Indicator switch SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 98 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-48 Engine General Information and Diagnosis:

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

Malfunction Indicator Lamp Remains ON after Engine StartsS7RS0B1104012

Wiring Diagram and Circuit Description

Refer to “MIL Does Not Come ON wit h Ignition Switch ON and Engine Stop (but Engine Can Be Started)”.

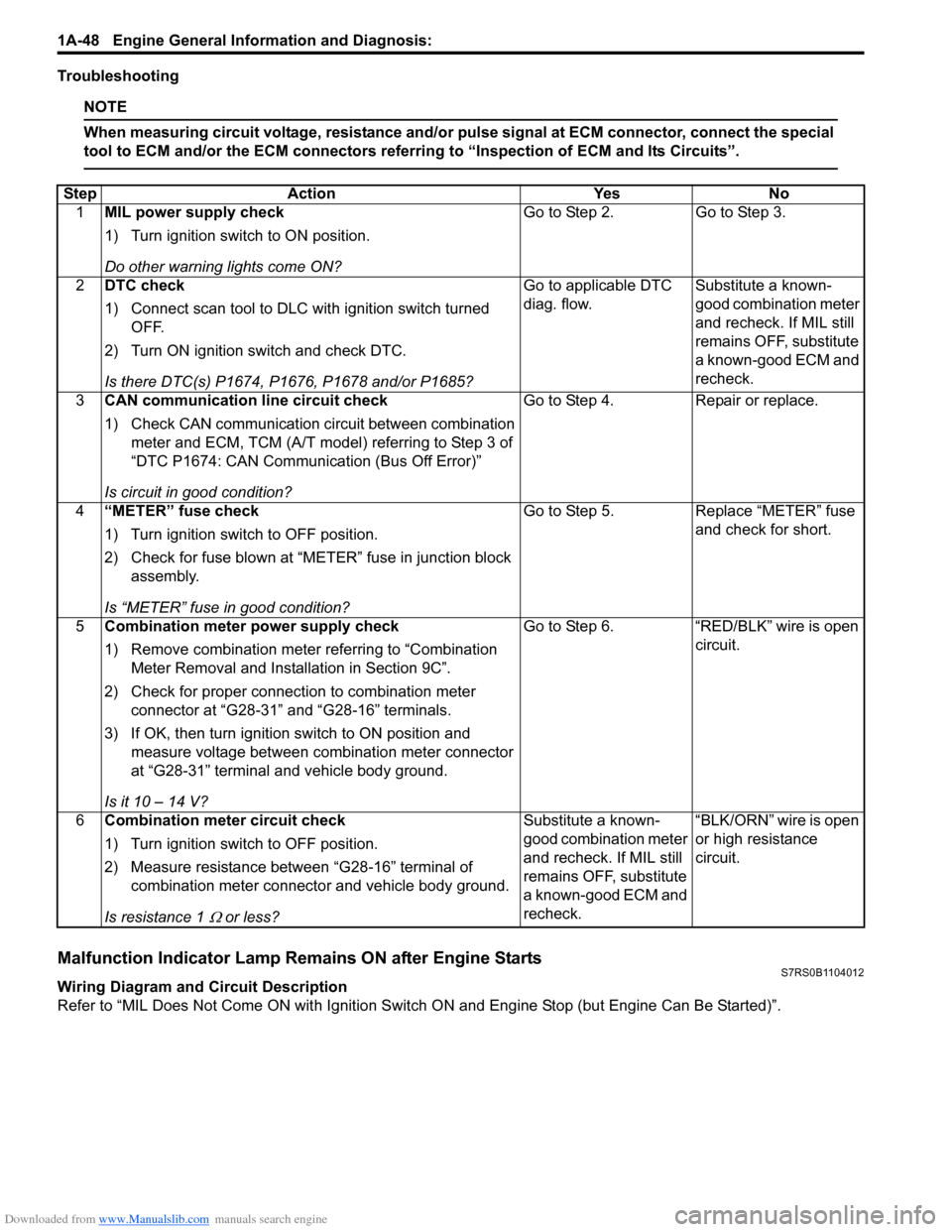

Step

Action YesNo

1 MIL power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC(s) P1674, P1676, P1678 and/or P1685? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

3 CAN communication line circuit check

1) Check CAN communication circuit between combination

meter and ECM, TCM (A/T model) referring to Step 3 of

“DTC P1674: CAN Communication (Bus Off Error)”

Is circuit in good condition? Go to Step 4.

Repair or replace.

4 “METER” fuse check

1) Turn ignition switch to OFF position.

2) Check for fuse blown at “M ETER” fuse in junction block

assembly.

Is “METER” fuse in good condition? Go to Step 5.

Replace “METER” fuse

and check for short.

5 Combination meter power supply check

1) Remove combination meter referring to “Combination

Meter Removal and Installation in Section 9C”.

2) Check for proper connection to combination meter connector at “G28-31” and “G28-16” terminals.

3) If OK, then turn ignition switch to ON position and measure voltage between combination meter connector

at “G28-31” terminal and vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

“RED/BLK” wire is open

circuit.

6 Combination meter circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “G28-16” terminal of

combination meter connector and vehicle body ground.

Is resistance 1

Ω or less? Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

“BLK/ORN” wire is open

or high resistance

circuit.

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

11) Connect negative cable at battery.

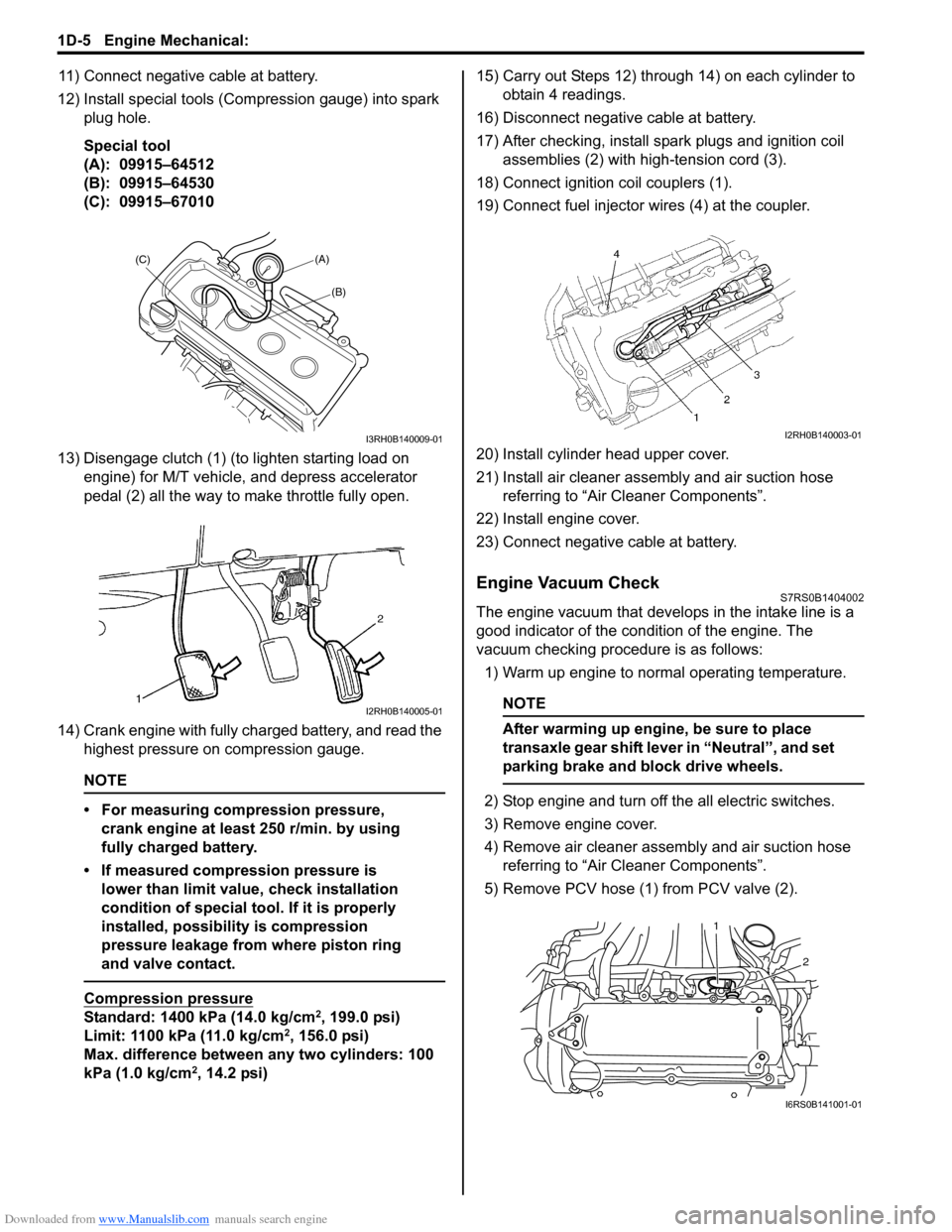

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 413 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

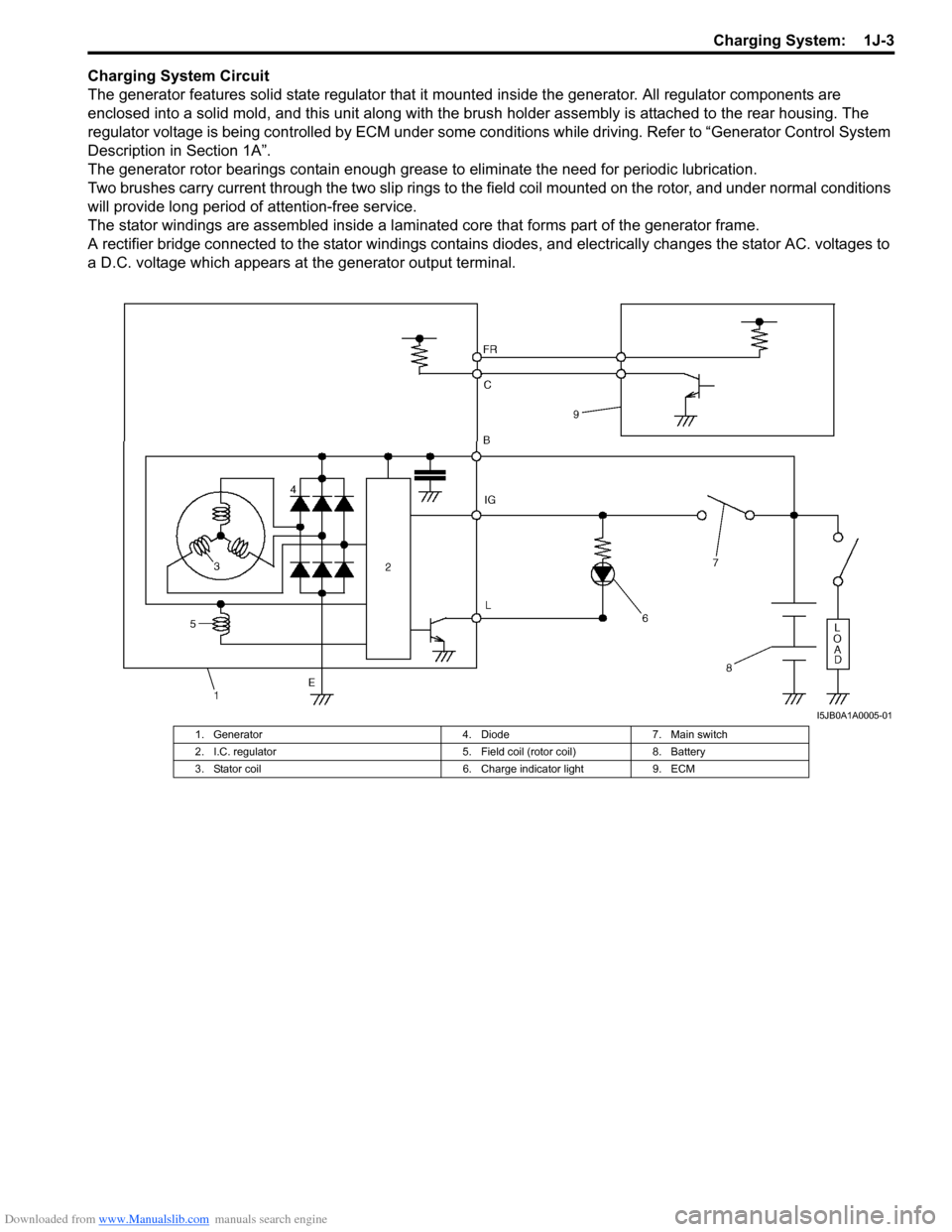

Charging System Circuit

The generator features solid state regulator that it mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brus h holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some cond itions while driving. Refer to “Generator Control System

Description in Section 1A”.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminate d core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes the stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

I5JB0A1A0005-01

1. Generator 4. Diode7. Main switch

2. I.C. regulator 5. Field coil (rotor coil)8. Battery

3. Stator coil 6. Charge indicator light9. ECM

Page 415 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-5

Generator Test (Undercharged Battery Check)S7RS0B1A04003

This condition, as evidenced by slow cranking or

indicator clear with dark or light yellow dot can be

caused by one or more of the following conditions even

though indicator lamp may be operating normal.

The following procedure also applies to cars with

voltmeter and ammeter.1) Make sure that undercharged condition has not been caused by accessories left on for extended period of

time.

2) Check drive belt for proper tension.

3) If battery defect is suspected, refer to “Battery Description”.

4) Inspect wiring for defects. Check all connections for tightness and cleanliness, battery cable connections

at battery, starting motor, ignition ground cable and

no “C” terminal circuit at ground.

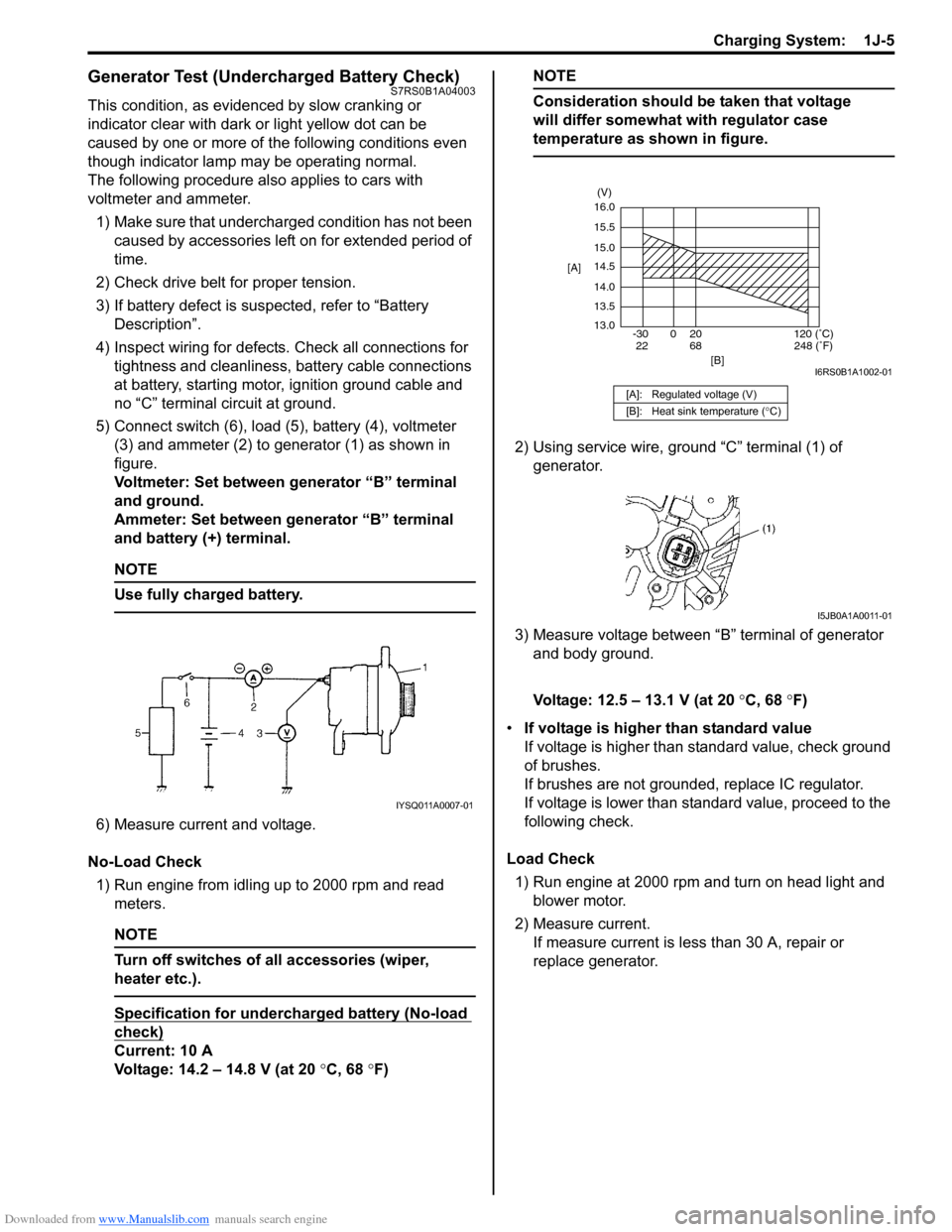

5) Connect switch (6), load (5), battery (4), voltmeter (3) and ammeter (2) to generator (1) as shown in

figure.

Voltmeter: Set between generator “B” terminal

and ground.

Ammeter: Set between generator “B” terminal

and battery (+) terminal.

NOTE

Use fully charged battery.

6) Measure current and voltage.

No-Load Check 1) Run engine from idling up to 2000 rpm and read meters.

NOTE

Turn off switches of all accessories (wiper,

heater etc.).

Specification for undercharged battery (No-load

check)

Current: 10 A

Voltage: 14.2 – 14.8 V (at 20 °C, 68 °F)

NOTE

Consideration should be taken that voltage

will differ somewhat with regulator case

temperature as shown in figure.

2) Using service wire, ground “C” terminal (1) of

generator.

3) Measure voltage between “B” terminal of generator and body ground.

Voltage: 12.5 – 13.1 V (at 20 °C, 68 °F)

• If voltage is higher than standard value

If voltage is higher than standard value, check ground

of brushes.

If brushes are not grounded, replace IC regulator.

If voltage is lower than standard value, proceed to the

following check.

Load Check 1) Run engine at 2000 rpm and turn on head light and blower motor.

2) Measure current. If measure current is less than 30 A, repair or

replace generator.

IYSQ011A0007-01

[A]: Regulated voltage (V)

[B]: Heat sink temperature ( °C)

16.0

15.5

15.0

14.5

14.0

13.5

13.0

-30 0 20

[A]

[B]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0B1A1002-01

I5JB0A1A0011-01

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 504 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

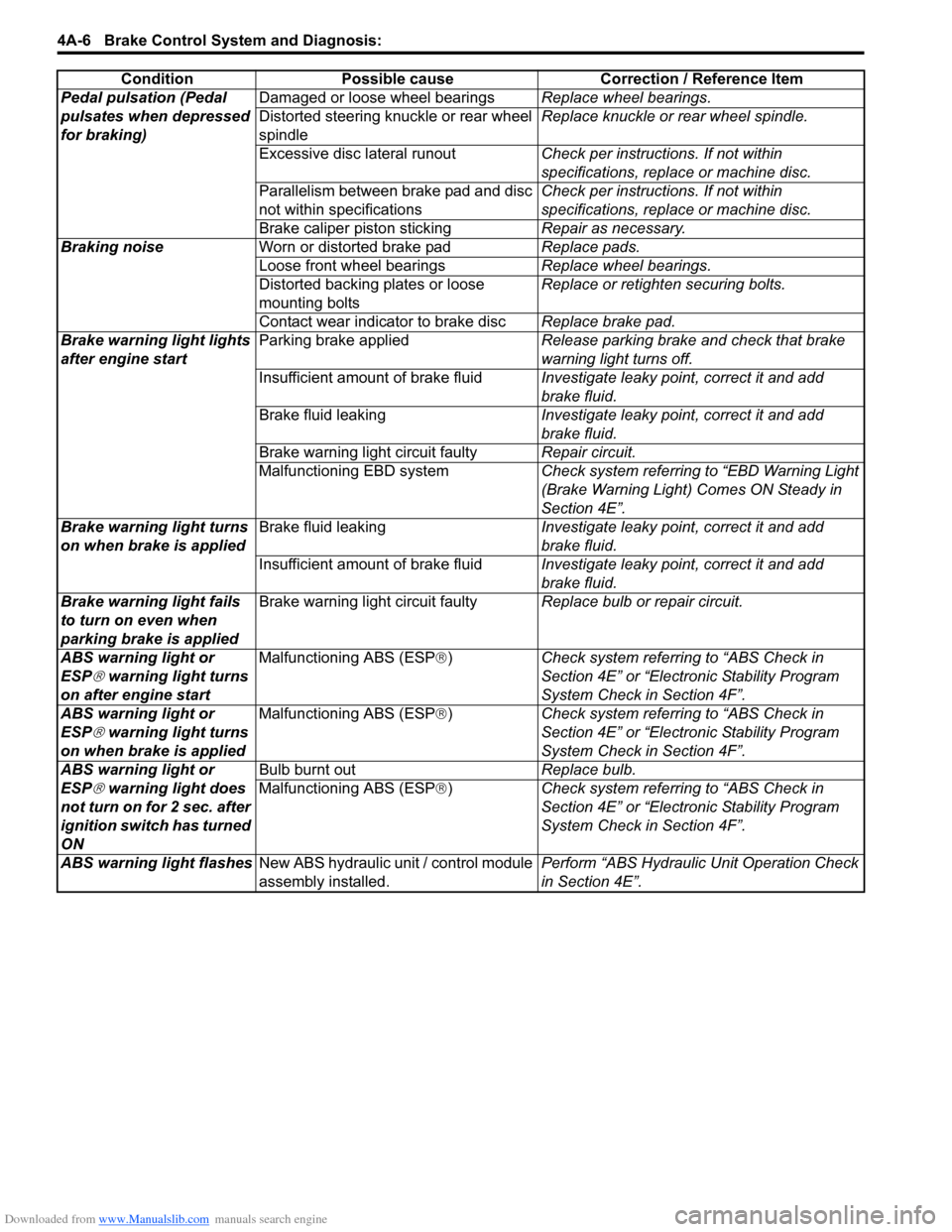

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 579 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-5

Yaw rate / G sensor

The yaw rate / G sensor consists of the yaw rate (angular velocity in the vehicle turning direction) sensor and right-left

G (acceleration in right-left direction) sensor and is mounted to the P/S controller B/K at the lower part of the center

console. It detects the angular velocity in the vehicle turn ing direction and movement in the right-left direction, and

then it sends that information to ESP ® control module.

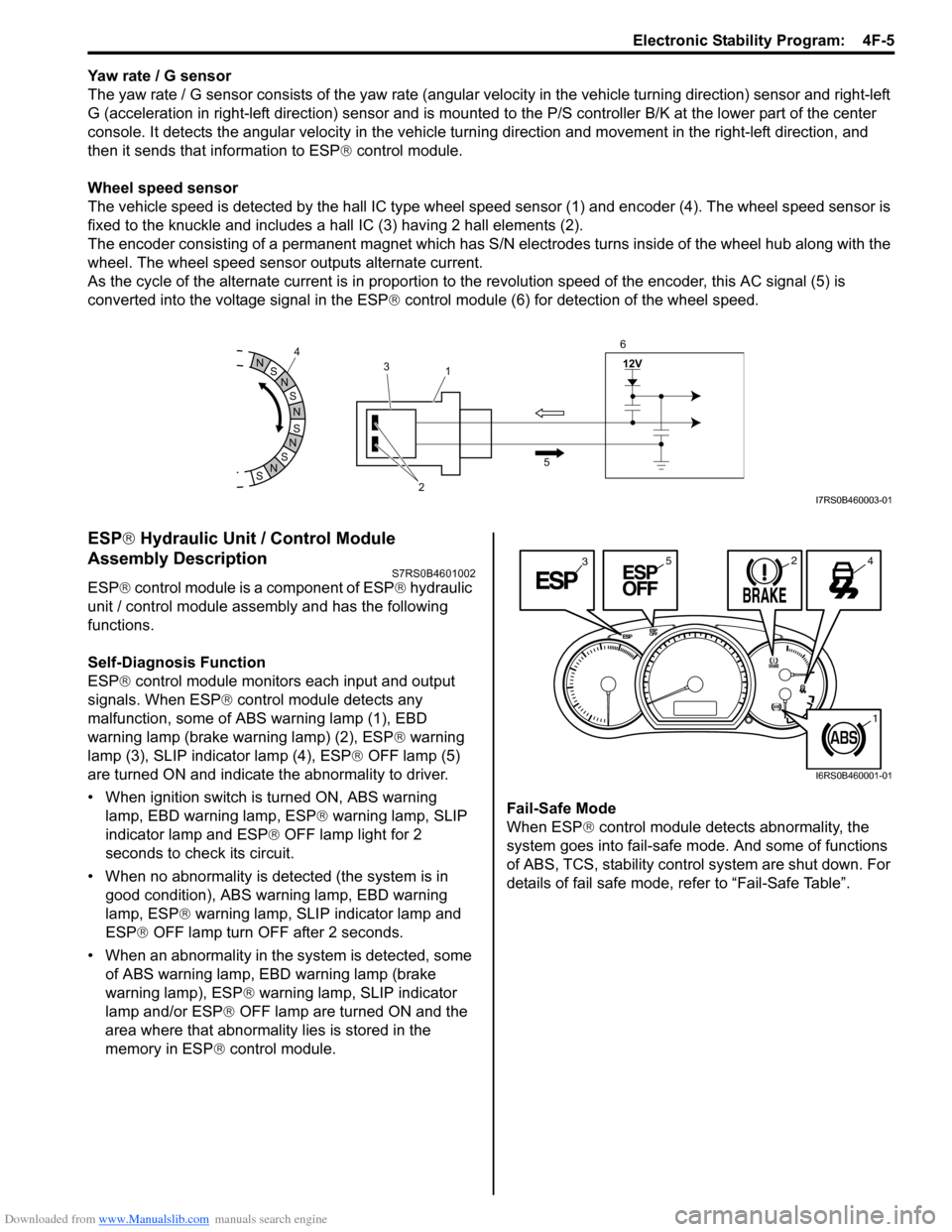

Wheel speed sensor

The vehicle speed is detected by the hall IC type wheel speed sensor (1) and encoder (4). The wheel speed sensor is

fixed to the knuckle and includes a hall IC (3) having 2 hall elements (2).

The encoder consisting of a permanent ma gnet which has S/N electrodes turns inside of the wheel hub along with the

wheel. The wheel speed sensor outputs alternate current.

As the cycle of the alternate current is in proportion to the revolution speed of the encoder, this AC signal (5) is

converted into the voltage signal in the ESP ® control module (6) for detection of the wheel speed.

ESP ® Hydraulic Unit / Control Module

Assembly Description

S7RS0B4601002

ESP ® control module is a component of ESP ® hydraulic

unit / control module assembly and has the following

functions.

Self-Diagnosis Function

ESP ® control module monitors each input and output

signals. When ESP ® control module detects any

malfunction, some of ABS warning lamp (1), EBD

warning lamp (brake warning lamp) (2), ESP ® warning

lamp (3), SLIP indicator lamp (4), ESP ® OFF lamp (5)

are turned ON and indicate the abnormality to driver.

• When ignition switch is turned ON, ABS warning lamp, EBD warning lamp, ESP ® warning lamp, SLIP

indicator lamp and ESP ® OFF lamp light for 2

seconds to check its circuit.

• When no abnormality is detected (the system is in good condition), ABS warning lamp, EBD warning

lamp, ESP ® warning lamp, SLIP indicator lamp and

ESP ® OFF lamp turn OFF after 2 seconds.

• When an abnormality in the system is detected, some of ABS warning lamp, EBD warning lamp (brake

warning lamp), ESP ® warning lamp, SLIP indicator

lamp and/or ESP ® OFF lamp are turned ON and the

area where that abnormality lies is stored in the

memory in ESP ® control module. Fail-Safe Mode

When ESP

® control module detects abnormality, the

system goes into fail-safe mode. And some of functions

of ABS, TCS, stability control system are shut down. For

details of fail safe mode, re fer to “Fail-Safe Table”.

S

N

S

N

S

N

N

S

N

S

12V

2

3

1

5

4

6I7RS0B460003-01

3245

1

I6RS0B460001-01

Page 580 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-6 Electronic Stability Program:

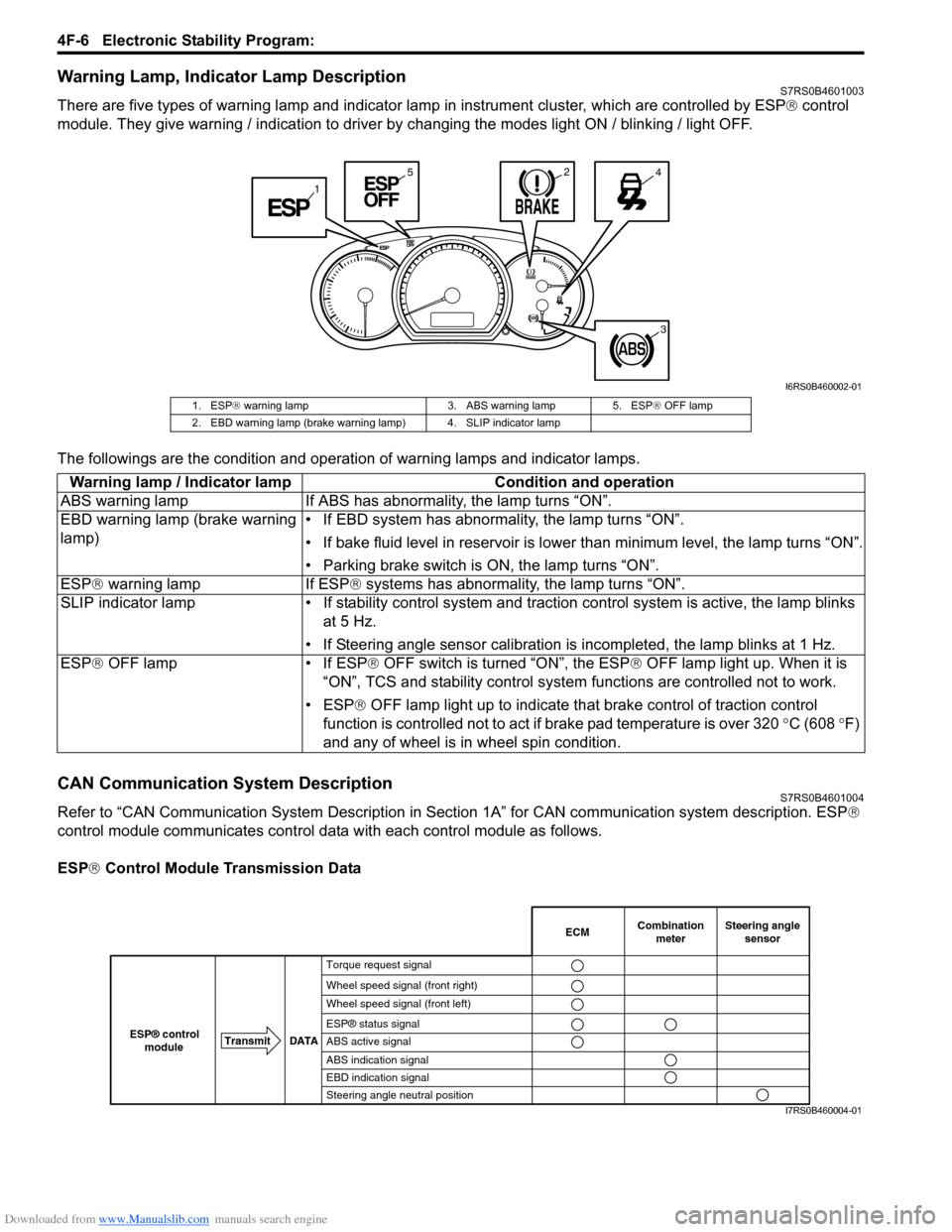

Warning Lamp, Indicator Lamp DescriptionS7RS0B4601003

There are five types of warning lamp and indicator lamp in instrument cluster, which are controlled by ESP ® control

module. They give warning / indication to driver by changing the modes light ON / blinking / light OFF.

The followings are the condition and operation of warning lamps and indicator lamps.

CAN Communication System DescriptionS7RS0B4601004

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description. ESP ®

control module communicates control data with each control module as follows.

ESP ® Control Module Transmission Data

1

245

3

I6RS0B460002-01

1. ESP ® warning lamp 3. ABS warning lamp 5. ESP ® OFF lamp

2. EBD warning lamp (brake warning lamp) 4. SLIP indicator lamp

Warning lamp / Indicator lamp Condition and operation

ABS warning lamp If ABS has abnor mality, the lamp turns “ON”.

EBD warning lamp (brake warning

lamp) • If EBD system has abnormality, the lamp turns “ON”.

• If bake fluid level in reservoir is lower

than minimum level, the lamp turns “ON”.

• Parking brake switch is ON, the lamp turns “ON”.

ESP ® warning lamp If ESP ® systems has abnormality, the lamp turns “ON”.

SLIP indicator lamp • If stability cont rol system and traction control system is active, the lamp blinks

at 5 Hz.

• If Steering angle sensor calibration is incompleted, the lamp blinks at 1 Hz.

ESP ® OFF lamp • If ESP ® OFF switch is turned “ON”, the ESP ® OFF lamp light up. When it is

“ON”, TCS and stability control system functions are controlled not to work.

• ESP® OFF lamp light up to indicate th at brake control of traction control

function is controlled not to act if brake pad temperature is over 320 °C (608 °F)

and any of wheel is in wheel spin condition.

Combination

meter

Transmit DATA

ESP® control

moduleECMSteering angle sensor

Torque request signal

Wheel speed signal (front right)

Wheel speed signal (front left)

ESP® status signal

ABS active signal

ABS indication signal

EBD indication signal

Steering angle neutral position

I7RS0B460004-01

Page 582 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-8 Electronic Stability Program:

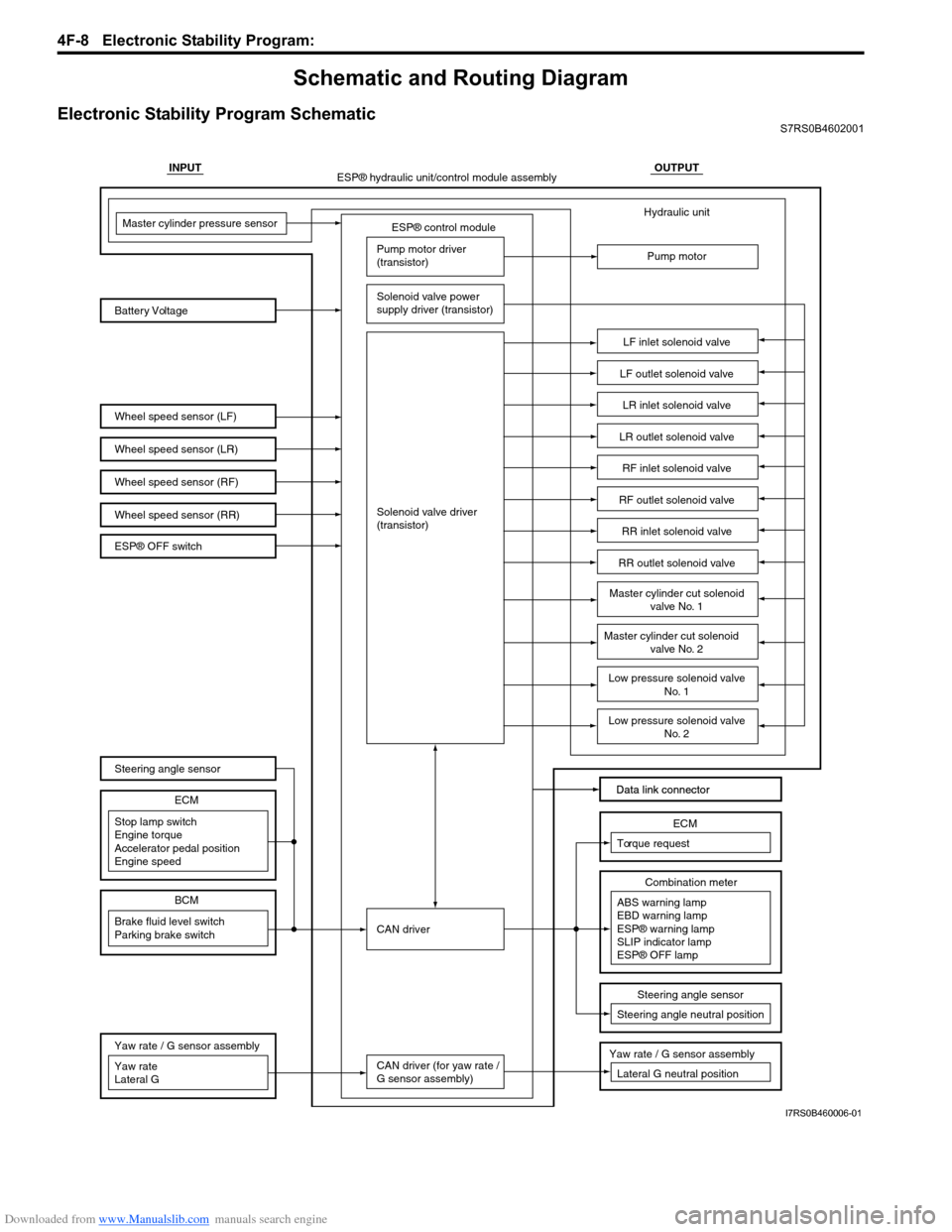

Schematic and Routing Diagram

Electronic Stability Program SchematicS7RS0B4602001

INPUTOUTPUT

ESP® control module

Wheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF) Battery VoltageMaster cylinder pressure sensor

Pump motor driver

(transistor)

Solenoid valve power

supply driver (transistor)

Solenoid valve driver

(transistor)

CAN driver

CAN driver (for yaw rate /

G sensor assembly) Hydraulic unit

Pump motor

LF inlet solenoid valve

LF outlet solenoid valve

LR inlet solenoid valve

LR outlet solenoid valve

RF inlet solenoid valve

RF outlet solenoid valve

RR inlet solenoid valve

RR outlet solenoid valve

Data link connector

Data link connector

ESP® hydraulic unit/control module assembly

Wheel speed sensor (RR)

Master cylinder cut solenoid valve No. 1

Master cylinder cut solenoid

valve No. 2

Low pressure solenoid valve No. 1

Low pressure solenoid valveNo. 2

Stop lamp switch

Engine torque

Accelerator pedal position

Engine speed ECM

Brake fluid level switch

Parking brake switch

BCM

Steering angle sensor

ESP® OFF switch

Yaw rate

Lateral G Yaw rate / G sensor assembly

ABS warning lamp

EBD warning lamp

ESP® warning lamp

SLIP indicator lamp

ESP® OFF lampCombination meter

Torque request

ECM

Steering angle neutral positionSteering angle sensor

Yaw rate / G sensor assembly

Lateral G neutral position

I7RS0B460006-01

Page 584 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-10 Electronic Stability Program:

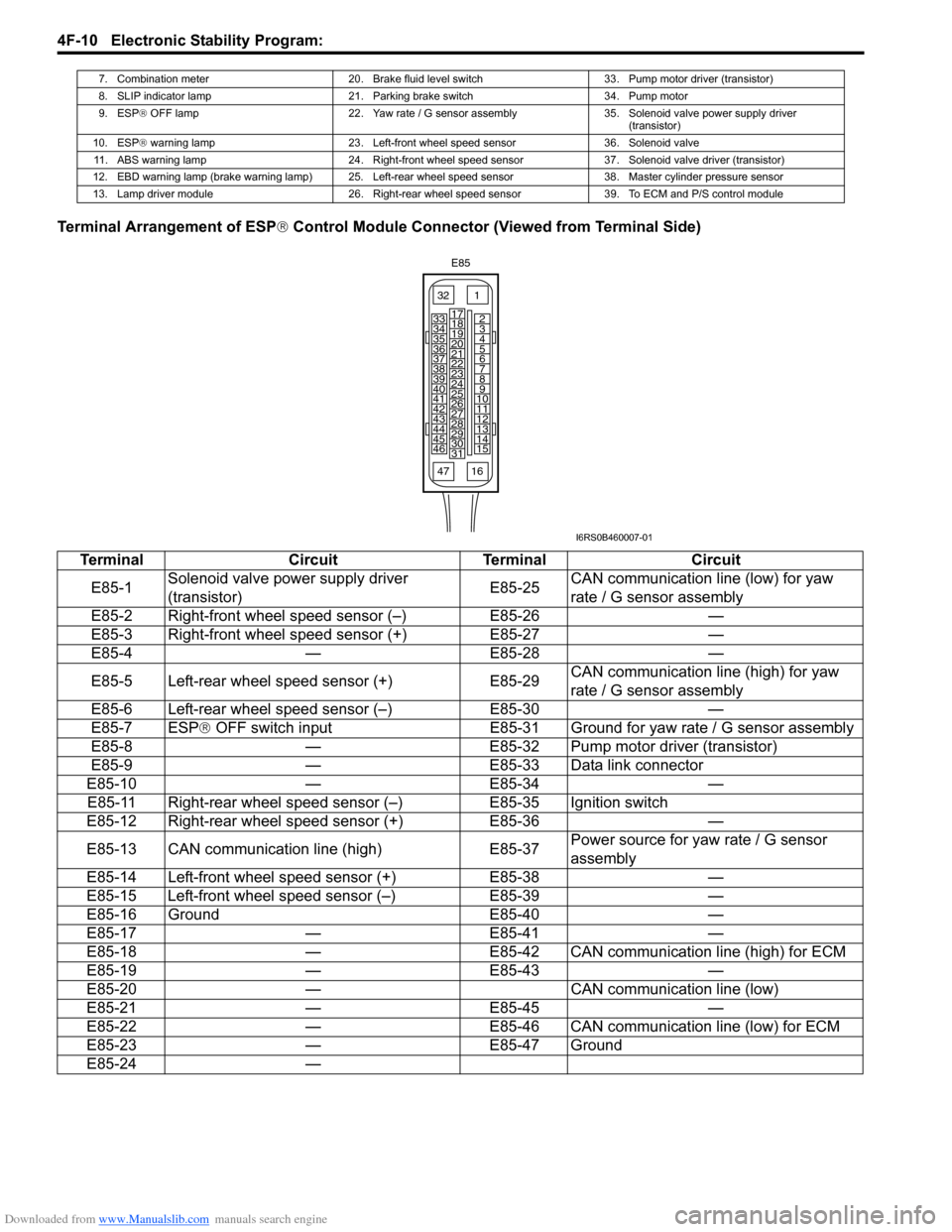

Terminal Arrangement of ESP® Control Module Connector (Viewed from Terminal Side)

7. Combination meter 20. Brake fluid level switch 33. Pump motor driver (transistor)

8. SLIP indicator lamp 21. Parking brake switch 34. Pump motor

9. ESP ® OFF lamp 22. Yaw rate / G sensor assembly 35. Solenoid valve power supply driver

(transistor)

10. ESP ® warning lamp 23. Left-front wheel speed sensor 36. Solenoid valve

11. ABS warning lamp 24. Right-front wheel speed sensor37. Solenoid valve driver (transistor)

12. EBD warning lamp (brake warning lamp) 25. Left-rear wheel speed sensor 38. Master cylinder pressure sensor

13. Lamp driver module 26. Right-rear wheel speed sensor 39. To ECM and P/S control module

Terminal CircuitTerminal Circuit

E85-1 Solenoid valve power supply driver

(transistor) E85-25CAN communication line (low) for yaw

rate / G sensor assembly

E85-2 Right-front wheel speed sensor (–) E85-26—

E85-3 Right-front wheel speed sensor (+) E85-27—

E85-4 —E85-28 —

E85-5 Left-rear wheel speed sensor (+) E85-29CAN communication line (high) for yaw

rate / G sensor assembly

E85-6 Left-rear wheel speed sensor (–) E85-30—

E85-7 ESP® OFF switch input E85-31 Ground for yaw rate / G sensor assembly

E85-8 —E85-32 Pump motor driver (transistor)

E85-9 —E85-33 Data link connector

E85-10 —E85-34 —

E85-11 Right-rear wheel speed sensor (–) E85-35 Ignition switch

E85-12 Right-rear wheel speed sensor (+) E85-36—

E85-13 CAN communication line (high) E85-37Power source for ya

w rate / G sensor

assembly

E85-14 Left-front wheel speed sensor (+) E85-38—

E85-15 Left-front wheel speed sensor (–) E85-39—

E85-16 Ground E85-40—

E85-17 —E85-41 —

E85-18 —E85-42 CAN communication line (high) for ECM

E85-19 —E85-43 —

E85-20 — CAN communication line (low)

E85-21 —E85-45 —

E85-22 —E85-46 CAN communication line (low) for ECM

E85-23 —E85-47 Ground

E85-24 —

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

I6RS0B460007-01