Roof SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1192 of 1496

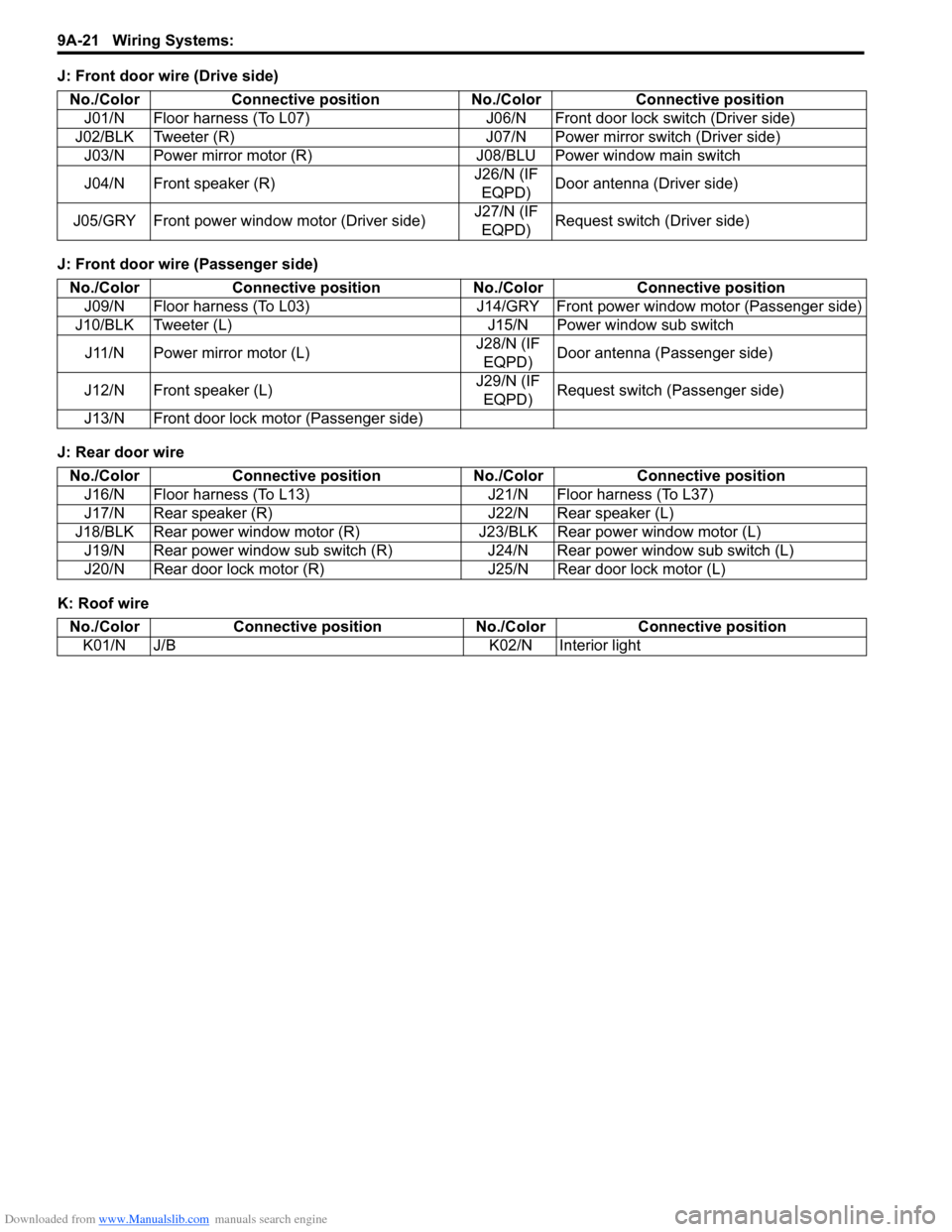

Downloaded from www.Manualslib.com manuals search engine 9A-21 Wiring Systems:

J: Front door wire (Drive side)

J: Front door wire (Passenger side)

J: Rear door wire

K: Roof wireNo./Color Connective position No.

/Color Connective position

J01/N Floor harness (To L07) J06/N Front door lock switch (Driver side)

J02/BLK Tweeter (R) J07/N Power mirror switch (Driver side) J03/N Power mirror motor (R) J08/BLU Power window main switch

J04/N Front speaker (R) J26/N (IF

EQPD) Door antenna (Driver side)

J05/GRY Front power window motor (Driver side) J27/N (IF

EQPD) Request switch (Driver side)

No./Color

Connective position No./ColorConnective position

J09/N Floor harness (To L03) J14/GRY Front power window motor (Passenger side)

J10/BLK Tweeter (L) J15/N Power window sub switch

J11/N Power mirror motor (L) J28/N (IF

EQPD) Door antenna (Passenger side)

J12/N Front speaker (L) J29/N (IF

EQPD) Request switch (Passenger side)

J13/N Front door lock motor (Passenger side)

No./Color Connective position No./ColorConnective position

J16/N Floor harness (To L13) J21/N Floor harness (To L37)

J17/N Rear speaker (R) J22/N Rear speaker (L)

J18/BLK Rear power window motor (R) J23/BLK Rear power window motor (L)

J19/N Rear power window sub switch (R) J24/N Rear power window sub switch (L)

J20/N Rear door lock motor (R) J25/N Rear door lock motor (L)

No./ColorConnective position No./Color Connective position

K01/N J/B K02/N Interior light

Page 1193 of 1496

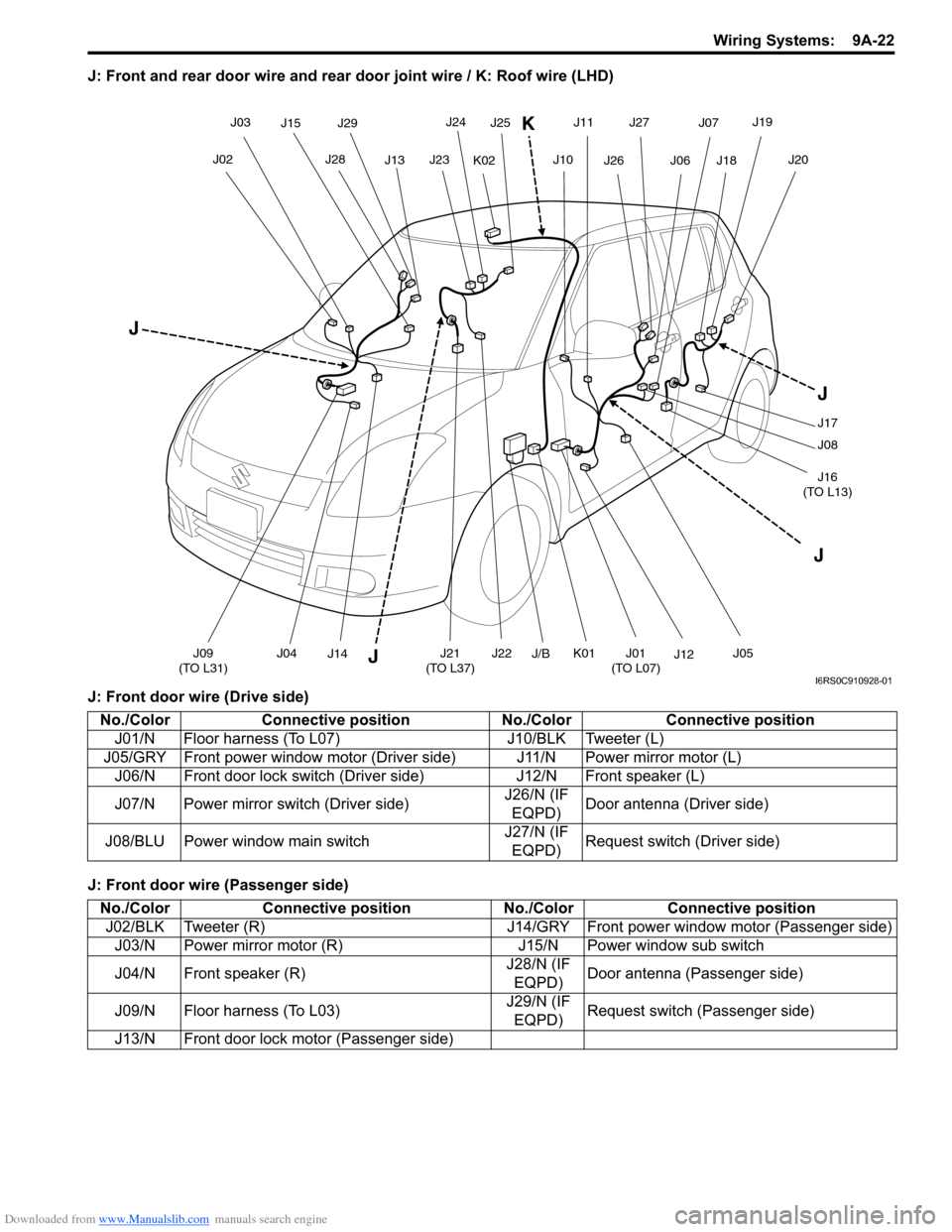

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-22

J: Front and rear door wire and rear door joint wire / K: Roof wire (LHD)

J: Front door wire (Drive side)

J: Front door wire (Passenger side)

J04J21

(TO L37)

J02

J03

J13

J15J29

J28 J25J23

J24

JJ09

(TO L31) J22J01

(TO L07)J12

J10J06J18

J19

J20

J J

J17

J08

J16

(TO L13)

J05

J11

J26

J07

J27

J14

J

K02

K

J/BK01

I6RS0C910928-01

No./Color Connective position No./Color Connective position

J01/N Floor harness (To L07) J10/BLK Tweeter (L)

J05/GRY Front power window motor (Driver side) J11/N Power mirror motor (L) J06/N Front door lock switch (Dri ver side)J12/N Front speaker (L)

J07/N Power mirror switch (Driver side) J26/N (IF

EQPD) Door antenna (Driver side)

J08/BLU Power window main switch J27/N (IF

EQPD) Request switch (Driver side)

No./Color

Connective position No./ColorConnective position

J02/BLK Tweeter (R) J14/GRY Front power window motor (Passenger side)

J03/N Power mirror motor (R) J15/N Power window sub switch

J04/N Front speaker (R) J28/N (IF

EQPD) Door antenna (Passenger side)

J09/N Floor harness (To L03) J29/N (IF

EQPD) Request switch (Passenger side)

J13/N Front door lock motor (Passenger side)

Page 1194 of 1496

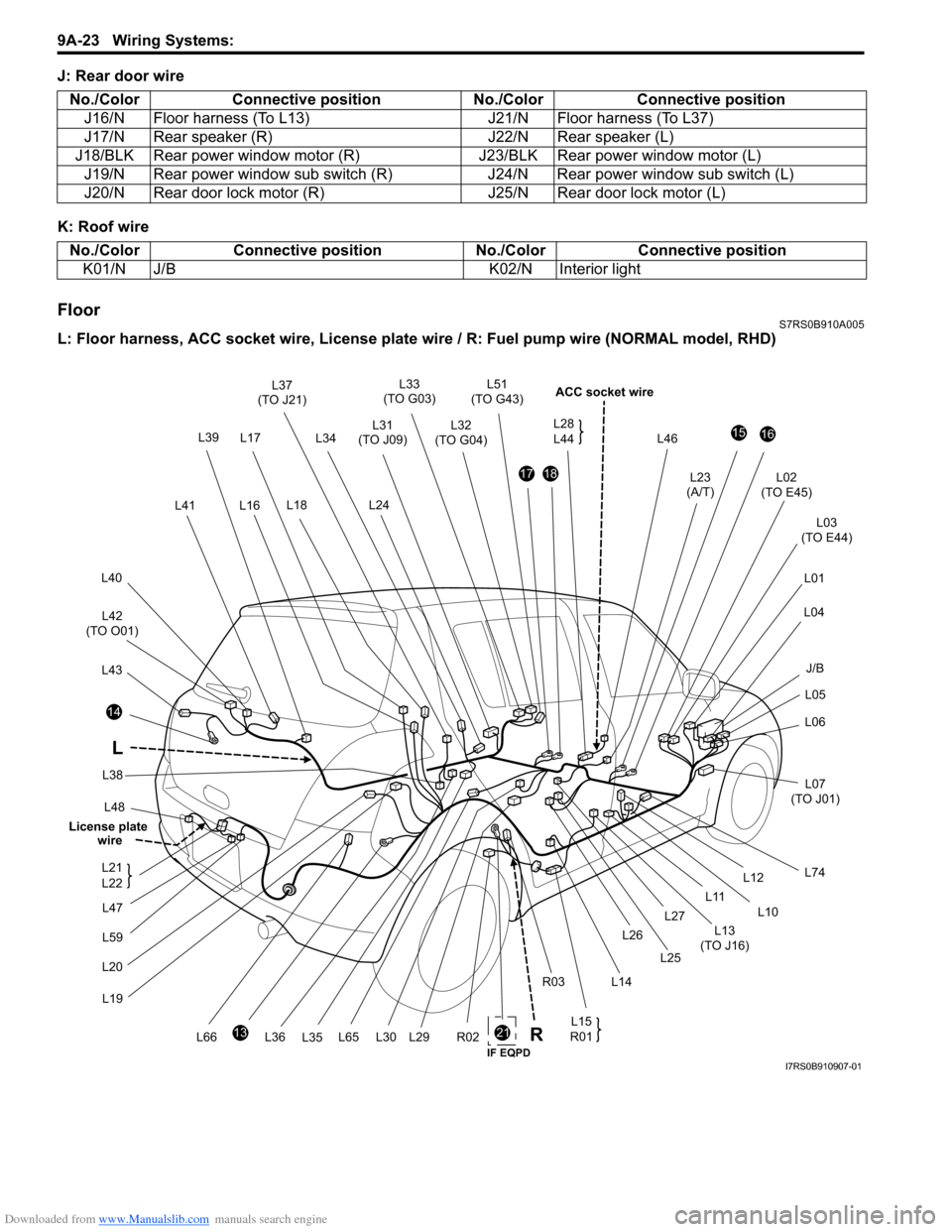

Downloaded from www.Manualslib.com manuals search engine 9A-23 Wiring Systems:

J: Rear door wire

K: Roof wire

FloorS7RS0B910A005

L: Floor harness, ACC socket wire, License plate wire / R: Fuel pum p wire (NORMAL model, RHD)

No./Color

Connective position No./ColorConnective position

J16/N Floor harness (To L13) J21/N Floor harness (To L37)

J17/N Rear speaker (R) J22/N Rear speaker (L)

J18/BLK Rear power window motor (R) J23/BLK Rear power window motor (L)

J19/N Rear power window sub switch (R) J24/N Rear power window sub switch (L)

J20/N Rear door lock motor (R) J25/N Rear door lock motor (L)

No./ColorConnective position No./Color Connective position

K01/N J/B K02/N Interior light

21

L48

14

L43

L42

(TO O01)

L40

L41

L33

(TO G03)

L32

(TO G04)

L46

ACC socket wire

L02

(TO E45)

L03

(TO E44)

L01

L04

L05

L06

L07

(TO J01)

L74

1516

L23

(A/T)1718

L31

(TO J09)

L24

13

L20L19

R02L65L66 L15

R01

L12

L10

L11

L13

(TO J16)

L14

R03 L26

L25

L27

L30L29

L17

L18 L51

(TO G43)

L36 L35

L37

(TO J21)

L34

L38

L16 L28

L44

L

L39

J/B

R

L47

L59

L21

L22

License plate

wire

IF EQPDI7RS0B910907-01

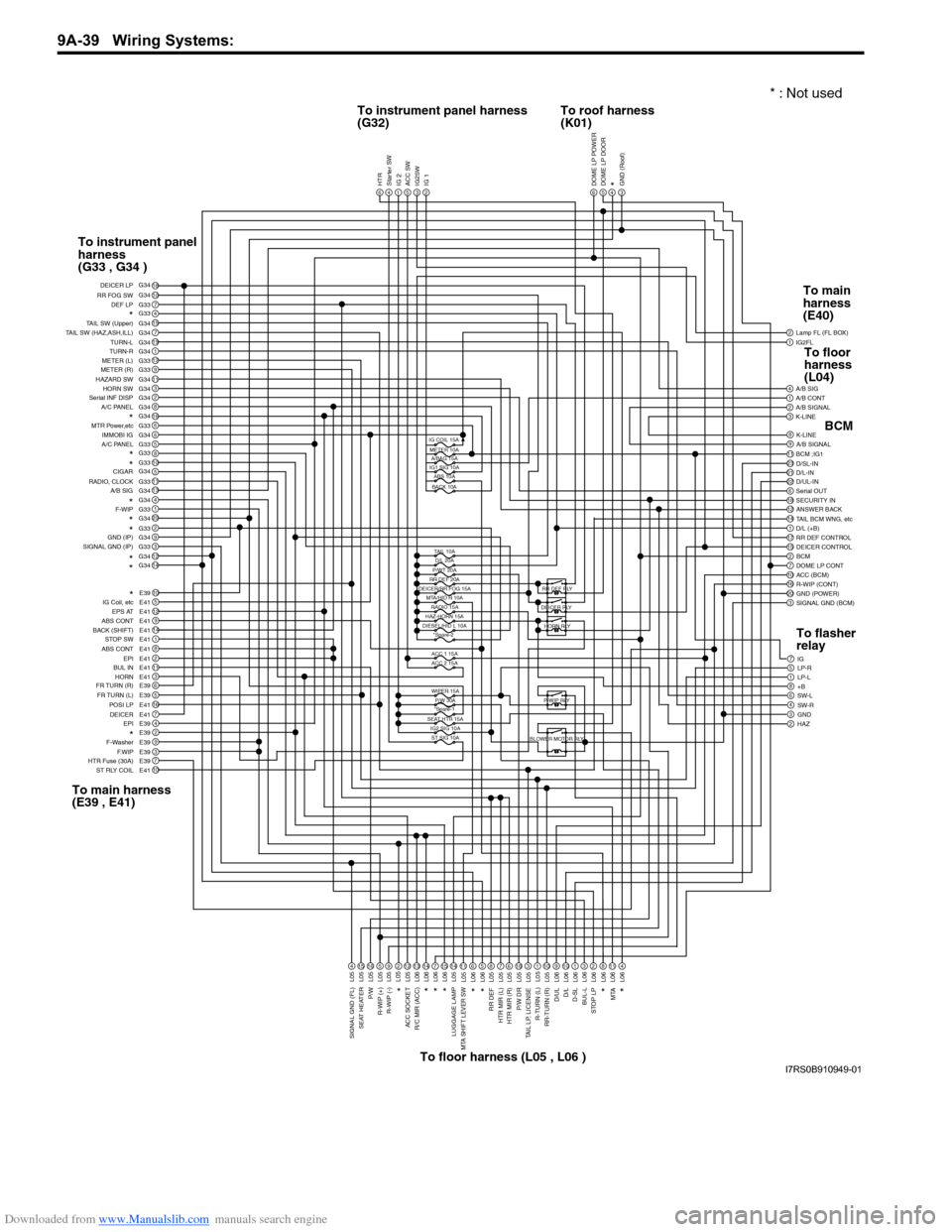

Page 1210 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-39 Wiring Systems:

1IG2FL2

6

Lamp FL (FL BOX)

1A/B CONT4A/B SIG

3K-LINE2A/B SIGNAL

9A/B SIGNAL8K-LINE

2311BCM ;IG1

22D/UL-IN21D/L-IN D/SL-IN

18SECURITY IN6Serial OUT

14TAIL BCM WNG, etc12ANSWER BACK

17RR DEF CONTROL1D/L (+B)

2BCM15DEICER CONTROL

10ACC (BCM)7DOME LP CONT

20GND (POWER)16R-WIP (CONT)

3SIGNAL GND (BCM)

7IG

1LP-L5LP-R

8+B6SW-L

3GND4SW-R

2HAZ

DOME LP POWER5DOME LP DOOR4*3GND (Roof)6HTR4Starter SW1IG 25ACC SW3IG2SW2IG 1

18107G33415G347G3419G341G3412G339G3311G343G342G348G34166G336G345G33810511G3313G344G341G3320G342G339G343G3312G3414G34

10E395E4112E419E4114E411E418E412E4111E413E416E395E3916E417E414E392E399E393E397E3910E41

DEF LP

RR FOG SW DEICER LP

*TAIL SW (Upper)

TAIL SW (HAZ,ASH,ILL) TURN-L

TURN-R

METER (L)

METER (R)

HAZARD SW HORN SW

Serial INF DISP

A/C PANEL

*MTR Power,etc

IMMOBI IG

A/C PANEL

*

*

RADIO, CLOCK

A/B SIGCIGAR

*F-WIP*

*GND (IP)

SIGNAL GND (IP)

*

*

*

IG Coil, etc EPS AT

ABS CONT

BACK (SHIFT) STOP SW

ABS CONT EPI

BUL IN

HORN

FR TURN (R)

FR TURN (L) POSI LP

EPI

DEICER

*F-Washer

F.WIP

HTR Fuse (30A)

ST RLY COIL

4L0515L0516L055L059L05212L0513L0614L067L0615L0614L0511L056L065L068L057L056L0518L053L051L0510L059L0610L061L063L062L068L0611L064L06

SIGNAL GND (FL)

SEAT HEATER

P/W

R-WIP (+) R-WIP (-)*

ACC SOCKET

R/C MIR (ACC)

*

*

*

LUGGAGE LAMPMTA SHIFT LEVER SW

*

*

RR DEF

HTR MIR (L)

HTR MIR (R)

P/W DR

TAIL LP, LICENSE

R-TURN (L)

RR-TURN (R)

D/ULD/L

D-SL

BUL-L

STOP LP

MTA

*

*

IG COIL 15AMETER 10A A/BAG 15A

IG1 SIG 10A ABS 10A

BACK 10A

TAIL 10AD/L 20A

P/WT 20A

RR DEF 20A

DEICER/RR FOG 15A

MTA/HID R 10A

ACC 1 15A

ACC 2 15A

WIPER 15A P/W 30A

*Spare-1

SEAT HTR 15A IG2 SIG 10AST SIG 10A

HAZ-HORN 15A

DIESEL/HID L 10A *Spare-2 RR DEF RLY

DEICER RLY HORN RLY

P-WIP RLY

BLOWER MOTOR RLY

G34 G34

G33

G34

G33

G34 G33

L05

RADIO 15A

To instrument panel harness

(G32) To roof harness

(K01)

To instrument panel

harness

(G33 , G34 )

To main harness

(E39 , E41) To floor harness (L05 , L06 ) To main

harness

(E40)

BCM

To flasher

relay To floor

harness

(L04)

* : Not used

I7RS0B910949-01

Page 1215 of 1496

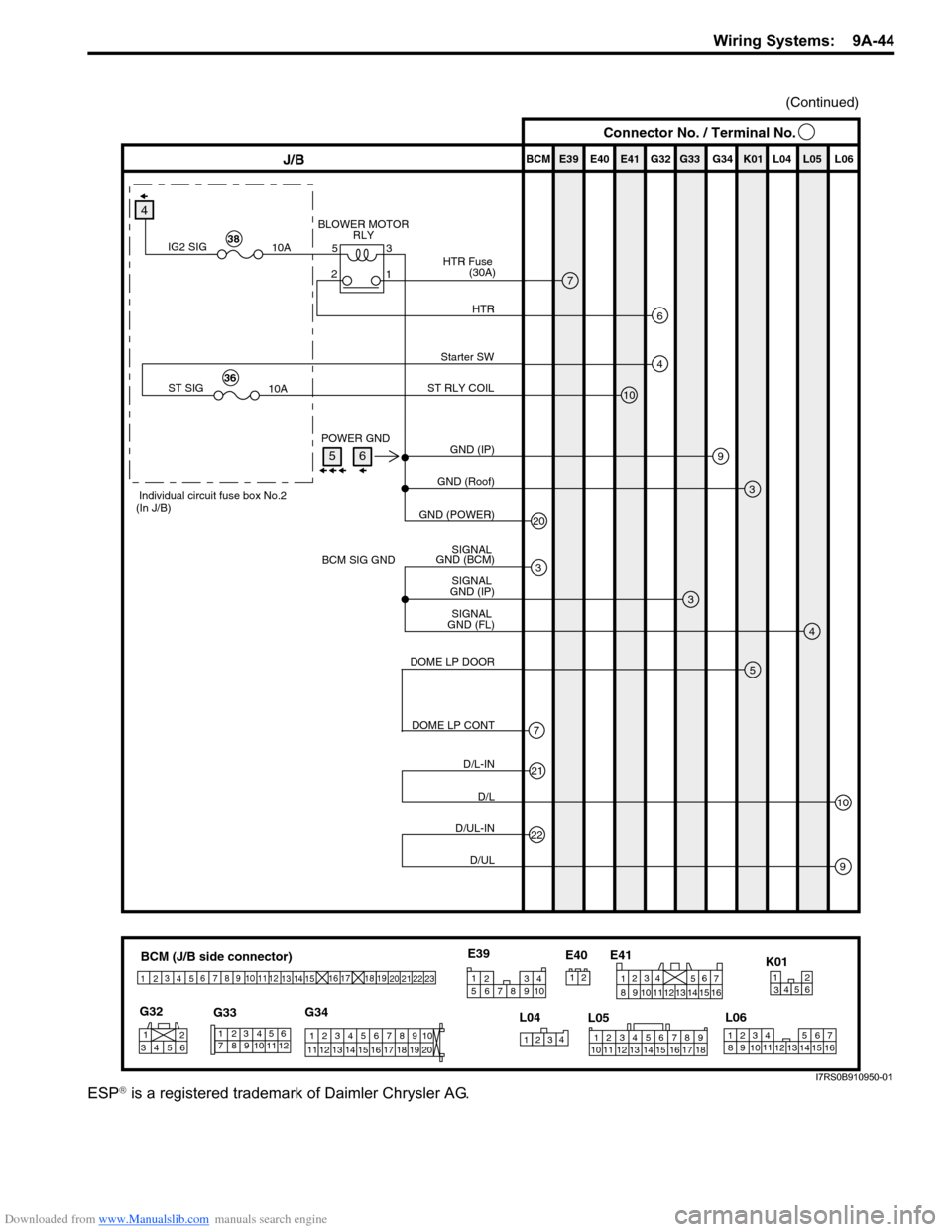

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-44

ESP® is a registered trademark of Daimler Chrysler AG.

BCM (J/B side connector)

34

1

2 5

15

14

12

13

10

11

9

8

6

7

17

161821 22

19

20

23

1234578 11 6

12

91034 6 52

1

G33

G32

G34

10

11 12 13 14 15 16 17 18 19 123456789

20

345612K01

23414

3

561214

11

10 157

2113 16

98

6

5

4

3

2

1

7

11

10

9

8

15

14

13

12 16

L04

L06

E41

21

12 34 5 6 78 9

15 16 17 18

1110 12 13 14

1

234

5 678 910

E39

L05

E40

E39 E41E40

BCM G34G33G32 K01 L04 L05 L06J/B

9

3

3

20

3

4

(Continued)

GND (IP)

POWER GND

BCM SIG GND GND (Roof)

GND (POWER)

SIGNAL

GND (FL) SIGNAL

GND (IP) SIGNAL

GND (BCM)

4

4

10

Starter SW

ST RLY COIL

ST SIG 10A36

Individual circuit fuse box No.2

(In J/B)

7

6

BLOWER MOTOR RLY

HTR

HTR Fuse

(30A)

IG2 SIG 10A38

5

7

DOME LP DOOR

DOME LP CONT

21

22

10

9

D/L-IN D/L

D/UL-IND/UL

3

5

2 1

Connector No. / Terminal No.

56

I7RS0B910950-01

Page 1381 of 1496

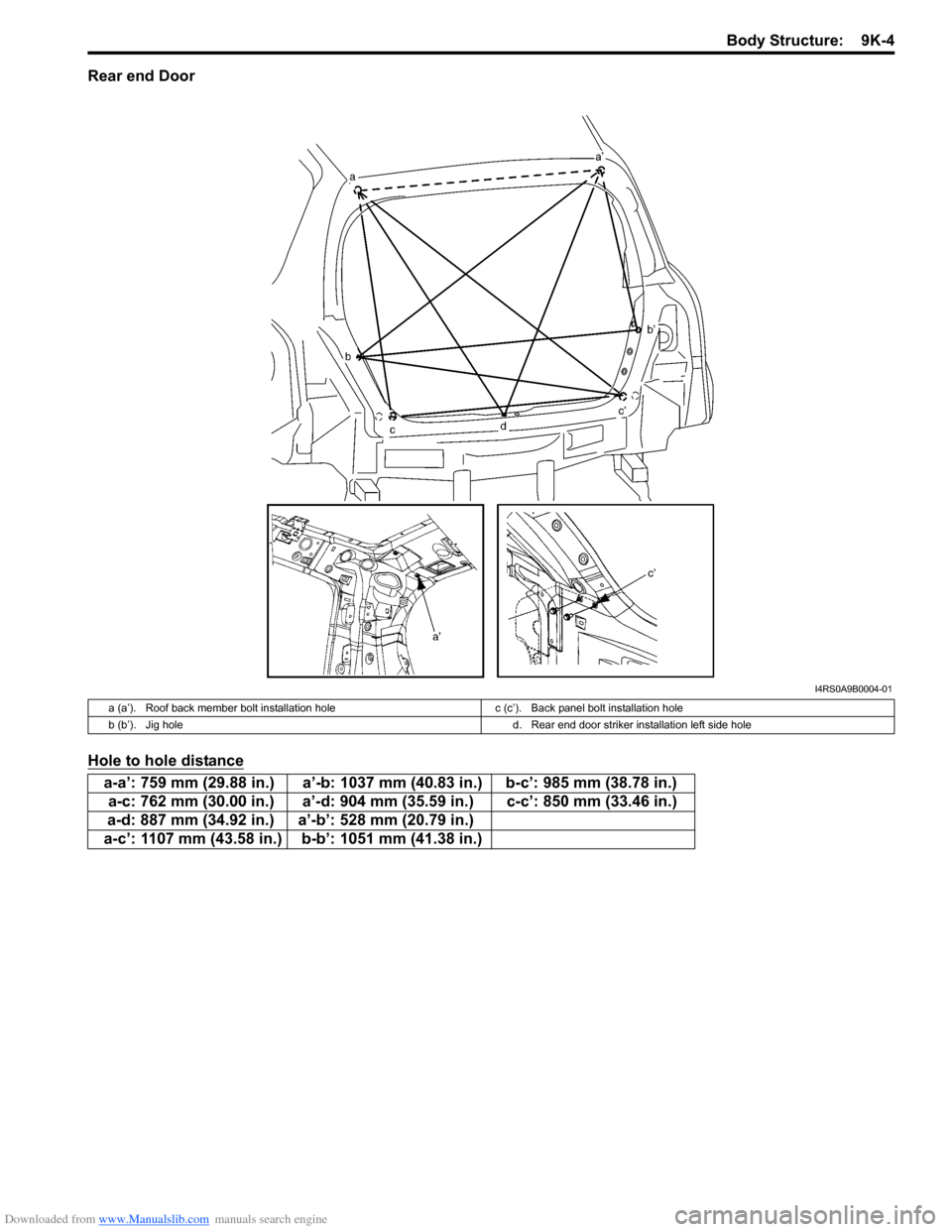

Downloaded from www.Manualslib.com manuals search engine Body Structure: 9K-4

Rear end Door

Hole to hole distance

I4RS0A9B0004-01

a (a’). Roof back member bolt installation holec (c’). Back panel bolt installation hole

b (b’). Jig hole d. Rear end door striker installation left side hole

a-a’: 759 mm (29.88 in.) a’-b: 1037 mm (40.83 in.) b-c’: 985 mm (38.78 in.)

a-c: 762 mm (30.00 in.) a’-d: 904 mm (35.59 in.) c-c’: 850 mm (33.46 in.)

a-d: 887 mm (34.92 in.) a’-b’: 528 mm (20.79 in.)

a-c’: 1107 mm (43.58 in.) b-b’: 1051 mm (41.38 in.)

Page 1388 of 1496

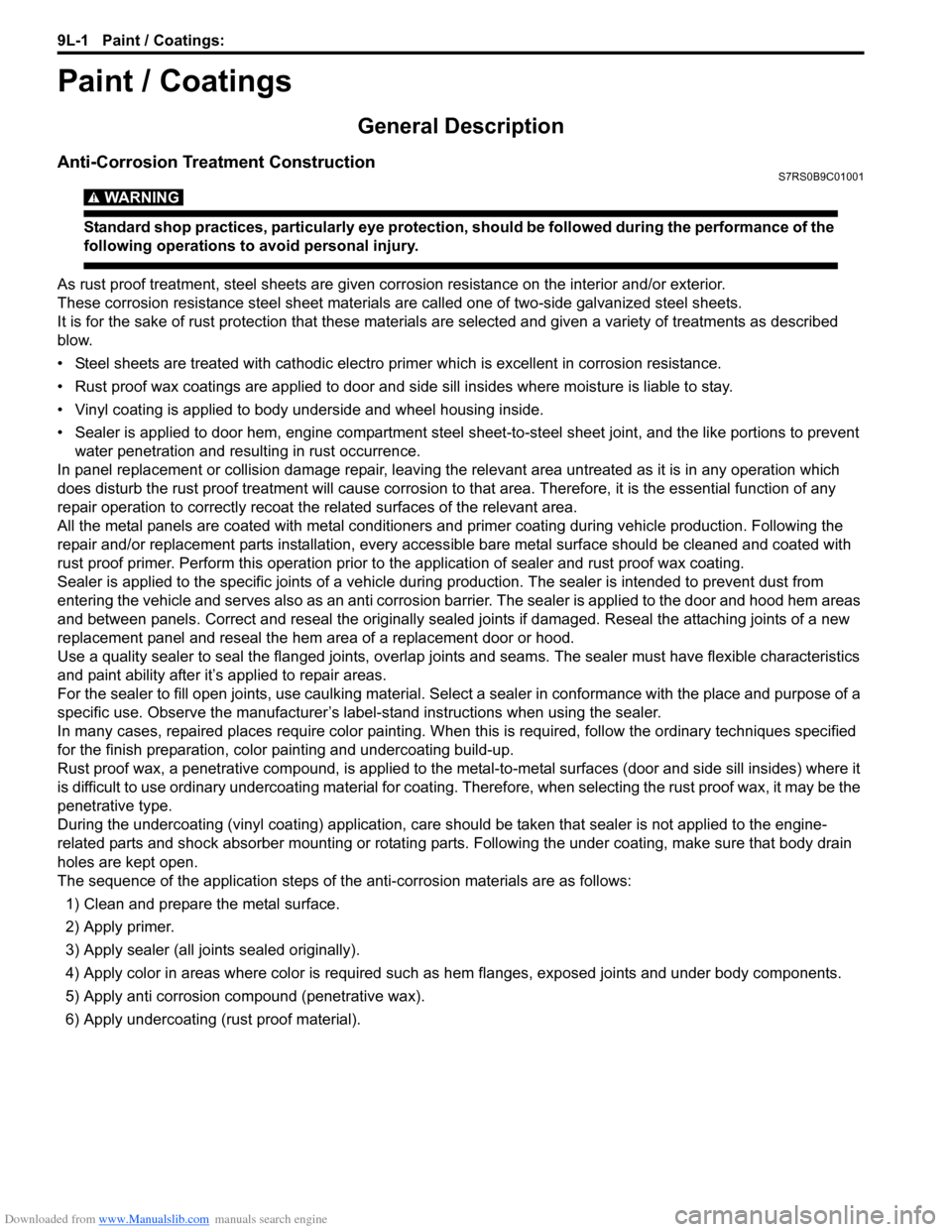

Downloaded from www.Manualslib.com manuals search engine 9L-1 Paint / Coatings:

Body, Cab and Accessories

Paint / Coatings

General Description

Anti-Corrosion Treatment ConstructionS7RS0B9C01001

WARNING!

Standard shop practices, particularly eye protection, should be followed during the performance of the

following operations to avoid personal injury.

As rust proof treatment, steel sheets are given corrosion resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials ar e called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials are selected and given a variety of treatments as described

blow.

• Steel sheets are treated with cathodic electro primer which is excellent in corrosion resistance.

• Rust proof wax coatings are applied to door and side sill insides where mois ture is liable to stay.

• Vinyl coating is applied to body underside and wheel housing inside.

• Sealer is applied to door hem, engine compartment steel sheet-to-steel sheet joint, and the like portions to prevent water penetration and resulting in rust occurrence.

In panel replacement or collision damage repair, leaving the relevant area untreated as it is in any operation which

does disturb the rust proof treatment will cause corrosion to th at area. Therefore, it is the essential function of any

repair operation to correctly recoat t he related surfaces of the relevant area.

All the metal panels are coated with metal conditioners an d primer coating during vehicle production. Following the

repair and/or replacement parts installation, every access ible bare metal surface should be cleaned and coated with

rust proof primer. Perform this operation prior to the application of sealer and rust proof wax coating.

Sealer is applied to the spec ific joints of a vehicle during production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anti corrosion barrier. The sealer is applied to the door and hood hem areas

and between panels. Correct and reseal the originally sealed joints if damaged. Reseal the attaching joints of a new

replacement panel and reseal the hem area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap joints and seams. The sealer must have flexible characteristics

and paint ability after it’s applied to repair areas.

For the sealer to fill open joints, use caulking material. Select a sealer in conf ormance with the place and purpose of a

specific use. Observe the ma nufacturer’s label-stand instructions when using the sealer.

In many cases, repaired places require color painting. When this is required, follow the ordinary techniques specified

for the finish preparation, color painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to the metal-to-metal surfaces (door and side sill insides) where it

is difficult to use ordinary undercoating material for coating. Therefore, when selecting the rust proof wax, it may be the

penetrative type.

During the undercoating (vinyl coating) application, care should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating parts. Following the under coating, make sure that body drain

holes are kept open.

The sequence of the application steps of the anti-corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as hem flanges, exposed joints and under body components.

5) Apply anti corrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).

Page 1397 of 1496

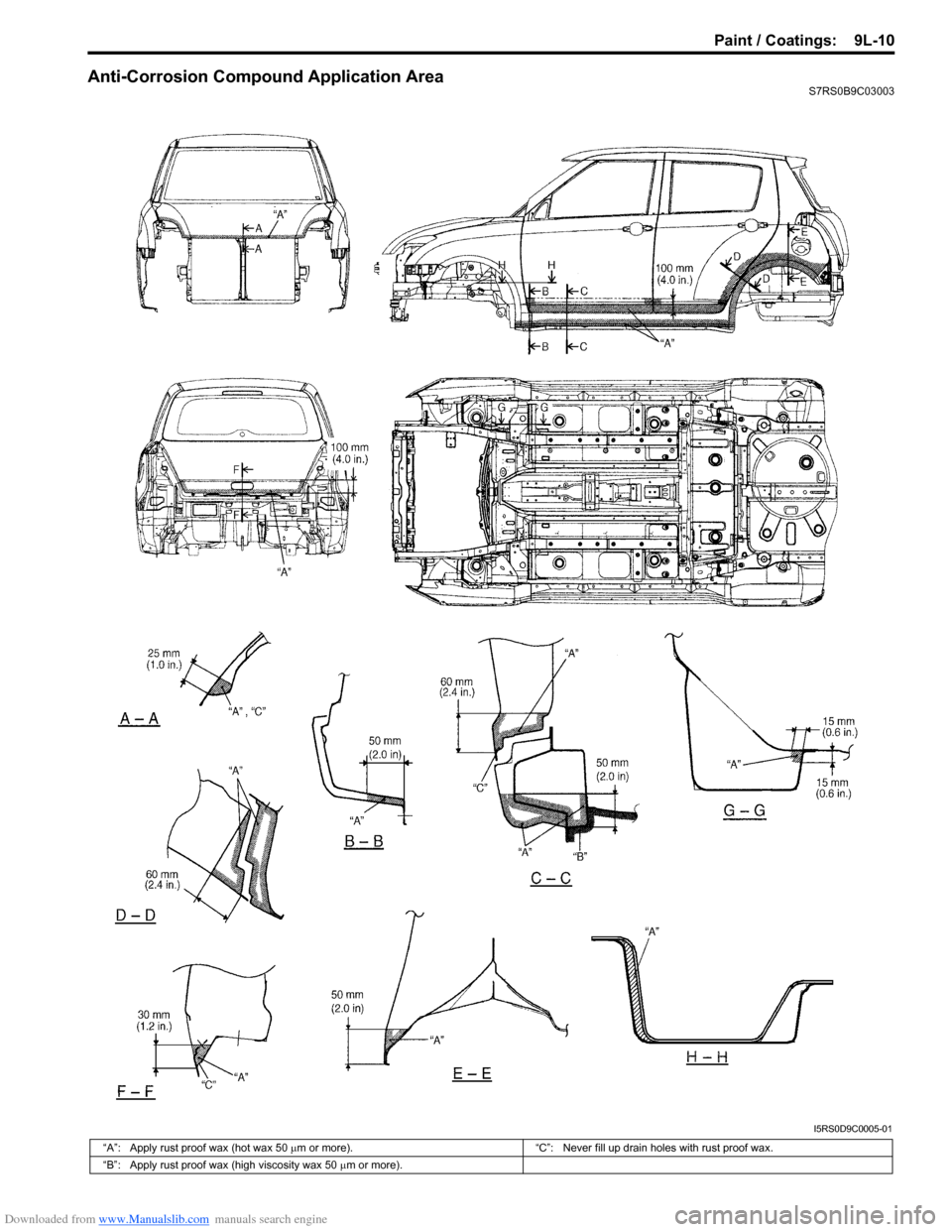

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-10

Anti-Corrosion Compound Application AreaS7RS0B9C03003

I5RS0D9C0005-01

“A”: Apply rust proof wax (hot wax 50 µm or more). “C”: Never fill up drain holes with rust proof wax.

“B”: Apply rust proof wax (high viscosity wax 50 µm or more).

Page 1398 of 1496

![SUZUKI SWIFT 2005 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.0 SUZUKI SWIFT 2005 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.0](/img/20/7607/w960_7607-1397.png)

Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.09 in.)

I6RS0C9D0001-01

[A]: Roof side weather-strip installation position

3. Roof molding clip (Push-in type)

: Install roof molding clip to specified position on body with epoxy adhesive applied.

1. Roof molding 4. Windshield side garnish

2. Roof side weather-strip