Transmission SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1296 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-1 Instrumentation / Driver Info. / Horn:

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS7RS0B9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, engine coolant temp meter, warning light and indicator light (other than air bag warning

light, high beam indicator light, EPS warn ing light and turn signal indicator light). Therefore, check that no DTC is

detected in each module before performing combination me ter symptom diagnosis. If any DTC is detected, correct

trouble indicated by that DTC troubleshooting first.

General Description

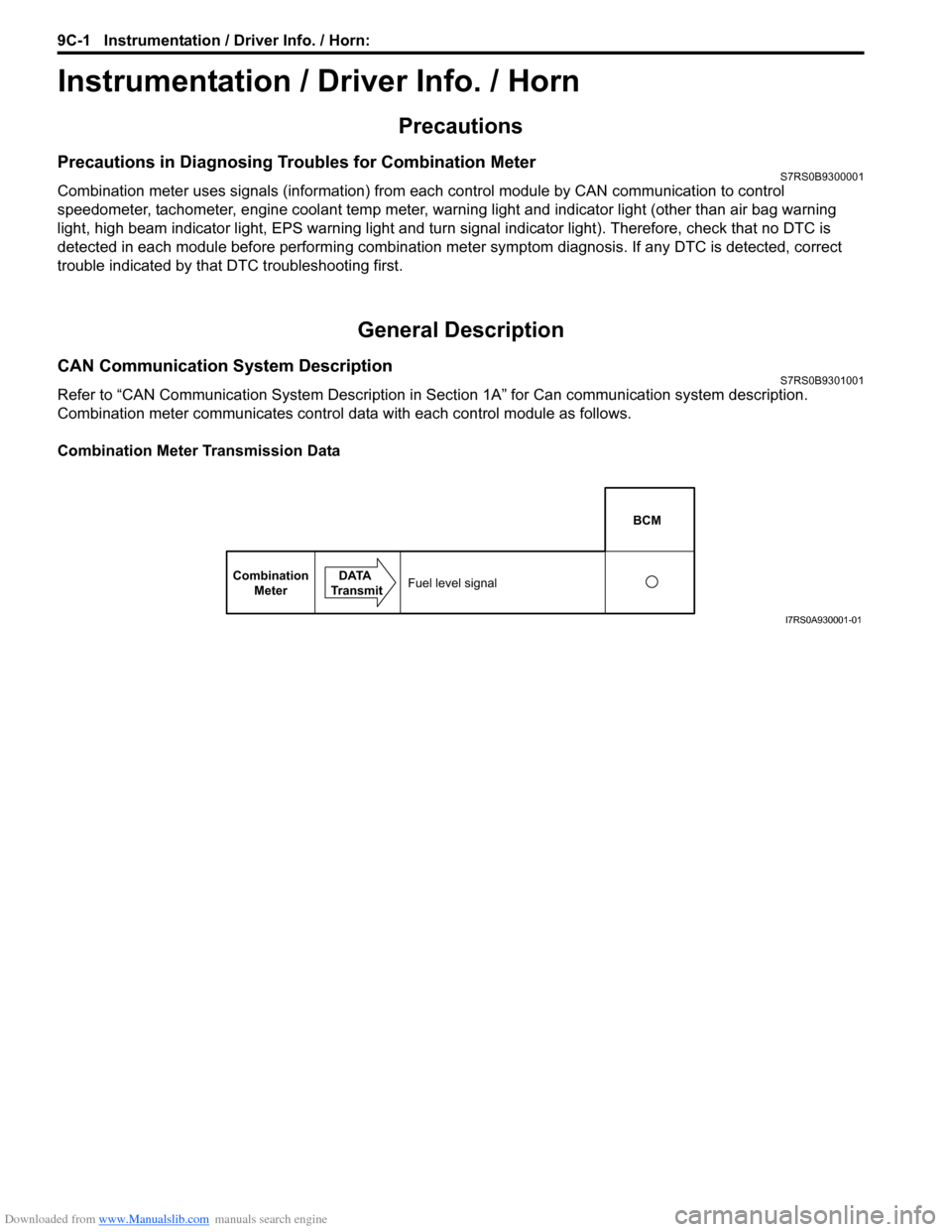

CAN Communication System DescriptionS7RS0B9301001

Refer to “CAN Communication System Description in Section 1A” for Can communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination Meter DATA

TransmitFuel level signal

I7RS0A930001-01

Page 1297 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-2

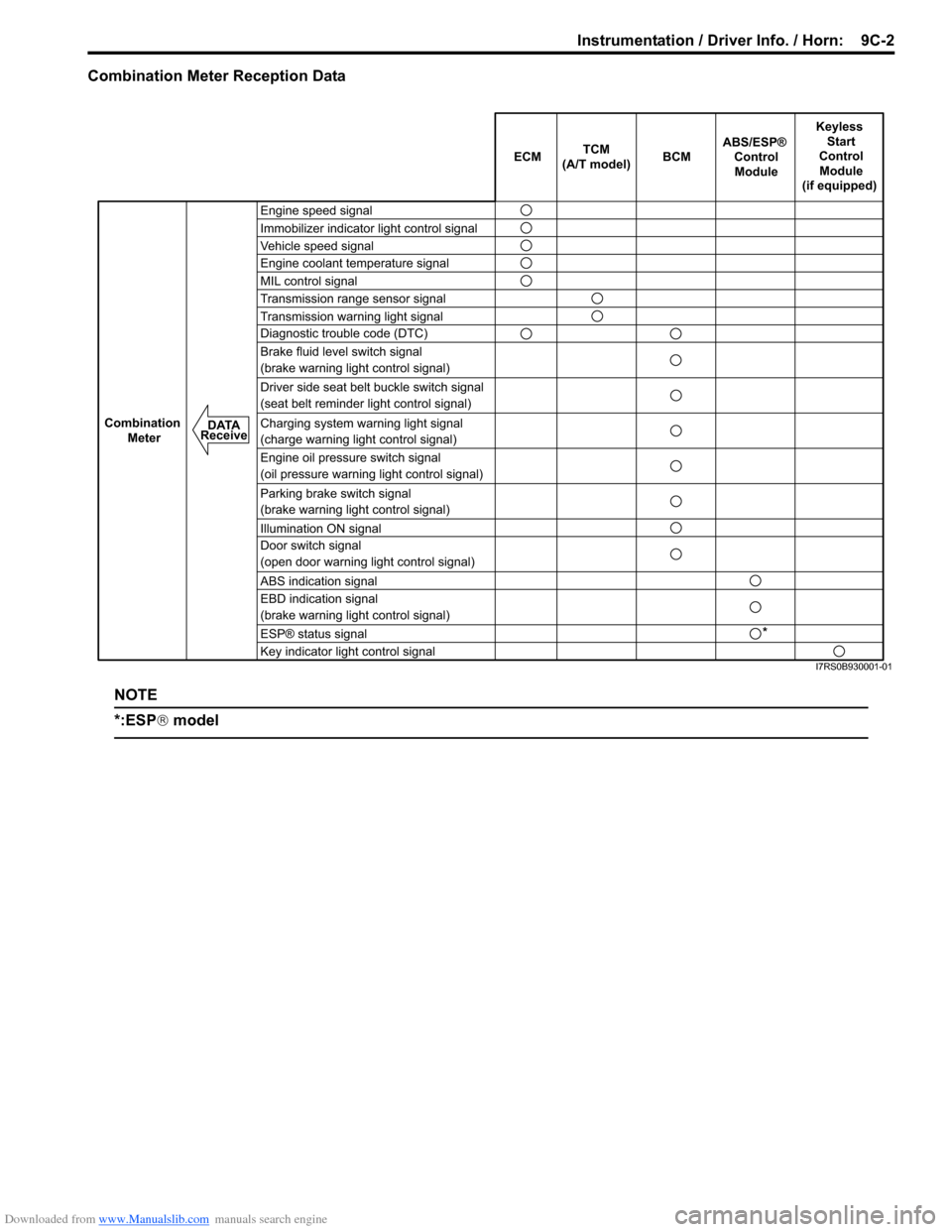

Combination Meter Reception Data

NOTE

*:ESP® model

ECM BCM

Keyless

Start

Control Module

(if equipped)

Combination Meter

TCM

(A/T model)

Engine speed signal

Immobilizer indicator light control signal

Vehicle speed signal

Engine coolant temperature signal

MIL control signal

Transmission range sensor signal

Transmission warning light signal

Diagnostic trouble code (DTC)

Brake fluid level switch signal

(brake warning light control signal)

Driver side seat belt buckle switch signal

(seat belt reminder light control signal)

Charging system warning light signal

(charge warning light control signal)

Engine oil pressure switch signal

(oil pressure warning light control signal)

Parking brake switch signal

(brake warning light control signal)

Illumination ON signal

Door switch signal

(open door warning light control signal)

ABS indication signal

EBD indication signal

(brake warning light control signal)

Key indicator light control signal ABS/ESP®

ControlModule

DATA

Receive

*

ESP® status signal

I7RS0B930001-01

Page 1304 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-9 Instrumentation / Driver Info. / Horn:

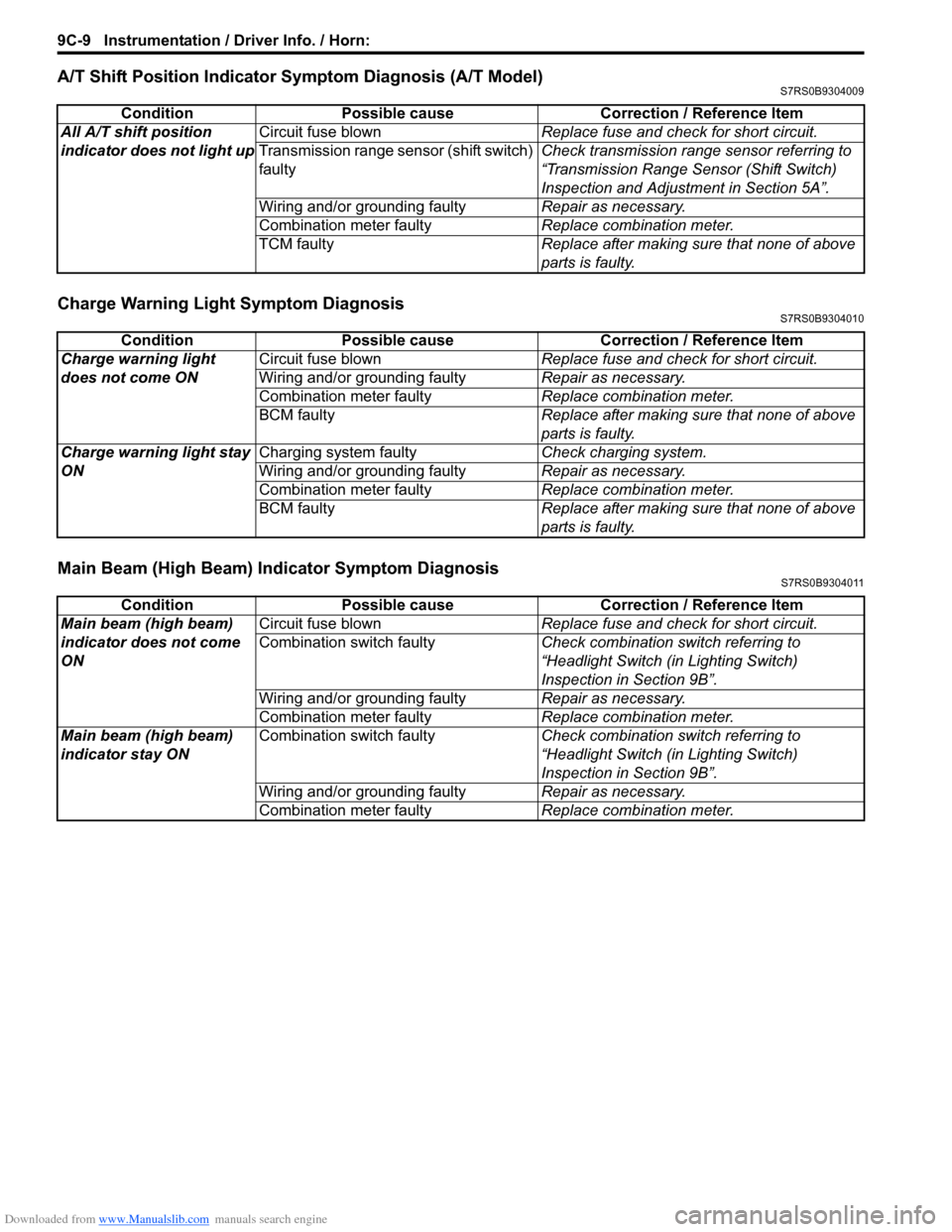

A/T Shift Position Indicator Symptom Diagnosis (A/T Model)S7RS0B9304009

Charge Warning Light Symptom DiagnosisS7RS0B9304010

Main Beam (High Beam) Indicator Symptom DiagnosisS7RS0B9304011

ConditionPossible cause Correction / Reference Item

All A/T shift position

indicator does not light up Circuit fuse blown

Replace fuse and check for short circuit.

Transmission range sens or (shift switch)

faulty Check transmission range sensor referring to

“Transmission Range Sensor (Shift Switch)

Inspection and Adjustment in Section 5A”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

TCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Charge warning light

does not come ON Circuit fuse blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

BCM faulty Replace after making sure that none of above

parts is faulty.

Charge warning light stay

ON Charging system faulty

Check charging system.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Main beam (high beam)

indicator does not come

ON Circuit fuse blown

Replace fuse and check for short circuit.

Combination switch faulty Check combination switch referring to

“Headlight Switch (in Lighting Switch)

Inspection in Section 9B”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Main beam (high beam)

indicator stay ON Combination switch faulty

Check combination switch referring to

“Headlight Switch (in Lighting Switch)

Inspection in Section 9B”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Page 1405 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-2

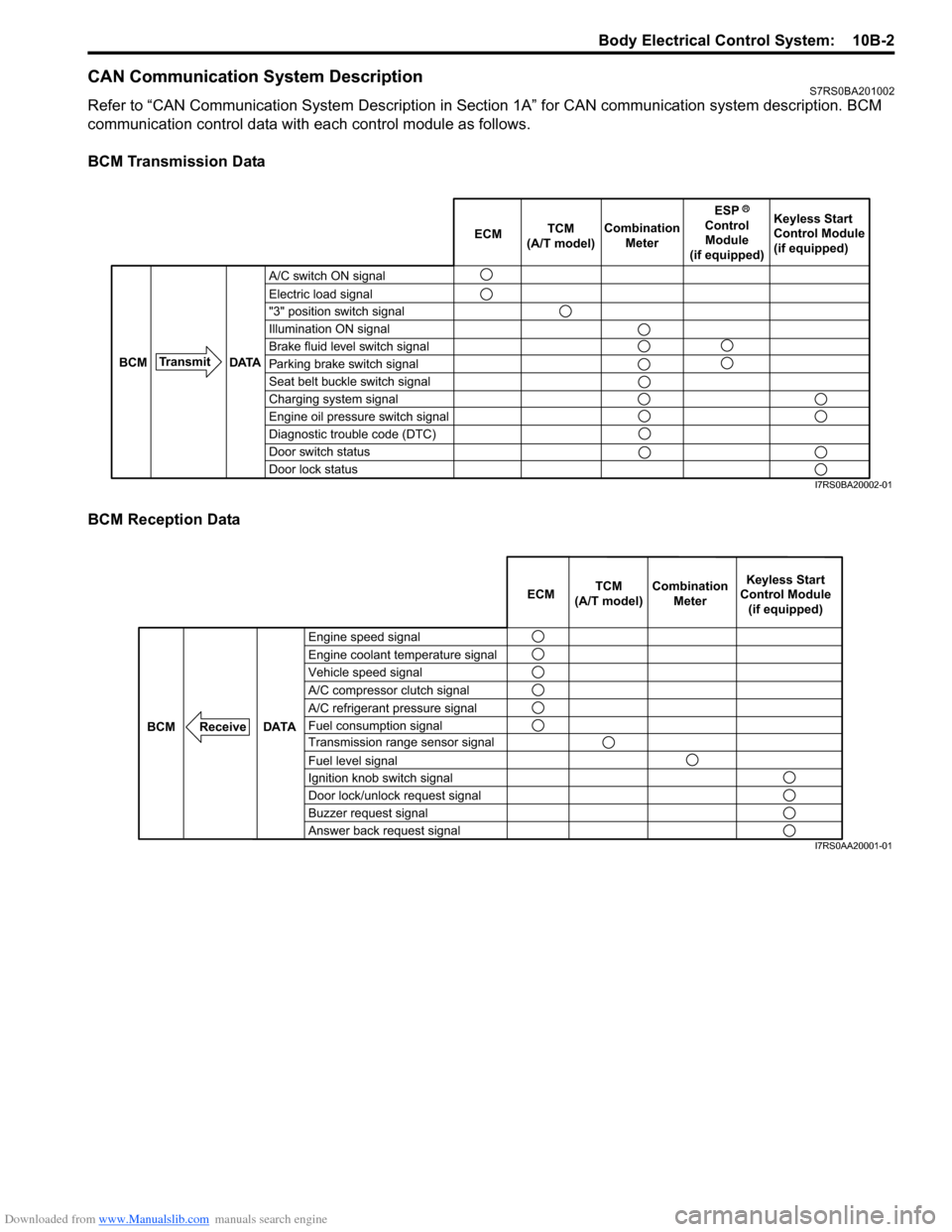

CAN Communication System DescriptionS7RS0BA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description. BCM

communication control data with ea ch control module as follows.

BCM Transmission Data

BCM Reception Data

A/C switch ON signal

Electric load signal

"3" position switch signal

Illumination ON signal

Brake fluid level switch signal

Parking brake switch signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Diagnostic trouble code (DTC)

Door switch status

Door lock status ECM

TCM

(A/T model) Combination

Meter Keyless Start

Control Module

(if equipped)

Transmit DATA

BCM

ESP

Control Module

(if equipped)

I7RS0BA20002-01

Engine speed signal

Vehicle speed signal Engine coolant temperature signal

A/C refrigerant pressure signal

Fuel consumption signal A/C compressor clutch signal

Transmission range sensor signal

Fuel level signal

Ignition knob switch signal

Door lock/unlock request signal

Buzzer request signal

Answer back request signal

DATA

BCM

Receive

Combination

Meter

TCM

(A/T model) Keyless Start

Control Module (if equipped)

ECM

I7RS0AA20001-01

Page 1416 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-13 Body Electrical Control System:

Scan Tool Data Definitions

Vehicle Speed (km/h, mph): It is computed based on pulse signals from vehicle speed sensor on transmission.

Outside air Temp ( °C, °F): It is detected by outside air temperature sensor.

Battery Voltage (V): This parameter indicates battery po sitive voltage inputted to BCM.

Coolant Temp (Engine coolant temperature) ( °C, °F): It is detected by engine coolant temperature sensor.

Engine Speed (RPM): It is computed by reference pulse signals from CMP sensor.

Fuel Consumption (km/l): This parameter indicates the fuel consumption computed by ECM.

Key Reminder Sw (Key reminder switch) (Pulled / Key in): This parameter indicates the state of the key reminder

switch.

Rear Wiper Sw (Rear wiper switch) (ON / INT / OFF): This parameter indicates the state of the rear wiper switch.

Door key Sw (Door key cylinder switch) (Lock / Neutral / Unlock): This parameter indicates the state of the door

key cylinder switch.

Door lock Sw (Manual door lock switch) (Lock / Neutral / Unlock): This parameter indicates the state of the

manual door lock switch.

Driv Door Sw (Driver side d oor switch) (Open / Close): This parameter indicates the state of the driver side door

switch.

Pass Door Sw (Other than driver side door switch) (Open / Close): This parameter indicates the state of the door

switches other than driver side door switch.

Brake Fluid Level (Low / Normal): Low: Brake fluid level is lower than specified level.

Normal: Brake fluid level is higher than MIN level.

Parking Brake Sw (Parking brake switch) (ON / OFF): ON: Parking brake lever is pulled up.

OFF: Parking brake lever is released.

Rear Defogger Sw (Rear end door window defogger switch) (ON / OFF): This parameter indicates the state of

the rear end door window defogger switch.

Tail Light Sw (Lighting switch) (ON / OFF): This parameter indicates the state of the lighting switch.

Driv Seatbelt Sw (Driver seat belt switch) (Fasten / Unfasten): This parameter indicates the state of the driver

side seat belt buckle switch.

Rear end Door Opener (Rear end door opener switch) (ON / OFF): This parameter indicates the state of the rear

end door opener switch.

“3” position Sw (ON/OFF): This parameter indicates the state of the “3 ” position switch included in A/T manual

selector assembly.

Charge lamp (ON / OFF): This parameter indicates the state of the charge system monitor switch.

Oil pressure switch (ON / OFF): This parameter indicates the state of the oil pressure switch.

A/C Switch (ON / OFF): This parameter indicates the state of the air conditioning switch.

Diagnosis Using Output Test Function of SUZUKI Scan Tool

SUZUKI scan tool has the output test function which can force operation of following actuators and relays of the

system controlled by BCM. When a malf unction is found in the system controlled by BCM, execute the output test

which enables easy judgment whether the malfunction is on the input side or output side of BCM. For detailed

information on operation of SUZUKI scan tool, refer to “SUZUKI Scan Tool Operator’s Manual”.

Output Teat Item Controlled Parts

Hazard Warning Light Turn signal and hazard warning relay

Interior (Dome) Light Interior (Dome) light (wh en interior light switch is at DOOR position)

Door Each door lock actuator

Rear end door open Rear end door opener relay

Warning buzzer Warning buzzer (in BCM)

Rear wiper Rear wiper relay

Alarm indicator Theft deterrent light (in information display or clock)

Rear defogger Rear end door window defogger relay

Page 1427 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-24

DTC U1073 (No. 1073): Control Module Communication Bus OffS7RS0BA204014

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Transmission error that is inconsistent between transmission data and

transmission monitor (CAN bus monitor) data is detected more than 7

times continuously.

(1 driving detection logic) • CAN communication circuit

• Combination meter

• BCM (included in junction block

assembly)

• TCM (A/T model)

• ABS/ESP ® control module

• Keyless start control module (if equipped)

•ECM

• Steering angle sensor (if equipped)

Step Action YesNo

1 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 detected? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 3.

Repair circuit.

Page 1467 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-5

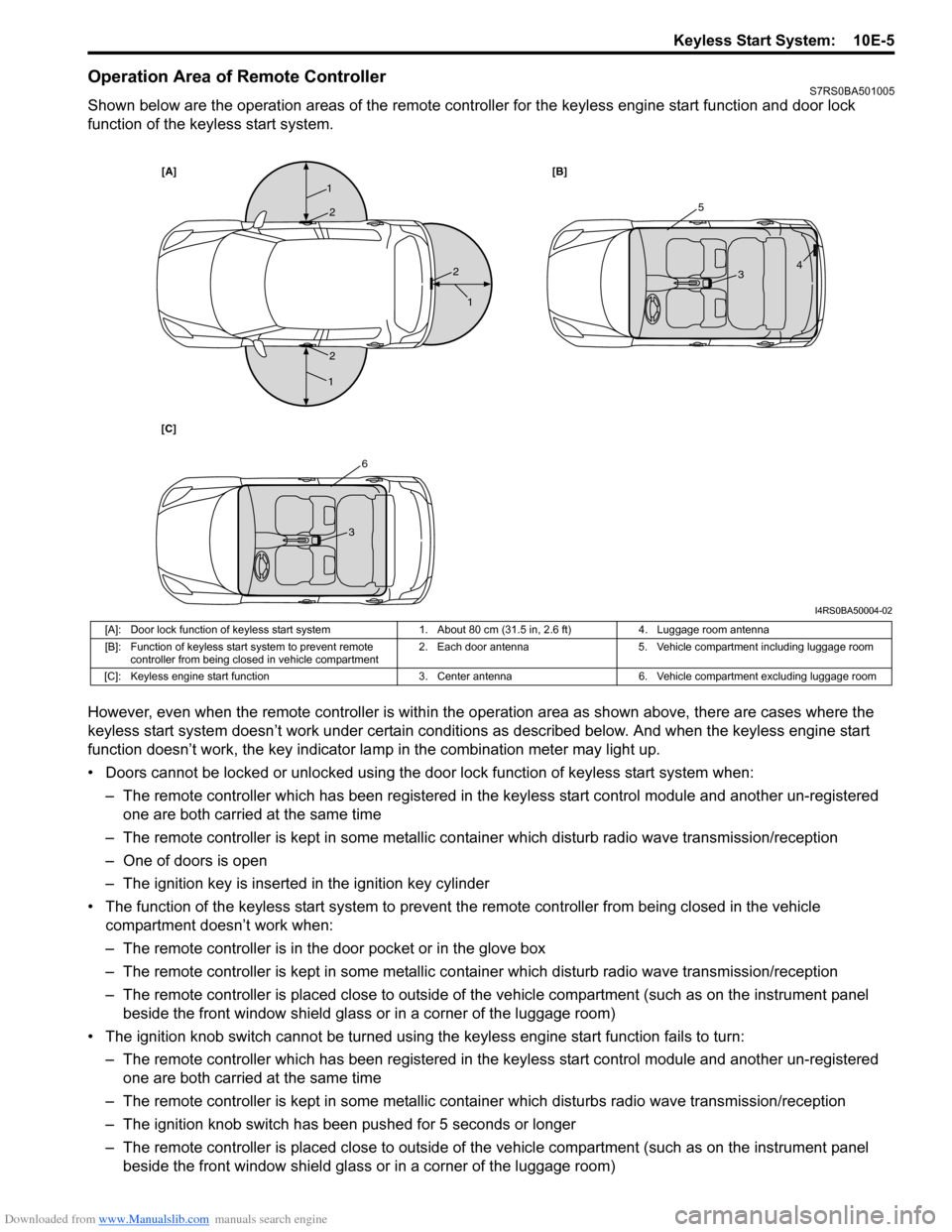

Operation Area of Remote ControllerS7RS0BA501005

Shown below are the operation areas of the remote controller for the keyless engine start function and door lock

function of the keyless start system.

However, even when the remote controller is within the operation area as shown above, there are cases where the

keyless start system doesn’t work under certain conditi ons as described below. And when the keyless engine start

function doesn’t work, the key indicator la mp in the combination meter may light up.

• Doors cannot be locked or unlocked using the doo r lock function of keyless start system when:

– The remote controller which has been registered in the keyless start control module and another un-registered one are both carried at the same time

– The remote controller is kept in some metallic co ntainer which disturb radio wave transmission/reception

– One of doors is open

– The ignition key is inserted in the ignition key cylinder

• The function of the keyless start system to prevent the remote controller from being closed in the vehicle

compartment doesn’t work when:

– The remote controller is in the door pocket or in the glove box

– The remote controller is kept in some metallic co ntainer which disturb radio wave transmission/reception

– The remote controller is placed close to outside of the vehicle compartment (such as on the instrument panel beside the front window shield glass or in a corner of the luggage room)

• The ignition knob switch cannot be turned usin g the keyless engine start function fails to turn:

– The remote controller which has been registered in the keyless start control module and another un-registered one are both carried at the same time

– The remote controller is kept in some metallic cont ainer which disturbs radio wave transmission/reception

– The ignition knob switch has been pushed for 5 seconds or longer

– The remote controller is placed close to outside of the vehicle compartment (such as on the instrument panel beside the front window shield glass or in a corner of the luggage room)

[A] [B]

[C]

1

1

1

25

6

3

3 4

2

2

I4RS0BA50004-02

[A]: Door lock function of keyless start system 1. About 80 cm (31.5 in, 2.6 ft)4. Luggage room antenna

[B]: Function of keyless start system to prevent remote controller from being closed in vehicle compartment 2. Each door antenna

5. Vehicle compartment including luggage room

[C]: Keyless engine start function 3. Center antenna6. Vehicle compartment excluding luggage room

Page 1468 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-6 Keyless Start System:

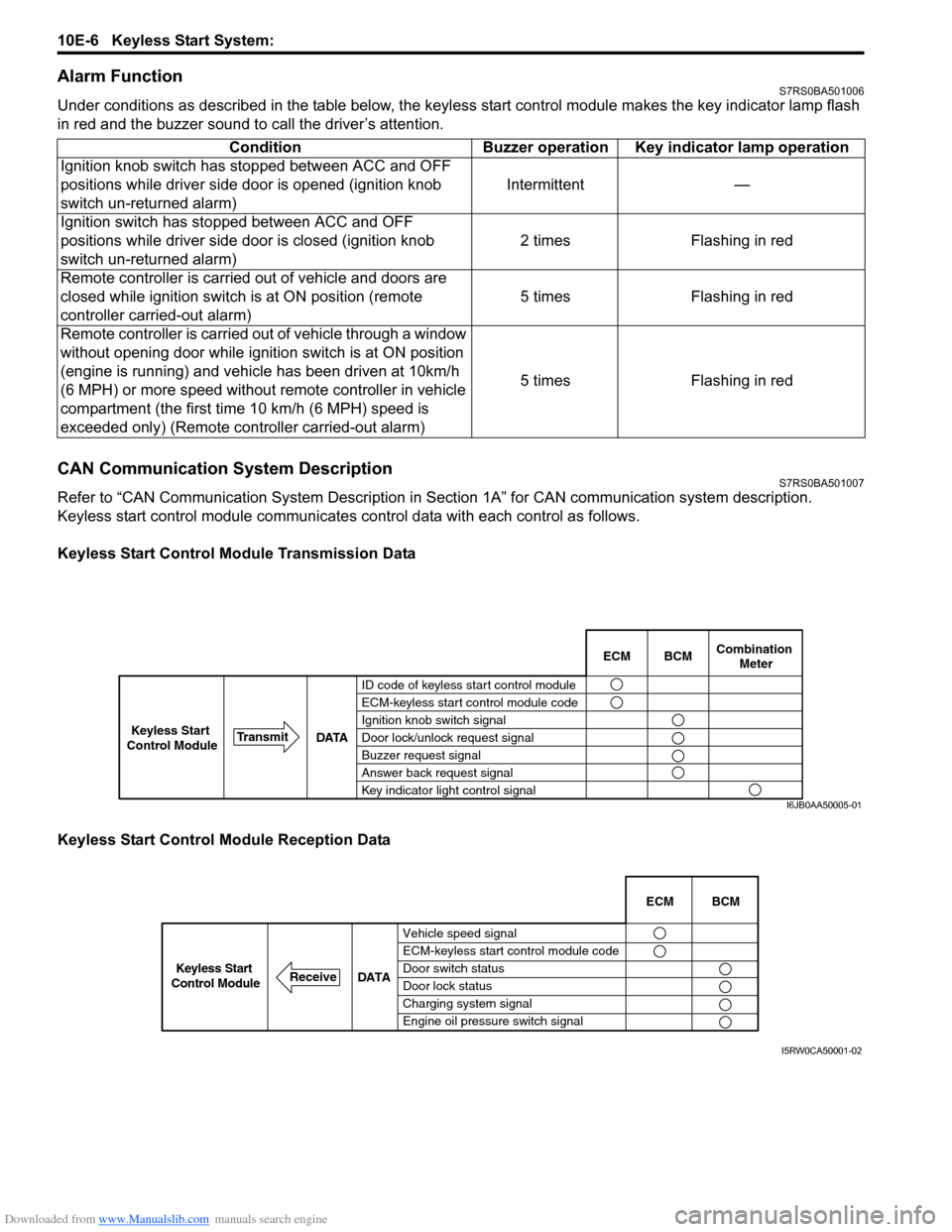

Alarm FunctionS7RS0BA501006

Under conditions as described in the table below, the keyless start control module makes the key indicator lamp flash

in red and the buzzer sound to call the driver’s attention.

CAN Communication System DescriptionS7RS0BA501007

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

Keyless start control module communicates control data wit h each control as follows.

Keyless Start Control Module Transmission Data

Keyless Start Control Module Reception Data Condition Buzzer operation Key indicator lamp operation

Ignition knob switch has stopped between ACC and OFF

positions while driver side door is opened (ignition knob

switch un-returned alarm) Intermittent —

Ignition switch has stopped between ACC and OFF

positions while driver side door is closed (ignition knob

switch un-returned alarm) 2 times Flashing in red

Remote controller is carried out of vehicle and doors are

closed while ignition switch is at ON position (remote

controller carried-out alarm) 5 times Flashing in red

Remote controller is carried out of vehicle through a window

without opening door while ignition switch is at ON position

(engine is running) and vehicle has been driven at 10km/h

(6 MPH) or more speed without remote controller in vehicle

compartment (the first time 10 km/h (6 MPH) speed is

exceeded only) (Remote cont roller carried-out alarm) 5 times Flashing in red

BCM

ECM Combination

Meter

ID code of keyless start control module

ECM-keyless start control module code

Ignition knob switch signal

Door lock/unlock request signal

Buzzer request signal

Answer back request signal

Key indicator light control signal

DATA

Transmit

Keyless Start

Control Module

I6JB0AA50005-01

Vehicle speed signal

ECM-keyless start control module code

Door switch status

Door lock status

Charging system signal

Engine oil pressure switch signal ECM BCM

DATA

ReceiveKeyless Start

Control Module

I5RW0CA50001-02

Page 1470 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-8 Keyless Start System:

Diagnostic Information and Procedures

Precautions in Diagnosing TroublesS7RS0BA504001

• The keyless start system executes data transmission/reception by means of th e radio wave. Therefore,

proper operation may not be obtained if use of the

door lock function and engine start function of the

keyless start system is attempted near the place

where strong radio wave is emitted (TV and radio

broadcasting stations, etc.).

• Diagnostic information stored in keyless start control

module memory can be checked only by key indicator

lamp.

• Be sure to use the trouble diagnosis procedure as described in “Keyless Start System Check”. Failure to

follow it may result in incorrect diagnosis. (Some other

DTC may be stored by mistake in the memory of

keyless start control module during inspection.)

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Communication of ECM, BCM, TCM (A/T model), ABS control module, keyless start control module and

combination meter is estab lished by CAN (Controller

Area Network). (For detail of CAN communication for

keyless start control module, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”. • Replacement of the keyless start control module

When keyless start control module is replaced with

new one, make sure that r egister remote controller ID

code to keyless start co ntrol module correctly

according to “Registration Procedure for Remote

Controller ID Code”.

• Keyless start control module substitution When the keyless start control module used in

another vehicle was installed in the vehicle, register

the ID code of the remote controller in the keyless

start control module as well as the ignition key

transponder code fo r the immobilizer control system in

ECM. For the registration procedure of the ignition key

transponder code, refer to “Registration of the Ignition

Key in Section 10C”.

Self-Diagnosis FunctionS7RS0BA504002

The keyless start control module has self-diagnosis

function to monitor the system components and circuits

while the keyless start system is at work. When the

keyless start control module detects an abnormality in

the system, it saves the ar ea where such abnormality

has occurred as a DTC in its memory. The DTC stored in

memory of the keyless start control module is indicated

by the key indicator lamp in the combination meter

flashing in a specific pattern. For DTC indication, refer to

“DTC Check” and for the clearing procedure, to “DTC

Clearance”.

Keyless Start System Diagnosis IntroductionS7RS0BA504003

To ensure that the trouble diagnosis is done accurately

and smoothly, observe “Precautions in Diagnosing

Troubles” and follow “Keyless Start System Check”.

Keyless Start System CheckS7RS0BA504004

Step Action YesNo

1 1) Record details of the problem. For your record, use of a questionnaire form will facilit ate collecting information for

proper analysis and diagnosis.

2) Check if the problem described in “Customer Questionnaire (Example)” actually occurs in the vehicle.

(This step should be performed with the customer if

possible.)

Perform “Keyless Start System Operation Inspection”

procedure to check if the symptom which has occurred is

abnormal or not.

3) Check for DTC referring to “DTC Check”, and then record DTC(s).

4) Clear DTC referring to “DTC Clearance” if any DTC exists, and then recheck for DTC.

Is any DTC still detected? Go to Step 2.

Go to Step 3.

2 1) Check and repair referring to applicable “DTC Table”. Are check and repair complete? Go to Step 5.

Check and repair

malfunction part(s), and

go to Step 5.

Page 1494 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-32 Keyless Start System:

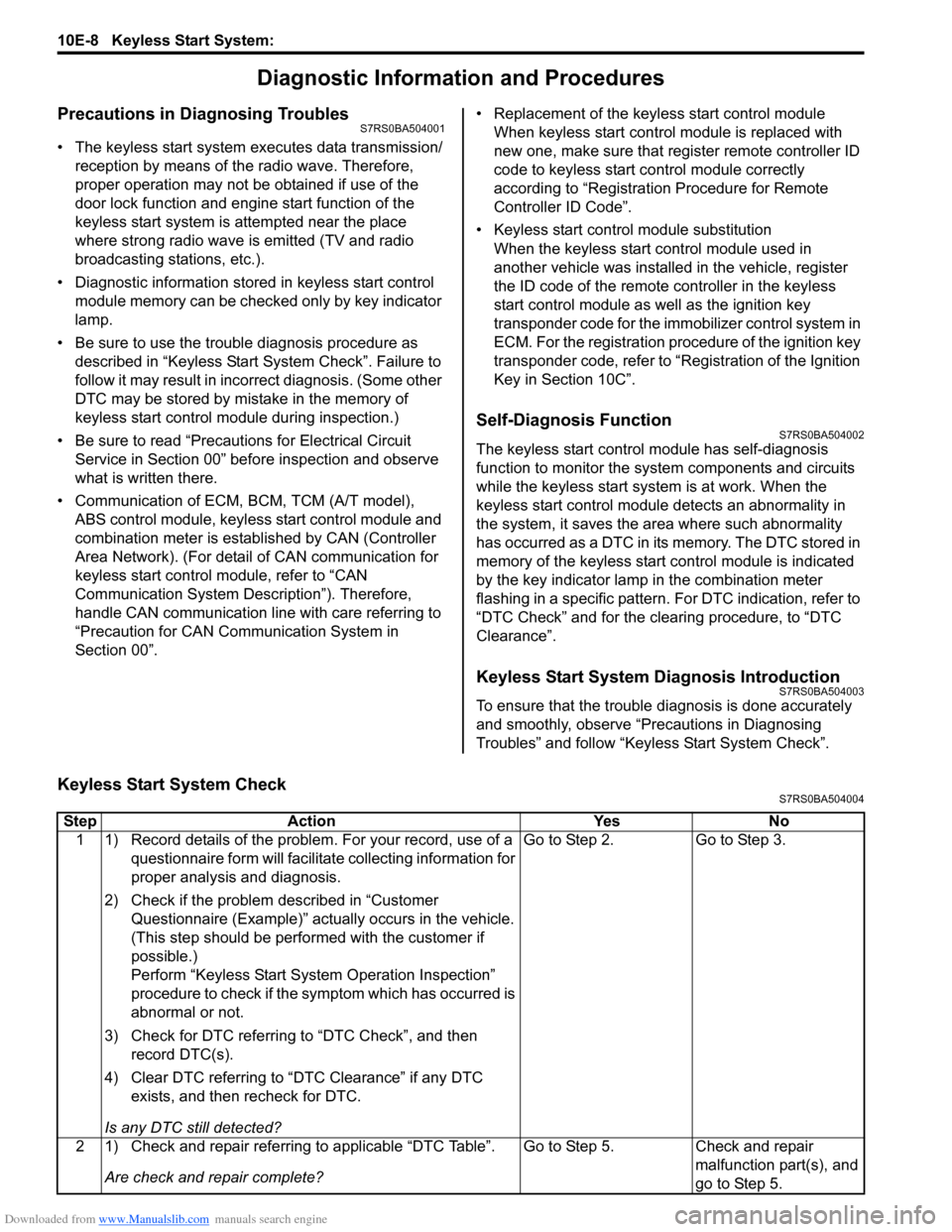

Keyless Start Control Module Removal and

Installation

S7RS0BA506006

Removal1) Disconnect negative (–) cable at battery.

2) Remove glove box from instrument panel.

3) Remove keyless start cont rol module (1) as follows.

• For vehicle equipped with M/T:

a. Disconnect connector from keyless start control module.

b. Remove keyless start control module mounting bolt and then remove keyless start

control module from steering support member

(2).

• For vehicle equipped with A/T: a. Remove TCM (3) from vehicle body referring to “Transmission Control Module (TCM)

Removal and Installation in Section 5A”.

b. Disconnect connector from keyless start control module.

c. Remove keyless start control module mounting bolt and then remove keyless start

control module from steering support member.

Installation

For installation, reverse removal procedure.

If Keyless start control module is replaced, register ID

code of remote controller in to Keyless start control

module, referring to “Registration Procedure for Remote

Controller ID Code”.

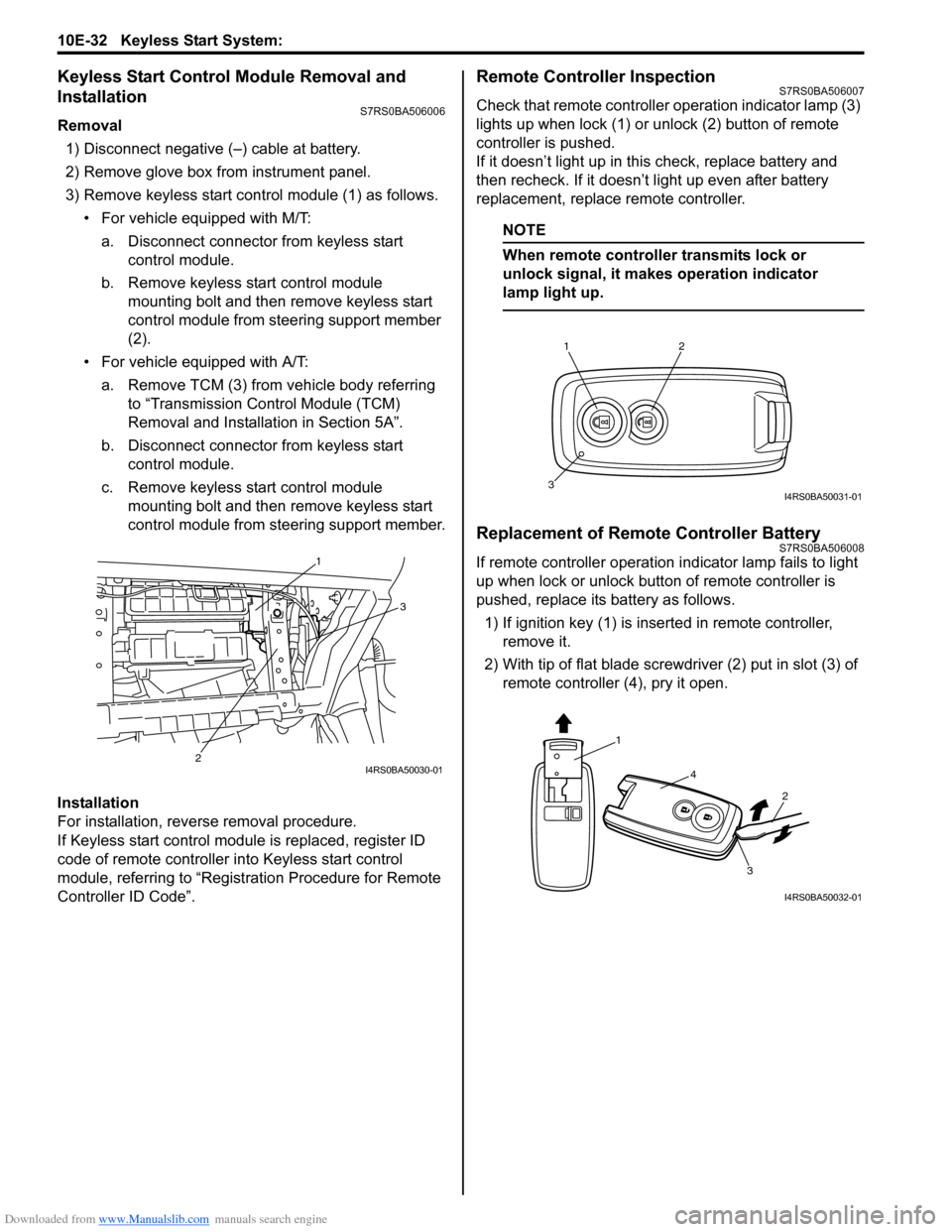

Remote Controller InspectionS7RS0BA506007

Check that remote controller operation indicator lamp (3)

lights up when lock (1) or un lock (2) button of remote

controller is pushed.

If it doesn’t light up in this check, replace battery and

then recheck. If it doesn’t light up even after battery

replacement, replace remote controller.

NOTE

When remote controller transmits lock or

unlock signal, it makes operation indicator

lamp light up.

Replacement of Remote Controller BatteryS7RS0BA506008

If remote controller operation i ndicator lamp fails to light

up when lock or unlock button of remote controller is

pushed, replace its battery as follows.

1) If ignition key (1) is inse rted in remote controller,

remove it.

2) With tip of flat blade screwdriver (2) put in slot (3) of remote controller (4), pry it open.1

3

2

I4RS0BA50030-01

12

3I4RS0BA50031-01

1

4

2

3

I4RS0BA50032-01