Pressure SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 685 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-41

No Gear Shift to 4th gearS7RS0B5104019

System Description

TCM does not shift to 4th gear under any of the following condition.

• “3” position switch is turned ON.

• Engine coolant temperature is less than 50 °C (122 °F).

• A/T fluid temperature is less than 20 °C (68 °F).

• A/T fluid temperature is more than 130 °C (266 °F) while TCM is detecting P2762, P2763 and P2764.

• TCM detects the following DTCs. P0712 / P0713 / P0717 / P0722 / P0787 / P0788 / P0961 / P0962 / P0963 / P0973 / P0974 / P0976 / P0977 / P1702

/ P1703 / P1774 / P1777

Troubleshooting

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Non operate TCC (lock-

up) system Faulty torque converter

Replace.

Excessive “N”

→ “D” time

lag Faulty oil pump

Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Leakage from “D” range fluid pressure

circuit Replace valve body assembly.

Excessive “N”

→ “R” time

lag Faulty oil pump

Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Leakage from “R” range fluid pressure

circuit Replace valve body assembly.

Poor engine brake in

downshift to “2” range Faulty O/D and 2nd coast brake

Inspect. If NG, replace.

Poor engine brake in

downshift to “L” range Faulty 1st and reverse brake

Inspect. If NG, replace.

Condition Possible cause Correction / Reference Item

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Check DTC

Is DTC P0712, P0713, P0717, P0722, P0961, P0962,

P0963, P0973, P0974, P0976, P0977, P1702, P1703,

P1774 and/or P1777 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

Page 702 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-58 Automatic Transmission/Transaxle:

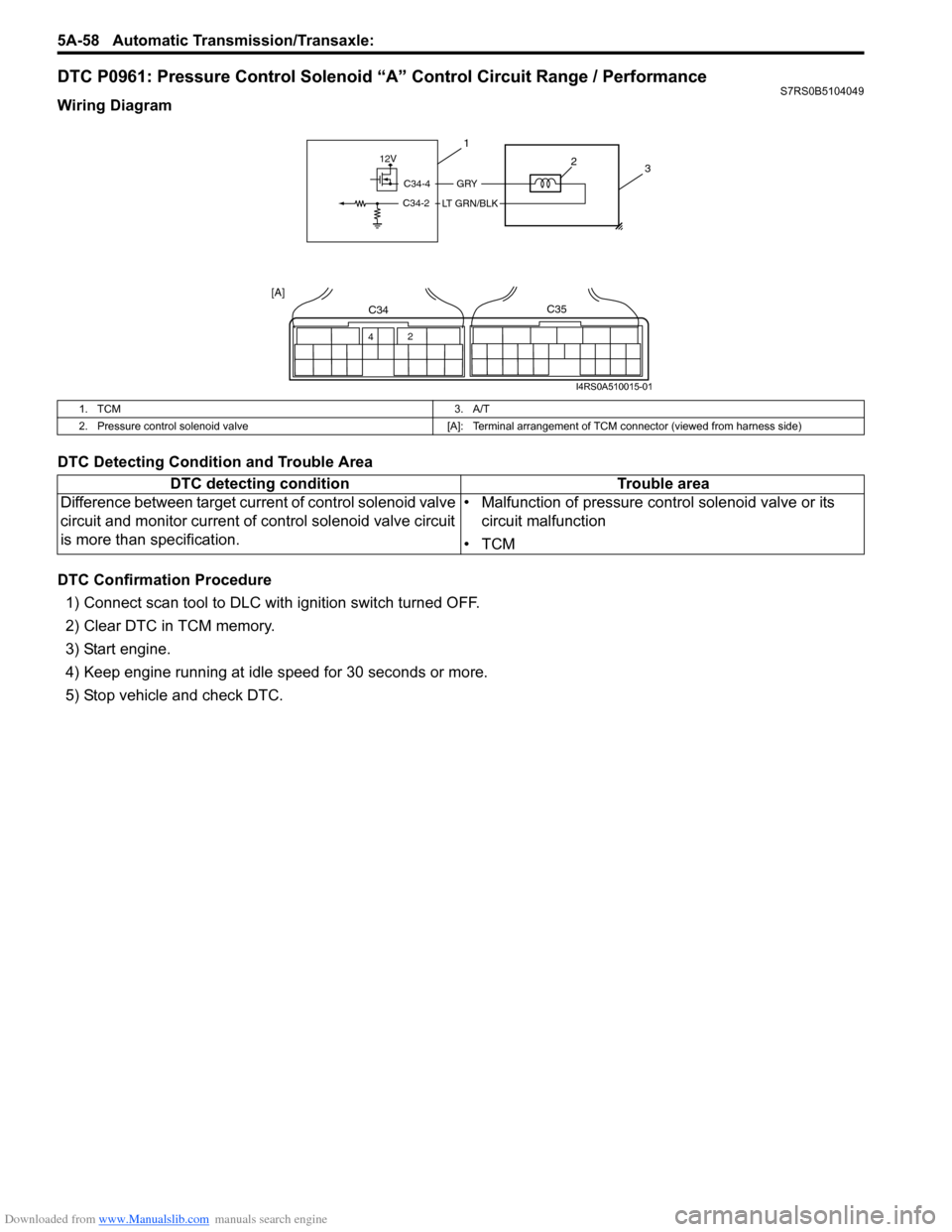

DTC P0961: Pressure Control Solenoid “A” Control Circuit Range / PerformanceS7RS0B5104049

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

1. TCM 3. A/T

2. Pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Difference between target current of control solenoid valve

circuit and monitor current of control solenoid valve circuit

is more than specification. • Malfunction of pressure control solenoid valve or its

circuit malfunction

•TCM

12V

C34-4

C34-2

GRY

LT GRN/BLK

3

1

2

42

C34C35

[A]

I4RS0A510015-01

Page 703 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-59

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

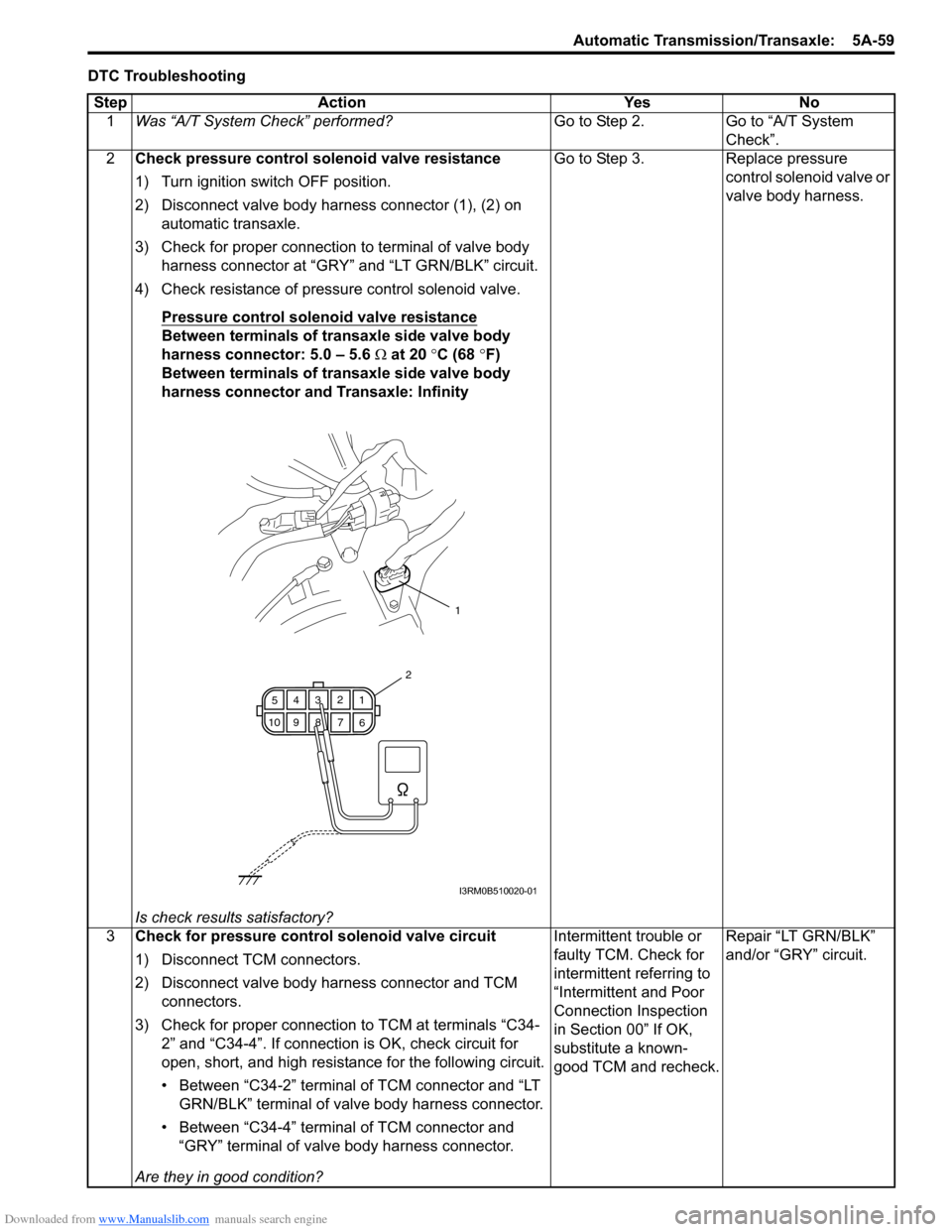

2 Check pressure control solenoid valve resistance

1) Turn ignition switch OFF position.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to terminal of valve body harness connector at “GRY” and “LT GRN/BLK” circuit.

4) Check resistance of pressure control solenoid valve.

Pressure control solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and Transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace pressure

control solenoid valve or

valve body harness.

3 Check for pressure control solenoid valve circuit

1) Disconnect TCM connectors.

2) Disconnect valve body harness connector and TCM

connectors.

3) Check for proper connection to TCM at terminals “C34- 2” and “C34-4”. If connection is OK, check circuit for

open, short, and high resistance for the following circuit.

• Between “C34-2” terminal of TCM connector and “LT GRN/BLK” terminal of valve body harness connector.

• Between “C34-4” terminal of TCM connector and “GRY” terminal of valve body harness connector.

Are they in good condition? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00” If OK,

substitute a known-

good TCM and recheck.

Repair “LT GRN/BLK”

and/or “GRY” circuit.

1

6

7

89

10 5

43 2

1

2

I3RM0B510020-01

Page 704 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-60 Automatic Transmission/Transaxle:

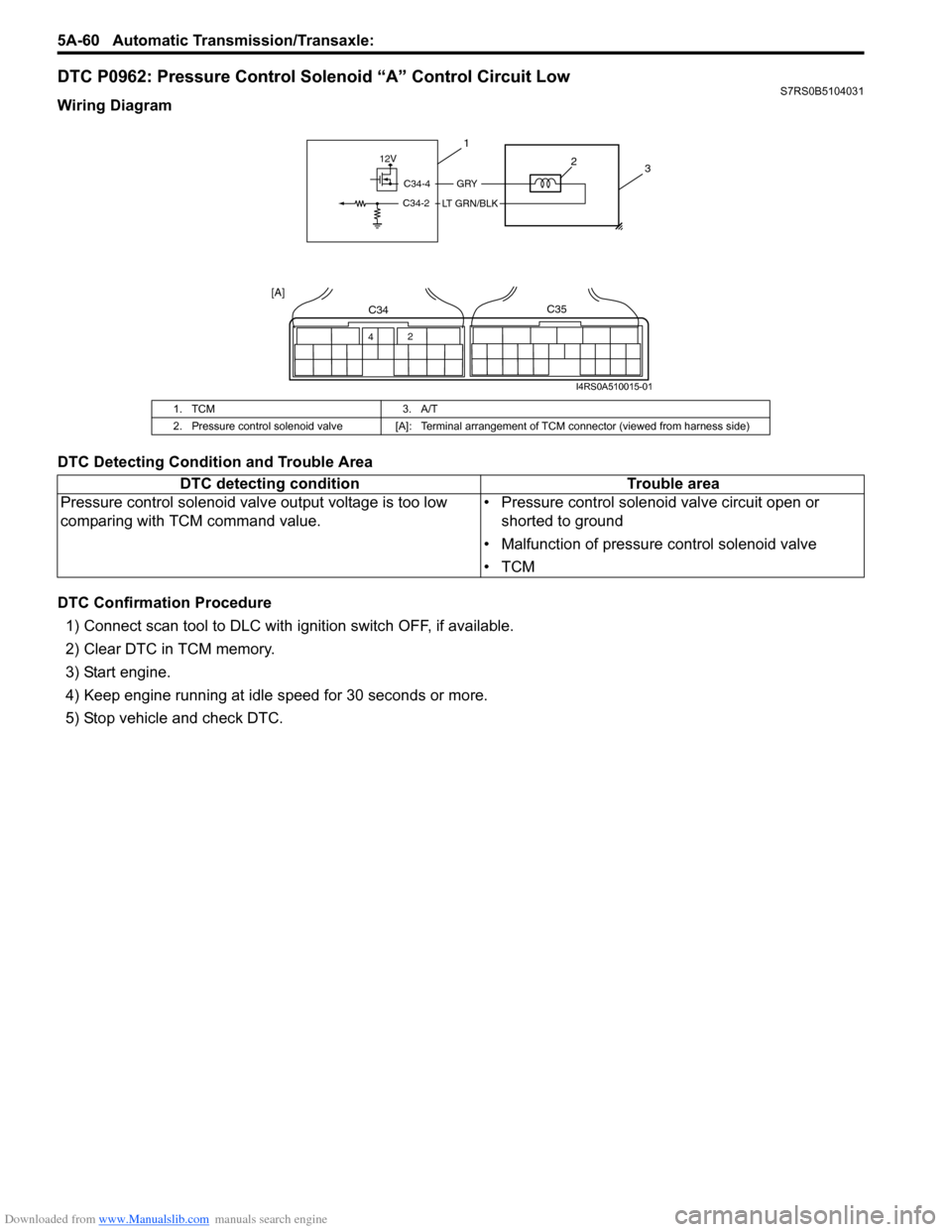

DTC P0962: Pressure Control Solenoid “A” Control Circuit LowS7RS0B5104031

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

1. TCM 3. A/T

2. Pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Pressure control solenoid valv e output voltage is too low

comparing with TCM command value. • Pressure control solenoid valve circuit open or

shorted to ground

• Malfunction of pressure control solenoid valve

•TCM

12V

C34-4

C34-2

GRY

LT GRN/BLK

3

1

2

42

C34C35

[A]

I4RS0A510015-01

Page 705 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-61

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check pressure control solenoid valve resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to solenoid at “GRY” and “LT GRN/BLK” circuit.

4) Check resistance of pressure control solenoid.

Pressure control solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and Transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace pressure

control solenoid valve or

valve body harness.

3 Check pressure control solenoid valve circuit for

ground short

1) Connect valve body harness connector.

2) Disconnect TCM connectors.

3) Check for proper connection to TCM at terminals “C34-

2” and “C34-4”. If connection is OK, check continuity

between terminal “C34-4” of disconnected harness side

TCM connector and ground.

Is continuity indicated? “GRY” or “LT GRN/BLK”

circuit shorted to

ground.

Go to Step 4.

1

6

7

89

10 5

43 2

1

2

I3RM0B510020-01

Page 706 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-62 Automatic Transmission/Transaxle:

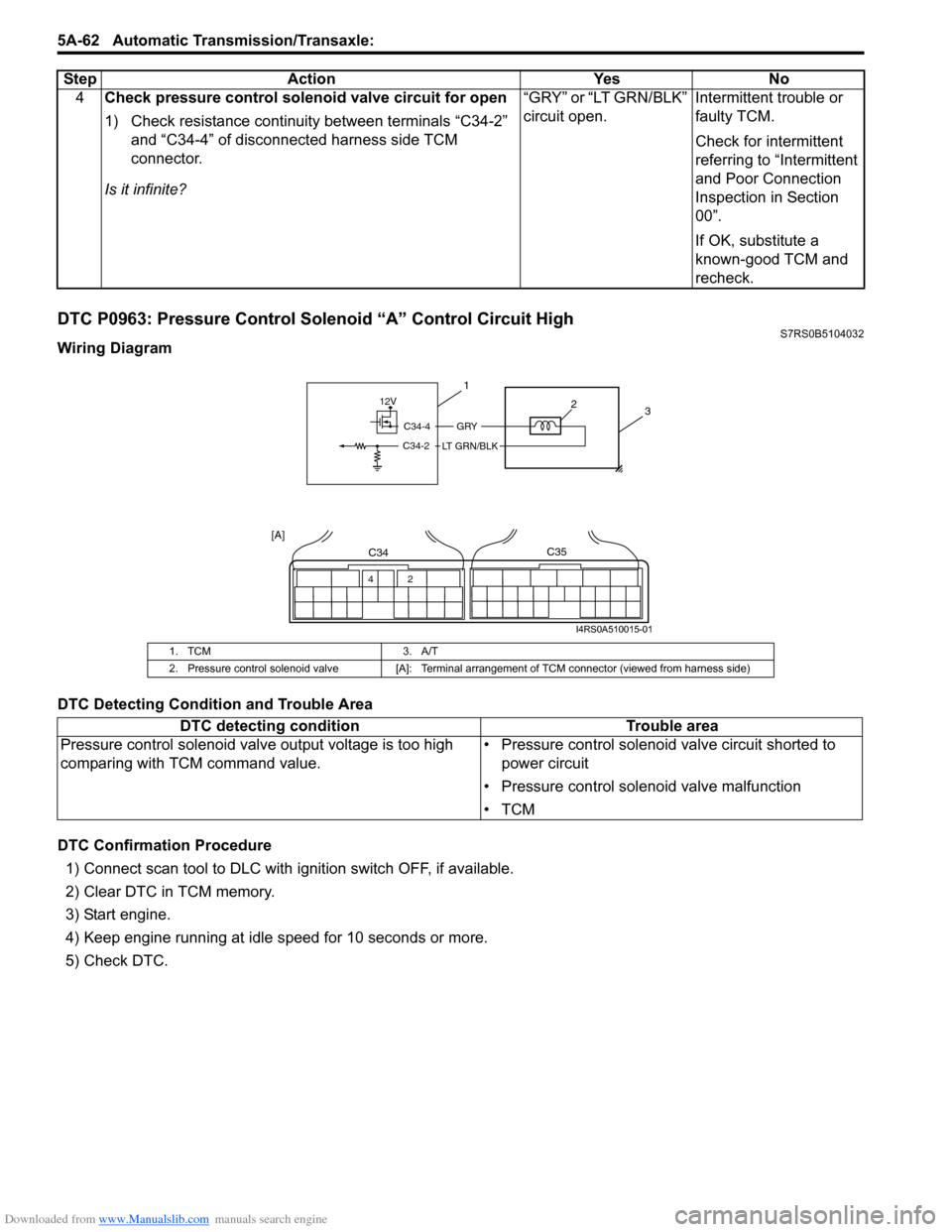

DTC P0963: Pressure Control Solenoid “A” Control Circuit HighS7RS0B5104032

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 10 seconds or more.

5) Check DTC. 4

Check pressure control solenoid valve circuit for open

1) Check resistance continuity between terminals “C34-2”

and “C34-4” of disconnected harness side TCM

connector.

Is it infinite? “GRY” or “LT GRN/BLK”

circuit open.

Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

Step Action Yes No

1. TCM

3. A/T

2. Pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Pressure control solenoid valve output voltage is too high

comparing with TCM command value. • Pressure control solenoid valve circuit shorted to

power circuit

• Pressure control solenoid valve malfunction

•TCM

12V

C34-4

C34-2

GRY

LT GRN/BLK

3

1

2

42

C34C35

[A]

I4RS0A510015-01

Page 707 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-63

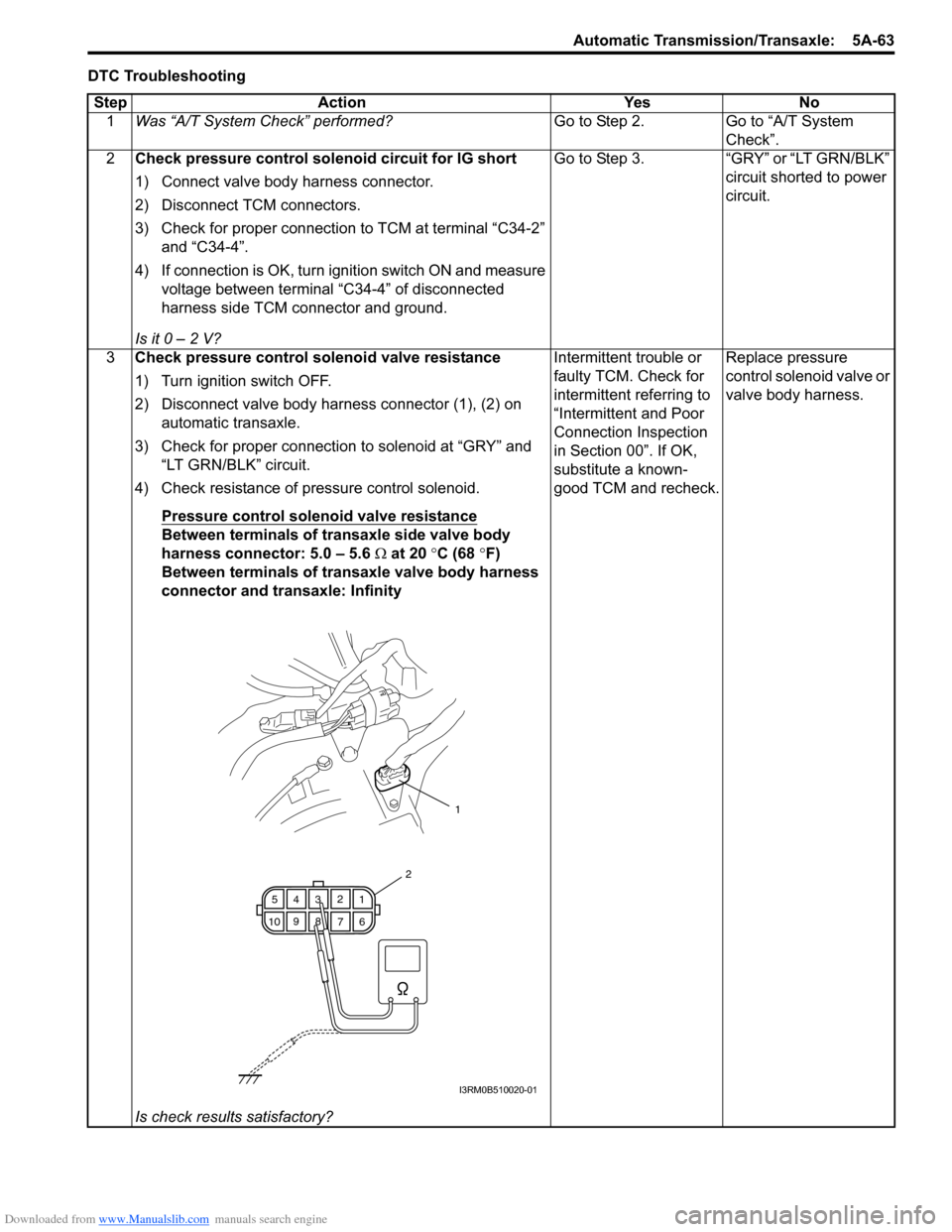

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check pressure control solenoid circuit for IG short

1) Connect valve body harness connector.

2) Disconnect TCM connectors.

3) Check for proper connection to TCM at terminal “C34-2”

and “C34-4”.

4) If connection is OK, turn ignition switch ON and measure voltage between terminal “C34-4” of disconnected

harness side TCM connector and ground.

Is it 0 – 2 V? Go to Step 3. “GRY” or “LT GRN/BLK”

circuit shorted to power

circuit.

3 Check pressure control solenoid valve resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to solenoid at “GRY” and “LT GRN/BLK” circuit.

4) Check resistance of pressure control solenoid.

Pressure control solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle valve body harness

connector and transaxle: Infinity

Is check results satisfactory? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.

Replace pressure

control solenoid valve or

valve body harness.

1

6

7

89

10 5

43 2

1

2

I3RM0B510020-01

Page 720 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-76 Automatic Transmission/Transaxle:

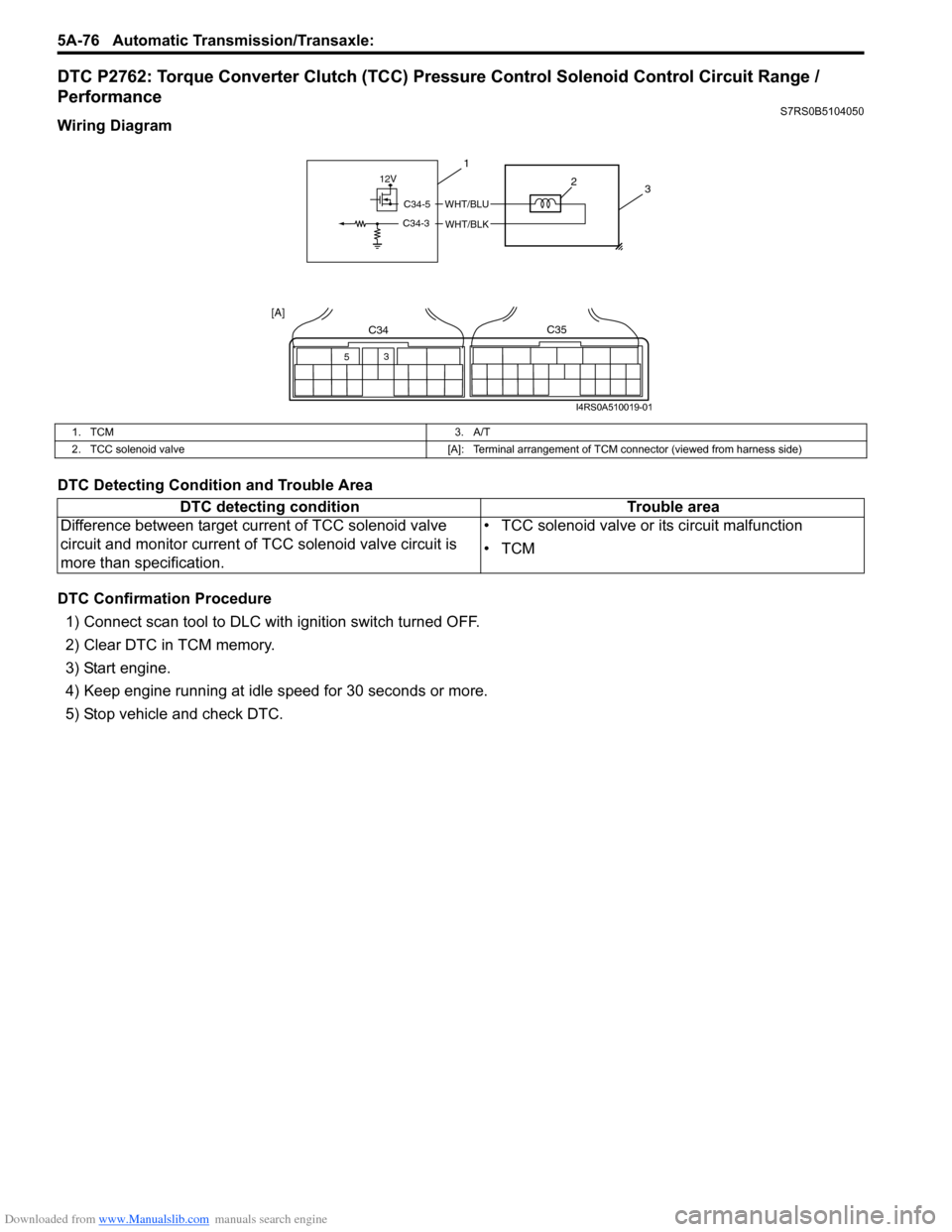

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit Range /

Performance

S7RS0B5104050

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

1. TCM

3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Difference between target current of TCC solenoid valve

circuit and monitor current of TCC solenoid valve circuit is

more than specification. • TCC solenoid valve or its circuit malfunction

•TCM

Page 721 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-77

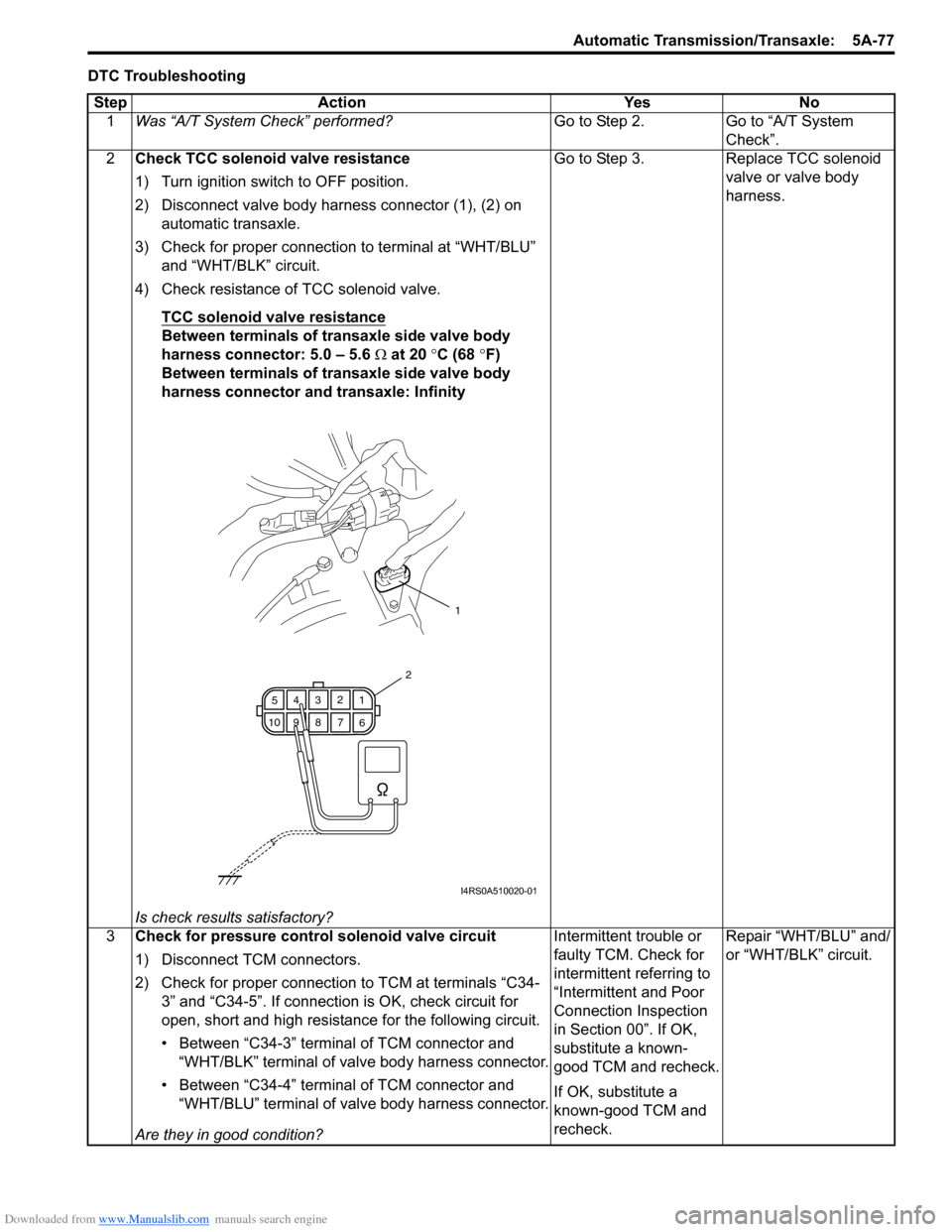

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check TCC solenoid valve resistance

1) Turn ignition switch to OFF position.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to terminal at “WHT/BLU” and “WHT/BLK” circuit.

4) Check resistance of TCC solenoid valve.

TCC solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace TCC solenoid

valve or valve body

harness.

3 Check for pressure control solenoid valve circuit

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminals “C34-

3” and “C34-5”. If connection is OK, check circuit for

open, short and high resistance for the following circuit.

• Between “C34-3” terminal of TCM connector and “WHT/BLK” terminal of valve body harness connector.

• Between “C34-4” terminal of TCM connector and “WHT/BLU” terminal of valve body harness connector.

Are they in good condition? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.

If OK, substitute a

known-good TCM and

recheck.

Repair “WHT/BLU” and/

or “WHT/BLK” circuit.

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 722 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-78 Automatic Transmission/Transaxle:

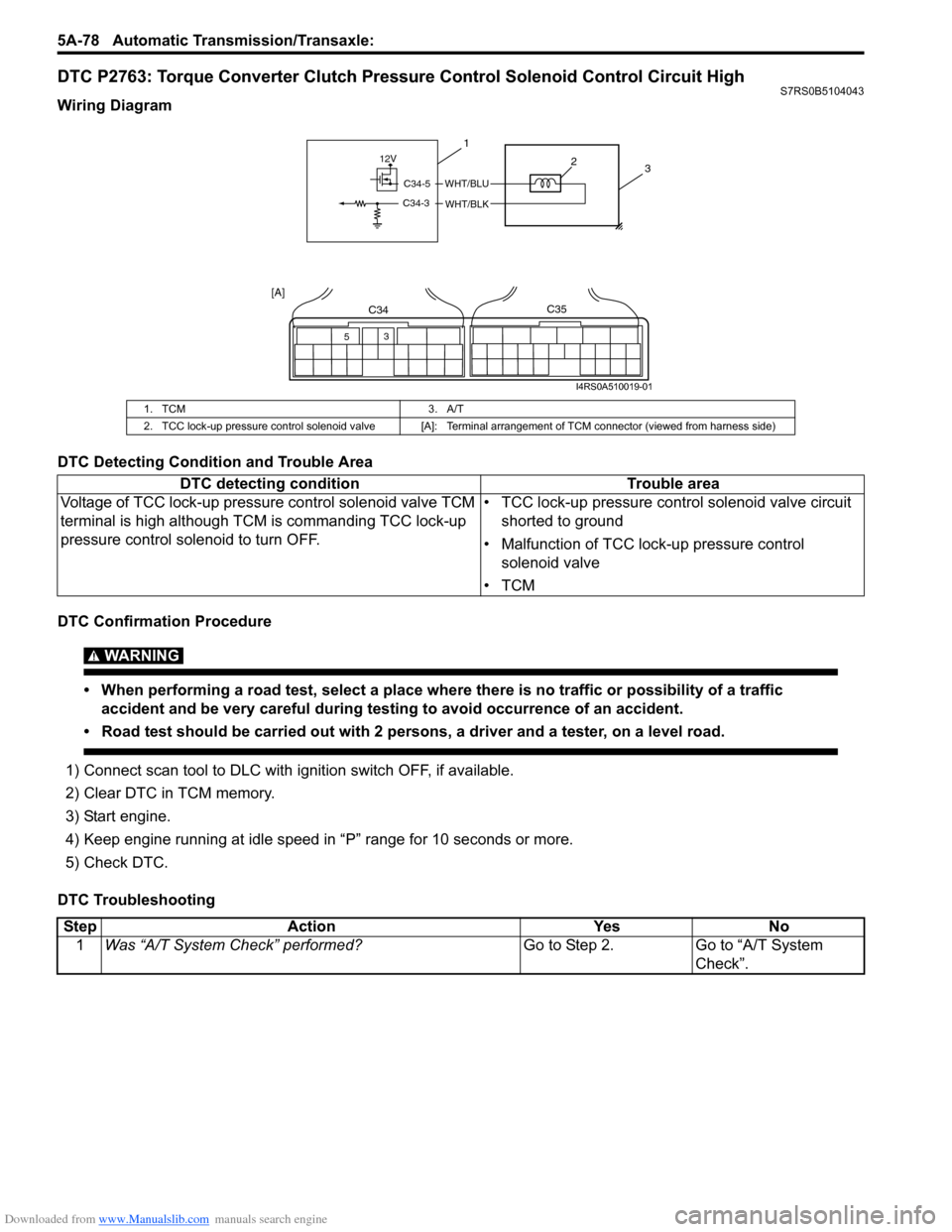

DTC P2763: Torque Converter Clutch Pressure Control Solenoid Control Circuit HighS7RS0B5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 10 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC lock-up pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is high although TCM is commanding TCC lock-up

pressure control sole noid to turn OFF. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.