Engine oil type SUZUKI SWIFT 2005 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 965 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-17

NOTE

• After recovering refrigerant from system, the amount of removed compressor oil must be measured

for replenishing compressor oil.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

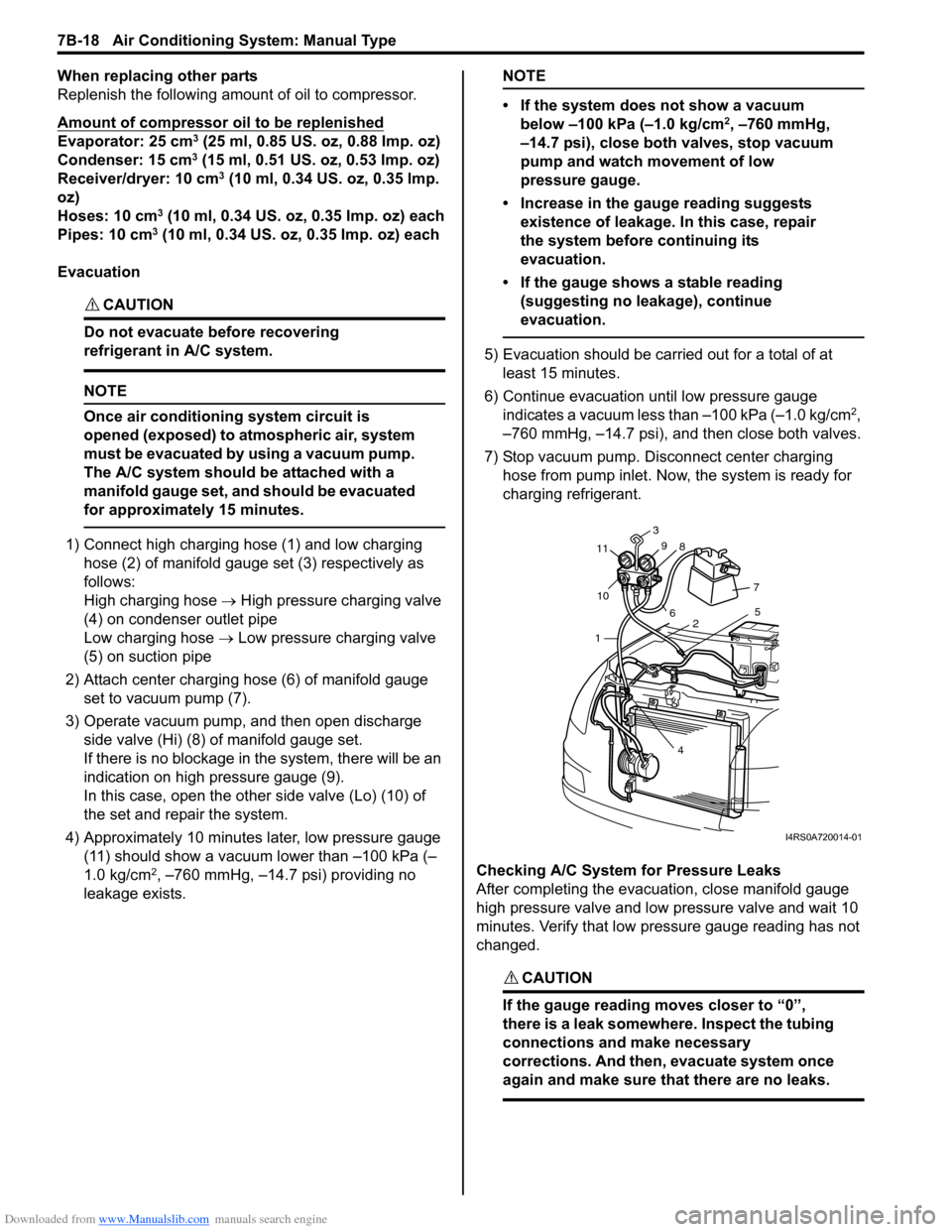

Replenishing Compressor Oil

It is necessary to replenish specified amount of

compressor oil to compressor from compressor suction

side hole (1) before evacuating and charging refrigerant.

When charging refrigerant only

When charging refrigerant without replacing any

component, replenish the same amount of measured oil

when recovering refrigerant (if not measure, replenish 10

cm

3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) oil).

When replacing compressor

CAUTION!

Be sure to use specified compressor oil or an

equivalent compressor oil.

Compressor oil is sealed in each new compressor by the

amount required for A/C system. Therefore, when using

a new compressor, drain the calculated amount of oil

from it. “C” = “A” – “B”

“C”: Amount of oil to be drained

“A”: Amount of oil in a new compressor

“B”: Amount of oil in removed compressor

NOTE

Compressor assembly su

pplied from factory

is filled up with the following amount of oil.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

Oil amount in compressor

90 ± 5 cm3 (90 ± 5 ml, 3.04 ± 0.17 US. oz, 3.17 ± 0.18

Imp. oz)

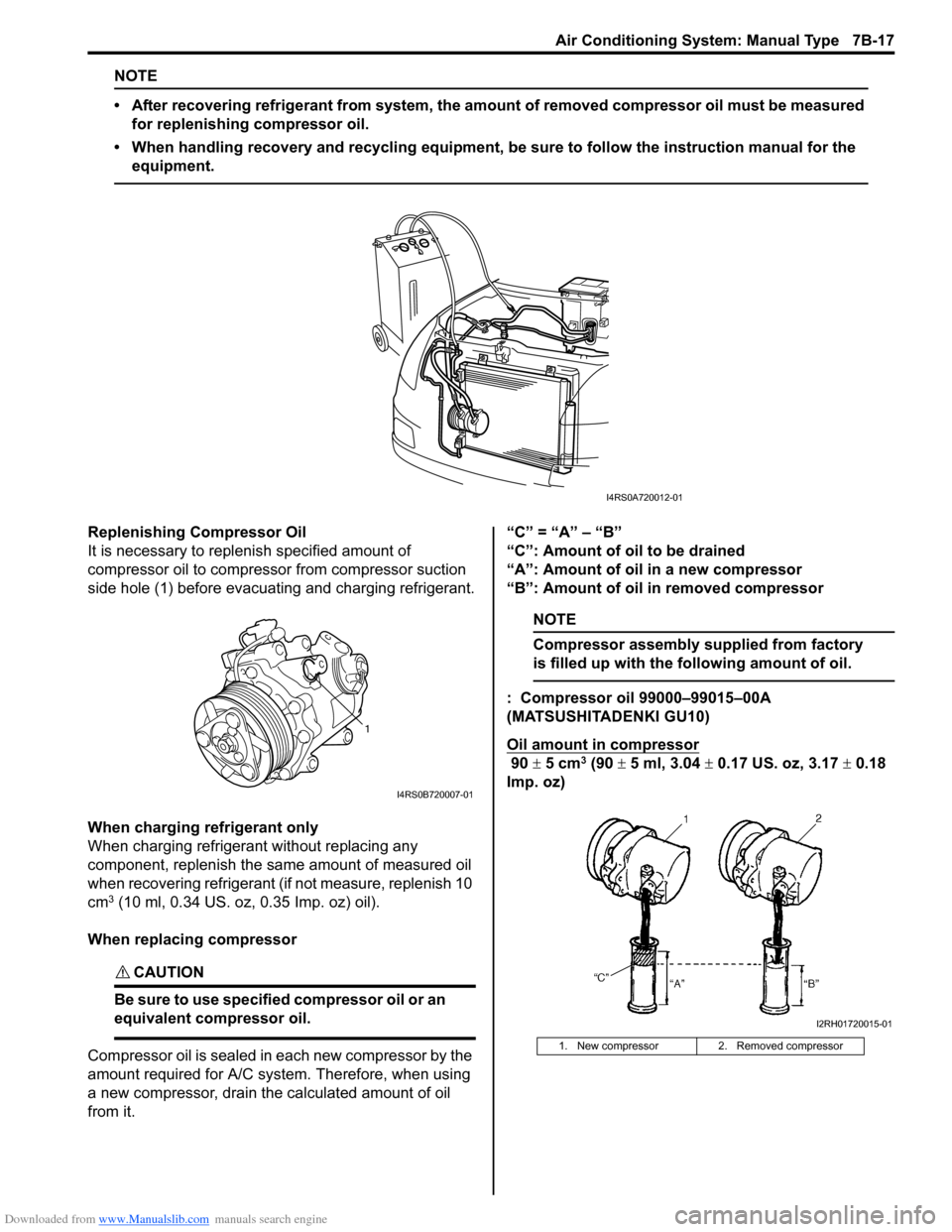

I4RS0A720012-01

1

I4RS0B720007-01

1. New compressor 2. Removed compressor

I2RH01720015-01

Page 966 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-18 Air Conditioning System: Manual Type

When replacing other parts

Replenish the following amount of oil to compressor.

Amount of compressor oil to be replenished

Evaporator: 25 cm3 (25 ml, 0.85 US. oz, 0.88 Imp. oz)

Condenser: 15 cm3 (15 ml, 0.51 US. oz, 0.53 Imp. oz)

Receiver/dryer: 10 cm3 (10 ml, 0.34 US. oz, 0.35 lmp.

oz)

Hoses: 10 cm

3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) each

Pipes: 10 cm3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) each

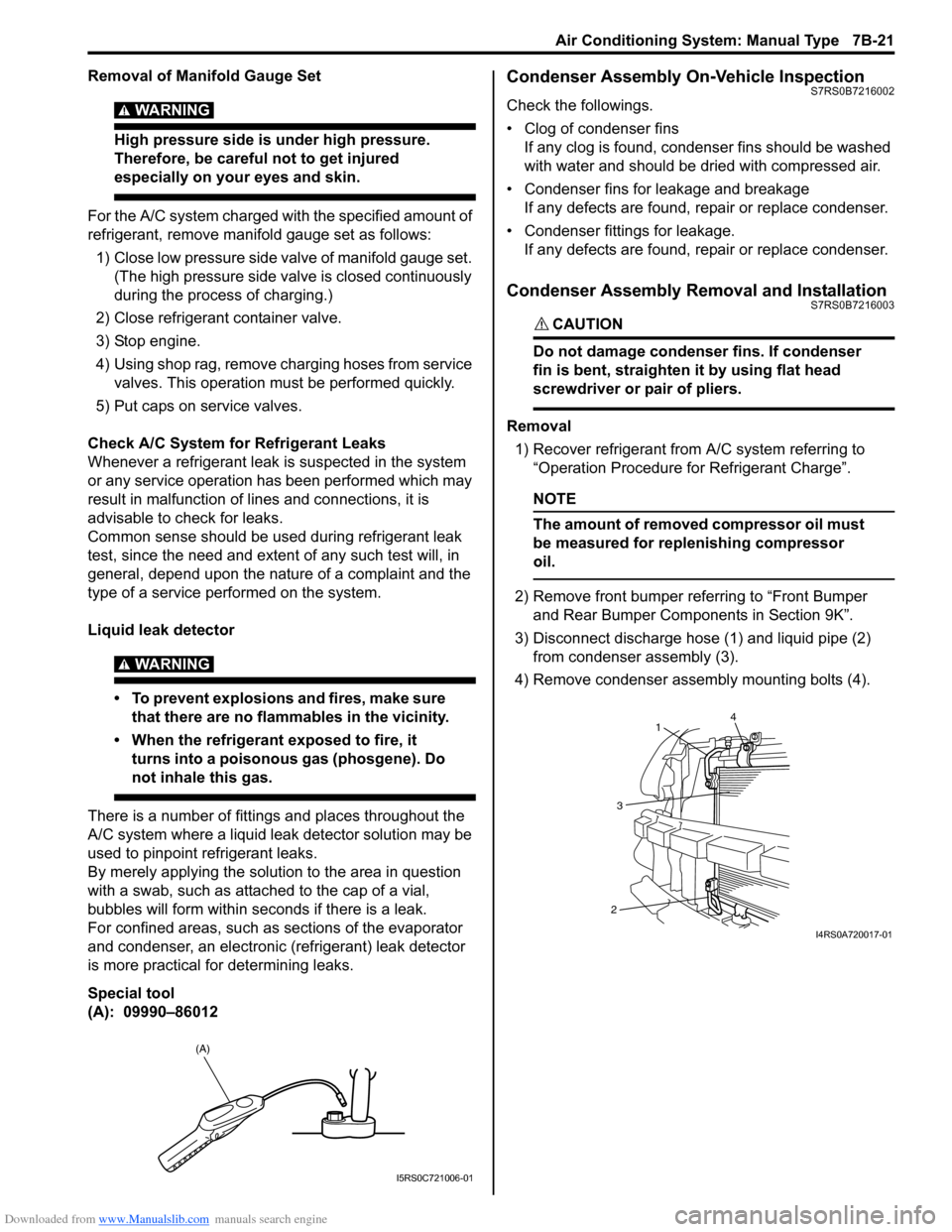

Evacuation

CAUTION!

Do not evacuate before recovering

refrigerant in A/C system.

NOTE

Once air conditioning system circuit is

opened (exposed) to atmospheric air, system

must be evacuated by using a vacuum pump.

The A/C system should be attached with a

manifold gauge set, and should be evacuated

for approximately 15 minutes.

1) Connect high charging hose (1) and low charging hose (2) of manifold gauge set (3) respectively as

follows:

High charging hose → High pressure charging valve

(4) on condenser outlet pipe

Low charging hose → Low pressure charging valve

(5) on suction pipe

2) Attach center charging hose (6) of manifold gauge set to vacuum pump (7).

3) Operate vacuum pump, and then open discharge

side valve (Hi) (8) of manifold gauge set.

If there is no blockage in the system, there will be an

indication on high pressure gauge (9).

In this case, open the other side valve (Lo) (10) of

the set and repair the system.

4) Approximately 10 minutes later, low pressure gauge (11) should show a vacuum lower than –100 kPa (–

1.0 kg/cm

2, –760 mmHg, –14.7 psi) providing no

leakage exists.

NOTE

• If the system does not show a vacuum below –100 kPa (–1.0 kg/cm

2, –760 mmHg,

–14.7 psi), close both valves, stop vacuum

pump and watch movement of low

pressure gauge.

• Increase in the gauge reading suggests existence of leakage. In this case, repair

the system before continuing its

evacuation.

• If the gauge shows a stable reading (suggesting no leakage), continue

evacuation.

5) Evacuation should be carried out for a total of at least 15 minutes.

6) Continue evacuation until low pressure gauge indicates a vacuum less than –100 kPa (–1.0 kg/cm

2,

–760 mmHg, –14.7 psi), and then close both valves.

7) Stop vacuum pump. Disconnect center charging hose from pump inlet. No w, the system is ready for

charging refrigerant.

Checking A/C System for Pressure Leaks

After completing the evacuation, close manifold gauge

high pressure valve and low pressure valve and wait 10

minutes. Verify that low pressure gauge reading has not

changed.

CAUTION!

If the gauge reading moves closer to “0”,

there is a leak somewhere. Inspect the tubing

connections and make necessary

corrections. And then, evacuate system once

again and make sure that there are no leaks.

7 5

2

4

1

10

11

3

9 8

6

I4RS0A720014-01

Page 969 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set. (The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service valves. This operation must be performed quickly.

5) Put caps on service valves.

Check A/C System for Refrigerant Leaks

Whenever a refrigerant leak is suspected in the system

or any service operation has been performed which may

result in malfunction of lines and connections, it is

advisable to check for leaks.

Common sense should be used during refrigerant leak

test, since the need and extent of any such test will, in

general, depend upon the nature of a complaint and the

type of a service performed on the system.

Liquid leak detector

WARNING!

• To prevent explosions and fires, make sure that there are no flammables in the vicinity.

• When the refrigerant exposed to fire, it turns into a poisonous gas (phosgene). Do

not inhale this gas.

There is a number of fittings and places throughout the

A/C system where a liquid leak detector solution may be

used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question

with a swab, such as attached to the cap of a vial,

bubbles will form within seconds if there is a leak.

For confined areas, such as sections of the evaporator

and condenser, an electronic (refrigerant) leak detector

is more practical fo r determining leaks.

Special tool

(A): 09990–86012

Condenser Assembly On-Vehicle InspectionS7RS0B7216002

Check the followings.

• Clog of condenser fins If any clog is found, cond enser fins should be washed

with water and should be dried with compressed air.

• Condenser fins for leakage and breakage If any defects are found, repair or replace condenser.

• Condenser fittings for leakage. If any defects are found, repair or replace condenser.

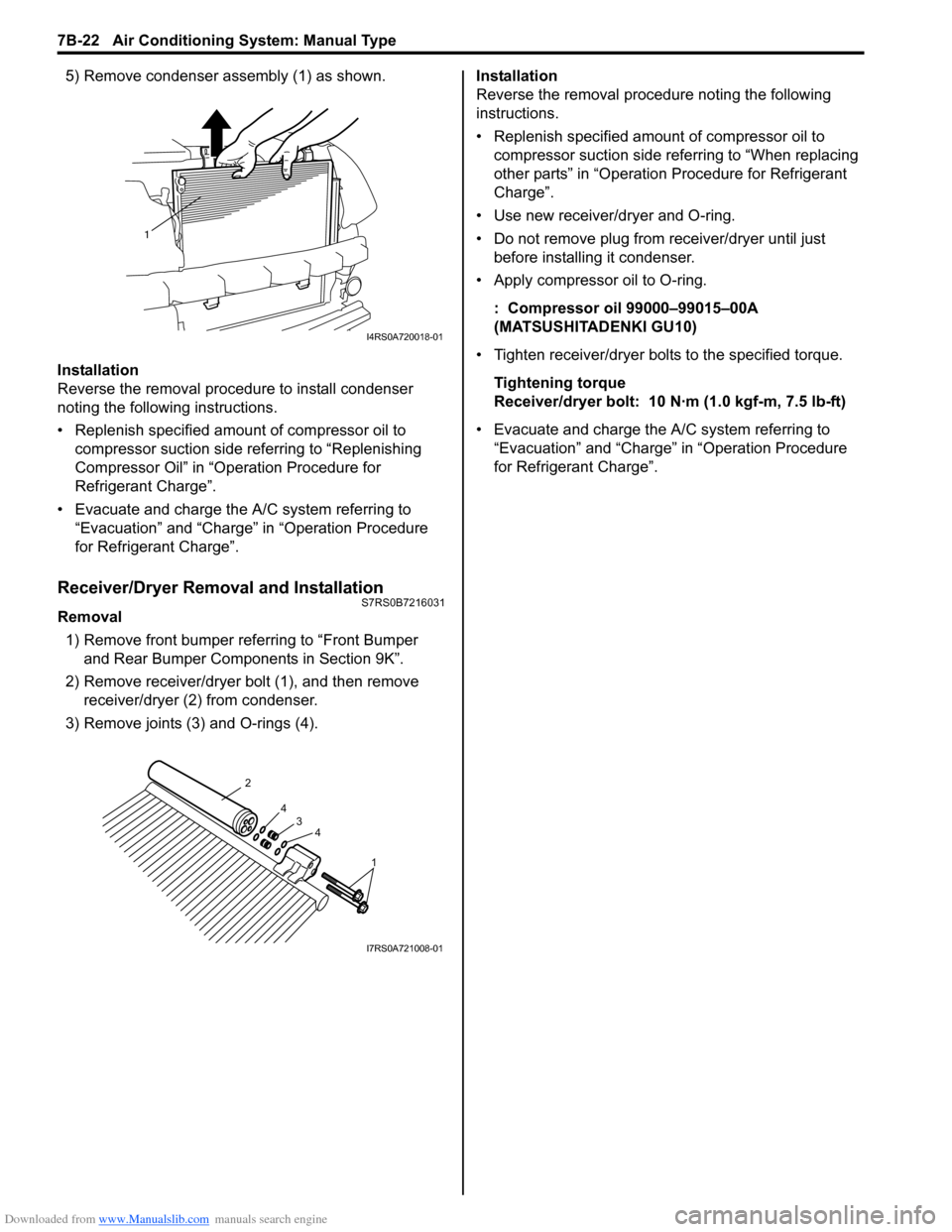

Condenser Assembly Removal and InstallationS7RS0B7216003

CAUTION!

Do not damage condenser fins. If condenser

fin is bent, straighten it by using flat head

screwdriver or pair of pliers.

Removal

1) Recover refrigerant from A/C system referring to “Operation Procedure for Refrigerant Charge”.

NOTE

The amount of removed compressor oil must

be measured for replenishing compressor

oil.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect discharge hose (1) and liquid pipe (2) from condenser assembly (3).

4) Remove condenser assembly mounting bolts (4).

(A)

I5RS0C721006-01

4

1

3

2

I4RS0A720017-01

Page 970 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-22 Air Conditioning System: Manual Type

5) Remove condenser assembly (1) as shown.

Installation

Reverse the removal procedure to install condenser

noting the following instructions.

• Replenish specified amount of compressor oil to compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Receiver/Dryer Removal and InstallationS7RS0B7216031

Removal

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove receiver/dryer bolt (1), and then remove receiver/dryer (2) from condenser.

3) Remove joints (3) and O-rings (4). Installation

Reverse the removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “When replacing

other parts” in “Operation Procedure for Refrigerant

Charge”.

• Use new receiver/dryer and O-ring.

• Do not remove plug from receiver/dryer until just before installin g it condenser.

• Apply compressor oil to O-ring.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

• Tighten receiver/dryer bolts to the specified torque. Tightening torque

Receiver/dryer bolt: 10 N· m (1.0 kgf-m, 7.5 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

I4RS0A720018-01

1

4

4

3

2

I7RS0A721008-01

Page 972 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-24 Air Conditioning System: Manual Type

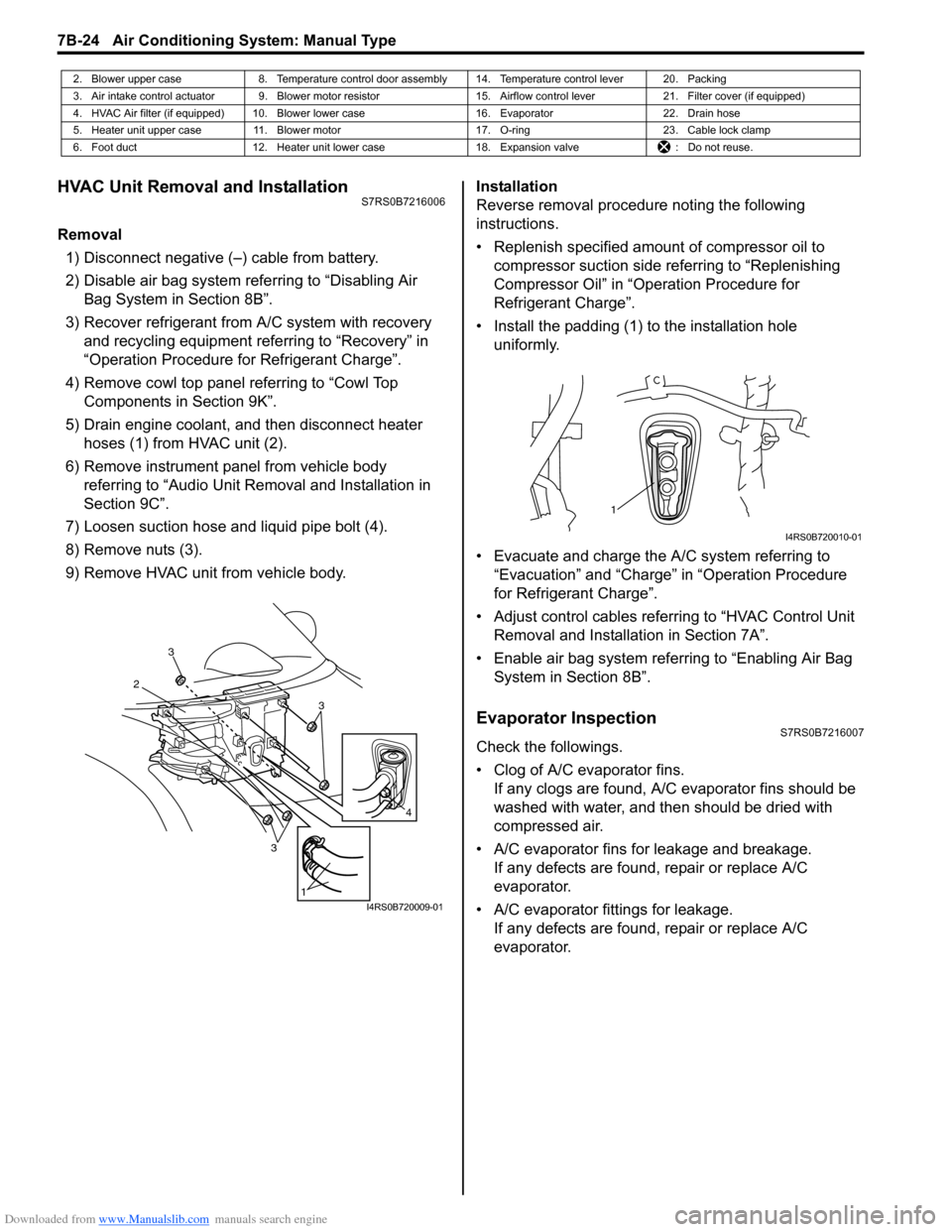

HVAC Unit Removal and InstallationS7RS0B7216006

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Recover refrigerant from A/C system with recovery and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

4) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

5) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

6) Remove instrument panel from vehicle body referring to “Audio Unit Re moval and Installation in

Section 9C”.

7) Loosen suction hose and liquid pipe bolt (4).

8) Remove nuts (3).

9) Remove HVAC unit from vehicle body. Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole uniformly.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust control cables referr ing to “HVAC Control Unit

Removal and Installati on in Section 7A”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Evaporator InspectionS7RS0B7216007

Check the followings.

• Clog of A/C evaporator fins.If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage. If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage. If any defects are found, repair or replace A/C

evaporator.

2. Blower upper case 8. Temperature control door assembly 14. Temperature control lever 20. Packing

3. Air intake control actuator 9. Blower motor resistor 15. Airflow control lever21. Filter cover (if equipped)

4. HVAC Air filter (if equipped) 10. Blower lower case 16. Evaporator22. Drain hose

5. Heater unit upper case 11. Blower motor 17. O-ring23. Cable lock clamp

6. Foot duct 12. Heater unit lower case 18. Expansion valve: Do not reuse.

3

2

3

3

1

4

I4RS0B720009-01

1

I4RS0B720010-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

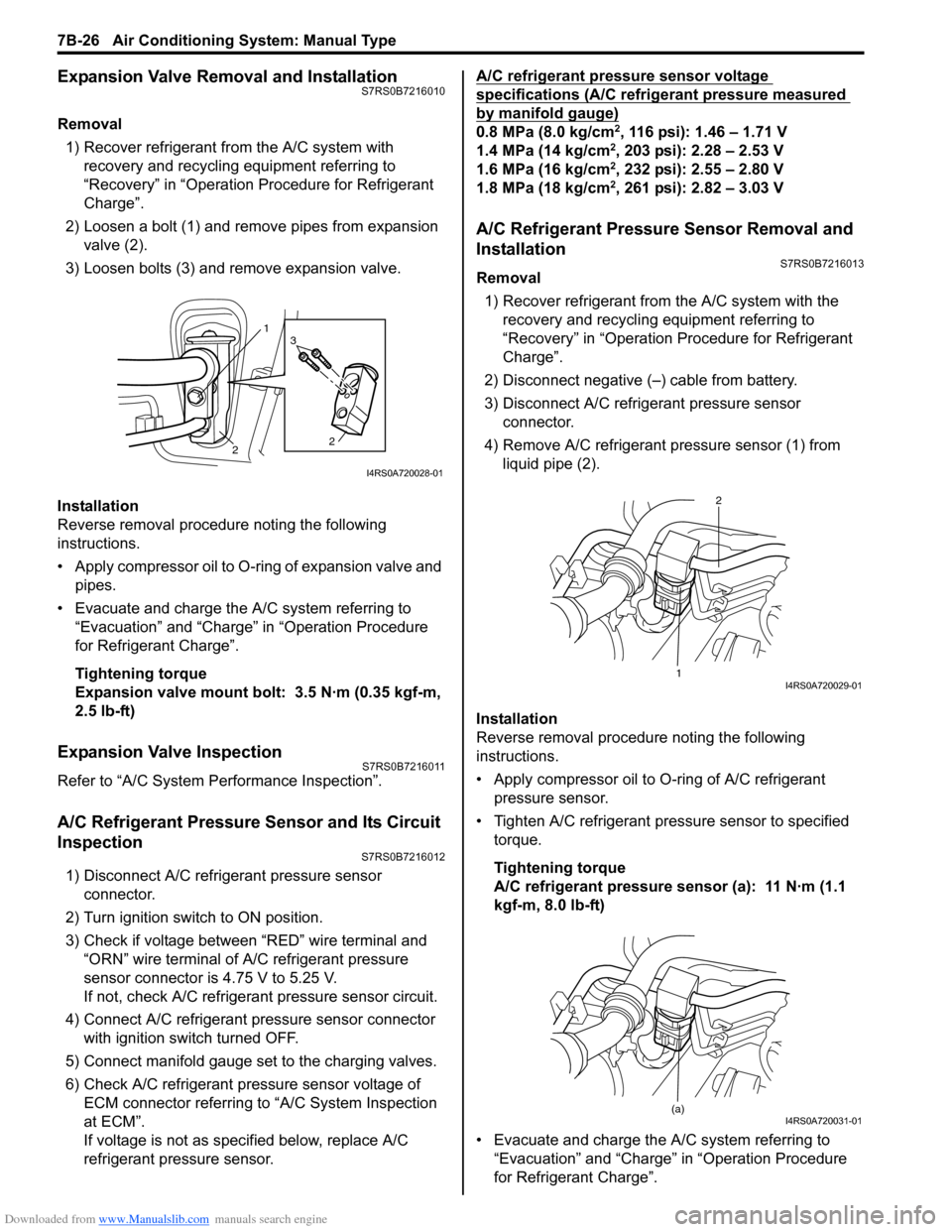

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 976 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-28 Air Conditioning System: Manual Type

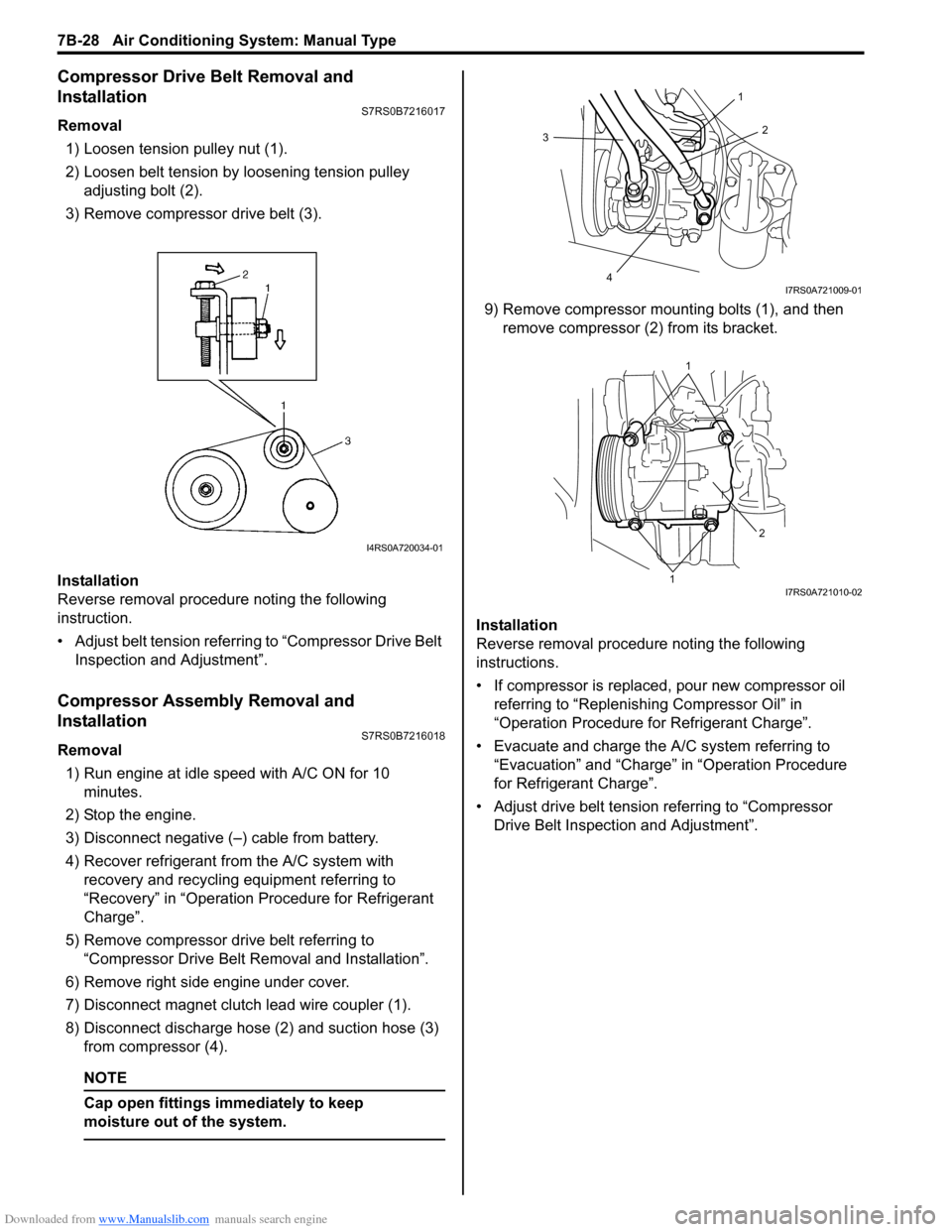

Compressor Drive Belt Removal and

Installation

S7RS0B7216017

Removal1) Loosen tension pulley nut (1).

2) Loosen belt tension by loosening tension pulley adjusting bolt (2).

3) Remove compressor drive belt (3).

Installation

Reverse removal procedure noting the following

instruction.

• Adjust belt tension referring to “Compressor Drive Belt Inspection and Adjustment”.

Compressor Assembly Removal and

Installation

S7RS0B7216018

Removal

1) Run engine at idle speed with A/C ON for 10 minutes.

2) Stop the engine.

3) Disconnect negative (–) cable from battery.

4) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

5) Remove compressor drive belt referring to “Compressor Drive Belt Re moval and Installation”.

6) Remove right side engine under cover.

7) Disconnect magnet clutch lead wire coupler (1).

8) Disconnect discharge hose (2) and suction hose (3) from compressor (4).

NOTE

Cap open fittings immediately to keep

moisture out of the system.

9) Remove compressor mounting bolts (1), and then remove compressor (2 ) from its bracket.

Installation

Reverse removal procedure noting the following

instructions.

• If compressor is replaced, pour new compressor oil referring to “Replenishi ng Compressor Oil” in

“Operation Procedure for Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust drive belt tension referring to “Compressor Drive Belt Inspecti on and Adjustment”.

I4RS0A720034-01

3

4 2

1

I7RS0A721009-01

1

1 2

I7RS0A721010-02

Page 977 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-29

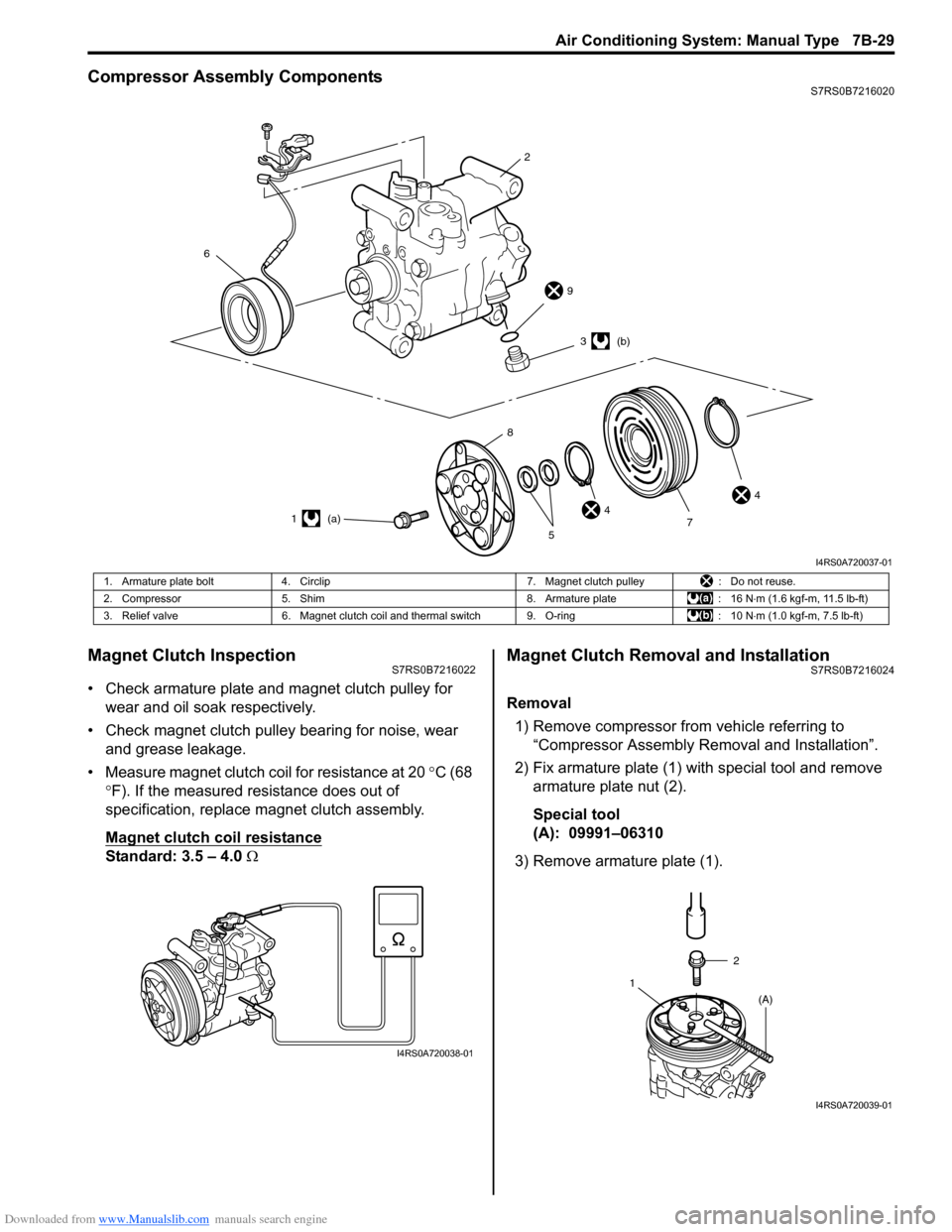

Compressor Assembly ComponentsS7RS0B7216020

Magnet Clutch InspectionS7RS0B7216022

• Check armature plate and magnet clutch pulley for wear and oil soak respectively.

• Check magnet clutch pulley bearing for noise, wear and grease leakage.

• Measure magnet clutch coil for resistance at 20 °C (68

° F). If the measured resistance does out of

specification, replace magnet clutch assembly.

Magnet clutch coil resistance

Standard: 3.5 – 4.0 Ω

Magnet Clutch Removal and InstallationS7RS0B7216024

Removal

1) Remove compressor from vehicle referring to “Compressor Assembly Re moval and Installation”.

2) Fix armature plate (1) with special tool and remove armature plate nut (2).

Special tool

(A): 09991–06310

3) Remove armature plate (1).

6

2

9

44

3 (b)

1 (a) 7

5

8

I4RS0A720037-01

1. Armature plate bolt

4. Circlip 7. Magnet clutch pulley: Do not reuse.

2. Compressor 5. Shim 8. Armature plate: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Relief valve 6. Magnet clutch coil and thermal switch 9. O-ring : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

I4RS0A720038-01

2

1 (A)

I4RS0A720039-01

Page 978 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-30 Air Conditioning System: Manual Type

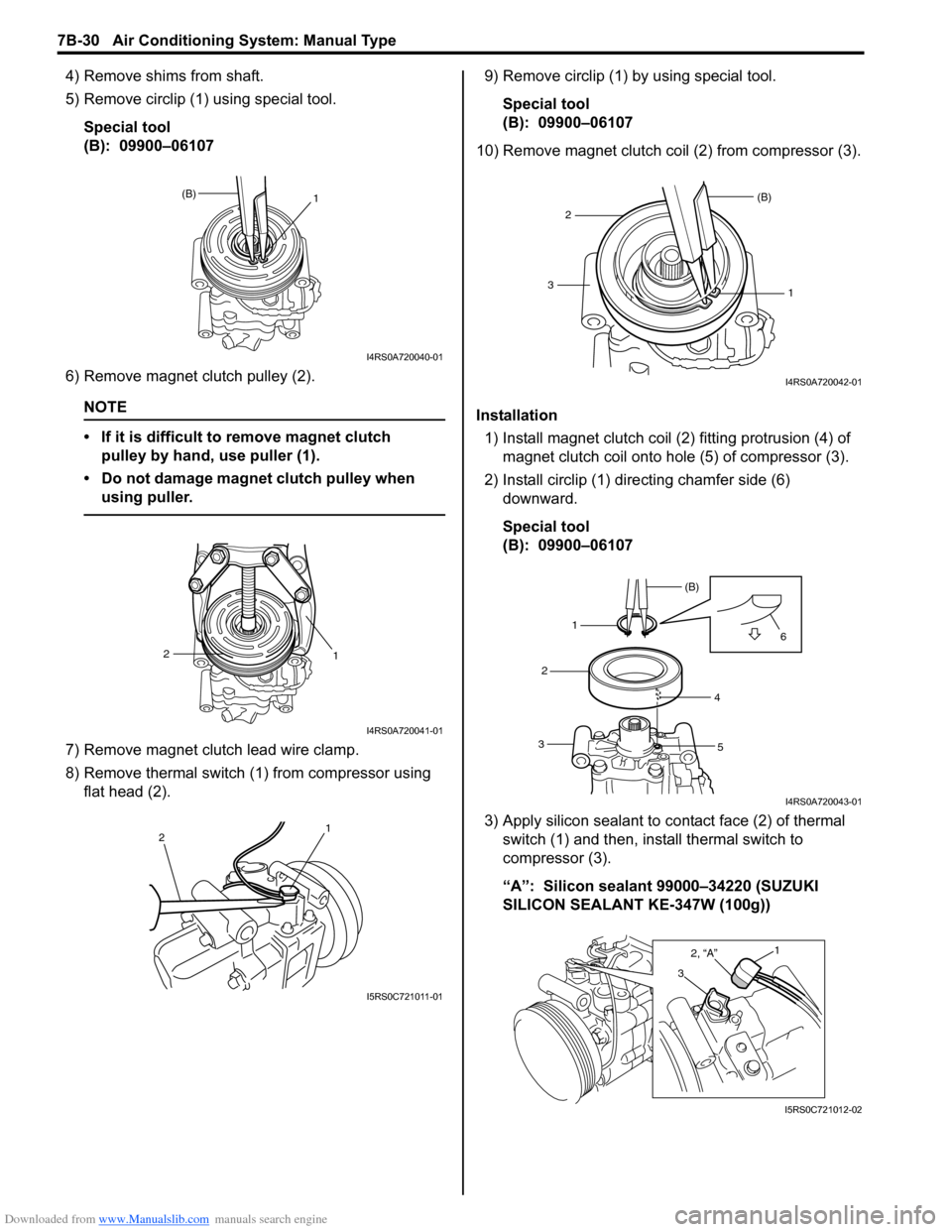

4) Remove shims from shaft.

5) Remove circlip (1) using special tool.Special tool

(B): 09900–06107

6) Remove magnet clutch pulley (2).

NOTE

• If it is difficult to remove magnet clutch pulley by hand, use puller (1).

• Do not damage magnet clutch pulley when using puller.

7) Remove magnet clutch lead wire clamp.

8) Remove thermal switch (1) from compressor using flat head (2). 9) Remove circlip (1) by using special tool.

Special tool

(B): 09900–06107

10) Remove magnet clutch coil (2) from compressor (3).

Installation 1) Install magnet clutch coil (2) fitting protrusion (4) of magnet clutch coil onto hole (5) of compressor (3).

2) Install circlip (1) dire cting chamfer side (6)

downward.

Special tool

(B): 09900–06107

3) Apply silicon sealant to co ntact face (2) of thermal

switch (1) and then, inst all thermal switch to

compressor (3).

“A”: Silicon sealant 99000–34220 (SUZUKI

SILICON SEALANT KE-347W (100g))

(B) 1

I4RS0A720040-01

1

2

I4RS0A720041-01

2 1

I5RS0C721011-01

1

(B)

23

I4RS0A720042-01

1 (B)

2

3 4

5 6

I4RS0A720043-01

3

2, “A”1

I5RS0C721012-02

Page 979 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-31

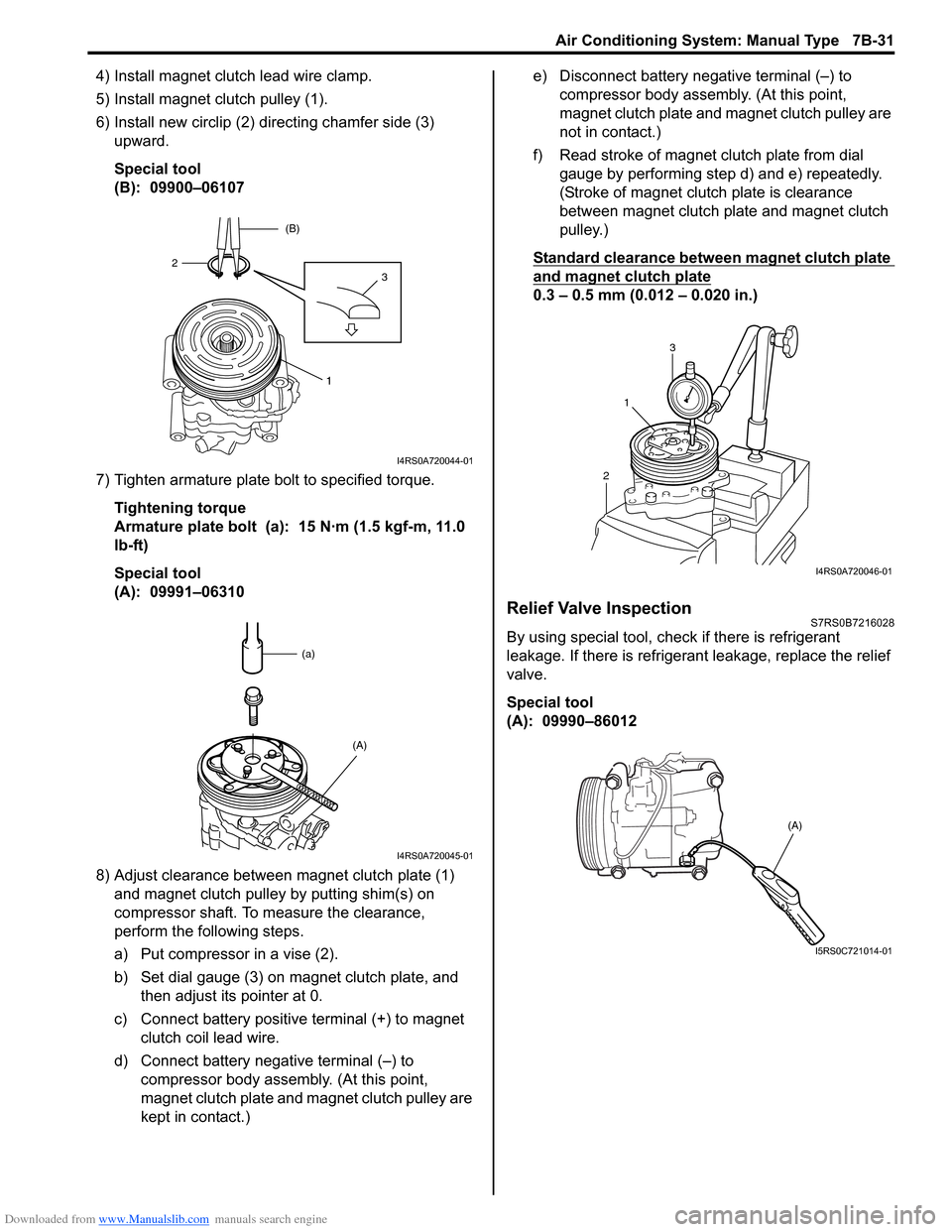

4) Install magnet clutch lead wire clamp.

5) Install magnet clutch pulley (1).

6) Install new circlip (2) directing chamfer side (3) upward.

Special tool

(B): 09900–06107

7) Tighten armature plate bolt to specified torque. Tightening torque

Armature plate bolt (a): 15 N·m (1.5 kgf-m, 11.0

lb-ft)

Special tool

(A): 09991–06310

8) Adjust clearance between magnet clutch plate (1) and magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on magnet clutch plate, and then adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet clutch coil lead wire.

d) Connect battery negative terminal (–) to compressor body assemb ly. (At this point,

magnet clutch plate and magnet clutch pulley are

kept in contact.) e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

magnet clutch plate and magnet clutch pulley are

not in contact.)

f) Read stroke of magnet clutch plate from dial gauge by performing step d) and e) repeatedly.

(Stroke of magnet clutch plate is clearance

between magnet clutch plate and magnet clutch

pulley.)

Standard clearance between magnet clutch plate

and magnet clutch plate

0.3 – 0.5 mm (0.012 – 0.020 in.)

Relief Valve InspectionS7RS0B7216028

By using special tool, chec k if there is refrigerant

leakage. If there is refrigerant leakage, replace the relief

valve.

Special tool

(A): 09990–86012

1

32 (B)

I4RS0A720044-01

(a)

(A)

I4RS0A720045-01

21

3

I4RS0A720046-01

(A)

I5RS0C721014-01