can bus SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 200 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-150 Engine General Information and Diagnosis:

DTC P1685: CAN Communication (Reception Error for ABS/ESP® Control Module)S7RS0B1104066

Wiring Diagram

Refer to “DTC P1674: CAN Communication (Bus Off Error)”

DTC detecting Condition and Trouble Area

DTC confirmation procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC. 6

CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors fo rm ECM, BCM and ABS/ESP®

control modules.

3) Check CAN communication circuit for open, short or high resistance.

• Between ECM and ABS/ESP ® control module

• Between ECM and BCM

Is each CAN communication circuit in good condition? Go to Step 7. Repair circuit.

7 DTC check in ECM

1) Connect connectors to ECM, BCM and ABS/ESP ®

control module with ignition switch turned.

2) Check ECM for DTC.

Does ECM communicate with control module other than

BCM (i.e. DTC P1676 and/or DTC P1685 are not detected)? Substitute a known-

good BCM and recheck.

Substitute a known-

good ECM and recheck.

Step

Action YesNo

DTC detecting condition Trouble area

Reception error of communication data for ABS/ESP ®

control module is detected for longer than specified time

continuously.

(1 driving cycle detection logic) •ECM

• ABS/ESP®

control module

• CAN communication circuit

Page 201 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-151

TroubleshootingStep Action Yes No 1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 DTC check in ECM

1) Check ECM for DTC.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error)”.

Go to Step 3.

3 ECM and ABS/ESP ® control module connector check

1) Check for proper connection at each ECM and ABS/ ESP® control module connector terminals with ignition

switch turned OFF.

2) If connections are OK, recheck ECM for DTC with engine running.

Is there DTC P1685? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 DTC check of ABS/ESP ® control module

1) Check DTC U1073 in ABS/ESP ® control module.

Is it indicated? Go to “DTC U1073:

Control Module

Communication Bus Off

in Section 4E” (Non-

ESP®

model) or “DTC

U1073: Control Module

Communication Bus Off

in Section 4F” (ESP ®

module). Go to Step 5.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connector s form ECM and ABS/ESP ®

control module.

3) Check CAN communication circuit between ECM and ABS/ESP ® control module for open, short or high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check in ECM

1) Connect connectors to ECM and ABS/ESP ® control

module with ignition switch turned.

2) Check ECM for DTC.

Does ECM communicate with control module other than

ABS/ESP

® control module (i.e. DTC P1676 and/or DTC

P1678 are not detected)? Substitute a known-

good ABS/ESP

®

control module and

recheck. Substitute a known-

good ECM and recheck.

Page 322 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-37 Engine Mechanical:

Valves and Cylinder Head Disassembly and

Assembly

S7RS0B1406025

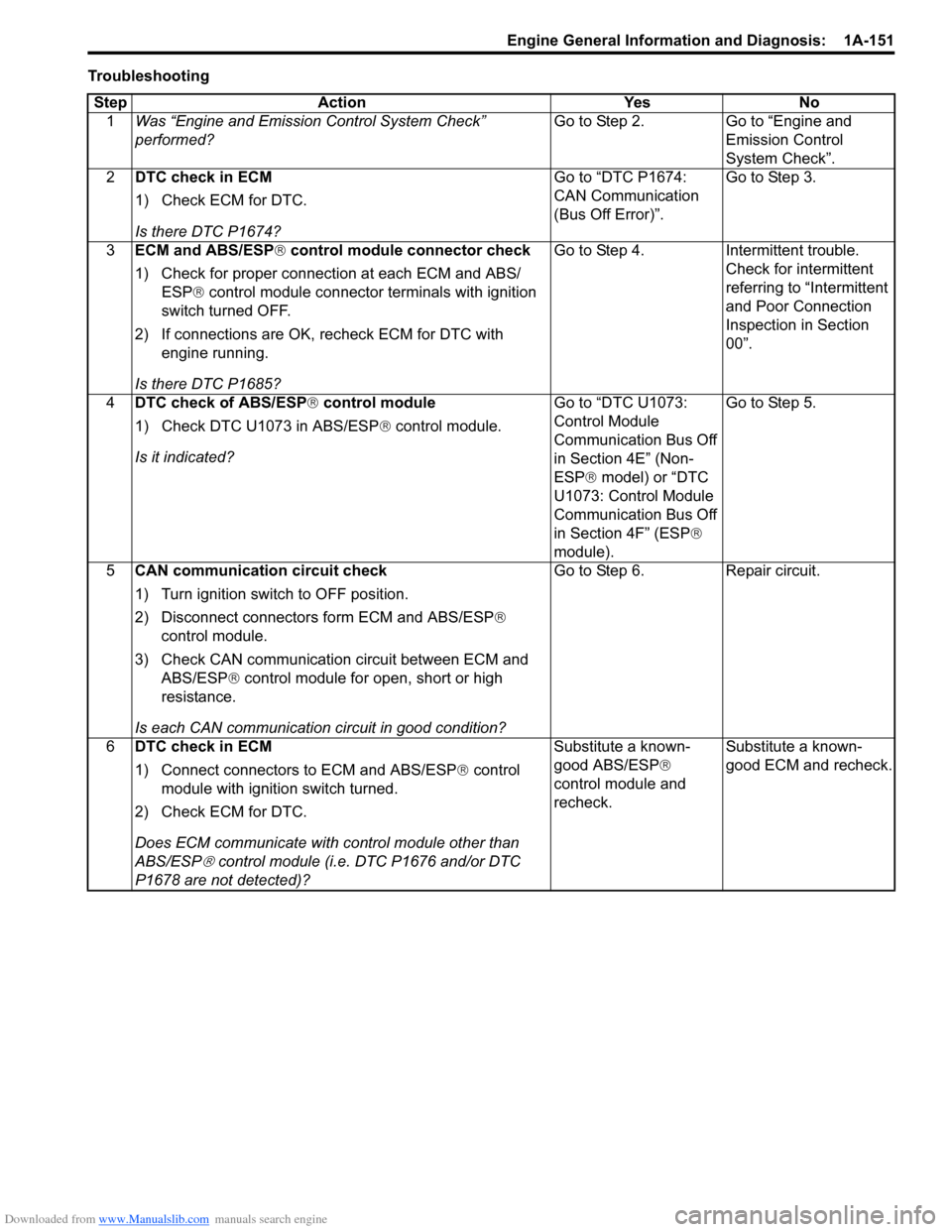

Disassembly1) For ease in servicing cylinder head, remove intake manifold, injectors, exhaust manifold from cylinder

head.

2) Using special tools (Val ve lifter), compress valve

spring and then remove valve cotters (1) also by

using special tool (Forceps).

Special tool

(A): 09916–14510

(B): 09916–14521

(C): 09916–84511 3) Release special tools (Valve lifter), and remove

spring retainer and valve spring.

4) Remove valve from combustion chamber side.

5) Remove valve stem seal (1) from valve guide and valve spring seat (2).

NOTE

Do not reuse valve stem seal once

disassembled. Be sure to use new seal when

assembling.

6) Using special tool (Valve guide remover), drive valve guide out from combustion chamber side to valve

spring side.

Special tool

(A): 09916–44910

NOTE

Do not reuse valve guide once disassembled.

Be sure to use new va lve guide (oversize)

when assembling.

7) Place disassembled parts except valve stem seal

and valve guide in order so that they can be installed

in their original position.

I2RH0B140093-01

I2RH0B140094-01

I2RH0B140095-01

Page 447 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-14

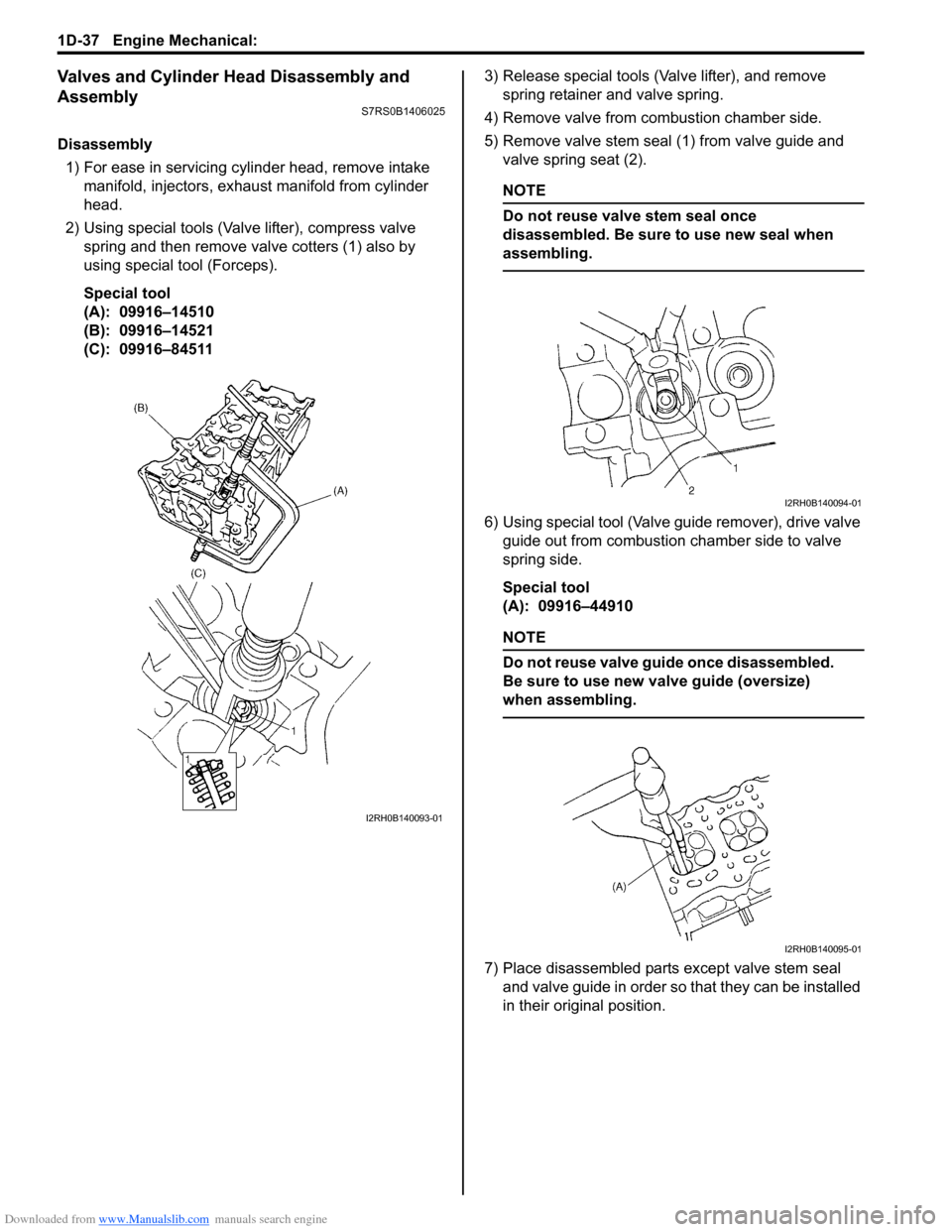

Assembly1) Front bushing Press-fit front bushing (1) by using special tools and

press (2).

Special tool

(A): 09943–76310

(B): 09913–75821

CAUTION!

Be sure to use new bushing.

NOTE

• Before installing bushing, apply soap water on its circumference to facilitate

bushing installation.

2) Press-fit bushing (1) so that dimensions “A” and “B” in figure become equal.

Suspension Control Arm / Steering Knuckle

Check

S7RS0B2206011

Inspect for cracks, deformation or damage.

If defective, replace.

Suspension Control Arm Bushing CheckS7RS0B2206012

Inspect for damage, wear or deterioration.

If defective, replace.

Suspension Control Arm Joint CheckS7RS0B2206013

• Check smooth rotation of ball stud.

• Check damages of ball stud.

• Check damages of dust cover.

NOTE

Suspension control a rm and arm joint cannot

be separated.

If there is any damage to either parts, control arm

assembly must be replaced as a complete unit.

1 2

(A)

(B)

I6RS0C220014-01

I4RS0A220033-01

I6RS0C220015-01

I4RS0B220023-01

Page 452 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-19 Front Suspension:

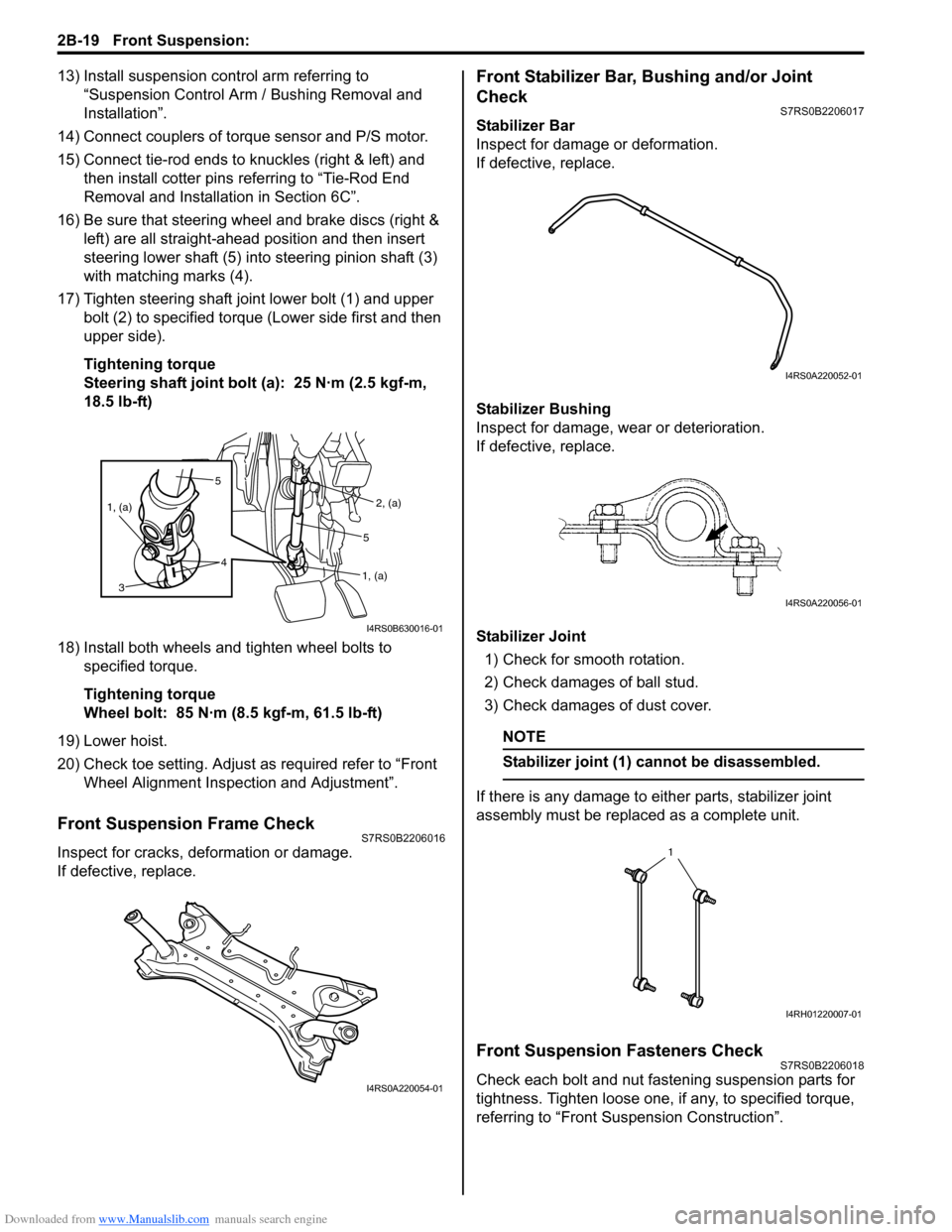

13) Install suspension control arm referring to

“Suspension Control Arm / Bushing Removal and

Installation”.

14) Connect couplers of torque sensor and P/S motor.

15) Connect tie-rod ends to knuckles (right & left) and then install cotter pins referring to “Tie-Rod End

Removal and Installa tion in Section 6C”.

16) Be sure that steering wheel and brake discs (right & left) are all straight-ahead position and then insert

steering lower shaft (5) into steering pinion shaft (3)

with matching marks (4).

17) Tighten steering shaft joint lower bolt (1) and upper bolt (2) to specified torque (Lower side first and then

upper side).

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

18) Install both wheels and tighten wheel bolts to specified torque.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

19) Lower hoist.

20) Check toe setting. Adjust as required refer to “Front Wheel Alignment Inspection and Adjustment”.

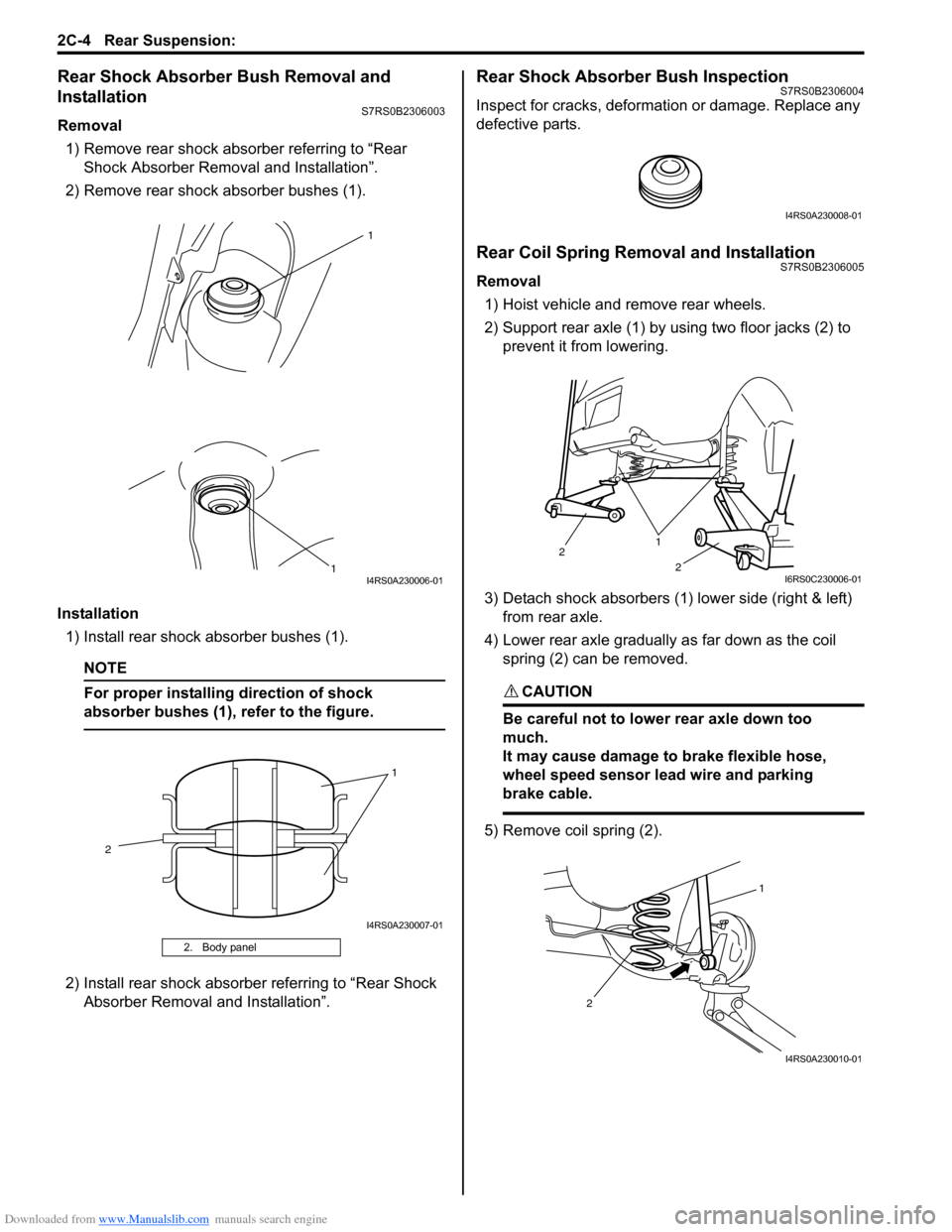

Front Suspension Frame CheckS7RS0B2206016

Inspect for cracks, deformation or damage.

If defective, replace.

Front Stabilizer Bar, Bushing and/or Joint

Check

S7RS0B2206017

Stabilizer Bar

Inspect for damage or deformation.

If defective, replace.

Stabilizer Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

Stabilizer Joint

1) Check for smooth rotation.

2) Check damages of ball stud.

3) Check damages of dust cover.

NOTE

Stabilizer joint (1) cannot be disassembled.

If there is any damage to either parts, stabilizer joint

assembly must be replaced as a complete unit.

Front Suspension Fasteners CheckS7RS0B2206018

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque,

referring to “Front Suspension Construction”.

5

4

1, (a)

3

2, (a)

1, (a)

5

I4RS0B630016-01

I4RS0A220054-01

I4RS0A220052-01

I4RS0A220056-01

1

I4RH01220007-01

Page 458 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-4 Rear Suspension:

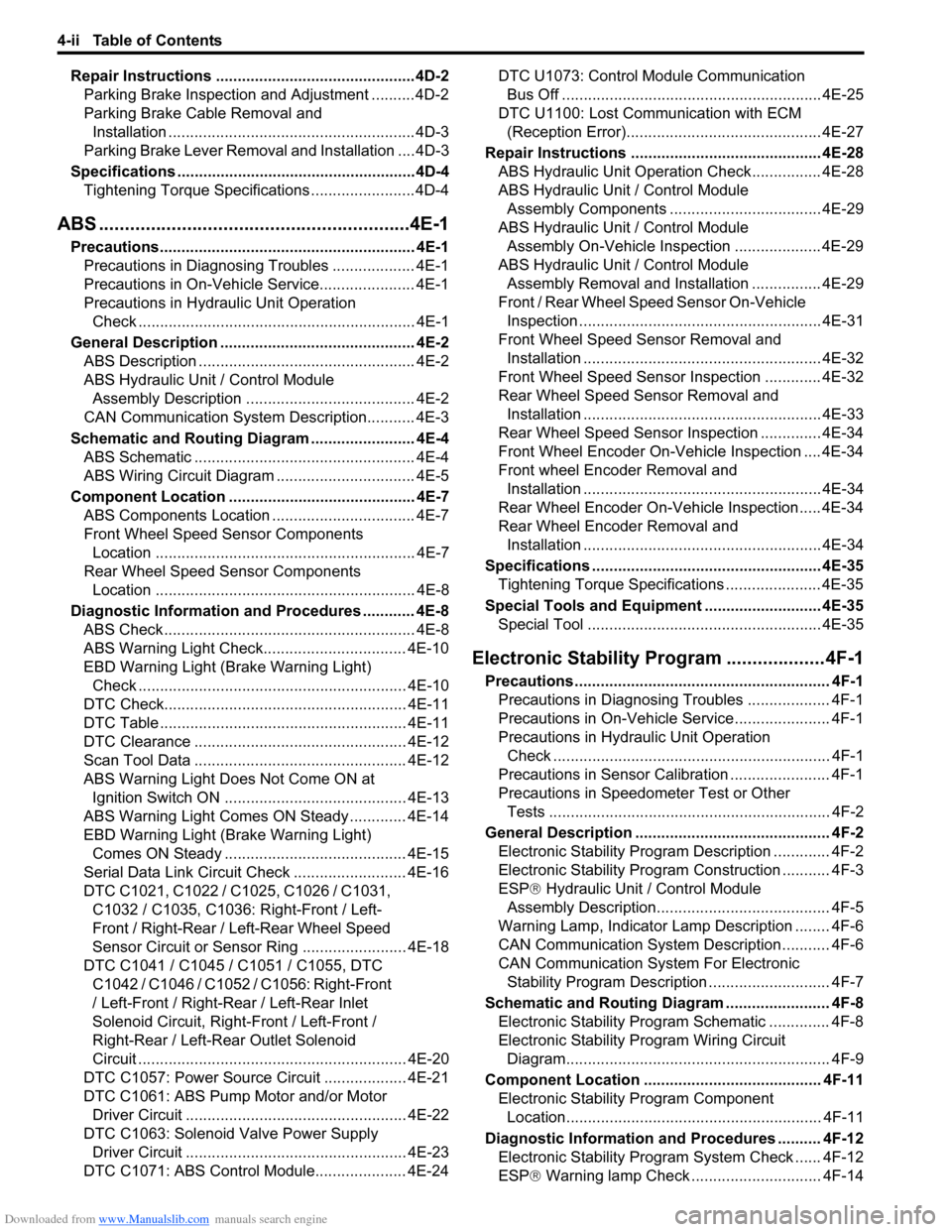

Rear Shock Absorber Bush Removal and

Installation

S7RS0B2306003

Removal1) Remove rear shock absorber referring to “Rear Shock Absorber Remova l and Installation”.

2) Remove rear shock absorber bushes (1).

Installation 1) Install rear shock absorber bushes (1).

NOTE

For proper installing direction of shock

absorber bushes (1), refer to the figure.

2) Install rear shock absorber referring to “Rear Shock Absorber Removal and Installation”.

Rear Shock Absorber Bush InspectionS7RS0B2306004

Inspect for cracks, deformation or damage. Replace any

defective parts.

Rear Coil Spring Removal and InstallationS7RS0B2306005

Removal

1) Hoist vehicle and remove rear wheels.

2) Support rear axle (1) by using two floor jacks (2) to prevent it from lowering.

3) Detach shock absorbers (1) lower side (right & left) from rear axle.

4) Lower rear axle gradually as far down as the coil spring (2) can be removed.

CAUTION!

Be careful not to lowe r rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

5) Remove coil spring (2).

2. Body panel

1

1

I4RS0A230006-01

1

2

I4RS0A230007-01

I4RS0A230008-01

1

2

2

I6RS0C230006-01

1

2

I4RS0A230010-01

Page 496 of 1496

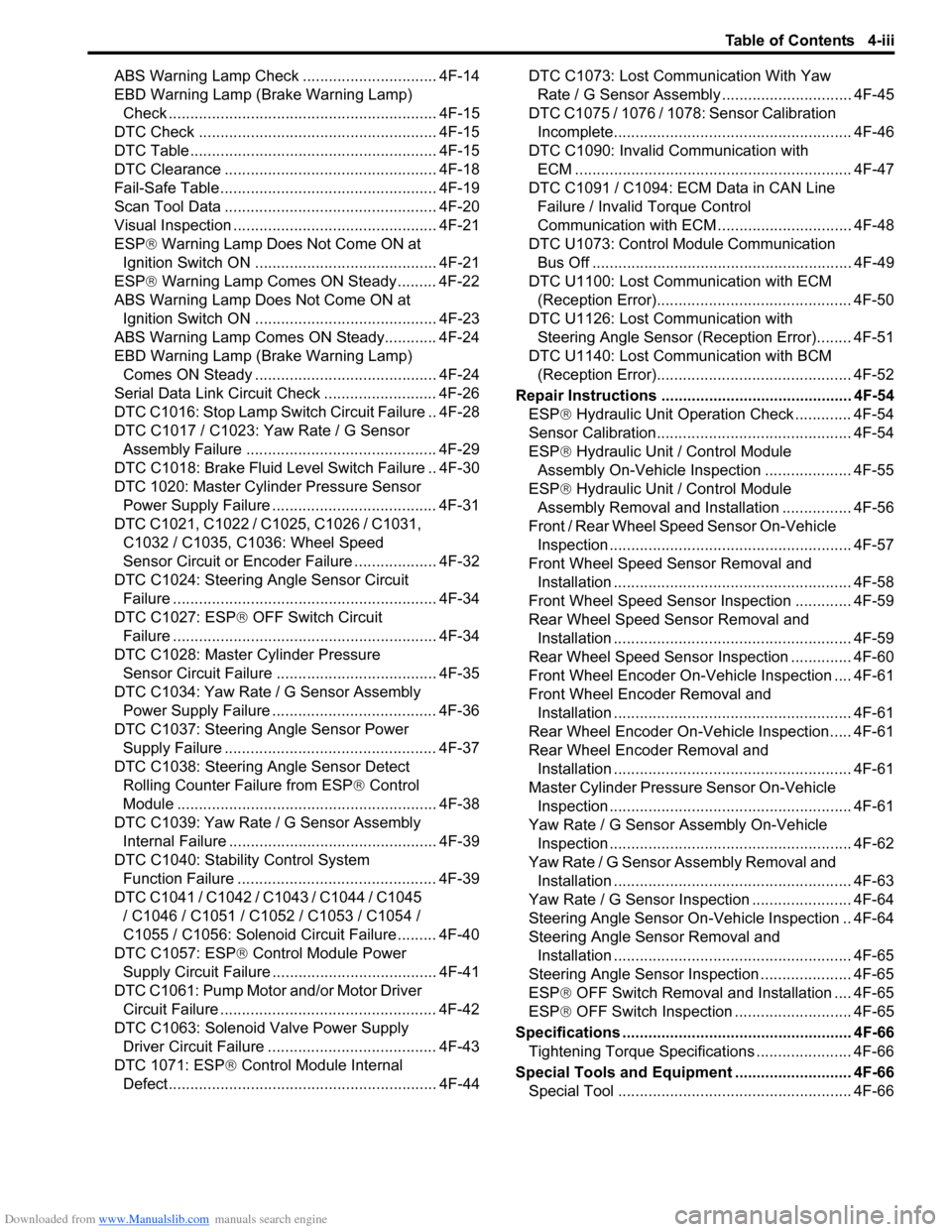

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 550 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-11 ABS:

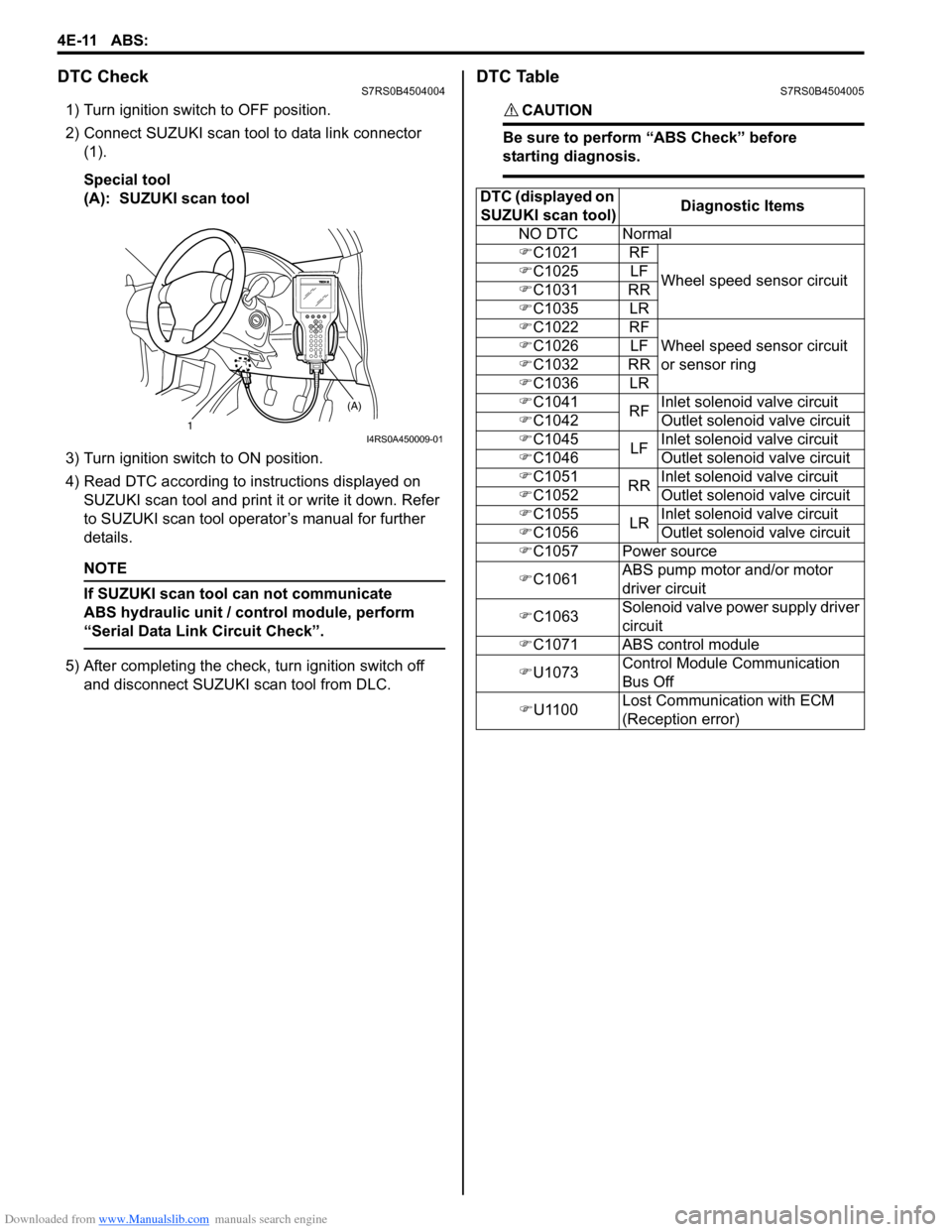

DTC CheckS7RS0B4504004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (1).

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

NOTE

If SUZUKI scan tool can not communicate

ABS hydraulic unit / control module, perform

“Serial Data Link Circuit Check”.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from DLC.

DTC TableS7RS0B4504005

CAUTION!

Be sure to perform “ABS Check” before

starting diagnosis.

1 (A)I4RS0A450009-01

DTC (displayed on

SUZUKI scan tool) Diagnostic Items

NO DTC Normal

�) C1021 RF

Wheel speed sensor circuit

�)

C1025 LF

�) C1031 RR

�) C1035 LR

�) C1022 RF

Wheel speed sensor circuit

or sensor ring

�)

C1026 LF

�) C1032 RR

�) C1036 LR

�) C1041

RFInlet solenoid valve circuit

�) C1042 Outlet solenoid valve circuit

�) C1045

LFInlet solenoid valve circuit

�) C1046 Outlet solenoid valve circuit

�) C1051

RRInlet solenoid valve circuit

�) C1052 Outlet solenoid valve circuit

�) C1055

LRInlet solenoid valve circuit

�) C1056 Outlet solenoid valve circuit

�) C1057 Power source

�) C1061 ABS pump motor and/or motor

driver circuit

�) C1063 Solenoid valve power supply driver

circuit

�) C1071 ABS control module

�) U1073 Control Module

Communication

Bus Off

�) U1100 Lost Communication with ECM

(Reception error)

Page 552 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-13 ABS:

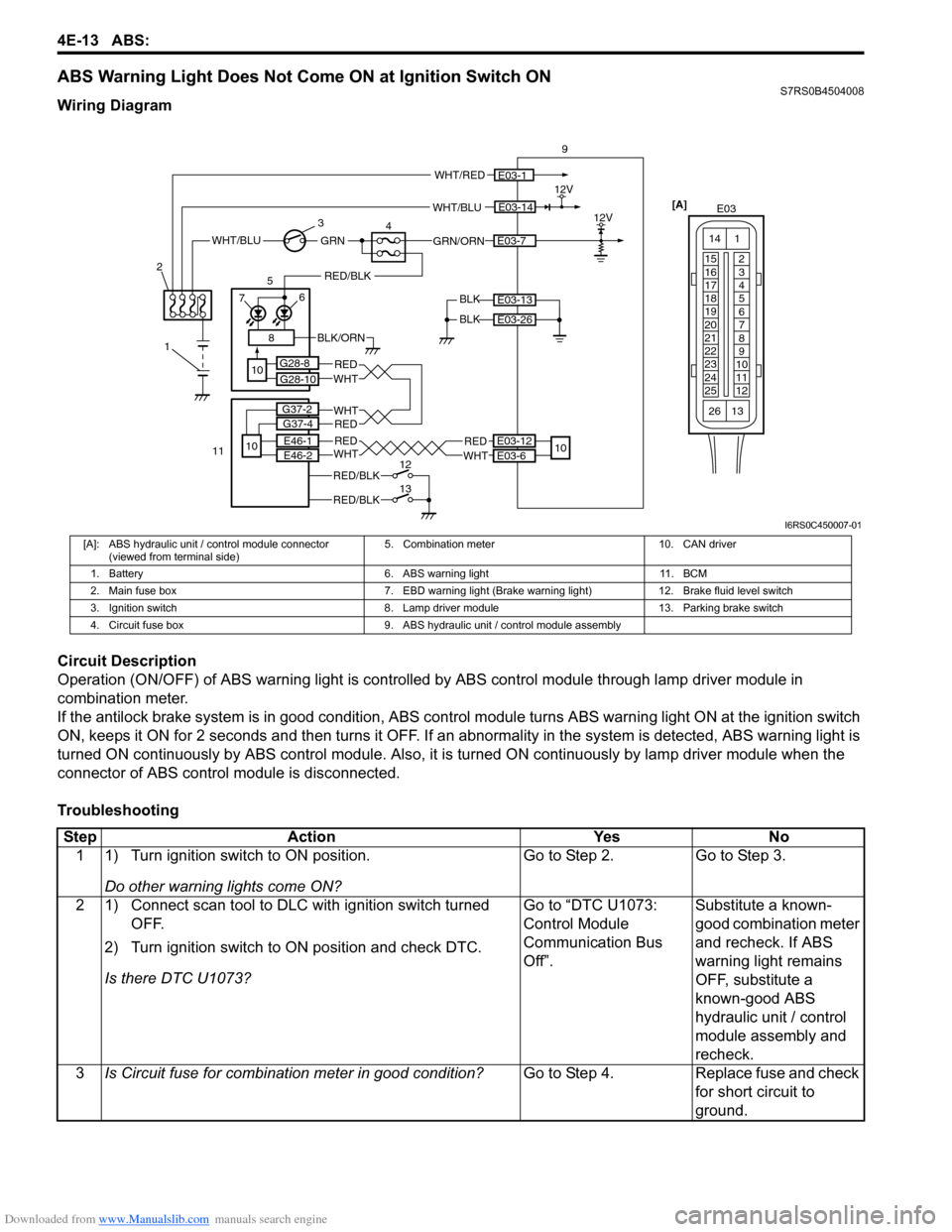

ABS Warning Light Does Not Come ON at Ignition Switch ONS7RS0B4504008

Wiring Diagram

Circuit Description

Operation (ON/OFF) of ABS warning light is controlled by ABS contro l module through lamp driver module in

combination meter.

If the antilock brake system is in good condition, ABS control module turns ABS warning light ON at the ignition switch

ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ABS warning light is

turned ON continuously by ABS control module. Also, it is turned ON continuously by la mp driver module when the

connector of ABS control module is disconnected.

Troubleshooting

WHT/BLU

BLK 12V

9

BLK

E03-14

E03-13

E03-26

WHT/RED

GRN/ORNE03-7WHT/BLUGRN

1

2

3

48

RED/BLK

76

5

10

E03-112V[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

BLK/ORN

E03-12

E03-6

REDWHT

10

G28-8

G28-10

REDWHTE46-1

E46-2

RED/BLK

RED/BLK

RED

RED

WHT

WHT

12

13

11

10

G37-2

G37-4

I6RS0C450007-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 5. Combination meter 10. CAN driver

1. Battery 6. ABS warning light 11. BCM

2. Main fuse box 7. EBD warning light (Brake warning light) 12. Brake fluid level switch

3. Ignition switch 8. Lamp driver module 13. Parking brake switch

4. Circuit fuse box 9. ABS hydraulic unit / control module assembly

Step Action YesNo

1 1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ignition switch to ON position and check DTC.

Is there DTC U1073? Go to “DTC U1073:

Control Module

Communication Bus

Off”.

Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

OFF, substitute a

known-good ABS

hydraulic unit / control

module assembly and

recheck.

3 Is Circuit fuse fo r combination meter in good condition? Go to Step 4.Replace fuse and check

for short circuit to

ground.