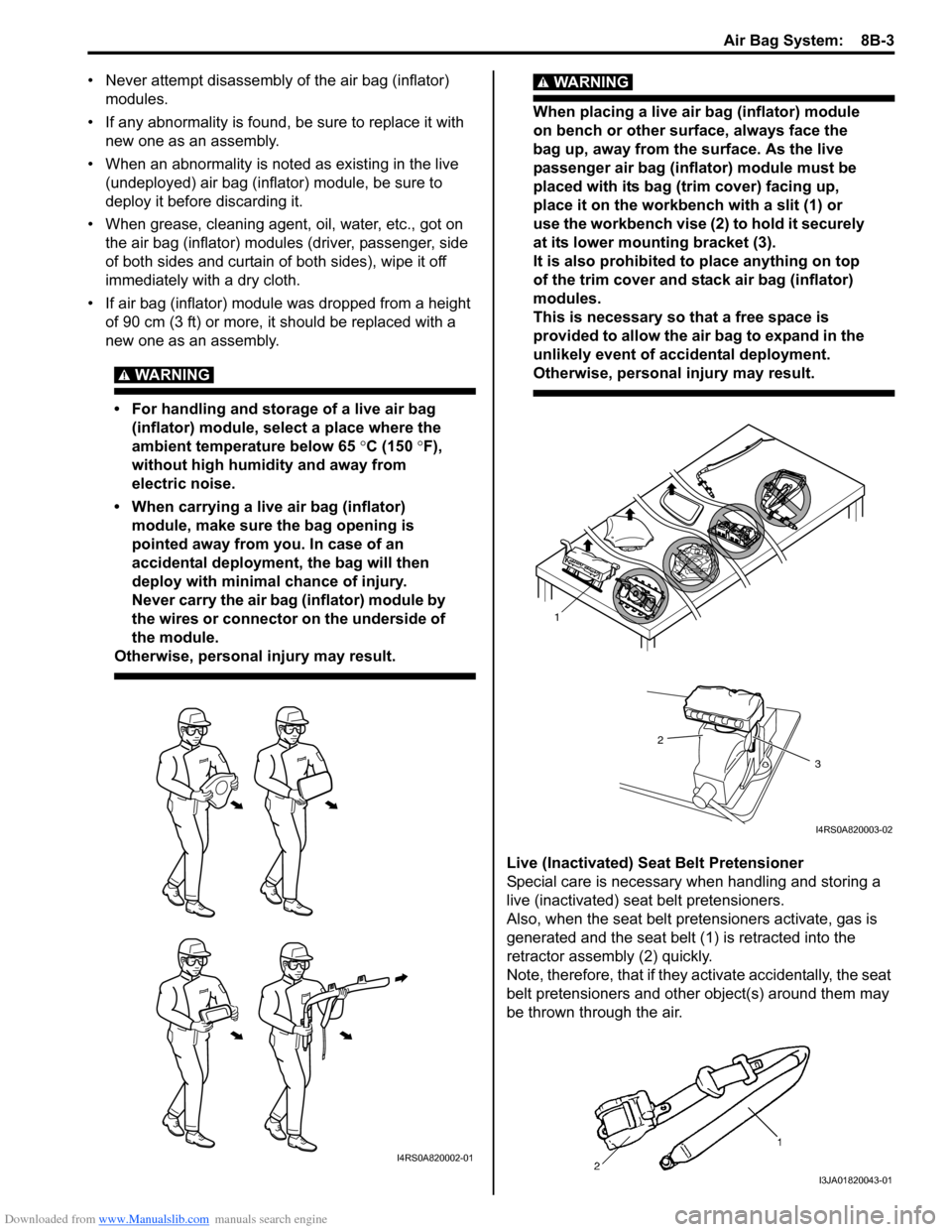

• Never attempt disassembly of the air bag (inflator) modules.

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live (undeployed) air bag (inflator) module, be sure to

deploy it before discarding it.

• When grease, cleaning agent, oil, water, etc., got on the air bag (inflator) modules (driver, passenger, side

of both sides and curtain of both sides), wipe it off

immediately with a dry cloth.

• If air bag (inflator) module was dropped from a height of 90 cm (3 ft) or more, it should be replaced with a

new one as an assembly.

WARNING!

• For handling and storage of a live air bag (inflator) module, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you. In case of an

accidental deployment, the bag will then

deploy with minimal chance of injury.

Never carry the air bag (inflator) module by

the wires or connector on the underside of

the module.

Otherwise, personal injury may result.

WARNING!

When placing a live air bag (inflator) module

on bench or other surface, always face the

bag up, away from the surface. As the live

passenger air bag (inflator) module must be

placed with its bag (trim cover) facing up,

place it on the workbench with a slit (1) or

use the workbench vise (2) to hold it securely

at its lower mounting bracket (3).

It is also prohibited to place anything on top

of the trim cover and stack air bag (inflator)

modules.

This is necessary so that a free space is

provided to allow the air bag to expand in the

unlikely event of accidental deployment.

Otherwise, personal injury may result.

Live (Inactivated) Seat Belt Pretensioner

Special care is necessary when handling and storing a

live (inactivated) seat belt pretensioners.

Also, when the seat belt pretensioners activate, gas is

generated and the seat belt (1) is retracted into the

retractor assembly (2) quickly.

Note, therefore, that if they activate accidentally, the seat

belt pretensioners and other object(s) around them may

be thrown through the air.

I4RS0A820002-01

1

2

3

I4RS0A820003-02

I3JA01820043-01

Page 1053 of 1496

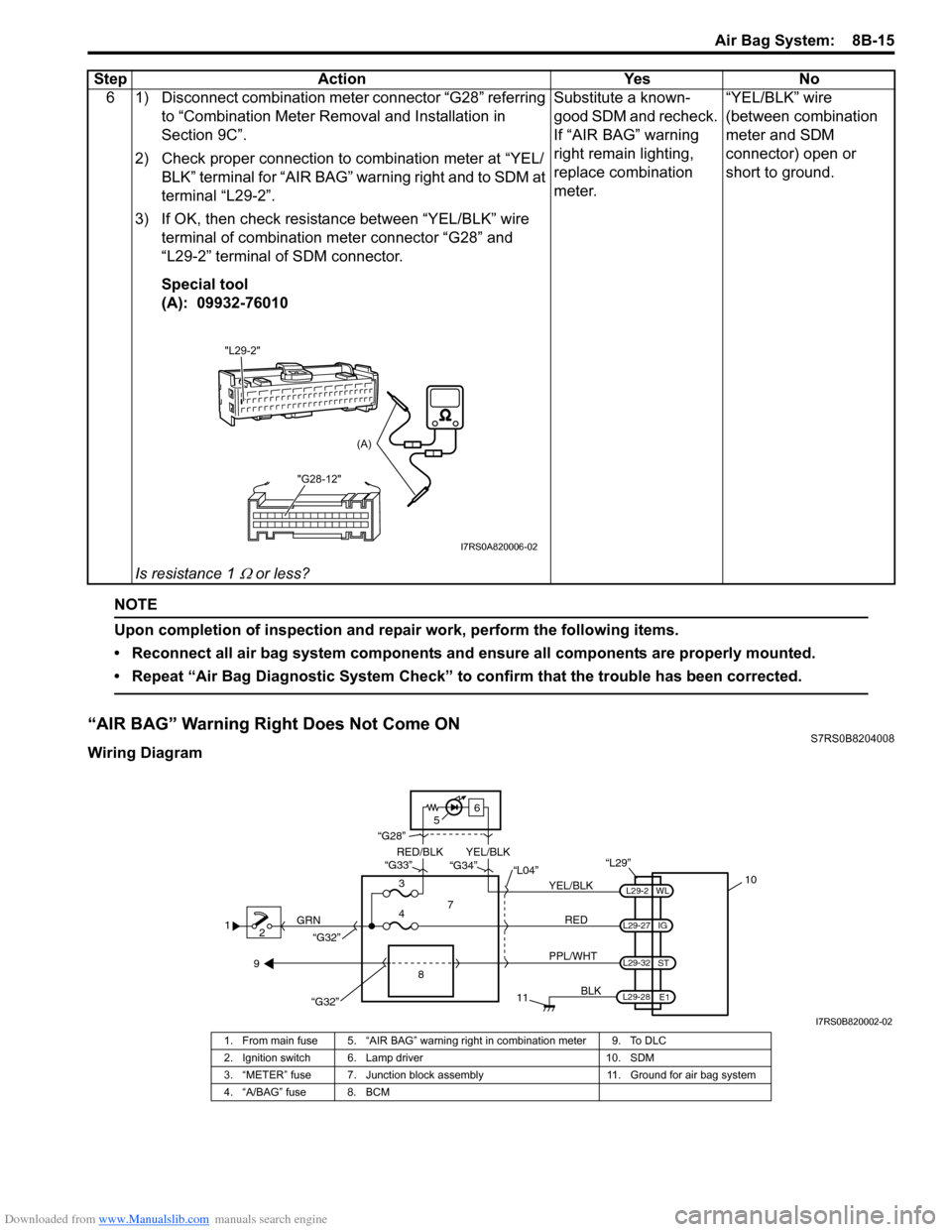

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-15

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

“AIR BAG” Warning Right Does Not Come ONS7RS0B8204008

Wiring Diagram6 1) Disconnect combination meter connector “G28” referring

to “Combination Meter Removal and Installation in

Section 9C”.

2) Check proper connection to combination meter at “YEL/ BLK” terminal for “AIR BAG” warning right and to SDM at

terminal “L29-2”.

3) If OK, then check resistance between “YEL/BLK” wire terminal of combination meter connector “G28” and

“L29-2” terminal of SDM connector.

Special tool

(A): 09932-76010

Is resistance 1

Ω or less? Substitute a known-

good SDM and recheck.

If “AIR BAG” warning

right remain lighting,

replace combination

meter.

“YEL/BLK” wire

(between combination

meter and SDM

connector) open or

short to ground.

Step Action Yes No

"L29-2"

"G28-12"

(A)

I7RS0A820006-02

12 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1054 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-16 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

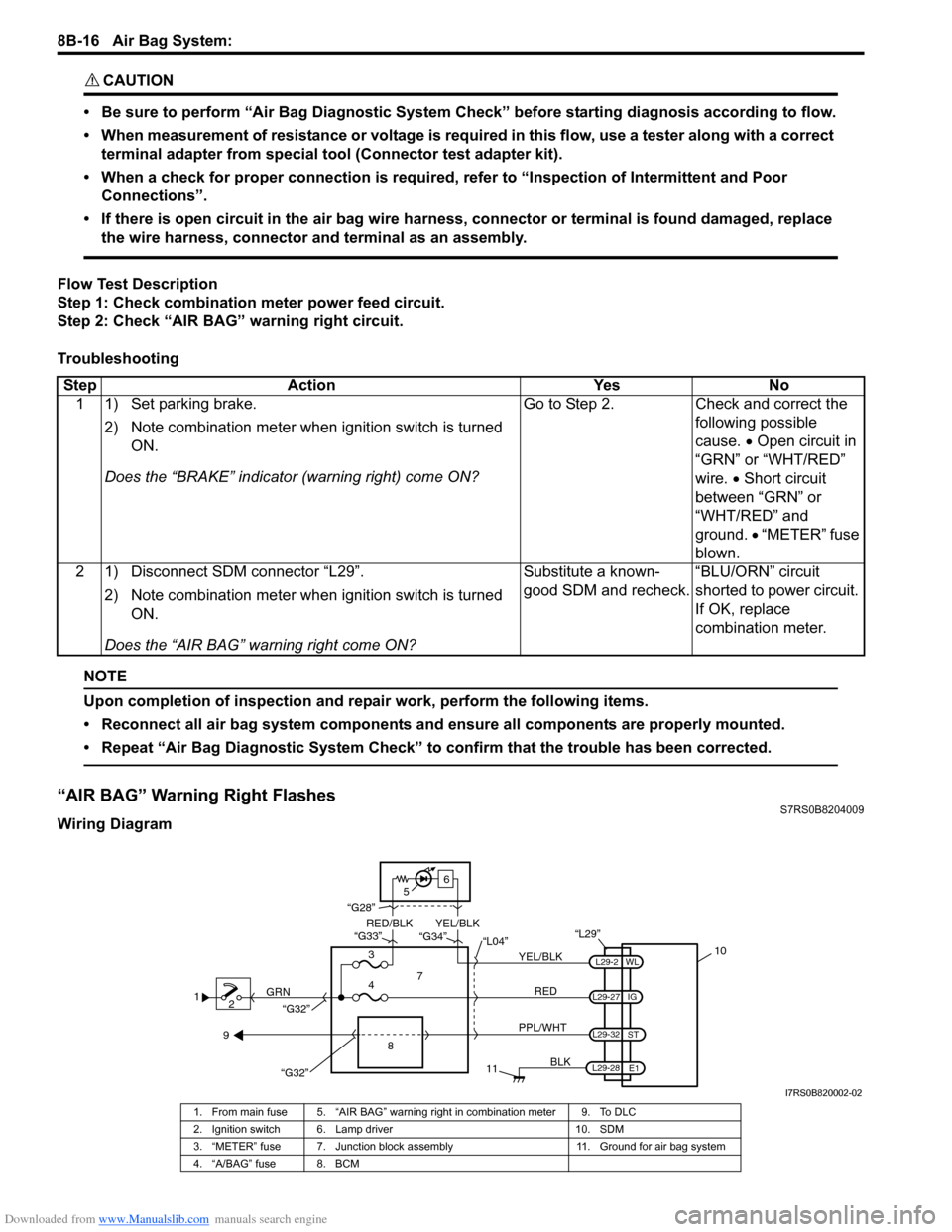

Flow Test Description

Step 1: Check combination meter power feed circuit.

Step 2: Check “AIR BAG” warning right circuit.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

“AIR BAG” Warning Right FlashesS7RS0B8204009

Wiring Diagram Step Action Yes No

1 1) Set parking brake.

2) Note combination me ter when ignition switch is turned

ON.

Does the “BRAKE” in dicator (warning right) come ON? Go to Step 2. Check and correct the

following possible

cause. • Open circuit in

“GRN” or “WHT/RED”

wire. • Short circuit

between “GRN” or

“WHT/RED” and

ground. • “METER” fuse

blown.

2 1) Disconnect SDM connector “L29”.

2) Note combination me ter when ignition switch is turned

ON.

Does the “AIR BAG” warning right come ON? Substitute a known-

good SDM and recheck.

“BLU/ORN” circuit

shorted to power circuit.

If OK, replace

combination meter.

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1055 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-17

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

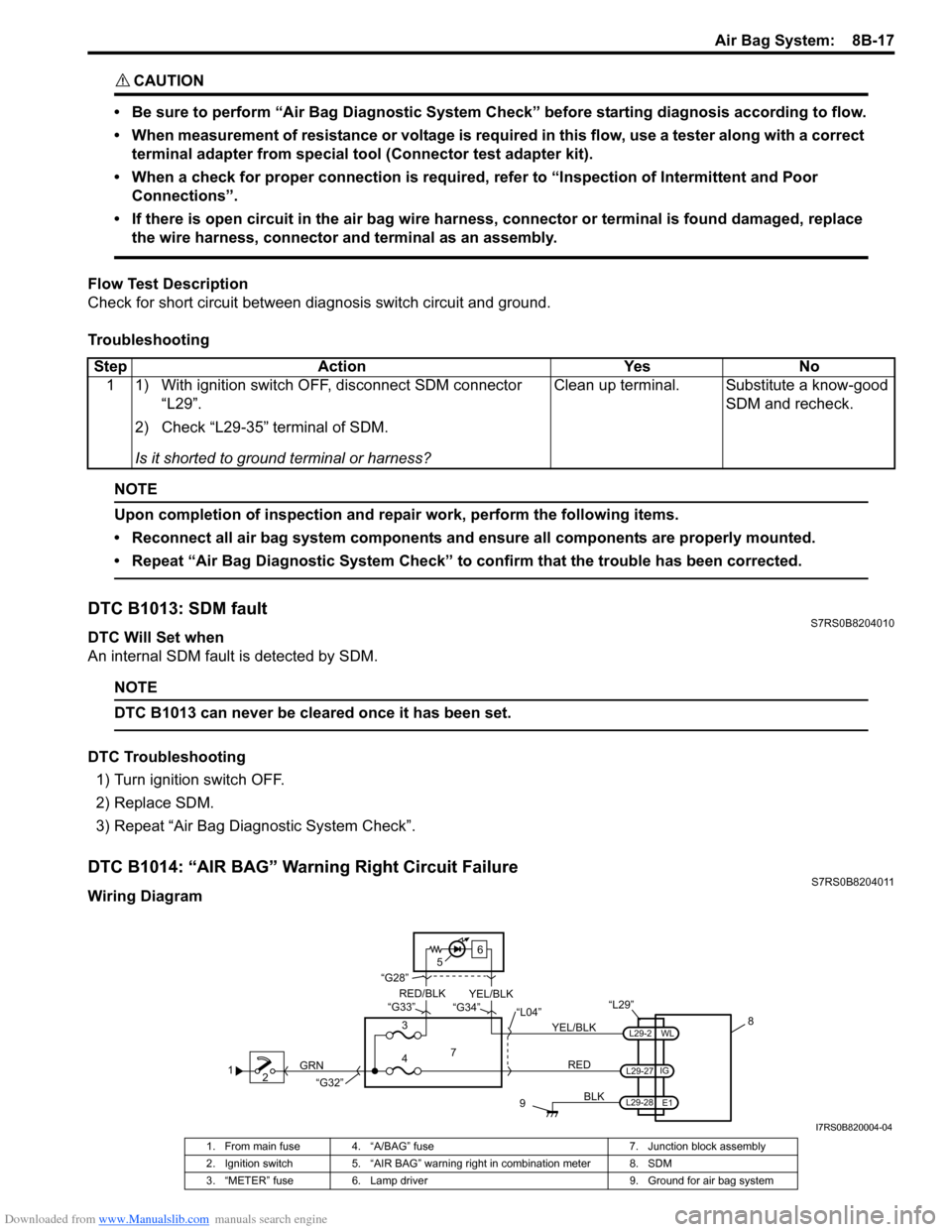

Flow Test Description

Check for short circuit between diag nosis switch circuit and ground.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1013: SDM faultS7RS0B8204010

DTC Will Set when

An internal SDM fault is detected by SDM.

NOTE

DTC B1013 can never be cleared once it has been set.

DTC Troubleshooting 1) Turn ignition switch OFF.

2) Replace SDM.

3) Repeat “Air Bag Diagnostic System Check”.

DTC B1014: “AIR BAG” Warning Right Circuit FailureS7RS0B8204011

Wiring DiagramStep Action Yes No

1 1) With ignition switch OFF, disconnect SDM connector “L29”.

2) Check “L29-35” terminal of SDM.

Is it shorted to ground terminal or harness? Clean up terminal. Substitute a know-good

SDM and recheck.

12 GRN

9

BLK

L29-2

L29-27

L29-28 IG

E1

WL

8

“L29”

RED

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

YEL/BLK

YEL/BLK

RED/BLK

I7RS0B820004-04

1. From main fuse 4. “A/BAG” fuse

7. Junction block assembly

2. Ignition switch 5. “AIR BAG” warning right in combination meter 8. SDM

3. “METER” fuse 6. Lamp driver 9. Ground for air bag system