instrument panel removal SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1022 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-74 Air Conditioning System: Automatic Type

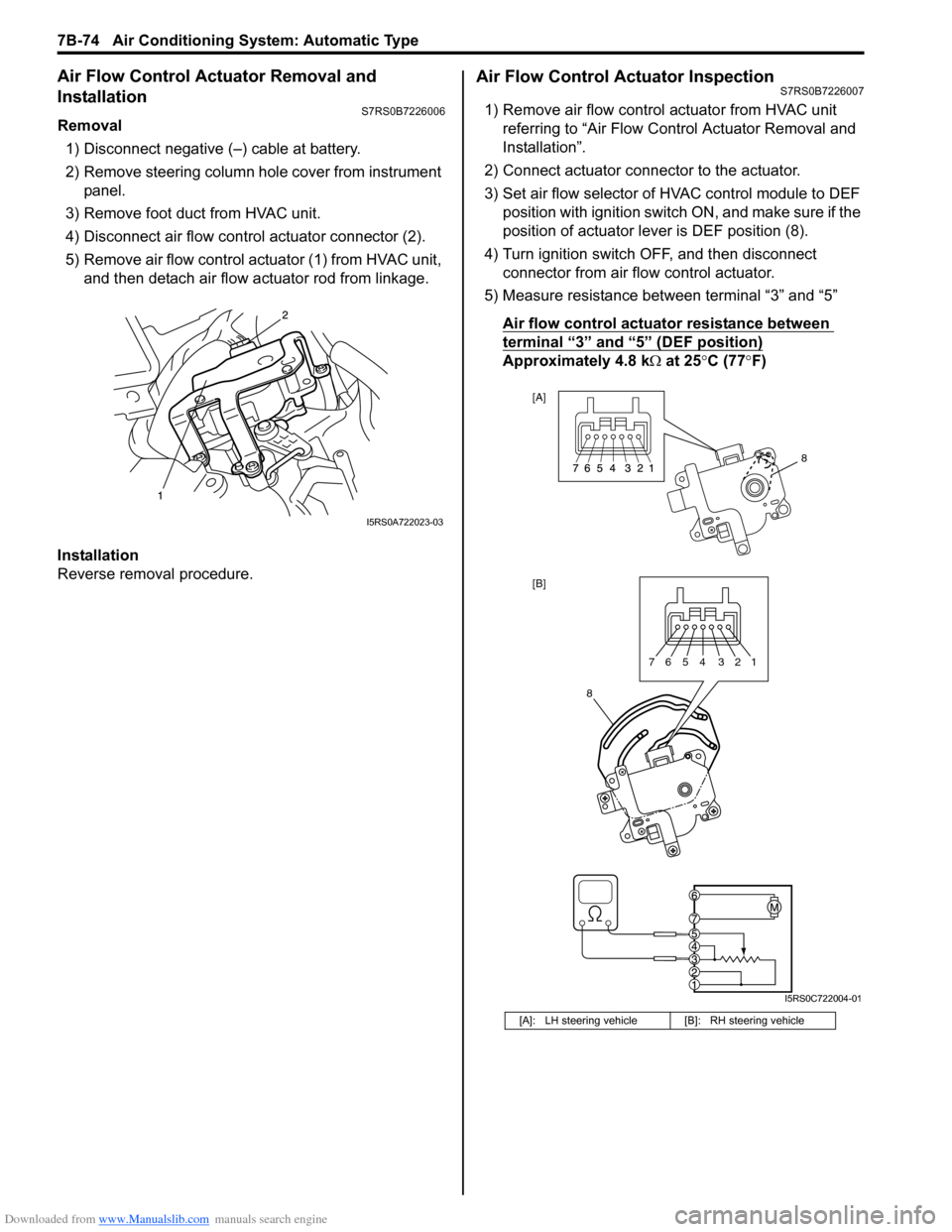

Air Flow Control Actuator Removal and

Installation

S7RS0B7226006

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect air flow contro l actuator connector (2).

5) Remove air flow control actuator (1) from HVAC unit, and then detach air flow actuator rod from linkage.

Installation

Reverse removal procedure.

Air Flow Control Actuator InspectionS7RS0B7226007

1) Remove air flow control actuator from HVAC unit referring to “Air Flow C ontrol Actuator Removal and

Installation”.

2) Connect actuator connector to the actuator.

3) Set air flow selector of HVAC control module to DEF position with ignition switch ON, and make sure if the

position of actuator lever is DEF position (8).

4) Turn ignition switch OFF, and then disconnect connector from air flow control actuator.

5) Measure resistance between terminal “3” and “5”

Air flow control actuator resistance between

terminal “3” and “5” (DEF position)

Approximately 4.8 k Ω at 25 °C (77 °F)

I5RS0A722023-03

[A]: LH steering vehicle [B]: RH steering vehicle

8

[A]

[B]

8

7654 321

I5RS0C722004-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

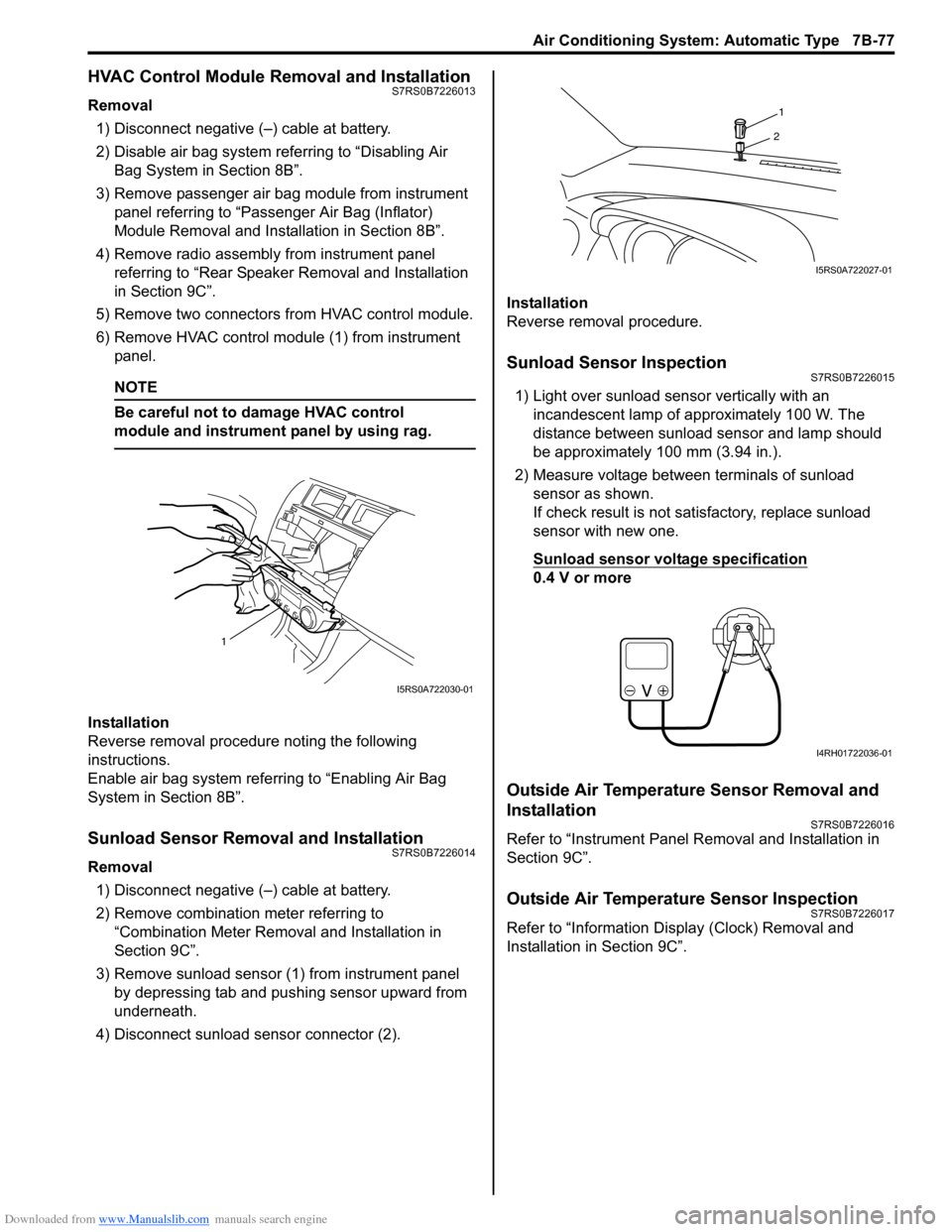

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

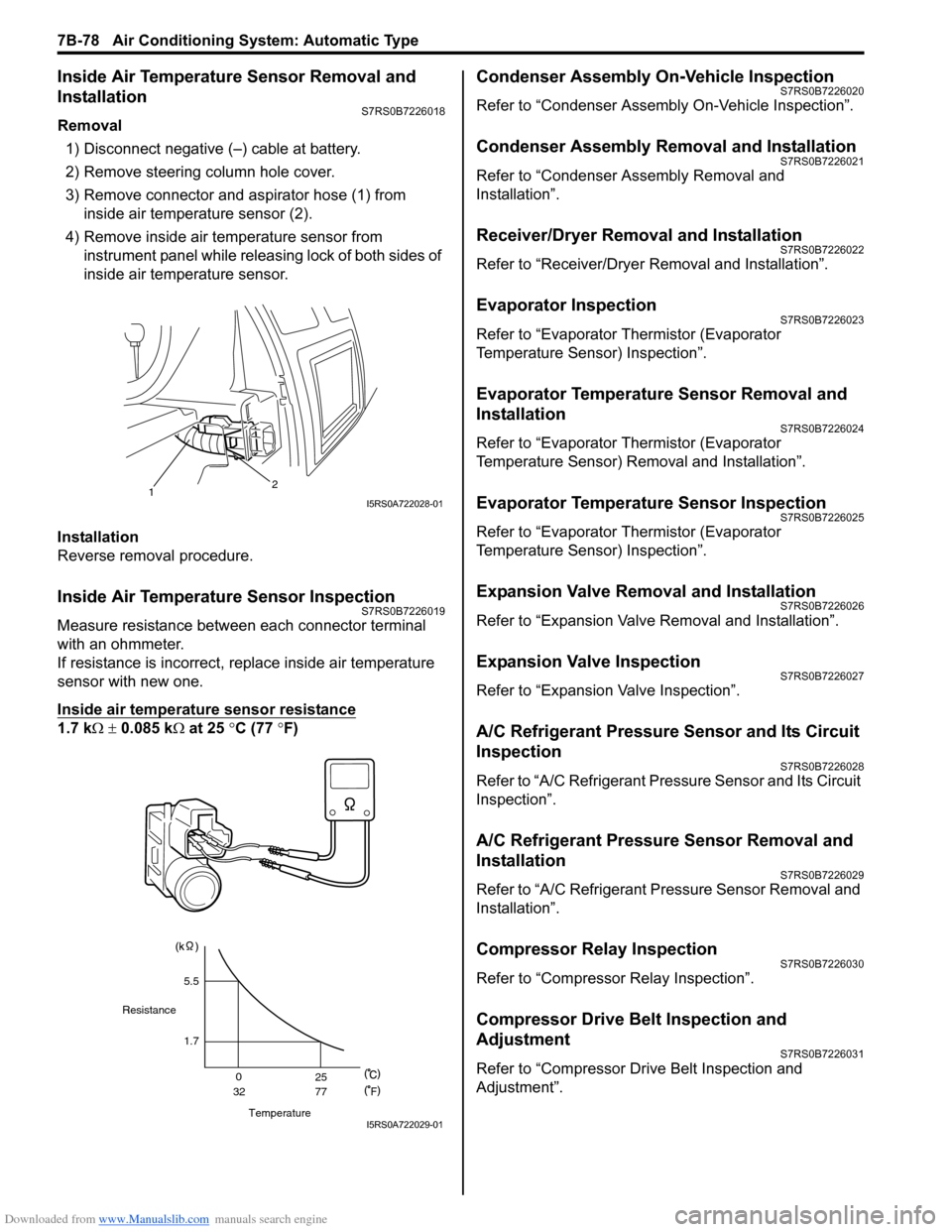

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01

Page 1086 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-48 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adaptor from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The combined resistance of the passenger air bag (inflator) module, harness wiring and connector terminal contact is

below a specified value for specified time.

Flow Test Description

Step 1: Check if malfunction is in passenger air bag (inflator) module.

Step 2: Check passenger air bag (inflator) module initiator circuit. (in instrument panel harness)

Step 3: Check passenger air bag (inflator) module initiator circuit. (in floor harness)

DTC Troubleshooting Step Action YesNo

1 1) With ignition switch OFF, disconnect passenger air bag (inflator) module connector.

2) Check proper connection to passenger air bag (inflator) module at terminals in “G10” connector.

3) If OK, then connect special tools (A), (B) and (D) to “G10” connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(D): 09932–78310

4) Check SDM DTC.

With ignition switch ON , is DTC B1042 indicated? Go to Step 2.

Turn ignition switch

OFF. Replace

passenger air bag

(inflator) module

referring to “Passenger

Air Bag (Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(D)

(A)

"G10"

I4RS0A820021-01

Page 1089 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-51

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adaptor from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at passenger air bag (initiator) circuit is below a specified value for specified time.

Flow Test Description

Step 1: Check if malfunction is in passenger air bag (inflator) module.

Step 2: Check passenger air bag (inflator) module initiator circuit. (in instrument panel harness)

Step 3: Check passenger air bag (inflator) module initiator circuit. (in floor harness)

DTC Troubleshooting Step Action YesNo

1 1) With ignition switch OFF, disconnect passenger air bag (inflator) module connector.

2) Check proper connection to passenger air bag (inflator) module at terminals in “G10” connector.

3) If OK, then connect special tools (A), (B) and (D) to “G10” connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(D): 09932–78310

4) Check SDM DTC.

With ignition switch ON , is DTC B1043 indicated? Go to Step 2.

Turn ignition switch

OFF. Replace

passenger air bag

(inflator) module

referring to “Passenger

Air Bag (Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(D)

(A)

"G10"

I4RS0A820021-01

Page 1092 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-54 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adaptor from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at passenger air bag (initiator) circuit is above a specified value for specified time.

Flow Test Description

Step 1: Check if malfunction is in passenger air bag (inflator) module.

Step 2: Check passenger air bag (inflator) module initiator circuit. (in instrument panel harness)

Step 3: Check passenger air bag (inflator) module initiator circuit. (in floor harness)

DTC Troubleshooting Step Action YesNo

1 1) With ignition switch OFF, disconnect passenger air bag (inflator) module connector.

2) Check proper connection to passenger air bag (inflator) module at terminals in “G10” connector.

3) If OK, then connect special tools (A), (B) and (D) to “G10” connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(D): 09932–78310

4) Check SDM DTC.

With ignition switch ON , is DTC B1044 indicated? Go to Step 3.

Turn ignition switch

OFF. Replace

passenger air bag

(inflator) module

referring to “Passenger

Air Bag (Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(D)

(A)

"G10"

I4RS0A820021-01

Page 1141 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-103

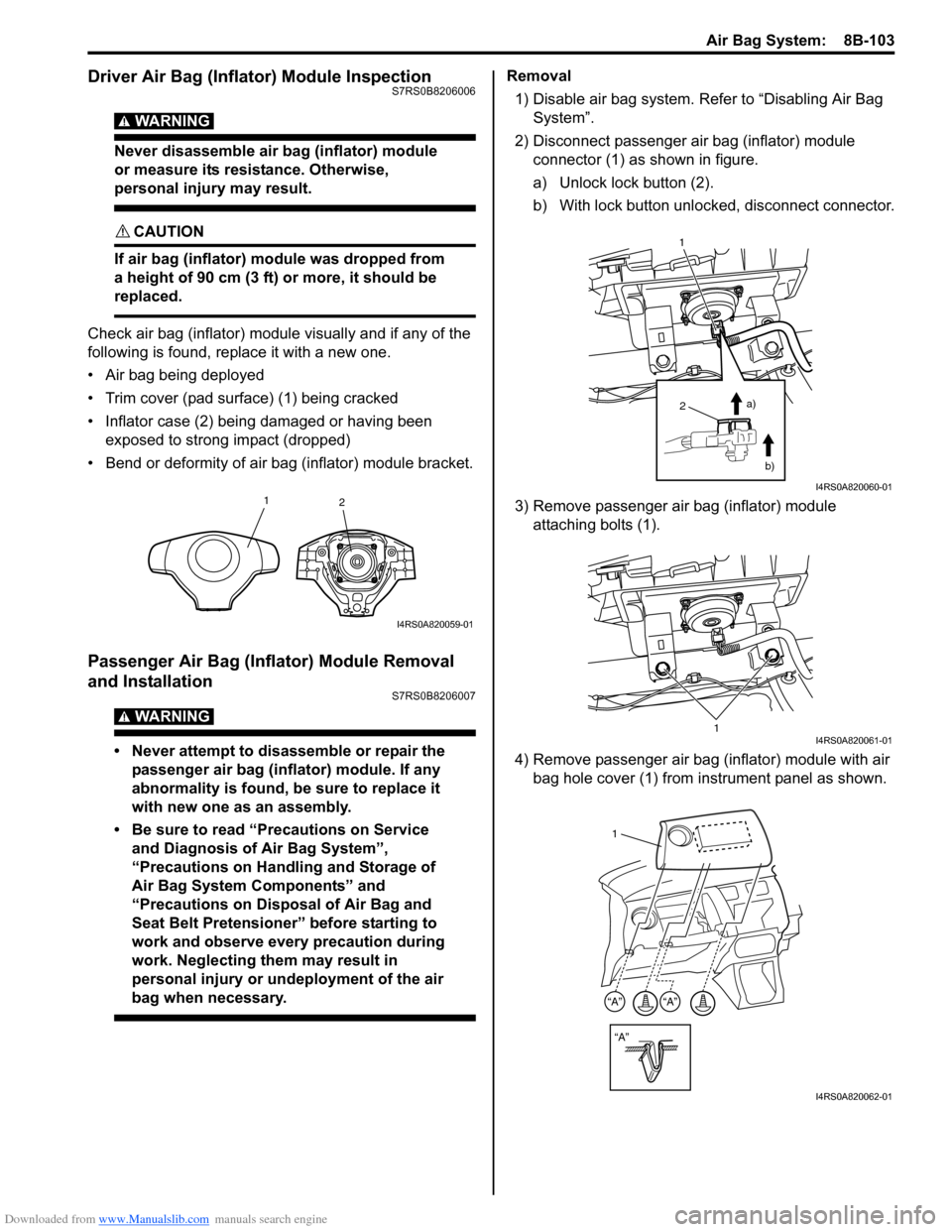

Driver Air Bag (Inflator) Module InspectionS7RS0B8206006

WARNING!

Never disassemble air bag (inflator) module

or measure its resistance. Otherwise,

personal injury may result.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module visually and if any of the

following is found, replace it with a new one.

• Air bag being deployed

• Trim cover (pad surface) (1) being cracked

• Inflator case (2) being damaged or having been exposed to strong impact (dropped)

• Bend or deformity of air bag (inflator) module bracket.

Passenger Air Bag (Inflator) Module Removal

and Installation

S7RS0B8206007

WARNING!

• Never attempt to disassemble or repair the passenger air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

Removal

1) Disable air bag system. Re fer to “Disabling Air Bag

System”.

2) Disconnect passenger air bag (inflator) module connector (1) as shown in figure.

a) Unlock lock button (2).

b) With lock button unlocked, disconnect connector.

3) Remove passenger air bag (inflator) module attaching bolts (1).

4) Remove passenger air bag (inflator) module with air bag hole cover (1) from instrument panel as shown.

1 2

I4RS0A820059-01

2

1

a)b)

I4RS0A820060-01

1I4RS0A820061-01

“A”

“A”“A”

1

I4RS0A820062-01

Page 1169 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-iii

Door Switch (Front / Rear Door) Inspection ...... 9C-17

Rear End Door Switch Inspection ..................... 9C-17

Outside Air Temperature Sensor Removal and Installation (If Equipped) .......................... 9C-17

Outside Air Temperature Sensor Inspection (If Equipped) ................................................... 9C-17

Instrument Panel Removal and Installation....... 9C-18

Information Display (Clock) Removal and Installation ....................................................... 9C-19

Audio Unit Removal and In stallation ................. 9C-19

Front Speaker Removal and Installation ........... 9C-19

Rear Speaker Removal and Installation............ 9C-20

Horn Removal and Installation .......................... 9C-20

Horn Inspection ................................................. 9C-20

Horn Relay Inspection ....................................... 9C-20

Antenna Amplifier Removal and Installation ..... 9C-21

Remote Audio Control Switch Removal and Installation (If Equipped) ................................. 9C-21

Remote Audio Control Switch Inspection (If Equipped)........................................................ 9C-22

Vehicle Speed Signal Inspection (For Audio Unit) (If Equipped) ........................................... 9C-22

Specifications ..................................................... 9C-22

Tightening Torque Specifications ...................... 9C-22

Wipers / Washers............ ......................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis .... 9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions .............................................. 9D-2 Wipers and Washers Components ..................... 9D-2

Washer Tank and Washer Pump Removal and Installation .................................................. 9D-3

Washer Pump Inspection .................................... 9D-3

Windshield Wiper Removal and Installation ........ 9D-4

Windshield Wiper Motor Inspection..................... 9D-5

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection .............................. 9D-7

Windshield Wiper and Washer Switch Removal and Installation................................... 9D-7

Windshield Wiper and Washer Switch Inspection.......................................................... 9D-8

Rear Wiper and Washer Switch Removal and Installation ......................................................... 9D-9

Rear Wiper and Washer Switch Inspection......... 9D-9

Rear Wiper Relay Removal and Installation ..... 9D-10

Rear Wiper Relay Inspection ............................ 9D-10

Specifications ..................................................... 9D-10

Tightening Torque Specifications ...................... 9D-10

Glass / Windows / Mirrors.. ..................... 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System Description ........................................................ 9E-1

Windshield Construction ..................................... 9E-1

Diagnostic Information and Procedures ............ 9E-2 Rear End door Window Defogger Symptom Diagnosis .......................................................... 9E-2 Power Window Control System Symptom

Diagnosis .......................................................... 9E-2

Power Door Mirror Control System Symptom Diagnosis .......................................................... 9E-3

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-3

Repair Instructions ........... ................................... 9E-4

Windshield Removal and In stallation .................. 9E-4

Front Door Window Components ........................ 9E-8

Front Door Glass Removal and Installation ........ 9E-8

Front Door Window Re gulator Removal and

Installation ......................................................... 9E-9

Front Door Window Regula tor Inspection ......... 9E-10

Rear Door Window Components ...................... 9E-10

Rear Door Glass Removal and Installation ....... 9E-11

Rear Door Window Regulator Removal and Installation ....................................................... 9E-12

Rear Door Window Regulato r Inspection .......... 9E-12

Rear End Door Window Components ............... 9E-13

Rear End Door Glass Removal and Installation ....................................................... 9E-13

Rear End Door Window Defogger Switch Inspection ........................................................ 9E-14

Rear End Door Window Defogger Relay Inspection ........................................................ 9E-14

Rear End Door Window Defogger Wire Inspection ........................................................ 9E-15

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-15

Power Window Main Switch Inspection ............ 9E-16

Power Window Sub Switch Inspection .............. 9E-17

Door Mirror Components.. ................................. 9E-18

Door Mirror Removal and In stallation................ 9E-18

Power Door Mirror Switch Inspection ................ 9E-18

Power Door Mirror Actuator Inspection ............. 9E-19

Door Mirror Heater Switch Inspection (If Equipped) ........................................................ 9E-19

Door Mirror Heater Inspec tion (If Equipped) ..... 9E-19

Special Tools and Equipmen t ........................... 9E-19

Recommended Service Material ....................... 9E-19

Security and Locks......... ..........................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ............ ............................... 9F-2

Power Door Lock and Keyless Entry System

Component Location ......................................... 9F-2

Diagnostic Information and Procedures ............ 9F-3 Power Door Lock System Symptom Diagnosis .......................................................... 9F-3

Power Door Lock System Operation Inspection .......................................................... 9F-3

Keyless Entry System Symptom Diagnosis (If

Equipped) .......................................................... 9F-4

Keyless Entry System Operation Inspection ....... 9F-5

Door Lock Function of Keyless Start System Symptom Diagnosis (If Equipped)..................... 9F-5

Page 1310 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-15 Instrumentation / Driver Info. / Horn:

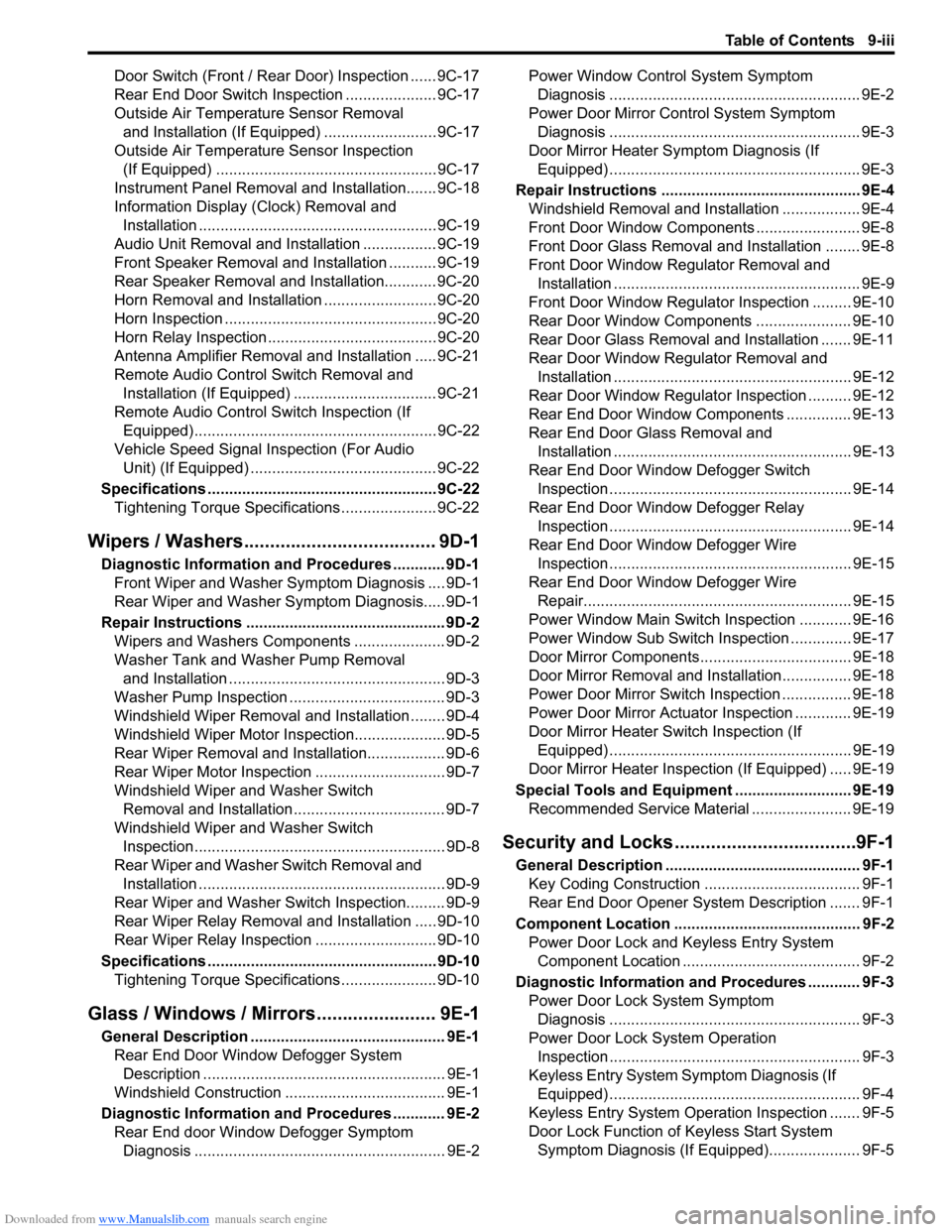

Combination Meter Removal and InstallationS7RS0B9306003

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover (1) pulling it in arrow direction shown in figure.

3) Remove combination mete r cluster panel (1) pulling

it in arrow direction shown in figure.

4) Remove screws (1) fast ening combination meter.

5) Remove combination me ter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

Fuel Level Sensor Removal and InstallationS7RS0B9306004

For removal and installation, refer to “Main Fuel Level

Sensor Removal and Installation in Section 1G”.

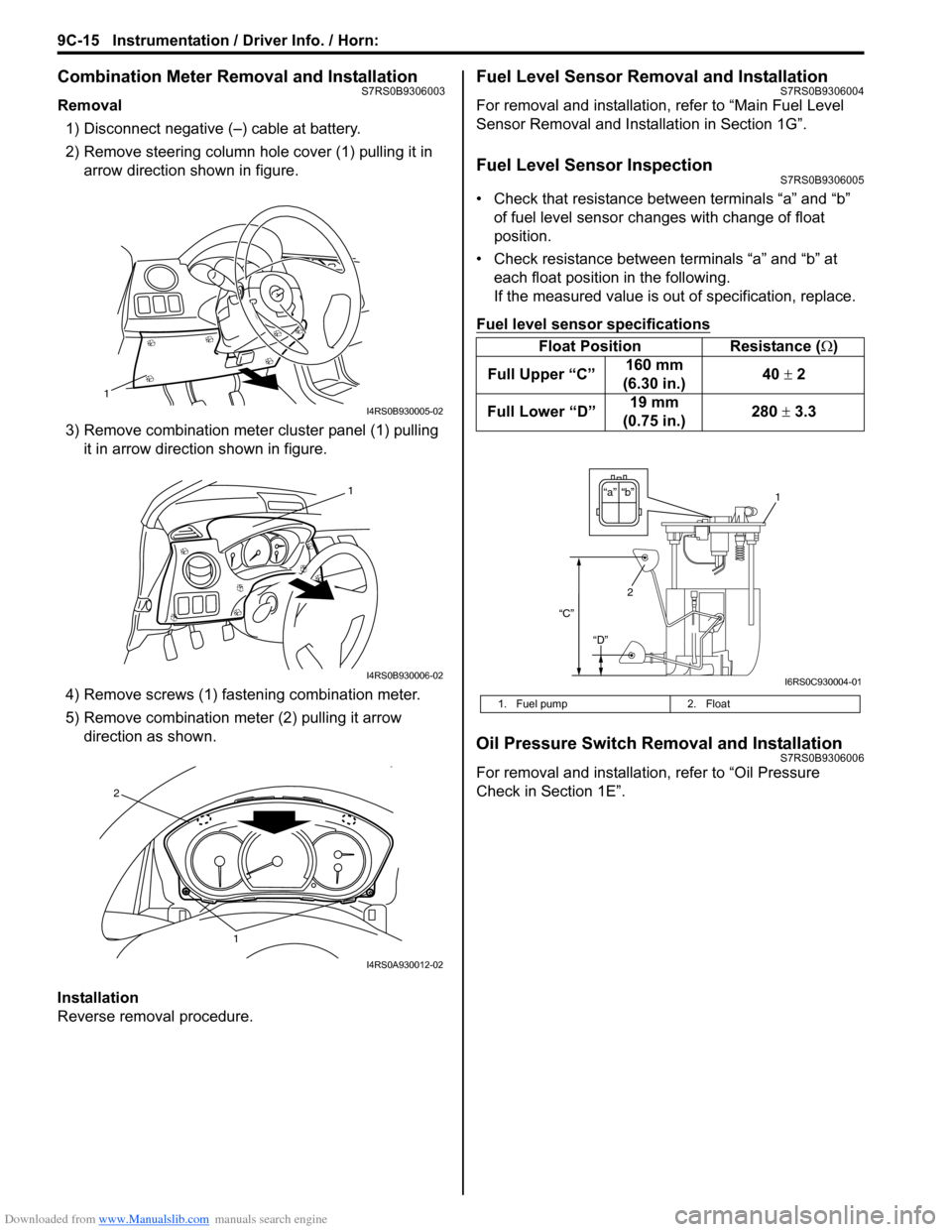

Fuel Level Sensor InspectionS7RS0B9306005

• Check that resistance between terminals “a” and “b” of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS7RS0B9306006

For removal and installation , refer to “Oil Pressure

Check in Section 1E”.

1

I4RS0B930005-02

1

I4RS0B930006-02

1

2

I4RS0A930012-02

Float Position Resistance (Ω)

Full Upper “C” 160 mm

(6.30 in.) 40

± 2

Full Lower “D” 19 mm

(0.75 in.) 280

± 3.3

1. Fuel pump 2. Float

“b”“a”

2

“C”

“D”

1

I6RS0C930004-01

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

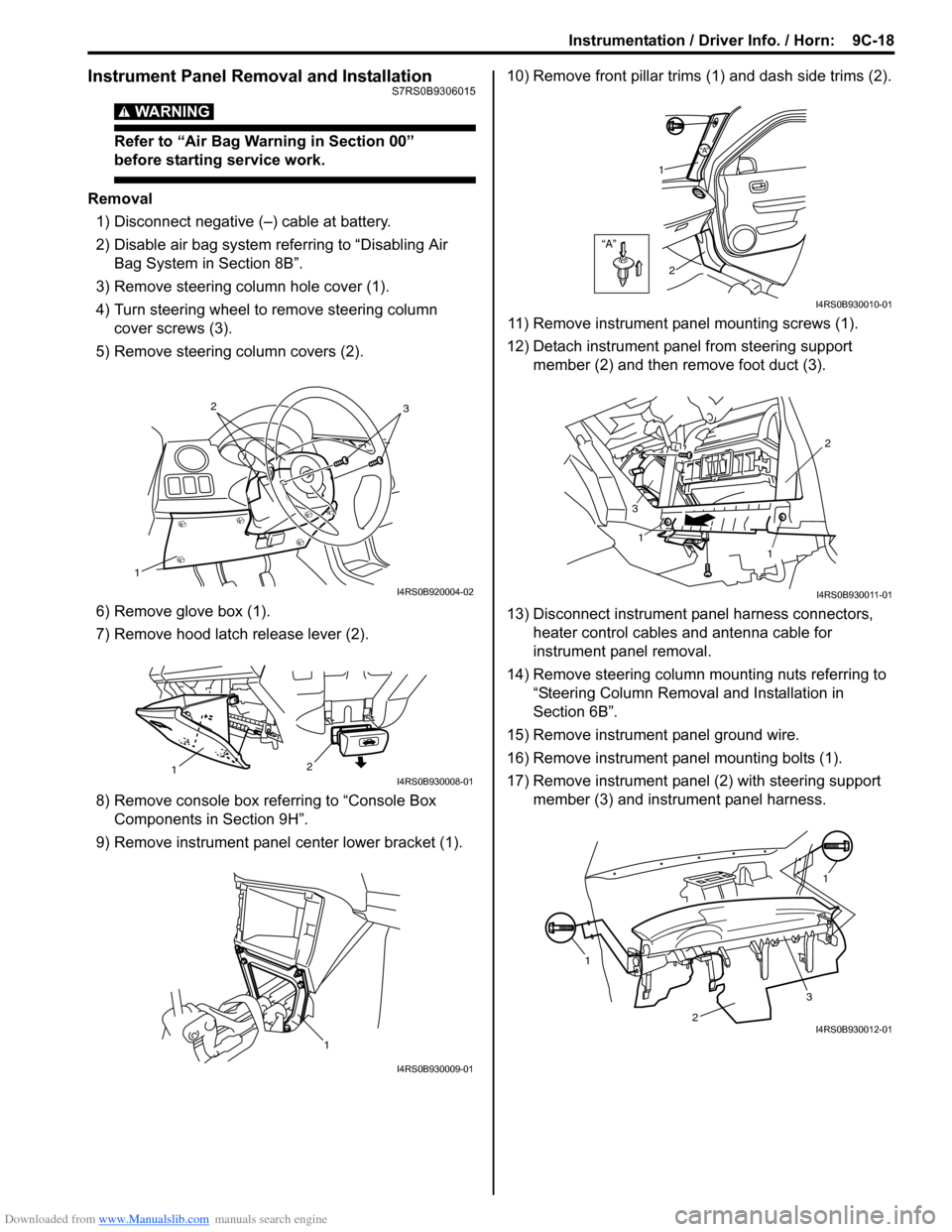

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01