Code SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 81 of 1496

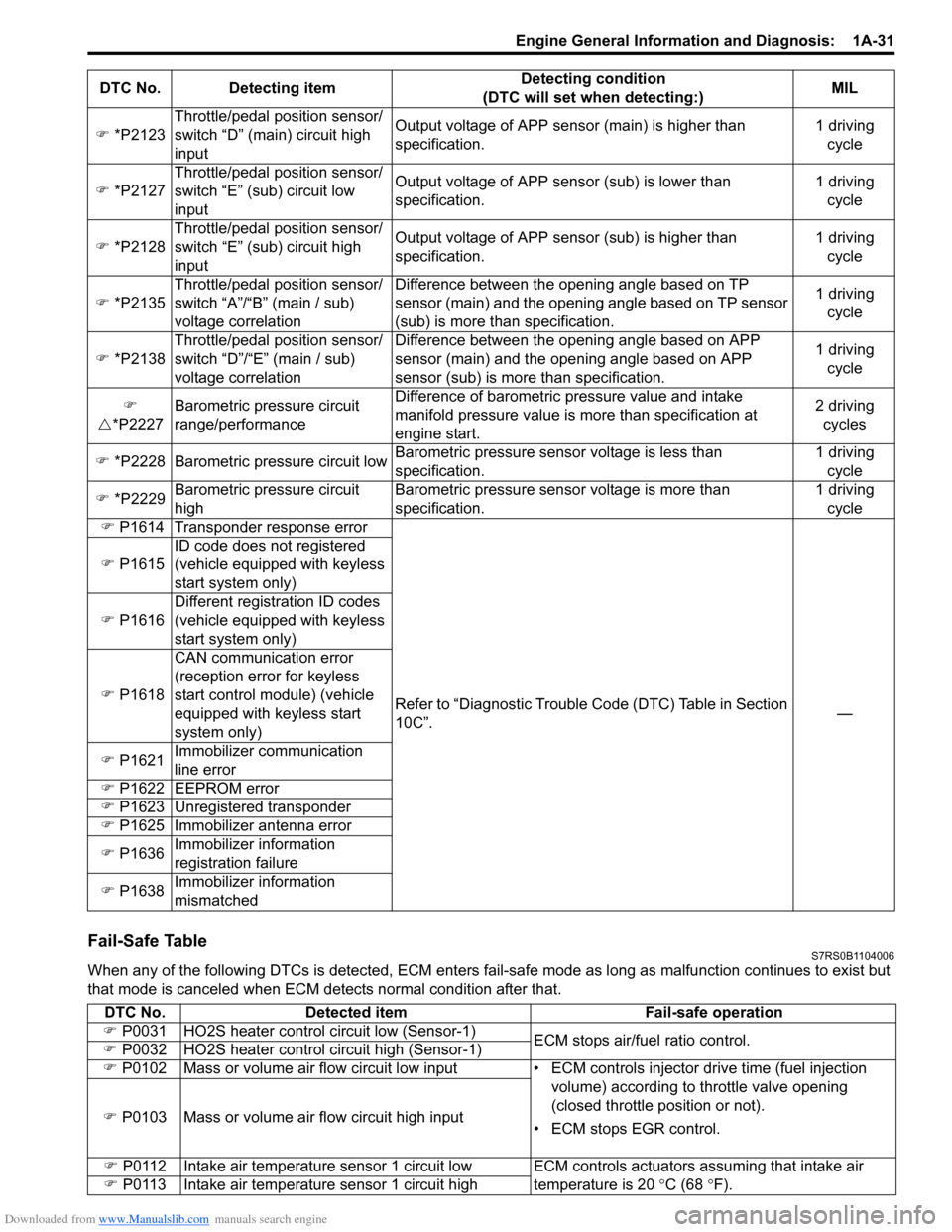

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-31

Fail-Safe TableS7RS0B1104006

When any of the following DTCs is detected, ECM enters fail-safe mode as long as malfunction continues to exist but

that mode is canceled when ECM de tects normal condition after that.

�)

*P2123 Throttle/pedal position sensor/

switch “D” (main) circuit high

input Output voltage of APP sensor (main) is higher than

specification.

1 driving

cycle

�) *P2127 Throttle/pedal position sensor/

switch “E” (sub) circuit low

input Output voltage of APP sens

or (sub) is lower than

specification. 1 driving

cycle

�) *P2128 Throttle/pedal position sensor/

switch “E” (sub) circuit high

input Output voltage of APP sensor (sub) is higher than

specification.

1 driving

cycle

�) *P2135 Throttle/pedal position sensor/

switch “A”/“B” (main / sub)

voltage correlation Difference between the opening angle based on TP

sensor (main) and the opening angle based on TP sensor

(sub) is more than specification.

1 driving

cycle

�) *P2138 Throttle/pedal position sensor/

switch “D”/“E” (main / sub)

voltage correlation Difference between the opening angle based on APP

sensor (main) and the opening angle based on APP

sensor (sub) is more

than specification. 1 driving

cycle

�)

�U *P2227 Barometric pressure circuit

range/performance Difference of barometric pressure value and intake

manifold pressure value is

more than specification at

engine start. 2 driving

cycles

�) *P2228 Barometric pressure circuit low Barometric pressure sens

or voltage is less than

specification. 1 driving

cycle

�) *P2229 Barometric pressure circuit

high Barometric pressure sensor voltage is more than

specification. 1 driving

cycle

�) P1614 Transponder response error

Refer to “Diagnostic Trouble Code (DTC) Table in Section

10C”. —

�) P1615 ID code does not registered

(vehicle equipped with keyless

start system only)

�) P1616 Different registration ID codes

(vehicle equipped with keyless

start system only)

�) P1618 CAN communication error

(reception error for keyless

start control module) (vehicle

equipped with keyless start

system only)

�) P1621 Immobilizer communication

line error

�) P1622

EEPROM error

�) P1623 Unregistered transponder

�) P1625 Immobilizer antenna error

�) P1636 Immobilizer information

registration failure

�) P1638 Immobilizer information

mismatched

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL

DTC No.

Detected item Fail-safe operation

�) P0031 HO2S heater control circuit low (Sensor-1)

ECM stops air/fuel ratio control.

�) P0032 HO2S heater control circuit high (Sensor-1)

�) P0102 Mass or volume air flow circuit low input • ECM controls injector drive time (fuel injection

volume) according to throttle valve opening

(closed throttle position or not).

• ECM stops EGR control.

�)

P0103 Mass or volume air flow circuit high input

�) P0112 Intake air temperature sensor 1 circuit low ECM controls actuators assuming that intake air

temperature is 20 °C (68 ° F).

�) P0113 Intake air temperature sensor 1 circuit high

Page 89 of 1496

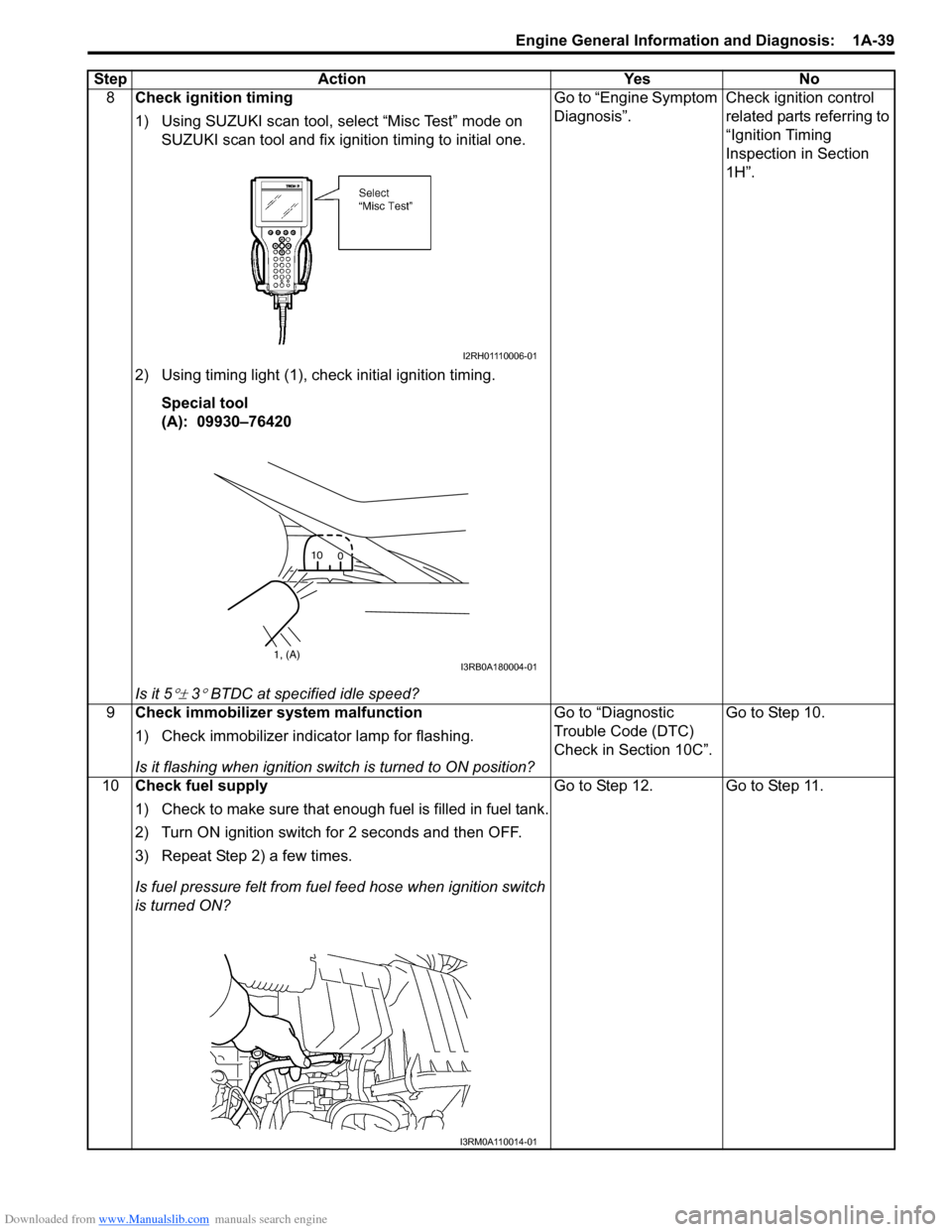

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-39

8Check ignition timing

1) Using SUZUKI scan tool, select “Misc Test” mode on

SUZUKI scan tool and fix ignition timing to initial one.

2) Using timing light (1), check initial ignition timing. Special tool

(A): 09930–76420

Is it 5

°± 3° BTDC at specif ied idle speed? Go to “Engine Symptom

Diagnosis”.

Check ignition control

related parts referring to

“Ignition Timing

Inspection in Section

1H”.

9 Check immobilizer system malfunction

1) Check immobilizer indica tor lamp for flashing.

Is it flashing when ignition switch is turned to ON position? Go to “Diagnostic

Trouble Code (DTC)

Check in Section 10C”.

Go to Step 10.

10 Check fuel supply

1) Check to make sure that enough fuel is filled in fuel tank.

2) Turn ON ignition switch for 2 seconds and then OFF.

3) Repeat Step 2) a few times.

Is fuel pressure felt from fuel feed hose when ignition switch

is turned ON? Go to Step 12. Go to Step 11.

Step Action Yes No

I2RH01110006-01

1, (A)

10

0I3RB0A180004-01

I3RM0A110014-01

Page 194 of 1496

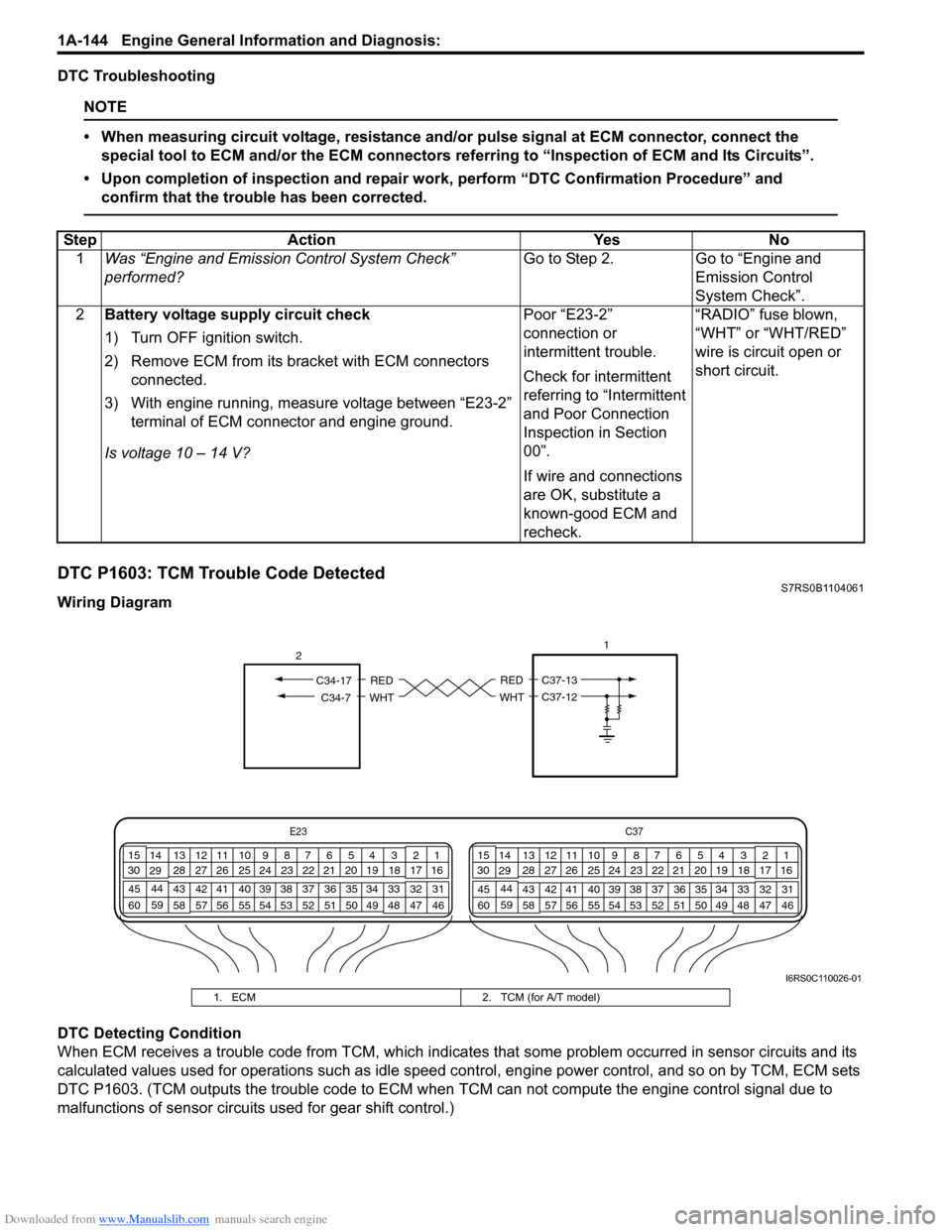

Downloaded from www.Manualslib.com manuals search engine 1A-144 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P1603: TCM Trouble Code DetectedS7RS0B1104061

Wiring Diagram

DTC Detecting Condition

When ECM receives a trouble code from TCM, which indicates that some problem occurred in sensor circuits and its

calculated values used for operations such as idle speed control, engine power control, and so on by TCM, ECM sets

DTC P1603. (TCM outputs the trouble code to ECM when TCM can not compute the engine control signal due to

malfunctions of sensor circuits used for gear shift control.) Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 Battery voltage supply circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) With engine running, measure voltage between “E23-2” terminal of ECM connector and engine ground.

Is voltage 10 – 14 V? Poor “E23-2”

connection or

intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If wire and connections

are OK, substitute a

known-good ECM and

recheck.“RADIO” fuse blown,

“WHT” or “WHT/RED”

wire is circuit open or

short circuit.

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

1

RED

WHT

C37-13

C37-12

RED

WHTC34-7

C34-17

2

I6RS0C110026-01

1. ECM

2. TCM (for A/T model)

Page 268 of 1496

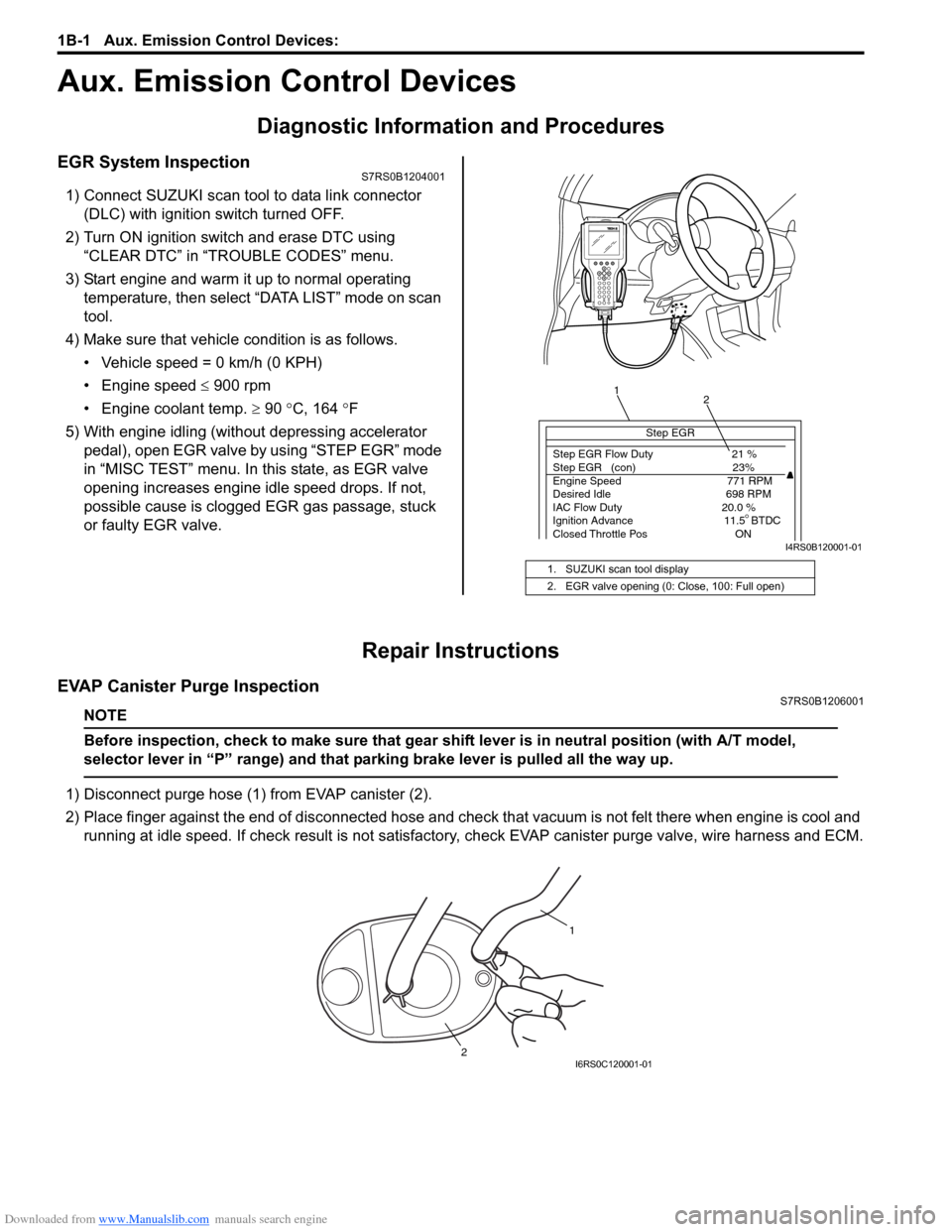

Downloaded from www.Manualslib.com manuals search engine 1B-1 Aux. Emission Control Devices:

Engine

Aux. Emission Control Devices

Diagnostic Information and Procedures

EGR System InspectionS7RS0B1204001

1) Connect SUZUKI scan tool to data link connector (DLC) with ignition switch turned OFF.

2) Turn ON ignition switch and erase DTC using “CLEAR DTC” in “TROUBLE CODES” menu.

3) Start engine and warm it up to normal operating temperature, then select “DATA LIST” mode on scan

tool.

4) Make sure that vehicle condition is as follows.

• Vehicle speed = 0 km/h (0 KPH)

• Engine speed ≤ 900 rpm

• Engine coolant temp. ≥ 90 °C, 164 °F

5) With engine idling (without depressing accelerator pedal), open EGR valve by using “STEP EGR” mode

in “MISC TEST” menu. In this state, as EGR valve

opening increases engine idle speed drops. If not,

possible cause is clogged EGR gas passage, stuck

or faulty EGR valve.

Repair Instructions

EVAP Canister Purge InspectionS7RS0B1206001

NOTE

Before inspection, check to make sure that gear shift lever is in neutral position (with A/T model,

selector lever in “P” range) and that parking brake lever is pulled all the way up.

1) Disconnect purge hose (1) from EVAP canister (2).

2) Place finger against the end of disconne cted hose and check that vacuum is not felt there when engine is cool and

running at idle speed. If check result is not satisfacto ry, check EVAP canister purge valve, wire harness and ECM.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full open)

Step EGR

Step EGR Flow Duty 21 %

Step EGR (con) 23%

Engine Speed 771 RPM

Desired Idle 698 RPM

IAC Flow Duty 20.0 %

Ignition Advance 11.5 BTDC

Closed Throttle Pos ON

1 2

I4RS0B120001-01

1

2

I6RS0C120001-01

Page 465 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-11

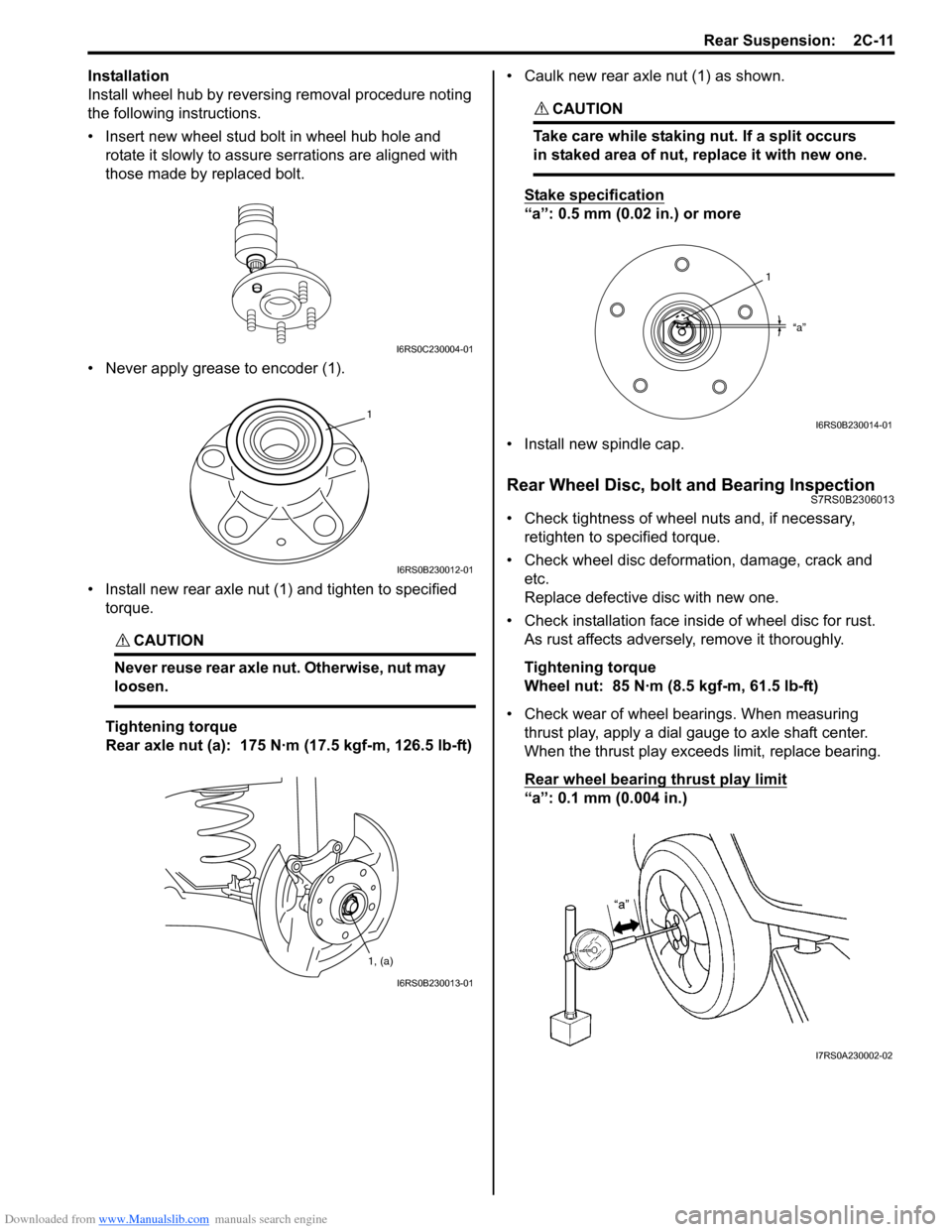

Installation

Install wheel hub by reversing removal procedure noting

the following instructions.

• Insert new wheel stud bolt in wheel hub hole and rotate it slowly to assure serrations are aligned with

those made by replaced bolt.

• Never apply grease to encoder (1).

• Install new rear axle nut (1) and tighten to specified torque.

CAUTION!

Never reuse rear axle nut. Otherwise, nut may

loosen.

Tightening torque

Rear axle nut (a): 175 N·m (17.5 kgf-m, 126.5 lb-ft) • Caulk new rear axle nut (1) as shown.

CAUTION!

Take care while staking nut. If a split occurs

in staked area of nut,

replace it with new one.

Stake specification

“a”: 0.5 mm (0.02 in.) or more

• Install new spindle cap.

Rear Wheel Disc, bolt and Bearing InspectionS7RS0B2306013

• Check tightness of wheel nuts and, if necessary, retighten to specified torque.

• Check wheel disc deformation, damage, crack and etc.

Replace defective disc with new one.

• Check installation face insi de of wheel disc for rust.

As rust affects adversely, remove it thoroughly.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Check wear of wheel bearings. When measuring thrust play, apply a dial gauge to axle shaft center.

When the thrust play exce eds limit, replace bearing.

Rear wheel bearing thrust play

limit

“a”: 0.1 mm (0.004 in.)

I6RS0C230004-01

1

I6RS0B230012-01

1, (a)

I6RS0B230013-01

1

“a”

I6RS0B230014-01

I7RS0A230002-02

Page 473 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-6

Repair Instructions

General Balance ProceduresS7RS0B2406001

Deposits of mud, etc. must be cleaned from inside of rim.

WARNING!

Stones should be removed from the tread in

order to avoid operator injury during spin

balancing and to obtain good balance.

Each tire should be inspected for any damage, then

balanced according to equipment manufacturer’s

recommendation.

Off-Vehicle Balancing

Most electronic off-vehicle balancers are more accurate

than the on-vehicle spin balancers. They are easy to use

and give a dynamic (two plane) balance. Although they

do not correct for drum or disc unbalance as does on-

vehicle spin balancing, this is overcome by their

accuracy, usually to within 1/8 ounce.

On-Vehicle Balancing

On-vehicle balancing methods vary with equipment and

tool manufacturers. Be sure to follow each

manufacturer’s instructions during balancing operation.

WARNING!

Wheel spin should be limited to 55 km/h (35

mph) as indicated on speedometer.

This limit is necessary because speedometer

only indicates one-half of actual wheel speed

when one drive wheel is spinning and the

other drive wheel is stopped.

Unless care is taken in limiting drive wheel

spin, spinning wheel can reach excessive

speeds. This can result in possible tire

disintegration or differential failure, which

could cause serious personal injury or

extensive vehicle damage.

CAUTION!

Using on-vehicle balancing method with

ignition switch ON may set malfunction

diagnostic trouble code (DTC) of ESP® and

ABS even when system is in good condition.

Never turn ignition swit ch ON while spinning

wheel.

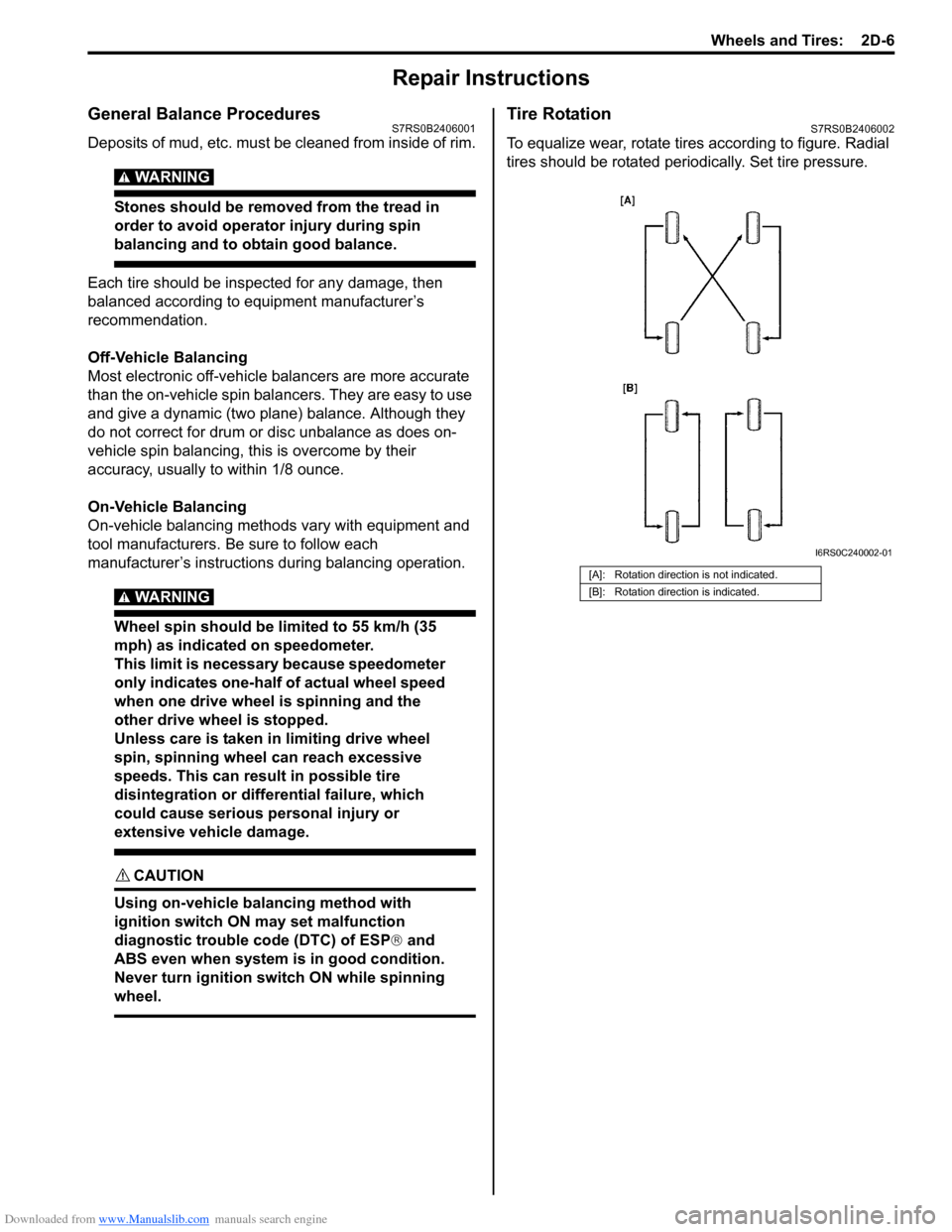

Tire RotationS7RS0B2406002

To equalize wear, rotate tires according to figure. Radial

tires should be rotated periodi cally. Set tire pressure.

[A]: Rotation direction is not indicated.

[B]: Rotation direction is indicated.

I6RS0C240002-01

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

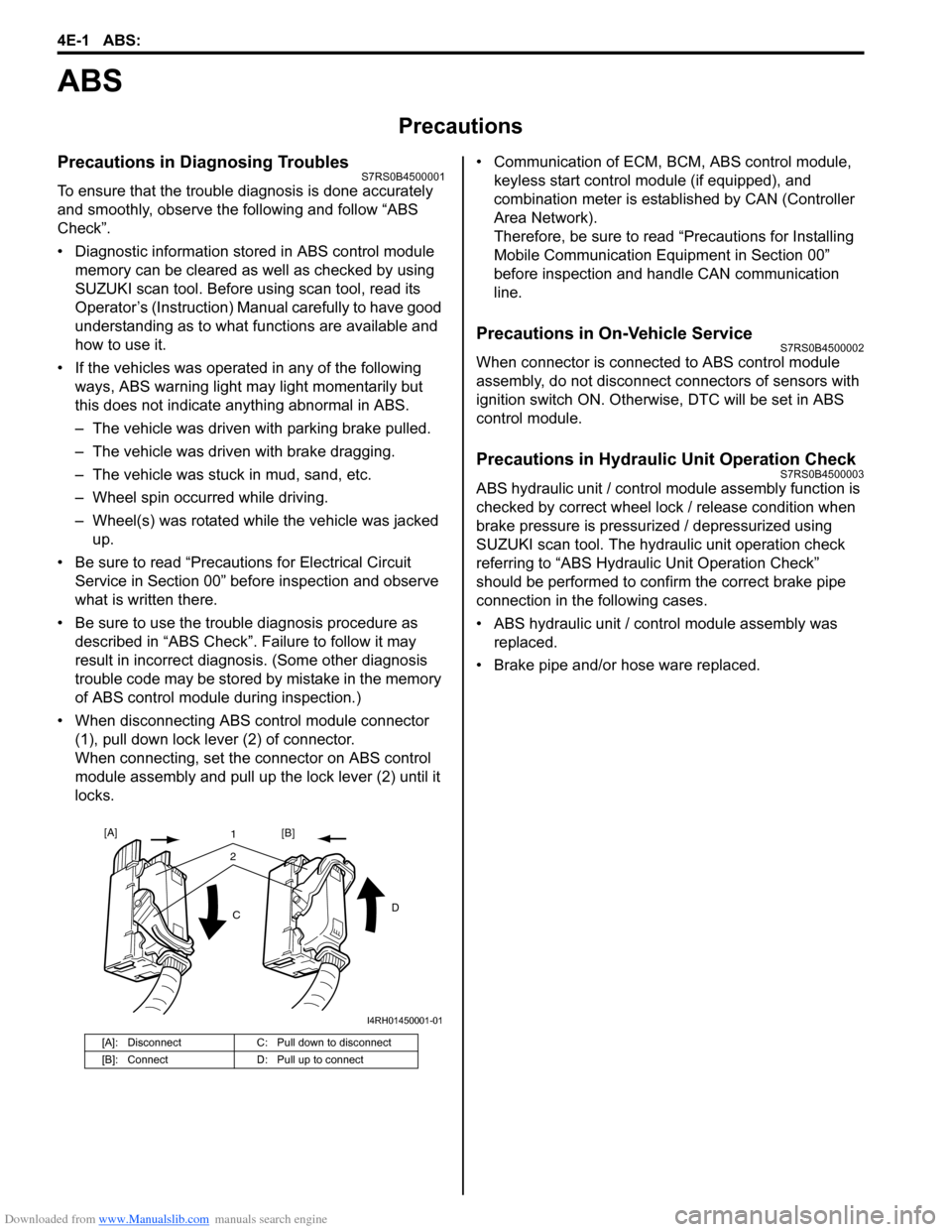

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 547 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-8

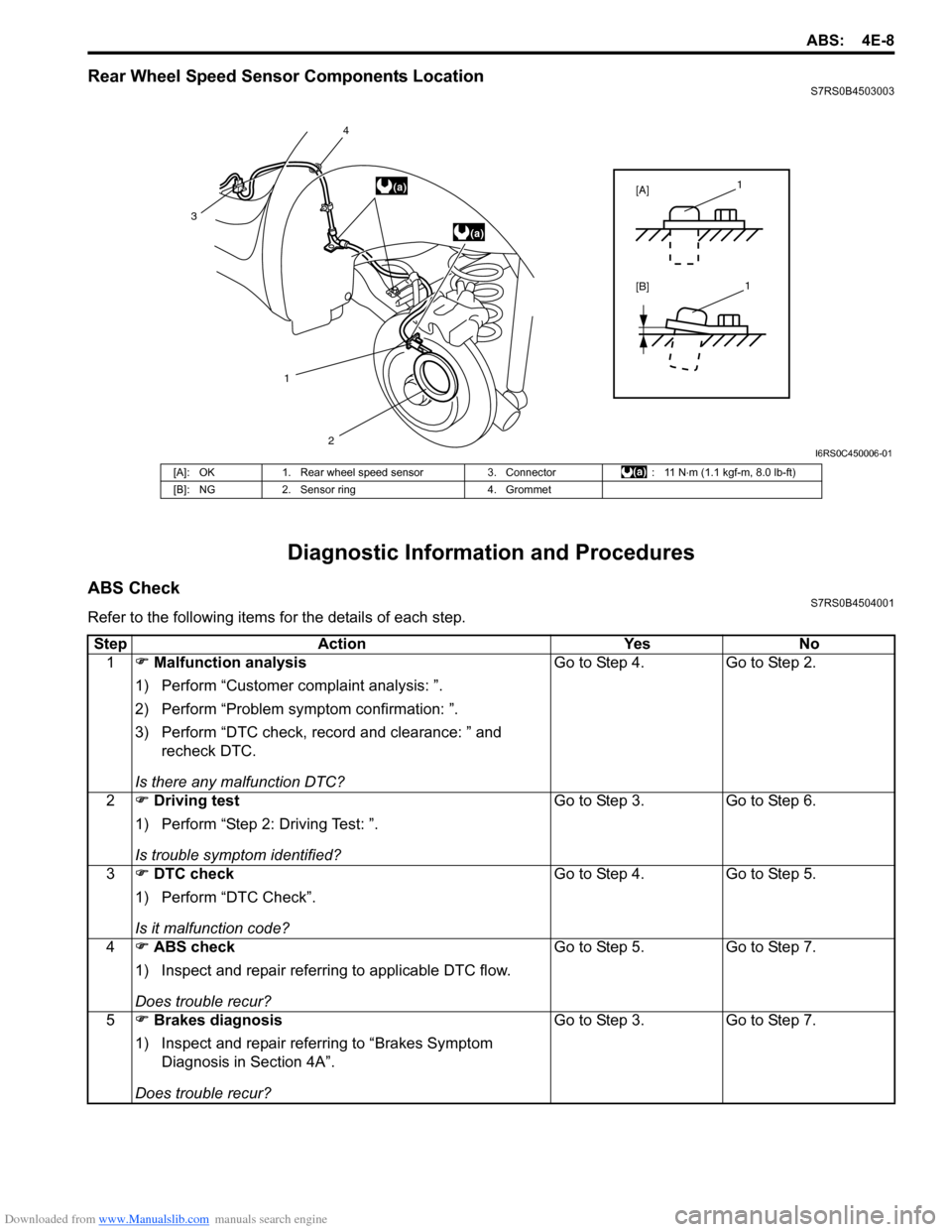

Rear Wheel Speed Sensor Components LocationS7RS0B4503003

Diagnostic Information and Procedures

ABS CheckS7RS0B4504001

Refer to the following items for the details of each step.

12

3

4

[A]

[B]1

1

(a)

(a)

I6RS0C450006-01

[A]: OK

1. Rear wheel speed sensor 3. Connector: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

[B]: NG 2. Sensor ring 4. Grommet

StepAction YesNo

1 �) Malfunction analysis

1) Perform “Customer complaint analysis: ”.

2) Perform “Problem symptom confirmation: ”.

3) Perform “DTC check, record and clearance: ” and recheck DTC.

Is there any malfunction DTC? Go to Step 4.

Go to Step 2.

2 �) Driving test

1) Perform “Step 2: Driving Test: ”.

Is trouble symptom identified? Go to Step 3.

Go to Step 6.

3 �) DTC check

1) Perform “DTC Check”.

Is it malfunction code? Go to Step 4.

Go to Step 5.

4 �) ABS check

1) Inspect and repair referring to applicable DTC flow.

Does trouble recur? Go to Step 5.

Go to Step 7.

5 �) Brakes diagnosis

1) Inspect and repair referring to “Brakes Symptom Diagnosis in Section 4A”.

Does trouble recur? Go to Step 3.

Go to Step 7.