6C-1 SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 899 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-17

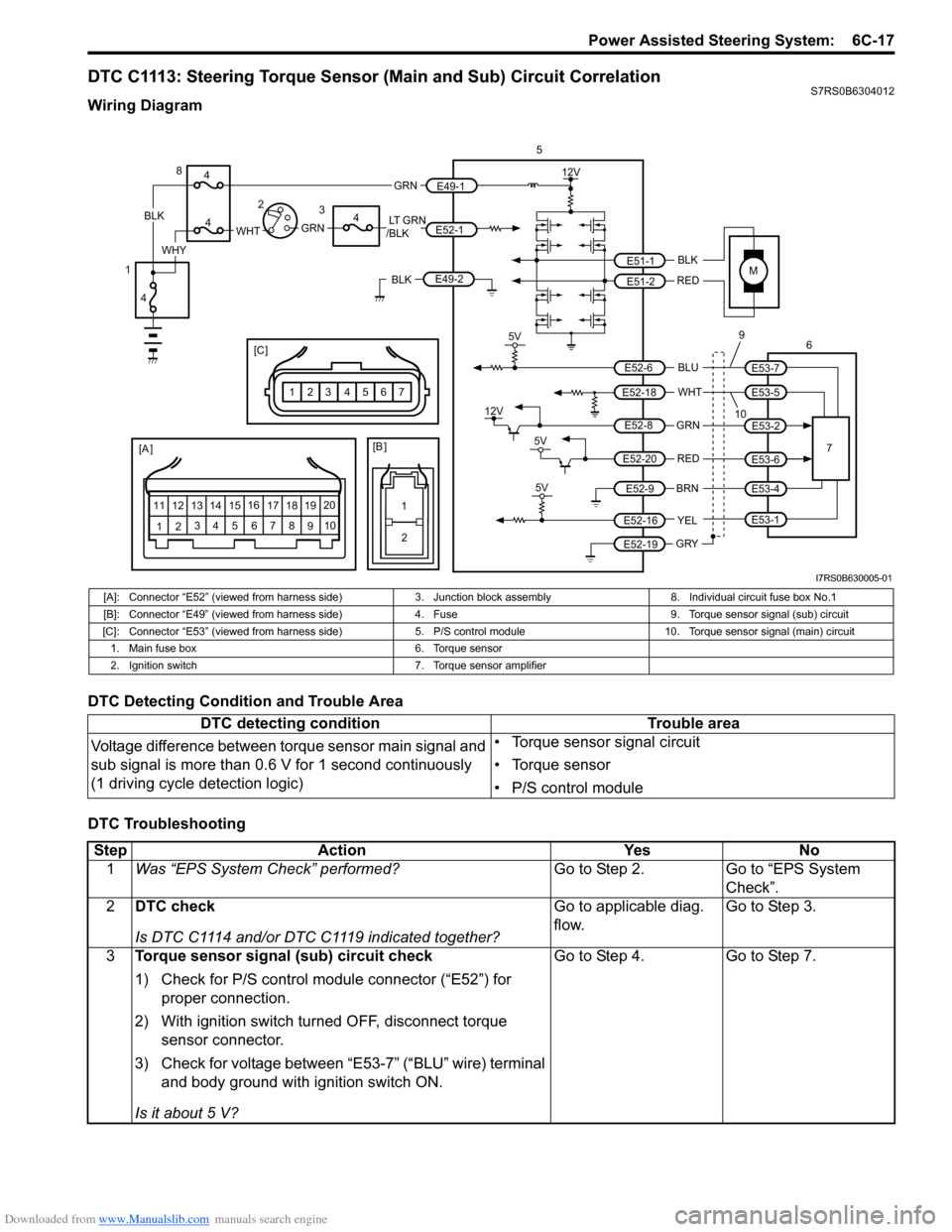

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit CorrelationS7RS0B6304012

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

109

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630005-01

[A]: Connector “E52” (viewed from harness side)

3. Junction block assembly 8. Individual circuit fuse box No.1

[B]: Connector “E49” (viewed from harness side )4. Fuse 9. Torque sensor signal (sub) circuit

[C]: Connector “E53” (viewed from harness side) 5. P/S control module 10. Torque sensor signal (main) circuit

1. Main fuse box 6. Torque sensor

2. Ignition switch 7. Torque sensor amplifier

DTC detecting condition Trouble area

Voltage difference between torque sensor main signal and

sub signal is more than 0.6 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor signal circuit

• Torque sensor

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 DTC check

Is DTC C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor signal (sub) circuit check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) With ignition switch turned OFF, disconnect torque sensor connector.

3) Check for voltage between “E53-7” (“BLU” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 4.

Go to Step 7.

Page 900 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-18 Power Assisted Steering System:

4Torque sensor signal (main) voltage check

1) Check for voltage between “E53-5” (“WHT” wire)

terminal and body ground with ignition switch ON.

Is it about 0 V? Go to Step 5. Torque sensor signal

circuit is shorted to

other circuit.

5 Torque sensor signal (main) resistance check

1) Check for resistance “E53-5” (“WHT” wire) terminal and

body ground terminal with ignition switch OFF.

Is it about 1 M

Ω? Go to Step 6. Go to Step 8.

6 Torque sensor output voltage check

1) Connect connector to torque sensor with ignition switch

turned OFF.

2) Check torque sensor out put voltage referring to “Torque Sensor and Its Circuit Inspection”.

Is torque sensor in good condition? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case.

7 Torque sensor (sub) circuit wire check

1) Disconnect P/S control module.

2) Check that torque sensor signal (sub) circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor signal (sub) circuit” terminal

and other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor signal (sub) circuit” is less than 1 Ω.

• Insulation resistance between “Torque sensor (sub) signal circuit” and vehicle body ground is infinity.

• Circuit voltage between “Torque sensor signal (sub) circuit” circuit and ground circuit is 0 – 1 V with ignition

switch turned ON.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

8 Torque sensor (main) circuit wire check

1) Disconnect P/S control module.

2) Check that torque sensor (main) signal circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor (main) signal circuit” terminal

and other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor (main) signal circuit” is less than 1 Ω.

• Insulation resistance between “Torque sensor (main) signal circuit” and vehicle body ground is infinity.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

Step Action Yes No

Page 901 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-19

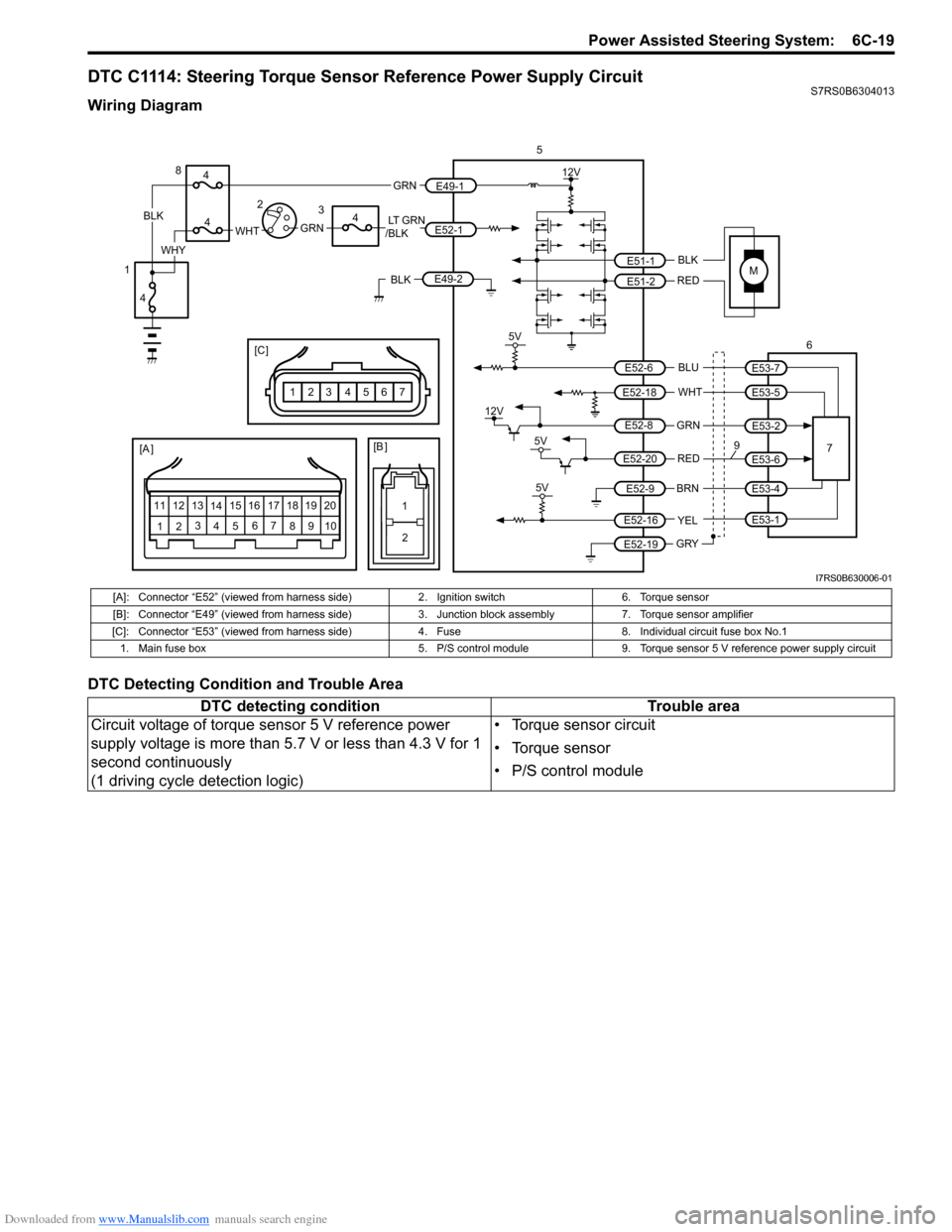

DTC C1114: Steering Torque Sensor Reference Power Supply CircuitS7RS0B6304013

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630006-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Torque sensor 5 V reference power supply circuit

DTC detecting condition Trouble area

Circuit voltage of torque sensor 5 V reference power

supply voltage is more than 5.7 V or less than 4.3 V for 1

second continuously

(1 driving cycle detection logic) • Torque sensor circuit

• Torque sensor

• P/S control module