Crankshaft torque SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

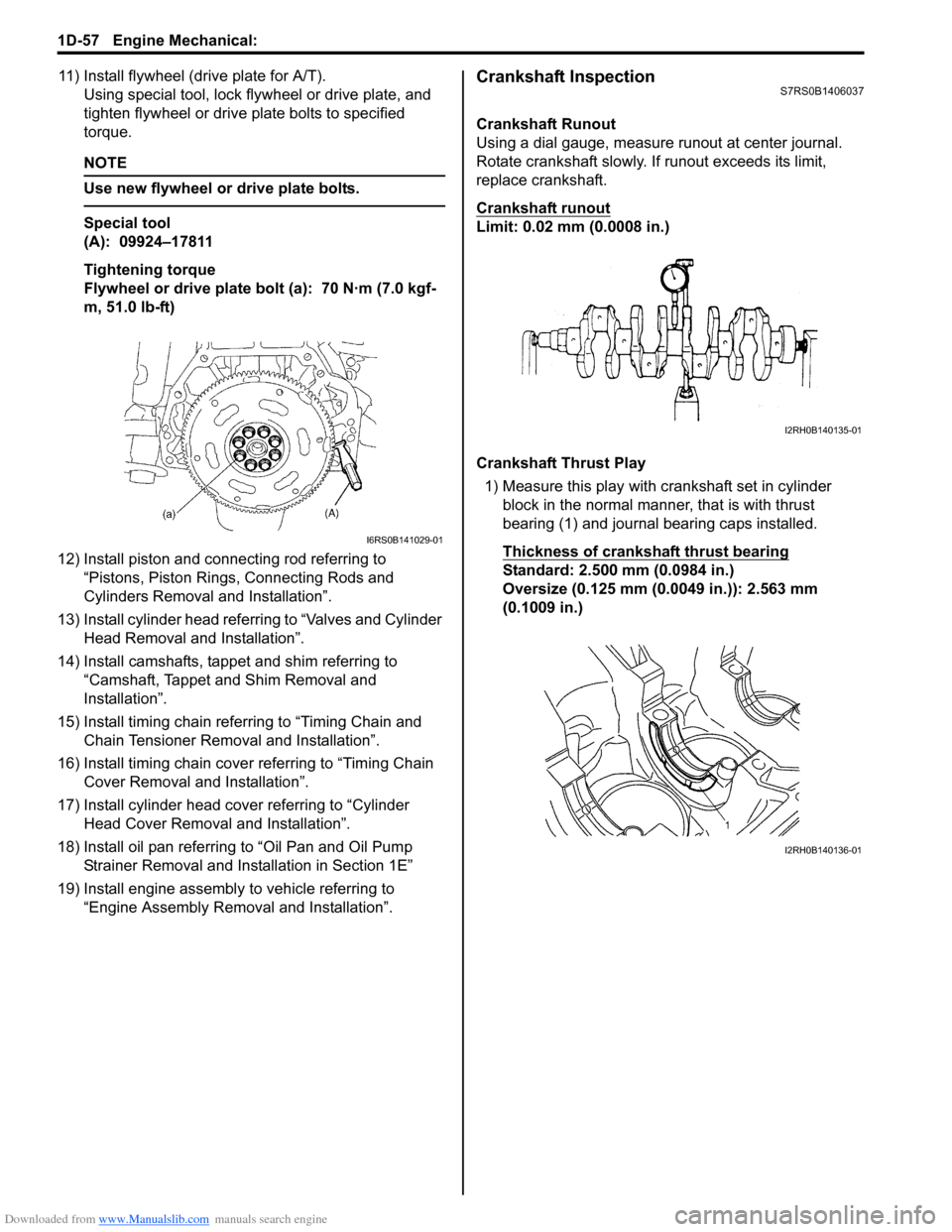

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 343 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-58

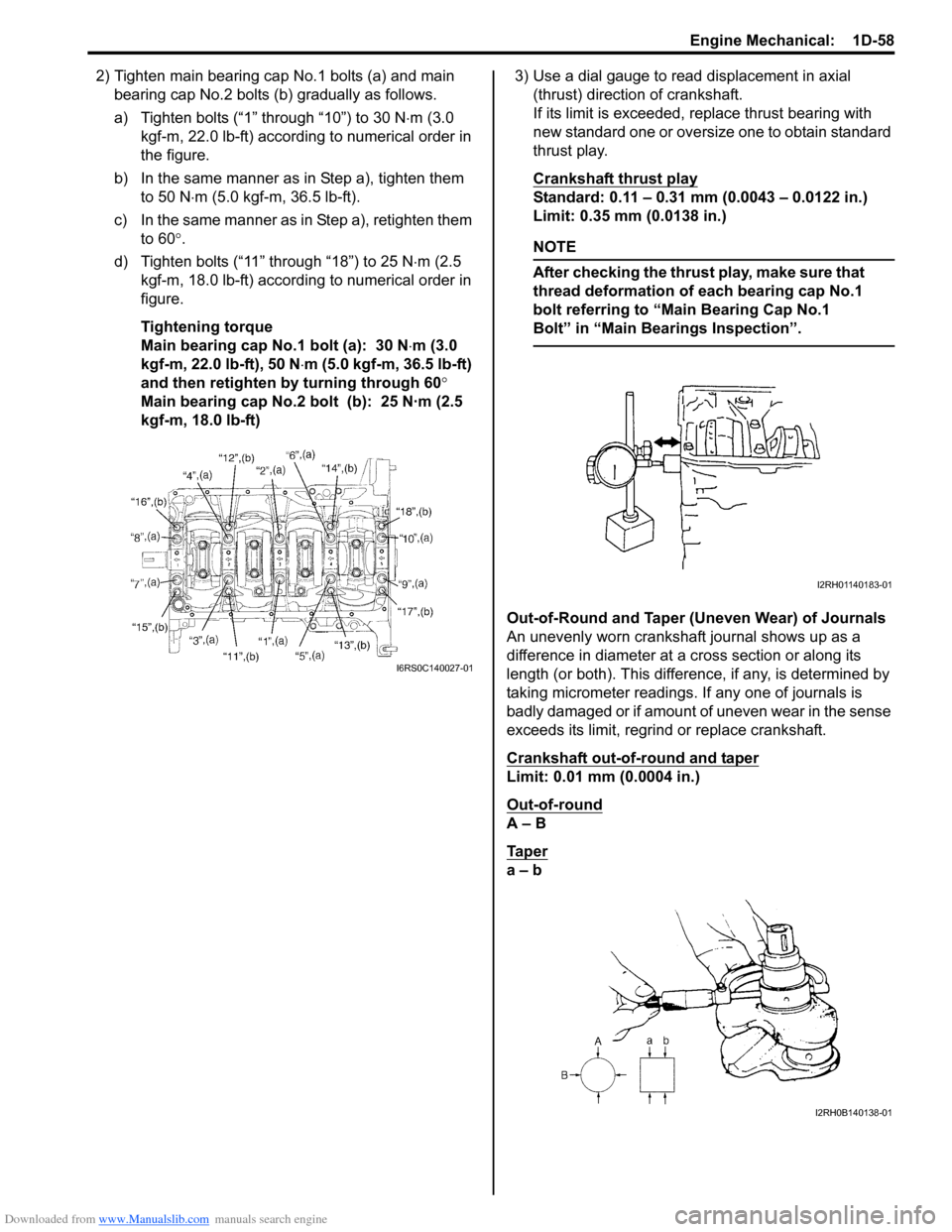

2) Tighten main bearing cap No.1 bolts (a) and main bearing cap No.2 bolts (b ) gradually as follows.

a) Tighten bolts (“1” through “10”) to 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft) according to numerical order in

the figure.

b) In the same manner as in Step a), tighten them to 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60 °.

d) Tighten bolts (“11” through “18”) to 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) according to numerical order in

figure.

Tightening torque

Main bearing cap No.1 bolt (a): 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft)

and then retighten by turning through 60 °

Main bearing cap No.2 bolt (b): 25 N·m (2.5

kgf-m, 18.0 lb-ft) 3) Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If its limit is exceeded, replace thrust bearing with

new standard one or oversize one to obtain standard

thrust play.

Crankshaft thrust play

Standard: 0.11 – 0.31 mm (0.0043 – 0.0122 in.)

Limit: 0.35 mm (0.0138 in.)

NOTE

After checking the thrust play, make sure that

thread deformation of each bearing cap No.1

bolt referring to “Main Bearing Cap No.1

Bolt” in “Main Bear ings Inspection”.

Out-of-Round and Taper (Uneven Wear) of Journals

An unevenly worn crankshaft journal shows up as a

difference in diameter at a cross section or along its

length (or both). This difference, if any, is determined by

taking micrometer readings. If any one of journals is

badly damaged or if amount of uneven wear in the sense

exceeds its limit, regrind or replace crankshaft.

Crankshaft out-of-round and taper

Limit: 0.01 mm (0.0004 in.)

Out-of-round

A – B

Ta p e r

a – b

I6RS0C140027-01

I2RH01140183-01

I2RH0B140138-01

Page 344 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-59 Engine Mechanical:

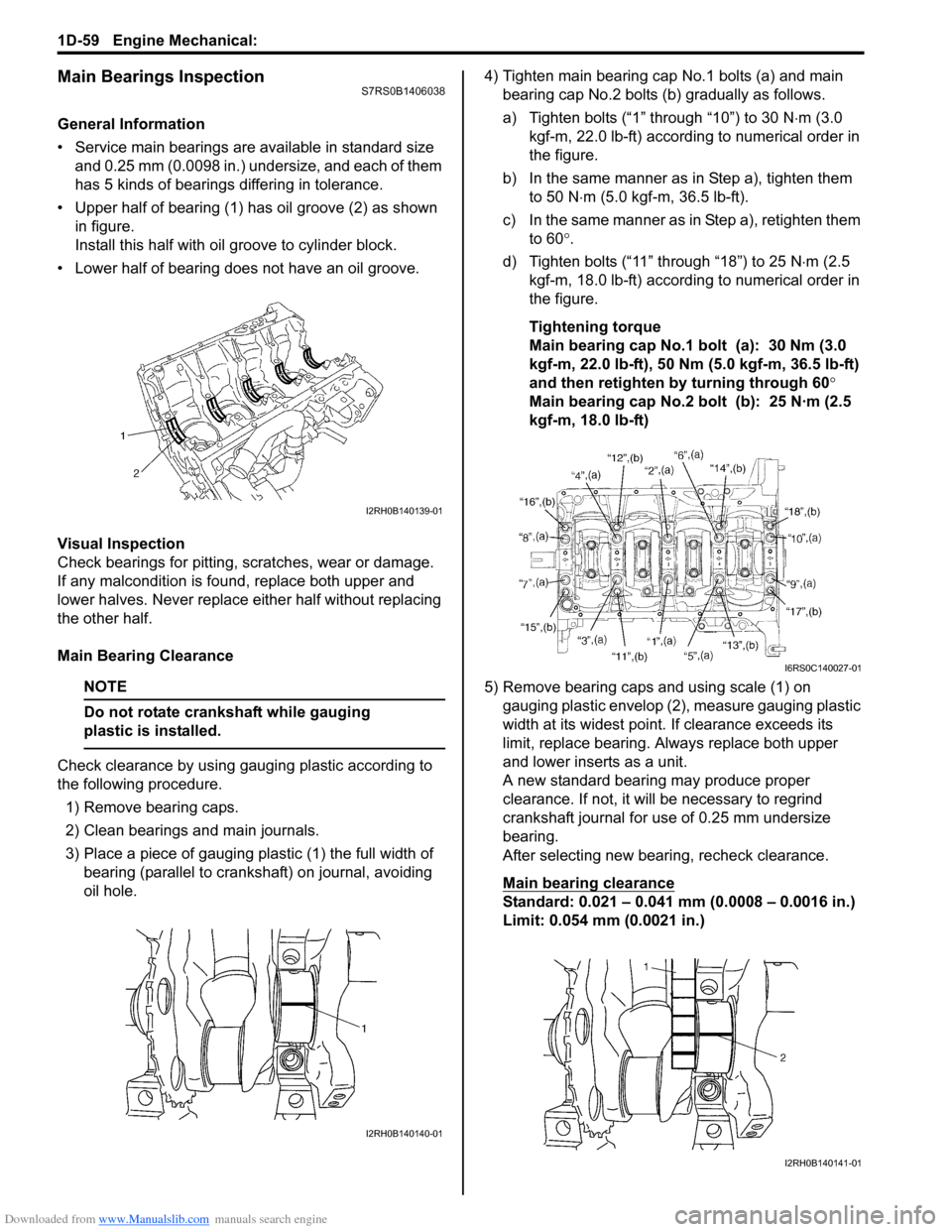

Main Bearings InspectionS7RS0B1406038

General Information

• Service main bearings are available in standard size and 0.25 mm (0.0098 in.) undersize, and each of them

has 5 kinds of bearings differing in tolerance.

• Upper half of bearing (1) has oil groove (2) as shown in figure.

Install this half with o il groove to cylinder block.

• Lower half of bearing does not have an oil groove.

Visual Inspection

Check bearings for pitting, scratches, wear or damage.

If any malcondition is foun d, replace both upper and

lower halves. Never replace either half without replacing

the other half.

Main Bearing Clearance

NOTE

Do not rotate crankshaft while gauging

plastic is installed.

Check clearance by using ga uging plastic according to

the following procedure.

1) Remove bearing caps.

2) Clean bearings and main journals.

3) Place a piece of gauging plastic (1) the full width of bearing (parallel to crankshaft) on journal, avoiding

oil hole. 4) Tighten main bearing cap No.1 bolts (a) and main

bearing cap No.2 bolts (b) gradually as follows.

a) Tighten bolts (“1” through “10”) to 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft) according to numerical order in

the figure.

b) In the same manner as in Step a), tighten them to 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60 °.

d) Tighten bolts (“11” through “18”) to 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) according to numerical order in

the figure.

Tightening torque

Main bearing cap No.1 bolt (a): 30 Nm (3.0

kgf-m, 22.0 lb-ft), 50 Nm (5.0 kgf-m, 36.5 lb-ft)

and then retighten by turning through 60°

Main bearing cap No.2 bolt (b): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

5) Remove bearing caps and using scale (1) on gauging plastic envelop (2), measure gauging plastic

width at its widest point. If clearance exceeds its

limit, replace bearing. Always replace both upper

and lower inserts as a unit.

A new standard bearing may produce proper

clearance. If not, it will be necessary to regrind

crankshaft journal for use of 0.25 mm undersize

bearing.

After selecting new bearing, recheck clearance.

Main bearing clearance

Standard: 0.021 – 0.041 mm (0.0008 – 0.0016 in.)

Limit: 0.054 mm (0.0021 in.)

I2RH0B140139-01

I2RH0B140140-01

I6RS0C140027-01

I2RH0B140141-01

Page 349 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-64

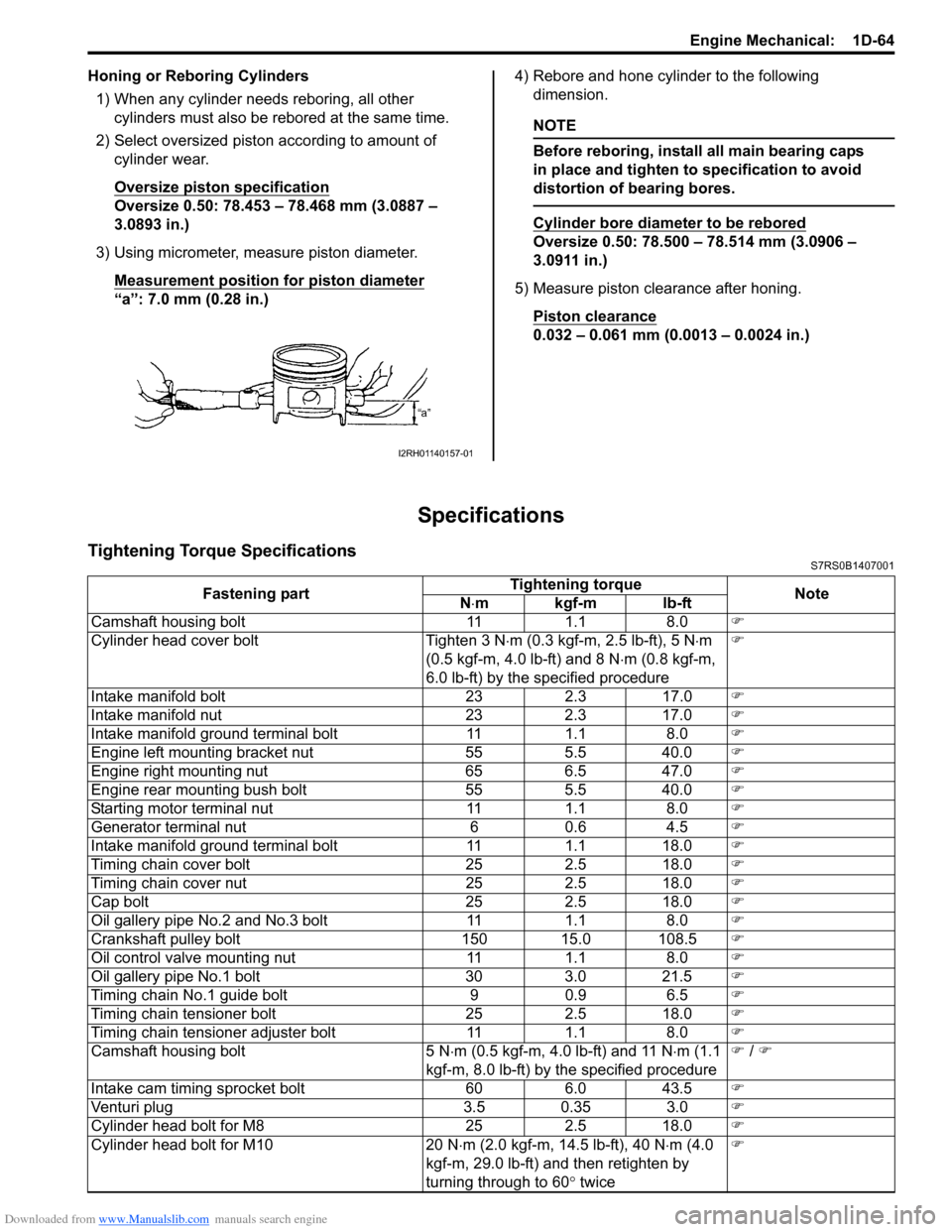

Honing or Reboring Cylinders1) When any cylinder needs reboring, all other cylinders must also be rebored at the same time.

2) Select oversized piston according to amount of cylinder wear.

Oversize piston specification

Oversize 0.50: 78.453 – 78.468 mm (3.0887 –

3.0893 in.)

3) Using micrometer, measure piston diameter. Measurement position for piston diameter

“a”: 7.0 mm (0.28 in.) 4) Rebore and hone cylinder to the following

dimension.

NOTE

Before reboring, install all main bearing caps

in place and tighten to specification to avoid

distortion of bearing bores.

Cylinder bore diameter to be rebored

Oversize 0.50: 78.500 – 78.514 mm (3.0906 –

3.0911 in.)

5) Measure piston clearance after honing. Piston clearance

0.032 – 0.061 mm (0.0013 – 0.0024 in.)

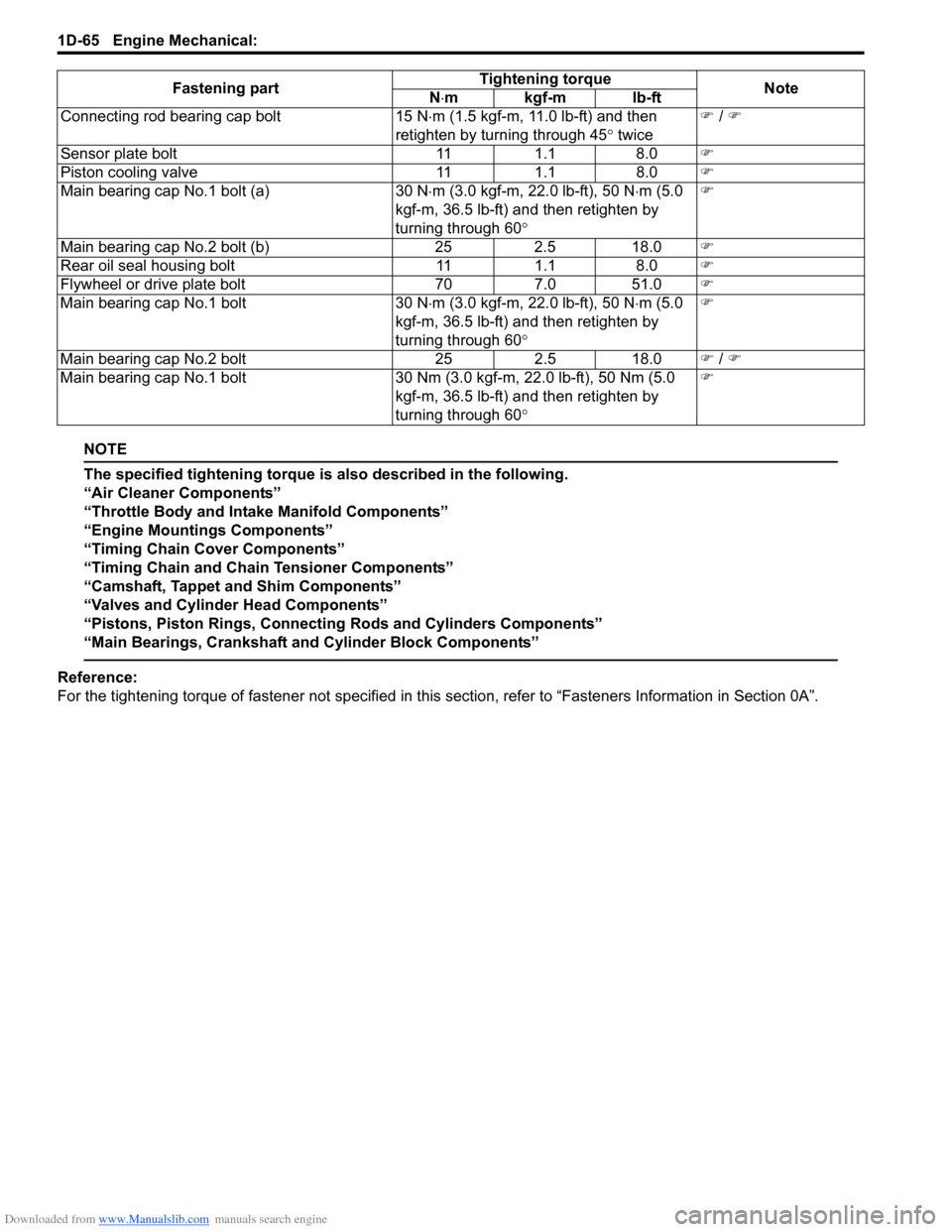

Specifications

Tightening Torque SpecificationsS7RS0B1407001

I2RH01140157-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Camshaft housing bolt 11 1.1 8.0 �)

Cylinder head cover bolt Tighten 3 N ⋅m (0.3 kgf-m, 2.5 lb-ft), 5 N ⋅m

(0.5 kgf-m, 4.0 lb-ft) and 8 N ⋅m (0.8 kgf-m,

6.0 lb-ft) by the specified procedure �)

Intake manifold bolt 23 2.3 17.0 �)

Intake manifold nut 23 2.3 17.0 �)

Intake manifold ground terminal bolt 11 1.1 8.0 �)

Engine left mounting bracket nut 55 5.5 40.0 �)

Engine right mounting nut 65 6.5 47.0 �)

Engine rear mounting bush bolt 55 5.5 40.0 �)

Starting motor terminal nut 11 1.1 8.0 �)

Generator terminal nut 6 0.6 4.5 �)

Intake manifold ground terminal bolt 11 1.1 18.0 �)

Timing chain cover bolt 25 2.5 18.0 �)

Timing chain cover nut 25 2.5 18.0 �)

Cap bolt 25 2.5 18.0 �)

Oil gallery pipe No.2 and No.3 bolt 11 1.1 8.0 �)

Crankshaft pulley bolt 150 15.0 108.5 �)

Oil control valve mounting nut 11 1.1 8.0 �)

Oil gallery pipe No.1 bolt 30 3.0 21.5 �)

Timing chain No.1 guide bolt 9 0.9 6.5 �)

Timing chain tensioner bolt 25 2.5 18.0 �)

Timing chain tensioner adjuster bolt 11 1.1 8.0 �)

Camshaft housing bolt 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft) and 11 N ⋅m (1.1

kgf-m, 8.0 lb-ft) by the specified procedure �)

/ �)

Intake cam timing sprocket bolt 60 6.0 43.5 �)

Venturi plug 3.5 0.35 3.0 �)

Cylinder head bolt for M8 25 2.5 18.0 �)

Cylinder head bolt for M10 20 N ⋅m (2.0 kgf-m, 14.5 lb-ft), 40 N ⋅m (4.0

kgf-m, 29.0 lb-ft) and then retighten by

turning through to 60 ° twice �)

Page 350 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

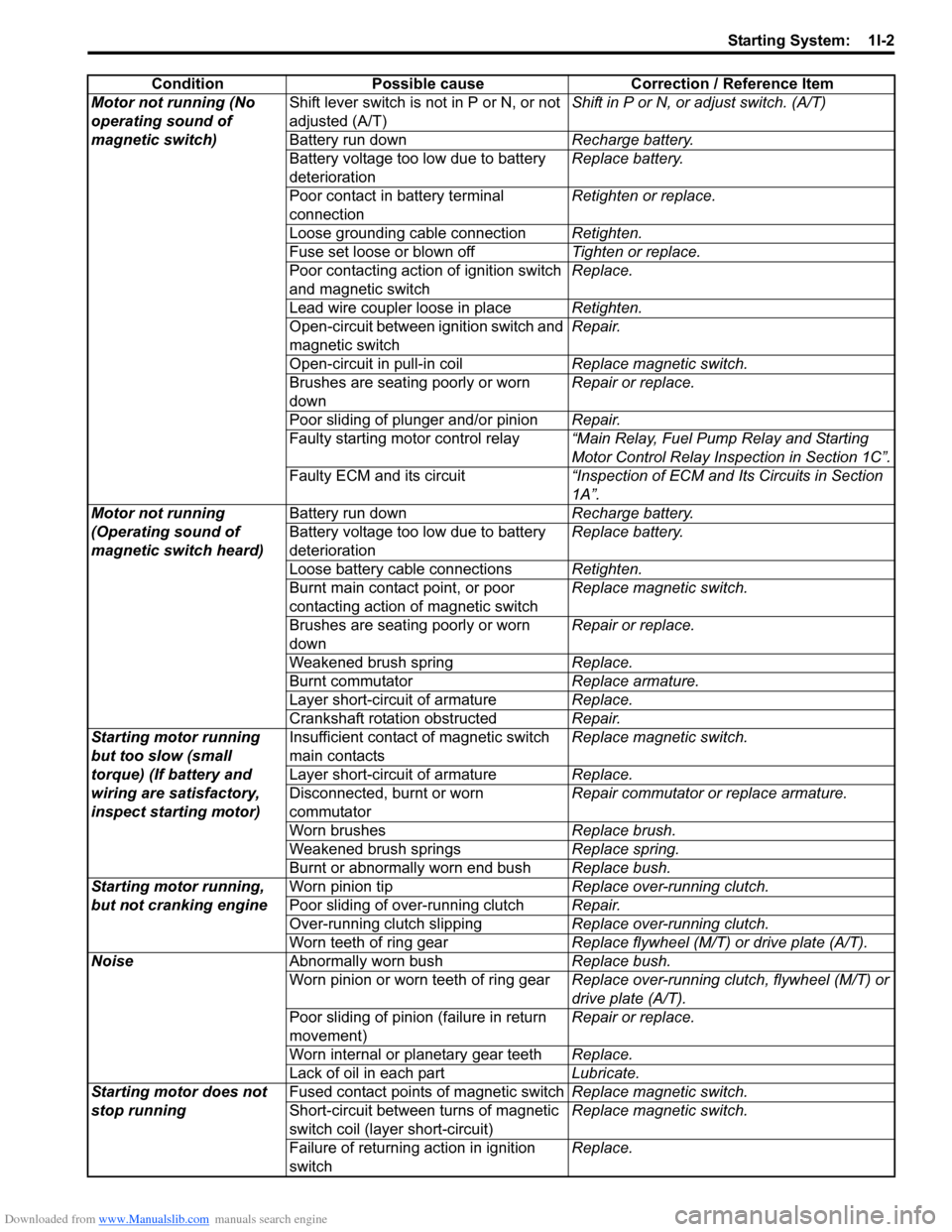

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 418 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

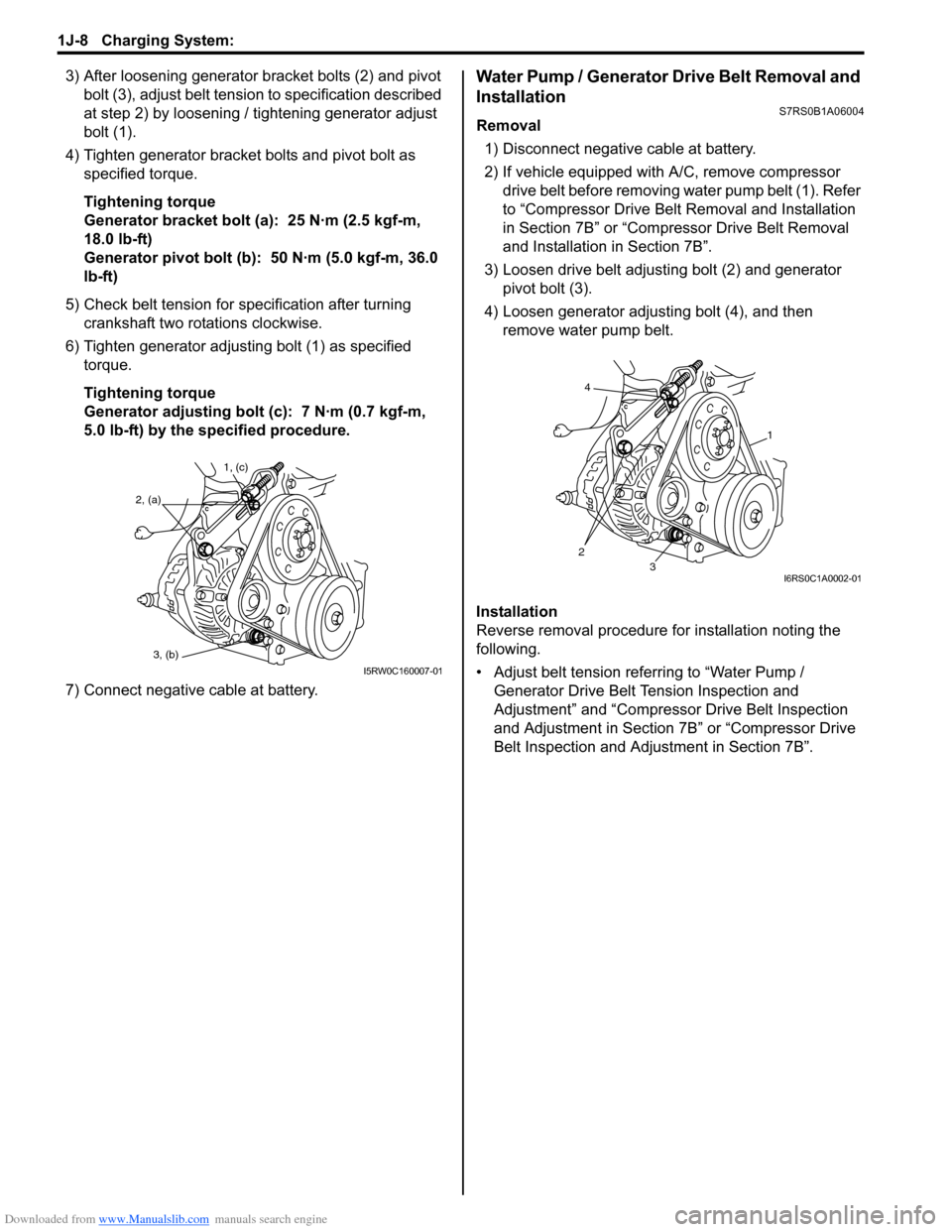

3) After loosening generator bracket bolts (2) and pivot bolt (3), adjust belt tensio n to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified torque.

Tightening torque

Generator adjusting bolt (c): 7 N·m (0.7 kgf-m,

5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.Water Pump / Generator Drive Belt Removal and

Installation

S7RS0B1A06004

Removal 1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor drive belt before removing water pump belt (1). Refer

to “Compressor Drive Belt Removal and Installation

in Section 7B” or “Compr essor Drive Belt Removal

and Installation in Section 7B”.

3) Loosen drive belt adjusting bolt (2) and generator pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then remove water pump belt.

Installation

Reverse removal procedure for installation noting the

following.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment” and “Compressor Drive Belt Inspection

and Adjustment in Section 7B” or “Compressor Drive

Belt Inspection and Adjustment in Section 7B”.

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I6RS0C1A0002-01

Page 669 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-25

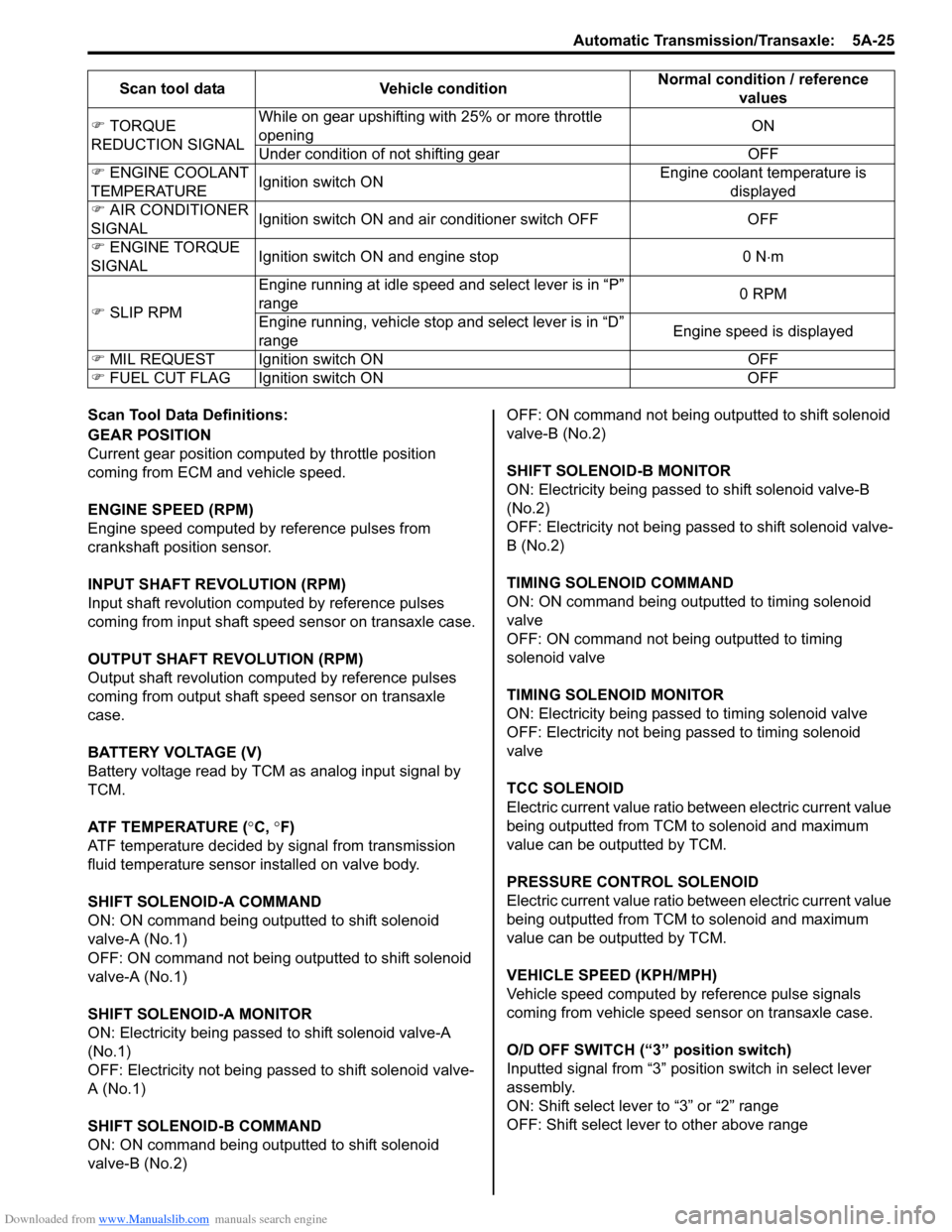

Scan Tool Data Definitions:

GEAR POSITION

Current gear position computed by throttle position

coming from ECM and vehicle speed.

ENGINE SPEED (RPM)

Engine speed computed by reference pulses from

crankshaft position sensor.

INPUT SHAFT REVOLUTION (RPM)

Input shaft revolution computed by reference pulses

coming from input shaft speed sensor on transaxle case.

OUTPUT SHAFT REVOLUTION (RPM)

Output shaft revolution computed by reference pulses

coming from output shaft speed sensor on transaxle

case.

BATTERY VOLTAGE (V)

Battery voltage read by TCM as analog input signal by

TCM.

ATF TEMPERATURE (°C, °F)

ATF temperature decided by signal from transmission

fluid temperature sensor installed on valve body.

SHIFT SOLENOID-A COMMAND

ON: ON command being outputted to shift solenoid

valve-A (No.1)

OFF: ON command not being outputted to shift solenoid

valve-A (No.1)

SHIFT SOLENOID-A MONITOR

ON: Electricity being passed to shift solenoid valve-A

(No.1)

OFF: Electricity not being passed to shift solenoid valve-

A (No.1)

SHIFT SOLENOID-B COMMAND

ON: ON command being outputted to shift solenoid

valve-B (No.2) OFF: ON command not being outputted to shift solenoid

valve-B (No.2)

SHIFT SOLENOID-B MONITOR

ON: Electricity being passed to shift solenoid valve-B

(No.2)

OFF: Electricity not being passed to shift solenoid valve-

B (No.2)

TIMING SOLENOID COMMAND

ON: ON command being outputted to timing solenoid

valve

OFF: ON command not being outputted to timing

solenoid valve

TIMING SOLENOID MONITOR

ON: Electricity being passed to timing solenoid valve

OFF: Electricity not being passed to timing solenoid

valve

TCC SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

PRESSURE CONTROL SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

VEHICLE SPEED (KPH/MPH)

Vehicle speed computed by reference pulse signals

coming from vehicle speed sensor on transaxle case.

O/D OFF SWITCH (“3” position switch)

Inputted signal from “3” position switch in select lever

assembly.

ON: Shift select lever to “3” or “2” range

OFF: Shift select lever to other above range

�)

TORQUE

REDUCTION SIGNAL While on gear upshifting with 25% or more throttle

opening

ON

Under condition of not shifting gear OFF

�) ENGINE COOLANT

TEMPERATURE Ignition switch ON Engine coolant temperature is

displayed

�) AIR CONDITIONER

SIGNAL Ignition switch ON and air conditioner switch OFF OFF

�) ENGINE TORQUE

SIGNAL Ignition switch ON and engine stop 0 N

⋅m

�) SLIP RPM Engine running at idle speed

and select lever is in “P”

range 0 RPM

Engine running, vehicle stop and select lever is in “D”

range Engine speed is displayed

�) MIL REQUEST Ignition switch ON OFF

�) FUEL CUT FLAG Ignition switch ON OFFScan tool data Vehicle condition

Normal condition / reference

values

Page 861 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-9

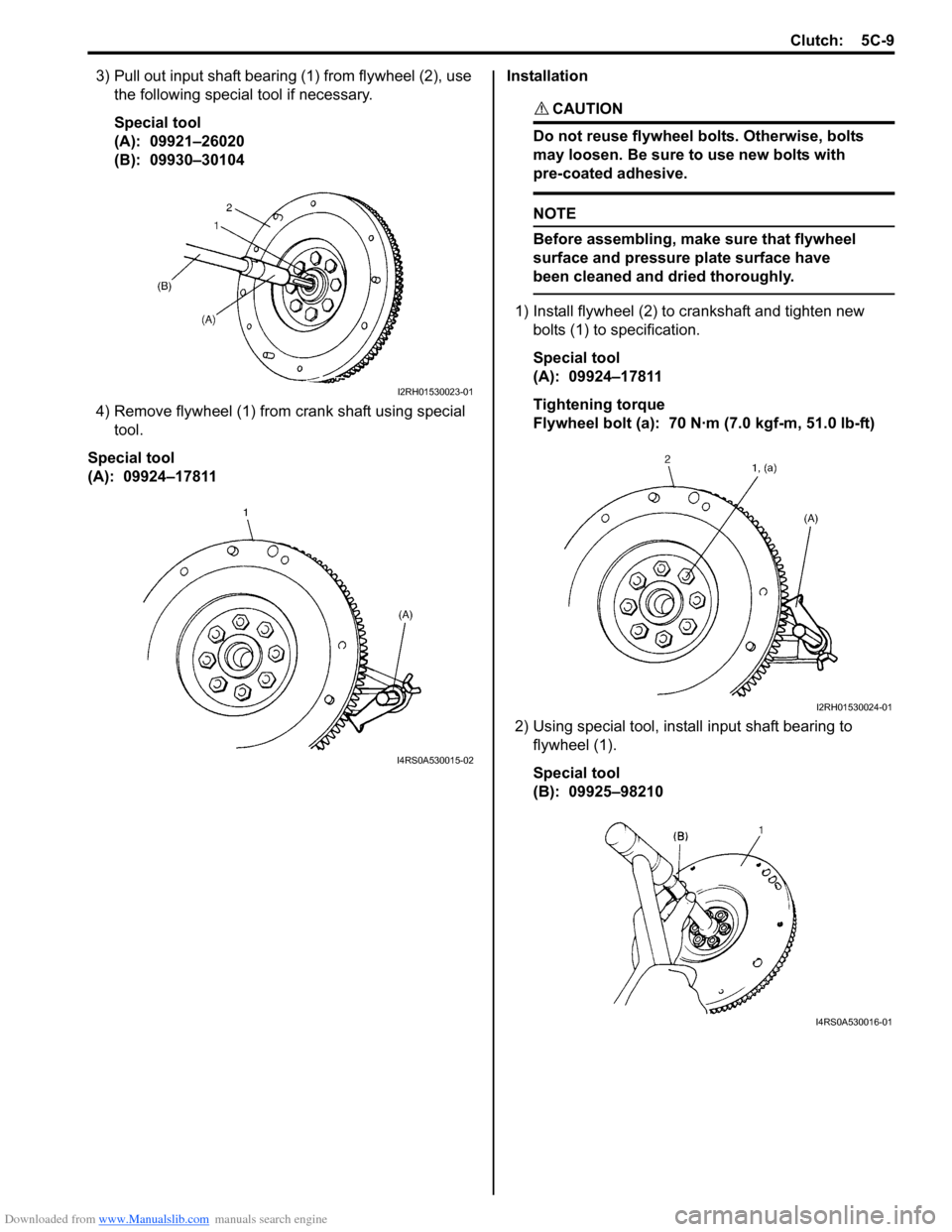

3) Pull out input shaft bearing (1) from flywheel (2), use the following special tool if necessary.

Special tool

(A): 09921–26020

(B): 09930–30104

4) Remove flywheel (1) from crank shaft using special tool.

Special tool

(A): 09924–17811 Installation

CAUTION!

Do not reuse flywheel bolts. Otherwise, bolts

may loosen. Be sure to use new bolts with

pre-coated adhesive.

NOTE

Before assembling, make

sure that flywheel

surface and pressure plate surface have

been cleaned and dried thoroughly.

1) Install flywheel (2) to crankshaft and tighten new bolts (1) to specification.

Special tool

(A): 09924–17811

Tightening torque

Flywheel bolt (a): 70 N·m (7.0 kgf-m, 51.0 lb-ft)

2) Using special tool, install input shaft bearing to flywheel (1).

Special tool

(B): 09925–98210

I2RH01530023-01

I4RS0A530015-02

I2RH01530024-01

I4RS0A530016-01

Page 862 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-10 Clutch:

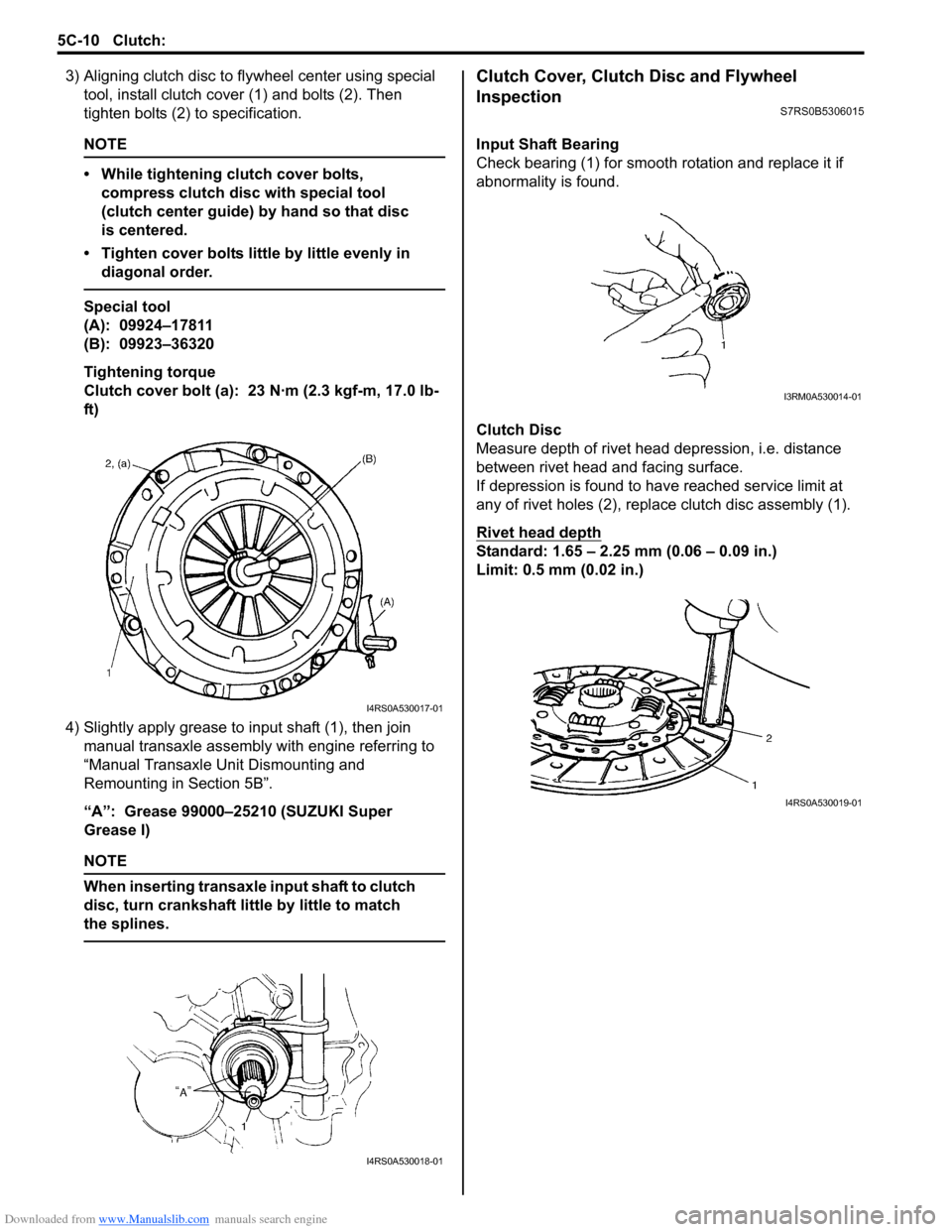

3) Aligning clutch disc to flywheel center using special

tool, install clutch cover (1) and bolts (2). Then

tighten bolts (2) to specification.

NOTE

• While tightening clutch cover bolts, compress clutch disc with special tool

(clutch center guide) by hand so that disc

is centered.

• Tighten cover bolts little by little evenly in diagonal order.

Special tool

(A): 09924–17811

(B): 09923–36320

Tightening torque

Clutch cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

4) Slightly apply grease to input shaft (1), then join manual transaxle assembly with engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

“A”: Grease 99000–25210 (SUZUKI Super

Grease I)

NOTE

When inserting transaxle input shaft to clutch

disc, turn crankshaft li ttle by little to match

the splines.

Clutch Cover, Clutch Disc and Flywheel

Inspection

S7RS0B5306015

Input Shaft Bearing

Check bearing (1) for smooth ro tation and replace it if

abnormality is found.

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to hav e reached service limit at

any of rivet holes (2), repl ace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)

I4RS0A530017-01

I4RS0A530018-01

I3RM0A530014-01

I4RS0A530019-01